A B2B Buyer’s Guide to Equipment Platform: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for equipment platform

In today’s dynamic global marketplace, sourcing effective equipment platforms is a pressing challenge for many businesses. As companies seek to maximize operational efficiency and optimize limited space, the demand for versatile and durable platforms has surged. This comprehensive guide delves into various types of equipment platforms, their diverse applications across industries, and essential criteria for vetting suppliers. By addressing critical cost factors and installation considerations, this resource equips international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Nigeria—with the knowledge needed to make informed purchasing decisions.

Understanding the intricacies of equipment platforms can significantly impact your facility’s productivity and safety. Whether you are looking to elevate heavy machinery, create additional storage space, or enhance worker safety, this guide will provide actionable insights tailored to your specific needs. We will explore industry standards, innovative design options, and the importance of compliance with local regulations. By the end of this guide, you will be empowered to navigate the complexities of sourcing equipment platforms, ensuring that your investment aligns with both operational goals and budgetary constraints. Join us as we unlock the potential of equipment platforms in transforming your workspace into a more efficient and organized environment.

Understanding equipment platform Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mezzanine Platforms | Elevated structures, often built with steel; uses vertical space efficiently. | Warehousing, manufacturing, retail | Pros: Maximizes space; reduces ground clutter. Cons: Requires structural assessment for load capacity. |

| Modular Equipment Platforms | Customizable designs, easy assembly, and transport; can be relocated. | Temporary storage, event setups, trade shows | Pros: Flexibility; quick setup. Cons: May lack durability for heavy equipment. |

| Heavy-Duty Platforms | Designed to support substantial weight; reinforced materials. | Industrial machinery, heavy equipment storage | Pros: High load-bearing capacity; enhanced safety. Cons: Higher cost and installation complexity. |

| Mobile Equipment Platforms | Portable platforms on wheels; can be moved as needed. | Maintenance, manufacturing, assembly lines | Pros: Versatile; adaptable to various tasks. Cons: Stability concerns with heavy loads. |

| Seismic-Resistant Platforms | Built to withstand seismic activity; reinforced structures. | Regions prone to earthquakes; safety-critical applications | Pros: Enhanced safety; compliance with regulations. Cons: Often more expensive due to specialized design. |

What are Mezzanine Platforms and Their B2B Suitability?

Mezzanine platforms are elevated structures commonly constructed from steel, allowing businesses to utilize vertical space effectively. They are particularly suited for warehousing and manufacturing environments where floor space is limited. Buyers should consider the load capacity and structural integrity, as these platforms must support heavy equipment and materials without compromising safety. Installation typically requires professional assessment to ensure compliance with local building codes.

How Do Modular Equipment Platforms Offer Flexibility?

Modular equipment platforms are characterized by their customizable designs, which allow for easy assembly and relocation. This makes them ideal for temporary storage solutions, event setups, or trade shows. B2B buyers appreciate their flexibility and quick installation, but should also assess the durability of the materials, especially when used for heavy equipment. The ability to adapt to changing needs can be a significant advantage for businesses in dynamic environments.

