A B2B Buyer’s Guide to Flange Gasket Material: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for flange gasket material

Flange gaskets are essential components in various industrial applications, yet sourcing the right flange gasket material can be a complex challenge for B2B buyers. Factors such as material compatibility, thermal stability, and cost-effectiveness must be carefully considered to ensure optimal performance and longevity in demanding environments. This comprehensive guide delves into the diverse types of flange gasket materials available, including rubber and fiber options, and their specific applications across different industries.

In addition to offering insights into material properties, this guide also addresses the critical aspects of supplier vetting and procurement strategies. It equips international buyers—especially those from regions like Africa, South America, the Middle East, and Europe—with the knowledge necessary to make informed purchasing decisions. Understanding the nuances of each material type, such as the benefits of aramid fibers or the durability of fluoroelastomers, can significantly impact the reliability of their operations.

By navigating the intricacies of the global market for flange gasket materials, buyers will be better positioned to select the ideal products that meet their unique needs. Ultimately, this guide serves as a valuable resource for enhancing procurement efficiency, reducing costs, and ensuring compliance with industry standards, fostering a more robust supply chain in an increasingly interconnected world.

Understanding flange gasket material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compressed Fiber Gaskets | Made from aramid fibers with NBR or EPDM binders | Oil & gas, chemical processing | Pros: Excellent sealability, cost-effective. Cons: Limited temperature range. |

| Fluoroelastomer (FKM/Viton) Gaskets | High chemical resistance, suitable for extreme temperatures | Pharmaceutical, food processing | Pros: Exceptional durability, versatile. Cons: Higher cost than standard materials. |

| Inorganic Fiber Gaskets | Excellent thermal stability, minimal weight loss | Power generation, mining | Pros: High performance under heat, low creep relaxation. Cons: May require specific installation techniques. |

| Nitrile Rubber Gaskets | Resistant to oils and hydrocarbons, flexible | Automotive, machinery | Pros: Good sealing properties, economical. Cons: Limited to moderate temperatures. |

| Non-Asbestos Gaskets | Safe alternative to asbestos, made from synthetic fibers | Various industrial applications | Pros: Environmentally friendly, good sealing capability. Cons: Potentially lower temperature resistance than metal gaskets. |

What Are the Key Characteristics of Compressed Fiber Gaskets?

Compressed fiber gaskets are primarily composed of aramid fibers combined with binders such as NBR (Nitrile Butadiene Rubber) or EPDM (Ethylene Propylene Diene Monomer). These gaskets are known for their excellent sealability and are widely used in applications within the oil and gas, and chemical processing sectors. When considering purchasing, buyers should evaluate the operating conditions, as these gaskets have a limited temperature range compared to other materials, making them suitable for moderate environments.

Why Choose Fluoroelastomer (FKM/Viton) Gaskets for Specific Applications?

Fluoroelastomer gaskets, commonly known as Viton gaskets, are renowned for their high chemical resistance and ability to withstand extreme temperatures. This makes them ideal for critical applications in the pharmaceutical and food processing industries, where safety and compliance are paramount. Buyers should weigh the benefits of their durability against their higher cost, especially when long-term reliability is a priority in demanding environments.

What Are the Advantages of Using Inorganic Fiber Gaskets?

Inorganic fiber gaskets offer excellent thermal stability and minimal weight loss, making them a preferred choice in power generation and mining industries. Their performance under high temperatures and low creep relaxation rates ensure a reliable seal over time. Buyers should consider the specific installation requirements and ensure compatibility with their systems, as improper handling can affect performance.

How Do Nitrile Rubber Gaskets Fit into Industrial Applications?

Nitrile rubber gaskets are specifically designed to resist oils and hydrocarbons, making them suitable for automotive and machinery applications. Their flexibility and good sealing properties offer an economical solution for many businesses. However, buyers should be cautious of their limitations regarding temperature ranges, ensuring that their operational environment does not exceed the gasket’s capabilities.

What Makes Non-Asbestos Gaskets a Safer Choice?

Non-asbestos gaskets are manufactured using synthetic fibers, providing a safer alternative to traditional asbestos-based products. They are suitable for various industrial applications and are appreciated for their good sealing capabilities. While they are environmentally friendly, buyers should assess their temperature resistance and application compatibility, as these gaskets may not perform as well in high-temperature scenarios compared to metal options.

Key Industrial Applications of flange gasket material

| Industry/Sector | Specific Application of flange gasket material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Sealing flanged connections in pipelines | Enhances safety by preventing leaks and spills. | Ensure compliance with international standards and local regulations. |

| Chemical Processing | Gaskets for reactors and storage tanks | Protects against chemical corrosion and ensures operational integrity. | Look for materials resistant to specific chemicals used in processes. |

| Water and Wastewater Management | Flange gaskets in treatment plants | Reduces maintenance costs and downtime due to leaks. | Consider durability and compatibility with water treatment chemicals. |

| Food and Beverage | Gaskets in processing equipment | Maintains hygiene and prevents contamination. | Verify compliance with food safety standards and certifications. |

| Power Generation | Flanged connections in turbines and boilers | Improves energy efficiency by ensuring tight seals. | Focus on high-temperature resistance and reliability under pressure. |

In the oil and gas sector, flange gaskets are critical for sealing flanged connections in pipelines. These gaskets help prevent leaks that could lead to environmental hazards and financial losses. International B2B buyers must prioritize gaskets that comply with local and international safety standards, particularly in regions like Nigeria and Brazil, where regulations can be stringent. Sourcing materials that offer high durability and resistance to extreme temperatures and pressures is also essential.

In chemical processing, flange gaskets are used in reactors, storage tanks, and pipelines to ensure safe handling of corrosive substances. The right gasket material can significantly reduce the risk of leaks and maintain operational integrity. Buyers should focus on sourcing gaskets made from materials that are resistant to specific chemicals encountered in their processes, ensuring compatibility and longevity.

For water and wastewater management, flange gaskets play a vital role in treatment plants, where they are used to seal connections on pipes and tanks. A reliable gasket reduces maintenance costs and minimizes downtime due to leaks, directly impacting operational efficiency. Buyers should consider the durability of materials and their compatibility with various chemicals used in water treatment processes to ensure long-lasting performance.

