A B2B Buyer’s Guide to Fancy Steel: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for fancy steel

In the ever-evolving landscape of international trade, sourcing high-quality fancy steel presents a unique set of challenges for B2B buyers. As industries across Africa, South America, the Middle East, and Europe seek innovative materials for specialized applications, understanding the nuances of fancy steel becomes critical. This guide aims to demystify the complexities involved in procuring fancy steel, covering essential aspects such as types of fancy steel, their diverse applications, effective supplier vetting processes, and cost considerations.

By equipping international buyers with actionable insights, this comprehensive resource empowers them to make informed purchasing decisions. Whether you are based in Vietnam, Germany, or anywhere in between, understanding the market dynamics of fancy steel can enhance your procurement strategy and ensure the selection of materials that meet your specific operational needs. With a focus on quality, functionality, and supplier reliability, this guide serves as an invaluable tool for navigating the global market, ultimately driving your business success in an increasingly competitive environment.

Engage with this guide to unlock the potential of fancy steel and elevate your sourcing capabilities, ensuring you stay ahead in your respective industry.

Understanding fancy steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel | Corrosion-resistant, durable, low maintenance | Construction, automotive, food processing | Pros: Long lifespan, aesthetic appeal; Cons: Higher cost compared to carbon steel. |

| Alloy Steel | Enhanced strength and toughness through alloying | Oil & gas, aerospace, heavy machinery | Pros: High strength-to-weight ratio; Cons: Can be more brittle than other steels. |

| Tool Steel | Designed for high wear resistance and toughness | Manufacturing tools, dies, and molds | Pros: Excellent durability; Cons: Expensive and requires specialized heat treatment. |

| Carbon Steel | High carbon content for increased hardness | Structural applications, pipelines | Pros: Cost-effective, versatile; Cons: Prone to rust without proper coating. |

| Decorative Steel | Aesthetic designs, finishes, and patterns | Architecture, interior design | Pros: Unique visual appeal; Cons: May require additional maintenance to preserve appearance. |

What Are the Characteristics of Stainless Steel in B2B Applications?

Stainless steel is renowned for its corrosion resistance, making it an ideal choice for industries like construction, automotive, and food processing. Its low maintenance requirements and durability ensure that products made from stainless steel have a long lifespan, which is a critical factor for B2B buyers looking for reliability. However, the higher initial cost compared to carbon steel can be a consideration, especially for budget-sensitive projects. Buyers should evaluate the total lifecycle cost and potential savings in maintenance when considering stainless steel for their applications.

How Does Alloy Steel Enhance Performance in Specific Industries?

Alloy steel incorporates various elements to improve its strength and toughness, making it suitable for demanding applications in sectors such as oil and gas, aerospace, and heavy machinery. Its unique properties allow it to withstand extreme conditions and heavy loads, which are common in these industries. While alloy steel offers a high strength-to-weight ratio, buyers should be aware that it can be more brittle than other types of steel, necessitating careful selection based on the specific application requirements.

Why Choose Tool Steel for Manufacturing Tools and Dies?

Tool steel is specifically designed for high wear resistance and toughness, making it essential for manufacturing tools, dies, and molds. Its ability to maintain hardness at elevated temperatures is crucial for industries that require precision and durability. However, the expense associated with tool steel and the need for specialized heat treatment can be a drawback for some buyers. When considering tool steel, businesses should weigh the long-term benefits of durability against the initial investment costs.

What Are the Advantages and Disadvantages of Carbon Steel?

Carbon steel is characterized by its high carbon content, which enhances hardness and strength, making it a cost-effective option for structural applications and pipelines. Its versatility allows it to be used in various industries, but it is prone to rust without proper protective coatings. Buyers should consider the environmental conditions their products will face and factor in the costs of maintenance and protective measures when opting for carbon steel.

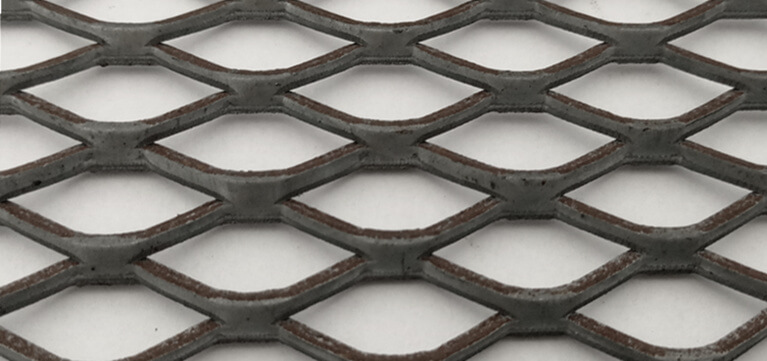

How Does Decorative Steel Differ from Other Types?