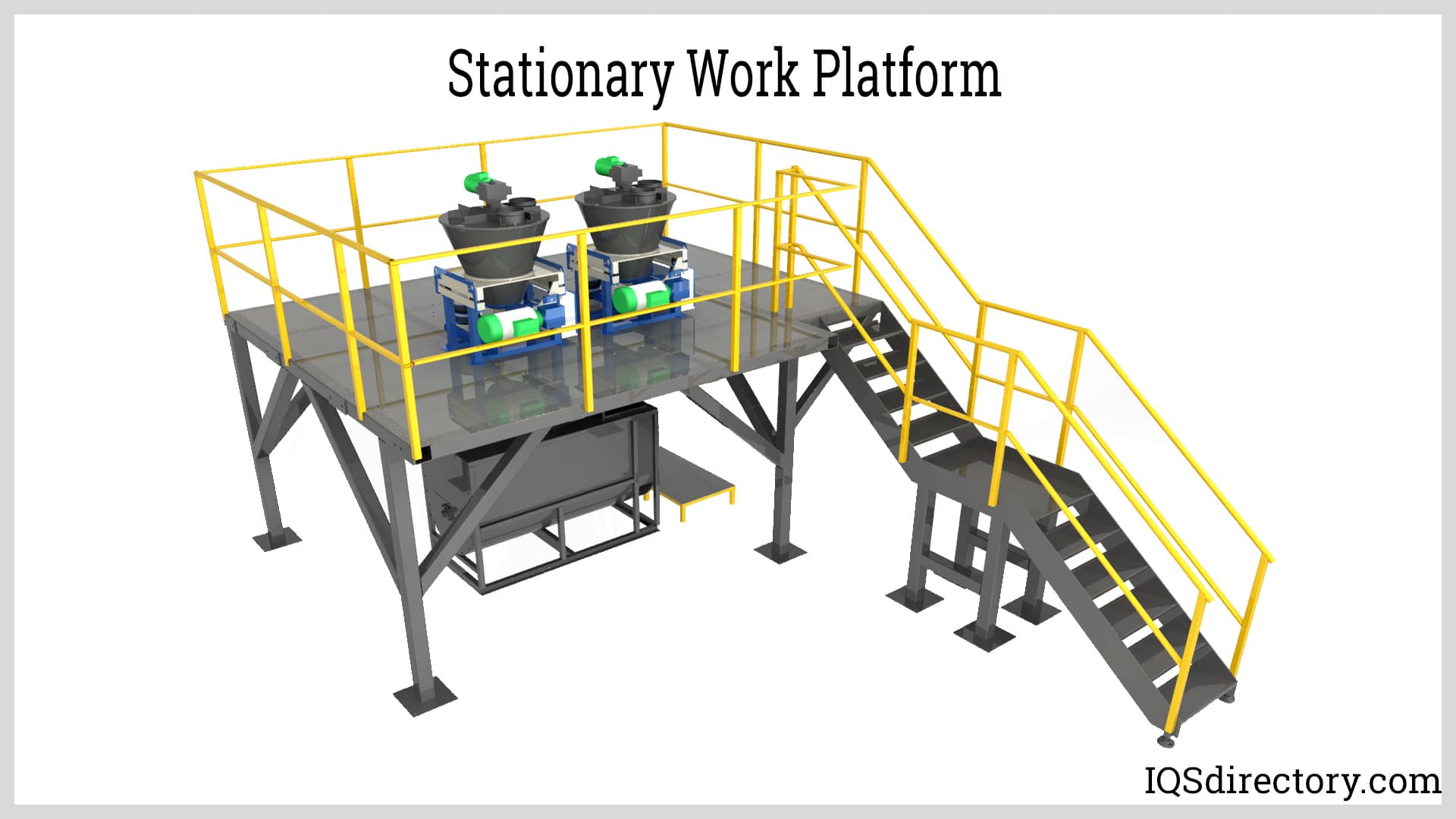

What Makes Heavy-Duty Platforms Essential for Industrial Applications?

Heavy-duty platforms are engineered to support substantial weights, making them essential in industrial settings where heavy machinery and equipment are common. These platforms are often reinforced with robust materials, ensuring safety and reliability. When considering a heavy-duty platform, buyers should evaluate the total load requirements and any specific safety standards relevant to their industry, as these factors will influence both cost and design.

Why Choose Mobile Equipment Platforms for Versatility?

Mobile equipment platforms are designed for portability, featuring wheels that allow for easy movement across the workspace. They are particularly useful in maintenance and assembly line applications where flexibility is needed. While they offer a versatile solution, buyers must weigh the benefits against potential stability concerns when heavy loads are involved. Ensuring that the platform can handle the required weight while maintaining mobility is crucial for operational efficiency.

Illustrative image related to equipment platform

How Do Seismic-Resistant Platforms Enhance Safety?

Seismic-resistant platforms are specifically designed to withstand seismic activity, making them vital in regions prone to earthquakes. Their reinforced structures provide enhanced safety for equipment and personnel. When purchasing these platforms, businesses should consider the additional costs associated with specialized design and compliance with local regulations. Investing in seismic-resistant platforms can significantly reduce risks during natural disasters, ensuring business continuity and employee safety.

Key Industrial Applications of equipment platform

| Industry/Sector | Specific Application of Equipment Platform | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Elevated assembly lines and workstations | Maximizes floor space and enhances workflow efficiency | Load capacity, customization options, compliance with safety standards |

| Warehousing | Storage platforms for inventory management | Increases storage capacity without expanding the footprint | Structural integrity, ease of installation, cost-effectiveness |

| Oil & Gas | Equipment platforms for drilling and maintenance | Protects equipment from environmental hazards, improves safety | Seismic resistance, weatherproofing, regulatory compliance |

| Pharmaceuticals | Elevated platforms for clean room environments | Ensures compliance with hygiene standards and optimizes space | Material specifications, customization for cleanroom standards, ease of access |

| Automotive | Platforms for machinery and parts storage | Streamlines operations and reduces equipment damage risks | Durability, load-bearing capacity, compatibility with existing layouts |

How Are Equipment Platforms Used in Manufacturing?

In the manufacturing sector, equipment platforms are commonly utilized to create elevated assembly lines and workstations. These structures allow manufacturers to optimize their floor space, facilitating smoother workflows and improving overall efficiency. International buyers must consider load capacity and customization options to meet specific operational needs. Additionally, compliance with safety standards is crucial to ensure worker safety and equipment integrity.

What Role Do Equipment Platforms Play in Warehousing?

In warehouses, equipment platforms serve as storage solutions for inventory management. By elevating storage areas, businesses can increase their storage capacity without the need for costly expansions. This is particularly valuable for companies looking to maximize their existing footprint. When sourcing platforms, buyers should prioritize structural integrity, ease of installation, and cost-effectiveness to ensure a solid return on investment.

How Are Equipment Platforms Beneficial in the Oil & Gas Industry?

In the oil and gas sector, equipment platforms are essential for drilling and maintenance operations. These platforms protect sensitive equipment from environmental hazards, such as flooding or harsh weather, while also enhancing worker safety. For international buyers, it’s vital to ensure that the platforms are designed to be seismic-resistant and weatherproofed, in addition to meeting regulatory compliance standards specific to their operational regions.

Why Are Equipment Platforms Important in Pharmaceuticals?

Pharmaceutical companies often require elevated platforms for clean room environments. These structures help maintain strict hygiene standards while maximizing the usable space for equipment and personnel. Buyers in this sector should focus on material specifications that comply with cleanroom standards, as well as customization options that allow for easy access while maintaining sterile conditions.

How Do Equipment Platforms Enhance Operations in the Automotive Industry?

