A B2B Buyer’s Guide to Elasticity Cord: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for elasticity cord

In the rapidly evolving landscape of international trade, sourcing high-quality elasticity cord can present a significant challenge for B2B buyers. From crafting durable products to meeting diverse customer needs, businesses must navigate a complex market filled with varying specifications and applications. This comprehensive guide addresses these challenges by providing an in-depth exploration of elasticity cord, including its types, uses across different industries, supplier vetting strategies, and cost considerations.

Designed specifically for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Saudi Arabia—this guide empowers decision-makers to make informed purchasing choices. With insights into the latest trends and best practices, buyers will gain a clearer understanding of the elasticity cord market, enabling them to identify reliable suppliers and negotiate competitive pricing.

By delving into the nuances of elasticity cord—from its applications in fashion and craft industries to its role in various manufacturing processes—this guide equips businesses with the knowledge necessary to enhance their product offerings and improve customer satisfaction. Whether you’re a seasoned buyer or new to the market, this resource aims to streamline your sourcing process and elevate your procurement strategy in a global context.

Understanding elasticity cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Elastic Cord | Commonly used, available in various diameters (0.5mm to 1.0mm) and colors. | Jewelry making, garment construction | Pros: Versatile and widely available. Cons: May lack durability for heavy-duty applications. |

| Heavy-Duty Elastic Cord | Thicker diameter (1.0mm and above) designed for higher tension. | Industrial applications, outdoor gear | Pros: High strength and durability. Cons: Less flexibility in design. |

| Clear Elastic Cord | Transparent material, less visible in finished products. | Crafting, jewelry, and fashion accessories | Pros: Aesthetic appeal for visible projects. Cons: Can be prone to wear and tear over time. |

| Braided Elastic Cord | Multi-stranded construction for enhanced elasticity and strength. | Activewear, swimwear, and sports gear | Pros: Superior stretch and recovery. Cons: Typically higher cost than standard options. |

| Shock Cord | Elastic cord with a protective outer layer, often used in outdoor applications. | Tarpaulin securing, camping gear | Pros: Weather-resistant and robust. Cons: Heavier and bulkier than other types. |

What are the Characteristics and Suitability of Standard Elastic Cord?

Standard elastic cord is the most commonly used type, characterized by its availability in a range of diameters, typically from 0.5mm to 1.0mm. This type is ideal for various applications, including jewelry making and garment construction. B2B buyers should consider the specific diameter and color options available, as these can significantly impact the final product’s aesthetics and functionality. Its versatility makes it a staple in crafting industries, but buyers should be mindful of its limitations in high-stress environments.

How Does Heavy-Duty Elastic Cord Stand Out?

Heavy-duty elastic cord is designed for applications requiring higher tensile strength. With diameters starting from 1.0mm, it is suitable for industrial uses and outdoor gear, where durability is paramount. B2B buyers should prioritize this type when selecting materials for products subjected to significant wear and tear. While it offers excellent strength, the trade-off is often reduced flexibility in design, which may limit creative applications.

What Advantages Does Clear Elastic Cord Offer?

Clear elastic cord is a transparent option that minimizes visibility in finished products, making it particularly popular in crafting, jewelry, and fashion accessories. This type enhances the aesthetic appeal of designs while maintaining functionality. B2B purchasers should consider the wear and tear characteristics of clear elastic, as it may not withstand heavy use as effectively as other options. Its versatility is a significant advantage for those focused on design quality.

Why Choose Braided Elastic Cord for Your Products?

Braided elastic cord features a multi-stranded construction that enhances its elasticity and strength, making it a preferred choice for activewear, swimwear, and sports gear. B2B buyers should consider this type for projects requiring superior stretch and recovery, as it provides a more comfortable fit. However, the cost may be higher compared to standard options, which is an important factor for bulk purchasing decisions.

In What Scenarios is Shock Cord the Best Choice?

Shock cord is an elastic cord encased in a protective outer layer, making it particularly suitable for outdoor applications, such as securing tarpaulins and camping gear. Its weather-resistant properties make it an excellent choice for B2B buyers in industries focused on outdoor products. While it offers robustness, its bulkiness may not be ideal for all applications, and buyers should weigh the benefits against the added weight in their product designs.

Key Industrial Applications of elasticity cord

| Industry/Sector | Specific Application of elasticity cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile and Fashion | Garment production and accessories | Enhances product versatility and comfort | Ensure durability and elasticity under varied conditions. |

| Automotive | Interior trim and fastening systems | Provides flexibility and durability in design | Look for high tensile strength and resistance to wear. |

| Construction and DIY | Securing tarps and temporary structures | Offers reliable, adjustable tension for stability | Consider UV resistance and weather durability for outdoor use. |

| Crafts and Hobbies | Jewelry making and craft projects | Facilitates creative designs with stretchability | Source in various diameters and colors for versatility. |

| Medical Devices | Elastic bands in medical equipment | Ensures reliability and safety in patient care | Prioritize biocompatibility and compliance with health standards. |

How is Elasticity Cord Used in Textile and Fashion Industries?

In the textile and fashion sectors, elasticity cord is integral in garment production, especially in creating comfortable and adjustable clothing. It is often used in waistbands, cuffs, and accessories, allowing garments to stretch and fit various body shapes. For international buyers, especially from regions like Africa and South America, sourcing high-quality elasticity cord that maintains its stretch over time is crucial. Buyers should focus on materials that withstand washing and wearing without losing elasticity, ensuring long-term value.

What Role Does Elasticity Cord Play in the Automotive Industry?

