A B2B Buyer’s Guide to Expanded Metal 4X8: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for expanded metal 4×8

Navigating the global market for expanded metal 4×8 sheets can be a complex endeavor, particularly for international B2B buyers seeking to procure high-quality materials at competitive prices. As the demand for versatile construction and manufacturing solutions grows, sourcing expanded metal—known for its strength, lightweight properties, and unique diamond-pattern openings—has become essential for diverse applications, from industrial flooring to decorative elements. However, the challenge lies not only in identifying reliable suppliers but also in understanding the various types, specifications, and costs associated with these products.

This comprehensive guide aims to equip B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Saudi Arabia—with the critical insights needed for informed purchasing decisions. Throughout this guide, we will explore the different types of expanded metal, their diverse applications, and effective strategies for vetting suppliers. Additionally, we will provide a detailed overview of pricing structures, helping you to navigate cost considerations and negotiate better deals.

By leveraging the information presented in this guide, international buyers can confidently approach their sourcing needs for expanded metal 4×8 sheets, ensuring they secure high-quality products that meet their specific requirements while optimizing their procurement processes.

Understanding expanded metal 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Expanded Metal | Diamond-shaped openings, raised strands | Walkways, machine guards, security fencing | Pros: Lightweight, high strength; Cons: Can be less stable for small items. |

| Flattened Expanded Metal | Cold-rolled for a smooth surface, uniform thickness | Shelving, decorative applications | Pros: Easy to clean, stable surface; Cons: Less slip resistance compared to standard. |

| Heavy-Duty Expanded Metal | Thicker strands for increased strength | Industrial flooring, catwalks | Pros: Excellent load-bearing capacity; Cons: Heavier, potentially higher shipping costs. |

| Architectural Expanded Metal | Custom patterns and finishes for aesthetic appeal | Facades, decorative screens, furniture | Pros: Versatile design options; Cons: Can be more expensive due to customization. |

| Galvanized Expanded Metal | Coated for corrosion resistance, suitable for outdoor use | Outdoor applications, marine environments | Pros: Enhanced durability; Cons: Slightly higher initial cost. |

