A B2B Buyer’s Guide to Douglas Corp Eden Prairie: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for douglas corp eden prairie

In the dynamic landscape of global business, sourcing high-quality product graphics and electronic interfaces, such as those offered by Douglas Corporation in Eden Prairie, presents unique challenges for international B2B buyers. As companies seek to enhance their brand image and functionality in a competitive marketplace, understanding the variety of products, their applications, and the complexities of supplier vetting becomes crucial. This guide provides a comprehensive overview of Douglas Corporation’s offerings, including nameplates, membrane switches, graphic overlays, and decorative trim, tailored for diverse industries ranging from medical devices to consumer electronics.

Our aim is to empower B2B buyers from Africa, South America, the Middle East, and Europe—particularly in key markets like Germany and Brazil—with the insights needed to make informed purchasing decisions. By exploring the specifications, manufacturing processes, and cost considerations associated with Douglas Corporation’s products, this guide will help you navigate the intricacies of sourcing. You’ll gain actionable knowledge on how to evaluate suppliers effectively, assess product quality, and ultimately choose solutions that align with your business objectives.

As you delve into the sections that follow, expect to uncover valuable information that not only demystifies the procurement process but also positions your business for success in a global market increasingly driven by innovation and quality.

Understanding douglas corp eden prairie Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Product Nameplates | Customizable designs, durable materials, various finishes | OEMs in electronics, appliances, automotive | Pros: High visibility, long-lasting branding. Cons: Potentially higher upfront costs. |

| Membrane Switches | User-friendly interface, customizable layouts, robust design | Medical devices, industrial machinery | Pros: Durable, easy to clean. Cons: Limited tactile feedback compared to mechanical switches. |

| Graphic Overlays | High-quality printing, various textures, and finishes | Consumer electronics, automotive dashboards | Pros: Enhances aesthetics, protects underlying components. Cons: May require specific installation techniques. |

| Decorative Trim and Parts | Custom shapes and sizes, multiple materials available | Appliances, furniture, automotive interiors | Pros: Customizable for branding, aesthetically pleasing. Cons: Longer lead times for custom orders. |

| Flex Circuits | Thin, lightweight, flexible designs, multi-layer options | Electronics, medical devices, aerospace | Pros: Space-saving, versatile applications. Cons: More complex manufacturing process can increase costs. |

What Are the Key Characteristics of Product Nameplates from Douglas Corporation?

Product nameplates from Douglas Corporation are designed with a focus on customization and durability. They offer a wide range of finishes, including chrome and gold electroplating, which enhance the visual appeal of products. These nameplates are primarily used by original equipment manufacturers (OEMs) in sectors like electronics, appliances, and automotive. When considering a purchase, buyers should assess the long-term branding benefits against potential upfront costs, especially for custom designs.

How Do Membrane Switches Enhance User Experience in Various Industries?

Membrane switches serve as crucial interfaces in many electronic devices, providing a seamless user experience. Douglas Corporation’s membrane switches are known for their durability and reliability, making them suitable for demanding applications in medical devices and industrial machinery. Buyers should consider the switch’s design flexibility and the potential need for customization to meet specific operational requirements. While they offer ease of maintenance, the tactile feedback may not match that of traditional mechanical switches, which could be a consideration for some applications.

What Advantages Do Graphic Overlays Provide to OEMs?

Graphic overlays manufactured by Douglas Corporation are crafted to enhance the visual appeal and functionality of electronic devices. These overlays can be printed with high-quality graphics and come in various textures to fit different applications. They are commonly used in consumer electronics and automotive dashboards. When purchasing, B2B buyers should focus on the overlay’s protective qualities and how it complements the underlying components. However, installation techniques may vary, necessitating careful planning to ensure proper application.

Why Are Decorative Trim and Parts Important for Branding?

Decorative trim and parts from Douglas Corporation are essential for adding a touch of customization and branding to products. They can be tailored in shape and size, using various materials to fit the aesthetic needs of appliances, furniture, and automotive interiors. Buyers should evaluate the benefits of branding against the lead times associated with custom orders, as these can vary significantly based on design complexity. While they enhance product appeal, the customization process may require more time and investment.

How Do Flex Circuits Contribute to Modern Electronics?

Flex circuits are a standout product from Douglas Corporation, known for their lightweight and flexible designs. They are particularly beneficial in electronics and medical devices where space is at a premium. These circuits can accommodate complex layouts and multiple layers, making them versatile for various applications. B2B buyers should consider the potential complexities involved in manufacturing flex circuits, which may lead to increased costs. However, their space-saving characteristics and adaptability can justify the investment for innovative design solutions.

Key Industrial Applications of douglas corp eden prairie

| Industry/Sector | Specific Application of douglas corp eden prairie | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Custom membrane switches for diagnostic equipment | Enhanced user interface and reliability | Compliance with medical standards, durability, and customization |

| Aerospace | Durable nameplates for aircraft components | Long-lasting identification and branding | Resistance to extreme conditions, lightweight materials |

| Industrial Machinery | Graphic overlays for control panels | Improved functionality and user experience | Compatibility with various machinery designs and environments |

| Consumer Electronics | Injection-molded bezels for electronic devices | Aesthetic appeal and product differentiation | Precision in design, material selection, and volume production |

| Automotive | Decorative trim components for vehicle interiors | Enhanced visual appeal and brand recognition | Customization options, durability, and compliance with industry standards |

How Are Custom Membrane Switches Used in Medical Devices?

