A B2B Buyer’s Guide to Dippin Dots Maker: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for dippin dots maker

In the dynamic landscape of the frozen dessert industry, sourcing a Dippin’ Dots maker presents unique challenges for international B2B buyers. Whether you’re operating a bustling amusement park in Brazil or a trendy café in Vietnam, understanding the nuances of these innovative machines is crucial to meeting consumer demand for unique, high-quality frozen treats. This guide is meticulously crafted to navigate the complexities of selecting the right Dippin’ Dots maker, addressing key factors such as types of machines, their applications, supplier vetting processes, and cost considerations.

As an international buyer, you face the challenge of ensuring that your investment not only meets local taste preferences but also complies with regional regulations. This comprehensive resource empowers you to make informed purchasing decisions by providing insights into the various types of Dippin’ Dots makers available, their operational efficiencies, and how to effectively assess suppliers. From understanding the production capabilities to analyzing flavor offerings and serving sizes, this guide equips you with the essential knowledge to enhance your business’s competitive edge in the frozen dessert market.

By leveraging this information, B2B buyers from Africa, South America, the Middle East, and Europe can confidently navigate the global market, ensuring they select the right equipment to delight their customers and drive profitability.

Understanding dippin dots maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Dippin’ Dots Maker | High production capacity, consistent dot size, integrated cooling | Amusement parks, ice cream shops | Pros: High efficiency, reliable output. Cons: Higher initial investment. |

| Home Dippin’ Dots Maker | Smaller, user-friendly design, limited production | Family entertainment, small events | Pros: Affordable, easy to use. Cons: Low output, less durable. |

| Mobile Dippin’ Dots Cart | Portable, compact design, customizable branding options | Festivals, outdoor events, catering | Pros: Flexible location, brand visibility. Cons: Requires setup and transport. |

| Industrial Dippin’ Dots Equipment | Large-scale production, advanced freezing technology | Large-scale food manufacturers | Pros: High volume, consistent quality. Cons: Significant space and power requirements. |

| DIY Dippin’ Dots Kit | Basic components for home use, includes molds and tools | Educational settings, home use | Pros: Cost-effective, fun for kids. Cons: Limited flavor options, inconsistent results. |

What Are the Key Features of Commercial Dippin’ Dots Makers?

Commercial Dippin’ Dots makers are designed for high-volume production, making them ideal for businesses such as amusement parks and ice cream shops. These machines ensure consistent dot size and quality through integrated cooling systems that rapidly freeze the mixture. When considering a purchase, B2B buyers should evaluate production capacity, maintenance requirements, and warranty options to ensure they meet customer demand efficiently.

How Do Home Dippin’ Dots Makers Differ?

Home Dippin’ Dots makers are smaller, user-friendly devices intended for personal use or small gatherings. They typically allow users to create frozen treats with various liquids, such as juices and sodas. While they are affordable and easy to operate, the output is limited, making them less suitable for commercial applications. B2B buyers in the family entertainment sector may find these useful for enhancing customer experiences at small events.

Why Choose a Mobile Dippin’ Dots Cart?

Mobile Dippin’ Dots carts offer flexibility for businesses wanting to serve frozen treats at festivals, outdoor events, or catering services. These carts are portable and can be customized with branding, providing visibility while serving customers. However, they require setup and transportation logistics that B2B buyers must consider, along with local regulations for food service.

What Advantages Do Industrial Dippin’ Dots Equipment Offer?

Industrial Dippin’ Dots equipment is designed for large-scale food manufacturers looking to produce high volumes of frozen treats efficiently. These machines utilize advanced freezing technology to maintain quality and consistency. B2B buyers should consider the significant space and power requirements, as well as the potential return on investment through high output and reduced labor costs.

How Do DIY Dippin’ Dots Kits Work?

DIY Dippin’ Dots kits provide a fun, interactive way to make frozen treats at home, often appealing to educational settings or family activities. These kits usually include molds and basic tools for creating the dots, but they may offer limited flavor options and result in inconsistent quality. B2B buyers should assess their target audience’s interest in hands-on experiences versus the desire for high-quality products.

Key Industrial Applications of dippin dots maker

| Industry/Sector | Specific Application of Dippin’ Dots Maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Theme Parks and Amusement Parks | Enhances customer experience with unique treats | Consider flavor variety, ease of use, and maintenance requirements. |

| Retail and Grocery | Pop-Up Shops and Seasonal Stands | Attracts foot traffic and boosts sales | Evaluate packaging options and supply chain logistics for consistency. |

| Hospitality and Catering | Events and Banquet Services | Provides a fun and interactive dessert option | Look for customization capabilities and bulk supply options. |

| Education and Childcare | Schools and Daycare Centers | Offers a creative snack that appeals to children | Ensure compliance with nutritional standards and allergy considerations. |

| Franchise Opportunities | Dippin’ Dots Franchises | Expands brand recognition and market presence | Assess franchise support, training, and equipment reliability. |

How Can Dippin’ Dots Makers Enhance Theme Parks and Amusement Parks?