Decorative steel is designed with aesthetic qualities, featuring unique designs, finishes, and patterns that enhance architectural and interior design projects. While it offers a distinct visual appeal, buyers must also consider the maintenance required to preserve its appearance over time. Decorative steel is often used in high-end projects where aesthetics are paramount, but the additional care needed may influence purchasing decisions in more utilitarian applications.

Key Industrial Applications of fancy steel

| Industry/Sector | Specific Application of fancy steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Machinery Components | Enhanced durability and performance in production. | Ensure material specifications meet industrial standards. |

| Aerospace | Structural Components for Aircraft | Lightweight yet strong materials for safety and efficiency. | Compliance with aerospace regulations and certifications. |

| Automotive | High-Performance Parts | Improved safety and longevity of vehicle components. | Consider sourcing from suppliers with advanced fabrication capabilities. |

| Construction | Decorative Steel Elements | Aesthetic appeal combined with structural integrity. | Evaluate design flexibility and customization options. |

| Energy Production | Components for Renewable Energy Systems | Increased efficiency and reliability in energy generation. | Look for suppliers with experience in energy sector applications. |

How is Fancy Steel Applied in Manufacturing Industries?

In the manufacturing sector, fancy steel is utilized to create custom machinery components that require superior durability and performance. This material is particularly beneficial for businesses looking to enhance production efficiency and reduce maintenance costs. International buyers should ensure that the steel meets specific industrial standards to avoid complications in assembly and operation.

What Role Does Fancy Steel Play in Aerospace Applications?

In the aerospace industry, fancy steel is employed in the production of structural components for aircraft, where weight reduction is crucial without compromising safety. The unique properties of fancy steel allow for the creation of lightweight yet robust parts that meet strict safety regulations. Buyers in this sector must prioritize compliance with aerospace standards and certifications to ensure reliability.

How is Fancy Steel Used in Automotive Manufacturing?

Fancy steel finds its application in high-performance automotive parts, contributing to improved safety and longevity of vehicles. Its strength and durability make it ideal for components that face high stress during operation. Buyers should consider sourcing from manufacturers with advanced fabrication capabilities to ensure that the parts meet the rigorous demands of modern automotive engineering.

What Are the Benefits of Using Fancy Steel in Construction?

In construction, fancy steel is used for decorative elements that also serve structural purposes, providing both aesthetic appeal and strength. This dual functionality is crucial for modern architecture, where design and safety must coexist. Buyers should evaluate the design flexibility and customization options available to meet specific project requirements effectively.

How Does Fancy Steel Enhance Energy Production Systems?

Fancy steel components are increasingly utilized in renewable energy systems, such as wind turbines and solar panels, where reliability and efficiency are paramount. The use of this material can significantly enhance the performance and lifespan of energy generation equipment. Buyers should seek suppliers experienced in energy sector applications to ensure the components are designed for optimal functionality in demanding environments.

3 Common User Pain Points for ‘fancy steel’ & Their Solutions

Scenario 1: Navigating Quality Standards for Custom Steel Products

The Problem: B2B buyers often face challenges when sourcing fancy steel products that meet their specific quality standards. The variability in craftsmanship, material quality, and manufacturing processes can lead to inconsistencies in the final product. For instance, a buyer from Europe may be concerned about the compliance of the products with EU regulations, while a buyer in Africa may be looking for assurance regarding the durability and environmental impact of the materials used. These uncertainties can result in wasted time, increased costs, and potential harm to their reputation if the products do not meet client expectations.

The Solution: To overcome these challenges, buyers should prioritize sourcing from manufacturers with transparent quality assurance processes. Begin by requesting detailed specifications and compliance certifications for the fancy steel products. Engage in direct communication with the manufacturer to discuss quality control measures, such as third-party inspections or audits. Additionally, consider visiting the production facility if feasible, as this allows buyers to assess the craftsmanship firsthand and ensure that the materials used align with their standards. Establishing a clear set of quality benchmarks and including these in purchase agreements can also safeguard against discrepancies and facilitate smoother transactions.

Illustrative image related to fancy steel

Scenario 2: Addressing Lead Time and Supply Chain Issues

The Problem: Lead times can be a significant pain point when procuring fancy steel products, particularly in a globalized market where supply chain disruptions are common. A buyer may experience delays due to unexpected demand surges, transportation challenges, or production bottlenecks, which can impact project timelines and lead to financial losses. For instance, a construction firm in South America may find that the promised delivery of custom steel components is delayed, affecting their ability to meet deadlines.

The Solution: To mitigate lead time issues, buyers should adopt a proactive approach to inventory management and supplier relationships. Engage with multiple suppliers to create a diversified supply chain that can provide alternative options in case of disruptions. Implementing just-in-time inventory practices can also help manage stock levels and reduce waste. Additionally, work closely with suppliers to understand their production capabilities and plan orders well in advance, allowing for buffer time in case of unforeseen delays. Establishing a communication protocol for real-time updates on order status can further help manage expectations and ensure timely project execution.