Within the automotive sector, elasticity cord is commonly employed in interior trim and fastening systems. It provides the flexibility needed for components like door panels and seat covers, contributing to a sleek and functional design. For B2B buyers in the Middle East and Europe, it’s essential to source cords that offer high tensile strength and durability to withstand the rigors of daily use. Buyers should also consider the cord’s resistance to temperature fluctuations and wear, ensuring that it meets automotive standards.

How is Elasticity Cord Utilized in Construction and DIY Projects?

In construction and DIY applications, elasticity cord is used for securing tarps and creating temporary structures. Its ability to provide adjustable tension makes it ideal for various projects, from outdoor events to home renovations. Buyers from regions with diverse climates, such as the Middle East, need to prioritize elasticity cords that are UV resistant and durable against weather elements. Sourcing from reliable suppliers who can provide consistent quality and bulk options is essential for project success.

What Benefits Does Elasticity Cord Offer in Crafts and Hobbies?

In the crafts and hobbies domain, elasticity cord is a favorite among artisans for jewelry making and other creative projects. Its stretchability allows for the creation of designs that fit different sizes, such as bracelets and necklaces. B2B buyers in Europe and South America should look for cords available in various diameters and colors to cater to diverse market preferences. Ensuring that the cord is easy to work with and maintains its elasticity over time is vital for customer satisfaction.

How is Elasticity Cord Used in Medical Devices?

Elasticity cord finds significant applications in the medical field, particularly in devices that require reliable elastic bands. These cords are essential for ensuring safety and effectiveness in medical equipment, such as prosthetics and compression garments. Buyers, particularly from Africa and the Middle East, must prioritize sourcing cords that meet stringent biocompatibility and health regulations. Ensuring that the elasticity cord can withstand sterilization processes while maintaining its properties is crucial for compliance and patient safety.

Illustrative image related to elasticity cord

3 Common User Pain Points for ‘elasticity cord’ & Their Solutions

Scenario 1: Sourcing Quality Elasticity Cord for Diverse Applications

The Problem: Many B2B buyers struggle with sourcing high-quality elasticity cord that meets their specific needs, particularly when catering to a diverse range of applications. For instance, a supplier of handmade jewelry might require different elasticity cord specifications for bracelets, necklaces, and hair accessories. The challenge lies in ensuring that the cord is durable enough to withstand regular use, while also being flexible enough to accommodate various designs. Additionally, buyers may face difficulties in finding suppliers who can provide consistent quality across different orders, which can impact their production timelines and product offerings.

The Solution: To overcome this challenge, buyers should prioritize working with established suppliers who specialize in elasticity cord and offer detailed product specifications. Conduct thorough research to identify manufacturers that provide samples, enabling you to assess the cord’s quality before making larger orders. Look for suppliers that offer a variety of cord thicknesses and materials, as this will allow you to select the right type for each application. Additionally, consider suppliers that can guarantee consistent quality through certifications or quality assurance processes. Establishing a good relationship with your supplier can also facilitate better communication regarding your specific needs, ensuring that you receive the right product every time.

Scenario 2: Managing Inventory and Stock Levels Efficiently

The Problem: B2B buyers often face difficulties in managing inventory levels of elasticity cord, leading to either surplus stock or stockouts. For companies that rely on just-in-time manufacturing, running out of elasticity cord can halt production, causing delays and potential losses. Conversely, overstocking can tie up capital and increase storage costs, especially for businesses in regions where warehousing is expensive. This balancing act becomes even more challenging when dealing with fluctuating demand across different seasons or trends.

The Solution: Implementing an inventory management system tailored to your specific needs can significantly enhance stock control. Consider using software that allows for real-time tracking of inventory levels, sales forecasts, and supplier lead times. This can help you determine optimal stock levels and reorder points based on historical data and predicted demand. Regularly review your inventory turnover rates to identify slow-moving products, allowing you to adjust your purchasing strategy accordingly. Furthermore, establishing a strong communication line with suppliers can help you respond quickly to changes in demand, enabling you to adjust orders proactively and avoid stockouts.

Scenario 3: Ensuring Compatibility with Other Materials

The Problem: Compatibility issues between elasticity cord and other materials used in production can be a significant pain point for B2B buyers. For instance, when creating jewelry or crafting products, the elasticity cord must work seamlessly with various beads, clasps, and other components. An incompatible cord can lead to breakage or failure of the final product, resulting in customer dissatisfaction and increased return rates. This scenario is particularly critical for businesses aiming to maintain high-quality standards and positive customer relationships.