In the food and beverage sector, particularly within theme and amusement parks, the Dippin’ Dots maker can be utilized to create unique frozen treats that enhance the overall customer experience. These parks thrive on providing memorable experiences, and offering customizable frozen treats can attract more visitors. Businesses should consider the variety of flavors and ease of operation, ensuring the equipment can handle high foot traffic while maintaining quality.

What Role Do Dippin’ Dots Makers Play in Retail and Grocery Pop-Up Shops?

Retailers and grocery stores can leverage Dippin’ Dots makers in pop-up shops or seasonal stands to draw attention and increase sales. The novelty of Dippin’ Dots can entice customers, especially during peak seasons. When sourcing, businesses should assess packaging options that facilitate quick service and consider logistics for consistent supply to meet demand.

How Can Dippin’ Dots Makers Benefit Hospitality and Catering Services?

In the hospitality sector, particularly for events and banquets, Dippin’ Dots makers can provide a fun and interactive dessert option. This can elevate the dining experience at weddings, corporate events, and parties, making them more memorable. Buyers should look for customization options that allow for tailored flavors and themes, as well as bulk supply capabilities to meet large guest counts.

Why Are Dippin’ Dots Makers Important for Schools and Daycare Centers?

For educational institutions and daycare centers, offering Dippin’ Dots as a snack can be a creative way to engage children and promote healthier eating habits. These frozen treats can be a fun alternative to traditional snacks, appealing to kids’ preferences. Buyers in this sector must ensure that the products meet nutritional standards and consider allergy concerns when selecting flavors.

How Do Dippin’ Dots Makers Support Franchise Opportunities?

Franchise opportunities centered around Dippin’ Dots can significantly enhance brand recognition and market presence. Entrepreneurs can capitalize on the established popularity of Dippin’ Dots while providing a unique product offering. Key considerations for potential franchisees include the level of support provided by the franchisor, training programs, and the reliability of the equipment to ensure consistent quality and service.

3 Common User Pain Points for ‘dippin dots maker’ & Their Solutions

Scenario 1: Difficulty in Achieving Desired Product Consistency

The Problem: One of the primary challenges B2B buyers face when utilizing the Dippin’ Dots maker is achieving the desired consistency and texture of the final product. Users often report that the homemade dots do not resemble the iconic Dippin’ Dots they know and love. This discrepancy can lead to customer dissatisfaction, especially in a competitive food service environment where product quality is paramount. Additionally, the lack of specific guidance on ratios and preparation methods often leaves buyers frustrated, as they struggle to replicate the unique experience of Dippin’ Dots.

The Solution: To overcome this issue, B2B buyers should invest in thorough training for their staff on the correct usage of the Dippin’ Dots maker. This includes understanding the importance of ingredient quality and the right temperature settings during the freezing process. Suppliers can provide sample recipes and detailed instruction manuals that focus on achieving the right consistency. Regularly testing different mixtures and freezing times can help fine-tune the process. Moreover, establishing a feedback loop with customers can provide valuable insights into preferences, allowing businesses to adjust their offerings accordingly. By prioritizing training and consistent experimentation, businesses can enhance product quality and customer satisfaction.

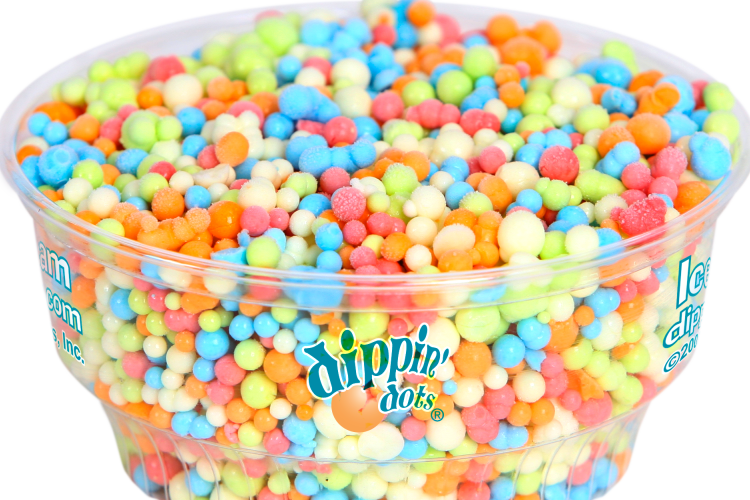

Illustrative image related to dippin dots maker

Scenario 2: Inefficiency in Production and Workflow

The Problem: Many businesses find that the Dippin’ Dots maker can be a bottleneck in their production workflow. The process of preparing the dots, freezing them, and then serving can be time-consuming, particularly during peak hours. This inefficiency can lead to longer wait times for customers, negatively impacting the overall experience and potentially resulting in lost sales.

