A B2B Buyer’s Guide to Exchanger Channel Head: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for exchanger channel head

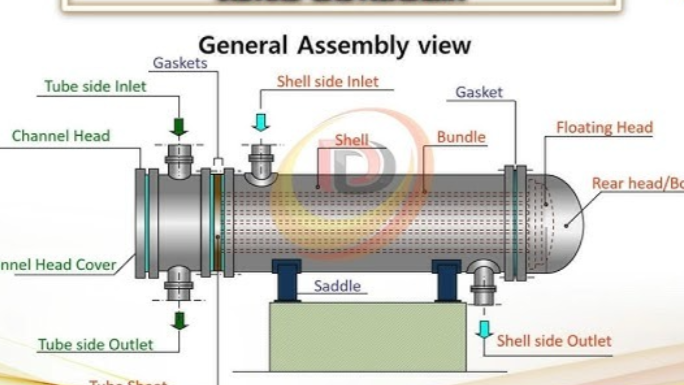

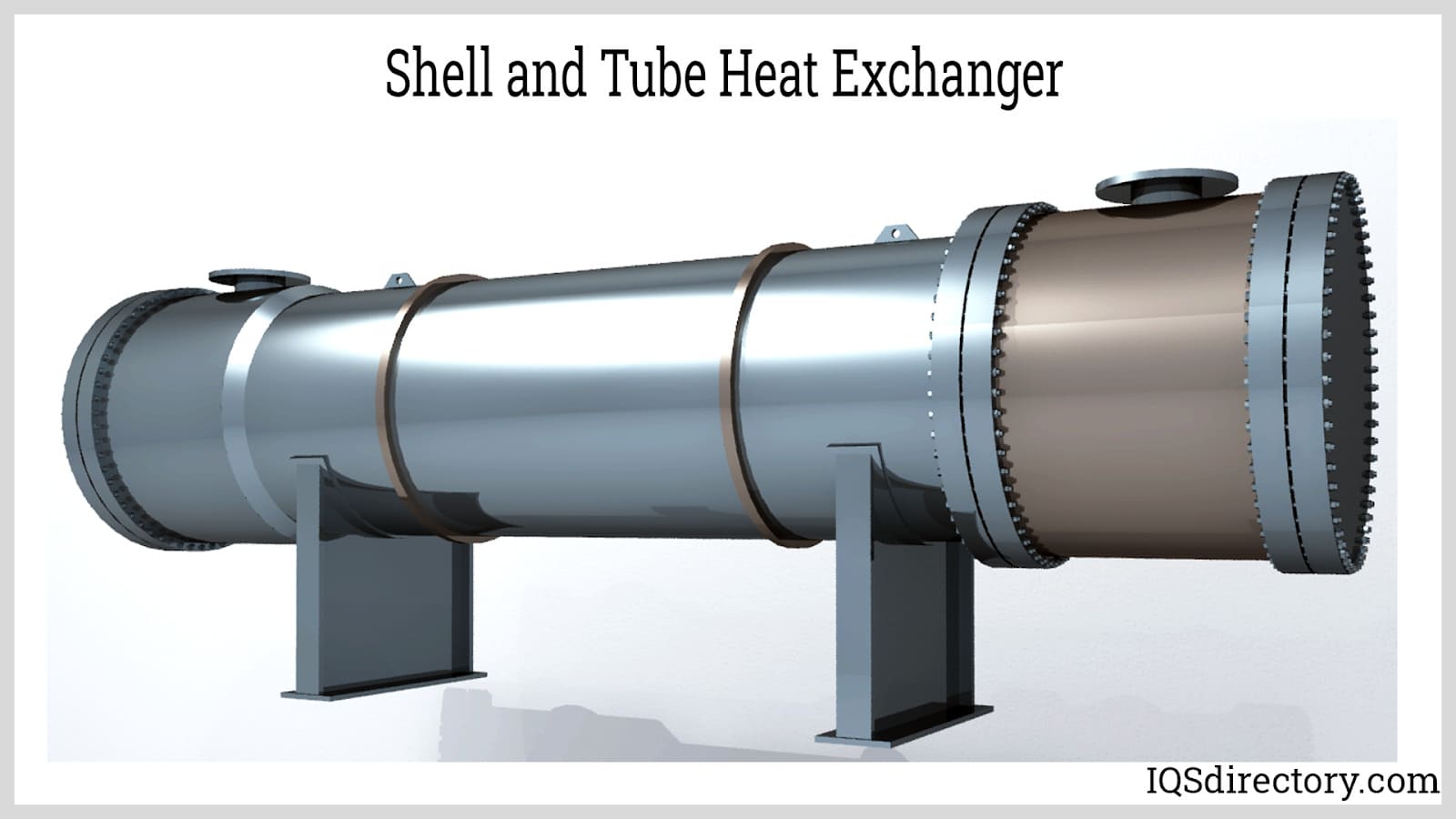

In today’s global market, sourcing high-quality exchanger channel heads presents a significant challenge for B2B buyers, especially in rapidly developing regions like Africa, South America, the Middle East, and Europe. With various types and specifications to consider, the process can be overwhelming. This guide aims to demystify the complexities of exchanger channel heads by providing a comprehensive overview of their types, applications, and the critical role they play in industries such as petrochemicals and power generation.

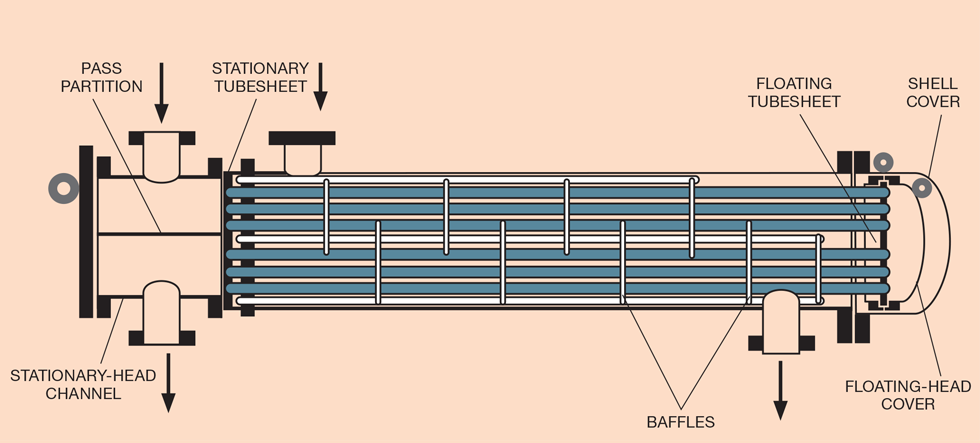

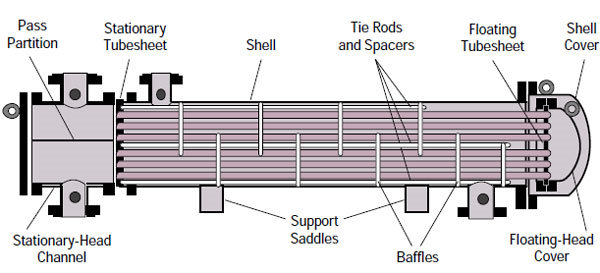

Throughout this guide, we will explore essential factors including supplier vetting processes, cost considerations, and industry standards, empowering international buyers to make informed purchasing decisions. Understanding the nuances of different designs—such as fixed tubesheet, U-tube, and floating head exchangers—will enable businesses to choose the right equipment tailored to their operational needs.