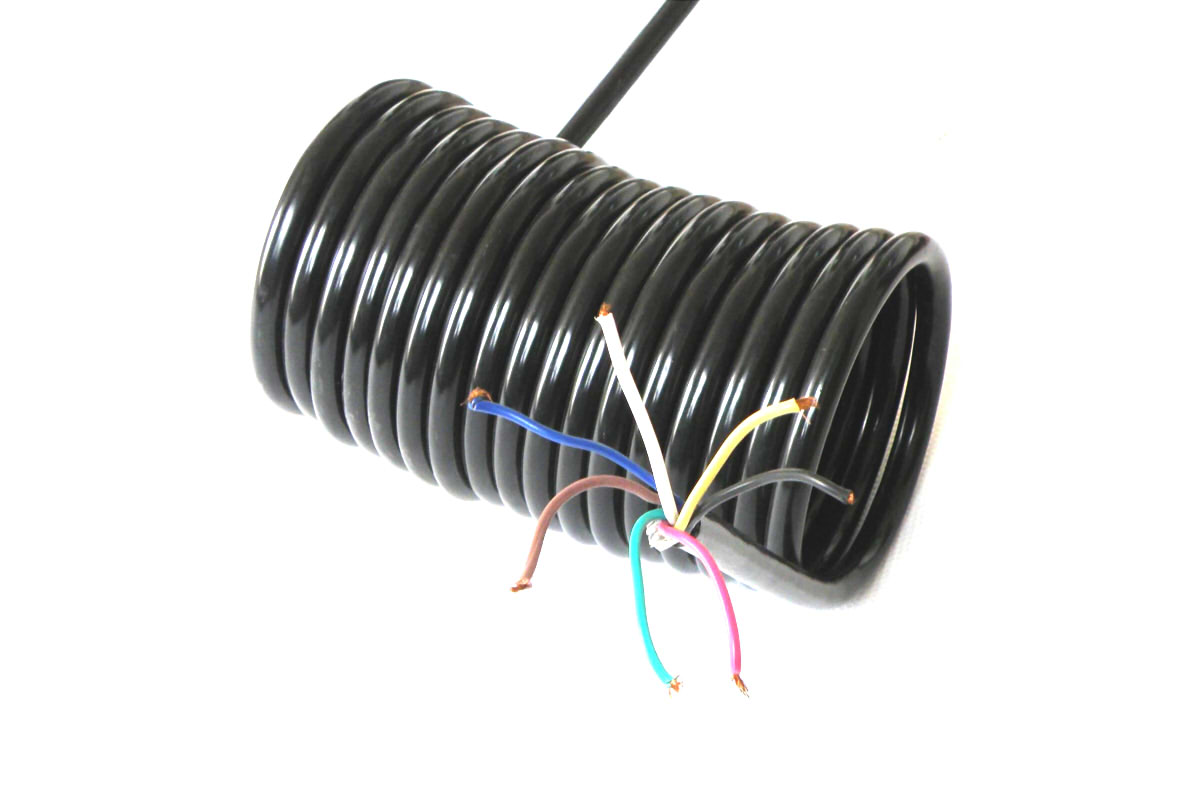

Illustrative image related to elasticity cord

The Solution: To ensure compatibility, buyers should conduct thorough testing with the materials they plan to use alongside the elasticity cord. Start by creating sample products that incorporate different combinations of elasticity cord and other materials. This testing phase will help you identify any weaknesses or issues before full-scale production. Additionally, seek recommendations from suppliers regarding which cords pair best with specific materials. Engaging in discussions with industry peers or joining forums can also provide insights into successful combinations that others have tested. Lastly, documenting your findings can create a reference guide for future projects, streamlining your production process and minimizing compatibility issues.

Strategic Material Selection Guide for elasticity cord

What Are the Common Materials Used in Elasticity Cord?

When selecting elasticity cord for various applications, understanding the properties, advantages, and limitations of common materials is crucial for B2B buyers. Below is an analysis of four prevalent materials used in elasticity cord, focusing on their performance, suitability, and considerations for international buyers.

What Are the Key Properties of Natural Rubber Elasticity Cord?

Natural rubber is one of the most traditional materials used for elasticity cords. It exhibits excellent elasticity and flexibility, making it ideal for applications requiring significant stretch.

- Key Properties: Natural rubber can withstand a temperature range from -40°C to 70°C and offers good resistance to wear and tear. However, it is susceptible to UV degradation and ozone, which can limit its outdoor applications.

- Pros & Cons: The primary advantage of natural rubber is its superior elasticity and comfort. However, it can be less durable compared to synthetic alternatives and may require more frequent replacement. The cost is generally low, but manufacturing complexity can be moderate due to the need for specific processing techniques.

- Impact on Application: Natural rubber is suitable for applications like crafting and lightweight strapping but may not be ideal for environments exposed to harsh weather conditions.

- Considerations for International Buyers: Compliance with ASTM D412 standards is essential for quality assurance. Buyers from regions like Africa and South America should be aware of potential import regulations concerning natural rubber products.

How Does Polyester Compare as a Material for Elasticity Cord?

Polyester is a synthetic material known for its strength and durability. It is often used in applications where high tensile strength is required.

- Key Properties: Polyester cords can endure temperatures ranging from -50°C to 150°C and exhibit excellent resistance to UV radiation and chemicals. They also have a lower stretch compared to natural rubber.

- Pros & Cons: The main advantage of polyester is its durability and resistance to environmental factors. However, it may not provide the same level of stretch as natural rubber, which can limit its use in specific applications. The cost is moderate, and manufacturing complexity is relatively low.

- Impact on Application: Polyester is ideal for applications requiring high strength, such as outdoor gear and industrial uses, where exposure to the elements is a concern.

- Considerations for International Buyers: Buyers should ensure compliance with international standards such as ISO 9001 for quality management systems, which is crucial for suppliers in Europe and the Middle East.

What Are the Benefits of Nylon Elasticity Cord?

Nylon is another synthetic option that offers a balance between elasticity and strength, making it a versatile choice for various applications.

- Key Properties: Nylon cords can handle temperatures from -40°C to 90°C and have good abrasion resistance. However, they can absorb moisture, which may affect their performance in humid conditions.

- Pros & Cons: The flexibility and strength of nylon make it suitable for a wide range of applications. However, its moisture absorption can lead to reduced elasticity over time, and the cost is generally moderate to high, depending on the grade.

- Impact on Application: Nylon is commonly used in crafting, sports equipment, and medical applications due to its durability and flexibility.

- Considerations for International Buyers: Compliance with ASTM D638 for tensile properties is essential. Buyers from regions like Saudi Arabia should also consider local regulations regarding synthetic materials.