Scenario 3: Overcoming Misalignment Between Product Design and Application

The Problem: B2B buyers frequently encounter misalignment between the design of fancy steel products and their intended application. For example, a company may order bespoke steel components that are aesthetically pleasing but not functional for their specific use case, leading to performance issues and additional costs for modifications. This is especially critical in industries such as construction or automotive, where precision and functionality are paramount.

The Solution: To address this issue, buyers should engage in thorough pre-order consultations with manufacturers to clarify their specific application needs and design requirements. Provide detailed technical specifications, including load capacities, environmental conditions, and aesthetic preferences. Utilizing prototypes or samples can also help ensure that the final product meets functional and design criteria before committing to larger orders. Regular feedback loops during the design and production phases can further ensure alignment, allowing for adjustments before final production, thereby minimizing the risk of costly errors.

Strategic Material Selection Guide for fancy steel

What Are the Key Materials Used in Fancy Steel Production?

When selecting materials for fancy steel applications, particularly in the manufacturing of bespoke chastity products, it’s crucial to consider the unique properties and performance characteristics of each material. Below, we analyze four common materials used in the production of fancy steel, focusing on their advantages, disadvantages, and suitability for international B2B buyers.

How Does Stainless Steel Perform in Fancy Steel Applications?

Stainless steel is a popular choice due to its excellent corrosion resistance and durability. It can withstand various environmental conditions, making it suitable for applications that may involve moisture or bodily fluids. Key properties include a high tensile strength and the ability to maintain structural integrity under pressure.

Illustrative image related to fancy steel

Pros: Its durability and aesthetic appeal make stainless steel ideal for high-quality products. It is also relatively easy to manufacture and can be polished to a high shine, enhancing the product’s visual appeal.

Cons: The cost of stainless steel can be higher than other materials, and it may require specialized machining processes, which can increase manufacturing complexity.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and various lubricants, which is essential for products designed for personal use.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is critical. Buyers from regions like Europe and the Middle East often prefer materials that meet stringent quality certifications.

Why Is Titanium Considered a Premium Option for Fancy Steel?

Titanium is known for its exceptional strength-to-weight ratio and superior corrosion resistance. It is particularly valuable in applications where weight is a concern, such as in wearable products.

Pros: Titanium is highly durable and can withstand extreme temperatures, making it suitable for a variety of environments. Its biocompatibility is a significant advantage for products that come into contact with skin.

Cons: The primary drawback of titanium is its high cost and the complexity involved in machining and manufacturing, which can lead to longer lead times.

Impact on Application: Titanium’s compatibility with various media, including saline solutions, makes it an excellent choice for products intended for diverse uses.

Considerations for International Buyers: Buyers should be aware of the specific grades of titanium (like Ti-6Al-4V) that meet international standards, ensuring compliance with local regulations.

What Role Does Aluminum Play in Fancy Steel Manufacturing?

Aluminum is often used for its lightweight properties and ease of fabrication. It is less common in high-stress applications but can be suitable for decorative elements or components that do not require high strength.

Pros: Aluminum is cost-effective and can be easily shaped and anodized, providing aesthetic versatility. It is also resistant to corrosion, particularly when treated.

Cons: Its lower strength compared to stainless steel and titanium limits its applications in high-stress scenarios. Additionally, aluminum may not be as durable in prolonged exposure to certain chemicals.

Impact on Application: Aluminum is suitable for lightweight designs but may not be appropriate for products requiring high durability or strength.

Considerations for International Buyers: Buyers should consider the specific aluminum alloys that comply with international standards, ensuring that the product meets both performance and regulatory requirements.

How Does Carbon Steel Compare in Fancy Steel Applications?

Carbon steel is valued for its strength and affordability. It is often used in applications where high tensile strength is required but does not require the corrosion resistance of stainless steel.

Pros: Carbon steel is durable and cost-effective, making it an attractive option for manufacturers looking to minimize costs while maintaining product integrity.

Cons: Its susceptibility to rust and corrosion limits its use in applications exposed to moisture or chemicals unless adequately treated.

Impact on Application: Carbon steel is suitable for structural components but may not be ideal for products intended for personal use without protective coatings.

Considerations for International Buyers: Buyers should ensure that carbon steel products are treated or coated to meet local standards, particularly in humid or corrosive environments.

Summary Table of Material Selections

| Material | Typical Use Case for fancy steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-quality chastity products | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Titanium | Premium bespoke items | Exceptional strength-to-weight ratio | High cost and machining complexity | High |

| Aluminum | Decorative components | Lightweight and cost-effective | Lower strength and durability | Low |

| Carbon Steel | Structural components | Durable and affordable | Susceptible to rust without treatment | Medium |

This guide provides a comprehensive overview of materials relevant to fancy steel applications, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for fancy steel

What Are the Main Stages of Manufacturing Fancy Steel Products?