In the automotive industry, equipment platforms are used for machinery and parts storage, significantly streamlining operations. By elevating storage solutions, companies can reduce the risk of equipment damage and improve accessibility. When sourcing platforms, international buyers should pay attention to durability, load-bearing capacity, and compatibility with existing warehouse layouts to ensure seamless integration into their operations.

Illustrative image related to equipment platform

3 Common User Pain Points for ‘equipment platform’ & Their Solutions

Scenario 1: Limited Space for Equipment Storage

The Problem: Many manufacturing facilities and warehouses face the challenge of limited floor space. As businesses expand, the need for more equipment often conflicts with the physical constraints of the facility. This leads to cluttered workspaces, inefficiencies, and potential safety hazards. In environments where equipment is not stored properly, the risk of accidents increases, and operational efficiency suffers.

The Solution: To address space limitations, B2B buyers should consider investing in equipment platforms, specifically designed to optimize vertical space. By elevating equipment, businesses can free up valuable ground-level area for other essential operations. When sourcing an equipment platform, it’s critical to assess the load-bearing requirements and ensure that the platform is custom-engineered to accommodate the weight of the equipment being stored. Collaborating with a supplier who offers prefabricated, easy-to-install systems can significantly reduce downtime. Look for platforms that come with pre-welded components to streamline assembly. Additionally, consider integrating storage solutions beneath the platform to maximize utility, creating a more organized and efficient workspace.

Scenario 2: Safety Concerns During Equipment Maintenance

The Problem: Safety is a paramount concern in any industrial setting, especially when it comes to maintaining heavy equipment. Workers often find themselves in precarious positions when accessing machinery for maintenance, risking falls or injury due to inadequate support structures. Furthermore, equipment left on the ground is more susceptible to damage from foot traffic or accidental collisions.

The Solution: Implementing a well-designed equipment platform can dramatically improve safety during maintenance procedures. These platforms should include features such as guardrails and gates, which provide secure access points for workers. When specifying an equipment platform, it’s important to involve safety experts to ensure compliance with local regulations, such as IBC standards. Opt for platforms that not only elevate equipment but also offer ample space for maintenance tasks to be performed safely. Additionally, training employees on the proper use of these platforms and establishing clear safety protocols can further mitigate risks. Regular inspections and maintenance of the platform itself are crucial to ensure its integrity and safety over time.

Illustrative image related to equipment platform

Scenario 3: High Installation Costs and Downtime

The Problem: B2B buyers often face the daunting prospect of high costs and extended downtime when installing new equipment storage solutions. Traditional construction methods can be time-consuming and disruptive, leading to lost productivity and increased labor costs. Businesses need a solution that minimizes installation time while remaining cost-effective.

The Solution: To overcome the challenges of installation costs and downtime, businesses should consider prefabricated equipment platforms that allow for quick assembly. These platforms typically come with pre-drilled holes and bolt-together systems that eliminate the need for extensive on-site welding, reducing labor costs significantly. When evaluating potential suppliers, prioritize those that offer rapid installation services and can provide a detailed project timeline. Additionally, consider modular designs that allow for future expansion without the need for complete reinstallation. This flexibility not only saves money but also ensures that the equipment platform can adapt to changing business needs. By planning ahead and choosing a reputable supplier, companies can streamline the installation process and maintain operational efficiency.

Strategic Material Selection Guide for equipment platform

What Are the Key Properties of Common Materials for Equipment Platforms?

When selecting materials for equipment platforms, it is essential to consider their properties, performance, and suitability for specific applications. Below, we analyze four common materials used in the construction of equipment platforms: steel, aluminum, fiberglass, and composite materials.

Illustrative image related to equipment platform

How Does Steel Perform as a Material for Equipment Platforms?

Steel is one of the most widely used materials for equipment platforms due to its strength and durability. It offers excellent load-bearing capabilities, making it suitable for heavy machinery and equipment. Steel platforms can withstand high temperatures and pressures, which is critical in industrial settings. However, steel is susceptible to corrosion, particularly in humid environments, unless treated with protective coatings.

Pros: Steel is highly durable, cost-effective, and readily available. Its strength allows for the construction of robust platforms that can support significant weight.

Cons: The primary drawback is its weight, which can complicate installation. Additionally, without proper treatment, steel can corrode, leading to increased maintenance costs.

What Are the Advantages of Using Aluminum for Equipment Platforms?

Aluminum is another popular choice for equipment platforms, especially in environments where weight reduction is crucial. It is lightweight, corrosion-resistant, and has good thermal conductivity. This material can be particularly advantageous in regions with high humidity or exposure to chemicals.

Pros: Aluminum platforms are easy to install due to their lightweight nature. They also require minimal maintenance and offer excellent resistance to corrosion.

Illustrative image related to equipment platform

Cons: The main limitation of aluminum is its lower load-bearing capacity compared to steel, which may restrict its use for very heavy equipment. Additionally, aluminum can be more expensive than steel.

How Do Fiberglass Platforms Compare in Terms of Performance and Suitability?

Fiberglass-reinforced plastic (FRP) is increasingly used in equipment platforms, particularly in environments where chemical exposure is a concern. Fiberglass is non-corrosive and can withstand a wide range of temperatures, making it suitable for various industrial applications.

Pros: Fiberglass platforms are resistant to chemicals, lightweight, and do not rust. They provide good slip resistance, enhancing safety in operational environments.

Cons: The cost of fiberglass can be higher than both steel and aluminum, and it may not support as much weight as steel platforms. Installation can also be more complex due to the need for specialized fasteners.