The Solution: To address production inefficiencies, B2B buyers should consider implementing a streamlined workflow that optimizes the use of the Dippin’ Dots maker. This can involve preparing larger batches in advance and utilizing efficient storage solutions to keep the product ready for service. Additionally, investing in multiple machines can significantly increase production capacity during busy times. Collaborating with suppliers for bulk purchasing of raw materials can also help ensure that the necessary ingredients are always on hand, reducing downtime. Finally, training staff on quick and efficient serving techniques can further enhance productivity and customer satisfaction.

Scenario 3: Limited Flavor Options and Innovation

The Problem: A common pain point for businesses using the Dippin’ Dots maker is the limited flavor options available. Many buyers find that the standard flavors do not attract a diverse customer base, leading to stagnation in sales. Additionally, the challenge of creating new and exciting flavors can be daunting, especially without proper guidance or resources.

The Solution: To tackle the issue of flavor variety, B2B buyers should actively engage in flavor experimentation and innovation. This can involve gathering customer feedback to identify popular flavors or trends within the market. Businesses can collaborate with flavor specialists or suppliers who can provide insights into trending tastes and seasonal flavors. Furthermore, hosting tasting events can help gauge customer interest in potential new offerings before launching them. Implementing a limited-time flavor promotion can also create excitement and encourage customers to try new products. By embracing creativity and customer input, businesses can keep their offerings fresh and appealing, ultimately boosting sales and customer loyalty.

Illustrative image related to dippin dots maker

Strategic Material Selection Guide for dippin dots maker

What Materials Are Commonly Used in Dippin’ Dots Makers?

When selecting materials for Dippin’ Dots makers, several factors influence performance, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these machines, focusing on their properties, advantages and disadvantages, and considerations for international buyers.

Stainless Steel: The Durable Choice for Food Equipment

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating that can handle the freezing processes involved in making Dippin’ Dots.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for food applications. However, it can be more expensive than other materials and may require specialized manufacturing processes, which could increase production costs.

Impact on Application: Stainless steel is compatible with various food media, ensuring that it does not impart any flavors or contaminants into the product. It is also easy to clean, which is essential in food production.

Illustrative image related to dippin dots maker

Considerations for International Buyers: Compliance with food safety standards (like FDA or EU regulations) is crucial. Buyers from regions such as Africa and South America should ensure that the stainless steel used meets local health regulations and standards like ASTM or DIN.

Plastic: A Cost-Effective Alternative

Key Properties: High-density polyethylene (HDPE) and polypropylene are common plastics used in Dippin’ Dots makers. They offer good impact resistance and can withstand low temperatures, although they are not as heat-resistant as metals.

Pros & Cons: The primary advantage of plastic is its lower cost and lightweight nature, which can reduce shipping expenses. However, plastics can be less durable over time and may not withstand extreme conditions as well as metals.

Impact on Application: Plastic components can be effective in non-critical areas of the machine, such as trays and dispensers. However, they may not be suitable for parts that require high strength or thermal stability.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with food safety standards and are free from harmful chemicals. Additionally, understanding local recycling regulations is essential for sustainability.

Aluminum: Lightweight and Versatile

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can be easily machined. It typically has a lower melting point than stainless steel, making it suitable for various applications.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can reduce shipping costs. However, it is less durable than stainless steel and may require additional coatings to improve corrosion resistance.

Impact on Application: Aluminum can be used in areas where weight savings are crucial, such as portable Dippin’ Dots makers. However, it may not be ideal for components subjected to extreme cold or high pressure.

Considerations for International Buyers: Buyers should verify that the aluminum used meets international standards for food safety and corrosion resistance. Understanding local market preferences for lightweight versus heavy-duty equipment can also influence purchasing decisions.

Silicone: Flexibility in Design

Key Properties: Silicone is flexible, heat-resistant, and can withstand extreme temperatures. It is often used in trays and molds for its non-stick properties.

Pros & Cons: The flexibility of silicone allows for easy removal of frozen dots, making it user-friendly. However, it may not be as durable as other materials and can degrade over time if not properly maintained.

Impact on Application: Silicone is particularly useful in areas where easy release of the product is necessary. Its non-stick properties can enhance the user experience but may limit its use in structural components.

Considerations for International Buyers: Buyers should ensure that the silicone used is food-grade and complies with relevant health regulations. Additionally, understanding local preferences for materials can guide purchasing decisions.

Summary Table of Material Selection for Dippin’ Dots Makers

| Material | Typical Use Case for dippin dots maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Trays and dispensers | Cost-effective and lightweight | Less durable over time | Low |

| Aluminum | Portable components | Lightweight and versatile | Less durable than stainless steel | Medium |

| Silicone | Molds and trays | Flexibility and non-stick properties | May degrade over time | Medium |

This analysis provides B2B buyers with actionable insights into material selection for Dippin’ Dots makers, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dippin dots maker

What Are the Main Stages in the Manufacturing Process of a Dippin’ Dots Maker?

The manufacturing process for a Dippin’ Dots maker involves several critical stages, each designed to ensure the highest quality and functionality of the final product. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials that meet industry standards. Stainless steel and durable plastics are often preferred for their resistance to corrosion and ease of cleaning. Suppliers should provide material certifications to ensure compliance with safety and health regulations.