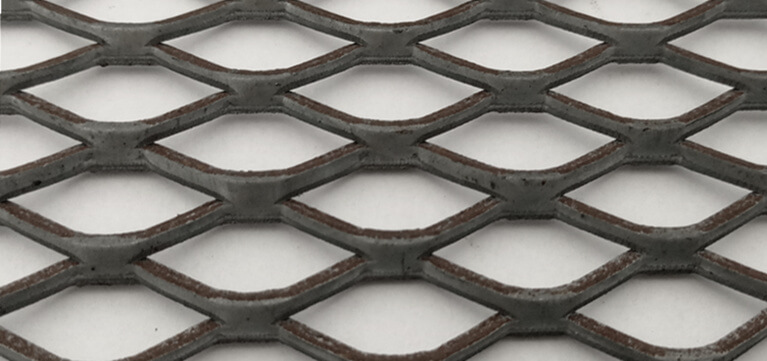

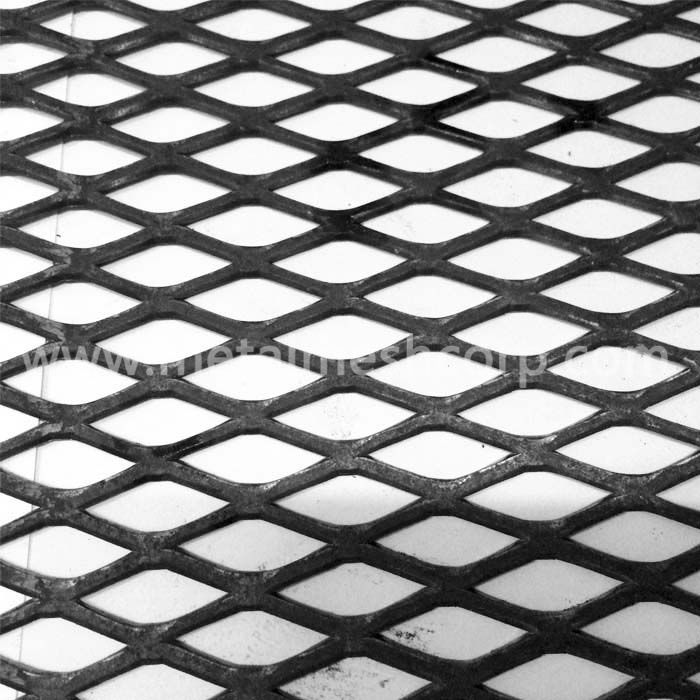

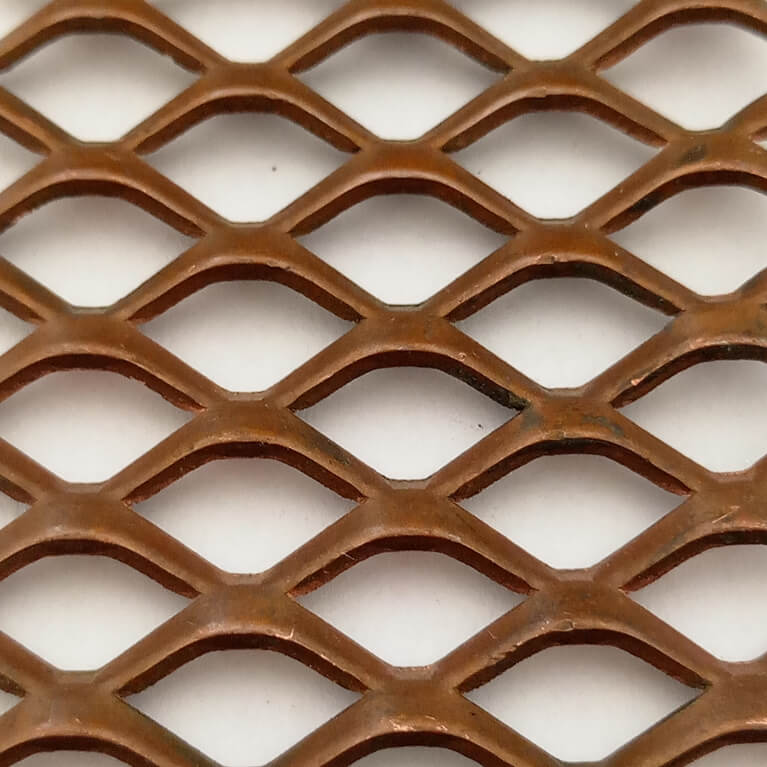

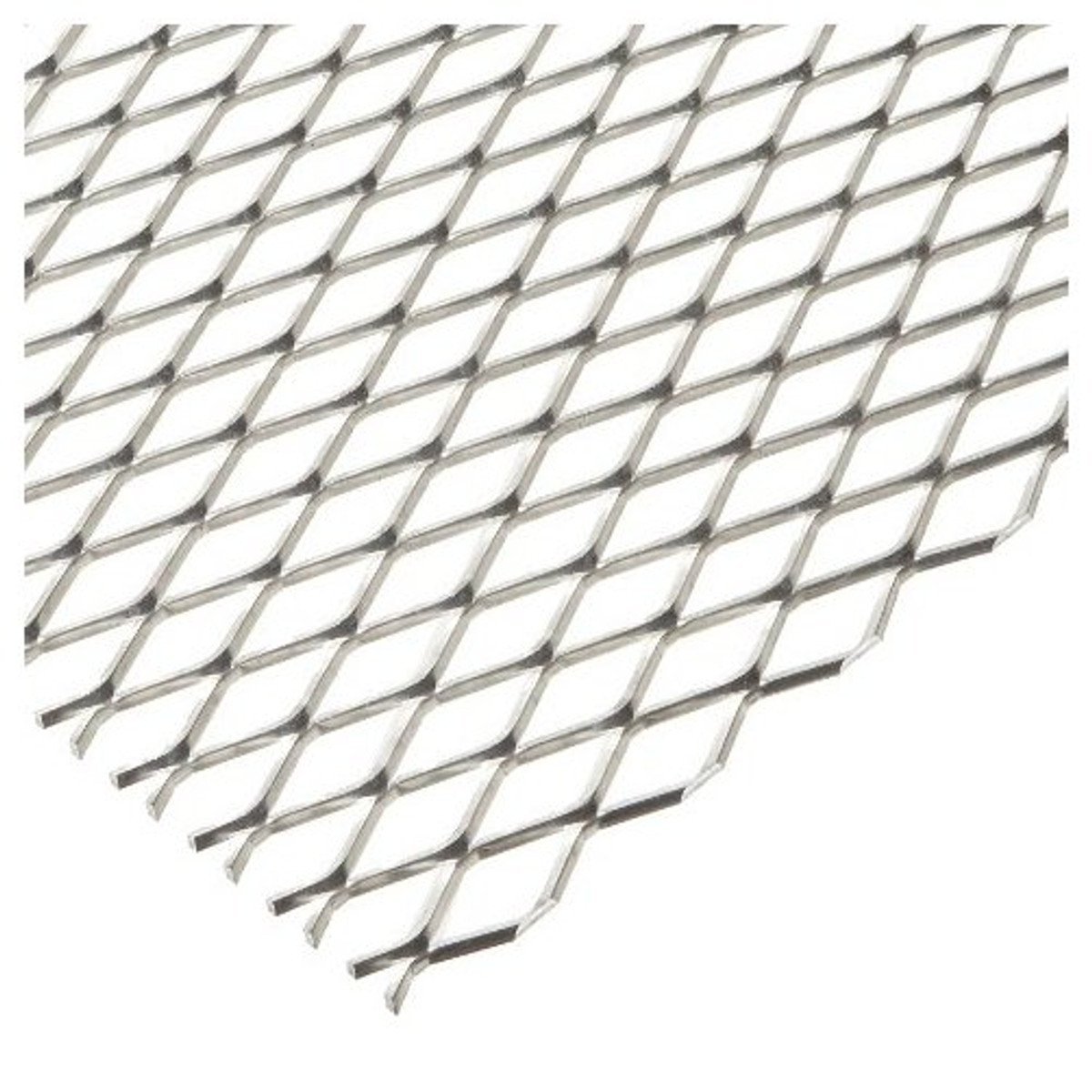

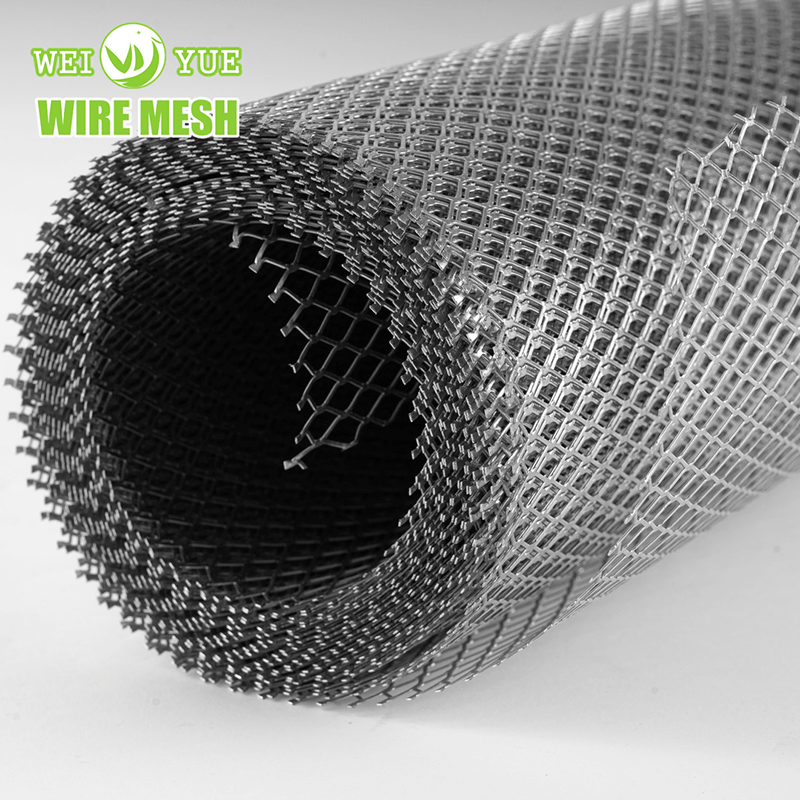

What Are the Characteristics of Standard Expanded Metal?

Standard expanded metal is characterized by its diamond-shaped openings created through a slitting and stretching process. This type is widely used in applications such as walkways, machine guards, and security fencing due to its lightweight yet strong structure. B2B buyers should consider its load-bearing capabilities and cost-effectiveness, although its raised strands may not provide a stable surface for smaller objects.

Illustrative image related to expanded metal 4×8

How Does Flattened Expanded Metal Differ from Other Types?

Flattened expanded metal undergoes a cold-rolling process, resulting in a smooth, uniform surface. This type is ideal for shelving and decorative applications where aesthetics are important. Buyers should consider its easy maintenance and stable surface, although it may lack the slip resistance found in standard expanded metal. Its versatility makes it a popular choice in various industries.

Why Choose Heavy-Duty Expanded Metal for Industrial Applications?

Heavy-duty expanded metal features thicker strands, providing superior strength and load-bearing capacity. This makes it suitable for demanding applications such as industrial flooring and catwalks. While it offers excellent durability, B2B buyers should be mindful of its weight and potential shipping costs, which may increase overall project expenses.