How Does Latex Stand in Terms of Elasticity Cord?

Latex is a highly elastic material often used in specialized applications, particularly in the medical field.

- Key Properties: Latex cords can stretch significantly and have a temperature tolerance similar to natural rubber. However, they are also prone to degradation from UV exposure and are not suitable for all users due to potential allergies.

- Pros & Cons: The exceptional elasticity of latex makes it ideal for applications requiring high stretchability. However, its susceptibility to environmental factors and potential allergic reactions can limit its use. The cost is generally low, with moderate manufacturing complexity.

- Impact on Application: Latex is commonly used in medical devices and personal protective equipment but may not be suitable for outdoor applications.

- Considerations for International Buyers: Compliance with medical device regulations is critical for buyers in the healthcare sector, especially in Europe, where stringent standards apply.

Summary Table of Elasticity Cord Materials

| Material | Typical Use Case for elasticity cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Crafting, lightweight strapping | Superior elasticity and comfort | Susceptible to UV and ozone | Low |

| Polyester | Outdoor gear, industrial applications | High strength and durability | Lower stretch compared to rubber | Med |

| Nylon | Crafting, sports equipment | Flexibility and strength | Moisture absorption affects elasticity | Med to High |

| Latex | Medical devices, personal protective equipment | Exceptional stretchability | Environmental degradation and allergies | Low |

This guide provides B2B buyers with a comprehensive understanding of the materials used in elasticity cords, facilitating informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for elasticity cord

What Are the Main Stages of Manufacturing Elasticity Cord?

The manufacturing process of elasticity cord involves several key stages that ensure the final product meets the necessary standards for quality and performance. Understanding these stages can help B2B buyers assess the capabilities of their suppliers.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing elasticity cord is the selection and preparation of raw materials. Typically, high-quality synthetic rubber or elastomeric materials are chosen due to their excellent stretchability and durability. These materials are often sourced from reputable suppliers who adhere to international quality standards.

Once the materials are selected, they undergo a thorough inspection to ensure they meet the required specifications. This initial quality check is crucial, as any defects in the raw materials can compromise the integrity of the final product.

Forming Process: How Is Elasticity Cord Shaped?

After material preparation, the next stage is the forming process. This involves extruding the raw materials into long, continuous strands of elasticity cord. Extrusion is a common technique used in the industry, allowing for precise control over the diameter and uniformity of the cord. For instance, cords can be manufactured in various thicknesses, typically ranging from 0.5 mm to 1.0 mm, depending on their intended application.

During this stage, additives such as colorants and UV stabilizers may be introduced to enhance the cord’s aesthetic appeal and performance characteristics. The mixture is then heated and forced through a die, creating the desired shape.

Assembly and Finishing: What Happens After Forming?

Once the cord is extruded, it undergoes assembly and finishing processes. This may involve cutting the cord to specified lengths, packaging, and labeling. For B2B buyers, it’s essential to know that the finishing stage can also include applying additional treatments to improve the cord’s elasticity and resistance to wear and tear.

Illustrative image related to elasticity cord

Some manufacturers may also offer customization options, such as adding different colors or finishes to cater to specific market demands. This flexibility can be a significant advantage for buyers looking for unique solutions.

What Quality Assurance Measures Are in Place for Elasticity Cord?

Quality assurance is a critical component in the production of elasticity cord, ensuring that products meet international standards and customer expectations. Various quality control measures are implemented throughout the manufacturing process.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with relevant international standards, such as ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO standards indicates that a manufacturer has established processes for consistent product quality and continuous improvement.

In addition, industry-specific certifications, such as CE marking for European markets and API standards for products used in the oil and gas sector, may also be relevant. These certifications help buyers verify that the products meet specific safety and performance criteria.

Illustrative image related to elasticity cord

What Are the Key Quality Control Checkpoints?

Quality control typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This stage includes inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor production processes and identify any deviations from standards.

- Final Quality Control (FQC): After the cord has been manufactured and finished, a final inspection is carried out to verify that the product meets all quality criteria before shipping.

What Testing Methods Are Commonly Used in Elasticity Cord Production?

To ensure the elasticity cord meets performance expectations, various testing methods are employed:

- Tensile Strength Testing: This measures the maximum amount of tensile (stretch) stress the cord can withstand before failure.

- Elongation Testing: Evaluates how much the cord can stretch without breaking, which is crucial for applications requiring high flexibility.

- Durability Testing: Simulates wear and tear to assess the cord’s longevity and resistance to environmental factors, such as UV exposure and temperature fluctuations.

These tests help manufacturers identify any weaknesses in the cord and make necessary adjustments before shipping the product to buyers.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are some methods to consider:

- Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This hands-on approach allows buyers to assess compliance with international standards directly.

- Quality Reports: Requesting detailed quality reports and documentation from suppliers can help buyers understand the quality control measures in place, including test results and certifications.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing capabilities and quality assurance processes. This is particularly valuable for buyers in regions such as Africa and South America, where local standards may vary.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must navigate various nuances when it comes to quality control in different regions. For instance, regulatory requirements may differ significantly between markets in Africa, South America, the Middle East, and Europe. Understanding these regional differences is crucial for ensuring compliance and avoiding potential legal issues.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Buyers should establish clear lines of communication with suppliers and consider using bilingual representatives or local intermediaries to facilitate discussions.

In summary, understanding the manufacturing processes and quality assurance measures for elasticity cord can empower B2B buyers to make informed decisions when selecting suppliers. By focusing on key stages of production and quality control protocols, buyers can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘elasticity cord’

Introduction

In the competitive landscape of B2B procurement, sourcing quality elasticity cord is critical for various applications, including crafting, manufacturing, and packaging. This guide aims to equip international buyers, particularly from Africa, South America, the Middle East, and Europe, with a practical checklist to ensure an efficient and effective sourcing process.

1. Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing elasticity cord. Consider factors such as diameter, material composition, tensile strength, and stretchability. This will help you communicate effectively with suppliers and ensure you receive products that meet your exact needs.

Illustrative image related to elasticity cord

- Diameter: Common sizes include 0.5 mm to 1.0 mm. Choose based on the intended application.

- Material: Look for high-quality materials that provide durability and flexibility.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Utilize online platforms, trade shows, and industry networks to gather a list of manufacturers and distributors. Evaluate their reputation in the market to ensure reliability.

- Online Reviews: Check platforms like Alibaba or industry-specific directories for supplier ratings.

- Trade Associations: Engage with local trade associations to find reputable suppliers in your region.

3. Request Product Samples

Before finalizing any order, always request samples of the elasticity cord. Testing samples allows you to assess the quality, elasticity, and suitability for your specific applications.

- Testing Performance: Ensure the cord meets your strength and stretch requirements by conducting real-world tests.

- Evaluate Aesthetics: For crafting applications, consider the color and finish of the samples.

4. Verify Supplier Certifications

Confirm that the suppliers hold relevant certifications and comply with industry standards. Certifications can indicate product quality and adherence to safety regulations, which is particularly important when sourcing from international markets.

- ISO Certifications: Look for ISO 9001 for quality management systems.

- Material Safety Data Sheets (MSDS): Ensure compliance with safety regulations relevant to your region.

5. Assess Pricing and Payment Terms

Evaluate the pricing structure and payment terms offered by potential suppliers. Compare quotes from multiple suppliers to ensure competitive pricing while considering the total cost of ownership, including shipping and customs duties.

- Bulk Discounts: Inquire about pricing for bulk orders to optimize your procurement costs.

- Payment Flexibility: Understand payment terms, including deposits, payment methods, and credit options.

6. Establish Communication Channels

Effective communication with suppliers is vital for a successful sourcing experience. Set clear expectations regarding response times, order processing, and after-sales support.

Illustrative image related to elasticity cord

- Language Proficiency: Ensure that communication can be conducted in a language comfortable for both parties.

- Regular Updates: Establish a routine for updates on order status and shipment tracking.

7. Finalize Contracts and Terms

Once you select a supplier, finalize the contract terms. Ensure that all specifications, pricing, delivery schedules, and payment terms are documented to avoid any misunderstandings later.

- Legal Review: Consider having a legal professional review contracts to protect your interests.

- Dispute Resolution: Include terms for dispute resolution to manage any potential issues effectively.

By following this checklist, B2B buyers can navigate the complexities of sourcing elasticity cord with confidence, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for elasticity cord Sourcing

What Are the Key Cost Components in Sourcing Elasticity Cord?

When analyzing the cost structure for sourcing elasticity cord, several key components need to be considered. The primary costs include:

-

Materials: The type of elastic material used (e.g., natural rubber, synthetic elastomers) significantly impacts the cost. High-quality materials that offer better elasticity and durability tend to be priced higher.

-

Labor: Labor costs vary based on the manufacturing location. Countries with lower labor costs can offer more competitive pricing, but this may come with trade-offs in terms of quality.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient factories may have lower overhead, allowing them to offer better pricing.

-

Tooling: Initial setup costs for manufacturing processes, including molds and machinery, are part of the tooling costs. Custom designs can increase these costs significantly.

-

Quality Control (QC): Implementing stringent quality control measures ensures product reliability, which can add to overall costs. However, investing in QC can save money in the long run by reducing defects.

-

Logistics: Transportation costs, including shipping and handling, must be factored in. International shipping can vary widely based on destination and shipping method, affecting overall pricing.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Affect Elasticity Cord Sourcing?

Several factors influence the pricing of elasticity cord:

-

Volume/MOQ: Bulk orders typically lead to lower per-unit costs. Suppliers often have a minimum order quantity (MOQ), which can affect pricing strategies for smaller buyers.

-

Specifications and Customization: Custom sizes, colors, or formulations can lead to higher prices. Buyers should assess whether customization is necessary for their projects.

-

Materials and Quality Certifications: Premium materials that meet specific industry standards can increase costs. Certifications such as ISO or ASTM can also influence pricing due to the rigorous testing and compliance processes involved.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer companies may offer competitive pricing to gain market share.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is crucial for determining who bears the risk and costs at various stages of the shipping process. Incoterms can affect the overall landed cost of the product.

What Tips Can Buyers Use for Cost-Efficiency When Sourcing Elasticity Cord?

B2B buyers can implement several strategies to enhance cost-efficiency when sourcing elasticity cord:

-

Negotiate Pricing: Always negotiate with suppliers. Bulk purchasing or long-term contracts can lead to better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with quality, maintenance, and potential product failures. A lower upfront cost may lead to higher overall expenses if the product does not perform well.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe need to factor in currency fluctuations, tariffs, and import duties, which can significantly affect the total cost.

-

Supplier Diversification: Engaging multiple suppliers can foster competition and lead to better pricing options. However, ensure that all suppliers meet quality and compliance standards.

-

Stay Informed About Market Trends: Understanding market demand and material availability can provide leverage during negotiations. Price fluctuations can occur based on raw material costs and supply chain disruptions.