The manufacturing of fancy steel products, particularly bespoke chastity belts and related accessories, is a meticulous process that ensures both aesthetic appeal and functional integrity. This process is generally divided into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Fancy Steel Products?

Material preparation begins with the selection of high-quality steel, often sourced from reputable suppliers to ensure durability and safety. The steel is then cut to size using precision tools, ensuring that each piece meets the exact specifications required for the final product. In the case of bespoke items, this stage may involve consultation with clients to ensure their specific needs are met.

Additionally, before any forming processes begin, the materials undergo surface treatment to remove impurities and enhance adhesion for subsequent processes. This may include cleaning, grinding, or polishing, which is crucial for ensuring that the final product not only looks good but also adheres to quality standards.

What Techniques Are Used in Forming Fancy Steel Products?

Forming is where the design comes to life. Various techniques are employed depending on the complexity of the item. Common methods include:

- Pressing and Stamping: These techniques allow for the mass production of parts by applying pressure to shape the material.

- Welding: For assembly, welding techniques are used to join different components. This requires skilled craftsmen to ensure strong and durable joints.

- CNC Machining: Computer Numerical Control (CNC) machining is often utilized for precision cutting and shaping, allowing for intricate designs that are difficult to achieve through traditional methods.

These techniques not only enable the creation of aesthetically pleasing products but also ensure their functionality and durability, which are critical for the end-users.

How Is Assembly Conducted in the Manufacturing of Fancy Steel Products?

Assembly involves bringing together all the components that have been formed and processed. Each piece is meticulously checked for fit and finish before being permanently joined. Quality artisans often oversee this stage, ensuring that every product meets the design specifications and quality standards.

In the case of fancy steel products, assembly may also include the integration of advanced features, such as WiFi-controlled mechanisms in chastity belts. This step requires precise alignment and calibration to ensure proper functionality.

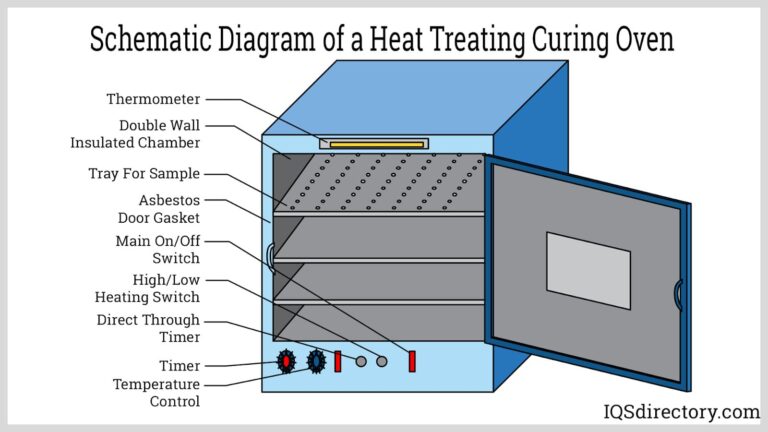

What Finishing Processes Are Critical for Fancy Steel Products?

Finishing processes are vital in enhancing the product’s aesthetics and providing protective coatings. This stage includes:

- Polishing: This enhances the surface finish, giving the product a sleek and appealing look.

- Coating: Protective coatings may be applied to prevent rust and wear, extending the life of the product.

- Quality Inspections: Before the products are packaged and shipped, they undergo final inspections to ensure they meet all specifications and standards.

This attention to detail in the finishing processes contributes significantly to the perceived value of fancy steel products, making them more attractive to B2B buyers.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is paramount in the manufacturing of fancy steel products. B2B buyers should be familiar with international quality standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with this standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications like CE marking (which indicates compliance with European health, safety, and environmental protection standards) and API specifications (for products used in the oil and gas industry) may also be relevant, depending on the end-use of the products.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to the manufacturing process and can be categorized into three main phases:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is performed to catch any defects early in the process. This may involve regular checks of dimensions, weight, and visual appearance.

- Final Quality Control (FQC): Once the products are fully assembled, they undergo a final inspection to ensure they meet all specifications before shipping.

These checkpoints help identify potential issues early, reducing waste and ensuring that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is crucial in establishing trust and ensuring product reliability. Here are some actionable strategies:

-

Request Documentation: Suppliers should provide documentation of their quality management systems, including certifications and quality control procedures.

-

Conduct Audits: Regular audits of suppliers can help buyers assess compliance with quality standards. This may include on-site visits to observe manufacturing practices and QC measures firsthand.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality control processes and product quality.

-

Review Reports: Suppliers should be willing to share results from quality tests and inspections, helping buyers understand the reliability of the products they intend to purchase.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances when it comes to quality control:

-

Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. It is essential to ensure that suppliers comply with both local and international standards applicable to the target market.