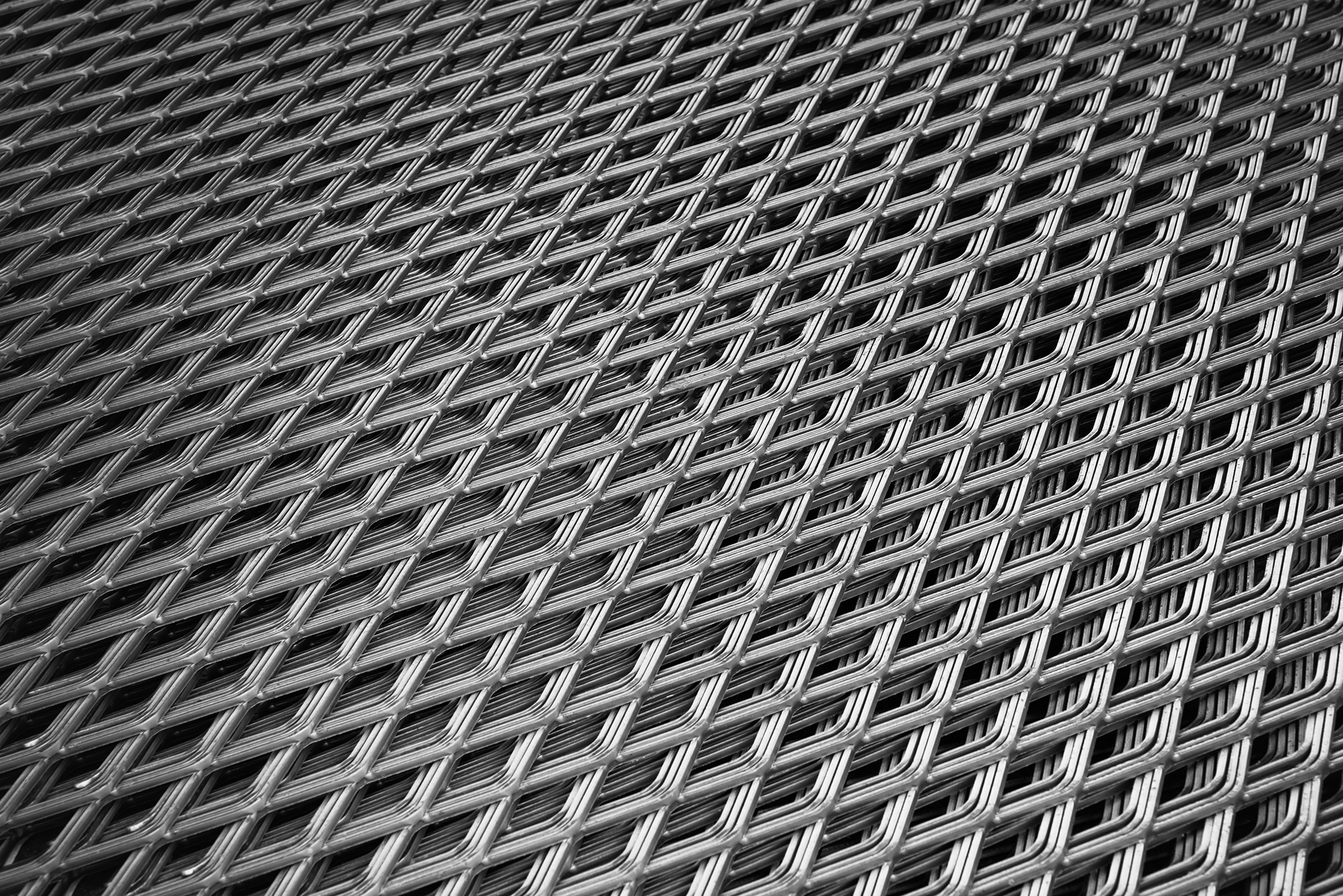

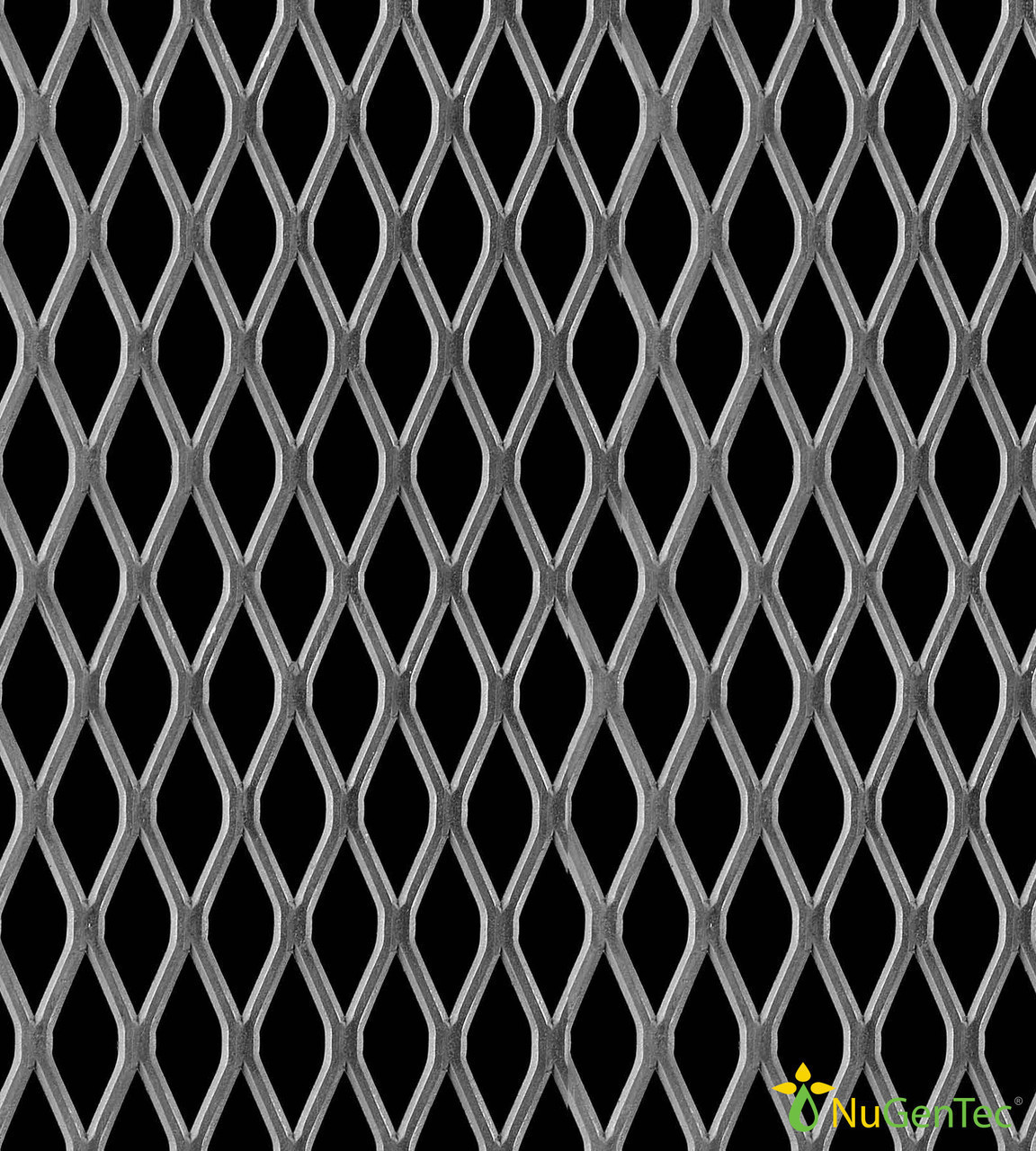

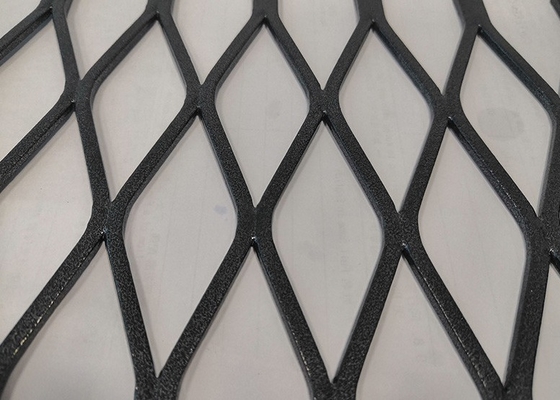

What Are the Benefits of Architectural Expanded Metal?

Architectural expanded metal is designed for aesthetic applications, offering custom patterns and finishes. It is commonly used in facades, decorative screens, and furniture, allowing for creative designs in commercial and residential projects. While it provides versatility and visual appeal, buyers should be prepared for potentially higher costs associated with customization.

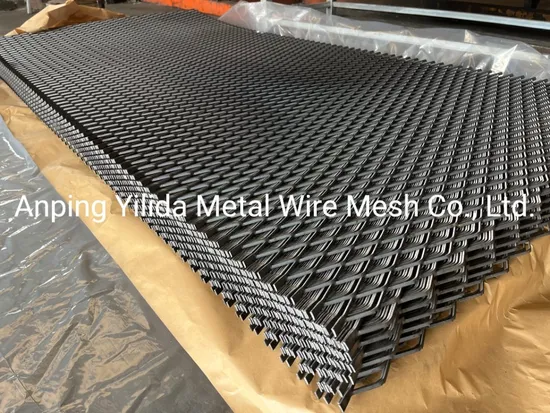

Illustrative image related to expanded metal 4×8

How Does Galvanized Expanded Metal Enhance Durability?

Galvanized expanded metal is coated to resist corrosion, making it an ideal choice for outdoor applications and environments prone to moisture. Its durability ensures a longer lifespan, which can be a cost-saving factor for B2B buyers. However, the initial investment may be higher than non-galvanized options, so it is crucial to weigh the long-term benefits against upfront costs.

Key Industrial Applications of expanded metal 4×8

| Industry/Sector | Specific Application of expanded metal 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Walkways and Stair Treads | Provides safe, durable surfaces with excellent drainage | Ensure compliance with local safety regulations; consider load-bearing capacity. |

| Agriculture | Greenhouse Benches | Enhances air circulation while supporting plant growth | Look for corrosion-resistant materials for longevity in humid environments. |

| Manufacturing | Machine Guards and Safety Barriers | Protects personnel and equipment from hazards | Verify strength and thickness according to specific industrial standards. |

| Mining and Heavy Industry | Catwalks and Platforms | Offers lightweight yet strong solutions for worker access | Assess weight tolerance and environmental factors like exposure to chemicals. |

| Security | Fencing and Window Guards | Provides visibility while ensuring security | Choose materials that meet local security standards and are resistant to tampering. |

How is Expanded Metal 4×8 Used in Construction?