Douglas Corporation specializes in manufacturing custom membrane switches that serve as vital interfaces in medical devices. These components are crucial for ensuring user-friendly interaction with diagnostic equipment and other medical technologies. The challenges faced by international buyers include stringent compliance with health regulations and the need for high durability in demanding environments. Douglas Corporation’s ability to provide tailored solutions addresses these needs, ensuring reliability and functionality in critical medical applications.

What Role Do Durable Nameplates Play in Aerospace?

In the aerospace industry, Douglas Corporation provides high-quality nameplates designed to withstand extreme conditions. These nameplates are essential for identifying aircraft components, ensuring safety and compliance with aviation regulations. Buyers from regions such as Europe and the Middle East must consider the materials’ resistance to corrosion and temperature fluctuations. Douglas’s expertise in creating durable, lightweight solutions meets these rigorous demands, enhancing both safety and operational efficiency in aerospace applications.

How Do Graphic Overlays Improve Industrial Machinery?

Graphic overlays designed by Douglas Corporation enhance the functionality of control panels in industrial machinery. These overlays not only provide clear visual instructions but also protect underlying components from wear and tear. For B2B buyers, particularly in regions like Africa and South America, sourcing overlays that can withstand harsh operational conditions is critical. Douglas’s commitment to quality and customization ensures that each overlay meets specific machinery requirements, improving overall user experience and operational efficiency.

Why Are Injection-Molded Bezels Important in Consumer Electronics?

Douglas Corporation’s injection-molded bezels play a significant role in the aesthetics and functionality of consumer electronic devices. These components are designed to provide a sleek appearance while ensuring the durability required in everyday use. For international buyers, particularly in competitive markets such as Brazil and Germany, selecting high-quality bezels can differentiate products in a crowded marketplace. Douglas’s advanced manufacturing capabilities ensure precision and high-volume production, meeting the demands of the consumer electronics sector.

How Does Decorative Trim Enhance Automotive Interiors?

In the automotive industry, Douglas Corporation offers decorative trim components that significantly enhance vehicle interiors. These trims not only contribute to the visual appeal of vehicles but also reflect brand identity and quality. Buyers should consider customization options to align with specific automotive designs and consumer preferences. Douglas’s extensive experience in creating durable and stylish automotive components ensures that businesses can meet both aesthetic and functional requirements, driving customer satisfaction in the automotive market.

3 Common User Pain Points for ‘douglas corp eden prairie’ & Their Solutions

Scenario 1: Difficulty in Customization of Product Graphics

The Problem: B2B buyers often face challenges when seeking customized product graphics that align with their brand identity and functional requirements. This is particularly true for manufacturers in sectors such as medical devices or consumer electronics, where the appearance and usability of product components are critical. Buyers may struggle with finding a supplier that not only understands their unique needs but can also deliver high-quality, customized solutions within a reasonable timeframe.