-

Cultural Differences: Understanding the cultural context of suppliers can help in building stronger relationships and ensuring that quality expectations are clearly communicated.

-

Logistics Considerations: International shipping can introduce additional risks to product quality. Buyers should ensure that suppliers have robust packaging and shipping protocols to protect products during transit.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance measures is essential for B2B buyers looking to procure fancy steel products. By focusing on these aspects, buyers can ensure they partner with reliable suppliers who meet their quality expectations and provide value for their investments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fancy steel’

The following guide serves as a practical checklist for B2B buyers looking to procure ‘fancy steel.’ This step-by-step approach will help ensure that you make informed purchasing decisions while navigating the complexities of sourcing in international markets.

Step 1: Define Your Technical Specifications

Start by clearly outlining your technical requirements for fancy steel products. Consider factors such as the intended application, dimensions, and material properties. Detailing these specifications upfront will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

- Consider Product Types: Identify whether you need custom designs, standard products, or specific features like advanced technology integration.

- Quality Standards: Ensure that your specifications align with industry standards relevant to your market.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in fancy steel products. Utilize online resources, industry forums, and trade shows to gather a list of potential candidates.

- Evaluate Online Presence: Check their websites for product catalogs, client testimonials, and case studies. A strong online presence often indicates a reputable supplier.

- Industry Reputation: Look for reviews and ratings from previous clients to gauge reliability and product quality.

Step 3: Verify Supplier Certifications

Before entering into negotiations, verify that potential suppliers hold the necessary certifications and quality assurances. This is crucial for ensuring compliance with international standards and regulations.

- ISO Certifications: Look for ISO 9001 or other relevant certifications that indicate quality management systems.

- Material Certifications: Ensure the steel used meets specific standards (e.g., ASTM, EN) for your industry.

Step 4: Request Samples

Always request product samples before making bulk purchases. This allows you to evaluate the quality and suitability of the fancy steel products firsthand.

- Assess Quality: Examine the craftsmanship, finish, and functionality of the samples to ensure they meet your specifications.

- Test Performance: If applicable, conduct tests to confirm that the products perform as expected in real-world conditions.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms. Understanding the financial implications is key to successful procurement.

- Transparent Pricing: Ensure that the supplier provides a clear breakdown of costs, including shipping and handling.

- Payment Flexibility: Inquire about payment options, such as upfront payments, credit terms, or installment plans that may suit your cash flow.

Step 6: Evaluate Logistics and Delivery Options

Consider the logistics involved in the procurement process. Assess delivery times, shipping methods, and any associated costs.

- Shipping Arrangements: Confirm how the supplier handles shipping and whether they provide tracking information.

- Customs and Duties: Be aware of any customs requirements or duties that could affect the total cost and timeline.

Step 7: Establish a Communication Plan

Set up a communication plan to maintain clear and consistent contact with your supplier throughout the procurement process.

- Regular Updates: Schedule regular check-ins to discuss project progress, address any concerns, and ensure timelines are being met.

- Feedback Mechanism: Create a system for providing feedback on the products and services received to foster a collaborative relationship.

By following this checklist, B2B buyers can navigate the complexities of sourcing fancy steel with confidence, ensuring that they secure high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for fancy steel Sourcing

Understanding the intricacies of cost and pricing for fancy steel sourcing is crucial for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. This section explores the fundamental cost components, pricing influencers, and actionable buyer tips that can facilitate more effective procurement strategies.

What Are the Key Cost Components in Fancy Steel Sourcing?

When analyzing the cost structure for fancy steel products, several components must be considered:

-

Materials: The quality and type of steel significantly affect costs. Premium materials, such as high-grade stainless steel or specialized alloys, may incur higher prices but can enhance product longevity and performance.

-

Labor: The craftsmanship involved in producing bespoke products like chastity belts requires skilled labor. Labor costs can vary based on geographical location, expertise, and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes indirect costs related to factory operations, such as utilities, depreciation, and maintenance of equipment. Efficient production processes can help minimize these expenses.

-

Tooling: Custom tooling for specific designs can be a significant upfront investment. Buyers should consider whether the supplier has the necessary tooling capabilities to meet their specifications.

-

Quality Control (QC): Rigorous QC processes ensure that products meet required standards. The costs associated with quality assurance are essential for maintaining brand reputation and customer satisfaction.

-

Logistics: Transportation and warehousing costs can vary widely based on the shipping distance, mode of transport, and the volume of goods ordered. Incoterms will also play a crucial role in defining who bears these costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market conditions and the competitive landscape.

How Do Various Factors Influence Pricing for Fancy Steel Products?

Several factors can influence the pricing of fancy steel products:

-

Volume/MOQ: Larger orders often qualify for discounts due to economies of scale. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Customized products generally come with higher costs due to the additional labor and materials required. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: Certifications such as ISO or ASTM can impact pricing. Products that require additional certifications may incur higher costs due to the compliance processes.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can significantly affect pricing. Established suppliers with a strong track record may charge a premium for their reliability.