Moreover, we will address common pitfalls in the procurement process and provide actionable insights to enhance negotiation strategies. By leveraging this guide, B2B buyers from diverse regions, including Vietnam and Nigeria, will not only streamline their sourcing efforts but also ensure compliance with international standards and improve their operational efficiencies. Equip yourself with the knowledge to navigate the complexities of the exchanger channel head market and secure the best solutions for your business.

Understanding exchanger channel head Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Tubesheet | Welded tubesheets, simple construction, limited access to tubes | Oil & gas, chemical processing | Pros: Cost-effective; Cons: Limited maintenance access. |

| U-Tube | Allows for thermal expansion, removable bundle for cleaning | Power generation, HVAC systems | Pros: Easy maintenance; Cons: Difficult internal cleaning. |

| Floating Head | Tubesheet can move, allowing for thermal expansion and easy access | High-temperature, high-pressure applications | Pros: Flexible design; Cons: Higher initial costs. |

| A-Type Front Header | Easy to repair, dual seals for tube access | General industrial applications | Pros: Accessibility; Cons: Increased risk of leakage. |

| B-Type Front Header | Single seal design, suited for high pressure | Petrochemical industry | Pros: Cost-effective; Cons: Requires pipework disturbance for access. |

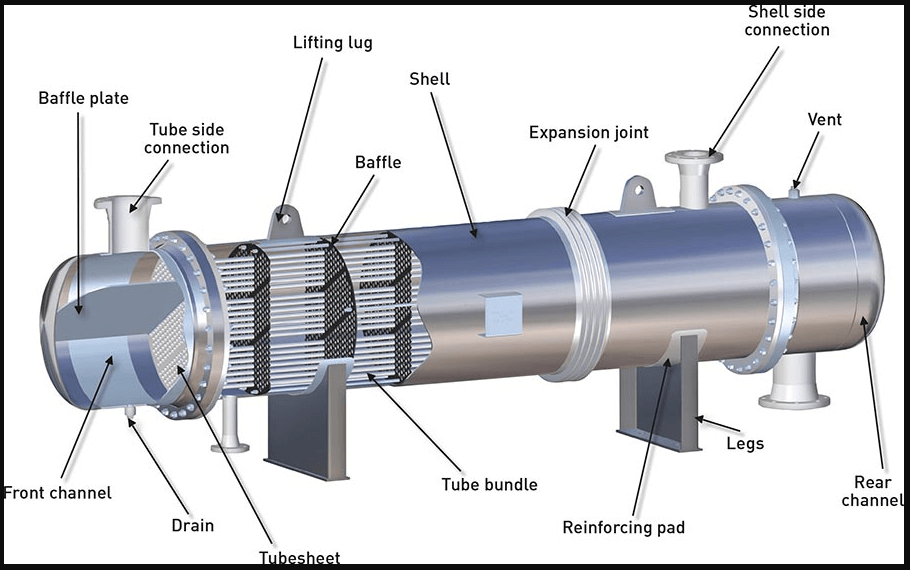

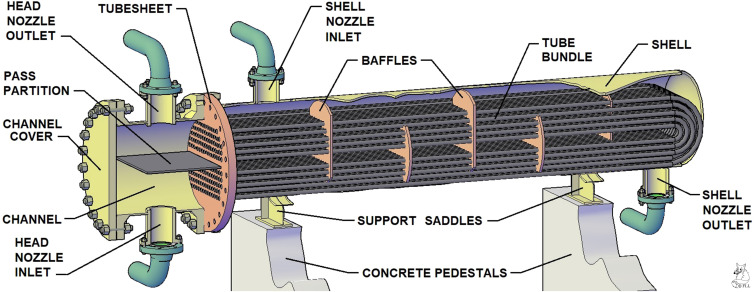

What Are the Characteristics of Fixed Tubesheet Exchangers?

Fixed tubesheet exchangers feature welded tubesheets that provide a robust and economical design. They are commonly used in oil and gas, as well as chemical processing industries, where reliability is paramount. However, the limitation lies in their accessibility; once installed, cleaning and maintenance can only be performed through chemical means, making it crucial for buyers to consider the operational environment and maintenance plans before procurement.

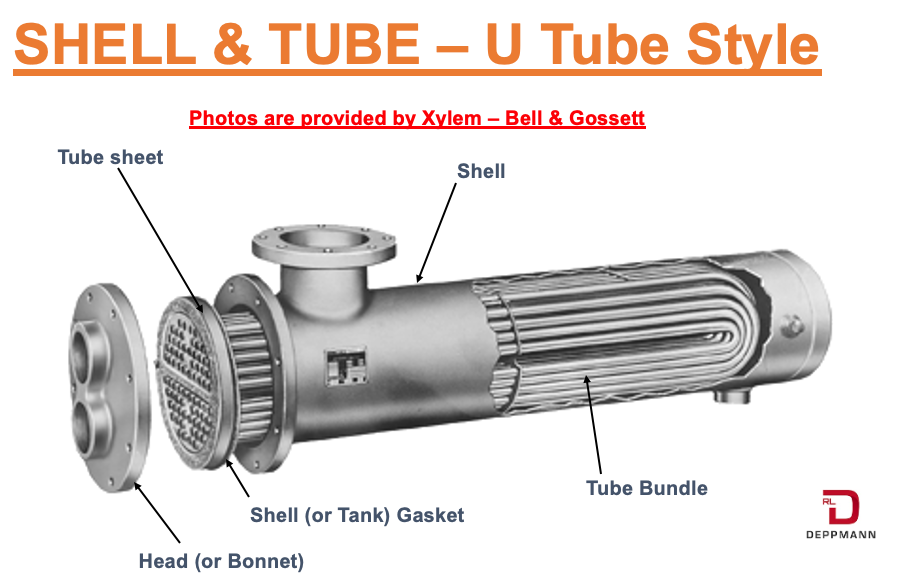

How Do U-Tube Exchangers Stand Out?

U-tube exchangers are characterized by their ability to accommodate thermal expansion, making them ideal for power generation and HVAC systems. The removable tube bundle facilitates easy cleaning, enhancing operational efficiency. However, due to their design, internal cleaning can be challenging, which is a critical consideration for buyers in industries where fluid cleanliness is essential. Understanding the cleanliness of the tube-side fluids is vital for effective utilization.