In the food and beverage industry, flange gaskets are essential in processing equipment to maintain hygiene and prevent contamination. Given the stringent health regulations in this sector, international buyers must ensure that the gaskets sourced comply with food safety standards, including certifications for materials used. Sourcing from reputable suppliers who can provide documentation on compliance is crucial.

Lastly, in power generation, flange gaskets are utilized in turbines and boilers to ensure tight seals. This application is vital for improving energy efficiency and reducing operational costs. Buyers should look for gaskets that can withstand high temperatures and pressures, focusing on materials that offer reliability and longevity in demanding environments. Understanding local market conditions and sourcing from trusted manufacturers can enhance procurement strategies in this sector.

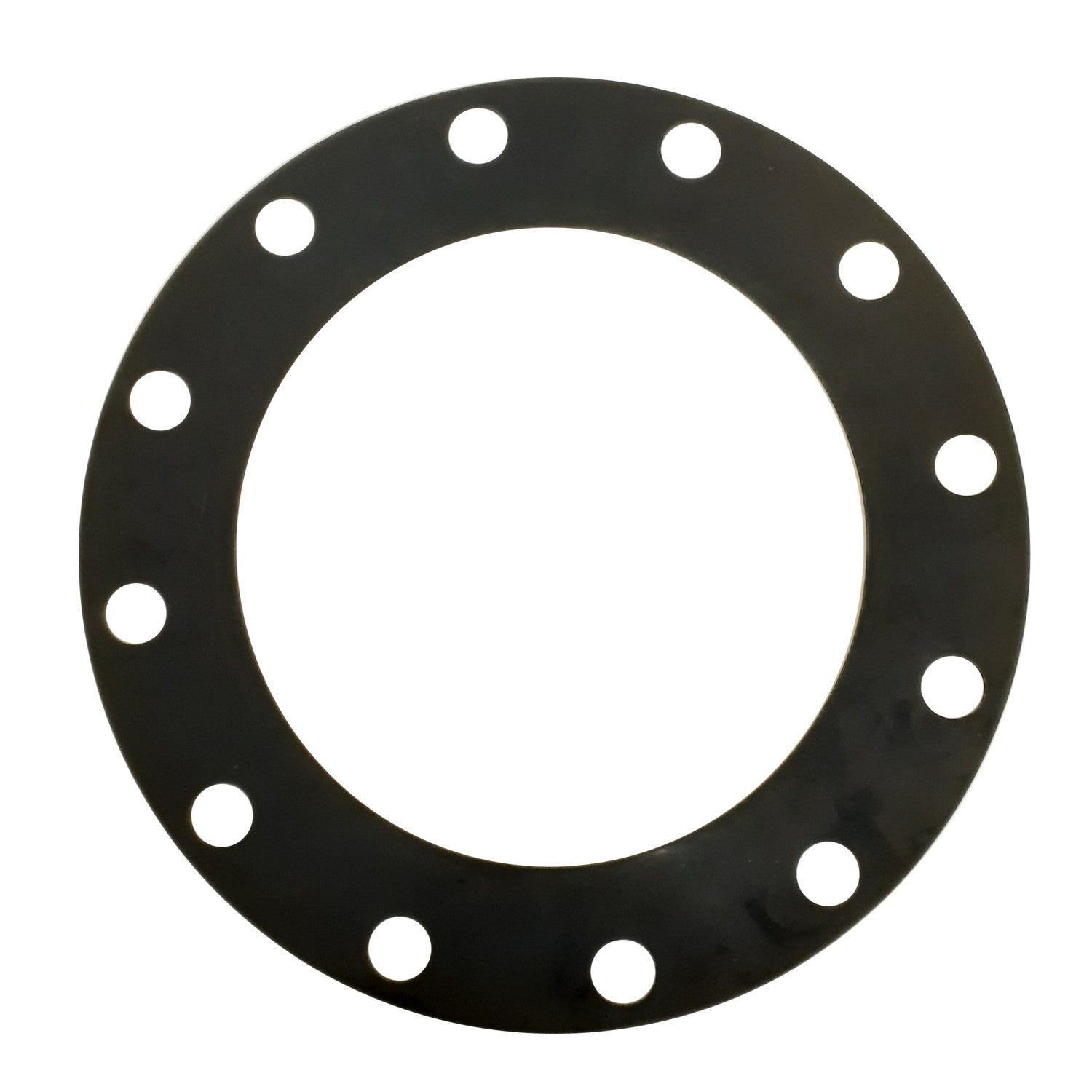

Illustrative image related to flange gasket material

3 Common User Pain Points for ‘flange gasket material’ & Their Solutions

Scenario 1: Compromised Sealing Performance Leading to Downtime

The Problem: One of the most pressing challenges B2B buyers face when sourcing flange gasket materials is the risk of compromised sealing performance. In industries such as oil and gas, chemical processing, or water treatment, even a minor leak can lead to catastrophic failures, safety hazards, and significant downtime. Buyers often struggle to select the right material that can withstand the specific temperature, pressure, and chemical exposure their applications demand, resulting in costly replacements and repairs.

The Solution: To overcome this challenge, B2B buyers should engage in thorough material selection based on application requirements. They must assess the operating conditions, including temperature ranges and the types of fluids involved. For example, using a high-performance gasket material such as Garlock’s BLUE-GARD Style 3000, which features aramid fibers with an NBR binder, can provide excellent torque retention and sealability under demanding conditions. Additionally, buyers should leverage technical resources and consult with manufacturers to obtain data sheets and performance specifications. This proactive approach not only ensures optimal gasket selection but also minimizes the risk of operational disruptions.

Scenario 2: Inconsistent Gasket Sizing and Fit Issues

The Problem: A common issue faced by B2B buyers is the inconsistency in gasket sizing, which can lead to improper fits on flanged connections. This challenge often arises when sourcing gaskets from multiple suppliers or using generic sizes that do not account for unique flange dimensions. Such misalignments can result in leaks, inefficient system performance, and the need for costly rework or replacements.

