A B2B Buyer’s Guide to Dust Collection System Diagram: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for dust collection system diagram

In today’s global marketplace, sourcing an effective dust collection system diagram is critical for businesses aiming to enhance operational efficiency while ensuring compliance with environmental regulations. One of the foremost challenges B2B buyers face is navigating the complex landscape of dust collection systems, which vary greatly in design, application, and regulatory compliance across regions. This comprehensive guide delves into the intricacies of dust collection systems, covering essential aspects such as types of systems, their specific applications in various industries, supplier vetting processes, and cost considerations.

By equipping international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including countries like Brazil and Nigeria—this guide empowers informed purchasing decisions. It provides actionable insights that help businesses select the most suitable dust collection solutions tailored to their unique operational needs. Understanding the critical components of a dust collection system not only aids in improving air quality and workplace safety but also fosters compliance with local regulations. With detailed diagrams, expert recommendations, and practical tips, this guide serves as an invaluable resource for companies seeking to optimize their dust management strategies and enhance their overall productivity.

Understanding dust collection system diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centralized Dust Collection | Central unit connected to multiple machines through ductwork | Manufacturing plants, woodworking shops | Pros: Efficient for large spaces, reduces noise. Cons: Higher installation costs, requires space for ductwork. |

| Portable Dust Collector | Standalone units that can be moved as needed | Small workshops, construction sites | Pros: Flexible, cost-effective for limited use. Cons: Limited capacity, may require frequent emptying. |

| Cyclone Dust Collection System | Uses centrifugal force to separate dust from air | Metalworking, heavy industrial sectors | Pros: High efficiency, minimal maintenance. Cons: Requires more space, can be expensive. |

| Baghouse Dust Collector | Utilizes fabric filters to capture fine dust particles | Cement, food processing industries | Pros: Effective for fine dust, high filtration efficiency. Cons: Regular filter maintenance required, larger footprint. |

| Downdraft Tables | Work surfaces with integrated dust collection | Metal fabrication, sanding operations | Pros: Direct capture at the source, improves air quality. Cons: Limited application scope, may not handle high volumes. |

What are the Key Characteristics of Centralized Dust Collection Systems?

Centralized dust collection systems are designed to serve multiple machines within a facility through a network of ductwork leading to a central collector. This type is particularly effective in larger manufacturing plants or woodworking shops where multiple dust-producing machines operate simultaneously. When considering a centralized system, buyers should evaluate the layout of their facility, the number of machines, and the required airflow to ensure optimal performance. Installation costs can be significant, but the long-term efficiency and noise reduction often justify the investment.

How Do Portable Dust Collectors Fit into B2B Operations?

Portable dust collectors are versatile units that can be easily moved around job sites or workshops. They are ideal for small-scale operations or businesses that require flexibility, such as construction sites or small workshops. Buyers should consider the capacity and power of these units, as they often have limitations in terms of dust collection volume and may need frequent emptying. While they are generally more affordable and easier to install, their effectiveness diminishes in larger or more complex environments.

What Makes Cyclone Dust Collection Systems Effective?

Cyclone dust collection systems leverage centrifugal force to separate dust from the air, making them highly efficient in industrial settings such as metalworking or heavy manufacturing. These systems can handle larger volumes of dust and require less maintenance than traditional bag filters. B2B buyers should assess the space available for installation and the specific dust types they will be dealing with, as cyclone systems can be more expensive upfront but offer long-term savings through reduced maintenance costs.

Why Choose Baghouse Dust Collectors for Fine Dust?

Baghouse dust collectors utilize fabric filters to capture fine dust particles, making them highly effective in industries like cement production and food processing. They provide high filtration efficiency and can handle various dust types, but they do require regular maintenance to keep filters clean and effective. B2B buyers should consider the volume and type of dust generated in their operations, as well as the maintenance capabilities of their team, when deciding on a baghouse system.

How Do Downdraft Tables Improve Workplace Safety?

Downdraft tables are specialized work surfaces equipped with integrated dust collection systems, allowing for direct capture of dust at the source. These tables are particularly beneficial in metal fabrication and sanding operations, where airborne dust can pose health risks. Buyers should evaluate the specific needs of their operations, including the type of work being performed and the volume of dust generated. While they offer excellent air quality improvements, their application is more limited compared to other dust collection systems.

Key Industrial Applications of dust collection system diagram

| Industry/Sector | Specific Application of dust collection system diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Designing systems for sawdust and wood shavings | Improved air quality, compliance with safety standards, and increased operational efficiency | Compliance with local regulations, capacity requirements, and filter specifications |

| Metalworking | Collecting metal shavings and dust from machining | Enhanced worker safety, reduced equipment wear, and lower cleanup costs | Material compatibility, static pressure calculations, and maintenance needs |

| Food Processing | Managing flour and grain dust in processing plants | Minimized contamination risks, enhanced hygiene, and compliance with food safety regulations | Explosion-proof designs, filter types, and ease of cleaning and maintenance |

| Pharmaceutical | Containing hazardous powder during manufacturing | Ensured worker safety, regulatory compliance, and product integrity | Compliance with health regulations, containment levels, and filter efficiency |

| Construction | Dust control for concrete and masonry work | Improved air quality, reduced respiratory risks, and compliance with environmental regulations | Mobility of equipment, dust collection efficiency, and ease of installation |

How is the Dust Collection System Diagram Used in Woodworking?

In the woodworking industry, a dust collection system diagram is crucial for mapping out the most efficient layout for collecting sawdust and wood shavings from various machines, such as table saws and planers. This diagram helps in determining the required duct sizes and air velocity to ensure effective dust capture, thus enhancing air quality and safety in the workspace. For B2B buyers in regions like Brazil and Nigeria, understanding local regulations regarding air quality and safety standards is essential when sourcing equipment.

What Role Does the Dust Collection System Diagram Play in Metalworking?

Metalworking environments generate significant amounts of metal shavings and dust, which can pose safety hazards and equipment maintenance issues. A dust collection system diagram assists in planning the ductwork and equipment needed to efficiently capture and transport these particles. Buyers, particularly from South America and the Middle East, should consider the static pressure requirements and material compatibility of their dust collection systems to ensure optimal performance and compliance with local industrial standards.