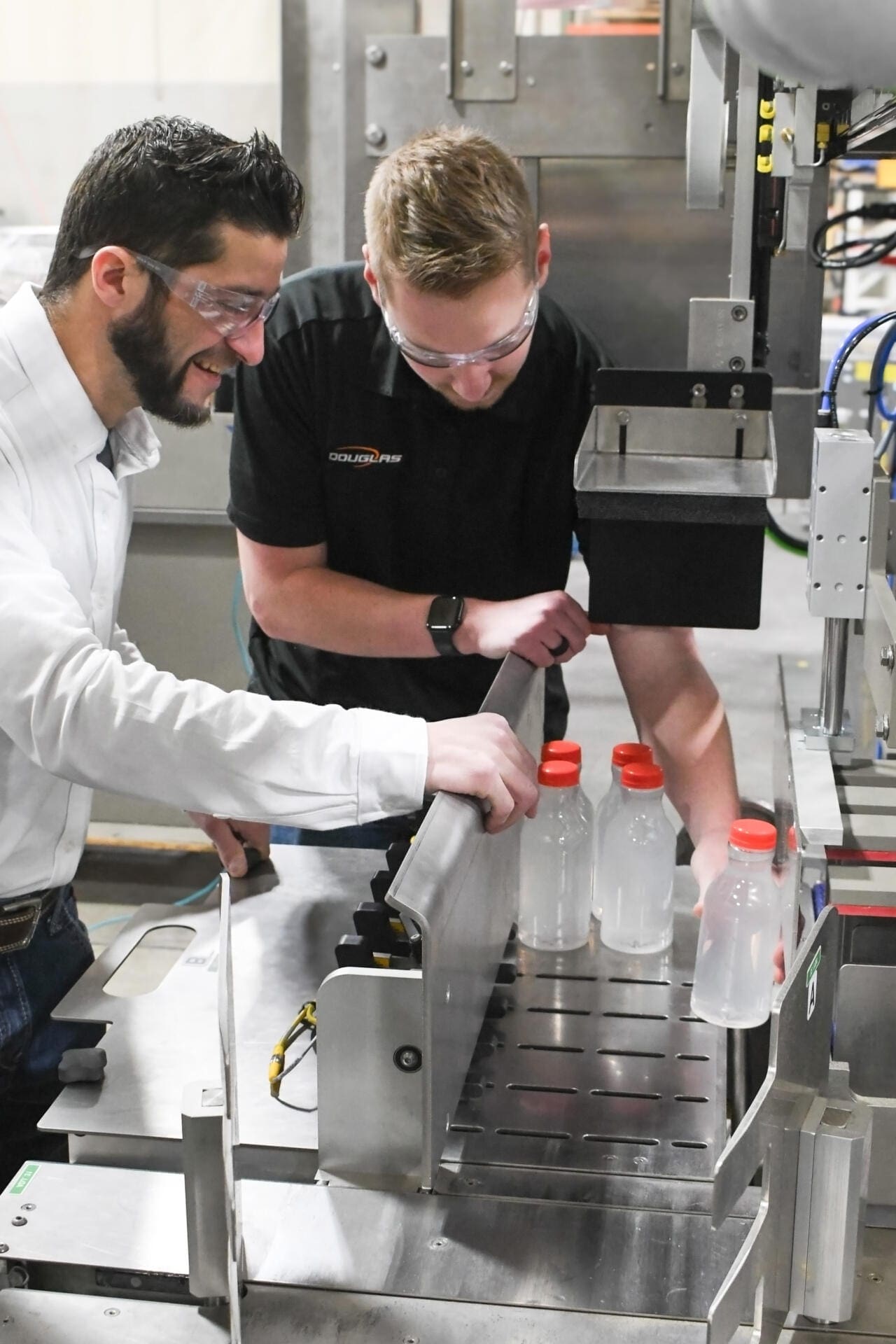

Illustrative image related to douglas corp eden prairie

The Solution: To effectively utilize Douglas Corporation’s offerings, buyers should begin by engaging in a detailed consultation with their design and engineering teams. By providing comprehensive specifications regarding design preferences, materials, and intended use, buyers can leverage Douglas’s expertise in creating tailored product graphics. Utilizing their advanced manufacturing capabilities, including screen printing and digital printing, buyers can ensure that their product graphics are not only visually appealing but also functional. It is advisable to request prototypes and samples early in the process, allowing for adjustments and ensuring that the final product aligns with the buyer’s expectations before mass production.

Scenario 2: Concerns Over Quality and Compliance Standards

The Problem: International buyers often worry about the quality and compliance of products manufactured in a foreign country. For companies in regions like Africa or South America, this concern is magnified due to varying standards and regulations. Buyers may fear that their products, such as membrane switches or nameplates, won’t meet industry-specific certifications like ISO 9001, leading to potential compliance issues and costly delays.

The Solution: Douglas Corporation addresses these concerns by maintaining a strong commitment to quality control and certifications. Buyers should take advantage of Douglas’s ISO 9001:2015 certification, which ensures that products meet high-quality standards. When sourcing, buyers should inquire about specific quality assurance processes, including testing and certification services. Establishing clear communication regarding compliance expectations at the outset will allow Douglas to adapt their manufacturing processes to meet the buyer’s specific requirements, thereby mitigating concerns over quality and compliance. Additionally, potential buyers can request detailed documentation of compliance standards and quality testing results as part of their procurement process.

Scenario 3: Challenges in Timely Delivery and Lead Times

The Problem: Timeliness is critical in the B2B space, especially for businesses relying on rapid product development cycles. Buyers may encounter challenges related to long lead times when sourcing components like graphic overlays or decorative trims. Delays in receiving these essential components can disrupt production schedules, leading to financial losses and strained customer relationships.

The Solution: To alleviate concerns regarding lead times, buyers should proactively communicate their timelines and requirements to Douglas Corporation. Early engagement is key; by sharing production schedules and anticipated launch dates, buyers can work collaboratively with Douglas to prioritize their orders. Additionally, utilizing Douglas’s rapid prototyping and in-house tooling capabilities can significantly reduce turnaround times. Buyers should consider placing bulk orders or establishing long-term contracts to secure more favorable lead times. By leveraging Douglas’s extensive manufacturing capabilities in Eden Prairie, buyers can ensure a more reliable supply chain and maintain their project timelines effectively.

Strategic Material Selection Guide for douglas corp eden prairie

When selecting materials for products manufactured by Douglas Corporation in Eden Prairie, it is essential to consider the specific properties and applications of each material. This guide analyzes four common materials used in the production of nameplates, membrane switches, and graphic overlays, providing insights for international B2B buyers.

What Are the Key Properties of Polycarbonate in Douglas Corp Products?

Polycarbonate is a versatile thermoplastic known for its excellent impact resistance and optical clarity. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environments. Additionally, polycarbonate exhibits good chemical resistance, particularly against acids and bases, which is vital for applications in industrial settings.

Illustrative image related to douglas corp eden prairie

Pros and Cons: Polycarbonate is highly durable and can be manufactured with complex geometries, making it ideal for intricate designs. However, it can be more expensive than other plastics, which may affect the overall cost of the final product. Its susceptibility to scratching can also be a limitation unless coated with protective films.

Impact on Application: Polycarbonate is often used in environments where high impact resistance is crucial, such as in medical devices and aerospace equipment. Its compatibility with various media makes it a preferred choice for applications requiring transparency and durability.

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with standards such as ASTM and DIN for safety and performance. The preference for sustainable materials is growing, and polycarbonate can be sourced in recycled forms, aligning with environmental regulations.

How Does Acrylic Compare as a Material Choice for Douglas Corp?

Acrylic, another popular thermoplastic, is known for its clarity and light weight. It has a temperature tolerance of -30°C to 80°C and offers good weather resistance, making it suitable for outdoor applications.

Pros and Cons: Acrylic is less expensive than polycarbonate and can be easily molded into complex shapes. However, it is less impact-resistant and can shatter under high stress. Its surface can also be prone to scratching, although it can be polished to restore clarity.

Impact on Application: Acrylic is commonly used in signage and decorative elements due to its aesthetic appeal. It is compatible with various inks and adhesives, making it versatile for graphic overlays.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for acrylic in different regions. European buyers may prefer materials that meet REACH regulations, ensuring safety in applications involving consumer products.

What Are the Advantages of Using Metal in Douglas Corp Products?

Metal components, such as aluminum and stainless steel, are often used in Douglas Corporation’s products for their strength and durability. Metals can withstand extreme temperatures and pressures, with stainless steel offering excellent corrosion resistance.