Conclusion

Sourcing elasticity cord requires a comprehensive understanding of the associated costs and pricing influences. By focusing on cost components, understanding price influencers, and employing strategic buyer tips, international B2B buyers can make informed decisions that enhance their purchasing efficiency and profitability. Always remember that prices can vary widely based on specific circumstances, so it’s advisable to request quotations and conduct thorough market research before finalizing any sourcing agreements.

Illustrative image related to elasticity cord

Alternatives Analysis: Comparing elasticity cord With Other Solutions

When considering the best solutions for applications requiring stretchable materials, it’s important to evaluate alternatives to elasticity cord. This analysis aims to provide B2B buyers with a comparative overview of elasticity cord against other viable options, such as bungee cords and silicone bands. Each alternative offers unique benefits and potential drawbacks, making it essential for buyers to assess their specific needs and use cases.

| Comparison Aspect | Elasticity Cord | Bungee Cord | Silicone Bands |

|---|---|---|---|

| Performance | High elasticity; ideal for jewelry making and light crafts | Strong tensile strength; suitable for heavy-duty applications | Moderate stretch; good for lightweight uses |

| Cost | Generally low-cost; varies by diameter and length | Moderate cost; generally more expensive due to durability | Affordable; typically sold in bulk |

| Ease of Implementation | Simple to cut and tie; user-friendly for DIY projects | Requires anchoring points; slightly more complex to use | Easy to use; no special tools required |

| Maintenance | Minimal maintenance; may degrade over time with exposure | Durable; requires periodic checks for wear | Low maintenance; resistant to environmental factors |

| Best Use Case | Ideal for crafting, jewelry, and light accessories | Best for securing loads, outdoor gear, and heavy items | Suitable for organizing items, lightweight bundling, and crafting |

What Are the Pros and Cons of Bungee Cords Compared to Elasticity Cord?

Bungee cords are renowned for their durability and ability to handle significant loads, making them ideal for securing items during transport or outdoor activities. They come equipped with hooks or fasteners, allowing for quick attachment and detachment. However, their complexity in setup can be a disadvantage for users looking for a straightforward solution. Bungee cords may also be overkill for lightweight applications, where elasticity cord would suffice, potentially leading to unnecessary expenditure.

How Do Silicone Bands Compare to Elasticity Cord in Terms of Usability?

Silicone bands offer a moderate level of stretch, making them suitable for a range of applications, from crafting to organizing. They are often more resistant to environmental factors like UV rays and moisture, which enhances their longevity in outdoor conditions. However, silicone bands may not provide the same level of elasticity as elasticity cord, limiting their effectiveness in applications requiring significant stretch. Their affordability and ease of use make them a compelling choice for bulk purchases, particularly in crafting and educational settings.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the most appropriate solution, B2B buyers should consider the specific requirements of their projects, such as the desired performance characteristics, budget constraints, and ease of use. If the project involves heavy-duty applications or outdoor gear, bungee cords may be the most suitable choice. Conversely, for lightweight crafting tasks, elasticity cord offers the needed flexibility at a lower cost. Silicone bands are excellent for buyers looking for a durable, versatile option that can withstand environmental stressors. Ultimately, understanding the project requirements and comparing the pros and cons of each alternative will lead to informed purchasing decisions that align with operational needs and budgetary guidelines.

Essential Technical Properties and Trade Terminology for elasticity cord

What Are the Key Technical Properties of Elasticity Cord?

When sourcing elasticity cord, understanding its technical properties is crucial for making informed purchasing decisions. Here are the essential specifications to consider:

Illustrative image related to elasticity cord

-

Material Grade: Elasticity cords are typically made from synthetic materials such as nylon, polyester, or rubber. The choice of material affects durability, stretchability, and environmental resistance. For B2B buyers, selecting the right material grade ensures that the cord meets specific application requirements, such as outdoor use or heavy-duty applications.

-

Diameter (Gauge): The diameter of elasticity cord can range from 0.5 mm to 1.0 mm or more. A smaller diameter provides greater flexibility and is suitable for light applications like jewelry making, while larger diameters offer increased strength for heavy-duty tasks. Understanding the appropriate gauge for your application can help prevent breakage and improve product reliability.

-

Stretch Ratio: This property indicates how much the cord can stretch compared to its original length. A higher stretch ratio allows for more flexibility, making it ideal for applications that require significant movement, such as in clothing or accessories. Buyers need to consider this when determining the suitability of the cord for their specific use cases.

-

Tensile Strength: Measured in pounds or kilograms, tensile strength refers to the maximum load the cord can withstand before breaking. High tensile strength is essential for applications that involve significant weight or stress. B2B buyers should prioritize tensile strength to ensure safety and longevity in their products.

-

Color Options and UV Resistance: Elasticity cords come in various colors and finishes, which can enhance the aesthetic appeal of the final product. Additionally, UV resistance is critical for outdoor applications, as it prevents degradation from sunlight exposure. Buyers should evaluate color and UV properties based on their target market’s preferences and usage conditions.

What Common Trade Terms Should B2B Buyers Understand?

Familiarity with industry-specific jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms related to elasticity cord:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products that are used in another company’s end product. Understanding OEM relationships is vital for B2B buyers seeking custom solutions or bulk purchasing agreements.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For elasticity cord, MOQs can vary significantly based on the supplier and product specifications. Buyers must be aware of MOQs to manage their inventory and budget effectively.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers asking for pricing on specific products or services. This is a critical step for B2B buyers when sourcing elasticity cord, as it allows for comparison of costs and terms from multiple suppliers.

-

Incoterms: Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers clarify shipping responsibilities, insurance, and liability, which is particularly important for buyers from diverse regions like Africa, South America, and the Middle East.