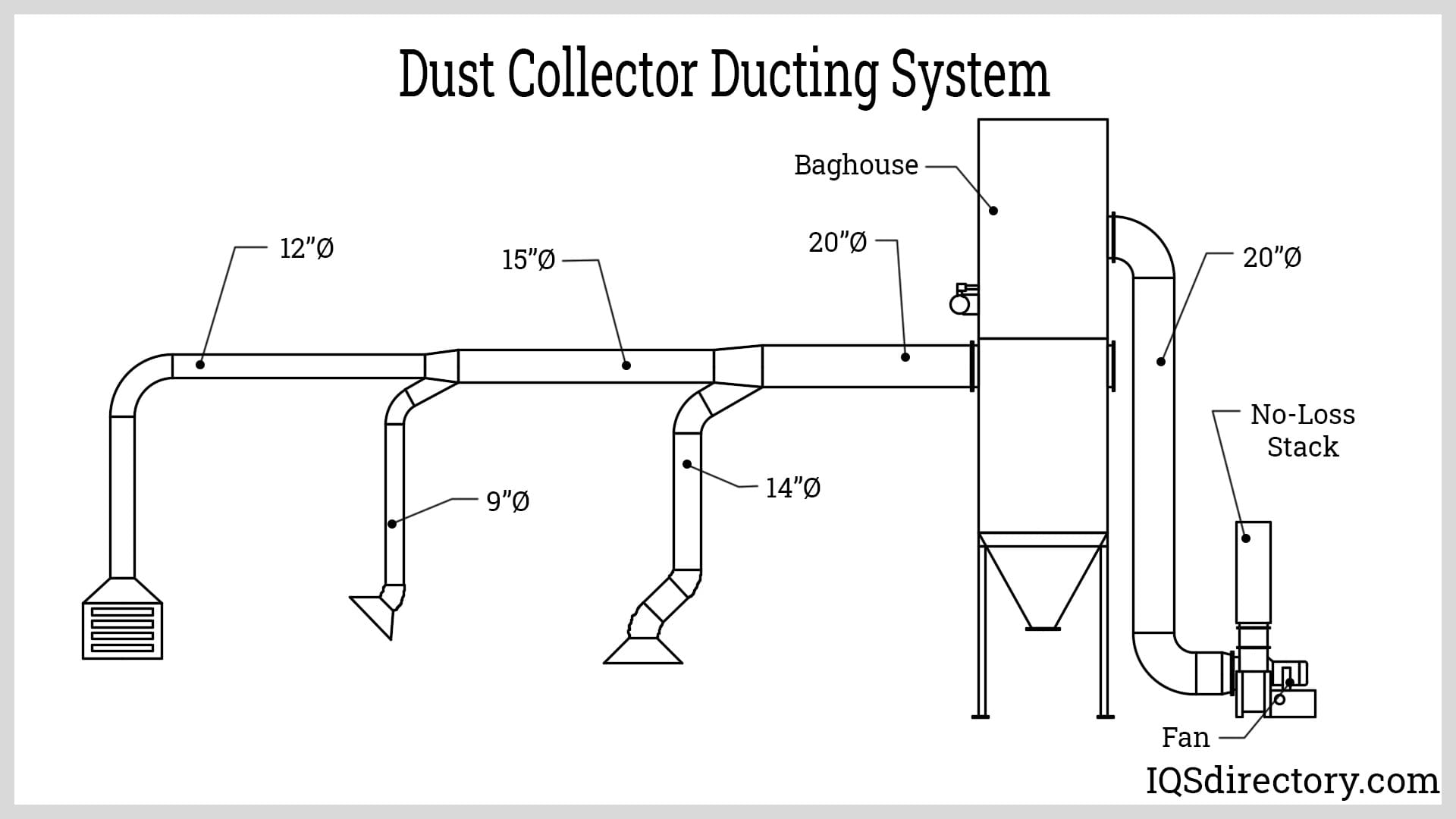

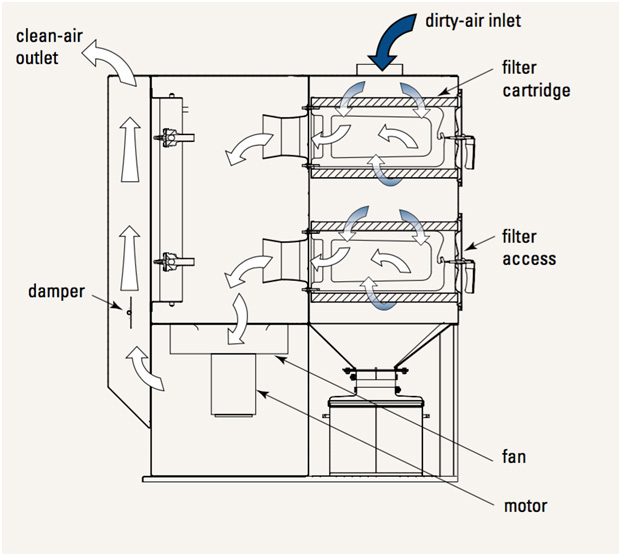

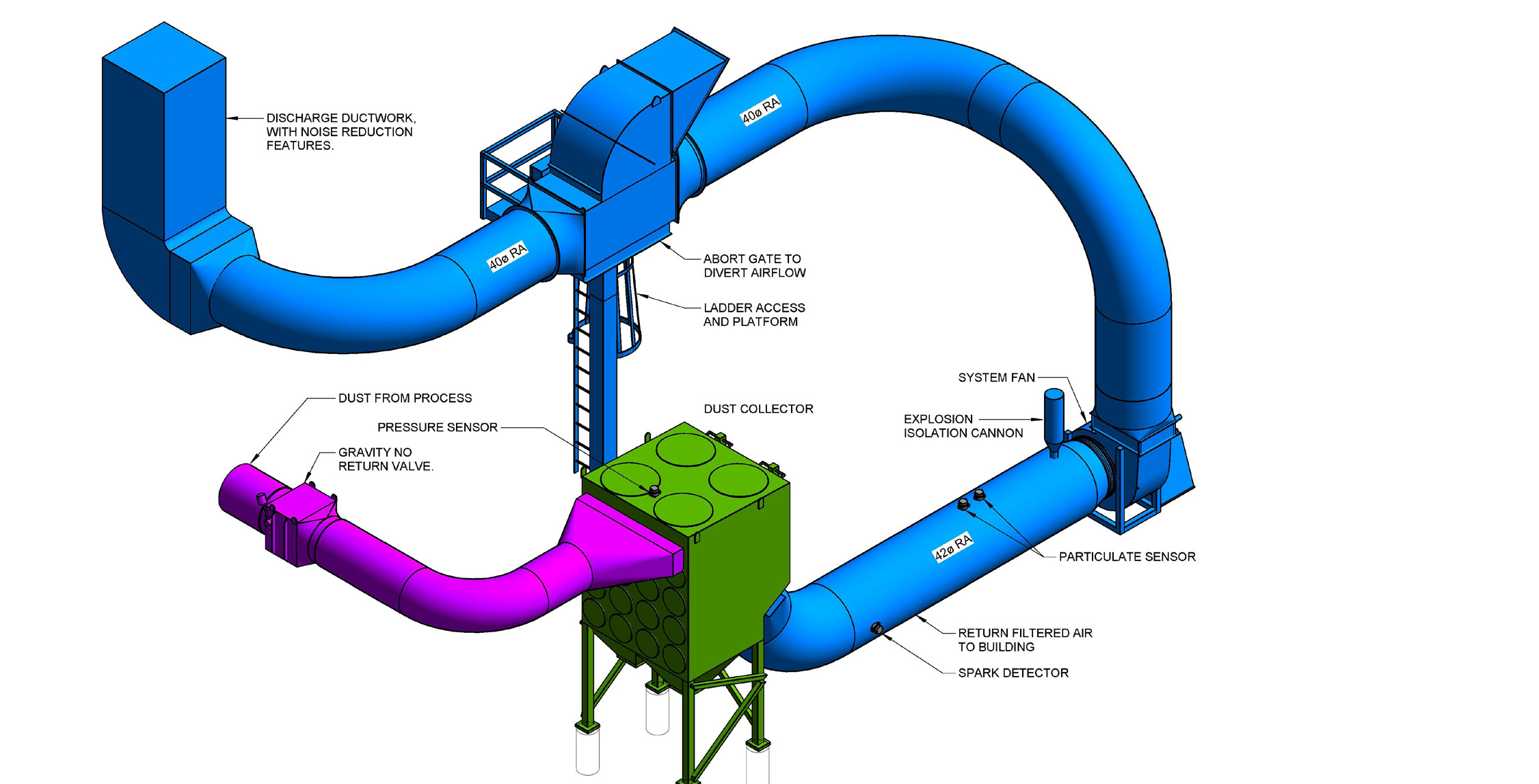

Illustrative image related to dust collection system diagram

How is the Dust Collection System Diagram Relevant in Food Processing?

In food processing facilities, managing dust from flour and grains is critical to maintaining hygiene and preventing contamination. A dust collection system diagram is used to design systems that contain and filter these particles effectively. For international B2B buyers, particularly in regions with stringent food safety regulations, it is vital to ensure that the dust collection system includes explosion-proof designs and filters that meet health standards, thus safeguarding product integrity and worker safety.

Why is the Dust Collection System Diagram Important in Pharmaceuticals?

In the pharmaceutical sector, the containment of hazardous powders is paramount. A dust collection system diagram helps in strategizing the layout for capturing airborne particles during manufacturing processes. This is crucial for ensuring compliance with health regulations and maintaining a safe working environment. B2B buyers from Europe should prioritize sourcing systems that offer high filtration efficiency and robust containment capabilities, as these factors are critical for regulatory compliance and operational safety.

How Does the Dust Collection System Diagram Aid in Construction?

