A B2B Buyer’s Guide to Digital Pressure Transducer: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for digital pressure transducer

In the ever-evolving landscape of industrial technology, sourcing high-quality digital pressure transducers can pose significant challenges for B2B buyers across various global markets. These precision instruments play a vital role in monitoring and controlling processes in sectors ranging from oil and gas to water treatment. However, the diversity of types, applications, and technological specifications can make the selection process daunting. This guide serves as a comprehensive resource, illuminating the complexities of digital pressure transducer options, including their various configurations, applications, and the nuances of supplier vetting.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—such as Brazil and Saudi Arabia—will find actionable insights that empower informed purchasing decisions. We delve into critical aspects such as cost considerations, performance metrics, and industry standards, ensuring you have the necessary knowledge to navigate supplier landscapes effectively. Furthermore, we highlight the importance of understanding local market dynamics and regulatory requirements that can influence your procurement strategy.

By equipping you with the right tools and knowledge, this guide not only streamlines your sourcing process but also enhances your operational efficiency. Join us as we explore the intricate world of digital pressure transducers, ensuring your organization remains competitive in a global market defined by precision and reliability.

Understanding digital pressure transducer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Piezoresistive Pressure Transducer | High sensitivity, fast response time, cost-effective | Oil & gas, HVAC, automotive testing | Pros: Affordable, reliable; Cons: Limited accuracy at extreme pressures. |

| Capacitive Pressure Transducer | High accuracy, stable output, suitable for low pressure | Chemical processing, water treatment | Pros: High precision; Cons: More expensive, sensitive to temperature changes. |

| Strain Gauge Pressure Transducer | Robust design, wide pressure range, versatile output | Industrial automation, aerospace | Pros: Durable, versatile; Cons: Requires calibration, can be affected by environmental factors. |

| Digital Pressure Transmitter | Real-time data transmission, high stability | Process control, remote monitoring | Pros: Continuous monitoring, easy integration; Cons: Higher initial investment. |

| Differential Pressure Transducer | Measures pressure difference, high rangeability | HVAC systems, filtration, fluid dynamics | Pros: Accurate, effective in complex systems; Cons: More complex installation and setup. |

What Are the Characteristics of Piezoresistive Pressure Transducers?

Piezoresistive pressure transducers are known for their high sensitivity and fast response times, making them ideal for applications in oil and gas, HVAC systems, and automotive testing. They convert pressure changes into electrical signals through a change in resistance. When considering these transducers, B2B buyers should evaluate their cost-effectiveness and reliability, especially for applications where budget constraints are a priority. However, it’s important to note that their accuracy may diminish at extreme pressure levels, which could impact critical operations.

How Do Capacitive Pressure Transducers Stand Out?

Capacitive pressure transducers excel in high accuracy and stable output, particularly in low-pressure environments. They are commonly used in chemical processing and water treatment applications, where precision is crucial for compliance and safety. Buyers should consider the advantages of high precision and low drift, but they must also account for the higher costs and sensitivity to temperature fluctuations that can affect performance.

Why Choose Strain Gauge Pressure Transducers?

Strain gauge pressure transducers offer a robust design and a wide pressure range, making them versatile for various applications, including industrial automation and aerospace. They operate by measuring the deformation of a material under pressure, providing reliable readings. Buyers should appreciate their durability and versatility, but they should also be aware of the need for calibration and potential susceptibility to environmental factors, which can affect accuracy.

What Are the Benefits of Digital Pressure Transmitters?

Digital pressure transmitters provide real-time data transmission and high stability, making them essential in process control and remote monitoring applications. Their ability to integrate easily with existing systems enhances operational efficiency. While they offer the benefit of continuous monitoring, buyers must consider the higher initial investment compared to traditional sensors, which may be a barrier for budget-conscious organizations.

What Makes Differential Pressure Transducers Unique?

Differential pressure transducers are designed to measure the difference in pressure between two points, offering high rangeability and accuracy. They are particularly useful in HVAC systems, filtration processes, and fluid dynamics applications. B2B buyers should recognize their effectiveness in managing complex systems, but they should also be prepared for more complex installation and setup requirements, which may necessitate additional training or technical support.