The Solution: Buyers should invest in accurate measuring tools and ensure that they have precise flange dimensions before ordering gasket materials. Utilizing a digital caliper or a laser measuring device can help achieve accurate measurements. Furthermore, working closely with manufacturers that offer custom gasket solutions can significantly reduce sizing errors. Suppliers often provide the option to create gaskets tailored to specific flange dimensions, ensuring a perfect fit and enhancing sealing reliability. Establishing a relationship with a trusted supplier who understands the nuances of your industry can also facilitate better communication and reduce errors.

Scenario 3: Difficulty in Selecting the Right Gasket Material for Diverse Applications

The Problem: Many B2B buyers encounter challenges when trying to navigate the vast array of gasket materials available, each designed for specific applications. This often leads to confusion regarding which material is best suited for their particular needs, especially when dealing with various industries and fluid types. The consequence of using an inappropriate gasket can lead to premature failure and increased maintenance costs.

The Solution: To address this issue, buyers should implement a systematic approach to material selection by developing a comprehensive understanding of the properties of different gasket materials. Buyers can create a decision matrix based on critical factors such as chemical compatibility, temperature resistance, and mechanical properties. For example, utilizing fluoroelastomer (FKM/Viton) gaskets for chemical applications can offer superior resistance to harsh chemicals, while compressed fiber gaskets may be more suitable for general-purpose use. Additionally, conducting supplier-led training sessions or workshops can provide valuable insights into material properties and help buyers make informed decisions. Collaborating with industry experts can also guide buyers in selecting the most effective gasket material for diverse applications, ultimately enhancing operational efficiency and reducing costs.

Strategic Material Selection Guide for flange gasket material

What are the Key Properties of Common Flange Gasket Materials?

When selecting flange gasket materials for industrial applications, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and chemical compatibility. Here, we analyze four common materials used in flange gaskets: compressed fiber, rubber, PTFE, and metal.

1. Compressed Fiber Gaskets

Key Properties: Compressed fiber gaskets, often made from aramid or inorganic fibers, provide excellent sealing capabilities under moderate temperatures (up to 300°C) and pressures. They exhibit good resistance to various chemicals, making them suitable for many applications.

Illustrative image related to flange gasket material

Pros & Cons: These gaskets are relatively inexpensive and easy to manufacture, allowing for quick production runs. However, they may not perform well under extreme temperatures or aggressive chemical environments. Their durability can also be compromised if exposed to high-stress conditions.

Impact on Application: Compressed fiber gaskets are ideal for applications involving oil, water, and mild chemicals. They are widely used in the oil and gas, chemical processing, and water treatment industries.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the selected materials comply with local standards such as ASTM or DIN. Additionally, understanding the local environmental conditions can influence the choice of gasket material.

2. Rubber Gaskets

Key Properties: Rubber gaskets, particularly those made from nitrile (NBR) or fluorocarbon (FKM), offer excellent sealing properties and flexibility. They can typically withstand temperatures ranging from -40°C to 120°C, depending on the type of rubber.

Pros & Cons: The primary advantage of rubber gaskets is their ability to provide a tight seal even under fluctuating pressure conditions. However, they can degrade when exposed to certain chemicals and may have a shorter lifespan compared to other materials.

Impact on Application: Rubber gaskets are commonly used in automotive, HVAC, and general industrial applications, particularly where oil and fuel resistance is needed.

Considerations for International Buyers: Buyers should be aware of the specific chemical compatibility requirements for their applications, especially in regions with varying environmental regulations. Certifications such as ISO or local standards may also be necessary.

3. PTFE Gaskets

Key Properties: Polytetrafluoroethylene (PTFE) gaskets are known for their exceptional chemical resistance and can handle temperatures up to 260°C. They are non-reactive and suitable for a wide range of chemicals.

Pros & Cons: PTFE gaskets excel in harsh environments, making them ideal for chemical processing industries. However, they can be more expensive and may require specialized manufacturing processes, which can increase lead times.

Impact on Application: These gaskets are particularly effective in applications involving aggressive chemicals, high temperatures, and pressures, such as in the pharmaceutical and petrochemical industries.