Construction sites often generate excessive dust from concrete and masonry work, necessitating effective dust control measures. A dust collection system diagram provides a visual representation of how to implement a dust collection system that minimizes airborne particles. For buyers in the construction sector, especially in developing markets, sourcing portable and easy-to-install dust collection systems can significantly enhance air quality and comply with environmental regulations, protecting both workers and the surrounding community.

3 Common User Pain Points for ‘dust collection system diagram’ & Their Solutions

Scenario 1: Inadequate Airflow Due to Poor Design Choices

The Problem: Many B2B buyers encounter significant issues when the airflow within their dust collection systems is insufficient. This often stems from improperly sized ductwork or inadequate planning during the design phase. For instance, a woodworking facility may experience frequent clogs and dust accumulation if the ducts are too narrow or the system lacks adequate velocity to transport the dust particles effectively. This not only hampers productivity but also poses safety risks due to the potential for dust explosions and respiratory hazards for workers.

The Solution: To address this challenge, buyers should begin with a thorough understanding of airflow requirements based on the type of dust being collected. Utilizing a dust collection system diagram, ensure that the ductwork is appropriately sized according to industry standards. For example, woodworking dust typically requires a minimum airflow velocity of 4500 feet per minute (FPM) in branch lines. Buyers should calculate the required cubic feet per minute (CFM) for each machine and confirm that the duct diameter corresponds to these specifications. Engaging with a professional engineer during the design phase can also provide invaluable insights into optimizing duct layout, ensuring the fewest bends and turns to maintain airflow efficiency.

Scenario 2: Compliance with Local Regulations and Standards

The Problem: Navigating the complex landscape of local and national regulations can be a daunting task for international B2B buyers. Many companies, particularly in regions like Africa and South America, may not be fully aware of the specific codes that govern dust collection systems in their jurisdictions. Non-compliance can result in hefty fines, operational delays, and even shutdowns, which can severely impact business continuity and reputation.

The Solution: To mitigate compliance issues, buyers should conduct a comprehensive review of relevant local regulations before finalizing their dust collection system design. This can be achieved by consulting with local regulatory bodies or hiring compliance experts who specialize in industrial systems. Buyers can also utilize resources such as compliance checklists or guidelines tailored to their specific industry. Incorporating compliance checkpoints into the dust collection system diagram will ensure that all elements—from the dust collector unit to the exhaust systems—meet regulatory requirements. Regular training and updates on local laws for staff involved in the design and installation process will further enhance adherence to compliance standards.