Key Industrial Applications of digital pressure transducer

| Industry/Sector | Specific Application of Digital Pressure Transducer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Monitoring pipeline pressure and safety systems | Enhances safety by preventing overpressure incidents | Need for high accuracy, explosion-proof designs, and quick response time. |

| Chemical Processing | Process control in reactors and distillation columns | Improves process efficiency and product quality | Customizable output signals and compatibility with harsh chemicals. |

| Water Treatment | Pressure monitoring in filtration systems | Ensures operational efficiency and water quality | Durability against corrosion and ability to operate in varying temperatures. |

| HVAC Systems | Pressure measurement in ductwork and chillers | Optimizes energy consumption and system performance | Low power consumption and precise calibration for varying conditions. |

| Agricultural Systems | Irrigation system pressure monitoring | Enhances water usage efficiency and crop yield | Robust construction to withstand environmental factors and varying pressure ranges. |

How Are Digital Pressure Transducers Used in the Oil and Gas Industry?

In the oil and gas sector, digital pressure transducers are essential for monitoring pipeline pressure and safety systems. These devices help prevent overpressure incidents that can lead to catastrophic failures. Buyers in this industry require transducers that offer high accuracy, robust construction, and explosion-proof designs, especially when operating in hazardous environments. Additionally, the ability to transmit real-time data is crucial for maintaining operational safety and compliance with industry regulations.

What Role Do Digital Pressure Transducers Play in Chemical Processing?

Digital pressure transducers are pivotal in chemical processing, where they control pressure in reactors and distillation columns. By providing precise pressure measurements, these transducers help improve process efficiency and product quality. For international buyers, sourcing options should include customizable output signals and compatibility with harsh chemicals, as the environment can be aggressive. Buyers must also consider the reliability and accuracy of these devices to ensure optimal performance in complex chemical processes.

How Are Digital Pressure Transducers Applied in Water Treatment?

In water treatment facilities, digital pressure transducers are used to monitor pressure in filtration systems. This monitoring ensures operational efficiency and maintains water quality standards. Buyers from regions with diverse water treatment needs, such as Africa and South America, should focus on sourcing durable transducers that can withstand corrosion and operate effectively under varying temperatures. The ability to provide continuous and accurate data is vital for maintaining compliance with health and safety regulations.

Why Are Digital Pressure Transducers Important for HVAC Systems?

Digital pressure transducers are critical in HVAC systems for measuring pressure in ductwork and chillers. Accurate pressure measurements help optimize energy consumption and improve system performance, leading to significant cost savings. Buyers should prioritize transducers that offer low power consumption and precise calibration capabilities to adapt to varying conditions. This is particularly important for international buyers who may face different environmental challenges and energy regulations.

How Do Digital Pressure Transducers Benefit Agricultural Systems?

In agricultural systems, digital pressure transducers are utilized for monitoring irrigation system pressure. This application enhances water usage efficiency and ultimately increases crop yield. Buyers looking to source these devices must consider robust construction to withstand environmental factors such as moisture and temperature fluctuations. Additionally, transducers with a wide range of pressure capabilities are essential to accommodate the varying needs of different agricultural setups.

3 Common User Pain Points for ‘digital pressure transducer’ & Their Solutions

Scenario 1: Inaccurate Readings Leading to Operational Delays

The Problem: In high-stakes industries such as oil and gas or chemical processing, precise pressure measurements are critical. B2B buyers often encounter issues with inaccurate readings from digital pressure transducers, leading to operational delays, safety risks, and costly downtime. These inaccuracies can arise from several factors, including environmental conditions, electrical noise, or improper installation. When pressure transducers fail to provide reliable data, it can disrupt entire processes, leading to inefficiencies and potential hazards.

The Solution: To mitigate these issues, it is essential to select a digital pressure transducer with robust specifications tailored to the operating environment. Buyers should prioritize transducers that offer features such as high accuracy ratings (±0.25% or better), overpressure protection, and compatibility with the specific media being measured. Additionally, ensure proper installation by consulting manufacturer guidelines or working with technical specialists who can assist in the setup. Regular calibration and maintenance are also crucial; establishing a routine check-up schedule can help identify potential inaccuracies before they impact operations. Investing in high-quality transducers with advanced noise immunity can significantly enhance measurement reliability.

Illustrative image related to digital pressure transducer

Scenario 2: Integration Challenges with Existing Systems

The Problem: Many businesses face integration challenges when introducing new digital pressure transducers into existing automated systems. Compatibility issues can arise due to different output signals, communication protocols, or physical connection types. For B2B buyers, this can lead to frustration and additional costs, as they may need to modify their systems or purchase additional equipment to facilitate integration, thereby delaying project timelines.