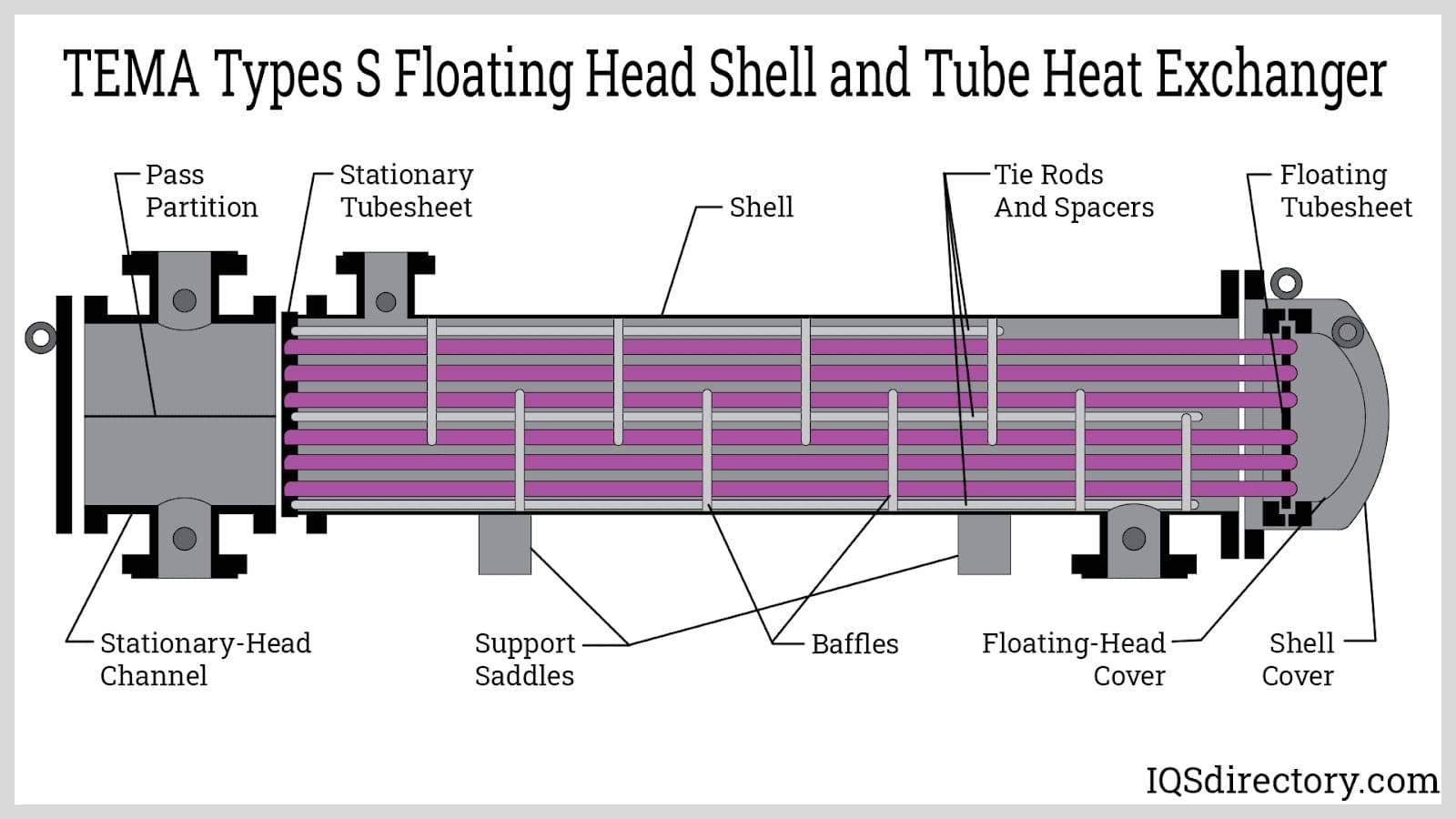

What Benefits Do Floating Head Exchangers Offer?

Floating head exchangers are designed with a tubesheet that can move, allowing for thermal expansion and easy access to the tube bundle for maintenance. This design is particularly beneficial in high-temperature and high-pressure applications, where flexibility and durability are essential. While they offer significant advantages in terms of maintenance and operational reliability, buyers should be prepared for a higher initial investment, making it essential to assess long-term operational costs versus upfront expenses.

What Should Buyers Know About A-Type Front Headers?

A-Type front headers are designed for ease of repair and maintenance, featuring dual seals that allow access to the tubes without disturbing the surrounding pipework. This design is suitable for general industrial applications where maintenance access is a priority. However, the presence of two seals increases the risk of leakage, which buyers should carefully evaluate against the convenience offered by this header type.

Why Choose B-Type Front Headers for High-Pressure Applications?

B-Type front headers are preferred in high-pressure scenarios due to their single seal design, which reduces the risk of leakage. This makes them particularly popular in the petrochemical industry, where safety and reliability are critical. While they are cost-effective, buyers must consider the need for pipework disturbance to access the tubes, which may impact operational efficiency during maintenance activities.

Key Industrial Applications of exchanger channel head

| Industry/Sector | Specific Application of exchanger channel head | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Petrochemical | Heat exchange in crude oil distillation processes | Enhances efficiency and reduces energy costs | Compliance with TEMA standards, material compatibility for high temperatures and pressures |

| Power Generation | Feedwater heating in steam power plants | Improves thermal efficiency and reduces fuel consumption | Reliability under high pressure, ease of maintenance, and access for cleaning |

| Food and Beverage | Temperature control in pasteurization processes | Ensures product safety and quality while saving energy | Hygiene standards, material certifications, and thermal performance requirements |

| Chemical Processing | Cooling of exothermic reactions in reactors | Prevents overheating and maintains optimal reaction conditions | Material resilience to corrosive substances, and customizable designs for specific processes |

| HVAC Systems | Heat recovery in large commercial buildings | Reduces operational costs and improves energy efficiency | Compatibility with existing systems, ease of installation, and maintenance support |

How is the Exchanger Channel Head Used in the Petrochemical Industry?

In the petrochemical industry, exchanger channel heads are integral to heat exchange processes, particularly during crude oil distillation. They allow for efficient heat transfer between fluids, ensuring optimal temperatures for various stages of processing. This efficiency translates to significant energy savings and reduced operational costs. Buyers should prioritize suppliers that adhere to TEMA standards and offer materials capable of withstanding high pressures and temperatures, which are common in these applications.