Pros and Cons: The primary advantage of metal is its longevity and structural integrity, making it suitable for heavy-duty applications. However, metal parts can be more expensive and may require additional manufacturing processes, such as machining and finishing, which can increase lead times.

Impact on Application: Metals are ideal for environments where strength and durability are paramount, such as industrial machinery and automotive applications. Their compatibility with various media, including oils and chemicals, enhances their usability.

Considerations for International Buyers: Compliance with international standards such as ISO and ASTM is crucial for metal components, especially in regulated industries. Buyers from the Middle East and Africa should consider the availability of specific grades of metal that meet local standards.

How Do Adhesives and Coatings Enhance Douglas Corp Products?

Adhesives and coatings play a critical role in enhancing the performance and appearance of Douglas Corporation’s products. Various adhesives are used for bonding materials, while coatings can provide additional protection against environmental factors.

Pros and Cons: The use of specialized adhesives can enhance the durability and functionality of products, allowing for the combination of different materials. However, the selection of the wrong adhesive can lead to product failure, making expertise in material compatibility essential.

Impact on Application: Coatings can improve resistance to UV light, chemicals, and abrasion, extending the life of products used in harsh environments. This is particularly important for outdoor applications and products exposed to wear and tear.

Considerations for International Buyers: Buyers should ensure that adhesives and coatings comply with local regulations regarding VOC emissions and safety standards. Preferences for eco-friendly options are increasing globally, influencing purchasing decisions.

Summary Table of Material Selection for Douglas Corp Products

| Material | Typical Use Case for douglas corp eden prairie | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Medical devices, aerospace components | Excellent impact resistance | Higher cost, susceptible to scratching | High |

| Acrylic | Signage, decorative overlays | Cost-effective, easy to mold | Less impact-resistant, prone to scratches | Medium |

| Metal | Industrial machinery, automotive applications | High durability and strength | Higher manufacturing complexity | High |

| Adhesives/Coatings | Product assembly, protective finishes | Enhances durability and functionality | Risk of compatibility issues | Medium |

This strategic material selection guide offers valuable insights for international B2B buyers looking to source high-quality products from Douglas Corporation in Eden Prairie, ensuring informed decisions that align with regional standards and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for douglas corp eden prairie

What Are the Key Manufacturing Processes at Douglas Corp in Eden Prairie?

Douglas Corporation, a leader in the manufacturing of nameplates, membrane switches, and graphic overlays, employs a meticulous approach to its manufacturing processes. This ensures that each product meets the highest standards of quality and functionality. The primary stages of manufacturing at Douglas Corp include material preparation, forming, assembly, and finishing.

Illustrative image related to douglas corp eden prairie

How Is Material Prepared for Manufacturing?

Material preparation is the foundational step in Douglas Corp’s manufacturing process. High-quality raw materials are sourced, often tailored to specific product needs. This can include various types of plastics, metals, and specialty materials like holographic foils and acrylics. Each material undergoes rigorous inspection to ensure it meets the required specifications before moving to the next stage.

What Forming Techniques Are Utilized in Production?

In the forming stage, Douglas Corp employs advanced techniques such as injection molding, vacuum forming, and screen printing. Injection molding is particularly critical for creating intricate shapes and designs for nameplates and membrane switches. The use of state-of-the-art machinery allows for precise control over the forming process, ensuring that each piece is produced consistently and accurately.

How Does Assembly Take Place at Douglas Corp?

The assembly stage involves bringing together various components to create the final product. For example, in the case of membrane switches, layers of graphic overlays, tactile domes, and circuit components are assembled meticulously. Douglas Corp’s skilled technicians ensure that each component is correctly aligned and secured, reducing the risk of defects. This stage is crucial for ensuring the functionality and durability of the final product.

What Finishing Techniques Enhance Product Quality?

Finishing techniques at Douglas Corp include processes such as painting, hot stamping, and vacuum metalizing. These methods not only enhance the aesthetic appeal of the products but also contribute to their durability. For instance, vacuum metalizing provides a reflective surface that adds a premium look while protecting the underlying material from wear and tear. The finishing stage is where the products undergo final inspections to ensure they meet the company’s high-quality standards.

How Does Douglas Corp Ensure Quality Assurance Throughout Its Manufacturing?

Quality assurance is embedded in every stage of the manufacturing process at Douglas Corporation. The company adheres to international standards such as ISO 9001:2015, ensuring that its quality management systems are robust and effective. This commitment to quality is crucial for international B2B buyers looking for reliable suppliers.

What International Standards and Certifications Are Relevant?

Douglas Corp is ISO 9001:2015 certified, which signifies its adherence to global quality management standards. In addition, the company complies with industry-specific certifications that may be necessary depending on the end-use of the products, such as CE for European markets and API for certain industrial applications. These certifications provide buyers with confidence in the quality and safety of the products.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control at Douglas Corp includes several critical checkpoints:

- Incoming Quality Control (IQC): This initial inspection phase ensures that all raw materials meet the specified requirements before they enter the production process.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, continuous monitoring occurs to identify and rectify any issues that may arise. This proactive approach helps maintain product integrity.

- Final Quality Control (FQC): Once production is complete, a comprehensive final inspection is conducted to verify that all products meet quality standards before shipping.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers like Douglas Corp is essential. Here are some actionable steps:

-

Conduct Audits: Buyers can schedule on-site audits to assess the manufacturing processes and quality control measures directly. This firsthand observation can provide insights into the supplier’s operational efficiency and commitment to quality.

-

Request Quality Reports: Buyers should ask for detailed quality reports that outline the results of quality control checks, including any issues identified and how they were resolved. These documents can help buyers gauge the reliability of the supplier.