The Solution: To ensure seamless integration, buyers should conduct thorough research on the specifications of both the pressure transducer and the existing system. It’s advisable to choose transducers that offer versatile output options, such as 4-20 mA or digital communication protocols like HART. This flexibility allows for easier compatibility with various control systems. Engaging with suppliers who provide technical support can also streamline the process, as they can offer insights on integration best practices and potential challenges. Furthermore, consider pilot testing the transducer in a smaller system segment before full deployment to identify any integration issues early.

Scenario 3: Delays in Customization and Delivery

The Problem: In industries that require specific pressure measurement solutions, delays in obtaining customized digital pressure transducers can significantly hinder project timelines. B2B buyers often face extended lead times, which may reach several months, when seeking tailored configurations. Such delays can lead to missed deadlines and increased costs, especially in sectors like manufacturing and construction where timing is critical.

The Solution: To address customization delays, buyers should proactively communicate their requirements to suppliers and seek manufacturers known for their agility and responsiveness. When sourcing, look for companies that offer in-house customization capabilities and quick turnaround times. Many manufacturers can provide customized solutions within 3-5 days, which is significantly faster than the industry average. Establishing strong relationships with suppliers can also facilitate faster responses to requests and ensure that buyers are informed of the latest available options. Additionally, planning ahead by ordering transducers with standard specifications can help mitigate the impact of customization delays on project timelines.

Strategic Material Selection Guide for digital pressure transducer

What Are the Key Materials Used in Digital Pressure Transducers?

Digital pressure transducers are essential components in various industries, and the choice of materials significantly impacts their performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the construction of these devices, focusing on their properties, advantages, limitations, and implications for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures and pressures. It typically has a temperature rating of up to 400°C and can handle pressures exceeding 20,000 PSI.

Pros & Cons: The primary advantage of stainless steel is its durability and long lifespan, making it suitable for harsh environments, such as oil and gas or chemical processing industries. However, it can be more expensive than other materials and may require complex manufacturing processes, which could lead to longer lead times.

Illustrative image related to digital pressure transducer

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it a versatile choice for many applications. However, buyers must ensure that the specific grade of stainless steel used is appropriate for the intended media.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America may also need to consider local regulations regarding material certifications.

2. Aluminum

Key Properties: Aluminum is lightweight and offers good corrosion resistance, with a temperature rating typically around 150°C and pressure ratings up to 10,000 PSI.

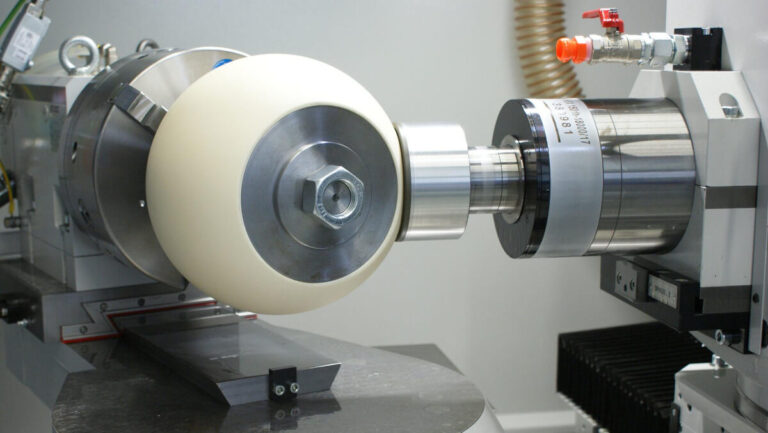

Illustrative image related to digital pressure transducer

Pros & Cons: The advantages of aluminum include its lower cost and ease of manufacturing, which can result in quicker turnaround times. However, its lower strength compared to stainless steel may limit its use in high-pressure applications.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as in aerospace or automotive industries. However, it may not be suitable for highly corrosive environments unless properly treated.

Considerations for International Buyers: Buyers should ensure that aluminum components meet local standards for pressure equipment, particularly in regions with stringent safety regulations like Europe.

3. Piezoresistive Materials

Key Properties: Piezoresistive materials, such as silicon, are used in the sensing element of digital pressure transducers. They offer high sensitivity and can operate effectively in a temperature range of -40°C to 125°C.

Pros & Cons: The key advantage of piezoresistive materials is their high accuracy and fast response time, making them ideal for applications requiring precise pressure measurements. However, they may be sensitive to environmental conditions and require careful handling during manufacturing.