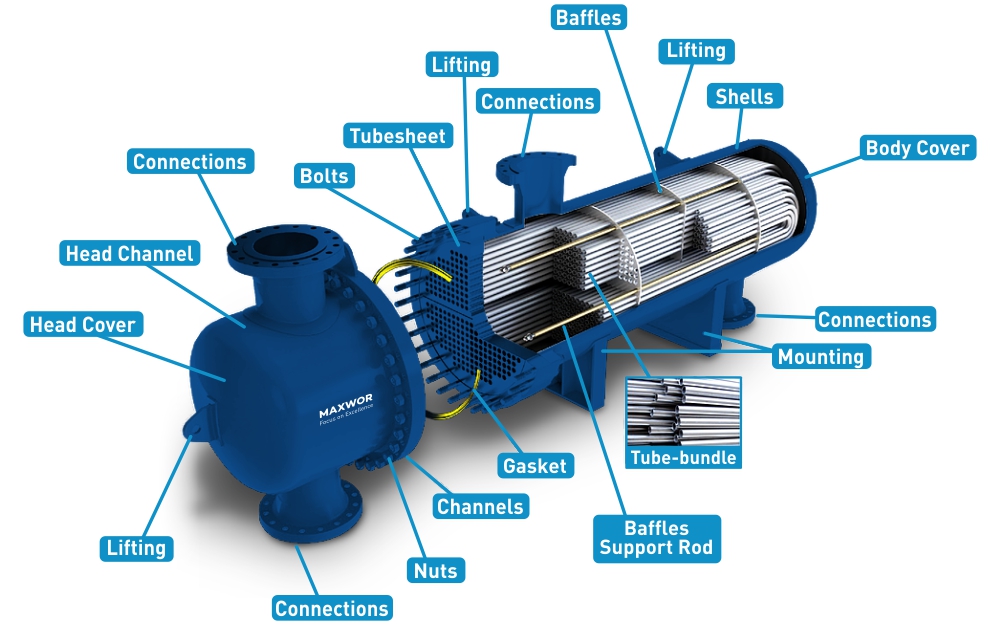

Illustrative image related to exchanger channel head

What Role Does the Exchanger Channel Head Play in Power Generation?

In power generation, particularly in steam plants, exchanger channel heads are utilized in feedwater heaters to preheat water before it enters the boiler. This process enhances thermal efficiency, significantly lowering fuel consumption. For international buyers, especially from regions with diverse energy regulations, sourcing reliable and durable channel heads is crucial. They must consider factors such as high-pressure resistance and ease of maintenance, ensuring long-term operational efficiency.

How is the Exchanger Channel Head Beneficial in the Food and Beverage Sector?

The food and beverage industry employs exchanger channel heads in pasteurization processes to maintain precise temperature control, which is critical for ensuring product safety and quality. By efficiently transferring heat, these systems help minimize energy consumption while meeting stringent hygiene standards. Buyers should focus on sourcing channel heads that comply with food safety regulations and are made from materials that can withstand high temperatures without compromising product integrity.

Why is the Exchanger Channel Head Essential in Chemical Processing?

In chemical processing, exchanger channel heads are used to cool exothermic reactions, preventing overheating and maintaining optimal conditions for chemical reactions. This is vital for safety and efficiency in production. Buyers in this sector need to ensure that the materials used can resist corrosion from various chemicals, and they may require custom designs tailored to specific processes. Reliability and performance under demanding conditions are key considerations for sourcing.

How Does the Exchanger Channel Head Contribute to HVAC Systems?

In HVAC systems, exchanger channel heads facilitate heat recovery in large commercial buildings, significantly enhancing energy efficiency. By reclaiming waste heat, businesses can lower operational costs and reduce their environmental footprint. For international buyers, compatibility with existing systems and ease of installation are critical factors when sourcing these components. Additionally, ongoing maintenance support should be considered to ensure long-term performance and efficiency.

3 Common User Pain Points for ‘exchanger channel head’ & Their Solutions

Scenario 1: Challenges with Sourcing the Right Exchanger Channel Head

The Problem: B2B buyers often face difficulties when sourcing the appropriate exchanger channel head for their specific applications. This challenge can stem from a lack of clear specifications, leading to confusion over material compatibility, pressure ratings, and design types. For instance, a company in Nigeria may require a channel head that can withstand high temperatures and corrosive fluids but may struggle to find suppliers that meet these criteria. The absence of standardized information can lead to costly errors, delays in procurement, and potential equipment failures.

The Solution: To effectively source the right exchanger channel head, buyers should begin by conducting a comprehensive needs assessment. This involves identifying the operational parameters such as temperature, pressure, and fluid types. Engaging with suppliers who specialize in customized solutions can also enhance the procurement process. Buyers should request detailed technical data sheets and material specifications from potential suppliers. Additionally, leveraging industry standards such as those outlined by the Tubular Exchanger Manufacturers Association (TEMA) can guide buyers in selecting the correct design and material for their needs. Establishing strong relationships with trusted manufacturers who can provide ongoing technical support and after-sales service will further mitigate sourcing challenges.

Scenario 2: Issues with Maintenance and Downtime Due to Design Complexity

The Problem: Another common pain point for B2B buyers is the maintenance challenges associated with complex exchanger channel head designs. Buyers may opt for sophisticated designs that promise high efficiency but can lead to increased downtime during maintenance. For example, a petrochemical plant in Brazil may find that its floating head exchanger requires specialized tools and expertise for routine maintenance, leading to extended downtime and loss of productivity.

The Solution: To address maintenance-related challenges, buyers should prioritize selecting exchanger channel heads that balance efficiency with ease of maintenance. A thorough evaluation of the design is crucial; choosing simpler designs like fixed tubesheet exchangers can facilitate easier access for cleaning and repairs. Buyers should also invest in training for their maintenance teams, ensuring they have the necessary skills and knowledge to perform maintenance tasks efficiently. Collaborating with suppliers who offer maintenance support and training services can further streamline operations and minimize downtime. Establishing a regular maintenance schedule based on the specific operating conditions can also help anticipate issues before they lead to significant operational disruptions.

Scenario 3: Overcoming Performance Variability and Inefficiency

The Problem: Performance variability in heat exchangers is a critical concern for B2B buyers, particularly when dealing with fluctuating operational conditions. For example, a manufacturing facility in Europe may experience inefficient heat transfer rates due to improper channel head design, leading to increased energy costs and reduced output quality. This situation can frustrate buyers who expect their systems to operate reliably under varying loads.

The Solution: To mitigate performance variability, buyers should focus on the proper specification and integration of the exchanger channel head within the overall system. Conducting thorough thermal and hydraulic analyses can help identify the optimal design for specific operational conditions. Buyers should collaborate closely with engineering teams to ensure that the exchanger is properly sized and that the fluid flow arrangements are optimized. Furthermore, utilizing advanced simulation software can provide insights into potential performance issues before implementation. Regular monitoring and performance assessments should be established to identify and rectify inefficiencies promptly. Implementing real-time monitoring systems can also enable quick adjustments to operational parameters, enhancing overall system performance and energy efficiency.

Strategic Material Selection Guide for exchanger channel head

When selecting materials for exchanger channel heads, it is crucial to consider factors such as temperature and pressure ratings, corrosion resistance, and overall compatibility with the media being processed. Below, we analyze four common materials used in the construction of exchanger channel heads, providing insights tailored for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What are the Key Properties of Carbon Steel for Exchanger Channel Heads?

Carbon steel is one of the most widely used materials for exchanger channel heads due to its favorable mechanical properties and cost-effectiveness. It typically has a temperature rating of up to 400°C and can handle pressures exceeding 100 bar, making it suitable for many industrial applications.

Pros: Carbon steel is durable, relatively inexpensive, and easy to fabricate. It is suitable for a variety of fluids, including water and oil.

Cons: Its susceptibility to corrosion, especially in aggressive environments, necessitates protective coatings or linings, which can increase manufacturing complexity and costs.

Illustrative image related to exchanger channel head

Impact on Application: Carbon steel is often used in oil and gas applications but may not be ideal for corrosive media without adequate protection.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A106 or DIN 17100. In regions with high humidity or saline environments, additional corrosion protection measures are advisable.