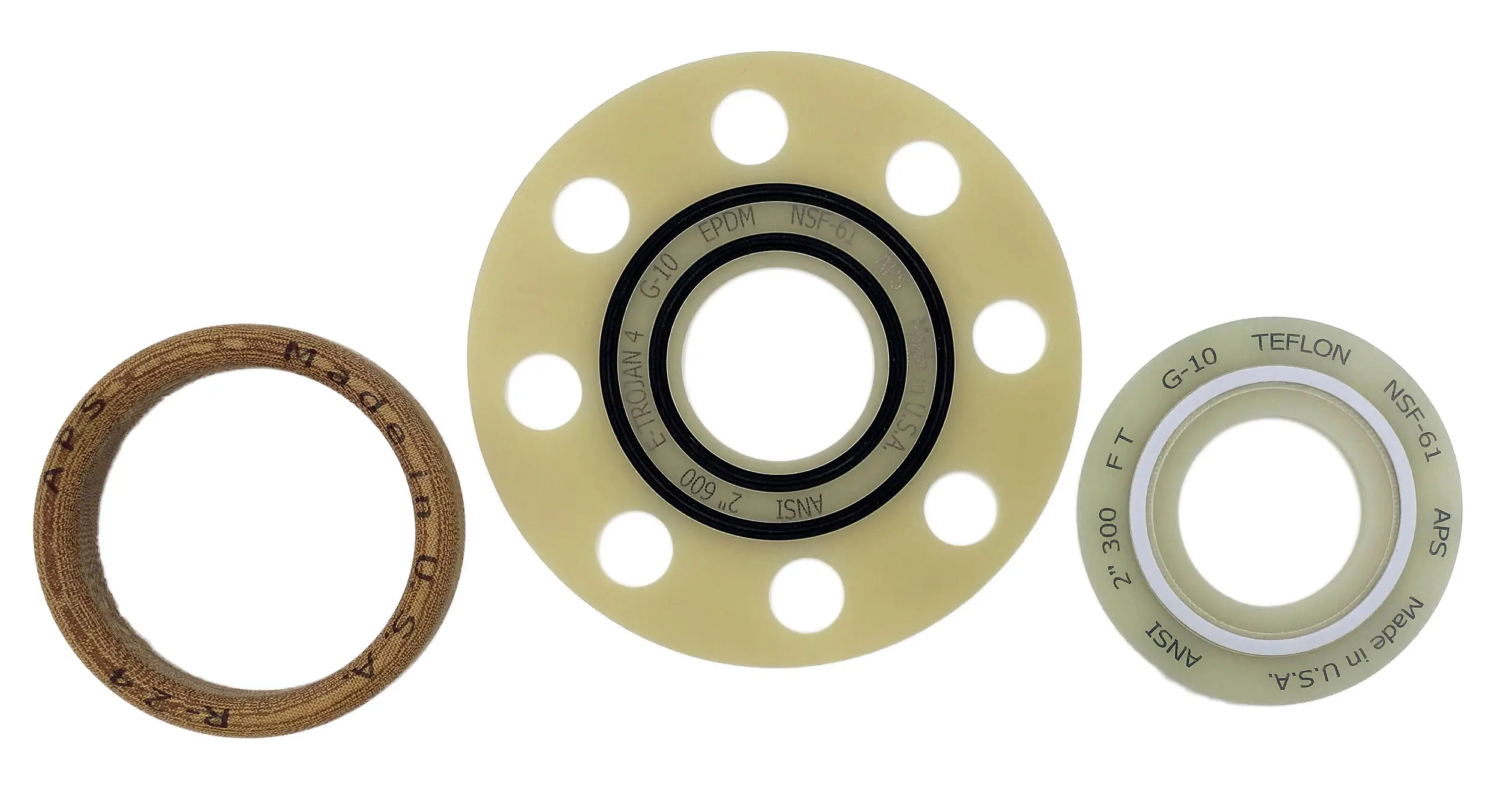

Illustrative image related to flange gasket material

Considerations for International Buyers: Buyers should ensure that PTFE gaskets meet specific international standards and certifications, especially when used in critical applications. Understanding the local market’s preference for PTFE versus other materials can also guide purchasing decisions.

4. Metal Gaskets

Key Properties: Metal gaskets, including spiral wound and ring-type gaskets, provide excellent sealing capabilities under high temperatures (up to 1000°C) and pressures. They are durable and highly resistant to corrosion.

Pros & Cons: The main advantage of metal gaskets is their ability to withstand extreme conditions. However, they can be more expensive and may require precise machining for proper installation, which can complicate manufacturing.

Impact on Application: Metal gaskets are commonly used in high-pressure applications, such as in the oil and gas, power generation, and aerospace industries.

Considerations for International Buyers: Buyers should consider the specific requirements for material grades and compliance with international standards, especially in regions with stringent regulations like Europe.

Summary Table of Flange Gasket Materials

| Material | Typical Use Case for flange gasket material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Compressed Fiber | Oil and gas, water treatment | Cost-effective and easy to manufacture | Limited performance under extreme conditions | Low |

| Rubber | Automotive, HVAC, general industrial | Excellent flexibility and sealing | Susceptible to chemical degradation | Medium |

| PTFE | Chemical processing, pharmaceuticals | Exceptional chemical resistance | Higher cost and specialized manufacturing | High |

| Metal | Oil and gas, power generation, aerospace | High durability and extreme condition resistance | More expensive and requires precise machining | High |

This guide should assist international B2B buyers in making informed decisions regarding flange gasket material selection, ensuring compliance and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for flange gasket material

What are the Main Stages in the Manufacturing Process of Flange Gasket Material?

The manufacturing process of flange gasket materials is a multi-step procedure that ensures the final product meets stringent quality and performance standards. The primary stages include:

Material Preparation

The initial stage involves selecting the appropriate raw materials based on the gasket’s intended application. Common materials include rubber, fiber, and composites, each chosen for specific properties such as temperature resistance, chemical compatibility, and mechanical strength. The raw materials undergo rigorous quality checks to ensure they meet defined specifications. Proper storage conditions are also maintained to prevent contamination or degradation.

Forming Techniques: How are Flange Gaskets Shaped?

Once the materials are prepared, they are subjected to various forming techniques. Common methods include:

-

Compression Molding: This technique involves placing a pre-measured amount of material into a heated mold. Pressure is applied to shape the gasket, ensuring uniform thickness and density. This method is particularly effective for rubber and fiber-based gaskets.

-

Die Cutting: For flat gaskets, die cutting is a prevalent method where sheets of material are cut into specific shapes using sharp dies. This process allows for high precision and consistency across large production runs.

-

Water Jet Cutting: This technique utilizes high-pressure water jets to cut complex shapes from gasket materials. It is advantageous for intricate designs and reduces waste.

Assembly: How are Different Gasket Components Brought Together?

In some cases, flange gaskets may consist of multiple layers or components. Assembly involves stacking these layers or integrating different materials to enhance performance characteristics. For instance, a gasket might combine a rubber base with a metal insert for added strength. This stage often requires precise alignment and bonding techniques to ensure optimal sealing properties.

Finishing: What Final Touches are Applied to Flange Gaskets?

The final stage of manufacturing includes finishing processes such as trimming excess material, surface treatment, and quality inspections. Surface treatments may involve applying coatings for additional chemical resistance or lubrication. Markings for identification, such as part numbers and specifications, are also added at this stage.

What Quality Assurance Standards are Relevant for Flange Gasket Manufacturing?

Quality assurance (QA) is critical in the production of flange gaskets, particularly for international B2B transactions. Several international standards and industry-specific regulations govern the quality of gasket materials:

International Standards: How Does ISO 9001 Ensure Quality?

ISO 9001 is a widely recognized international standard that sets criteria for a quality management system (QMS). Manufacturers of flange gaskets must demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Adherence to ISO 9001 involves regular audits, documentation of processes, and continuous improvement initiatives.

Industry-Specific Certifications: What Does CE and API Mean for Gasket Quality?

In addition to ISO standards, certain industries require specific certifications. For example:

-

CE Marking: This certification indicates that a product meets European Union safety, health, and environmental protection standards. Flange gaskets used in various industrial applications in Europe must often carry this mark.