-

Forming: During this phase, raw materials are shaped into various components of the Dippin’ Dots maker using techniques such as injection molding and die casting. Injection molding is particularly beneficial for creating intricate shapes and designs, ensuring that parts fit together seamlessly.

-

Assembly: Once all components are formed, they are assembled into the final product. This stage may involve both manual and automated processes, depending on the scale of production. Skilled workers ensure that each part is correctly positioned and secured, which is vital for the operational efficiency of the machine.

-

Finishing: The final stage includes surface treatments, such as polishing and coating, to enhance durability and aesthetic appeal. A thorough cleaning process is also conducted to remove any residues from manufacturing, ensuring the product is ready for consumer use.

How Is Quality Assurance Implemented in the Manufacturing of Dippin’ Dots Makers?

Quality assurance (QA) is a crucial aspect of manufacturing, particularly for products that will be widely distributed. For Dippin’ Dots makers, implementing QA practices involves adhering to international standards and conducting various quality checks throughout the production process.

-

International Standards Compliance: Manufacturers typically aim to comply with ISO 9001, an internationally recognized standard for quality management systems. This certification demonstrates a commitment to quality and continuous improvement, which can be a deciding factor for B2B buyers.

-

Industry-Specific Standards: In addition to general quality standards, Dippin’ Dots makers may need to meet specific industry regulations such as CE marking for safety and compliance in Europe, and API standards for food-grade machinery. Understanding these standards can help B2B buyers identify reliable suppliers.

-

Quality Checkpoints: Quality control is implemented at several checkpoints during the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection ensures that all raw materials meet specified standards before they enter the production line.

– In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to catch any defects early. This can include monitoring the accuracy of machinery and ensuring that assembly processes are followed correctly.

– Final Quality Control (FQC): Before the product is packaged and shipped, a final inspection is performed to ensure that the Dippin’ Dots maker meets all quality criteria, including functionality and safety.

What Testing Methods Are Commonly Used to Ensure Product Quality?

To assure B2B buyers of the Dippin’ Dots maker’s quality, various testing methods are employed. These methods help to validate that the product operates as intended and meets regulatory requirements.

-

Functional Testing: This involves running the Dippin’ Dots maker to ensure it produces the desired product consistently and efficiently. Functional tests may include measuring the freezing time and the size of the frozen dots produced.

-

Safety Testing: Compliance with safety standards is critical, especially for machinery intended for food production. Safety tests may include electrical safety assessments and checks for mechanical hazards.

-

Durability Testing: Manufacturers often conduct stress tests to determine how the machine holds up under prolonged use. This may include simulating high-volume production scenarios to ensure reliability.

-

Hygiene Testing: Given that the Dippin’ Dots maker is a food-related device, hygiene testing is essential. This involves checking for any contaminants and ensuring that materials used in the product can withstand regular cleaning and sanitization.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. This is crucial to ensure that the Dippin’ Dots makers they are purchasing meet the expected standards.

-

Supplier Audits: Conducting on-site audits can provide firsthand insights into the supplier’s manufacturing processes and quality control systems. Buyers should check for certifications, inspect the production line, and review the quality control documentation.

-

Quality Control Reports: Requesting detailed quality control reports from suppliers can help assess their commitment to quality. These reports should outline inspection results, testing methodologies, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of verification. These independent organizations can assess the supplier’s adherence to quality standards and provide unbiased reports to buyers.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International B2B buyers must navigate additional complexities when it comes to quality control, particularly when sourcing from regions such as Africa, South America, the Middle East, and Europe.

-

Regulatory Differences: Different countries have varying regulations regarding product safety and quality. Buyers must be familiar with local laws and ensure that suppliers comply with them.

-

Cultural and Language Barriers: Communication can sometimes hinder the quality assurance process. Buyers should establish clear lines of communication and consider using translators or local representatives to facilitate discussions.

-

Shipping and Logistics: Quality control doesn’t end at production. Buyers should consider how the products are packaged and shipped to prevent damage during transit. This includes ensuring that the machinery is adequately protected and that shipping conditions meet any relevant standards.

-

Post-Purchase Support: Understanding the supplier’s ability to provide ongoing support and service is essential. This includes warranty terms, spare parts availability, and access to customer service for troubleshooting any issues that may arise post-purchase.

By thoroughly understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions and ensure they source high-quality Dippin’ Dots makers for their businesses.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dippin dots maker’

To assist B2B buyers in sourcing a Dippin’ Dots maker effectively, this guide provides a practical checklist that emphasizes critical steps in the procurement process. This ensures that buyers can make informed decisions, maximizing their investment and operational efficiency.

Illustrative image related to dippin dots maker

Step 1: Define Your Technical Specifications

Before starting the sourcing process, clearly outline the technical specifications you require from a Dippin’ Dots maker. This includes production capacity, size, and types of products it can produce. Knowing these details will help you filter suppliers who meet your operational needs and avoid wasting time on unsuitable options.