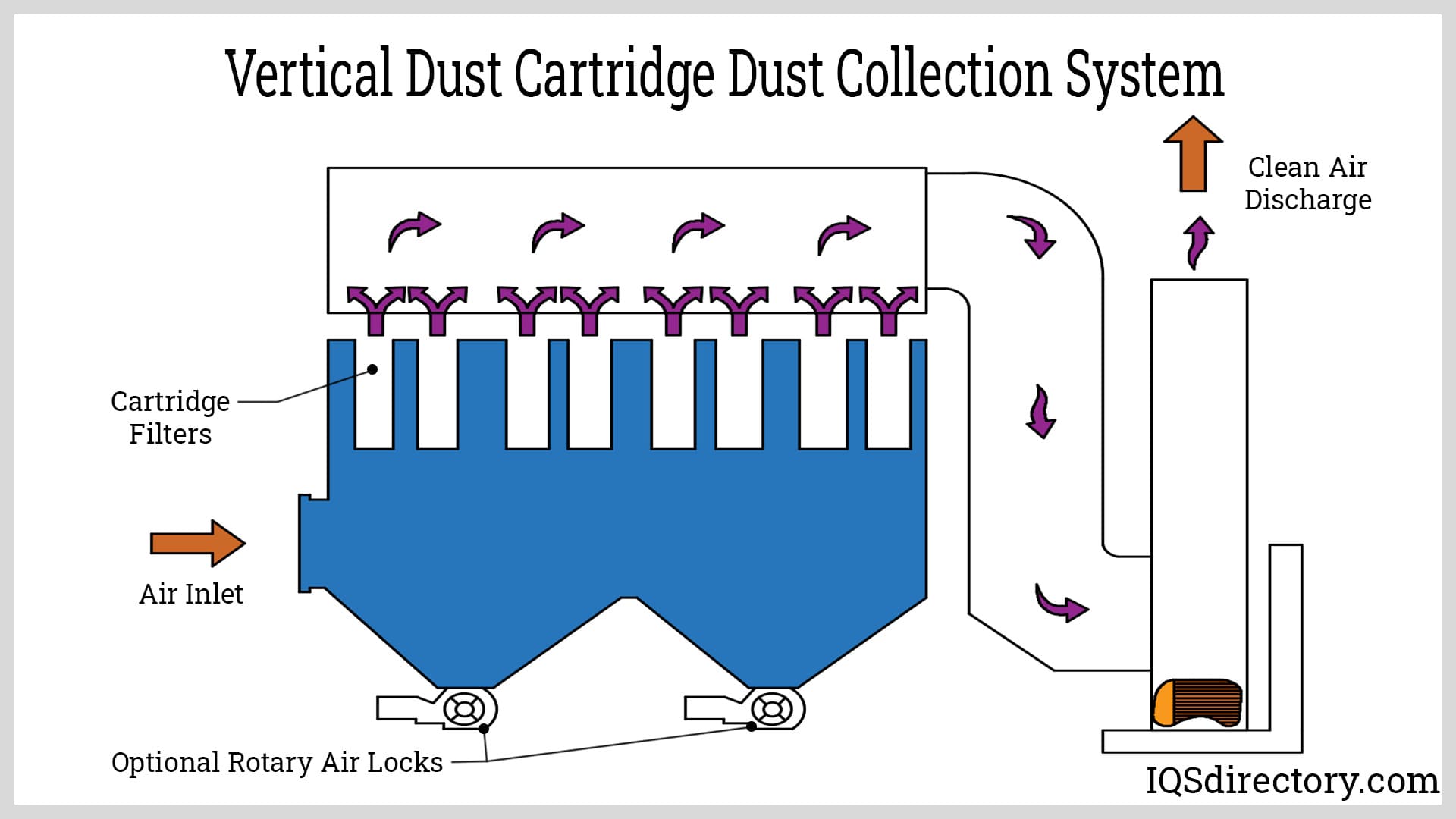

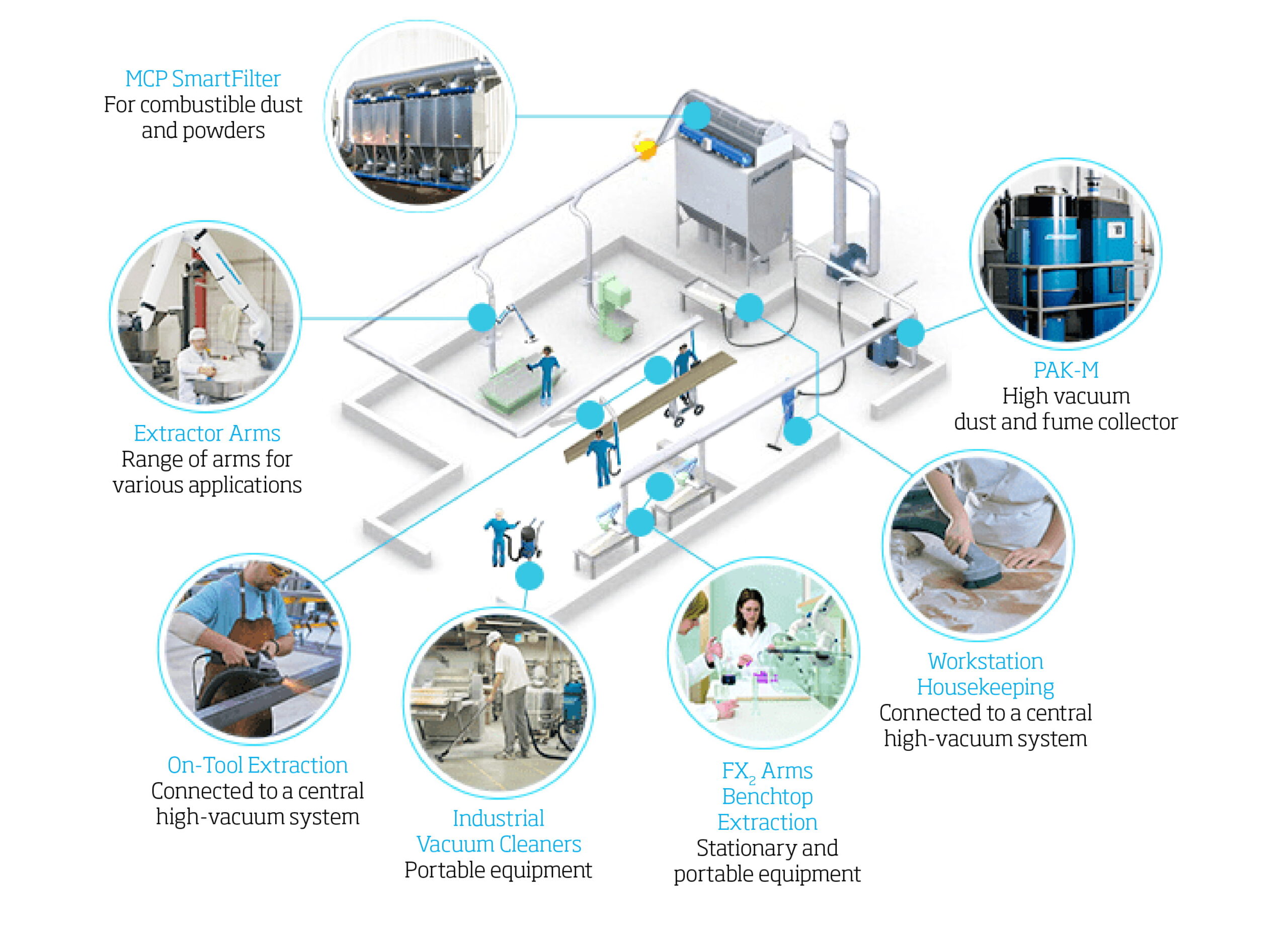

Illustrative image related to dust collection system diagram

Scenario 3: Difficulty in System Maintenance and Upgrades

The Problem: Over time, as operations scale and machinery changes, many businesses face challenges in maintaining and upgrading their dust collection systems. A common pain point is the inability to easily access various components for cleaning, repairs, or upgrades. This can lead to increased downtime and operational inefficiencies, particularly in facilities that rely heavily on dust management systems.

The Solution: To enhance maintainability, B2B buyers should design their dust collection systems with accessibility in mind. This means incorporating features into the dust collection system diagram that allow for easy access to critical components such as filters, ductwork, and collection bins. For example, strategically placing clean-out ports along the duct lines can facilitate quick maintenance and reduce downtime. Additionally, using modular components can make it easier to replace or upgrade parts without overhauling the entire system. Buyers should also schedule regular maintenance checks and keep a detailed maintenance log to track performance and issues, ensuring the system remains efficient and effective over time.

Strategic Material Selection Guide for dust collection system diagram

What are the Key Materials for Dust Collection Systems?

When selecting materials for dust collection systems, it is crucial to consider their properties, advantages, and limitations. Here, we analyze four common materials used in dust collection systems: galvanized steel, PVC, stainless steel, and aluminum. Each material has distinct characteristics that can impact performance, durability, and compliance with international standards.

How Does Galvanized Steel Perform in Dust Collection Systems?

Galvanized steel is a popular choice for dust collection systems due to its strength and corrosion resistance. It has a good temperature rating, typically up to 400°F (204°C), making it suitable for various industrial applications. The primary advantage of galvanized steel is its durability and resistance to rust, which enhances its lifespan.

However, galvanized steel can be heavier and more expensive than alternatives like PVC. Its manufacturing process can also be complex, requiring specialized equipment for cutting and joining. For international buyers, compliance with standards such as ASTM A653 is essential, especially in regions like Europe and the Middle East, where stringent regulations exist.

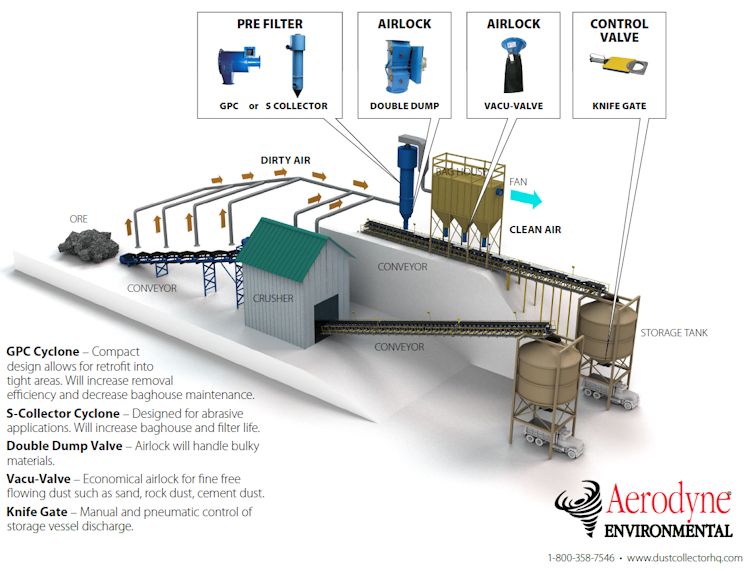

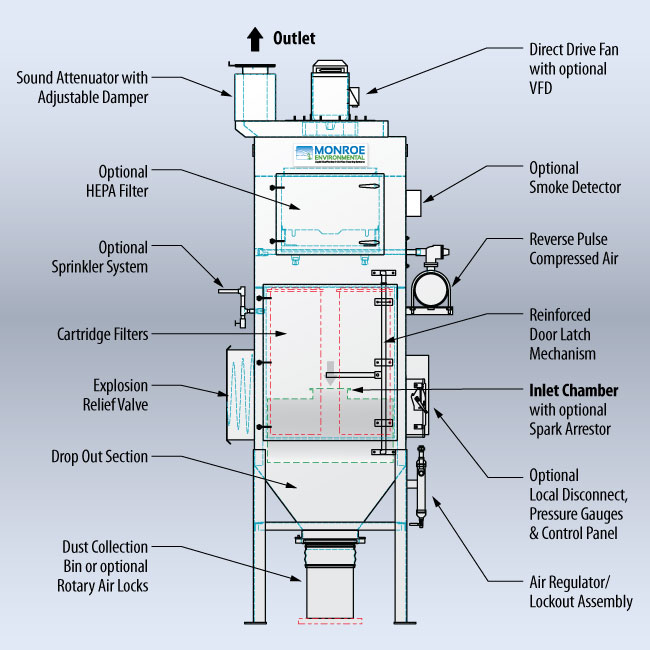

Illustrative image related to dust collection system diagram

What are the Benefits of Using PVC in Dust Collection Systems?

PVC (Polyvinyl Chloride) is another common material used in dust collection systems, particularly for smaller operations. It offers excellent corrosion resistance and is lightweight, making installation easier. PVC can handle temperatures up to 140°F (60°C), which is suitable for many dust types but may not be adequate for high-temperature applications.

On the downside, PVC is less durable than metals and can become brittle over time, especially in colder climates. It is also more susceptible to damage from UV exposure, which can limit its use in outdoor applications. International buyers should ensure that the PVC used meets local standards like ASTM D1784 for pipe quality.

Why Choose Stainless Steel for Dust Collection Systems?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it ideal for harsh environments where chemical exposure is a concern. It can withstand high temperatures and pressures, making it suitable for a wide range of applications, including those involving combustible dust.

Illustrative image related to dust collection system diagram

The primary disadvantage of stainless steel is its high cost compared to other materials. Additionally, its weight can complicate installation and handling. Buyers from regions like Africa and South America should consider compliance with standards such as ASTM A240 to ensure the material meets local requirements.