-

Incoterms: These terms dictate the responsibilities of buyers and sellers regarding shipping and logistics. Understanding the implications of different Incoterms can help buyers calculate total costs more accurately.

What Are Some Effective Buyer Tips for Negotiating Fancy Steel Prices?

For international B2B buyers, especially in emerging markets, implementing strategic negotiation tactics can lead to significant cost savings:

-

Negotiate on Volume: Leverage larger orders to negotiate better prices. Suppliers are often willing to offer discounts for bulk purchases.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and potential replacements. Investing in higher-quality products may yield better overall value.

-

Understand Pricing Nuances: Familiarize yourself with local market conditions and pricing trends in the regions you’re sourcing from. This knowledge can empower you during negotiations.

-

Build Relationships: Developing strong relationships with suppliers can lead to better pricing, priority service, and more favorable terms. Regular communication can foster trust and collaboration.

Disclaimer on Indicative Prices

Prices for fancy steel products can vary significantly based on the factors discussed above. Buyers are encouraged to conduct comprehensive market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing fancy steel With Other Solutions

Understanding Alternatives for Fancy Steel Products

When exploring solutions for unique craftsmanship and quality in the realm of bespoke chastity belts and fetish gear, it’s essential to consider alternatives that may fulfill similar needs. This analysis aims to compare Fancy Steel against other viable options, allowing international B2B buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best-use cases.

Illustrative image related to fancy steel

| Comparison Aspect | Fancy Steel | Alternative 1: Custom Leather Gear | Alternative 2: Stainless Steel Products |

|---|---|---|---|

| Performance | High-quality craftsmanship and aesthetic design | Good quality, but variable craftsmanship | Durable and long-lasting, less aesthetic |

| Cost | Premium pricing ($466 – $1,599 AUD) | Moderate pricing ($200 – $800 AUD) | Competitive pricing ($150 – $600 AUD) |

| Ease of Implementation | Requires custom orders and lead times | Typically ready-made or semi-custom | Generally off-the-shelf, minimal lead time |

| Maintenance | Low maintenance; regular cleaning needed | Moderate; depends on the leather care | Very low; resistant to corrosion |

| Best Use Case | High-end fetish markets; bespoke needs | Customizable for unique designs; niche markets | General use; durable, functional applications |

What Are the Pros and Cons of Custom Leather Gear?

Custom leather gear represents a popular alternative for those seeking a balance between aesthetics and functionality. The craftsmanship involved can be high-quality, offering unique designs tailored to individual preferences. However, the variability in craftsmanship can lead to inconsistencies in product quality. Leather also requires regular maintenance and care to ensure longevity, which may not be ideal for all users. Its moderate pricing makes it accessible for a broader audience, particularly those looking to enter niche markets.

How Do Stainless Steel Products Compare?

Stainless steel products are often recognized for their durability and low maintenance requirements. They are generally more affordable than bespoke options like Fancy Steel, making them an attractive choice for bulk purchases or general use. However, they may lack the aesthetic appeal and customizability that high-end clients seek. Stainless steel products are usually available off-the-shelf, which means quicker delivery times. Yet, for clients looking for a unique and bespoke experience, they might not meet the desired expectations.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right solution involves weighing the specific needs of your business against the offerings of each alternative. If your focus is on high-end markets that require unique craftsmanship and aesthetic appeal, Fancy Steel is a compelling choice despite its premium pricing. However, if you’re targeting broader markets or seeking quicker turnaround times, custom leather gear or stainless steel products may provide better value. Ultimately, understanding your target audience and their preferences will guide you in making the most informed decision.

Essential Technical Properties and Trade Terminology for fancy steel

What Are the Key Technical Properties of Fancy Steel?

When it comes to fancy steel, understanding its technical properties is crucial for international B2B buyers. Here are some essential specifications that should be considered:

1. Material Grade

Material grade indicates the quality and characteristics of the steel. Different grades offer varying levels of strength, ductility, and corrosion resistance. For instance, stainless steel grades like 304 or 316 are commonly used in applications requiring high corrosion resistance. For buyers, selecting the right material grade ensures that the final product meets performance requirements and regulatory standards.

2. Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension of a material. It is vital in manufacturing processes to ensure that components fit together correctly. In fancy steel applications, precise tolerances are critical for aesthetic and functional purposes. Understanding tolerances helps buyers avoid costly rework or product failures.

3. Yield Strength

Yield strength is the amount of stress that a material can withstand without permanent deformation. This property is particularly important in applications where the steel will be subjected to heavy loads or stress. For buyers, knowing the yield strength helps in selecting materials that will not fail under expected operational conditions, ensuring safety and longevity.