Impact on Application: These materials are particularly effective in applications involving low-pressure measurements, such as HVAC systems. However, their sensitivity to temperature fluctuations can impact performance in extreme conditions.

Considerations for International Buyers: Buyers should verify that piezoresistive components comply with relevant international standards, especially for applications in regulated industries like pharmaceuticals and food processing.

4. Thermoplastic Materials

Key Properties: Thermoplastics, such as polycarbonate and nylon, are lightweight and offer good chemical resistance, with temperature ratings typically up to 100°C and pressure ratings around 1,500 PSI.

Pros & Cons: The primary advantage of thermoplastics is their cost-effectiveness and ease of manufacturing, allowing for rapid production. However, they may not be suitable for high-pressure applications or extreme temperatures.

Impact on Application: Thermoplastic pressure transducers are ideal for low-pressure applications and environments where weight savings are essential. However, their limitations in pressure and temperature resistance may restrict their use in more demanding applications.

Considerations for International Buyers: Compliance with local and international standards is essential, especially in industries with strict safety and environmental regulations.

Summary Table of Material Selection for Digital Pressure Transducers

| Material | Typical Use Case for Digital Pressure Transducer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil & gas, chemical processing | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace, automotive | Lightweight and cost-effective | Lower strength and pressure limits | Medium |

| Piezoresistive Materials | HVAC systems, low-pressure applications | High accuracy and fast response | Sensitive to environmental conditions | Medium |

| Thermoplastic Materials | Low-pressure applications, consumer products | Cost-effective and easy to manufacture | Limited pressure and temperature resistance | Low |

This guide provides a comprehensive overview of the materials used in digital pressure transducers, enabling B2B buyers to make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for digital pressure transducer

What Are the Main Stages in the Manufacturing Process of Digital Pressure Transducers?

The manufacturing of digital pressure transducers involves several critical stages, each designed to ensure that the final product meets the high standards required in various industrial applications.

Material Preparation

The first step in the manufacturing process is material preparation. High-quality materials such as stainless steel, aluminum, and specialized polymers are selected based on the specific requirements of the pressure transducer. These materials must exhibit durability, corrosion resistance, and the ability to withstand extreme temperatures and pressures. Suppliers often provide certificates of compliance to ensure that the materials meet international standards.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. Common methods include machining, stamping, and molding. For instance, stainless steel housings may be machined to precise specifications to ensure a perfect fit for internal components. Advanced techniques like laser cutting and CNC machining are often utilized to achieve the required tolerances, which are crucial for the accuracy of the transducer.

Assembly Process

The assembly of digital pressure transducers is a meticulous process that requires skilled labor and precision equipment. Components such as sensors, electronic circuits, and pressure diaphragms are assembled in a controlled environment to minimize contamination. Automated assembly systems may be employed to enhance efficiency and reduce human error. Each component is carefully inspected before assembly to ensure quality standards are met.

Finishing Techniques

After assembly, the transducers undergo finishing processes, which may include surface treatment, coating, and calibration. Surface treatments like anodizing or powder coating enhance corrosion resistance and improve durability. Calibration is a critical step, ensuring that each transducer provides accurate readings across its operational range. This process often involves comparing the transducer’s output against known pressure standards.

How is Quality Assurance Implemented in the Manufacturing of Digital Pressure Transducers?

Quality assurance is an integral part of the manufacturing process, ensuring that each digital pressure transducer performs reliably and meets industry standards.

What International Standards Are Relevant for Quality Assurance?

Manufacturers of digital pressure transducers typically adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards demonstrates a commitment to consistent quality and customer satisfaction. Additionally, specific industry certifications, such as CE marking for products sold in Europe and API standards for oil and gas applications, are also critical for market acceptance.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented through various checkpoints during the manufacturing process, including:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon receipt to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of ongoing production. This includes checking dimensions, material properties, and assembly integrity.

-

Final Quality Control (FQC): After assembly and finishing, each transducer undergoes final testing to verify its performance against specified criteria. This may include pressure testing, electrical testing, and calibration checks.

What Common Testing Methods Are Used for Quality Assurance?

Various testing methods are employed to ensure the reliability and accuracy of digital pressure transducers. Common methods include:

-

Pressure Testing: This involves subjecting the transducer to known pressure levels to ensure it can accurately measure and respond without failure.

-

Electrical Testing: This ensures that the output signals are consistent and within specified tolerances.