Step 2: Research Market Trends and Demand

Understanding current market trends and consumer demand for Dippin’ Dots is crucial. Investigate what flavors or varieties are popular and how they can influence your product offerings. This insight will guide your purchasing decisions and help you align your inventory with market preferences, ensuring better sales potential.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before committing to a purchase. Request company profiles, product certifications, and case studies that demonstrate their experience in the industry. Look for reviews or references from businesses in similar markets, as this can provide insight into their reliability and product quality.

- Tip: Consider suppliers who have a proven track record in your region to ensure they understand local regulations and market dynamics.

Step 4: Check for Compliance and Certifications

Verify that the suppliers comply with local health and safety regulations and have the necessary certifications for food processing equipment. Compliance is essential not only for legal reasons but also for maintaining product quality and safety standards.

Illustrative image related to dippin dots maker

- Consider: Certificates such as ISO 9001 or specific food safety certifications can indicate a supplier’s commitment to quality.

Step 5: Request Samples and Conduct Testing

Before finalizing your order, request samples of the Dippin’ Dots maker to test its performance. This allows you to evaluate the product firsthand, ensuring it meets your expectations in terms of functionality and output quality. Testing is particularly important if you are considering different models or suppliers.

Step 6: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms and pricing. Consider factors such as bulk order discounts, payment terms, and warranty provisions. Clear agreements on these aspects can lead to significant savings and ensure a smooth purchasing experience.

Step 7: Plan for Logistics and After-Sales Support

Consider the logistics involved in receiving and installing the Dippin’ Dots maker. Discuss shipping options, delivery times, and installation support with the supplier. Additionally, inquire about after-sales service and technical support, as this will be vital for troubleshooting and maintenance once the equipment is operational.

By following this checklist, B2B buyers can effectively navigate the sourcing process for a Dippin’ Dots maker, ensuring they select a product that aligns with their business objectives and market demands.

Comprehensive Cost and Pricing Analysis for dippin dots maker Sourcing

When evaluating the cost and pricing structure for sourcing a Dippin’ Dots maker, it is essential to understand the various components that contribute to the overall expense. This analysis will provide actionable insights for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, enabling them to make informed purchasing decisions.

Illustrative image related to dippin dots maker

What Are the Key Cost Components in Dippin’ Dots Maker Production?

-

Materials: The primary materials for a Dippin’ Dots maker include high-quality plastics, stainless steel components, and electronic parts. The cost of these materials can vary based on market fluctuations and the quality standards required for food safety. Buyers should consider sourcing from regions with lower material costs without compromising quality.

-

Labor: Labor costs encompass the wages for skilled workers involved in the assembly of the machines. Regions with lower labor costs can significantly impact the final pricing. However, it is crucial to ensure that labor is skilled enough to maintain production standards.

-

Manufacturing Overhead: This includes utilities, rent, and other operational costs associated with the manufacturing facility. Buyers should look for suppliers who optimize their overhead costs, as this can lead to more competitive pricing.

-

Tooling: The initial investment in tooling and molds can be substantial, especially for custom designs. Buyers should inquire about the tooling costs and whether these can be amortized over larger orders, thus reducing per-unit costs.

-

Quality Control (QC): Ensuring the safety and quality of the machines is vital, particularly for food-related equipment. QC processes can add to costs, but they are essential for maintaining product integrity and meeting regulatory standards.

-

Logistics: Shipping and handling costs must also be factored in. This includes freight charges, customs duties, and insurance. Choosing suppliers that offer favorable Incoterms can help manage logistics expenses effectively.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the margin expectations can aid buyers in negotiating better prices.

How Do Price Influencers Affect the Sourcing of Dippin’ Dots Makers?

-

Volume and Minimum Order Quantity (MOQ): Pricing often improves with higher order volumes. Buyers should assess their demand to negotiate better rates based on expected order sizes.

-

Specifications and Customization: Custom features or specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Machines that meet specific quality certifications (e.g., ISO, CE) may carry a higher price tag. However, investing in certified equipment can save costs related to compliance and product returns.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact total costs, especially for international shipments.

What Tips Can Buyers Use to Enhance Cost-Efficiency in Sourcing?

-

Negotiate Effectively: Leverage volume purchasing and long-term relationships to negotiate better terms. Always be open to discussing price adjustments based on order size or repeat business.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term operational costs, including maintenance and energy consumption. Choosing energy-efficient models can lead to significant savings.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and local market conditions that can affect pricing. Researching local suppliers might reveal more cost-effective options.

-

Request Quotations from Multiple Suppliers: Gathering quotes from various suppliers can provide a clearer picture of market pricing and allow for better negotiation leverage.

-

Invest in Quality: While it may be tempting to choose the lowest-priced option, investing in high-quality machines can yield better performance and longevity, reducing replacement and repair costs over time.

In conclusion, a comprehensive understanding of the cost components, price influencers, and effective negotiation strategies can empower international B2B buyers to make informed decisions when sourcing Dippin’ Dots makers. By considering these factors, buyers can optimize their purchasing strategy and achieve a favorable return on investment.