In the construction industry, expanded metal 4×8 sheets are commonly utilized for walkways and stair treads. These applications require materials that provide safety and durability while allowing for drainage. The diamond-shaped openings in the expanded metal facilitate water runoff, reducing slip hazards. For international buyers, especially from regions with varying safety regulations, it is crucial to ensure that the selected expanded metal complies with local building codes and can withstand the expected load-bearing requirements.

What Role Does Expanded Metal 4×8 Play in Agriculture?

In agriculture, expanded metal 4×8 is frequently used for greenhouse benches. These benches support plant growth while promoting air circulation, which is vital for healthy crops. The lightweight nature of expanded metal allows for easy handling and installation. Buyers from humid climates, such as parts of Africa and South America, should prioritize corrosion-resistant materials to ensure longevity and minimize maintenance costs associated with rust and deterioration.

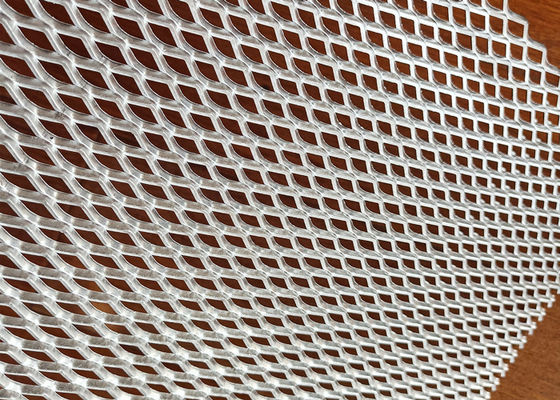

Illustrative image related to expanded metal 4×8

How is Expanded Metal 4×8 Essential in Manufacturing?

Manufacturers utilize expanded metal 4×8 sheets for machine guards and safety barriers. These applications require robust materials that can withstand the rigors of industrial environments while ensuring worker safety. Expanded metal provides visibility, allowing operators to monitor machinery while protecting against accidental contact. When sourcing for these applications, businesses should confirm that the thickness and strength of the expanded metal meet specific industry standards to ensure adequate protection.

Why is Expanded Metal 4×8 Important in Mining and Heavy Industry?

In the mining and heavy industry sectors, expanded metal 4×8 is employed for catwalks and platforms, enabling safe access to elevated areas. The material’s lightweight yet strong characteristics make it ideal for environments where heavy loads and worker safety are concerns. International buyers must evaluate the environmental conditions, such as exposure to chemicals and extreme weather, to select suitable materials that will endure these challenges without compromising safety.

How Does Expanded Metal 4×8 Enhance Security Applications?

Expanded metal 4×8 is widely used in security applications, including fencing and window guards. This material allows for visibility while providing a formidable barrier against unauthorized access. It is essential for buyers to select materials that meet local security standards and consider options that resist tampering and vandalism. For regions with high-security needs, such as urban areas in the Middle East, sourcing expanded metal with enhanced durability features can be a critical factor in ensuring effective protection.

3 Common User Pain Points for ‘expanded metal 4×8’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Expanded Metal 4×8 for Specific Applications

The Problem: Many B2B buyers, especially those in construction and manufacturing sectors, struggle to find the appropriate type of expanded metal 4×8 sheets that meet their specific application needs. With various materials (like steel, aluminum, and stainless steel) and finishes (such as galvanized or painted), selecting the right product can be overwhelming. This often leads to delays in projects, increased costs due to ordering the wrong specifications, and dissatisfaction with the end product’s performance.

The Solution: To effectively source the right expanded metal 4×8, buyers should start by clearly defining their project requirements. This includes understanding the load-bearing capacity, environmental conditions (e.g., corrosion resistance), and aesthetic preferences. Working closely with suppliers who offer a range of customization options can help ensure that the chosen material aligns with these specifications. Buyers should also request samples or detailed product datasheets to assess physical characteristics and performance before finalizing orders. Establishing a relationship with a reliable supplier who understands local market needs can facilitate better sourcing decisions and minimize errors.

Illustrative image related to expanded metal 4×8

Scenario 2: Challenges with Lead Times and Order Fulfillment

The Problem: In regions like Africa and the Middle East, B2B buyers often face long lead times for expanded metal 4×8 sheets, especially when custom processing is required. This can severely impact project timelines and result in financial penalties for missed deadlines. Additionally, suppliers may experience high order volumes, leading to inconsistent communication and delayed responses, which adds to the frustration.

The Solution: To mitigate lead time issues, buyers should proactively discuss timelines with suppliers before placing orders. It’s essential to inquire about current order volumes and processing capacities. Opting for stock sizes rather than custom orders can also expedite fulfillment. Furthermore, establishing contracts that include clear delivery timelines and penalties for delays can incentivize suppliers to prioritize your orders. Buyers should maintain open lines of communication, providing suppliers with regular updates on project timelines and any adjustments needed to ensure timely delivery.

Scenario 3: Misunderstanding Product Specifications and Applications

The Problem: B2B buyers often misinterpret product specifications, such as strand thickness and diamond sizes, which can lead to selecting expanded metal sheets that are unsuitable for their intended applications. For example, choosing a sheet with a larger diamond opening for a security application can compromise safety and functionality. This misunderstanding can result in costly reorders and wasted materials.

Illustrative image related to expanded metal 4×8

The Solution: To overcome this challenge, buyers should invest time in understanding the technical specifications of expanded metal products. Engaging with suppliers for educational resources or workshops can provide valuable insights into how different specifications impact performance. Buyers should also create a checklist of key attributes to consider based on their specific application—like load capacity, airflow requirements, and aesthetic preferences. Additionally, collaborating with engineers or product specialists can provide guidance on the most suitable products for unique applications, ensuring that the selected expanded metal sheets meet performance standards without compromising safety or functionality.

Strategic Material Selection Guide for expanded metal 4×8

What Are the Key Materials for Expanded Metal 4×8?

When selecting expanded metal 4×8 sheets for various applications, the choice of material is crucial. Each material offers unique properties and benefits that can significantly affect performance, durability, and cost. Below, we analyze four common materials used in the production of expanded metal sheets: mild steel, galvanized steel, aluminum, and stainless steel.

How Does Mild Steel Perform in Expanded Metal Applications?

Mild steel is one of the most commonly used materials for expanded metal sheets due to its excellent strength-to-weight ratio. It can withstand moderate temperatures and pressures, making it suitable for various structural applications. However, mild steel is prone to corrosion, which can limit its use in outdoor or humid environments.

Pros:

– High strength and rigidity.

– Cost-effective compared to other metals.

– Easy to fabricate and weld.

Illustrative image related to expanded metal 4×8

Cons:

– Susceptible to rust and corrosion without protective coatings.

– Limited lifespan in harsh environments.

For international buyers, particularly in regions like Africa and South America, it is essential to consider local environmental conditions when opting for mild steel. Compliance with local standards, such as ASTM or DIN, should be verified to ensure product suitability.

Why Choose Galvanized Steel for Expanded Metal Sheets?

Galvanized steel is mild steel coated with a layer of zinc to enhance corrosion resistance. This makes it ideal for applications exposed to moisture, such as outdoor installations or in coastal areas. The zinc coating provides a protective barrier, extending the lifespan of the material.

Pros:

– Excellent corrosion resistance.

– Retains the strength of mild steel.

– Suitable for outdoor applications.

Cons:

– Higher cost than uncoated mild steel.

– The galvanizing process can complicate welding.

International buyers, especially in the Middle East and coastal regions, should prioritize galvanized steel for applications where moisture exposure is a concern. Compliance with galvanizing standards is also crucial for ensuring product quality and longevity.