What Are the Benefits and Limitations of Composite Materials for Equipment Platforms?

Composite materials, which combine different substances to enhance performance, are gaining traction in equipment platform applications. These materials can be tailored to specific needs, offering excellent strength-to-weight ratios and resistance to environmental factors.

Illustrative image related to equipment platform

Pros: Composites are lightweight, corrosion-resistant, and can be designed for specific load requirements. They also provide good thermal insulation and can be aesthetically pleasing.

Cons: The primary drawback is the cost, as composites tend to be more expensive than traditional materials. They may also require specialized manufacturing processes, which can complicate production.

What Should International B2B Buyers Consider When Selecting Materials?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of compliance with local standards such as ASTM, DIN, or JIS when selecting materials. Additionally, factors such as climate, potential exposure to corrosive environments, and logistical considerations for transportation and installation should influence material choice. Understanding local regulations and preferences can help ensure that the selected material meets both operational and safety requirements.

| Material | Typical Use Case for Equipment Platform | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery support in industrial settings | High load-bearing capacity | Susceptible to corrosion without treatment | Medium |

| Aluminum | Lightweight applications in humid environments | Corrosion-resistant and lightweight | Lower load capacity than steel | High |

| Fiberglass | Chemical processing facilities | Non-corrosive and good slip resistance | Higher cost and complex installation | High |

| Composite | Custom applications requiring tailored properties | Excellent strength-to-weight ratio | Expensive and specialized production | High |

In-depth Look: Manufacturing Processes and Quality Assurance for equipment platform

What Are the Main Stages of Manufacturing Equipment Platforms?

The manufacturing process for equipment platforms involves several critical stages, ensuring that each unit meets the specific needs of the client while adhering to industry standards. The typical stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, often structural steel, which is chosen for its strength and durability. The materials undergo rigorous inspections to ensure they meet the specifications required for the platform. This stage may include cutting and machining the steel to specific dimensions based on engineering designs.

-

Forming: In this stage, the prepared materials are shaped into the required components using techniques such as bending, welding, and stamping. Advanced machinery, including CNC machines, may be employed for precision cutting and forming, ensuring that components fit together seamlessly during assembly.

-

Assembly: Once the individual parts are formed, they are assembled into the final structure. This often involves bolting together components rather than welding, which enhances safety and reduces installation time. During assembly, engineers ensure that load specifications are met, and safety features, such as guardrails and gates, are integrated into the design.

-

Finishing: The final stage involves applying protective coatings to prevent corrosion and enhance durability. This can include galvanizing, powder coating, or painting. The finishing process not only improves aesthetics but also extends the lifespan of the equipment platform.

How Is Quality Assurance Implemented During Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for equipment platforms, ensuring that each product meets international standards and client expectations. Several key standards and checkpoints are involved in this process:

-

International Standards: Many manufacturers adhere to ISO 9001, a globally recognized standard for quality management systems. This ensures that the organization consistently provides products that meet customer and regulatory requirements. Additionally, equipment platforms may need to comply with industry-specific certifications such as CE marking in Europe or API standards for certain applications, ensuring safety and reliability.

-

Quality Control Checkpoints: To ensure quality throughout the manufacturing process, several checkpoints are established:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of incoming materials, ensuring they meet specifications before they are used in production.

– In-Process Quality Control (IPQC): During manufacturing, inspections occur at various stages to identify and rectify any issues early in the process. This may include dimensional checks and functional testing of components.

– Final Quality Control (FQC): Once the equipment platform is fully assembled, a final inspection is conducted to ensure that it meets all design specifications and quality standards before shipment. -

Common Testing Methods: Various testing methods may be employed to verify the integrity and safety of the platforms. This can include load testing, where the platform is subjected to weights exceeding its design load to ensure it can safely support operational loads. Non-destructive testing (NDT) methods, such as ultrasonic or magnetic particle inspection, may also be utilized to detect internal flaws in welds and materials.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of their suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. During these audits, buyers can assess the facility’s adherence to quality standards, observe production methods, and evaluate the handling of materials.

-

Reviewing Quality Reports: Requesting detailed quality reports and certifications from suppliers is essential. These documents should outline the quality control measures in place, results from recent inspections, and any relevant certifications. This information helps buyers understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These inspections can be scheduled at various stages of production and provide additional assurance that the equipment platforms meet specified standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control and certification, particularly when sourcing equipment platforms from different regions. Here are some key considerations:

-

Understanding Regional Standards: Different regions may have varying standards and certifications. For example, CE marking is mandatory in Europe, while other regions may have different regulatory requirements. Buyers should familiarize themselves with the applicable standards in their target markets to ensure compliance.

-

Language and Documentation: Language barriers can complicate the verification process. Buyers should ensure that all documentation, including quality reports and certifications, is available in a language they understand. This clarity is crucial for making informed purchasing decisions.

-

Cultural Differences in Business Practices: Different regions may have distinct approaches to quality management and business practices. Understanding these cultural differences can aid buyers in effectively communicating their quality expectations and ensuring compliance with their standards.

-

Risk Management: Buyers should incorporate risk management strategies into their procurement processes. This includes evaluating potential risks associated with supplier quality, geopolitical factors, and logistical challenges that may impact the delivery of quality products.