How Does Stainless Steel Perform as a Material for Exchanger Channel Heads?

Stainless steel, particularly grades like 304 and 316, is known for its excellent corrosion resistance and high-temperature capabilities, with performance ratings up to 800°C and pressures exceeding 150 bar.

Pros: Its resistance to oxidation and corrosion makes it ideal for chemical processing and food applications. Stainless steel also offers good mechanical strength and durability.

Illustrative image related to exchanger channel head

Cons: The primary drawback is its higher cost compared to carbon steel, which may be a limiting factor for budget-sensitive projects. Additionally, its fabrication can be more complex.

Impact on Application: Stainless steel is highly compatible with a wide range of media, including acids and chlorides, making it suitable for industries such as pharmaceuticals and food processing.

Considerations for International Buyers: Compliance with standards like ASTM A240 and EN 10088 is essential. Buyers should also be aware of the availability of specific grades in their region to avoid delays.

What are the Advantages of Using Alloy Steel in Exchanger Channel Heads?

Alloy steel, particularly those with chromium and molybdenum, offers enhanced strength and corrosion resistance, making it suitable for high-pressure and high-temperature applications.

Pros: Alloy steel can withstand extreme conditions, making it ideal for power generation and petrochemical applications. Its durability often results in a longer service life.

Cons: The cost is generally higher than carbon steel and may require specialized welding techniques, complicating manufacturing.

Impact on Application: Alloy steel is well-suited for harsh environments where high performance is critical, such as in oil refineries or chemical plants.

Considerations for International Buyers: Buyers should check for compliance with ASTM A335 or similar standards. The availability of specific alloy compositions may vary by region, affecting procurement.

How Does Titanium Compare as a Material for Exchanger Channel Heads?

Titanium is increasingly being used for exchanger channel heads due to its exceptional corrosion resistance and strength-to-weight ratio, with temperature ratings up to 600°C.

Pros: Titanium is highly resistant to corrosion in aggressive environments, including seawater and acidic media, making it suitable for marine and chemical applications.

Cons: The primary disadvantage is its high cost and difficulty in machining and welding, which can lead to increased manufacturing times.

Impact on Application: Titanium is ideal for applications involving highly corrosive fluids, such as in the chemical and aerospace industries.

Illustrative image related to exchanger channel head

Considerations for International Buyers: Buyers should ensure compliance with ASTM B265 or similar standards. Given its cost, titanium is often used in niche applications where performance justifies the investment.

Summary Table of Material Selection for Exchanger Channel Heads

| Material | Typical Use Case for exchanger channel head | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Oil and gas applications | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Chemical processing, food applications | Excellent corrosion resistance | Higher cost and complex fabrication | High |

| Alloy Steel | Power generation, petrochemical applications | High strength and durability | Expensive and specialized welding | Med |

| Titanium | Marine and chemical industries | Exceptional corrosion resistance | High cost and difficult to machine | High |

This strategic material selection guide aims to assist B2B buyers in making informed decisions regarding exchanger channel heads, factoring in performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for exchanger channel head

What Are the Key Stages in the Manufacturing Process of Exchanger Channel Heads?

The manufacturing of exchanger channel heads involves several critical stages, each designed to ensure precision and quality in the final product. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to exchanger channel head

-

Material Preparation: The process begins with selecting high-quality raw materials, typically carbon steel, stainless steel, or specialized alloys, depending on the application requirements. Suppliers often conduct material inspections to verify compliance with industry standards, ensuring that materials can withstand high temperatures and pressures.

-

Forming: In this stage, the selected materials are shaped into the required dimensions. Techniques such as welding, machining, and forging are commonly used. For channel heads, forming may involve the use of CNC machines for precise cutting and shaping. The use of advanced techniques such as hydroforming can also enhance the material’s structural integrity while allowing for complex geometries.

-

Assembly: After forming, the components of the channel head are assembled. This includes fitting the header to the shell and ensuring proper alignment of all parts. During assembly, it’s crucial to maintain tolerances to avoid future operational issues. Skilled technicians typically oversee this process to ensure accuracy.

-

Finishing: The final stage includes surface treatment, painting, and coating to enhance corrosion resistance and overall aesthetics. Techniques such as sandblasting and passivation are employed to prepare the surface for coatings, which can significantly extend the lifespan of the exchanger channel head.

How Is Quality Assurance Implemented in Exchanger Channel Head Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process for exchanger channel heads. Implementing robust QA practices helps ensure that the products meet international standards and customer expectations.

-

International Standards Compliance: Manufacturers often adhere to international quality management standards such as ISO 9001, which focuses on continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE marking for European markets and API standards for the oil and gas industry are crucial. These certifications validate that the manufacturing processes and end products meet stringent safety and performance criteria.

-

Quality Control Checkpoints: Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This is the first line of defense where raw materials are inspected for quality before they enter the production line.

– In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to ensure that each stage meets predefined standards. This includes monitoring dimensions, weld quality, and assembly accuracy.

– Final Quality Control (FQC): Once the product is complete, a final inspection is performed. This includes testing for leaks, pressure testing, and dimensional verification to ensure compliance with specifications. -

Common Testing Methods: Various testing methods are employed to validate the quality of exchanger channel heads. These include:

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and dye penetrant testing are used to detect flaws without damaging the product.

– Hydrostatic Testing: This method tests the integrity of the channel head under pressure, ensuring it can withstand operational conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, it is essential to verify the quality control practices of suppliers to mitigate risks associated with procurement.

-

Supplier Audits: Conducting on-site audits allows buyers to assess a supplier’s manufacturing processes, quality control measures, and overall operational capabilities. This firsthand observation can provide insights into the supplier’s commitment to quality and compliance with industry standards.

-

Quality Control Reports: Requesting detailed QC reports can help buyers understand the testing and inspection results for the products. These reports should include records of IQC, IPQC, and FQC, along with any corrective actions taken in response to identified issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These independent entities can conduct inspections and testing to verify that the products meet specified standards before shipment. This is particularly beneficial for buyers in regions where local standards may differ from international norms.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification can be particularly challenging for international B2B buyers. Understanding regional differences and requirements is crucial for successful procurement.

-

Regional Standards Variability: Different regions may have varying standards and regulations. For instance, buyers in Europe might prioritize CE compliance, while those in the Middle East may focus on API standards. Understanding these nuances ensures that the purchased products are not only compliant but also suitable for the intended application.

-

Documentation and Certification: Buyers should ensure that suppliers provide all necessary documentation, including certificates of compliance, material test reports, and inspection certificates. This documentation is essential for customs clearance and regulatory compliance in the buyer’s home country.

-

Cultural and Language Considerations: Effective communication is key in international transactions. Buyers should be aware of potential language barriers and cultural differences that may impact negotiations and quality assurance practices. Establishing clear communication channels can facilitate smoother transactions and enhance mutual understanding.

In conclusion, the manufacturing processes and quality assurance practices for exchanger channel heads are critical for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions and foster successful partnerships with suppliers, ultimately leading to improved operational efficiency and reduced risks.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘exchanger channel head’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in procuring exchanger channel heads, a critical component in various heat exchange systems. By following these steps, you can ensure that you select the right specifications and suppliers to meet your operational needs effectively.