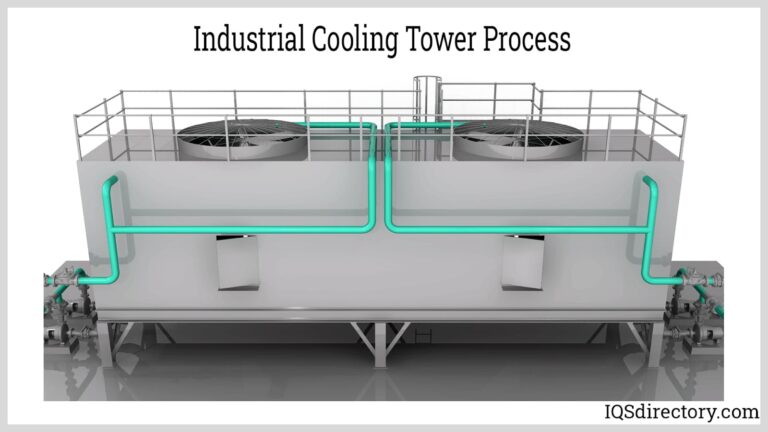

What Advantages Does Aluminum Offer in Expanded Metal Sheets?

Aluminum is a lightweight and corrosion-resistant material, making it ideal for applications requiring reduced weight without sacrificing strength. Its excellent thermal and electrical conductivity also makes it suitable for specialized applications, such as in electrical enclosures or heat exchangers.

Pros:

– Lightweight and easy to handle.

– Excellent corrosion resistance.

– Good thermal and electrical conductivity.

Cons:

– Generally more expensive than steel options.

– Lower strength compared to mild or galvanized steel.

For buyers in Europe and the Middle East, aluminum expanded metal can be an attractive option for decorative applications due to its aesthetic appeal and ease of fabrication. Compliance with relevant standards, such as EN or ISO, should be ensured.

How Does Stainless Steel Compare for Expanded Metal Use?

Stainless steel is renowned for its superior corrosion resistance and strength, making it suitable for demanding environments, including food processing and chemical industries. It can withstand high temperatures and pressures, offering versatility across various applications.

Pros:

– Exceptional corrosion and heat resistance.

– High strength and durability.

– Aesthetic appeal for decorative applications.

Illustrative image related to expanded metal 4×8

Cons:

– Higher cost compared to other materials.

– More challenging to fabricate and weld.

International buyers should consider stainless steel for applications requiring stringent hygiene standards, such as in the food and beverage sector. Compliance with food safety regulations and standards like ASTM or JIS is essential.

Summary Table of Material Selection for Expanded Metal 4×8

| Material | Typical Use Case for expanded metal 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | Structural applications, indoor use | High strength and cost-effective | Susceptible to corrosion | Low |

| Galvanized Steel | Outdoor applications, moisture exposure | Excellent corrosion resistance | Higher cost, complicates welding | Medium |

| Aluminum | Lightweight structures, decorative use | Lightweight and corrosion-resistant | More expensive, lower strength | High |

| Stainless Steel | Food processing, chemical industries | Exceptional corrosion and heat resistance | Higher cost, challenging fabrication | High |

This strategic material selection guide aims to provide B2B buyers with actionable insights into choosing the right expanded metal 4×8 material for their specific applications, taking into account performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for expanded metal 4×8

What Are the Key Stages in the Manufacturing Process of Expanded Metal 4×8?

The manufacturing process of expanded metal 4×8 sheets involves several critical stages, including material preparation, forming, assembly, and finishing. Each of these stages plays a vital role in ensuring the quality and functionality of the final product.

How Is Material Prepared for Expanded Metal Production?

The first step in manufacturing expanded metal is the careful selection and preparation of raw materials. Common materials used include mild steel, stainless steel, and aluminum, which are chosen based on the intended application and required properties.

Illustrative image related to expanded metal 4×8

Once selected, the materials undergo a thorough inspection for defects and impurities. They are then cut into sheets or coils of specified dimensions, typically 4 feet by 8 feet for expanded metal sheets. This preparation phase is crucial for minimizing defects in the final product.

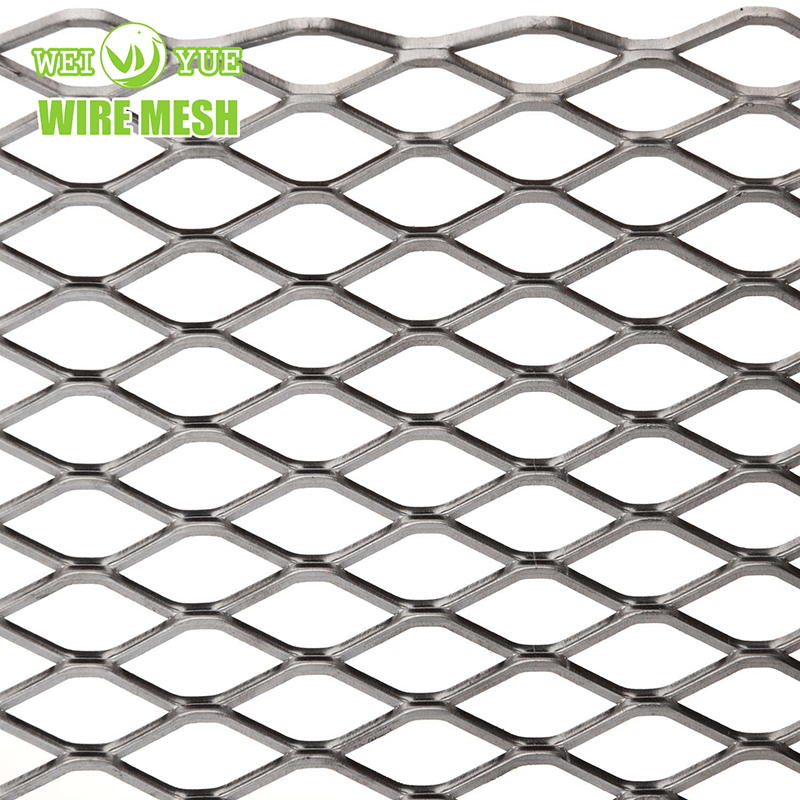

What Techniques Are Used in the Forming Process?

The forming stage employs a unique technique where the prepared sheets are slit and stretched to create diamond-shaped openings. This process is often referred to as “expansion.” The equipment used for this operation varies from hydraulic presses to mechanical expanding machines, each tailored to produce specific patterns and sizes of expanded metal.

The resulting structure is lightweight yet retains considerable strength, making it suitable for various applications, from architectural to industrial uses. The choice between raised and flattened patterns is determined during this stage, based on the desired functionality and aesthetic of the final product.

Illustrative image related to expanded metal 4×8

How Is Assembly Conducted in Expanded Metal Manufacturing?

Assembly in the context of expanded metal typically involves cutting the sheets to size or welding them into larger structures, depending on the customer’s specifications. While expanded metal sheets are often sold as full sheets, they can be fabricated into specific shapes or sizes to meet project requirements.

During this stage, attention is paid to the alignment and fit of components, especially if the expanded metal is part of a larger assembly, such as in construction or machinery applications.

What Finishing Techniques Enhance the Quality of Expanded Metal?

The finishing stage may involve various treatments to improve the durability and aesthetics of the expanded metal. Common techniques include galvanizing, powder coating, or painting to protect against corrosion and enhance visual appeal.

Moreover, surface treatments are essential for specific applications, such as food processing, where hygiene standards must be met. These processes also contribute to the product’s longevity, making it suitable for outdoor and industrial environments.

Illustrative image related to expanded metal 4×8

What Quality Assurance Standards Are Relevant for Expanded Metal Manufacturing?

Quality assurance is a critical component in the manufacturing process of expanded metal, especially for international B2B buyers. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain consistent quality across their products.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001:2015 certification is one of the most recognized quality management standards globally. It provides a framework for manufacturers to ensure their processes meet customer and regulatory requirements. Additionally, industry-specific standards like CE marking for products sold in Europe and API specifications for oil and gas applications may also apply.

B2B buyers in regions like Africa, South America, the Middle East, and Europe should prioritize suppliers with these certifications to mitigate risks associated with quality and compliance.