-

API Specification: The American Petroleum Institute (API) sets standards for products used in the oil and gas industry. Gaskets that meet API specifications are essential for ensuring safety and reliability in critical applications.

What are the Key Quality Control Checkpoints in Flange Gasket Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and address defects before the product reaches the customer. Key QC stages include:

Incoming Quality Control (IQC): What Happens Before Production?

IQC involves inspecting raw materials and components before they enter the production line. This stage ensures that only materials that meet predefined quality standards are used, thus minimizing the risk of defects in the final product.

In-Process Quality Control (IPQC): How is Quality Maintained During Manufacturing?

During the production process, IPQC checks are conducted at various stages. These may include monitoring the temperature and pressure during molding, verifying the accuracy of cutting tools, and ensuring proper assembly techniques are employed. Regular sampling and testing of produced gaskets can help catch defects early.

Final Quality Control (FQC): What Tests are Conducted Before Shipment?

FQC is the last line of defense before products are shipped to customers. This stage typically includes comprehensive testing of gaskets for mechanical properties, compression set, chemical resistance, and leak testing. Only products that pass these tests are approved for shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, ensuring the quality of flange gasket materials is vital. Here are actionable steps to verify supplier QC practices:

Supplier Audits: What Should Buyers Look For?

Conducting supplier audits can provide insights into a manufacturer’s QC processes. Buyers should look for evidence of compliance with international standards such as ISO 9001 and relevant industry certifications. Audits should evaluate the entire manufacturing process, from material sourcing to final testing.

Quality Reports and Documentation: What Information is Essential?

Requesting quality reports, test certificates, and documentation can help buyers assess a supplier’s commitment to quality. This documentation should detail the results of IQC, IPQC, and FQC processes, along with any corrective actions taken for identified issues.

Third-Party Inspections: How Can Independent Verification Enhance Trust?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These services can conduct random sampling and testing of products to ensure compliance with agreed specifications, providing additional assurance to B2B buyers.

Conclusion: Why is Quality Assurance Crucial for Flange Gasket Materials in Global Trade?

In the global marketplace, the quality of flange gasket materials directly impacts operational efficiency and safety in various industries. Understanding the manufacturing processes and quality assurance standards allows B2B buyers to make informed decisions when sourcing these critical components. By implementing rigorous verification methods, buyers can mitigate risks associated with product quality and ensure that they receive reliable and high-performance gaskets for their applications.

Illustrative image related to flange gasket material

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flange gasket material’

To effectively procure flange gasket material, it’s essential to follow a systematic approach that ensures you choose the right products and suppliers for your specific needs. This guide provides a step-by-step checklist tailored for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clarify the technical requirements of the flange gasket material needed for your application. Consider factors such as temperature resistance, chemical compatibility, and pressure ratings.

– Material Types: Decide if you require rubber, fiber, or composite materials based on the operational environment.

– Dimensions and Standards: Specify the size and any industry standards (e.g., ANSI, ASME) that the gaskets must meet.

Step 2: Research and Identify Reliable Suppliers

Conduct thorough research to identify potential suppliers that specialize in flange gaskets. Utilize online platforms, industry directories, and trade shows to gather a list of manufacturers and distributors.

– Supplier Reputation: Look for companies with positive reviews and a solid track record in the gasket industry.

– Regional Considerations: Favor suppliers that are familiar with the local market conditions in your region, as they may better understand your specific needs.

Illustrative image related to flange gasket material

Step 3: Evaluate Supplier Capabilities

Before making a commitment, assess the capabilities and reliability of your shortlisted suppliers. This includes evaluating their production capacity, quality control measures, and delivery timelines.

– Certifications: Verify if the supplier has relevant certifications (e.g., ISO 9001) that demonstrate their commitment to quality.

– Production Methods: Inquire about their manufacturing processes and technologies to ensure they can meet your quality and volume requirements.

Step 4: Request Samples for Testing

Always request samples of the flange gasket materials before finalizing your order. Testing samples allows you to evaluate the performance and compatibility of the gaskets in your specific applications.

– Application Testing: Conduct tests to ensure the gaskets can withstand the operational conditions they will encounter.

– Feedback Mechanism: Provide feedback to the supplier regarding the samples, which can also help in negotiating better terms.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier and tested the samples, enter into negotiations regarding pricing and contractual terms.

– Bulk Pricing: Discuss discounts for bulk orders or long-term contracts to optimize your purchasing costs.

– Payment Terms: Ensure that payment terms are clear, including any upfront payments, credit terms, and penalties for late deliveries.

Step 6: Verify After-Sales Support and Warranty

Before finalizing the purchase, confirm the level of after-sales support offered by the supplier, as well as any warranties on the products.

– Support Services: Inquire about the availability of technical support, installation guidance, and troubleshooting assistance.

– Warranty Conditions: Understand the warranty terms, including what is covered and the process for claims, as this can significantly impact your long-term satisfaction with the product.

Step 7: Establish a Long-Term Relationship

After successfully procuring flange gasket materials, consider establishing a long-term relationship with the supplier. Building a strategic partnership can lead to improved pricing, better service, and access to new products.

– Regular Communication: Maintain open lines of communication to ensure ongoing support and collaboration.

– Feedback Loop: Provide ongoing feedback on product performance and service, which can help the supplier improve their offerings.

By following these steps, B2B buyers can streamline their sourcing process for flange gasket materials, ensuring they make informed decisions that meet their operational requirements.

Comprehensive Cost and Pricing Analysis for flange gasket material Sourcing

Understanding the cost structure and pricing dynamics for flange gasket materials is crucial for international B2B buyers looking to optimize their sourcing strategies. This analysis focuses on the components that influence costs, pricing strategies, and valuable tips for enhancing negotiation outcomes.

What Are the Key Cost Components in Flange Gasket Material Sourcing?

When evaluating the costs associated with flange gaskets, several core components come into play:

-

Materials: The choice of materials significantly impacts pricing. Common materials include compressed fiber, rubber, and fluoropolymer options, each varying in cost. For instance, Garlock’s BLUE-GARD series features gaskets priced from $0.30 to over $300, depending on the material and specifications.