By understanding the manufacturing processes and quality assurance practices in the equipment platform industry, B2B buyers can make informed decisions, ensuring they partner with suppliers who prioritize quality and reliability. This knowledge not only enhances operational efficiency but also contributes to the long-term success of their enterprises.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘equipment platform’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of equipment platforms. By following this step-by-step checklist, businesses can ensure they make informed decisions that align with their operational needs, budget constraints, and safety requirements.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical specifications of the equipment platform you need. This includes load capacity, dimensions, and material requirements. Understanding these details will help you communicate effectively with suppliers and ensure that the platform meets your operational demands.

- Load Capacity: Determine the maximum weight the platform must support, including equipment and personnel.

- Dimensions: Measure the available space to ensure the platform fits within your facility’s layout.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in equipment platforms. Look for companies with a strong reputation in your industry and region. This step is critical as it lays the groundwork for selecting a reliable partner.

Illustrative image related to equipment platform

- Industry Experience: Focus on suppliers with a proven track record in your specific industry.

- Geographic Reach: Ensure the supplier can service your location, especially if you are operating in regions like Africa or South America.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications and comply with international safety and quality standards. This is essential for ensuring that the equipment platform is safe and reliable.

- ISO Certifications: Check for ISO 9001 or other relevant quality management certifications.

- Safety Standards Compliance: Ensure the platform meets local and international safety regulations, such as IBC compliance.

Step 4: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that include design options, pricing, lead times, and installation services. A comprehensive proposal allows for better comparison and helps clarify any uncertainties.

- Design Flexibility: Inquire about customization options to fit your specific needs.

- Transparent Pricing: Ensure the proposal outlines all costs involved, including shipping and installation.

Step 5: Assess Installation and Support Services

Evaluate the installation process and ongoing support offered by the supplier. A smooth installation minimizes downtime, while good support ensures that any issues are resolved quickly.

- Installation Method: Ask if the platform requires welding or if it is a bolt-together system, as this can affect installation time and costs.

- Post-Installation Support: Understand the warranty and maintenance services provided to ensure the longevity of the platform.

Step 6: Check References and Case Studies

Before finalizing your decision, check references and review case studies from other clients who have used the supplier’s equipment platforms. This step helps validate the supplier’s claims and provides insights into their reliability and service quality.

- Client Feedback: Reach out to references to inquire about their experiences, focusing on product quality and customer service.

- Case Studies: Review case studies relevant to your industry to see how the supplier’s solutions have been successfully implemented.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier, finalize your purchase agreement, ensuring that all terms and conditions are clearly outlined. This includes payment terms, delivery schedules, and installation timelines.

Illustrative image related to equipment platform

- Clear Terms: Make sure the agreement includes all negotiated points to avoid misunderstandings later.

- Contingency Clauses: Consider including clauses for potential delays or issues that may arise during installation or delivery.

By following these steps, B2B buyers can confidently procure equipment platforms that enhance operational efficiency and safety in their facilities.

Comprehensive Cost and Pricing Analysis for equipment platform Sourcing

What Are the Key Cost Components for Sourcing Equipment Platforms?

When considering the procurement of equipment platforms, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Steel is a common choice due to its strength and durability, but alternatives like aluminum or composite materials may also be considered for specific applications. Higher-grade materials often come with higher costs but can offer better longevity and performance.

-

Labor: Installation labor costs can vary widely based on regional labor rates, the complexity of the installation, and the need for skilled workers. In regions with higher labor costs, such as parts of Europe, this can significantly affect the total project cost.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Depending on the specifications of the equipment platform, specialized tooling may be required for manufacturing. This upfront investment can be significant, especially for custom designs.

-

Quality Control (QC): Ensuring that the equipment platforms meet safety and performance standards is crucial. Costs associated with QC can include testing, certifications, and compliance with industry regulations.

-

Logistics: Shipping costs, including freight and handling, must be factored into the total cost. International buyers should pay attention to the Incoterms agreed upon, as they dictate who bears the cost and risk during transportation.

-

Margin: Suppliers typically add a profit margin to cover their expenses and ensure profitability. This margin can vary based on market competition, demand, and supplier reputation.

What Influences the Pricing of Equipment Platforms?

Several factors can influence the pricing of equipment platforms, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities can lead to significant discounts. Understanding the supplier’s MOQ can help buyers negotiate better pricing, especially when sourcing for multiple facilities.

-

Specifications and Customization: Custom designs that meet specific operational needs can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Platforms constructed from high-quality materials or those that meet specific industry certifications may come at a premium. Buyers should evaluate whether the added costs align with their operational requirements.

-

Supplier Factors: Supplier reputation, reliability, and service level can affect pricing. Established suppliers may charge more but offer better warranties and support.

-

Incoterms: The agreed-upon Incoterms can impact the total landed cost. Buyers should negotiate terms that minimize their exposure to unexpected costs related to shipping and customs.

How Can Buyers Optimize Costs and Negotiate Effectively?

International B2B buyers can implement several strategies to ensure cost efficiency when sourcing equipment platforms:

Illustrative image related to equipment platform

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, operation, and potential downtime. A lower upfront cost may lead to higher TCO if quality is compromised.

-

Negotiation Strategies: Engage suppliers in discussions about pricing, especially if you can provide data on competitor pricing or bulk purchasing plans. Building a relationship with suppliers can also lead to better terms.

-

Awareness of Pricing Nuances: Be mindful of regional differences in pricing. For example, suppliers in regions like Africa and South America may have different cost structures compared to those in Europe or the Middle East. Understanding these nuances can aid in negotiations.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times. Moreover, local suppliers may have a better understanding of regional regulations and requirements.