Illustrative image related to expanded metal 4×8

What Are the Key Quality Control Checkpoints in Manufacturing Expanded Metal?

Quality control (QC) should be integrated throughout the manufacturing process to detect and address defects early. Typical QC checkpoints include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery to ensure they meet specified criteria.

-

In-Process Quality Control (IPQC): During the manufacturing stages, operators conduct checks to verify that processes are within acceptable limits. This includes monitoring the expansion process and ensuring that dimensional tolerances are met.

-

Final Quality Control (FQC): Before shipment, finished products are subjected to comprehensive inspections to ensure they conform to quality standards and customer specifications.

What Common Testing Methods Are Employed?

Manufacturers often use several testing methods to validate the quality of expanded metal sheets, including:

- Dimensional Verification: Measuring the thickness, width, and length to ensure compliance with specifications.

- Strength Testing: Assessing the structural integrity through tensile tests or load-bearing tests to confirm the material can withstand intended applications.

- Surface Quality Inspection: Checking for defects, such as sharp edges or burrs, especially for products intended for safety-sensitive applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing expanded metal, B2B buyers should conduct thorough due diligence on potential suppliers. Here are some strategies to verify quality control practices:

-

Supplier Audits: Conduct on-site inspections or audits of the manufacturing facility to assess adherence to quality standards and practices.

-

Requesting Quality Reports: Buyers should ask for documentation demonstrating compliance with relevant standards, including test results and certification copies.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide unbiased evaluations of product quality and manufacturing practices.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various challenges regarding quality assurance. Different regions may have distinct regulatory requirements, which can complicate compliance.

Illustrative image related to expanded metal 4×8

For instance, buyers from Europe may require CE marking for products, while those from the Middle East may have specific local standards. It is crucial for buyers to communicate their quality expectations clearly and ensure that suppliers can meet these requirements, thereby reducing the risk of non-compliance and enhancing the reliability of the supply chain.

In conclusion, understanding the manufacturing processes and quality assurance measures for expanded metal 4×8 sheets is essential for B2B buyers looking to source high-quality products. By prioritizing suppliers who adhere to international standards and maintain rigorous QC practices, businesses can ensure they receive reliable and durable materials for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expanded metal 4×8’

In today’s global market, sourcing expanded metal sheets, particularly the 4×8 size, requires a strategic approach. This guide provides a practical checklist to help B2B buyers navigate the complexities of procurement, ensuring they make informed decisions that meet their operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is essential to clearly define your technical specifications for the expanded metal. Consider the thickness, material (e.g., mild steel, stainless steel, or aluminum), and the pattern (raised or flattened) that aligns with your application. Specific details like strand width and diamond size also play a critical role in determining the product’s suitability for your project.

- Material Type: Evaluate if you need corrosion-resistant materials for specific environments, such as galvanized or stainless steel.

- Thickness and Size: Specify the required thickness, as this will affect both the weight and strength of the sheets.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers that specialize in expanded metal products. Look for companies with a strong reputation and positive feedback from previous clients. This step is crucial to ensure the quality of the materials you will be purchasing.

Illustrative image related to expanded metal 4×8

- Supplier Experience: Focus on suppliers with a track record in your industry to ensure they understand your specific needs.

- Product Range: Ensure they offer a variety of options in terms of materials, patterns, and custom sizes.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and quality assurance processes. Certifications such as ISO 9001 indicate adherence to quality management standards, which can significantly reduce risks associated with material defects.

- Quality Control Processes: Inquire about their quality control measures to ensure consistency and reliability in production.

- Compliance with Standards: Check if the supplier complies with local and international standards relevant to your industry.

Step 4: Request Samples and Quotes

Once you have shortlisted potential suppliers, request samples of the expanded metal sheets. This allows you to assess the quality and suitability of the product firsthand. Along with samples, obtaining detailed quotes will help you understand pricing structures and any additional costs.

- Sample Evaluation: Inspect the samples for dimensions, finish, and overall quality.

- Quote Breakdown: Ensure quotes include information about shipping, lead times, and any potential discounts for bulk orders.

Step 5: Negotiate Terms and Conditions

Negotiating favorable terms is vital to a successful procurement process. Discuss payment terms, delivery schedules, and any warranties or return policies that may apply. A clear agreement helps prevent misunderstandings later.

- Payment Flexibility: Explore options for payment terms that align with your cash flow management.

- Delivery Timelines: Confirm lead times, especially if your project has tight deadlines.

Step 6: Finalize the Order and Document Everything

After agreeing on terms, finalize your order and ensure that all details are documented. This includes specifications, pricing, delivery dates, and payment terms. Keeping a comprehensive record will protect both parties and provide a point of reference if issues arise.

- Order Confirmation: Request a written confirmation of your order to ensure accuracy.

- Documentation: Maintain all correspondence and contracts for future reference and accountability.

By following this checklist, B2B buyers can effectively source expanded metal 4×8 sheets that meet their specifications and requirements, ultimately leading to successful project outcomes.

Comprehensive Cost and Pricing Analysis for expanded metal 4×8 Sourcing

Understanding the cost structure and pricing dynamics of expanded metal 4×8 is crucial for international B2B buyers. This analysis delves into the various cost components, price influencers, and provides actionable tips for negotiating better deals, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Expanded Metal 4×8?

The cost of expanded metal 4×8 is influenced by several components:

-

Materials: The primary cost driver is the raw material used, which can range from mild steel and galvanized steel to aluminum and stainless steel. Prices fluctuate based on global market conditions, quality, and type of metal.

-

Labor: Labor costs encompass wages for workers involved in manufacturing, cutting, and finishing processes. In regions with higher labor costs, such as Europe, these expenses can significantly impact pricing.

-

Manufacturing Overhead: This includes utilities, factory maintenance, and equipment depreciation. Efficient operations can help mitigate overhead costs, which are often passed on to buyers.

-

Tooling: Custom tooling for specific designs or applications can add to the initial setup costs. Standard sizes typically incur lower tooling costs, making them more economical for bulk orders.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspections adds to overall costs. Certifications like ISO can enhance product credibility but may also increase pricing.

-

Logistics: Transportation costs vary based on supplier location, shipping methods, and international trade regulations. Buyers must consider freight charges and potential tariffs when calculating total costs.

-

Margin: Suppliers typically add a profit margin that can vary based on competition, demand, and market positioning. Understanding supplier pricing strategies can provide leverage in negotiations.

What Influences Pricing for Expanded Metal 4×8?

Several factors can influence the pricing of expanded metal sheets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, making it vital for buyers to assess their needs against supplier MOQs to optimize costs.

-

Specifications and Customization: Customized products usually come at a premium. Buyers should evaluate whether standard offerings can meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications can lead to increased costs but may be essential for specific applications, particularly in industries with strict compliance requirements.

-

Supplier Factors: The reputation, reliability, and production capacity of the supplier can impact pricing. Establishing long-term relationships with reputable suppliers may lead to better pricing and service.

-

Incoterms: Understanding shipping terms is critical for international transactions. Incoterms define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risks, directly affecting overall pricing.

How Can Buyers Negotiate Better Prices for Expanded Metal 4×8?

For international buyers, effective negotiation strategies are essential to achieving cost-efficiency:

-

Leverage Total Cost of Ownership (TCO): Consider not only the initial purchase price but also long-term costs such as maintenance, replacement, and logistics. A lower upfront cost may not always result in the best value.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing agreements and priority service. Frequent communication and transparency can foster trust.

-

Explore Alternative Suppliers: Diversifying your supplier base can create competitive pressure, driving prices down. It’s beneficial to assess multiple suppliers for quality and pricing.

-

Understand Pricing Nuances: Be aware of the pricing dynamics in different regions. Economic conditions, currency fluctuations, and trade agreements can impact costs, especially for buyers in Africa and South America.

-

Negotiate Terms: Don’t hesitate to discuss payment terms, delivery schedules, and discounts for early payment. Flexibility in these areas can yield significant savings.