-

Lead Time: This refers to the amount of time it takes from placing an order to receiving the product. Lead time can impact project timelines, so B2B buyers should consider this when planning their procurement strategies.

-

Customs Duties: These are tariffs imposed by governments on imported goods. For international buyers, understanding customs duties is essential for calculating the total landed cost of elasticity cord and ensuring compliance with local regulations.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing elasticity cord more effectively, ensuring that their procurement aligns with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the elasticity cord Sector

What Are the Key Market Trends Influencing the Elasticity Cord Sector?

The global elasticity cord market is experiencing significant growth, driven by diverse applications across various industries, including fashion, crafting, automotive, and medical sectors. One of the key trends is the increasing demand for customizable and high-quality elasticity cords, particularly among B2B buyers in Africa, South America, the Middle East, and Europe. This demand is fueled by the rise of e-commerce and online marketplaces, enabling manufacturers to reach a wider audience and tailor products to specific market needs.

Technological advancements are also shaping the market dynamics. The introduction of innovative materials and manufacturing techniques has led to the development of elasticity cords that offer enhanced durability, stretchability, and resistance to wear and tear. For international buyers, especially those in emerging markets like Vietnam and Saudi Arabia, sourcing elasticity cords that meet these criteria is crucial for maintaining product quality and competitiveness.

Furthermore, sustainability is becoming a significant consideration. Many buyers are now prioritizing suppliers who demonstrate a commitment to eco-friendly practices. As a result, manufacturers are increasingly investing in sustainable materials and production processes, which can influence sourcing decisions for B2B buyers seeking to align with global sustainability goals.

How Is Sustainability Shaping the Sourcing of Elasticity Cords in B2B?

Sustainability is a critical factor influencing sourcing decisions in the elasticity cord sector. The environmental impact of traditional manufacturing processes has prompted many businesses to adopt greener practices. Buyers are increasingly looking for suppliers who utilize recycled materials, biodegradable options, or eco-friendly production methods.

The importance of ethical supply chains cannot be overstated. B2B buyers are now more vigilant about the sources of their materials and the conditions under which they are produced. This scrutiny is particularly relevant for international buyers who may face different regulatory environments and consumer expectations in their home markets.

Certifications such as Global Recycled Standard (GRS) and OEKO-TEX® Standard 100 are becoming essential for suppliers aiming to appeal to environmentally conscious buyers. These certifications not only enhance the credibility of products but also provide reassurance to B2B buyers that the materials they are sourcing are environmentally friendly and ethically produced.

What Is the Historical Context of Elasticity Cord Production?

The production of elasticity cords has evolved significantly over the years. Initially, these cords were primarily made from natural rubber, limiting their applications due to durability concerns. As demand increased, manufacturers began to explore synthetic alternatives, leading to the development of materials like polyester and nylon, which offer superior strength and elasticity.

In recent decades, the focus has shifted towards innovation and customization, with manufacturers leveraging advanced technologies to produce cords that cater to specific applications. This evolution reflects the broader trends in the B2B landscape, where customization and quality are paramount. Today, elasticity cords are integral to a wide range of industries, from crafting and fashion to industrial applications, showcasing their versatility and the dynamic nature of their market.

Illustrative image related to elasticity cord

By understanding these trends, B2B buyers can make informed sourcing decisions that align with their operational needs and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of elasticity cord

-

How do I choose the right elasticity cord for my products?

Selecting the right elasticity cord depends on several factors, including the intended application, required thickness, and stretchability. For jewelry making, a thinner cord (0.5mm to 0.8mm) is typically preferred for comfort and aesthetics. For heavier applications, such as securing goods, a thicker cord (1.0mm or more) may be more suitable. Always consider the specific demands of your product, including weight and flexibility, to ensure optimal performance. -

What are the benefits of sourcing elasticity cord from international suppliers?

Sourcing elasticity cord from international suppliers can provide access to a wider variety of materials and competitive pricing. Countries such as Vietnam and Turkey have robust manufacturing capabilities that can deliver high-quality products at lower costs. Additionally, international suppliers often have the ability to customize orders, ensuring that you receive a product tailored to your specific needs, which can enhance your product offerings and market competitiveness. -

What should I consider when vetting suppliers for elasticity cord?

When vetting suppliers, consider factors such as their manufacturing capabilities, quality control processes, and reputation in the industry. Request samples to evaluate the quality of the elasticity cord, and check for certifications that indicate compliance with international standards. Additionally, assess their communication responsiveness and willingness to accommodate your specific requirements, such as minimum order quantities (MOQ) and customization options. -

What are the typical minimum order quantities (MOQ) for elasticity cord?

Minimum order quantities for elasticity cord can vary widely based on the supplier and the specifics of the order. Generally, MOQs can range from 100 meters to several kilometers. For bulk orders, some suppliers may offer lower MOQs, especially if you are open to purchasing a variety of colors or thicknesses. It’s advisable to discuss your needs upfront with potential suppliers to find a mutually beneficial arrangement. -

What payment terms are commonly accepted by elasticity cord suppliers?

Payment terms can differ by supplier and region. Common arrangements include upfront payment, a deposit followed by the balance upon delivery, or letters of credit for larger orders. International buyers should also consider currency exchange rates and transaction fees, which can affect the overall cost. Establishing clear payment terms upfront can help avoid misunderstandings and ensure a smooth transaction. -

How can I ensure quality assurance when purchasing elasticity cord?