-

Engage Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased assessment of product quality. This is particularly beneficial for buyers in regions with different regulatory standards, as third-party inspectors are familiar with international requirements.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers from regions such as Africa, South America, the Middle East, and Europe must be aware of specific nuances in quality control when dealing with suppliers like Douglas Corp.

-

Understanding Local Regulations: Different regions may have specific regulations that affect product specifications and quality standards. Buyers should familiarize themselves with these requirements to ensure compliance.

-

Cultural Considerations: Communication styles and business practices can vary significantly across regions. Establishing clear expectations and maintaining open lines of communication can help mitigate misunderstandings.

-

Building Long-Term Relationships: Establishing a long-term partnership with suppliers can lead to better quality assurance over time. By fostering a collaborative relationship, buyers can work with suppliers to continuously improve product quality and address any issues promptly.

In conclusion, Douglas Corporation’s comprehensive manufacturing processes and stringent quality assurance measures position it as a reliable partner for B2B buyers seeking high-quality nameplates, membrane switches, and graphic overlays. By understanding these processes and the associated quality control practices, international buyers can make informed decisions when selecting suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘douglas corp eden prairie’

To successfully source products from Douglas Corporation in Eden Prairie, Minnesota, it is essential to follow a structured approach. This guide serves as a practical checklist for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, who are interested in procuring high-quality nameplates, membrane switches, and graphic overlays.

Step 1: Define Your Technical Specifications

Before initiating contact with Douglas Corporation, clearly outline your technical requirements. This includes dimensions, materials, and design features of the products you need. Having a well-defined specification will streamline the communication process and help the supplier understand your needs accurately.

- Consider product functionality: Ensure your specifications address the intended use of the product, such as durability for industrial applications or aesthetic appeal for consumer electronics.

- Include tolerances and standards: Specify any industry standards or certifications that the products must comply with, such as ISO 9001.

Step 2: Research Douglas Corporation’s Product Offerings

Familiarize yourself with the range of products and services offered by Douglas Corporation. This company specializes in various product graphics, including nameplates and membrane switches, tailored for different industries.

- Explore their website: Review product catalogs, case studies, and technical data sheets available on their site to gain insights into their capabilities.

- Identify complementary products: Look for additional components that may enhance your project, such as graphic overlays or tactile domes.

Step 3: Evaluate Supplier Certifications

It is crucial to verify that Douglas Corporation holds relevant industry certifications, such as ISO 9001:2015. These certifications indicate a commitment to quality and consistent manufacturing practices.

- Request documentation: Ask for copies of certification documents to confirm their compliance.

- Understand quality control measures: Inquire about their quality assurance processes to ensure that the products meet your standards.

Step 4: Engage with Their Design and Engineering Team

Take advantage of Douglas Corporation’s engineering support to discuss your project requirements in detail. Their team can provide insights and suggestions for optimizing your product design.

- Schedule a consultation: Initiate a dialogue with their engineers to explore potential design enhancements.

- Discuss customization options: Clarify how they can tailor their offerings to fit your specific needs, ensuring that the final product aligns with your expectations.

Step 5: Request Samples and Prototypes

Before finalizing your order, it is advisable to request samples or prototypes of the products. This step allows you to assess the quality and functionality of the offerings firsthand.

- Evaluate the sample: Test the sample for durability, design accuracy, and usability in your application.

- Provide feedback: Use your evaluation to discuss any necessary adjustments with Douglas Corporation.

Step 6: Review Pricing and Payment Terms

Once you are satisfied with the product samples, request a detailed quote that outlines pricing, lead times, and payment terms. Understanding these factors upfront will help you manage your budget effectively.

Illustrative image related to douglas corp eden prairie

- Compare quotes: If you’re considering multiple suppliers, ensure you have a fair comparison based on price, quality, and delivery timelines.

- Negotiate terms: Don’t hesitate to discuss payment options and potential discounts for bulk orders.

Step 7: Finalize the Order and Establish Communication

After agreeing on pricing and terms, finalize your order with Douglas Corporation. Establish clear lines of communication for updates on production and delivery schedules.

- Confirm order details: Ensure all specifications, quantities, and timelines are documented and acknowledged by both parties.

- Set up regular check-ins: Schedule periodic updates to stay informed about the order progress and address any concerns promptly.

By following this checklist, international buyers can effectively navigate the sourcing process with Douglas Corporation, ensuring they receive high-quality products tailored to their needs.

Comprehensive Cost and Pricing Analysis for douglas corp eden prairie Sourcing

When considering sourcing from Douglas Corporation in Eden Prairie, it’s essential to understand the various cost components that contribute to the overall pricing structure. This analysis will provide insights into the elements that affect pricing and offer strategic tips for international B2B buyers.

What Are the Key Cost Components in Sourcing from Douglas Corporation?

-

Materials: The choice of materials significantly influences costs. Douglas Corporation utilizes various resins and advanced materials for products like nameplates and membrane switches. Higher quality materials may result in increased durability and performance, justifying a higher price point. Buyers should assess the long-term benefits of investing in premium materials versus lower-cost alternatives.

-

Labor: Labor costs are a crucial factor in the manufacturing process. Given that Douglas maintains multiple facilities in Minnesota, labor costs reflect the region’s wage standards. Skilled labor is essential for the intricate design and manufacturing processes, particularly for customized solutions. Understanding labor cost implications can help buyers evaluate the value proposition of Douglas’s offerings.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Douglas Corporation’s investment in state-of-the-art manufacturing technology contributes to efficient production but also influences overhead costs. Buyers should consider how these factors may impact pricing.