Final Thoughts

While the pricing of expanded metal 4×8 sheets can vary widely based on multiple factors, informed buyers can navigate the complexities of the market. By understanding the cost structure, recognizing price influencers, and employing strategic negotiation techniques, B2B buyers can secure favorable terms and optimize their sourcing strategies. As always, consider indicative prices, as they can fluctuate based on market conditions and supplier-specific factors.

Alternatives Analysis: Comparing expanded metal 4×8 With Other Solutions

Introduction to Alternative Solutions for Expanded Metal 4×8

When considering the right materials for construction, security, or design applications, it’s crucial to evaluate all available options. Expanded metal 4×8 sheets are known for their versatility and strength, but other alternatives may also provide similar benefits depending on specific requirements. This analysis compares expanded metal 4×8 with two viable alternatives: perforated metal sheets and welded wire mesh. Each option presents unique advantages and challenges, making it essential for B2B buyers to assess their needs carefully.

Illustrative image related to expanded metal 4×8

Comparison Table

| Comparison Aspect | Expanded Metal 4×8 | Perforated Metal Sheets | Welded Wire Mesh |

|---|---|---|---|

| Performance | High strength-to-weight ratio; allows airflow, light | Good strength; customizable hole patterns | Excellent tensile strength; ideal for security |

| Cost | Generally cost-effective; varies by material | Moderate to high; depends on hole size and pattern | Typically lower; varies by wire thickness |

| Ease of Implementation | Easily cut and welded; versatile applications | Requires precision cutting for custom sizes | Simple installation; can be cut to size easily |

| Maintenance | Low maintenance; resistant to corrosion when coated | Moderate; can require periodic cleaning | Low; resistant to rust and corrosion with proper treatment |

| Best Use Case | Walkways, decorative panels, machine guards | Architectural elements, filtration, sound dampening | Fencing, security barriers, livestock enclosures |

Detailed Breakdown of Alternatives

Perforated Metal Sheets: What Are the Benefits and Drawbacks?

Perforated metal sheets are created by punching holes into a solid sheet of metal, allowing for custom designs and patterns. This material provides good strength and can be tailored to fit specific aesthetic requirements. The primary advantages of perforated metal include its ability to control airflow and light while offering a unique visual appeal. However, the cost can escalate depending on the complexity of the hole pattern and size. Additionally, installation may require precise cutting, which can complicate the process for some applications.

Welded Wire Mesh: Is It a Suitable Alternative?

Welded wire mesh consists of wires that are welded together at intersections, forming a grid-like structure. This solution is particularly noted for its strength and security, making it an ideal choice for fencing and enclosures. The installation is generally straightforward, and it can be cut to size easily. While welded wire mesh is often more affordable than expanded metal, it may lack the aesthetic versatility that some projects require. Furthermore, while it is durable, it may not provide the same airflow benefits as expanded metal or perforated sheets.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right material depends on the specific application and desired outcomes. For projects requiring a strong, lightweight solution that allows for airflow and light, expanded metal 4×8 is an excellent choice. However, if aesthetic customization is paramount, perforated metal may be more suitable. For security applications, welded wire mesh offers a robust option with lower costs. Buyers should assess their project requirements, considering factors such as performance, cost, and maintenance, to select the most appropriate solution for their needs.

Essential Technical Properties and Trade Terminology for expanded metal 4×8

What Are the Key Technical Properties of Expanded Metal 4×8?

1. Material Grade

Expanded metal sheets are predominantly manufactured from various materials, including mild steel, galvanized steel, stainless steel, and aluminum. The material grade is crucial as it affects the durability, corrosion resistance, and overall weight of the product. For instance, stainless steel grades like 304 and 316 offer enhanced corrosion resistance, making them suitable for outdoor and marine applications. B2B buyers must choose the right material based on the specific environmental conditions their products will face.

Illustrative image related to expanded metal 4×8

2. Thickness

The thickness of expanded metal sheets typically ranges from 0.3mm to 10mm. This specification plays a vital role in determining the strength and load-bearing capacity of the expanded metal. Thicker sheets can withstand more weight and stress, which is essential for applications like flooring or grating. When sourcing, buyers should match the thickness to the intended use to ensure safety and performance.

3. Strand Width (SWD) and Long Way of the Diamond (LWD)

These dimensions define the size of the diamond openings created during the manufacturing process. Strand width refers to the width of the strands forming the diamond pattern, while the long way of the diamond indicates the length of the diamond shape. Common sizes include 2″x4″ and 3″x5″. Understanding these measurements helps buyers select expanded metal that meets specific airflow, visibility, and load requirements for their projects.

4. Surface Treatment Options

Expanded metal can undergo various surface treatments, such as powder coating, anodizing, or galvanization, to enhance its appearance and resistance to corrosion. Surface treatments are especially important for aesthetic applications or environments prone to moisture. B2B buyers should consider these options to align with their branding or functional needs.

5. Weight

The weight of expanded metal sheets is significantly lower than solid sheets, maintaining about one-tenth of the weight while providing comparable strength. This property makes expanded metal a cost-effective and versatile solution for various applications, from structural components to decorative elements. Buyers should assess weight for shipping and handling considerations, especially when ordering large quantities.

What Are Common Trade Terms Related to Expanded Metal 4×8?

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of expanded metal, OEMs may require specific sizes or grades that suit their production needs. Understanding OEM specifications is essential for B2B buyers who are sourcing materials for manufacturing processes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For expanded metal, MOQs can vary widely based on the material and supplier capabilities. B2B buyers should be aware of MOQs to avoid excess inventory or increased costs from ordering less than the required amount.

3. RFQ (Request for Quote)

An RFQ is a document used to solicit price proposals from suppliers. B2B buyers should prepare RFQs that detail specifications, quantities, and delivery timelines to receive accurate quotes for expanded metal. This process ensures that buyers can compare offers from multiple suppliers effectively.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for international B2B transactions involving expanded metal to avoid misunderstandings regarding costs and responsibilities.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For expanded metal, lead times can be affected by factors such as manufacturing capacity and customization requirements. B2B buyers should factor in lead times when planning their projects to ensure timely delivery and avoid delays in production.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing expanded metal sheets, optimizing their procurement processes and ensuring that their projects meet required specifications.

Illustrative image related to expanded metal 4×8

Navigating Market Dynamics and Sourcing Trends in the expanded metal 4×8 Sector

What Are the Current Trends Shaping the Expanded Metal 4×8 Market?

The expanded metal 4×8 market is experiencing significant growth driven by a combination of industrial demand, architectural innovation, and sustainability initiatives. Key sectors such as construction, manufacturing, and security are increasingly utilizing expanded metal due to its lightweight, durability, and versatility. In regions like Africa, South America, the Middle East, and Europe, the demand is further fueled by urbanization and infrastructure development projects.

Emerging technologies such as advanced manufacturing techniques and digital platforms are transforming sourcing trends. B2B buyers are increasingly leveraging e-commerce platforms to procure expanded metal sheets, allowing for easier access to a wider range of products, competitive pricing, and faster delivery times. Additionally, the integration of supply chain management software is enhancing transparency and efficiency in sourcing operations, enabling businesses to monitor inventory levels and manage orders more effectively.

Furthermore, buyers are prioritizing quality and customization in their procurement processes. The ability to order tailored specifications, such as specific thicknesses and finishes, is becoming a key differentiator among suppliers. This shift towards customization aligns with a broader trend towards personalized solutions in B2B transactions.

Illustrative image related to expanded metal 4×8

How Is Sustainability Influencing Sourcing Decisions in the Expanded Metal Sector?

Sustainability is increasingly becoming a focal point for B2B buyers in the expanded metal sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are showing a preference for suppliers who adopt sustainable practices, such as using recycled materials and implementing energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction, with companies seeking suppliers who can demonstrate responsible labor practices and compliance with environmental regulations. The demand for “green” certifications, such as ISO 14001 for environmental management, is on the rise. These certifications not only enhance a supplier’s credibility but also provide buyers with assurance that their procurement choices align with their corporate social responsibility goals.