What Makes Aluminum a Viable Option for Dust Collection Systems?

Aluminum is a lightweight material that offers good corrosion resistance and is easy to work with. It is suitable for applications where weight is a concern, such as portable dust collection systems. Aluminum can handle moderate temperatures, typically up to 300°F (149°C), making it versatile for various dust types.

However, aluminum is less durable than stainless steel and can be more expensive than PVC. It may also require additional coatings for enhanced protection against corrosion in specific environments. Buyers should be aware of international standards like ASTM B209 when sourcing aluminum for dust collection applications.

Summary Table of Material Selection for Dust Collection Systems

| Material | Typical Use Case for dust collection system diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Industrial dust collection systems | High durability and corrosion resistance | Heavier and more expensive than alternatives | High |

| PVC | Small to medium dust collection systems | Lightweight and easy to install | Less durable and temperature sensitive | Low |

| Stainless Steel | Harsh environments with chemical exposure | Exceptional corrosion resistance and strength | High cost and installation complexity | High |

| Aluminum | Portable dust collection systems | Lightweight and easy to work with | Less durable and may require coatings for corrosion | Medium |

This guide provides a comprehensive overview of material selection for dust collection systems, helping B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dust collection system diagram

What Are the Main Manufacturing Processes for Dust Collection System Diagrams?

The manufacturing of dust collection systems involves several key stages, each critical to ensuring the final product meets the required performance and quality standards. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

How Is Material Prepared for Dust Collection Systems?

The first step in the manufacturing process involves selecting and preparing raw materials. Most dust collection systems are made from durable materials such as galvanized steel, stainless steel, or high-density polyethylene (HDPE).

-

Material Selection: The choice of material depends on the type of dust being collected, as some materials may be prone to corrosion or wear from abrasive dust. For instance, stainless steel is preferred for metalworking dust due to its resistance to corrosion and durability.

-

Cutting and Shaping: Once materials are selected, they undergo cutting, which can be done using methods such as laser cutting or water jet cutting. These techniques provide precision and minimize waste, which is crucial for cost-effectiveness.

What Techniques Are Used for Forming Dust Collection Components?

After the materials are prepared, they are formed into specific components required for the dust collection system. This includes ductwork, filters, and collection units.

-

Forming Techniques: Common techniques include bending, welding, and stamping. Bending is used to create duct shapes, while welding is essential for assembling different parts of the system into a cohesive unit. Stamping may be employed for creating brackets and connectors.

-

Component Design: Each component is designed to optimize airflow and minimize static pressure loss. Advanced CAD (Computer-Aided Design) software is often utilized to create 3D models, ensuring that components fit together seamlessly.

How Is the Assembly of Dust Collection Systems Conducted?

The assembly stage is where all components come together to form the complete dust collection system.

-

Assembly Line Production: Many manufacturers employ assembly line techniques to enhance efficiency. Workers are trained to handle specific tasks, ensuring consistency and quality.

-

Integration of Components: During assembly, components such as blowers, filters, and ducting are integrated. Special attention is given to the alignment of ductwork to ensure there are no leaks, which could affect performance.

What Finishing Processes Are Applied to Dust Collection Systems?

Once the assembly is complete, the dust collection system undergoes finishing processes that enhance its durability and functionality.

-

Surface Treatment: Finishing treatments such as powder coating or galvanization are applied to protect against rust and corrosion. This is especially important in environments where dust collection systems may be exposed to moisture or chemicals.

-

Final Inspection: A thorough inspection is conducted to ensure that all components meet design specifications and quality standards. Any necessary adjustments or repairs are made before the system is packaged for shipping.

What Quality Assurance Measures Are Implemented in Dust Collection System Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for dust collection systems. Implementing robust QA measures ensures that products meet international standards and customer expectations.

Which International Standards Are Relevant for Dust Collection Systems?

B2B buyers should be familiar with various international and industry-specific standards that govern the manufacturing of dust collection systems.

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is essential for any manufacturing operation. Compliance with ISO 9001 indicates that a manufacturer has a systematic approach to managing quality.

-

CE Marking: In Europe, dust collection systems must comply with CE marking requirements, which demonstrate that products meet EU safety, health, and environmental protection standards.

-

API Standards: For systems used in the oil and gas industry, adherence to American Petroleum Institute (API) standards may be necessary, ensuring that equipment meets specific operational and safety criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

To ensure consistent quality, manufacturers implement several quality control (QC) checkpoints throughout the production process:

Illustrative image related to dust collection system diagram

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of incoming materials. Suppliers are often required to provide certificates of compliance and test reports to ensure materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are conducted to monitor the quality of components being produced. This may involve regular measurements and inspections to ensure components are within tolerance levels.

-

Final Quality Control (FQC): The final inspection occurs after assembly and before shipping. This includes functional testing of the dust collection system to ensure it operates as intended and meets performance specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers to ensure they are making informed purchasing decisions.

What Steps Can Buyers Take to Audit Supplier Quality?

-

Supplier Audits: Conducting on-site audits of suppliers provides insight into their manufacturing processes and quality control measures. This includes reviewing documentation, inspecting facilities, and evaluating compliance with international standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the supplier’s QC processes, including results from IQC, IPQC, and FQC stages. This transparency can help build trust and confidence in the supplier’s capabilities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance practices. These inspections can be particularly valuable for international transactions, where language barriers and distance may complicate direct communication.

What Nuances Should International Buyers Consider Regarding Quality Control?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances that can impact quality control in the procurement of dust collection systems.

-

Local Regulations: Each region may have unique regulations and standards governing dust collection systems. Buyers must ensure that suppliers comply with these local requirements, which may differ from international standards.

-

Cultural Differences: Understanding cultural differences in business practices can facilitate smoother negotiations and communication with suppliers. This is particularly relevant in regions where personal relationships play a significant role in business dealings.

-

Logistical Challenges: International shipping can introduce additional risks, such as damage during transit or delays in delivery. Buyers should work closely with suppliers to establish clear terms for shipping and handling, including insurance and liability clauses.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures associated with dust collection systems is essential for B2B buyers. By being informed about these aspects, buyers can make strategic decisions that ensure they procure high-quality, compliant products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dust collection system diagram’

Introduction

In the pursuit of an efficient dust collection system, creating a detailed diagram is a crucial first step. This guide provides a practical checklist designed for B2B buyers seeking to procure or design a dust collection system. Following these steps will ensure you have a comprehensive understanding of your requirements, enabling you to make informed decisions throughout the procurement process.

Step 1: Assess Your Operational Needs

Begin by evaluating the specific dust-producing processes within your facility. Identify the machines that generate dust and their respective dust output characteristics. This assessment is vital as it dictates the capacity and design requirements of your dust collection system.

- Considerations:

- Types of materials processed (wood, metal, plastic, etc.)

- Frequency and intensity of machine usage.

Step 2: Create a Detailed Floor Plan

A scaled floor plan serves as the blueprint for your dust collection system. Include the location and dimensions of each machine, dust ports, and the proposed placement of the dust collector unit.

- Tips:

- Mark potential obstructions that may affect airflow.

- Utilize graph paper or CAD software for precision.

Step 3: Define Your Technical Specifications

Establish the technical requirements for your dust collection system based on the operational needs and floor plan. This includes airflow (CFM), velocity (FPM), and static pressure (SP) needed for optimal performance.

- Key Metrics:

- Use industry tables to determine the CFM requirements for different types of dust.

- Ensure the specifications align with local and international safety regulations.

Step 4: Evaluate Potential Suppliers

Thoroughly vet suppliers before making a commitment. Look for companies with experience in your industry and ask for references from similar projects.

- What to Request:

- Company profiles, case studies, and client testimonials.

- Technical support and installation services offered.

Step 5: Review Compliance and Safety Standards

Ensure that your dust collection system complies with all relevant local, national, and international safety standards. Understanding these regulations is crucial to avoid legal and operational issues.

- Action Items:

- Consult with legal experts or compliance officers.

- Verify that suppliers can provide documentation of compliance.