-

Tooling: Custom tooling requirements for specific projects can add to upfront costs. Douglas Corporation’s capabilities in in-house tooling allow for tailored solutions but may involve higher initial investment. It’s advisable for buyers to clarify tooling costs during negotiations, especially for large-scale projects.

-

Quality Control (QC): Douglas Corporation is ISO 9001 certified, ensuring that rigorous quality standards are met. The costs associated with quality assurance processes are integral to the pricing structure. Buyers should recognize that investments in quality control can lead to fewer defects and lower total costs over time.

-

Logistics: Shipping and logistics costs can vary significantly based on the location of the buyer and chosen Incoterms. For international buyers, understanding the logistics involved in transporting goods from the U.S. to their countries is essential for accurate cost estimation.

-

Margin: Douglas Corporation’s pricing will also include a profit margin that reflects the company’s operational costs and market positioning. Buyers should be prepared to discuss margins during negotiations, particularly when placing large orders or establishing long-term partnerships.

What Influences Pricing for B2B Buyers?

Several factors can influence the final pricing offered to international buyers:

-

Volume/MOQ: Higher order volumes typically lead to lower per-unit costs. Buyers should inquire about minimum order quantities (MOQs) and the pricing structure related to volume discounts.

-

Specifications/Customization: Custom projects will generally incur additional costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Material Quality and Certifications: The level of material quality and compliance with industry standards can affect pricing. Buyers from regulated industries must ensure that the products meet necessary certifications, which may come at a premium.

-

Supplier Factors: Reliability, reputation, and service levels of the supplier can also influence pricing. A supplier with a track record of delivering quality products may justify higher costs.

-

Incoterms: The chosen Incoterms will dictate responsibilities for shipping, insurance, and tariffs, impacting the total landed cost. Buyers should familiarize themselves with these terms to make informed decisions.

What Are the Best Practices for Negotiating with Douglas Corporation?

-

Leverage Total Cost of Ownership (TCO): When negotiating, focus on the TCO rather than just the initial price. Highlighting potential savings from quality and durability can strengthen your position.

-

Build Long-Term Relationships: Establishing a solid relationship with Douglas Corporation can lead to better pricing and terms over time. Consider committing to long-term contracts for favorable rates.

-

Be Transparent About Needs: Clearly communicating your requirements and constraints can facilitate better pricing negotiations. Suppliers appreciate when buyers are upfront about their budgets and timelines.

Conclusion

Understanding the comprehensive cost and pricing structure of Douglas Corporation in Eden Prairie is crucial for international B2B buyers. By considering the various cost components and price influencers, buyers can make informed decisions that align with their business objectives. Always remember to negotiate effectively, focusing on the long-term value rather than just the upfront costs.

Illustrative image related to douglas corp eden prairie

Alternatives Analysis: Comparing douglas corp eden prairie With Other Solutions

In the competitive landscape of product graphics and electronic interface components, businesses often seek alternatives to meet their unique requirements. Douglas Corp Eden Prairie is a well-established manufacturer known for its high-quality nameplates, membrane switches, and graphic overlays. However, understanding other available options can provide valuable insights for international B2B buyers looking for tailored solutions that fit their specific needs. Below, we compare Douglas Corp with two viable alternatives: Membrane Switch Solutions Inc. and Graphic Overlay Technologies.

| Comparison Aspect | Douglas Corp Eden Prairie | Membrane Switch Solutions Inc. | Graphic Overlay Technologies |

|---|---|---|---|

| Performance | High durability and reliability | Excellent customizability | Versatile design options |

| Cost | Competitive pricing for quality | Moderate pricing with added features | Generally higher due to customization |

| Ease of Implementation | Streamlined process with support | Requires detailed specifications | User-friendly interface design |

| Maintenance | Low maintenance with high quality | Regular checks recommended | Minimal maintenance |

| Best Use Case | OEMs needing durable graphics | Custom applications in electronics | Aesthetic and functional overlays |

How Does Membrane Switch Solutions Inc. Compare?

Membrane Switch Solutions Inc. specializes in creating highly customizable membrane switches for various industries, including medical and aerospace. Their key strength lies in their ability to tailor products to specific customer needs, which can enhance user experience significantly. However, the customization process can lead to longer lead times and requires precise specifications, making it less suitable for projects with tight deadlines. The pricing is moderate, often reflecting the added features and custom work involved, which may not be ideal for budget-sensitive projects.

What About Graphic Overlay Technologies?

Graphic Overlay Technologies focuses on delivering versatile and aesthetically pleasing graphic overlays that can be integrated into various devices. Their design options are extensive, allowing for unique branding opportunities that can set a product apart. However, this level of customization often comes at a higher price point, which might not be feasible for all businesses. Additionally, while their products are user-friendly, they may require more frequent updates to stay aligned with technological advancements, leading to higher maintenance costs over time.

Conclusion: Which Solution Should a B2B Buyer Choose?

When evaluating alternatives to Douglas Corp Eden Prairie, B2B buyers should consider their specific needs, including performance requirements, budget constraints, and the desired level of customization. Douglas Corp offers a strong balance of durability and cost-effectiveness, making it a solid choice for OEMs focused on high-quality graphics. Conversely, if customization and aesthetic flexibility are paramount, exploring options like Membrane Switch Solutions Inc. or Graphic Overlay Technologies may provide the necessary features. Ultimately, the right solution will depend on the unique demands of the project and the strategic goals of the business.

Essential Technical Properties and Trade Terminology for douglas corp eden prairie

What Are the Essential Technical Properties of Douglas Corp’s Products?