-

Request Quotes from Multiple Suppliers: Obtaining quotes from various suppliers allows for comparative analysis, helping buyers identify the best value for their investment.

Disclaimer on Indicative Prices

Pricing for equipment platforms can vary widely based on specifications, location, and supplier conditions. Buyers should conduct thorough market research and obtain detailed quotations tailored to their specific needs to ensure accurate budgeting and cost management.

Alternatives Analysis: Comparing equipment platform With Other Solutions

Exploring Alternatives to Equipment Platforms for Space Optimization

When it comes to optimizing space within manufacturing and warehousing environments, equipment platforms are a popular choice. However, it’s essential to explore various alternatives that can achieve similar goals of maximizing space and enhancing operational efficiency. This section compares equipment platforms with other viable solutions to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Equipment Platform | Modular Storage Systems | Vertical Lifts |

|---|---|---|---|

| Performance | High load capacity; customizable designs | Flexible configurations; scalable | Efficient in vertical transport; space-saving |

| Cost | Moderate initial investment; long-term savings | Variable costs based on configuration | Higher upfront costs; potential savings in space |

| Ease of Implementation | Quick installation; prefabricated components | Can require more assembly time | Requires professional installation |

| Maintenance | Low maintenance; durable materials | Moderate; depends on design | Higher due to mechanical components |

| Best Use Case | Heavy equipment storage; maximizing floor space | General storage; inventory management | Transporting goods between levels |

Detailed Breakdown of Alternatives

1. Modular Storage Systems

Modular storage systems consist of adjustable shelving and storage units that can be tailored to specific needs. These systems are highly flexible and can be easily reconfigured as business requirements change. The primary advantage of modular systems is their scalability; they can grow with the business and adapt to different inventory types. However, they may require more assembly time compared to equipment platforms and might not support extremely heavy loads as effectively.

2. Vertical Lifts

Vertical lifts offer a different approach by transporting goods vertically, which is particularly useful in facilities with limited floor space. These systems are designed to move materials from one level to another efficiently, saving valuable ground space. The major benefit of vertical lifts is their ability to handle significant weight and optimize the vertical height of a facility. However, they typically involve higher upfront costs and require professional installation, which may not be ideal for all businesses.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution for space optimization in a B2B environment requires careful consideration of operational needs, budget constraints, and facility layout. Equipment platforms excel in providing robust support for heavy machinery while maximizing floor space. In contrast, modular storage systems offer flexibility and adaptability, while vertical lifts are ideal for vertical transportation needs. By analyzing the specific requirements of your operation, including load capacities and future growth plans, you can choose the most suitable solution that aligns with your business objectives and enhances efficiency.

Essential Technical Properties and Trade Terminology for equipment platform

What Are the Essential Technical Properties of Equipment Platforms?

When evaluating equipment platforms, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some key properties that B2B buyers should consider:

1. Material Grade

The material grade refers to the quality and type of materials used in the construction of the equipment platform, typically steel. Common grades include structural steel (e.g., ASTM A36) and higher-strength options (e.g., ASTM A992). Selecting the right material grade is vital for ensuring structural integrity, longevity, and safety, particularly in demanding industrial environments.

2. Load Capacity (DLL)

Design Live Load (DLL) is the maximum weight that a platform can safely support during normal use. This specification is expressed in pounds per square foot (psf) and is critical for determining whether the platform can accommodate the intended equipment and personnel. Accurately assessing DLL prevents overloading, which can lead to structural failure and safety hazards.

3. Clear Height and Top of Deck Height

Clear height is the distance from the finished floor to the lowest point of the platform, while top of deck height measures from the floor to the top surface of the platform. These measurements are crucial for ensuring that the platform fits within the available vertical space and accommodates any equipment or personnel below. Inadequate height can limit functionality and lead to operational inefficiencies.

4. Seismic Resistance

For regions prone to earthquakes or other seismic activities, the seismic resistance of an equipment platform is a key consideration. Platforms designed with seismic-resistant features enhance stability and ensure that heavy equipment remains secure during such events. This is particularly important for B2B buyers in regions like the Middle East and parts of South America, where seismic activity can be a concern.

5. Column Base Plate Pressure

This specification refers to the pressure exerted by the base plates of the platform’s columns on the underlying foundation. It is calculated by dividing the total load on each column by the area of the base plate. Understanding column base plate pressure is essential to ensure that the existing concrete slab can handle the load without requiring additional foundation work, thus avoiding unexpected costs and project delays.

What Are Common Trade Terms Related to Equipment Platforms?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some commonly used terms in the context of equipment platforms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of equipment platforms, OEMs provide the structural components and designs that meet specific industry standards. Understanding OEM relationships can help buyers ensure product quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For equipment platforms, MOQs can impact purchasing decisions, especially for smaller companies or startups that may not need large quantities. Knowing the MOQ can help businesses plan their budgets and inventory needs effectively.

Illustrative image related to equipment platform

3. RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers to request pricing and terms for specific products or services. When purchasing equipment platforms, issuing an RFQ allows buyers to compare costs and specifications from multiple suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for B2B buyers involved in cross-border transactions, as they outline who bears the risk and costs associated with shipping and delivery.

5. Prefabricated Design

This term refers to components that are manufactured off-site and assembled on-site. Prefabricated designs for equipment platforms can significantly reduce installation time and costs, making them an attractive option for businesses looking to maximize efficiency and minimize disruptions during setup.