Step 6: Plan for Future Scalability

Consider the potential for future expansion of your operations. Design your dust collection system to accommodate additional machines or increased dust output without significant modifications.

- Strategic Planning:

- Choose flexible components that can be easily upgraded.

- Discuss scalability options with suppliers during the procurement phase.

Step 7: Finalize Your Component List

Compile a comprehensive list of all components required for your dust collection system. This includes ductwork, fittings, and any additional accessories needed for installation.

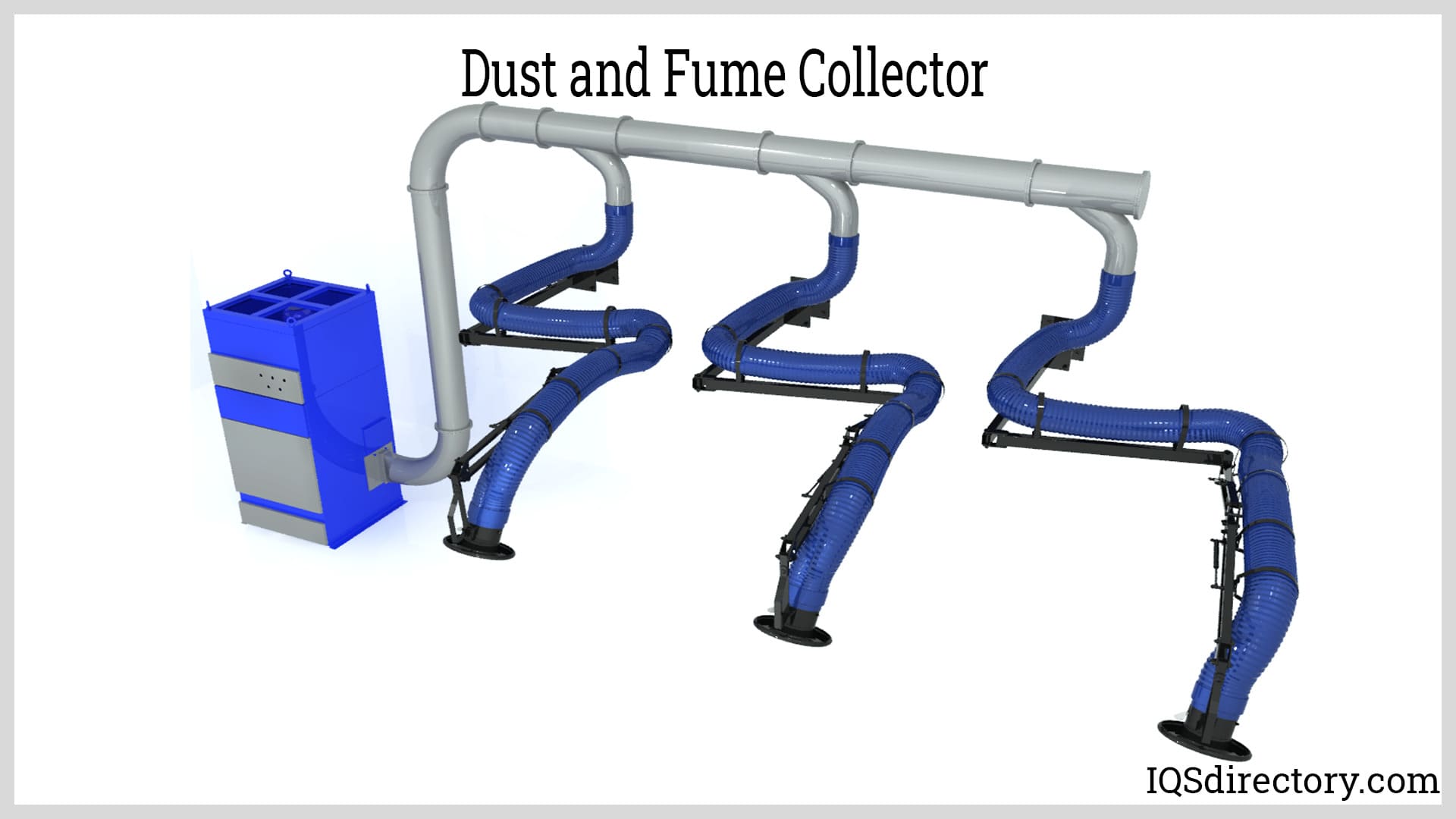

Illustrative image related to dust collection system diagram

- Checklist Items:

- Duct sizes and materials.

- Filters and dust collection units.

- Accessories like blast gates and clean-outs.

By following these steps, B2B buyers can ensure a well-structured approach to sourcing a dust collection system that meets their operational requirements while adhering to safety and compliance standards.

Comprehensive Cost and Pricing Analysis for dust collection system diagram Sourcing

What Are the Key Cost Components in Sourcing Dust Collection Systems?

When sourcing a dust collection system diagram, understanding the comprehensive cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: This encompasses the cost of ductwork, dust collection units, filters, and other components. The choice of materials can greatly influence the overall price; for instance, stainless steel may be more expensive than galvanized steel but offers superior durability and corrosion resistance.

-

Labor: Installation and maintenance labor costs can vary significantly by region. In countries like Nigeria or Brazil, labor may be less expensive compared to European nations, but it’s essential to factor in the quality and skill level of the workforce available.

-

Manufacturing Overhead: This includes costs related to the production process, such as utilities, rent, and administrative expenses. Manufacturers with efficient operations may offer competitive pricing.

-

Tooling: The initial setup costs for manufacturing equipment can influence pricing. Custom tooling for specific designs typically leads to higher upfront costs but may be justified by the improved efficiency and effectiveness of the dust collection system.

-

Quality Control (QC): Stringent quality assurance processes can increase costs but are vital for ensuring compliance with safety and environmental regulations. Systems that meet international standards may command higher prices but offer greater reliability.

-

Logistics: Transportation and shipping costs can vary widely based on the supplier’s location and the buyer’s destination. Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will affect the final pricing structure and should be clearly defined in contracts.

-

Margin: Suppliers typically apply a markup to cover their operational costs and profit margins. Understanding the industry standard margins in your region can help in negotiations.

How Do Price Influencers Affect Dust Collection System Costs?

Several factors can influence the pricing of dust collection systems:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Buyers from emerging markets should consider consolidating orders to meet MOQs, thereby reducing per-unit costs.

-

Specifications and Customization: Customized systems tailored to specific operational needs can incur additional costs. Buyers should clearly outline requirements to avoid unexpected expenses.

-

Material Selection: Choosing higher-quality or specialized materials impacts pricing. Evaluate the long-term benefits of investing in better materials against initial costs.

-

Quality Certifications: Systems that comply with international standards (ISO, CE, etc.) may cost more but provide assurance of quality and safety, which is particularly important for industries with stringent regulations.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their perceived value, while new entrants might offer lower prices to gain market share.

What Buyer Tips Can Help Optimize Dust Collection System Costs?

International buyers, especially from Africa, South America, the Middle East, and Europe, should consider the following tips for cost-effective sourcing:

-

Negotiate Terms: Engage suppliers in discussions regarding pricing, payment terms, and delivery schedules. Building long-term relationships can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider maintenance, operational efficiency, and potential downtime costs when assessing overall value.

-

Understand Pricing Nuances: Each region may have different pricing structures influenced by local demand, regulations, and economic conditions. Conduct market research to understand these dynamics.

-

Leverage Local Knowledge: Utilize local agents or consultants familiar with the dust collection system market to navigate complexities and ensure compliance with regional regulations.

Disclaimer on Indicative Prices

Prices for dust collection systems can vary widely based on numerous factors, including customization, regional economic conditions, and supplier negotiations. It is advisable to obtain multiple quotes and conduct a thorough analysis before making purchasing decisions.

Alternatives Analysis: Comparing dust collection system diagram With Other Solutions

Introduction to Alternative Dust Collection Solutions

In industries where dust generation is a common challenge, selecting the right dust collection system is crucial for maintaining a safe and efficient work environment. While the traditional dust collection system diagram serves as a foundational tool for designing effective systems, other alternatives may also provide viable solutions. Understanding the strengths and weaknesses of each option allows B2B buyers to make informed decisions tailored to their specific operational needs.