Understanding the technical properties of Douglas Corporation’s offerings is vital for international B2B buyers, especially those in markets such as Africa, South America, the Middle East, and Europe. Here are some critical specifications that can influence purchasing decisions:

-

Material Grade: Douglas Corporation utilizes various material grades, including high-quality plastics and metals, for its nameplates, membrane switches, and graphic overlays. The choice of material affects durability, aesthetics, and cost. For instance, electroplated metals provide a premium look but may have higher costs compared to standard plastics. Buyers should assess material properties to align with their product requirements and branding.

-

Tolerance Levels: Tolerance refers to the allowable deviation in dimensions during manufacturing. For components like membrane switches, precise tolerances (often within ±0.1 mm) are essential for functionality and integration with other parts. Understanding tolerance levels ensures that components fit correctly and function as intended, reducing the risk of product failures and enhancing customer satisfaction.

-

Durability Standards: Douglas Corporation products are designed to withstand various environmental conditions, which is critical for industries like medical and aerospace. Buyers should inquire about durability standards such as abrasion resistance, UV stability, and moisture resistance. These factors influence the lifespan and performance of the products, making them essential for long-term investment.

-

Design Flexibility: The company offers customizable solutions tailored to specific client needs, which is vital for OEMs seeking unique branding or functionality. Design flexibility includes options for graphics, layouts, and materials, allowing buyers to create products that align with their market requirements and consumer preferences.

-

Certifications: Douglas Corporation is ISO 9001:2015 certified, indicating adherence to rigorous quality management standards. For B2B buyers, certifications are a mark of reliability and quality assurance, providing confidence that the products meet international standards.

-

Production Capacity: Understanding the production capacity and lead times is essential for managing supply chain logistics. Douglas Corporation’s ability to scale production efficiently can help international buyers meet their market demands without delays.

What Are Common Trade Terminology and Jargon Relevant to Douglas Corp?

Navigating the world of B2B procurement requires familiarity with specific industry terms. Here are some key terms that are particularly relevant for buyers engaging with Douglas Corporation:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of Douglas Corporation, OEMs rely on their high-quality nameplates and membrane switches for their products, emphasizing the importance of reliable partnerships in product development.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest number of units a buyer can purchase from a supplier. Understanding MOQs is crucial for budget management and inventory planning, especially for international buyers who may need to consider shipping costs and storage capacities.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers requesting pricing and details for specific products or services. For buyers looking to procure Douglas Corporation products, issuing an RFQ can facilitate competitive pricing and ensure that all specifications are met.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping arrangements, risk allocation, and cost responsibilities.

-

Lead Time: This term refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for planning production schedules and managing customer expectations, particularly in industries that require just-in-time manufacturing.

-

Prototyping: This is the process of creating an early sample of a product to test concepts and functionality. Douglas Corporation offers rapid prototyping services, allowing buyers to visualize and test designs before full-scale production, which can significantly reduce time to market.

By familiarizing themselves with these properties and terms, international B2B buyers can make informed decisions when engaging with Douglas Corporation, ensuring that their procurement processes are efficient and effective.

Navigating Market Dynamics and Sourcing Trends in the douglas corp eden prairie Sector

What Are the Current Market Dynamics and Trends Affecting Douglas Corp in Eden Prairie?

The Douglas Corporation, based in Eden Prairie, Minnesota, operates in a dynamic market characterized by rapid technological advancements and changing consumer expectations. As global manufacturing evolves, there is an increasing demand for high-quality, customizable product graphics, nameplates, and membrane switches, particularly among Original Equipment Manufacturers (OEMs) across diverse sectors such as medical devices, aerospace, and consumer electronics. International buyers, especially from regions like Africa, South America, the Middle East, and Europe (notably Germany and Brazil), are increasingly seeking suppliers that can offer both innovation and cost-effectiveness.

Illustrative image related to douglas corp eden prairie

Emerging trends include the integration of smart technology in product graphics, such as touch-sensitive overlays and interactive displays, which enhance user experience and functionality. Additionally, the rise of e-commerce and global supply chains necessitates a more agile approach to sourcing, emphasizing the need for manufacturers like Douglas to adapt quickly to changing market demands. The shift toward digital solutions, including online ordering and real-time inventory management, further supports international buyers looking for efficiency and transparency in their procurement processes.

How Does Sustainability Influence B2B Sourcing Decisions in the Douglas Corp Sector?

Sustainability has become a crucial consideration for B2B buyers in today’s market. Companies are increasingly aware of their environmental impact and the importance of ethical supply chains. For Douglas Corporation, this means prioritizing sustainable practices in both manufacturing and sourcing. The use of eco-friendly materials, such as recycled plastics and low-VOC (volatile organic compound) inks, not only minimizes environmental impact but also meets the growing demand for “green” certifications among international buyers.

Additionally, ethical sourcing practices are critical for maintaining brand reputation and customer loyalty. Buyers from regions like Europe and North America often prefer suppliers who adhere to stringent environmental standards and demonstrate corporate social responsibility. Douglas Corporation’s commitment to quality and sustainability aligns with these values, making it a compelling choice for international partners seeking to enhance their own sustainability initiatives.

How Has Douglas Corp Evolved to Meet the Needs of International B2B Buyers?

Founded in 1933, Douglas Corporation has a long history of innovation and adaptability in the manufacturing sector. Initially focused on traditional nameplate manufacturing, the company has evolved its product offerings to include advanced membrane switches and graphic overlays, catering to the needs of modern OEMs. This evolution reflects broader market trends, including the shift towards digital interfaces and the increasing complexity of consumer electronics.