Alternatives Analysis: Comparing dippin dots maker With Other Solutions

Exploring Alternatives to the Dippin’ Dots Maker: A Comparative Analysis

When considering the Dippin’ Dots Maker, it’s essential to evaluate other solutions that can create similar frozen treats. This analysis focuses on two alternatives: the traditional ice cream machine and the liquid nitrogen freezing method. Each option has unique features that may better suit various business needs and operational contexts.

| Comparison Aspect | Dippin’ Dots Maker | Traditional Ice Cream Machine | Liquid Nitrogen Freezing Method |

|---|---|---|---|

| Performance | Produces small frozen dots, but may not replicate the original texture perfectly. | Creates smooth ice cream, versatile in flavors and textures. | Rapid freezing produces high-quality, fine-textured frozen desserts. |

| Cost | Approximately $30, affordable for casual use. | Ranges from $100 to $500 depending on capacity and features. | Higher initial investment due to equipment and nitrogen costs, often $1,000+. |

| Ease of Implementation | Simple to use, but results can vary; requires freezing time. | Requires preparation time and skill to balance ingredients. | Requires expertise in handling liquid nitrogen safely. |

| Maintenance | Minimal maintenance needed; simple cleaning process. | Moderate maintenance; components may need periodic replacement. | High maintenance; equipment must be regularly serviced for safety. |

| Best Use Case | Ideal for casual settings, like parties or small events. | Perfect for restaurants, cafes, and events that require custom flavors. | Best for high-end dessert shops or catering that emphasizes unique textures. |

In-Depth Analysis of Alternatives

Traditional Ice Cream Machine

Traditional ice cream machines are designed to churn and freeze mixtures into creamy ice cream. They offer flexibility in flavor and texture, allowing businesses to create custom recipes and cater to diverse customer preferences. However, the process can be labor-intensive, requiring precise ingredient measurement and a longer freezing time. The cost can vary significantly based on the machine’s capacity and features, making it a worthwhile investment for businesses that plan to produce large quantities of ice cream regularly.

Liquid Nitrogen Freezing Method

This method involves using liquid nitrogen to rapidly freeze ice cream mixtures, resulting in exceptionally smooth and creamy textures. It is particularly appealing to businesses looking to create gourmet desserts with unique presentations. The rapid freezing process helps retain the original flavors and aromas, setting it apart from traditional methods. However, this method requires specialized equipment and trained personnel to handle liquid nitrogen safely, which can increase operational complexity and cost.

Conclusion: How to Choose the Right Solution for Your Business

Selecting the right frozen treat solution depends on your business’s specific needs, budget, and operational capabilities. If your focus is on producing small batches of unique desserts for casual settings, the Dippin’ Dots Maker may suffice. For establishments aiming to offer a broader range of ice cream flavors with a smooth texture, a traditional ice cream machine is a solid choice. Alternatively, if you are positioned in the high-end dessert market and are willing to invest in equipment and training, the liquid nitrogen method can elevate your offerings. Evaluating these factors will guide B2B buyers in making an informed decision that aligns with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for dippin dots maker

What Are the Key Technical Properties of a Dippin’ Dots Maker?

When considering the procurement of a Dippin’ Dots maker, understanding its technical specifications is crucial for ensuring optimal performance and product quality. Here are several essential properties to consider:

-

Material Grade

The construction materials of the Dippin’ Dots maker significantly impact durability and hygiene. Typically, high-grade stainless steel or food-safe plastics are preferred to resist corrosion and facilitate easy cleaning. In a B2B context, ensuring that the material complies with health regulations is vital for food safety and operational longevity. -

Cooling Capacity

This specification refers to the machine’s ability to rapidly freeze the liquid mix into small beads. Measured in BTUs (British Thermal Units), a higher cooling capacity indicates quicker production cycles. For businesses, this translates to increased output and the ability to meet consumer demand during peak hours. -

Production Rate

This metric defines how many servings the machine can produce in a given timeframe, often expressed in servings per hour. Understanding the production rate helps businesses project their sales capacity and manage inventory effectively. A higher production rate is essential for high-traffic venues, ensuring that customer wait times are minimized. -

Energy Efficiency

Energy consumption is a key factor in operational costs. Machines with energy-efficient designs not only reduce utility bills but also appeal to environmentally conscious consumers. B2B buyers should seek models that meet recognized energy standards to ensure cost-effectiveness over time. -

Temperature Control Range

The ability to maintain specific temperature settings is crucial for achieving the desired texture and quality of Dippin’ Dots. A precise temperature control system allows operators to fine-tune production parameters, ensuring consistency in product quality. This is particularly important for businesses that prioritize brand reputation and customer satisfaction. -

User Interface

A user-friendly interface enhances operational efficiency, particularly in high-volume settings. Features like digital displays, touch controls, and programmable settings can facilitate easier operation and maintenance. For B2B buyers, investing in machines with intuitive interfaces can reduce training time for staff and minimize operational errors.

What Are Common Trade Terms Used in the Dippin’ Dots Maker Industry?