Comparison Table of Dust Collection Solutions

| Comparison Aspect | Dust Collection System Diagram | Cyclone Dust Collector | Portable Dust Collector |

|---|---|---|---|

| Performance | High efficiency with proper design; captures fine dust effectively | Excellent for heavy-duty applications; separates larger particles efficiently | Adequate for small-scale operations; limited to specific work areas |

| Cost | Initial investment can be high due to installation complexity | Moderate to high; requires additional space for setup | Lower upfront cost; ideal for budget-conscious buyers |

| Ease of Implementation | Requires detailed planning and design; may need professional assistance | More complex setup; requires space and ventilation considerations | Quick setup; portable and easy to relocate |

| Maintenance | Regular maintenance needed to ensure efficiency; filter replacement required | Requires periodic cleaning and maintenance of collection bags | Minimal maintenance; filters need occasional cleaning |

| Best Use Case | Ideal for large facilities with multiple dust-generating machines | Best for industries generating heavy dust loads, like woodworking or metalworking | Suitable for smaller shops or mobile operations needing flexibility |

Detailed Breakdown of Alternatives

Cyclone Dust Collector

Cyclone dust collectors operate by using centrifugal force to separate dust and debris from the air stream. They are particularly effective in heavy-duty applications, where large volumes of dust are generated. The primary advantage of cyclone collectors is their ability to handle larger particles without clogging. However, their installation can be more complex and requires adequate space for setup. Additionally, while they perform well for heavy dust loads, they may not capture finer particles as efficiently as a well-designed duct system.

Portable Dust Collector

Portable dust collectors are designed for mobility and ease of use. They are an excellent solution for small workshops or job sites where flexibility is essential. Their lower cost and quick setup make them attractive to budget-conscious buyers. However, their performance is often limited to specific work areas, and they may not provide the same level of dust capture efficiency as fixed systems. Additionally, the capacity of portable units may restrict their effectiveness in larger operations.

Conclusion: How to Choose the Right Dust Collection Solution

When selecting the appropriate dust collection system, B2B buyers should evaluate their specific operational needs, space availability, and budget constraints. The dust collection system diagram offers a robust framework for larger facilities with intricate requirements, while alternatives like cyclone and portable dust collectors can serve specialized or smaller-scale operations effectively. By analyzing performance metrics, cost implications, and maintenance requirements, buyers can align their choice with their business goals, ensuring a safer and more efficient working environment.

Essential Technical Properties and Trade Terminology for dust collection system diagram

What Are the Essential Technical Properties of a Dust Collection System?

When evaluating a dust collection system, several critical technical specifications must be considered to ensure effective performance and compliance with industry standards. Understanding these properties will help B2B buyers make informed decisions.

1. Cubic Feet per Minute (CFM)

CFM measures the volume of air that a dust collector can move in one minute. This specification is crucial for determining the system’s capacity to handle dust generated by machinery. A higher CFM rating indicates a more powerful system, essential for industries with high dust output, such as woodworking or metalworking. Buyers should ensure that the CFM rating meets the demands of their specific applications to prevent inefficient dust removal and potential safety hazards.

2. Static Pressure (SP)

Static pressure refers to the resistance within the duct system that the dust collector must overcome to maintain airflow. Measured in inches of water gauge (˝wg), SP is critical for sizing the dust collection unit correctly. If the SP is underestimated, the system may fail to operate effectively, leading to increased maintenance costs and potential downtime. Understanding SP helps buyers select the right equipment and design an efficient duct layout.

3. Velocity Pressure (VP)

Velocity pressure is the pressure associated with the speed of the air flowing through the ducts, also measured in inches of water gauge. Maintaining the correct velocity is essential to ensure that dust particles remain suspended in the airflow and do not settle, which can lead to clogs. Buyers should be familiar with the recommended velocity ranges for different types of dust to optimize their system’s performance.

4. Duct Size and Material

The diameter and material of the ducting play a significant role in the system’s efficiency. Proper sizing ensures optimal airflow, while the choice of material (e.g., galvanized steel, PVC, or aluminum) affects durability and maintenance needs. In regions with high humidity, for example, corrosion-resistant materials may be necessary. Buyers should consider both the operational environment and the expected lifespan of the ducting when making their selection.

5. Filtration Efficiency

The filtration system’s efficiency is crucial for capturing harmful dust particles and maintaining air quality. Different filters are rated based on their ability to capture various particle sizes. High-efficiency filters can reduce health risks for employees and ensure compliance with local regulations. Buyers should assess the filtration options available and select a system that meets their industry’s health and safety standards.

Illustrative image related to dust collection system diagram

What Are Common Trade Terms Related to Dust Collection Systems?

Familiarity with industry terminology can facilitate smoother transactions and negotiations in the B2B landscape. Here are several essential terms buyers should understand.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of dust collection systems, buyers may need to source components from OEMs to ensure compatibility and quality. Understanding OEM relationships can enhance procurement strategies and product reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This term is important for budgeting and inventory management, especially for smaller businesses that may not require large quantities. Buyers should negotiate MOQs to align with their operational needs while ensuring cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products or services. This document is crucial for comparing options and making informed purchasing decisions. Buyers should provide detailed specifications in their RFQs to receive accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms can help buyers navigate the complexities of international procurement, ensuring clarity in delivery and payment responsibilities.

5. Duct Layout

Duct layout refers to the arrangement of ducting in a dust collection system. An efficient duct layout minimizes bends and turns to enhance airflow and reduce static pressure loss. Buyers should prioritize optimal duct design to maximize system performance and minimize installation costs.

By understanding these essential technical properties and industry terminology, B2B buyers can make informed choices when designing or upgrading their dust collection systems, ensuring compliance, efficiency, and safety in their operations.

Navigating Market Dynamics and Sourcing Trends in the dust collection system diagram Sector

What Are the Key Market Trends Impacting the Dust Collection System Diagram Sector?

The dust collection system market is experiencing significant growth, driven by increasing industrialization and stringent environmental regulations globally. Emerging markets in Africa, South America, the Middle East, and Europe are witnessing heightened demand for efficient dust collection solutions as manufacturing sectors expand. Technological advancements, such as IoT integration for real-time monitoring and predictive maintenance, are becoming pivotal in enhancing system efficiency and operational uptime. Furthermore, the shift towards automation in manufacturing processes is compelling businesses to invest in advanced dust collection systems that can seamlessly integrate with automated workflows.

International buyers, particularly from regions like Brazil and Nigeria, are also focusing on customizing dust collection systems to meet specific local regulatory requirements. The rise of e-commerce platforms has made it easier for these buyers to access a wider range of suppliers and products, increasing competition and driving innovation. Additionally, the growing awareness of workplace safety and health standards is pushing companies to prioritize dust control solutions, which is significantly impacting sourcing trends in the sector.

How Is Sustainability Influencing Sourcing Decisions in the Dust Collection System Diagram Sector?

Sustainability has emerged as a critical consideration in the sourcing of dust collection systems. Environmental impacts related to dust emissions and waste management are prompting businesses to adopt more responsible practices. Buyers are increasingly seeking suppliers who prioritize ethical sourcing and offer products that comply with environmental regulations. This trend is particularly relevant in regions like Europe, where stringent laws govern air quality and waste disposal.

Additionally, the use of ‘green’ certifications and materials in dust collection systems is gaining traction. Buyers are encouraged to evaluate suppliers based on their sustainability credentials, including the use of recyclable materials and energy-efficient designs. Implementing sustainable practices not only helps in compliance with regulations but also enhances brand reputation and customer loyalty. As a result, B2B companies are investing in research and development to innovate eco-friendly dust collection solutions that align with the growing demand for sustainability.

What Is the Historical Context of Dust Collection Systems in the B2B Sector?