4. Surface Finish

Surface finish describes the texture and quality of the steel’s surface. It can significantly affect not only the aesthetic appeal but also the performance of the final product, influencing factors like corrosion resistance and wear. For B2B buyers, specifying the required surface finish can enhance product appeal and functionality.

5. Machinability

Machinability refers to how easily a material can be cut, shaped, or finished. This property impacts production costs and timelines. Steel with high machinability allows for quicker and more efficient manufacturing processes, which is a key consideration for buyers looking to optimize their supply chain.

What Are Common Trade Terms in the Fancy Steel Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to the fancy steel sector:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the fancy steel industry, OEMs often design and manufacture bespoke products according to client specifications. Buyers should understand OEM capabilities to ensure alignment with their project needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and budget planning. Understanding the MOQ helps companies forecast costs and avoid overstocking.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. In the context of fancy steel, issuing an RFQ allows buyers to compare costs and terms from multiple suppliers, fostering competitive pricing and better negotiation outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in global trade. They cover aspects such as shipping, insurance, and tariffs. Familiarity with Incoterms is essential for buyers to understand their liabilities and rights in transactions involving fancy steel.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. This term is critical in supply chain management, as it affects project timelines and inventory levels. Buyers must consider lead times when planning their production schedules to avoid delays.

Understanding these technical properties and trade terminologies equips international B2B buyers with the knowledge needed to make informed decisions in the fancy steel marketplace. By leveraging this information, companies can enhance their procurement strategies, ensure product quality, and foster stronger supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the fancy steel Sector

What Are the Current Trends Shaping the Fancy Steel Market?

The fancy steel sector is witnessing a robust transformation driven by globalization and technological advancements. Key market dynamics include the increasing demand for customized products, facilitated by advancements in manufacturing technologies such as 3D printing and automated processes. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking unique and bespoke solutions, prompting suppliers to innovate continually. Additionally, the rise of e-commerce platforms is reshaping how buyers source fancy steel products, allowing for more efficient comparisons and transactions across borders.

Emerging sourcing trends are heavily influenced by digitalization. International buyers are leveraging data analytics and AI to optimize their procurement processes, ensuring they find the best suppliers and materials at competitive prices. Moreover, a growing emphasis on speed and flexibility in supply chains is compelling manufacturers to adopt just-in-time production methods. This shift allows for rapid response to market demands, catering specifically to niche markets within the fancy steel sector.

How Are Sustainability and Ethical Sourcing Impacting the Fancy Steel Industry?

Sustainability has become a cornerstone for B2B buyers in the fancy steel sector. The environmental impact of steel production is significant, necessitating a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who adopt eco-friendly methods, such as utilizing recycled materials and minimizing carbon footprints. This trend is not just a compliance issue; it has become a vital part of brand reputation and consumer trust.

Ethical sourcing is another critical aspect. Buyers are demanding transparency in the supply chain to ensure that materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and other green certifications serve as essential benchmarks for buyers looking to partner with manufacturers committed to ethical practices. By prioritizing sustainable and ethical sourcing, companies can not only comply with regulations but also appeal to a growing consumer base that values corporate responsibility.

How Has the Fancy Steel Sector Evolved Over Time?

The fancy steel sector has evolved significantly over the last few decades. Initially focused on traditional manufacturing processes, the industry has embraced innovation to meet the changing demands of consumers and B2B buyers. The introduction of advanced materials and technologies has allowed manufacturers to create unique products that cater to diverse markets, from construction to decorative arts.

As global trade has expanded, so too has the market for fancy steel. International buyers now have access to a broader array of products and suppliers than ever before, allowing for greater customization and specialization. This evolution reflects not only the technological advancements in manufacturing but also the growing importance of aesthetics and functionality in steel products, which are increasingly seen as integral to design and lifestyle choices.

In conclusion, understanding the dynamics of the fancy steel sector, particularly in the context of sustainability and ethical sourcing, is crucial for international B2B buyers. By staying informed about these trends, companies can position themselves strategically to meet the demands of an evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of fancy steel

-

How do I choose the right supplier for fancy steel?

Selecting the right supplier for fancy steel involves evaluating several key factors. First, assess their industry reputation and experience in manufacturing bespoke steel products. Look for certifications that ensure quality standards, such as ISO 9001. Additionally, request samples of their products to evaluate craftsmanship. Finally, consider their logistical capabilities, including shipping options and delivery timelines, especially if you’re sourcing internationally from regions like Africa or South America. -

What is the minimum order quantity (MOQ) for fancy steel products?

The minimum order quantity (MOQ) for fancy steel products varies by supplier and product type. Many manufacturers set an MOQ to ensure cost-effectiveness in production and shipping. Typically, MOQs can range from a few hundred to several thousand units. It is essential to communicate your specific needs with the supplier to negotiate terms that align with your procurement strategy and project requirements. -

What are the payment terms commonly offered for fancy steel purchases?