-

Labor and Manufacturing Overhead: Labor costs depend on the region and the manufacturing process. Automated production may reduce labor costs, while manual processes can increase them. Overhead includes utilities, maintenance, and facility costs, which should be factored into the total cost.

-

Tooling and Quality Control (QC): Initial tooling costs for custom gaskets can be significant, especially for unique designs or specifications. Quality control processes ensure that products meet industry standards, which can also add to overall expenses.

-

Logistics: Shipping costs vary based on the origin of the materials, destination, and shipping methods. Incoterms play a vital role here, influencing who bears the cost and risk during transportation.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the expected margins in different regions can help buyers gauge reasonable pricing.

How Do Pricing Influencers Affect Flange Gasket Costs?

Several factors influence the pricing of flange gaskets, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to reduced unit costs. Suppliers are more inclined to offer discounts on larger orders, which can significantly lower the overall cost.

-

Specifications and Customization: Customized gaskets tailored to specific applications may incur higher prices due to the additional design and manufacturing efforts required. Standardized products generally have lower costs.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., FDA-approved for food applications) typically command higher prices. Buyers should assess the balance between cost and necessary quality.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium, but they often provide better support, reliability, and quality assurance.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

B2B buyers can adopt several strategies to maximize cost efficiency in their sourcing of flange gaskets:

Illustrative image related to flange gasket material

-

Negotiate Wisely: Leverage volume commitments or long-term contracts to negotiate better terms. Building a relationship with suppliers can also enhance negotiation outcomes.

-

Consider Total Cost of Ownership (TCO): Beyond initial pricing, evaluate the TCO, which includes maintenance, replacement frequency, and potential downtime costs due to gasket failure. Investing in higher-quality gaskets may reduce long-term expenses.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, it is essential to understand local market conditions and currency fluctuations. This knowledge can aid in making informed purchasing decisions and avoiding unexpected costs.

-

Stay Informed on Industry Trends: Keep abreast of market trends, material innovations, and pricing fluctuations. This insight can provide leverage during negotiations and help identify potential cost-saving opportunities.

Conclusion

In summary, a comprehensive understanding of the cost components and pricing influencers in flange gasket sourcing allows buyers to make informed decisions. By employing strategic negotiation tactics and considering the total cost of ownership, international B2B buyers can enhance their procurement processes, ensuring both quality and cost-effectiveness in their operations. Always remember that prices may vary and should be viewed as indicative, reflecting the complexities of the global marketplace.

Alternatives Analysis: Comparing flange gasket material With Other Solutions

Understanding Alternatives to Flange Gasket Material

In the realm of industrial sealing solutions, flange gasket materials play a crucial role in ensuring leak-free connections in piping systems. However, various alternatives exist that can also meet the requirements of different applications. This analysis will compare flange gasket materials with innovative sealing technologies, such as spiral wound gaskets and metal gaskets, to help B2B buyers make informed decisions.

| Comparison Aspect | Flange Gasket Material | Spiral Wound Gasket | Metal Gasket |

|---|---|---|---|

| Performance | Excellent compression and sealing | High flexibility and adaptability | Superior strength and durability |

| Cost | Economical for bulk applications | Moderate cost, varies by type | Higher initial cost, long-lasting |

| Ease of Implementation | Easy to install and replace | Requires precise installation | May require specialized tools |

| Maintenance | Regular checks recommended | Low maintenance once installed | Minimal maintenance, high reliability |

| Best Use Case | General industrial applications | High-temperature and pressure systems | Extreme environments (e.g., high pressure) |

Exploring Spiral Wound Gaskets

Spiral wound gaskets are composed of alternating layers of metal and soft filler material, providing excellent sealing capabilities under varying temperatures and pressures. Their design allows for a high degree of flexibility, making them suitable for applications where flange surfaces may not be perfectly aligned. The advantages of spiral wound gaskets include their adaptability to different flange types and their ability to handle thermal cycling. However, they may require more precise installation techniques to ensure proper sealing, which could add to labor costs.

Evaluating Metal Gaskets

Metal gaskets, typically made from materials like stainless steel or copper, are renowned for their durability and strength. They provide exceptional sealing in high-pressure and high-temperature applications, making them ideal for industries such as oil and gas, chemical processing, and power generation. While metal gaskets have a higher initial cost compared to flange gasket materials, their longevity can lead to cost savings over time due to reduced maintenance and replacement needs. However, they may require specialized installation tools, and their rigidity can limit application in situations with flange misalignment.

Conclusion: Choosing the Right Sealing Solution

When selecting the right sealing solution, B2B buyers must carefully evaluate their specific application requirements, including pressure, temperature, and environmental conditions. While flange gasket materials offer a cost-effective and versatile option for a wide range of uses, alternatives like spiral wound and metal gaskets present unique benefits for specialized applications. By understanding the performance, cost, maintenance, and installation requirements of each option, buyers can make informed choices that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for flange gasket material

What Are the Essential Technical Properties of Flange Gasket Material?

Understanding the technical properties of flange gasket materials is crucial for B2B buyers, as these specifications directly impact the performance, reliability, and longevity of sealing solutions in industrial applications. Here are key properties to consider:

1. Material Composition

Flange gaskets are typically made from a variety of materials, including rubber, fiber, and metal. Each material has distinct properties tailored for specific applications. For example, rubber gaskets are often used for their flexibility and resistance to various chemicals, while fiber gaskets provide excellent compressibility and strength. Choosing the right material can enhance the efficiency of the sealing solution in different environments, such as chemical processing or oil and gas industries.

2. Temperature Resistance

Temperature resistance is a critical specification for flange gaskets, indicating the maximum and minimum temperatures a gasket can withstand without degrading or losing its sealing properties. This specification is vital in industries where extreme temperatures are common, such as power generation or chemical manufacturing. Selecting a gasket with appropriate temperature resistance ensures reliability and safety in operations, reducing the risk of leaks.

Illustrative image related to flange gasket material

3. Pressure Rating

The pressure rating of a flange gasket indicates the maximum pressure it can endure without failure. This specification is essential for ensuring that the gasket can withstand the operational conditions of the system it is used in. For instance, high-pressure applications in oil and gas extraction require gaskets that can sustain significant pressure without compromising the seal. Understanding pressure ratings helps buyers select suitable gaskets for their specific applications.