Step 1: Define Your Technical Specifications

Before starting your search, it’s essential to outline the technical specifications for the exchanger channel head. Consider factors such as pressure ratings, temperature ranges, and the type of fluids involved. Clear specifications will help you communicate your requirements to suppliers and ensure compatibility with your existing systems.

Step 2: Research Industry Standards and Regulations

Familiarize yourself with relevant industry standards, such as those set by the Tubular Exchanger Manufacturers Association (TEMA). Compliance with these standards ensures that the exchanger channel heads you consider are reliable and safe for operation. Understanding these regulations can also guide your procurement process, ensuring you avoid costly compliance issues later.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, thorough evaluation is crucial. Request company profiles, product catalogs, and case studies to assess their expertise and reliability. Additionally, seek references from other buyers in your industry or region to validate their credibility and service quality.

Step 4: Request Samples and Specifications

Once you have shortlisted potential suppliers, request samples and detailed specifications of the exchanger channel heads. This step is vital for verifying that the products meet your technical requirements. Pay attention to the materials used, as well as the manufacturing processes, to ensure they align with your operational standards.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. While price is an important factor, consider the overall value, including warranty, after-sales support, and delivery timelines. A slightly higher upfront cost may be justified by better service and longer-term reliability.

Illustrative image related to exchanger channel head

Step 6: Assess Delivery and Lead Times

Confirm the supplier’s delivery capabilities and lead times, as these can significantly impact your project schedules. Inquire about their logistics and any potential delays that might arise. Ensure that the timelines align with your operational needs to avoid disruptions in your processes.

Step 7: Finalize and Negotiate Contracts

Once you’ve selected a supplier, finalize the details and negotiate the contract terms. Pay close attention to the terms of warranty, maintenance support, and return policies. Clear contractual agreements can safeguard your investment and ensure accountability from the supplier.

By following this comprehensive checklist, you can streamline your procurement process for exchanger channel heads and make informed decisions that enhance your operational efficiency.

Comprehensive Cost and Pricing Analysis for exchanger channel head Sourcing

What Are the Key Cost Components in Sourcing Exchanger Channel Heads?

When sourcing exchanger channel heads, understanding the breakdown of costs is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials for channel heads include carbon steel, stainless steel, and specialized alloys. Prices vary based on market fluctuations, availability, and material specifications.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing, assembly, and quality control. Regions with higher labor costs, such as Europe, may see increased pricing compared to manufacturers in countries with lower labor costs.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these costs, thereby influencing the final price.

-

Tooling: The initial investment in tooling for production can be significant, particularly for custom designs. This cost is often amortized over production runs, meaning larger orders can benefit from lower per-unit tooling costs.

-

Quality Control (QC): Ensuring the channel heads meet industry standards and client specifications involves rigorous quality control processes. This may include testing, inspections, and certifications, which can add to overall costs but are essential for ensuring reliability and performance.

-

Logistics: Transportation and shipping costs can vary widely based on location, distance, and the chosen Incoterms. International buyers must consider duties, tariffs, and shipping timelines when evaluating logistics costs.

-

Margin: Suppliers will add a margin to cover their costs and profit. This margin can vary based on market demand, supplier relationships, and the complexity of the order.

How Do Price Influencers Impact Exchanger Channel Head Costs?

Several factors can influence the pricing of exchanger channel heads:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing structures. Larger orders typically yield better pricing due to economies of scale. Buyers should negotiate for volume discounts whenever possible.

-

Specifications and Customization: Custom designs and specific material requirements can increase costs. Buyers should clearly define specifications upfront to avoid unexpected price hikes during production.

-

Quality and Certifications: Products with higher quality standards or specific certifications (e.g., ASME, TEMA) may come at a premium. However, investing in certified products can reduce long-term maintenance costs and improve operational reliability.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and geographical location can influence pricing. Established suppliers may offer more reliability but could charge higher prices compared to newer entrants.

-

Incoterms: The chosen Incoterms will determine responsibility for shipping costs and risks. Buyers should select terms that align with their logistical capabilities and cost objectives.

What Negotiation Strategies Can Help Buyers Reduce Costs?

To enhance cost-efficiency when sourcing exchanger channel heads, buyers should consider the following strategies:

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the initial purchase price, evaluate the total cost of ownership, including maintenance, operational efficiency, and potential downtime. This approach may justify higher upfront costs for superior products.

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. A collaborative approach can lead to mutually beneficial agreements.

-

Explore Alternative Suppliers: Diversifying the supplier base can lead to competitive pricing. However, ensure that alternative suppliers meet the necessary quality and certification standards.

-

Stay Informed on Market Trends: Understanding market dynamics and material costs can provide leverage during negotiations. Buyers should stay updated on industry trends that may impact pricing.

-

Consider Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing structures and reliability. Suppliers may be more inclined to offer favorable terms to loyal customers.

Conclusion

In the competitive landscape of exchanger channel head sourcing, understanding the cost structure and pricing influencers is essential for international B2B buyers. By employing strategic negotiation tactics and considering the total cost of ownership, buyers from regions such as Africa, South America, the Middle East, and Europe can secure favorable terms and reliable products. Remember that prices may fluctuate based on market conditions, so it is wise to maintain flexibility and adaptability in your sourcing strategy.

Alternatives Analysis: Comparing exchanger channel head With Other Solutions

Exploring Alternative Solutions to Exchanger Channel Heads

In the industrial landscape, selecting the appropriate heat exchanger solution is crucial for optimizing performance and cost-efficiency. Exchanger channel heads, particularly in shell and tube heat exchangers, are widely recognized for their versatility and effectiveness. However, several alternative solutions exist that can also fulfill similar roles. This analysis compares exchanger channel heads with other viable alternatives, providing B2B buyers with insights into their respective advantages and limitations.

| Comparison Aspect | Exchanger Channel Head | Fixed Tubesheet Heat Exchanger | U-Tube Heat Exchanger |

|---|---|---|---|

| Performance | High thermal efficiency; suitable for varied pressures and temperatures | Good for low-pressure applications; limited thermal expansion | Excellent thermal expansion capability; effective in clean fluid applications |

| Cost | Moderate initial investment; maintenance can add costs | Economical design; lower initial costs | Higher upfront costs due to complexity |

| Ease of Implementation | Requires skilled labor for installation; adaptable design | Simple installation; less labor-intensive | More complex installation due to U-tube design |

| Maintenance | Regular cleaning and maintenance required; accessible tube bundle | Challenging cleaning; requires special tools | Moderate maintenance; cleaning is difficult without disassembly |

| Best Use Case | Ideal for high-pressure and temperature variations; versatile across industries | Suitable for low-pressure applications; economical for small-scale operations | Best for clean fluid applications; allows for thermal expansion |

In-Depth Analysis of Alternatives

Fixed Tubesheet Heat Exchanger

Fixed tubesheet exchangers are designed for applications where the operating conditions are less severe, typically involving lower pressures. Their simplicity and cost-effectiveness make them an attractive option for smaller operations. However, the maintenance can be cumbersome since the tube surfaces are not easily accessible for cleaning. This design may lead to higher long-term operational costs due to potential fouling.