-

Environmental Testing: Transducers are often subjected to extreme temperature and humidity conditions to verify their performance in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to ensure that their suppliers maintain rigorous quality control processes. Here are some strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request documentation of quality control processes, including audit reports from internal and external inspections. These documents should detail compliance with relevant international standards and any certifications that the supplier holds. Regular audits can reveal the supplier’s commitment to quality and adherence to best practices.

How Can Third-Party Inspections Provide Assurance?

Engaging third-party inspection agencies can provide an additional layer of verification. These independent organizations can assess the manufacturing process and quality control measures to ensure compliance with industry standards. Buyers should consider including third-party inspections as part of their procurement process, especially for high-value or critical components.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, there are unique considerations regarding quality control:

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying regulatory requirements and standards. For instance, products sold in Europe must comply with CE marking, while those in the Middle East may require adherence to specific local standards. Buyers should familiarize themselves with the relevant standards in their region and ensure that suppliers can meet these requirements.

What Are the Challenges of Ensuring Quality Across Borders?

International supply chains can introduce complexities in quality assurance due to differences in manufacturing practices, regulatory compliance, and language barriers. Buyers should establish clear communication channels with suppliers and consider using local representatives or agents who can facilitate quality oversight and ensure that the products meet the required standards.

Conclusion

Understanding the manufacturing processes and quality assurance practices associated with digital pressure transducers is crucial for B2B buyers. By focusing on the stages of manufacturing, key quality control measures, and the importance of international standards, buyers can make informed decisions and select suppliers that align with their quality expectations. Engaging in thorough due diligence, including audits and third-party inspections, will further enhance the reliability of their procurement process, ensuring that they receive products that perform consistently in demanding industrial applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘digital pressure transducer’

This guide serves as a comprehensive checklist for B2B buyers looking to procure digital pressure transducers. By following these steps, you can ensure that your sourcing process is efficient, informed, and tailored to your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for successful procurement. Identify the required pressure ranges, output signals (like 4-20 mA or 0-5V), and any specific environmental conditions (such as temperature and humidity) the transducer must withstand. This clarity will help you narrow down suitable products and avoid costly errors.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies that specialize in digital pressure transducers and have a solid track record in your industry. Consider supplier reviews, their product offerings, and their ability to provide technical support. This groundwork will help you establish a shortlist of potential vendors.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that the suppliers meet relevant industry certifications and standards. Certifications such as ISO 9001 for quality management and ATEX for equipment used in explosive atmospheres are essential indicators of reliability. These certifications ensure that the products comply with safety and quality regulations.

Step 4: Request Samples and Documentation

Once you have identified potential suppliers, request product samples and technical documentation. Samples allow you to assess the transducer’s performance in your specific application, while documentation provides insights into installation requirements and maintenance guidelines. This step is crucial for ensuring that the product meets your operational standards.

Step 5: Assess After-Sales Support and Warranty Terms

Evaluate the after-sales support and warranty terms provided by the supplier. Reliable technical support can significantly reduce downtime in case of issues. Inquire about the warranty duration and what it covers, as this can vary widely among suppliers. A robust support system is essential for long-term satisfaction.

Illustrative image related to digital pressure transducer

Step 6: Compare Pricing and Payment Terms

Gather and compare pricing from your shortlisted suppliers. While cost is important, consider the total cost of ownership, which includes installation, maintenance, and potential downtime. Additionally, discuss payment terms to ensure they align with your budgeting process. Transparent pricing will facilitate better financial planning.

Step 7: Finalize Your Order and Confirm Delivery Times

After selecting a supplier, finalize your order and confirm delivery timelines. Ensure that the agreed-upon timelines meet your project schedules, especially if you require custom configurations. Prompt delivery can be a crucial factor in your overall project success, so maintain clear communication with your supplier throughout this process.

Following this checklist will help you navigate the complexities of sourcing digital pressure transducers effectively, ensuring you make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for digital pressure transducer Sourcing

What Are the Key Cost Components in Digital Pressure Transducer Manufacturing?

Understanding the cost structure of digital pressure transducers is crucial for international B2B buyers. The main components include:

-

Materials: The choice of materials, such as stainless steel for wetted parts or advanced sensing technologies, significantly impacts cost. High-quality materials can increase durability and performance but may raise the price.

-

Labor: Skilled labor is required for the assembly, calibration, and testing of transducers. The labor cost can vary based on the region of production and the complexity of the device.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help mitigate overhead costs.