4. Compressibility and Recovery

Compressibility refers to how much a gasket material can compress under pressure, while recovery indicates how well it returns to its original thickness once the pressure is released. Both properties are essential for maintaining a reliable seal over time. A gasket that exhibits good compressibility and recovery can adapt to flange irregularities and maintain a tight seal, thus preventing leaks and reducing maintenance costs.

5. Chemical Compatibility

Chemical compatibility is crucial for determining whether a gasket material can withstand exposure to the substances it will encounter in its application. For example, certain gaskets may be resistant to oils but not to acids or solvents. Buyers must evaluate the chemical environment of their application to select the right gasket material that will not degrade over time, ensuring a longer lifespan and fewer replacements.

What Are the Common Trade Terms Used in Flange Gasket Materials?

Familiarity with industry jargon can streamline communication and negotiations between B2B buyers and suppliers. Here are some common terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of flange gaskets, understanding OEM specifications can help buyers ensure compatibility with existing equipment and maintain operational efficiency.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses looking to maintain stock levels without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document that companies send to suppliers to request pricing and terms for specific products. Submitting an RFQ allows buyers to compare offers from different suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms can help buyers navigate shipping costs, risks, and obligations effectively.

5. Tolerance

Tolerance in gasket manufacturing refers to the allowable deviation from a specified dimension. It is critical for ensuring proper fit and performance in applications. Buyers should be aware of tolerance specifications to avoid issues that can arise from improper gasket fitting.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing flange gasket materials, ultimately leading to more reliable and efficient industrial operations.

Navigating Market Dynamics and Sourcing Trends in the flange gasket material Sector

What are the Current Market Dynamics and Key Trends in the Flange Gasket Material Sector?

The flange gasket material sector is experiencing a significant transformation driven by several global factors. Increasing industrialization in emerging markets, particularly in Africa and South America, is boosting demand for reliable sealing solutions. This surge is primarily seen in sectors such as oil and gas, chemical processing, and manufacturing. Moreover, the growing emphasis on operational efficiency and safety in industrial applications is prompting companies to seek high-performance gasket materials that can withstand extreme temperatures and pressures.

Emerging technologies, such as digital sourcing platforms and advanced materials science, are reshaping how international buyers procure flange gasket materials. Digital marketplaces enable easier access to a wider array of suppliers and products, allowing buyers to compare prices and specifications effortlessly. Additionally, the rise of Industry 4.0 has led to increased automation in manufacturing processes, which is enhancing the quality and consistency of gasket materials. International buyers, especially in regions like the Middle East and Europe, are increasingly prioritizing suppliers who can demonstrate innovation and adaptability in their product offerings.

How is Sustainability and Ethical Sourcing Shaping the Flange Gasket Material Market?

Sustainability has become a critical consideration for B2B buyers in the flange gasket material sector. The environmental impact of manufacturing processes, particularly in terms of waste generation and energy consumption, is under scrutiny. As companies aim to reduce their carbon footprints, there is a growing demand for gasket materials that are not only durable but also environmentally friendly.

Ethical sourcing practices are gaining traction, with buyers increasingly favoring suppliers who maintain transparent supply chains and adhere to ethical labor standards. This shift is also reflected in the rising popularity of ‘green’ certifications and materials, such as biodegradable or recyclable gasket options. Suppliers that can demonstrate their commitment to sustainability—through certifications or the use of eco-friendly materials—are likely to gain a competitive edge in the market.

What is the Brief Evolution of Flange Gasket Materials?

The evolution of flange gasket materials has been marked by significant advancements in material science and engineering. Initially, gaskets were predominantly made from natural materials such as rubber and cork. However, as industrial applications became more demanding, the need for materials that could withstand higher temperatures and aggressive chemicals led to the development of synthetic options.

The introduction of composites, including aramid fibers and fluoropolymers, has revolutionized the sector, offering enhanced performance in various applications. Today, flange gaskets are available in a range of materials designed to meet specific operational requirements, including non-asbestos options for improved safety. This evolution reflects a broader trend towards innovation in the industrial sector, where performance, safety, and sustainability are paramount.

In conclusion, international B2B buyers navigating the flange gasket material market must stay informed about these dynamics and trends to make strategic sourcing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of flange gasket material

-

How do I ensure the quality of flange gasket materials from suppliers?

To ensure quality, request Material Safety Data Sheets (MSDS) and Certificates of Compliance from potential suppliers. Conduct thorough vetting by reviewing their production processes, certifications, and client testimonials. If feasible, visit the manufacturing facility or request samples for testing. Consider third-party inspections to verify the quality before placing larger orders. Establish clear quality assurance standards in your contracts to maintain product integrity throughout the supply chain. -

What is the best flange gasket material for high-temperature applications?

For high-temperature applications, fluoropolymer gaskets, such as Viton or PTFE, are ideal due to their excellent thermal stability and chemical resistance. Additionally, carbon fiber gaskets with nitrile binders can withstand extreme conditions while maintaining sealing integrity. When selecting the material, consider the specific temperature ranges and chemical exposure to ensure optimal performance in your application. -

How can I customize flange gaskets to fit specific dimensions?

Most reputable suppliers offer customization options for flange gaskets. Provide detailed specifications, including dimensions, thickness, and material type, to your supplier. Some manufacturers may require a minimum order quantity (MOQ) for customized gaskets, so be sure to clarify this in your discussions. Additionally, inquire about lead times and any design support they may offer to ensure your gaskets meet the necessary specifications. -

What are the typical minimum order quantities (MOQs) for flange gaskets?

MOQs for flange gaskets can vary widely depending on the supplier and the type of material. Generally, standard products may have lower MOQs, often starting from as few as 10 units. However, customized gaskets typically require larger orders, sometimes ranging from 50 to 500 units. Always discuss MOQs during negotiations to align your purchasing needs with supplier capabilities. -

What payment terms are common in international transactions for flange gaskets?

Common payment terms for international transactions often include upfront payment, partial payment upon order confirmation, or net 30-60 days after delivery. Letters of credit and escrow services are also popular for high-value orders, providing security for both parties. Ensure that you clearly define payment terms in your contract to avoid misunderstandings and facilitate smooth transactions. -

How do I manage logistics for importing flange gaskets from international suppliers?