By understanding these technical properties and trade terminology, B2B buyers can make more informed decisions when selecting equipment platforms that meet their operational needs and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the equipment platform Sector

What are the Key Market Drivers Influencing the Equipment Platform Sector?

The equipment platform sector is experiencing robust growth, driven by several global trends. Increased urbanization and industrialization, particularly in regions like Africa and South America, are prompting businesses to optimize their operational spaces. As companies strive to enhance efficiency and productivity, the demand for equipment platforms that utilize vertical space is rising. Additionally, the ongoing digital transformation in manufacturing and warehousing is facilitating smarter sourcing decisions and inventory management through advanced technologies like IoT and AI, which help in assessing space utilization and operational needs.

Emerging trends also highlight the shift towards prefabricated and modular solutions. These options not only reduce installation time but also lower costs, making them attractive for international B2B buyers. For instance, the ability to customize equipment platforms to specific operational requirements is becoming increasingly important, allowing businesses to adapt swiftly to changing market conditions. Furthermore, sustainability concerns are influencing purchasing decisions, with companies seeking equipment platforms that minimize environmental impact and promote efficient resource use.

How is Sustainability Shaping the Equipment Platform Supply Chain?

Sustainability is no longer just a buzzword; it has become a critical factor in B2B sourcing decisions. The equipment platform sector is witnessing a growing emphasis on minimizing environmental impact through responsible sourcing and production practices. Buyers are increasingly evaluating suppliers based on their commitment to sustainability, including the use of recycled materials and energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction, as companies are held accountable for their supply chain practices. This includes ensuring that materials are obtained from suppliers who adhere to fair labor practices and environmental regulations. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 for environmental management systems are becoming essential for companies looking to enhance their green credentials. By choosing equipment platforms that are certified for sustainability, buyers not only comply with regulations but also appeal to a conscientious customer base that values environmental responsibility.

What is the Evolution of Equipment Platforms in the B2B Context?

The evolution of equipment platforms can be traced back to the industrial revolution, where the need for maximizing space in warehouses and factories became evident. Initially, these structures were rudimentary and often relied on the building’s existing infrastructure for support. However, advancements in engineering and materials science have led to the development of independent, modular platforms that can be customized to specific operational needs.

Illustrative image related to equipment platform

In recent years, the focus has shifted towards prefabrication and modular design, enabling quicker installations and reducing costs. This evolution has made equipment platforms more accessible for international B2B buyers, particularly in emerging markets where space optimization is crucial. As technological advancements continue to influence the sector, the future promises even more innovative solutions that cater to the dynamic needs of businesses worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of equipment platform

-

1. How do I determine the right load capacity for my equipment platform?

To determine the appropriate load capacity for your equipment platform, first assess the weight of the equipment, materials, and personnel that will be on the platform. This includes calculating the Design Live Load (DLL), which is the maximum expected load during regular use. Consult with your supplier to understand their specifications and ensure the platform is designed to safely support the total load, factoring in both the dead load (the weight of the platform itself) and the DLL. Proper load assessment ensures safety and prevents structural failures. -

2. What are the key factors to consider when selecting an equipment platform supplier?

When choosing an equipment platform supplier, consider their experience and reputation in the industry, especially regarding international projects. Evaluate their ability to customize platforms to meet specific operational needs, including compliance with local regulations in your region. Additionally, inquire about their quality assurance processes, lead times, and after-sales support. It’s also beneficial to request references from previous clients to gauge reliability and service quality. -

3. What customization options are available for equipment platforms?

Customization options for equipment platforms may include varying heights, load capacities, and designs tailored to specific operational requirements. Buyers can also request features such as guard rails, gates, and seismic-resistant designs, depending on their location and use case. Discussing your specific needs with the supplier will help ensure the platform is designed to optimize your space effectively while adhering to safety standards and compliance regulations. -

4. What are the minimum order quantities (MOQ) for equipment platforms?

Minimum order quantities (MOQ) for equipment platforms can vary significantly by supplier and region. Many suppliers are flexible, especially for custom solutions, while others may have strict MOQs due to production costs. It’s essential to communicate your needs directly with potential suppliers to understand their policies. If your order is below the MOQ, inquire about potential alternatives, such as combining orders with other buyers or exploring off-the-shelf options. -

5. How do I ensure quality assurance for my equipment platform?

To ensure quality assurance for your equipment platform, request detailed information about the supplier’s manufacturing and testing processes. Look for certifications that demonstrate adherence to international quality standards, such as ISO. Additionally, consider conducting site visits or audits if feasible, and request documentation of quality control measures. Establishing clear communication regarding your quality expectations will also help ensure the final product meets your operational needs. -

6. What are the payment terms typically offered by equipment platform suppliers?

Payment terms can vary widely among suppliers, but common arrangements include upfront deposits, milestone payments, or net terms (e.g., net 30 or net 60). It’s crucial to negotiate terms that suit your cash flow and project timeline while ensuring that both parties are protected. Be sure to clarify the payment structure, including any penalties for late payments and the implications of changes in the order after payment has been made. -

7. How can I effectively manage logistics for importing equipment platforms?

Effective logistics management for importing equipment platforms involves planning for transportation, customs clearance, and delivery timelines. Work closely with your supplier to understand shipping options, including freight forwarders who specialize in heavy equipment. Familiarize yourself with local import regulations and tariffs to avoid unexpected delays. It’s also beneficial to establish a clear communication channel with all parties involved to address any issues promptly. -

8. What are the common challenges faced during the installation of equipment platforms?

Common challenges during the installation of equipment platforms include site space constraints, unexpected structural issues, and coordination among various contractors. To mitigate these challenges, conduct a thorough site assessment before installation, and ensure all stakeholders are aligned on the project timeline and responsibilities. Additionally, selecting a supplier that offers prefabricated components can streamline the installation process, reducing the need for extensive on-site assembly and minimizing downtime.