Payment terms for fancy steel purchases can differ significantly based on the supplier and the buyer’s location. Standard terms may include options such as 30% upfront payment with the balance due upon delivery or a letter of credit for larger orders. It’s crucial to clarify payment methods accepted (e.g., bank transfers, credit cards, or cryptocurrencies) and any potential financing options that could ease your cash flow management. -

How do I ensure quality assurance when sourcing fancy steel?

To ensure quality assurance when sourcing fancy steel, request detailed product specifications and certifications from your supplier. Conduct pre-production inspections and quality checks during the manufacturing process. Establish a clear agreement regarding quality standards, and consider third-party quality assurance services for independent verification. This diligence helps mitigate risks associated with defects or non-compliance with your specifications. -

What logistics considerations should I be aware of when importing fancy steel?

When importing fancy steel, consider several logistics aspects such as shipping methods, customs regulations, and tariffs in your destination country. Collaborate with a freight forwarder who is familiar with international trade in steel products to streamline the process. Additionally, assess lead times for production and shipping to ensure timely delivery, especially if you are working on a tight project schedule. -

Can I customize fancy steel products to meet my specific needs?

Yes, many suppliers of fancy steel offer customization options to meet specific project requirements. You can request alterations in design, dimensions, and finishes to align with your branding or functional needs. It’s advisable to provide detailed specifications and prototypes to the manufacturer to ensure that your customizations are accurately implemented. Discuss any additional costs associated with customization during the negotiation phase. -

What certifications should I look for in fancy steel suppliers?

When sourcing fancy steel, look for suppliers with relevant industry certifications that indicate adherence to quality and safety standards. Certifications such as ISO 9001 for quality management systems or ASTM standards for material properties can provide assurance of product reliability. Additionally, check for compliance with local regulations, especially if you are importing to regions with strict industrial standards. -

How can I mitigate risks when sourcing fancy steel internationally?

Mitigating risks in international sourcing of fancy steel involves comprehensive supplier vetting, including background checks and requesting references from previous clients. Establish clear contracts that outline terms and conditions, including quality expectations and delivery timelines. Consider using escrow services for transactions to protect your investment. Finally, stay informed about geopolitical factors or market fluctuations that could impact supply chains.

Top 6 Fancy Steel Manufacturers & Suppliers List

1. Pinterest – Steel Heels

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: This company, Pinterest – Steel Heels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Etsy – Fancy Steel Garden Decorations

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Fancy Steel Garden Decorations, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Schattdecor – Fancy Steel Decor

Domain: schattdecor.com

Registered: 1996 (29 years)

Introduction: This company, Schattdecor – Fancy Steel Decor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. IoST Index – Advanced Training Collar

Domain: iostindex.com

Registered: 2019 (6 years)

Introduction: This company, IoST Index – Advanced Training Collar, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Fancy Steel – Marketing Agency

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Fancy Steel – Marketing Agency, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

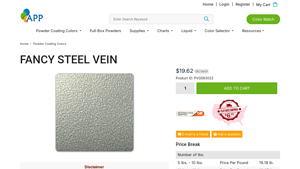

6. All Powder Paints – Fancy Steel Vein

Domain: allpowderpaints.com

Registered: 2011 (14 years)

Introduction: {“name”: “Fancy Steel Vein”, “price_per_lb”: 19.62, “product_id”: “PVGS83022”, “price_breaks”: [{“weight_range”: “5 lbs. – 10 lbs.”, “price_per_pound”: 19.18}, {“weight_range”: “11 lbs. – 19 lbs.”, “price_per_pound”: 18.67}, {“weight_range”: “20 lbs. – 29 lbs.”, “price_per_pound”: 18.13}, {“weight_range”: “30 lbs. – 39 lbs.”, “price_per_pound”: 17.33}, {“weight_range”: “40 lbs. – 200 lbs.”, “price…

Strategic Sourcing Conclusion and Outlook for fancy steel

As the global market for fancy steel continues to evolve, strategic sourcing emerges as a crucial component for international B2B buyers. This guide has highlighted the importance of understanding the unique attributes of fancy steel, including its craftsmanship and versatility in niche markets. Buyers are encouraged to engage with suppliers who demonstrate transparency in their sourcing practices, ensuring high-quality materials while fostering sustainable relationships.

Investing in strategic sourcing not only enhances product quality but also enables buyers to leverage competitive pricing and innovative solutions tailored to their specific needs. For stakeholders in Africa, South America, the Middle East, and Europe, forming partnerships with reputable manufacturers like Fancy Steel can lead to significant operational advantages and market differentiation.

Looking ahead, the demand for customized and high-performance products will only increase. International B2B buyers should proactively seek opportunities to collaborate with suppliers who prioritize craftsmanship and customer service. By doing so, they can position themselves effectively within the ever-competitive landscape of fancy steel, driving growth and innovation in their respective markets. Embrace the potential of strategic sourcing today to secure a prosperous future in the fancy steel industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.