The company’s dedication to quality is underscored by its ISO 9001 certification, ensuring that its products meet rigorous standards. With multiple manufacturing facilities located strategically in Minnesota, Douglas is well-positioned to serve international markets efficiently. This historical foundation, combined with a commitment to continuous improvement and customer satisfaction, has solidified Douglas Corporation’s reputation as a reliable partner for B2B buyers across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of douglas corp eden prairie

-

How do I ensure quality when sourcing from Douglas Corporation?

To guarantee quality, you should review Douglas Corporation’s certifications, such as ISO 9001:2015, which signifies adherence to international quality management standards. Request samples to assess product quality firsthand and inquire about their quality assurance processes. Establishing clear communication regarding your specifications and expectations will help ensure that the final product meets your requirements. -

What customization options are available for products from Douglas Corporation?

Douglas Corporation offers extensive customization for its products, including membrane switches and graphic overlays. You can work with their design team to tailor layouts, materials, and functionalities to suit your specific needs. It’s beneficial to discuss your design requirements early in the process to leverage their engineering expertise for optimal results. -

What are the minimum order quantities (MOQs) for products?

Minimum order quantities at Douglas Corporation can vary based on the specific product and customization requirements. Generally, they offer flexibility to accommodate both small and large orders. It’s advisable to contact their sales team directly to discuss your needs and receive precise information regarding MOQs for the products you are interested in. -

What payment terms does Douglas Corporation offer for international buyers?

Douglas Corporation typically provides various payment options for international transactions, including wire transfers and letters of credit. Payment terms may vary based on the order size and the buyer’s location. Discussing payment terms during the initial negotiations is essential to ensure clarity and mutual agreement before finalizing the order. -

How does Douglas Corporation handle logistics and shipping for international orders?

Douglas Corporation collaborates with reliable logistics partners to facilitate international shipping. They can provide different shipping options, including air and sea freight, depending on your urgency and budget. It’s advisable to clarify shipping costs, delivery timelines, and customs documentation during your order discussions to ensure a smooth logistics process. -

What industries does Douglas Corporation primarily serve?

Douglas Corporation serves a diverse range of industries, including medical devices, aerospace, industrial machinery, and consumer electronics. Their expertise in producing high-quality nameplates and membrane switches makes them a preferred supplier for OEM manufacturers worldwide. Identifying your industry-specific needs can help you leverage their tailored solutions effectively. -

How can I vet Douglas Corporation as a reliable supplier?

To vet Douglas Corporation, consider researching their history, customer reviews, and industry reputation. Request references from current clients and evaluate case studies that showcase their work. Additionally, visiting their facilities, if possible, can provide insight into their manufacturing capabilities and quality control processes. -

What support does Douglas Corporation provide for product development?

Douglas Corporation offers comprehensive design and engineering support to assist clients throughout the product development process. Their team can help with rapid prototyping, testing, and certification services to ensure compliance with industry standards. Engaging with their engineers early on can facilitate a smoother development process and lead to better product outcomes.

Top 4 Douglas Corp Eden Prairie Manufacturers & Suppliers List

1. Douglas Corporation – Product Graphics Solutions

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: Douglas Corporation produces product graphics for original equipment manufacturers, providing nameplates, membrane switches, graphic overlays, and decorative trim. The company serves various industries including industrial, vehicular, marine, electronic, appliance, recreational, medical, communications, and packaging.

2. Douglas Corporation – Name Plates & Switches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Douglas Corporation specializes in functional and unique name plates, electric switches, and membrane switches. They offer a variety of design options including vibrant colors, chrome plating, and classic patterns like marble and granite. Their nameplates feature high impact strength with multi-dimensional looks, including domed urocals with a liquid jewel appearance. They have over 30 years of ex…

3. Douglas Corporation – Product Identification Solutions

Domain: cascade-partners.com

Registered: 2012 (13 years)

Introduction: Douglas Corporation is a leading designer and manufacturer of product identification and user interface products for the automotive, truck, marine, agriculture, and construction industries. Their products include OEM badges, emblems, and nameplates; polyurethane decals and domed urocals; membrane switches and graphic overlays; and decorative trim. Douglas has proprietary paint-on-chrome capabiliti…

4. Douglas Corporation – PFAS Settlement

Domain: kstp.com

Registered: 1996 (29 years)

Introduction: Douglas Corporation agreed to a $1.375 million settlement with the Minnesota Pollution Control Agency and the Minnesota Department of Natural Resources for damage caused by per- and polyfluoroalkyl substances (PFAS) and hexavalent chromium that contaminated multiple metro area lakes, including Bass Lake, Bde Maka Ska, and Lake Harriet. At least $1 million of the settlement will fund projects aimed…

Strategic Sourcing Conclusion and Outlook for douglas corp eden prairie

In the evolving landscape of global manufacturing, Douglas Corporation in Eden Prairie stands out as a beacon of quality and innovation. By focusing on customized solutions for product graphics, membrane switches, and other electronic interface components, Douglas has established itself as a trusted partner for OEM manufacturers worldwide. Their commitment to high standards, evidenced by ISO certifications and advanced manufacturing capabilities, ensures that international buyers receive not only superior products but also the reliability necessary for their business operations.

Strategic sourcing with Douglas Corporation offers significant advantages, including access to cutting-edge technology, a diverse range of products, and unparalleled design support. Buyers from Africa, South America, the Middle East, and Europe can leverage these strengths to enhance their product offerings and meet market demands effectively.

As you consider your sourcing strategies, remember that partnering with a company like Douglas Corporation can elevate your brand presence and operational efficiency. We encourage you to reach out for personalized consultations and explore how Douglas can meet your unique needs, paving the way for a successful collaboration in the global marketplace. Embrace the opportunity to innovate and grow with a partner that understands the power of image and function.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.