Top 8 Equipment Platform Manufacturers & Suppliers List

1. ANDREW – Equipment Platforms & Accessories

Domain: tessco.com

Registered: 1995 (30 years)

Introduction: Platforms & Accessories include various equipment platforms and accessories from ANDREW an Amphenol company. Key products include: 1. 10′ x 20′ Equipment Platform with 8 Adjustable Legs (SKU: 275116) 2. Single Platform Step (SKU: 382347) 3. E20 Equipment Platform, 6 ft x 20 ft (SKU: 207226) 4. 10ft x 12ft Platform Handrail Kit (SKU: 244871) 5. Handrail kit for 10′ x 10′ Equipment Platform (SKU: 23…

2. Kenwood Telecom – Mounting Solutions

Domain: kenwoodtelecom.com

Introduction: Kenwood Telecom offers a variety of platforms and canopies including rooftop and wall non-penetrating roof mounts, penetrating roof mounts, rooftop bridge kits, straight sections, bends, tees, crosses, reducers, wall mounts, wall bridge kits, RRU mounting installation kits, H-frames, BTS, water tower mounts, and water tower accessories. Additional equipment includes safety harnesses, lanyards, car…

3. PHP Equipment Platform System – Rooftop Support Solutions

Domain: phpsd.com

Registered: 2005 (20 years)

Introduction: The PHP Equipment Platform System is designed to support various types of rooftop equipment for pipe sizes up to 2-1/2″ OD. It is available in high wind and seismic applications. The installation process includes laying isolation pads, placing substructures, laying bar grating with the serrated side up, fastening bar grating to substructures with provided clips, and checking for levelness.

4. SitePro1 – Equipment Platforms

Domain: sitepro1.com

Registered: 2003 (22 years)

Introduction: Equipment Platforms categories include Tower Sites, Monopole Sites, Rooftop Sites, Wall Mounts & Chimney Mounts, Ice Bridges & Equipment Racks, Cable Runway, Cable Support Hardware, Climb Systems, Guy Components & Tower Bracing, Cable Accessories, Boots & Panels, Grounding Tapes, Chemicals, & Banding.

5. FCP – Equipment Platforms

Domain: fcpmezzanine.com

Registered: 2004 (21 years)

Introduction: FCP Equipment Platforms allow for fast installation, future expansion, and can be dismantled and re-assembled if needed. They are custom-designed for a wide variety of applications including industrial, communication, utility, entertainment, and manufacturing equipment. The platforms are compliant with CBC and IBC building codes. Key features include the ability to fit around existing obstructions…

6. Up.Codes – Equipment Platform Regulations

Domain: up.codes

Introduction: Equipment platforms in buildings shall not be considered as a portion of the floor below. They do not contribute to the building area or the number of stories. The area of the equipment platform is excluded from determining the fire area. Equipment platforms are not part of any mezzanine and do not serve as means of egress. The aggregate area of all equipment platforms in a room must not exceed tw…

7. ANDREW – Structural Support Solutions

Domain: andrew.com

Registered: 1994 (31 years)

Introduction: ANDREW structural support solutions are engineered to comply with EIA/TIA codes and ISO-9001 standards, providing network stability and reliability for various installations. Key products include:

– Equipment platforms & canopies

– Waveguide/ice bridges

– Cable support brackets

– Attachment hangers

– Hoisting & support grips

– Pipes, pipe mounts & site hardware

– Custom kits

– VZWSMART MUK

These s…

8. Allied Modular – Equipment Platforms

Domain: alliedmodular.com

Registered: 1997 (28 years)

Introduction: Equipment platforms, also known as working platforms, are raised mezzanine structures designed to support heavy loads, maximize space, and improve safety in industrial environments such as manufacturing plants, warehouses, and distribution centers. They are constructed from heavy-duty materials like steel, allowing them to carry machinery and equipment while providing access for maintenance. Key b…

Strategic Sourcing Conclusion and Outlook for equipment platform

As businesses across diverse sectors grapple with space constraints and operational efficiency, the value of strategic sourcing for equipment platforms becomes paramount. These platforms not only optimize vertical space but also enhance safety and accessibility, leading to improved productivity. By investing in robust, prefabricated solutions that minimize installation downtime, companies can avoid the significant costs associated with new construction while maximizing existing facilities.

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider the long-term benefits of equipment platforms. Customized designs can cater to specific operational needs, ensuring compliance with local regulations while adapting to unique environmental challenges, such as seismic activity or flooding.

Looking ahead, the demand for innovative space solutions will continue to rise. By strategically sourcing high-quality equipment platforms, businesses can future-proof their operations and enhance their competitive edge. We encourage buyers to explore partnerships with reputable suppliers that prioritize safety, efficiency, and tailored solutions. Investing in equipment platforms today will pave the way for streamlined operations and robust growth tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to equipment platform

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.