U-Tube Heat Exchanger

U-tube heat exchangers are well-suited for applications where thermal expansion is a concern, as the U-shape allows for movement without stressing the tubes. They are particularly effective in scenarios involving clean fluids, as internal cleaning can be challenging. The complexity of their design usually results in a higher initial cost, which may deter some buyers. However, their ability to handle significant temperature variations makes them valuable for specific industrial applications.

Illustrative image related to exchanger channel head

Conclusion: Making the Right Choice for Your Needs

When selecting a heat exchanger solution, B2B buyers should carefully evaluate their specific operational requirements, including pressure, temperature, and fluid characteristics. While exchanger channel heads offer high versatility and efficiency, fixed tubesheet and U-tube heat exchangers present viable alternatives depending on the application context. Assessing the performance, cost, implementation ease, maintenance needs, and best use cases will empower buyers to make informed decisions that align with their operational goals and budget constraints. Ultimately, understanding the unique advantages and limitations of each solution is key to optimizing system performance and ensuring long-term operational success.

Essential Technical Properties and Trade Terminology for exchanger channel head

What Are the Key Technical Properties of an Exchanger Channel Head?

When sourcing an exchanger channel head, understanding its technical properties is crucial for ensuring optimal performance and longevity in various industrial applications. Here are some critical specifications to consider:

-

Material Grade

The material used for the channel head significantly impacts durability and corrosion resistance. Common materials include carbon steel, stainless steel, and exotic alloys. For example, stainless steel (like 316L) is often preferred in corrosive environments due to its excellent resistance to oxidation and pitting. Selecting the right material grade can reduce maintenance costs and extend the lifespan of the exchanger. -

Pressure Rating

The pressure rating indicates the maximum allowable pressure the channel head can withstand. Typically expressed in bar or psi, this specification is vital for ensuring safety and compliance with industry standards. Understanding the pressure requirements of your application helps prevent failures that could lead to costly downtime and safety hazards. -

Tolerance Levels

Tolerances refer to the acceptable variations in dimensions during manufacturing. These specifications are critical for ensuring that the channel head fits correctly within the overall design of the heat exchanger. Tight tolerances can enhance performance by ensuring efficient fluid flow and minimizing leakage, which is particularly important in high-pressure applications. -

Weld Joint Design

The design and quality of weld joints in the channel head are crucial for maintaining structural integrity and preventing leaks. Various weld types (such as butt welds or fillet welds) may be specified based on the application and material used. Proper weld joint design also affects the heat transfer efficiency, making it an essential consideration for performance-focused buyers. -

Surface Finish

The surface finish of the channel head influences both aesthetic appeal and functionality. A smoother surface finish can enhance heat transfer efficiency by reducing resistance to fluid flow. Additionally, certain applications may require specific finishes to minimize fouling or to comply with hygiene standards, especially in the food and pharmaceutical industries. -

End Connections

The type of end connections (flanged, threaded, or welded) determines how the channel head integrates with the rest of the system. Proper connection types are essential for ensuring leak-proof seals and accommodating thermal expansion. Understanding the compatibility of these connections with your existing infrastructure is vital for seamless installation.

What Are Common Trade Terms in the Exchanger Channel Head Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms you might encounter:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding whether a supplier is an OEM can indicate the quality and reliability of their products, which is critical for ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This specification is important for buyers to understand, especially when budgeting for large-scale projects or when sourcing for smaller operations where inventory costs need to be minimized. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. This process allows buyers to gather detailed pricing information and terms from multiple suppliers, enabling informed decision-making and fostering competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, outlining who is responsible for shipping, insurance, and tariffs. Understanding these terms helps buyers avoid unexpected costs and ensures clarity in the logistics of procurement. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This metric is crucial for project planning and inventory management, especially in industries where timing is critical. -

Certification Standards

Certifications (such as ASME, TEMA, or ISO) indicate that a product meets specific industry standards for quality and safety. Familiarity with these standards can help buyers assess the reliability of suppliers and ensure compliance with regulatory requirements.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right exchanger channel head for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the exchanger channel head Sector

What are the Key Trends Influencing the Exchanger Channel Head Market?

The global market for exchanger channel heads is experiencing dynamic shifts driven by several factors. Increased industrialization in emerging economies, particularly in Africa and South America, is fueling demand for efficient heat exchange solutions. In regions like Vietnam and Nigeria, the growth of the petrochemical and power generation sectors is leading to a surge in the adoption of shell and tube heat exchangers, where channel heads play a critical role.

Illustrative image related to exchanger channel head

Technological advancements are also transforming sourcing trends. The integration of IoT (Internet of Things) in heat exchanger systems allows for real-time monitoring and predictive maintenance, enhancing operational efficiency. B2B buyers are increasingly seeking suppliers that offer digital solutions alongside traditional products. Moreover, the rise of e-procurement platforms is streamlining the sourcing process, enabling buyers to compare options and negotiate prices more effectively.

Market dynamics are also influenced by regulatory changes, particularly in Europe and the Middle East, where stricter environmental standards are prompting manufacturers to innovate. Buyers are advised to stay informed about these regulations, as compliance can affect sourcing strategies and costs. Additionally, the fluctuation of raw material prices, exacerbated by geopolitical tensions and supply chain disruptions, necessitates agility in procurement strategies for B2B buyers.

How Can B2B Buyers Embrace Sustainability and Ethical Sourcing in the Exchanger Channel Head Sector?

Sustainability is becoming a cornerstone of purchasing decisions in the exchanger channel head market. The environmental impact of manufacturing processes, particularly in energy-intensive industries, has led to a heightened focus on ethical sourcing. B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices, such as reducing carbon emissions and minimizing waste.

The importance of ethical supply chains cannot be overstated. Suppliers that implement responsible sourcing practices not only enhance their reputations but also mitigate risks associated with supply chain disruptions. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential criteria for buyers evaluating potential vendors.

Illustrative image related to exchanger channel head

Moreover, the use of ‘green’ materials in the production of exchanger channel heads is gaining traction. Buyers should consider suppliers that utilize recyclable or sustainably sourced materials, as this not only reduces the environmental footprint but can also lead to cost savings in the long term. By aligning purchasing practices with sustainability goals, B2B buyers can contribute to a more responsible and eco-friendly industry.

What is the Historical Context of the Exchanger Channel Head Market?

The exchanger channel head market has evolved significantly since the introduction of shell and tube heat exchangers in the early 20th century. Initially designed for basic applications in heating and cooling processes, these systems have undergone substantial technological advancements. The introduction of standards by the Tubular Exchanger Manufacturers Association (TEMA) in the mid-1900s provided a framework for manufacturers, ensuring quality and performance across diverse applications.

Over the decades, the demand for more efficient and durable heat exchangers has driven innovation in design and materials. The evolution from fixed tubesheet designs to more complex floating head and U-tube configurations reflects the industry’s response to the increasing need for adaptability in high-pressure and temperature applications. As industries continue to modernize, the exchanger channel head market is poised for further growth, driven by technological advancements and a commitment to sustainability.