Additionally, the use of eco-friendly coatings and finishes on expanded metal products is becoming popular. Buyers are increasingly looking for options like powder coating, which reduces volatile organic compounds (VOCs) compared to traditional painting methods. This shift towards sustainable materials and practices is not just a trend; it is becoming a necessity for companies aiming to meet regulatory standards and consumer expectations.

How Has the Expanded Metal Industry Evolved Over Time?

The expanded metal industry has undergone significant evolution since its inception. Originally used primarily in construction and industrial applications, expanded metal’s versatility has led to its adoption in various sectors, including architecture, automotive, and interior design. The introduction of advanced manufacturing techniques has allowed for greater precision and customization, enabling suppliers to meet the specific needs of B2B buyers.

The 4×8 sheet size has become a standard in the industry, providing a convenient option for various applications while minimizing waste. As technology continues to advance, the future of expanded metal will likely see even greater innovations in production methods, materials, and applications, further solidifying its role in modern manufacturing and design.

Illustrative image related to expanded metal 4×8

In summary, the expanded metal 4×8 market is poised for growth, with sustainability and technological advancements shaping sourcing decisions. B2B buyers must remain informed about these trends to make strategic procurement choices that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of expanded metal 4×8

1. How do I ensure the quality of expanded metal 4×8 sheets?

To ensure the quality of expanded metal sheets, request certifications such as ISO 9001:2015 from suppliers. Verify if they conduct regular quality checks and provide material test reports. Additionally, ask for samples before placing a bulk order. This allows you to assess the material’s durability, finish, and dimensional accuracy. Engaging with suppliers who have a solid reputation and positive customer feedback can also provide insights into their quality assurance processes.

2. What are the best applications for expanded metal 4×8 sheets?

Expanded metal 4×8 sheets are versatile and can be used across various industries. Common applications include construction (as grating for walkways), security (for window guards and fencing), and decorative uses (in architecture and furniture). They are also ideal for industrial settings, serving as machine guards or screens that allow for ventilation and visibility while maintaining structural integrity. Understanding your specific needs will help you choose the right type of expanded metal.

3. What customization options are available for expanded metal 4×8?

Most suppliers offer customization options for expanded metal sheets, including different thicknesses, opening sizes, and finishes. You can request specific dimensions, patterns, and even surface treatments like powder coating or galvanization to enhance durability and aesthetics. Discuss your project requirements with suppliers to determine the best options available and ensure they can meet your specifications.

4. What is the minimum order quantity (MOQ) for expanded metal 4×8 sheets?

Minimum order quantities for expanded metal sheets vary by supplier and can depend on factors like material type and customization requirements. Some suppliers may have an MOQ of just one sheet, while others might require larger orders to justify production costs. It’s essential to clarify this with potential suppliers early in the negotiation process to avoid any misunderstandings.

5. How can I verify the reliability of an expanded metal supplier?

To verify a supplier’s reliability, check for industry certifications, customer reviews, and case studies. Request references from previous clients, especially those in your region or industry. Engage in direct communication to gauge their responsiveness and willingness to address your concerns. Additionally, consider visiting their facilities if possible, as this will provide you with a firsthand look at their operations and quality control measures.

6. What payment terms should I expect when sourcing expanded metal internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, deposits, or net terms (e.g., 30 or 60 days after delivery). Ensure to discuss and agree on payment terms that suit both parties before finalizing contracts. Using secure payment methods, such as letters of credit or escrow services, can also help protect your investment in international transactions.

7. How does shipping and logistics work for expanded metal orders?

Shipping logistics for expanded metal typically involve sea freight for bulk orders, which is cost-effective for international shipping. However, air freight may be used for smaller, urgent orders. Discuss shipping options with your supplier and confirm their experience with international logistics, including customs clearance. Always request tracking information and estimated delivery timelines to ensure your order arrives on schedule.

8. What should I know about the surface treatment options for expanded metal?

Surface treatments for expanded metal can significantly enhance its durability and appearance. Common treatments include galvanization for corrosion resistance, powder coating for aesthetics, and anodizing for aluminum sheets. When ordering, specify your intended use to choose the appropriate surface treatment. This is particularly important for outdoor applications or environments with high exposure to moisture or chemicals, where enhanced protection is necessary.

Top 4 Expanded Metal 4X8 Manufacturers & Suppliers List

1. MetalsDepot® – Expanded Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Expanded Steel Sheet Online! Steel Expanded Metal is a sheet product that has been slit and stretched to a wide array of diamond shaped openings. It offers savings in weight and metal, free passage of light, liquid, sound and air, while providing a decorative or ornamental effect. Specifications: MIL-M-17194D, ASTM F1267-91, Type I Standard (Raised) & Type II Flattened (smooth) …

2. Midwest Steel Supply – Steel Flattened Expanded Metal

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: Steel Flattened Expanded Metal (4ft x 8ft)\n- Sizes Available: 1/4″ x #18, 1/2″ x #18, 1/2″ x #16, 1/2″ x #13, 3/4″ x #16, 3/4″ x #13, 3/4″ x #9, 1-1/2″ x #13, 1-1/2″ x #9\n- Dimensions: 48″ x 96″ (4ft x 8ft)\n- Material: Steel\n- Features: Slit and stretched into diamond-shaped openings, cold rolled to flatten into one plane, lightweight, allows passage of air, light, or liquid.\n- Uses: Decorati…

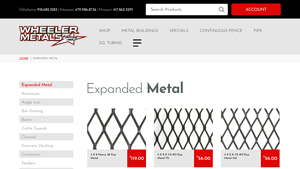

3. Wheeler Metals – Expanded Metal Solutions

Domain: wheelermetals.com

Registered: 1999 (26 years)

Introduction: [{‘size’: ‘4 X 8’, ‘weight’: ‘Heavy’, ‘type’: ‘Exp Metal’, ‘price’: ‘$119.00’}, {‘size’: ‘4 X 8’, ‘thickness’: ‘1/2’, ‘type’: ‘#13 Exp Metal Flt’, ‘price’: ‘$56.00’}, {‘size’: ‘4 X 8’, ‘thickness’: ‘1/2’, ‘type’: ‘#13 Exp Metal Std’, ‘price’: ‘$56.00’}, {‘size’: ‘4 X 8’, ‘thickness’: ‘3/4’, ‘type’: ‘#9 Exp Metal Flt’, ‘price’: ‘$58.80’}, {‘size’: ‘4 X 8’, ‘thickness’: ‘3/4’, ‘type’: ‘#9 Exp Metal …

4. Hole Metals – 4×8 Sheet Expanded Metal

Domain: holemetals.com

Registered: 2016 (9 years)

Introduction: Product Name: 4×8 Sheet Expanded Metal

Description: Versatile and economical expanded metal mesh product made from sheets or coils of mild steel, galvanized steel, stainless steel, and aluminum, uniformly slit and stretched to form a diamond pattern of openings. Available in various patterns and customizable shapes.

Materials: Mild Steel, Galvanized Steel, Aluminum (1060, Alloy 3003, 5005), Stainl…

Strategic Sourcing Conclusion and Outlook for expanded metal 4×8

How Can Strategic Sourcing Enhance Your Expanded Metal 4×8 Procurement?

In summary, strategic sourcing of expanded metal 4×8 presents a wealth of opportunities for B2B buyers across diverse markets. The lightweight yet robust nature of expanded metal, combined with its versatility in various applications—from industrial uses to decorative elements—underscores its growing demand. Engaging with reliable suppliers who offer customizable options and competitive pricing will enhance operational efficiency and reduce procurement costs.

As international buyers from regions such as Africa, South America, the Middle East, and Europe navigate their sourcing strategies, understanding the nuances of material specifications, lead times, and supply chain logistics is essential. By leveraging strategic partnerships with manufacturers who prioritize quality and service, businesses can ensure they meet their project requirements while optimizing their budgets.

Looking ahead, the demand for expanded metal will likely continue to rise, driven by innovation in architectural and industrial applications. Now is the time to engage with suppliers and explore tailored solutions that can elevate your projects. Embrace the future of sourcing—connect with trusted suppliers and make informed decisions that will propel your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.