Navigating the purchasing landscape for a Dippin’ Dots maker involves familiarizing oneself with industry jargon. Here are several key terms to understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the Dippin’ Dots maker market, understanding OEM relationships can help buyers identify reputable suppliers and assess product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For B2B buyers, negotiating the MOQ can be crucial for managing cash flow and inventory levels. A lower MOQ can allow smaller businesses to enter the market without excessive upfront investment. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. It is an essential step in the procurement process, enabling buyers to compare offers and select the best supplier based on cost and quality. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Understanding Incoterms is vital for B2B buyers engaged in international procurement, as they clarify who is responsible for shipping, insurance, and tariffs. -

Lead Time

This term refers to the amount of time it takes from placing an order until the product is delivered. Knowing the lead time helps businesses plan their inventory and meet customer demand without interruption. Shorter lead times can provide a competitive advantage in fast-paced markets. -

Warranty Period

The warranty period specifies the duration during which the manufacturer guarantees the product against defects. A longer warranty period can indicate higher product quality and reliability, which is crucial for B2B buyers looking to minimize maintenance costs and downtime.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market expectations.

Navigating Market Dynamics and Sourcing Trends in the dippin dots maker Sector

What Are the Key Market Trends Influencing the Dippin’ Dots Maker Sector?

The Dippin’ Dots maker sector is experiencing significant growth, driven by factors such as consumer demand for unique frozen treats and the rising popularity of experiential dining. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to diversify their product offerings, the Dippin’ Dots concept presents an appealing opportunity. The market is witnessing a shift towards automation and technology integration, with advancements in machinery that enhance the production process. Emerging trends include the development of compact, user-friendly machines that allow small businesses and franchises to offer Dippin’ Dots without heavy investment.

Moreover, the pandemic has accelerated digital transformation, leading to an increase in online sourcing platforms where buyers can easily compare suppliers and products. This trend is particularly evident in regions like Vietnam and Brazil, where buyers are leveraging e-commerce to streamline procurement processes. Additionally, health-conscious consumers are pushing manufacturers to explore healthier and organic ingredients for flavoring, which could impact sourcing strategies in the coming years.

Illustrative image related to dippin dots maker

How Does Sustainability and Ethical Sourcing Impact the Dippin’ Dots Maker Market?

Sustainability is becoming a crucial factor in the decision-making process for B2B buyers in the Dippin’ Dots maker sector. The environmental impact of production practices, packaging, and waste management is drawing increasing scrutiny. Buyers are now prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices. This includes sourcing raw materials from suppliers who adhere to environmental standards and utilizing eco-friendly packaging options.

Green certifications such as Fair Trade, Organic, and Rainforest Alliance can add value to products, making them more appealing to ethically-minded businesses. For instance, sourcing dairy and flavoring agents from certified organic farms not only supports sustainable agriculture but can also enhance the brand image among consumers who value environmental stewardship. As the market continues to evolve, B2B buyers should consider implementing sustainability criteria into their sourcing decisions to align with global trends and consumer expectations.

What Is the Evolution of the Dippin’ Dots Maker Sector?

The Dippin’ Dots concept originated in the 1980s, created by inventor Curt Jones, who developed a unique flash-freezing process that transformed ice cream into colorful, bead-like morsels. Initially a novelty item, it quickly gained popularity at amusement parks and events. The brand has since expanded its offerings, introducing various flavors and product formats to cater to diverse consumer preferences.

Over the years, technological advancements have led to the development of home and commercial Dippin’ Dots makers, allowing businesses to tap into this fun, interactive dessert experience. This evolution has opened new avenues for B2B buyers, particularly in the food service and retail sectors, providing them with a unique selling proposition to attract customers. The ongoing innovation in flavor profiles and production techniques continues to shape the market, making it an exciting time for stakeholders in the Dippin’ Dots maker sector.

Frequently Asked Questions (FAQs) for B2B Buyers of dippin dots maker

-

How do I solve issues with inconsistent Dippin’ Dots production?

To address inconsistencies in Dippin’ Dots production, it’s essential to ensure the equipment is set up correctly and that you’re using the right ingredients. Start by carefully following the manufacturer’s instructions for the Dippin’ Dots maker, as variations in temperature or ingredient viscosity can affect the final product. Additionally, consider conducting trials with different liquids to determine the best mixtures for optimal results. If problems persist, reach out to the supplier for troubleshooting guidance or technical support. -

What is the best machine for producing Dippin’ Dots in a commercial setting?

For commercial production, look for a Dippin’ Dots maker designed specifically for high-volume output. Key features to consider include capacity, speed of production, and ease of cleaning. Machines that offer customizable settings for different flavors and textures can enhance your product range. Additionally, read reviews from other businesses in similar markets to gauge reliability and performance before making a decision. -

What are the minimum order quantities (MOQs) for Dippin’ Dots makers?