In summary, B2B buyers in the exchanger channel head sector must navigate a landscape shaped by technological innovation, sustainability, and evolving market dynamics, ensuring their procurement strategies align with both current demands and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of exchanger channel head

-

How do I choose the right exchanger channel head for my application?

Choosing the right exchanger channel head involves assessing the specific requirements of your application, including fluid types, temperature, and pressure conditions. Consider the TEMA standards that apply to your industry, as they provide guidelines for header types suitable for various operational demands. Additionally, evaluate the accessibility for maintenance, potential thermal expansion needs, and the ease of cleaning. Consulting with manufacturers about your operational parameters can help in selecting a design that optimizes performance and longevity. -

What are the key differences between fixed tubesheet and floating head channel heads?

Fixed tubesheet channel heads are simpler and more economical, suitable for lower pressure applications. However, they limit access for cleaning and maintenance. In contrast, floating head channel heads allow for thermal expansion and easier cleaning, making them ideal for high-temperature and high-pressure applications. The choice between the two should be based on your operational needs, maintenance capabilities, and budget constraints. -

What customization options are available when sourcing exchanger channel heads?

Most manufacturers offer customization options for exchanger channel heads to meet specific application requirements. These can include variations in materials, dimensions, and configurations based on your operational conditions. You can also specify features like corrosion resistance, insulation, and specific header types. It’s advisable to communicate your precise needs to potential suppliers early in the discussion to ensure they can meet your customization requests. -

What should I look for when vetting suppliers of exchanger channel heads?

When vetting suppliers, consider their industry experience, reputation, and compliance with international standards such as TEMA. Review their certifications and quality assurance processes, as well as customer testimonials or case studies. It’s also beneficial to check their production capabilities, lead times, and after-sales support. Engaging with suppliers who understand your market and can provide tailored solutions will enhance the procurement process. -

What is the typical minimum order quantity (MOQ) for exchanger channel heads?

Minimum order quantities (MOQs) for exchanger channel heads can vary widely depending on the manufacturer and the complexity of the design. Generally, MOQs can range from a few units for standard models to larger quantities for custom designs. Always clarify the MOQ with suppliers during negotiations, as they may offer flexibility based on your specific needs or future orders. -

What payment terms should I expect when sourcing internationally?

Payment terms can vary by supplier and region. Common practices include upfront deposits (20-50%), with the balance due upon delivery or after installation. Letters of credit and escrow services may also be used to secure transactions. It’s essential to negotiate clear terms that protect both parties, especially when dealing with international shipments, to mitigate risks related to currency fluctuations and shipping delays. -

How can I ensure quality assurance (QA) for my exchanger channel heads?

To ensure quality assurance, request detailed documentation of the manufacturing process from your supplier, including certifications and compliance with relevant standards. Ask for inspection reports and testing results before shipment. Many manufacturers will provide a warranty or guarantee for their products, which can serve as an additional assurance of quality. Consider conducting an on-site visit to the production facility if feasible, or hiring a third-party inspector for critical orders. -

What logistics considerations should I keep in mind when importing exchanger channel heads?

Logistics considerations include shipping methods, customs regulations, and potential tariffs that may apply to your order. It’s crucial to work with a logistics partner experienced in international trade, especially in your region. Ensure that the supplier provides appropriate packaging to prevent damage during transit. Additionally, factor in lead times for production and shipping to align with your project schedules, as delays can significantly impact operations.

Top 5 Exchanger Channel Head Manufacturers & Suppliers List

1. Thermopedia – Shell and Tube Heat Exchangers

Domain: thermopedia.com

Registered: 2007 (18 years)

Introduction: Shell and Tube Heat Exchangers are popular for their flexibility in handling a wide range of pressures and temperatures. They are categorized into two main types: those used in the petrochemical industry, governed by TEMA standards, and those used in the power industry, such as feedwater heaters and condensers. The main components include: Front Header (fluid entry), Rear Header (fluid exit), Tube…

2. STI – Shell-and-Tube Heat Exchanger Channels

Domain: stirome.com

Registered: 2007 (18 years)

Introduction: Channels or heads are required for shell-and-tube heat exchangers to contain the tube side fluid and to provide the desired flow path. STI offers a wide range of materials and internal cladding for any Petrochemical application. The TEMA channel types are available.

3. Forged Components – Shell and Tube Heat Exchanger Parts

Domain: forgedcomponents.com

Registered: 2000 (25 years)

Introduction: Components of Shell and Tube Heat Exchangers include: 1. Shell – a cylindrical structure made from rolled plate metal or pipe, typically steel, designed to withstand high temperatures and corrosive agents. 2. Tubes – seamless or welded tubes, usually between 5/8 inch to 1 inch in diameter, which may include fins for enhanced heat transfer. 3. Tube Sheets – forged plates with drilled holes for tube…

4. Heat Exchanger World – TEMA Standards Overview

Domain: heat-exchanger-world.com

Registered: 2019 (6 years)

Introduction: TEMA standards for shell and tube heat exchangers include three major classes: TEMA C (General Service), TEMA B (Chemical Service), and TEMA R (Refinery Service). TEMA R is the most demanding standard, while TEMA C is the least. Each TEMA heat exchanger consists of a front-end stationary head (channel), tube bundle, rear head, and shell, with various modifications available. Key TEMA types include…

5. The Piping Talk – Heat Exchanger Types

Domain: thepipingtalk.com

Registered: 2018 (7 years)

Introduction: Types of Heat Exchanger according to construction: 1. Shell and Tube Heat Exchangers – Most commonly used in process plants, can operate on a wide range of temperatures and pressures, designed according to TEMA standards. Types include: A. Floating Head Exchanger – Allows for thermal expansion, used for high-temperature fluids. B. U Tube Exchanger – One stationary tube sheet, used for cold fluids….

Strategic Sourcing Conclusion and Outlook for exchanger channel head

What Are the Key Takeaways for B2B Buyers in Sourcing Exchanger Channel Heads?

In the evolving landscape of industrial applications, understanding the nuances of shell and tube heat exchangers, particularly the channel head configurations, is critical for optimizing performance and efficiency. The diversity in design—ranging from fixed tubesheet to floating head exchangers—allows buyers to tailor solutions that meet specific operational demands. Key considerations include pressure ratings, maintenance accessibility, and thermal expansion capabilities, all of which directly impact the longevity and reliability of your systems.

How Can Strategic Sourcing Enhance Your Procurement Process?

Strategic sourcing not only streamlines procurement but also fosters relationships with suppliers who understand regional requirements and compliance standards. By leveraging local partnerships, particularly in emerging markets across Africa, South America, the Middle East, and Europe, buyers can enhance supply chain resilience and reduce lead times.

What’s Next for International B2B Buyers?

Looking ahead, it’s essential for buyers to stay informed about advancements in heat exchanger technology and evolving market dynamics. Engage with suppliers who prioritize innovation and sustainability, ensuring your operations remain competitive. Now is the time to act—evaluate your sourcing strategies and explore opportunities to enhance efficiency and cost-effectiveness in your procurement processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.