The evolution of dust collection systems can be traced back to the industrial revolution when the need for improved air quality in manufacturing environments became evident. Initially, systems were rudimentary, often relying on manual methods to control dust. Over the decades, technological advancements led to the development of more sophisticated systems, integrating mechanical and electrical components to enhance efficiency and safety.

Illustrative image related to dust collection system diagram

As industries evolved, so did the regulatory landscape surrounding air quality and workplace safety. This shift necessitated the adoption of more effective dust collection solutions, prompting innovations such as cyclonic separators and high-efficiency particulate air (HEPA) filters. Today, the focus is on creating integrated systems that not only manage dust but also optimize energy use and improve overall operational efficiency, reflecting the ongoing evolution of market demands and regulatory requirements.

In summary, the dust collection system market is on an upward trajectory, fueled by technological advancements and a growing emphasis on sustainability. B2B buyers must navigate these dynamics carefully to ensure they invest in solutions that meet their operational needs while adhering to regulatory standards and promoting environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of dust collection system diagram

-

How do I design an efficient dust collection system for my facility?

Designing an efficient dust collection system begins with a thorough assessment of your workspace and equipment. Start by creating a scaled floor plan that includes the locations of all dust-producing machines and their respective dust ports. Calculate the required air flow in CFM (Cubic Feet per Minute) based on the type of dust generated and the machine specifications. Consider factors like static pressure and duct sizing to ensure optimal performance. Consulting industry guidelines or working with a professional can further enhance the effectiveness of your design. -

What should I consider when selecting a dust collection system supplier?

When choosing a supplier for dust collection systems, prioritize their experience and reputation in the industry. Verify their compliance with local and international regulations, especially if you’re sourcing from different regions like Africa or South America. Request references and case studies to assess their capability in handling similar projects. Additionally, evaluate their customer support, warranty terms, and the availability of replacement parts to ensure a reliable partnership. -

What are the common minimum order quantities (MOQs) for dust collection systems?

Minimum order quantities for dust collection systems can vary significantly by supplier and region. Typically, manufacturers may set MOQs ranging from one unit to several units, depending on production capabilities and inventory levels. For international buyers, it’s advisable to inquire about flexibility in MOQs, especially for customized systems. Establishing a good relationship with your supplier may lead to more favorable terms, especially for first-time orders or smaller operations. -

How can I ensure the quality of dust collection systems purchased internationally?

To ensure quality when sourcing dust collection systems internationally, request detailed product specifications and certifications from your supplier. Conducting a factory audit or quality control inspection prior to shipment can also help verify manufacturing standards. Establish clear quality assurance protocols, such as specifying material grades and performance metrics in your contract. Partnering with suppliers who have established quality management systems can further mitigate risks. -

What payment terms should I expect when buying dust collection systems?

Payment terms for dust collection systems can vary based on supplier policies and the nature of the transaction. Common arrangements include a deposit upfront, followed by the balance upon shipment or delivery. International buyers should also consider payment methods that offer security, such as letters of credit or escrow services, to protect against fraud. It’s crucial to clarify these terms in advance to avoid misunderstandings and ensure a smooth transaction. -

What customization options are available for dust collection systems?

Many suppliers offer customization options to tailor dust collection systems to specific operational needs. Customizations may include adjustments in duct size, additional filtration options, or unique configurations to fit your facility layout. When discussing customization, provide detailed specifications and any unique requirements you have. Ensure that the supplier can accommodate your requests while maintaining compliance with relevant safety and performance standards. -

How do I navigate international logistics for dust collection systems?

Navigating international logistics for dust collection systems involves understanding shipping regulations and potential tariffs that may apply. Work with freight forwarders experienced in handling industrial equipment to facilitate smooth transportation. Additionally, ensure that your supplier provides all necessary documentation for customs clearance. Establishing a clear timeline and communication plan will help manage expectations and reduce delays in receiving your equipment. -

What are the safety considerations when implementing a dust collection system?

Safety considerations for dust collection systems include ensuring compliance with local regulations regarding air quality and explosion hazards. Proper grounding of ductwork and installation of explosion-proof equipment may be necessary for certain materials. Additionally, conducting regular maintenance checks and filter replacements is crucial to maintaining safe operation. Providing adequate training for staff on system operation and safety protocols can further mitigate risks associated with dust exposure.

Top 6 Dust Collection System Diagram Manufacturers & Suppliers List

1. Spiral MFG – Galvanized & PVC Pipes and Fittings

Domain: spiralmfg.com

Registered: 1996 (29 years)

Introduction: High Pressure Galvanized Pipe, Low Pressure Galvanized Pipe, PVC Underground Pipe, Spiral Pipe, Elbows, Tees, 90° Laterals, 30°/45° Multi Branch Pant Wyes, Reducers, Fittings, Plugs, Caps, Couplings, Pickup Hoods, Weather Hoods, Rectangular & Round Transitions, Rectangular Duct, Single Wall Insulated Spiral Pipe, Dual Wall Insulated Spiral Pipe, Angle Rings & Flanges, Duct Sealants & Tapes, Hanger…

2. Facebook – Correct Positioning Diagrams

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Correct Positioning Diagrams, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Nordfab® – Dust Collection Ductwork

Domain: blog.ductingsystems.com

Registered: 2003 (22 years)

Introduction: Nordfab® dust collection ductwork provides a reliable and versatile solution for controlling airborne particles. Product range includes fittings and pipes from 3″ to 24″ in diameter. Features double-rolled connecting edges for secure clamping, eliminating the need for additional fasteners. Engineered for durability, minimizes air resistance, and reduces static pressure loss. Ideal for material han…

4. Harbor Freight – Dust Collection System

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Dust Collection System: 2 HP Harbor Freight Dust Collector, Rikon 60-200 impeller (optional upgrade), Wynn Filter Upgrade ($200), Thien Baffle, Galvanized Trash Can, Piping & connectors, Blast Gates, PVC pipe (3 sections of 10′-0″ 4″ PVC pipe, 10 4″ PVC wye, 2 4″ PVC end cap, 4 45* PVC elbow), DIY blast gates (11), DIY pipe clamps (10), Equipment Hookups (2 4″x10′ Flex Pipe, 3 4″ Whyes, 5 4″ PVC F…

5. Dust Collection Systems – Essential Components

Domain: slideshare.net

Registered: 2006 (19 years)

Introduction: The document outlines the importance of dust collection systems in raw material handling plants, detailing processes such as dust generation and control mechanisms. It explains various components of these systems, including exhaust hoods, ductwork, and cleaning devices, as well as the principles of operation and various dust control techniques. Advantages of dust collection systems include improve…

6. Oneida Air Systems – D.I.Y. Dust Collection Guide

Domain: oneida-air.com

Registered: 1998 (27 years)

Introduction: D.I.Y. Dust Collection Ductwork Installation Guide from Oneida Air Systems includes clear instructions for planning, assembling, and installing dust collection ductwork and flex-hose components. Available as a downloadable PDF or high-quality printed booklet. Key products include: 7″ Beginner Ductwork Starter Kit ($269.00), 7″ Intermediate Ductwork Starter Kit ($619.00), 7″ Deluxe Ductwork Starter…

Strategic Sourcing Conclusion and Outlook for dust collection system diagram

In conclusion, the effective design and implementation of a dust collection system are paramount for enhancing operational efficiency and compliance with health and safety regulations in various industries. Key takeaways from this guide emphasize the importance of accurately sizing ductwork, understanding airflow dynamics, and adhering to local regulations. Strategic sourcing plays a crucial role in procuring high-quality components that meet these specifications, ensuring that businesses can maintain a safe and productive working environment.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential to consider local market dynamics and regulatory requirements when sourcing dust collection systems. By investing in well-designed systems, businesses can not only improve air quality and worker safety but also enhance productivity and operational costs in the long run.

As industries evolve and regulations tighten, the demand for efficient dust collection solutions will only increase. Now is the time to act—evaluate your current systems, explore advanced technologies, and collaborate with suppliers who can offer tailored solutions to meet your unique needs. Together, we can forge a cleaner, safer future in workplaces around the globe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.