MOQs can vary significantly depending on the supplier and your location. Typically, manufacturers may set MOQs to ensure cost-effectiveness in production and shipping. For international buyers, it’s advisable to negotiate MOQs directly with suppliers, especially if you are a small or medium-sized business. Some suppliers may offer flexibility for first-time buyers or bulk orders, so always inquire about potential discounts or lower MOQs for initial purchases. -

How can I vet suppliers of Dippin’ Dots makers for international trade?

Vetting suppliers involves several key steps. Start by researching their reputation through reviews and testimonials from other B2B customers. Check for certifications and compliance with international standards to ensure product safety and quality. It’s also beneficial to ask for references and possibly visit the supplier’s facility if feasible. Establishing clear communication channels and understanding their logistics capabilities are crucial in ensuring a reliable partnership. -

What payment terms should I expect when sourcing Dippin’ Dots makers internationally?

Payment terms can vary widely among suppliers. Common terms include payment in full before shipment, a deposit with the balance due upon delivery, or payment against documents. It’s essential to clarify these terms upfront and negotiate favorable conditions that align with your cash flow needs. Utilizing secure payment methods such as letters of credit can provide additional security in international transactions. -

What quality assurance measures should be in place for Dippin’ Dots makers?

Quality assurance (QA) is critical when sourcing Dippin’ Dots makers. Ensure that the supplier follows rigorous QA protocols, including inspections of materials, adherence to production standards, and testing of finished products. Request documentation of their QA processes and any certifications they hold. Regular audits and the ability to trace defects back to the source can also help maintain product integrity. -

What logistics considerations should I keep in mind when importing Dippin’ Dots makers?

When importing equipment, consider shipping methods, customs regulations, and potential tariffs. Choose a logistics partner experienced in handling international shipments to navigate these complexities. Ensure that all documentation, including invoices and certificates of origin, is in order to avoid delays at customs. Additionally, factor in lead times for production and shipping to align with your operational timelines. -

Can I customize Dippin’ Dots makers for my business needs?

Many manufacturers offer customization options for Dippin’ Dots makers to meet specific business requirements. This can include branding, size variations, or modifications to accommodate different production capacities. Discuss your needs with potential suppliers early in the negotiation process to explore available options. Customization may involve additional costs or longer lead times, so plan accordingly to integrate these factors into your business strategy.

Top 4 Dippin Dots Maker Manufacturers & Suppliers List

1. Dippin’ Dots – Flash-Frozen Ice Cream Products

Domain: dippindots.com

Registered: 1996 (29 years)

Introduction: Dippin’ Dots offers a variety of flash-frozen ice cream products, including Classic Dippin’ Dots and Dippin’ Dots Sundaes. The products are available in different flavors such as Banana Split, Birthday Cake, Blue Raspberry, Chocolate Chip Cookie Dough, Chocolate, Cookie Monster, Cookies ‘n Cream, Cotton Candy, Hawaiian Crumble, ICEE Cherry ‘n Blue Raspberry, Lemon, Lime, Mint Chocolate, Orange, Ra…

2. Dippin’ Dots – Novelty Ice Cream

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Dippin’ Dots ice cream is a novelty ice cream product that is created by running unfrozen ice cream through a device that drips it into liquid nitrogen, resulting in small, bead-like ice cream pellets. The manufacturing process involves packaging the ice cream after it has been frozen in nitrogen and allowing it to set in a freezer to avoid instant freezing in consumers’ mouths. The product is sol…

3. Dippin’ Dots – Frozen Dot Maker

Domain: freakinreviews.com

Registered: 2013 (12 years)

Introduction: Dippin’ Dots Frozen Dot Maker, priced at $30.23 on Amazon, has a rating of 3.7 stars from over 500 reviews. It can transform soda, juice, or milk into frozen dots in 2-3 hours. The set includes the maker, six trays, four bowls, four spoons, two pop pens, and instructions. Common complaints include the product not resembling Dippin’ Dots, lack of flavorings, vague recipes, and difficulty in removin…

4. Cuisinart – Frozen Dippin’ Dots & Ice Cream Makers

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Cuisinart – Frozen Dippin’ Dots & Ice Cream Makers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for dippin dots maker

In conclusion, the strategic sourcing of Dippin’ Dots makers presents an exciting opportunity for international buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe. By focusing on high-quality suppliers and innovative products, businesses can enhance their offerings, appealing to consumers seeking unique frozen treats. The Dippin’ Dots model leverages nostalgia and novelty, making it a compelling addition to any food service operation or retail space.

Illustrative image related to dippin dots maker

Investing in Dippin’ Dots makers not only diversifies product lines but also fosters customer engagement and satisfaction. As consumer preferences shift towards unique experiences, the demand for such innovative products will likely grow. Strategic sourcing allows businesses to optimize their supply chains, ensuring they remain competitive and responsive to market trends.

Looking ahead, international buyers should consider forming partnerships with reliable suppliers to secure favorable terms and consistent quality. By embracing this forward-thinking approach, businesses can capitalize on the potential of Dippin’ Dots makers and position themselves as leaders in the frozen treat market. Now is the time to explore sourcing options and elevate your offerings to meet evolving consumer demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to dippin dots maker

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.