Managing logistics involves coordinating shipping, customs clearance, and local delivery. Work with a freight forwarder experienced in handling industrial goods to navigate international shipping regulations. Ensure all documentation, such as invoices and packing lists, is accurate and complete to avoid customs delays. Additionally, consider the lead time for production and shipping when planning your inventory to maintain supply chain efficiency. -

What certifications should I look for in flange gasket suppliers?

Look for suppliers with ISO certifications, which indicate adherence to international quality management standards. Additionally, certifications such as ASTM or API can verify that the materials meet industry-specific standards. These certifications not only enhance the credibility of the supplier but also ensure that the gaskets you receive are reliable and compliant with safety regulations. -

How can I evaluate supplier reliability in the flange gasket market?

To evaluate supplier reliability, examine their track record, including years in business, customer reviews, and case studies. Request references from other clients, particularly those in similar industries or regions. Utilize trade platforms and industry networks to gather insights about the supplier’s reputation. A reliable supplier should also have robust customer service and support systems in place to address any issues that may arise during the purchasing process.

Top 10 Flange Gasket Material Manufacturers & Suppliers List

1. Garlock – BLUE-GARD Style 3000 Gasket

Domain: gasketsupply.com

Registered: 2014 (11 years)

Introduction: [{‘name’: ‘Garlock BLUE-GARD Style 3000 Gasket’, ‘price_range’: ‘$0.30 – $92.39’, ‘description’: ‘Compressed fiber gasketing material made with aramid fibers and NBR binder, providing improved torque retention.’}, {‘name’: ‘Garlock Style 5500 Inorganic Fiber Gaskets’, ‘price_range’: ‘$0.27 – $90.68’, ‘description’: ‘Inorganic fiber gasketing material offering excellent thermal stability with minim…

2. Garlock – Pipe Flange Gaskets

Domain: garlock.com

Registered: 1995 (30 years)

Introduction: This company, Garlock – Pipe Flange Gaskets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Jones Stephens – Flange Gaskets & Gasket Material

Domain: jonesstephens.com

Registered: 1999 (26 years)

Introduction: Flange Gaskets & Gasket Material includes Full Face Gaskets, Insulation Kits, and Ring Gaskets.

4. Santop Seal – Rubber Flange Gaskets

Domain: santopseal.com

Registered: 2019 (6 years)

Introduction: Rubber flange gaskets are essential sealing components used to inhibit the escape of fluids or gases between two flanges. They are available in various types of rubber materials, including: 1. Nitrile Rubber (NBR): Used in automotive seals and hydraulic systems, resistant to oil, fuel, and grease. 2. Neoprene Rubber: Offers weather and ozone resistance, suitable for outdoor and marine applications…

5. Savree – Flange Gaskets

Domain: savree.com

Registered: 2017 (8 years)

Introduction: Flange gaskets are sealing elements installed between mating flange faces, maintained in position by compressive force from bolt torqueing. They are categorized into three main types: Non-metallic/Soft (e.g., Compressed Non-Asbestos Fibre, PTFE, rubber, ceramic fibre), Metallic/Hard (e.g., oval ring, octagonal ring), and Semi-metallic/Composite (e.g., spiral wound, metal jacketed, camprofile). Sof…

6. McMaster – Flange Gaskets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Flange Gaskets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Phelps – Standard Flange Gaskets

Domain: phelpsgaskets.com

Registered: 2016 (9 years)

Introduction: Standard flange gaskets are fabricated to be compatible with ASME/ANSI pipe flanges according to API Standards 601 and 605. Phelps offers all standard sizes in 125/150 lb., 250/300 lb., ring and full face styles. They are equipped to supply specialized full face gaskets for the Department of Defense. Materials include Compressed Buna-N, Flexible Graphite, Red Rubber, Viton (R), Cork, Silicone, and…

8. Hennig Gasket – Flange Gasket Materials

Domain: henniggasket.com

Registered: 1999 (26 years)

Introduction: Flange gasket materials include red rubber, buna N, silicone rubber, graphite, PTFE, and paper. The selection of gasket material is influenced by the condition and design of sealing surfaces or flanges, which can change over time due to factors like aging, temperature cycles, and repeated assembly. Soft, easily compressed gasket materials are recommended for flanges that cannot withstand high clam…

9. PRM Filtration – Flange Gaskets

Domain: shop.prmfiltration.com

Registered: 2016 (9 years)

Introduction: Flange Gaskets available in various materials including EPDM, Nitrile, Viton, Neoprene, and more.

10. Ram Gaskets – Pipe Gaskets

Domain: ramgaskets.com

Registered: 2010 (15 years)

Introduction: Pipe gaskets, also known as flange gaskets, are manufactured and supplied in a variety of materials. They can be standard sizes or custom-made to specific measurements. Pricing varies based on volume, material, and thickness. Common types include standard flange gaskets in rubber, fiber, or spiral wound designs. Gaskets are made to fit standard pipe or flange sizes, adhering to various standards s…

Strategic Sourcing Conclusion and Outlook for flange gasket material

In the evolving landscape of flange gasket materials, strategic sourcing remains pivotal for international B2B buyers. The choice of gasket materials—ranging from aramid fibers to fluoroelastomers—can directly impact the efficiency, safety, and longevity of industrial applications. By leveraging high-quality materials and robust supplier relationships, businesses can ensure optimal performance while minimizing downtime and maintenance costs.

Illustrative image related to flange gasket material

Understanding the specific requirements of your operations—such as temperature tolerance and chemical compatibility—is essential. Buyers should prioritize partnerships with manufacturers that offer comprehensive technical support and customization options, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

As industries face growing pressures to enhance sustainability and reduce costs, the importance of strategic sourcing will only intensify. Embracing innovative gasket solutions not only provides a competitive edge but also aligns with global sustainability goals.

Now is the time for international buyers to evaluate their sourcing strategies. Engage with trusted suppliers, explore advanced materials, and invest in training to ensure your team is equipped to make informed decisions. This proactive approach will not only drive operational excellence but also foster long-term growth in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.