To ensure quality assurance, work with suppliers who have established quality control processes. Request documentation that outlines their quality assurance protocols, such as inspections and testing procedures. Additionally, consider conducting third-party inspections or audits if you are placing a large order. This proactive approach can help mitigate risks associated with subpar materials and ensure that the elasticity cord meets your specifications. -

What logistics considerations should I keep in mind when importing elasticity cord?

When importing elasticity cord, consider shipping methods, lead times, and customs regulations. Choose a reliable shipping partner to ensure timely delivery, and factor in potential delays due to customs clearance. Familiarize yourself with import tariffs and duties that may apply to your shipments, as these can impact your overall costs. Having a clear logistics plan will help streamline the process and minimize disruptions. -

Are there customization options available for elasticity cord?

Yes, many suppliers offer customization options for elasticity cord, including variations in thickness, color, and even the type of material used. Customization can be particularly beneficial for businesses looking to create unique products or branding. When discussing customization with suppliers, be clear about your requirements, including any specific measurements or aesthetic preferences, to ensure that the final product aligns with your vision.

Top 7 Elasticity Cord Manufacturers & Suppliers List

1. Beadalon – Elasticity Stretch Cord

Domain: beadalon.com

Registered: 1999 (26 years)

Introduction: This company, Beadalon – Elasticity Stretch Cord, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Barrel of Beads – Elasticity Elastic Cord

Domain: barrelofbeads.com

Registered: 2004 (21 years)

Introduction: Elasticity Elastic Cord is available in various sizes and colors, designed for jewelry making and crafting. It offers excellent stretch and durability, making it ideal for beading projects. The cord is easy to work with and provides a secure hold for beads and other materials.

3. Hobby Lobby – Elasticity Stretch Cord

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Elasticity Stretch Cord”, “SKU”: “717496”, “Original Price”: “$2.99”, “Color”: “Satin Silver”, “Size Options”: [“0.5mm”, “0.8mm”, “1mm”], “Spool Length”: “16.4′”, “Gauge”: “0.8mm”, “Age Grade”: “18+”, “Quantity”: “1”, “Description”: “Elasticity Stretch Cord has a thin and sturdy construction with a healthy stretch that is great for making accessories that expand to fit many sizes…

4. Paracord Planet – High Quality Elastic Cords

Domain: paracordplanet.com

Registered: 2011 (14 years)

Introduction: High Quality Elastic Cords in various sizes. Free Standard Shipping with Orders of $8.99+ (US ONLY). Available sizes include 1/32″ Elastic Cord, 1/16″ Elastic Cord, and 5mm Soft Flat Elastic Cord. Prices range from $3.99 to $72.99 with free shipping options. Multiple color variations available for each size.

5. Beadalon – Elonga Multi-Strand Stretch Cord

Domain: artbeads.com

Registered: 1999 (26 years)

Introduction: Beadalon Elonga Multi-Strand Stretch Cord – 0.3mm ELONG-03 $2.04 Reg. $3.54; Beadalon Elonga Multi-Strand Stretch Cord – 1.0mm ELONG-10 $2.99 Reg.; Beadalon Elonga White Multi-Strand Stretch Cord – 1.0mm (25 meters) STRNG0533 $10.09 Reg.; Beadalon Elonga White Multi-Strand Stretch Cord – 0.3mm (25 meters) STRNG0531 $4.84 Reg.; Beadalon Stainless Steel Elastic Cord Needle NEED-30 $5.74 Reg.; Beadal…

6. Beadalon – Elasticity

Domain: cjbeaders.com

Registered: 2008 (17 years)

Introduction: Choosing the Right Beading Cords and Thread – Elasticity, Stretch Magic, Elonga, and Griffin. Key products include: 1. Elasticity – Manufactured by Beadalon, it’s a soft, supple elastic thread that stretches like a rubber band. Available in 5m, 25m, 100m, and 500m lengths, with diameters of 0.5mm, 0.8mm, and 1mm. Colors: Clear, Black, Satin Silver, Satin Gold, Satin Rose Gold. 2. Stretch Magic – A…

7. Tejas Beads – Elastic Stretchy Cords

Domain: tejasbeads.com

Registered: 2016 (9 years)

Introduction: Elastic stretchy cord sizes: 0.5mm, 0.8mm, 1.0mm. Standard elastic cords are firm rubber; Elastic Floss is fibrous, stretchy, and slightly smaller than stated diameter. Elastic Floss 0.5mm is versatile for bead sizes 4mm and larger. Pre-stretching is recommended for elastic cords. Use beading glue on knots for security. Standard elastic cord example: Beadalon Elasticity.

Strategic Sourcing Conclusion and Outlook for elasticity cord

How Can Strategic Sourcing Enhance Your Business with Elasticity Cord?

In the competitive landscape of elasticity cord sourcing, strategic partnerships and a keen understanding of market demands are paramount. Buyers from Africa, South America, the Middle East, and Europe must prioritize sourcing high-quality materials that meet their specific application needs, whether for jewelry making, crafting, or industrial uses. By focusing on reliable suppliers and leveraging bulk purchasing agreements, businesses can not only secure better pricing but also ensure consistent supply and quality.

Moreover, the versatility of elasticity cord opens doors to diverse market opportunities, particularly in regions with growing craft and manufacturing sectors. International buyers should take advantage of the expanding e-commerce platforms that facilitate cross-border trade, allowing for seamless access to a wide range of products.

Looking ahead, the demand for elasticity cord is expected to rise as industries continue to innovate. Buyers are encouraged to explore sustainable sourcing options and invest in suppliers that prioritize environmental stewardship. By doing so, businesses can enhance their brand reputation while meeting the evolving preferences of eco-conscious consumers. Engage with suppliers today to secure a competitive edge in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to elasticity cord

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.