-

Tooling: Customization often requires specific tooling, which can be a substantial upfront investment. This is particularly relevant for specialized applications or unique designs.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure the reliability of pressure transducers. These QC measures can add to the overall cost but are essential for maintaining product integrity.

-

Logistics: Shipping costs, including packaging and transportation, can vary significantly based on the destination and Incoterms used. Buyers should factor these costs into their total purchasing budget.

-

Margin: Supplier margins will affect the final price. Understanding a supplier’s pricing strategy can aid in negotiation.

How Do Volume and Customization Influence Pricing for Pressure Transducers?

Volume plays a critical role in pricing negotiations. Suppliers typically offer lower per-unit costs for larger orders due to economies of scale. When negotiating, buyers should consider:

-

Minimum Order Quantities (MOQ): Suppliers may set MOQs that can affect pricing. Understanding these thresholds can help buyers plan their purchases more effectively.

-

Specifications and Customization: Customized pressure transducers often come with a premium. Buyers should assess their requirements carefully—balancing the need for specific features against potential cost increases.

What Are the Key Price Influencers for Digital Pressure Transducers in Global Markets?

Several factors can influence the pricing of digital pressure transducers in international markets:

-

Material Quality and Certifications: Higher quality materials often correlate with better performance and reliability. Certifications (e.g., ISO standards) may also impact costs but can be crucial for compliance in regulated industries.

-

Supplier Reputation and Experience: Established suppliers may charge a premium due to their track record and reliability. Newer suppliers might offer lower prices but could lack in areas such as support and warranty.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) can help buyers predict total costs, including duties and shipping fees.

What Tips Can Help International Buyers Negotiate Better Prices for Digital Pressure Transducers?

To achieve cost-efficiency, buyers should consider the following strategies:

-

Negotiate Based on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with maintenance, downtime, and reliability. A slightly higher upfront cost can result in savings over time if the product proves more reliable.

-

Leverage Local Knowledge: For buyers in regions like Africa, South America, or the Middle East, understanding local market dynamics and supplier capabilities can provide leverage in negotiations.

-

Request Multiple Quotes: Comparing offers from various suppliers can provide insights into market pricing and help identify competitive offers.

-

Consider Long-term Partnerships: Building a relationship with suppliers can lead to better pricing, exclusive offers, and enhanced support.

Final Thoughts on Pricing Nuances for Digital Pressure Transducers

International buyers should remain aware that indicative prices can fluctuate based on market conditions, currency exchange rates, and supplier capacities. Therefore, it’s essential to maintain flexibility in negotiations and be prepared to adapt to changing circumstances in the supply chain. By focusing on the total cost of ownership and leveraging local market knowledge, buyers can ensure they make informed purchasing decisions.

Alternatives Analysis: Comparing digital pressure transducer With Other Solutions

When evaluating solutions for pressure measurement in industrial applications, B2B buyers often consider various technologies to ensure optimal performance, cost-effectiveness, and reliability. Digital pressure transducers are widely recognized for their precision and advanced features, but alternatives may also meet specific needs depending on the application. This analysis compares digital pressure transducers with two viable alternatives: analog pressure gauges and pressure transmitters.

| Comparison Aspect | Digital Pressure Transducer | Analog Pressure Gauge | Pressure Transmitter |

|---|---|---|---|

| Performance | High accuracy, real-time data, versatile output options (e.g., mV, 0-5V) | Moderate accuracy, limited to visual readings | High accuracy, stable performance, real-time data transmission |

| Cost | Moderate to high initial investment | Low initial cost | Moderate to high initial investment, depending on features |

| Ease of Implementation | Requires calibration and setup; often user-friendly | Simple installation, no calibration needed | Requires configuration; may need integration with control systems |

| Maintenance | Low maintenance; occasional recalibration | Minimal maintenance; mechanical wear may occur | Moderate maintenance; regular checks for signal integrity |

| Best Use Case | Ideal for complex systems needing precise control and data logging | Suitable for basic applications where visual pressure readings suffice | Best for automated systems requiring continuous monitoring and data reporting |

What Are the Pros and Cons of Using Analog Pressure Gauges?

Analog pressure gauges are often favored for their simplicity and low cost. They provide a straightforward visual representation of pressure levels, making them easy to interpret. However, their accuracy is generally lower compared to digital solutions, and they do not offer the ability to transmit data to remote monitoring systems. They are best suited for applications where basic pressure monitoring is sufficient, such as in non-critical machinery.

How Do Pressure Transmitters Compare to Digital Pressure Transducers?

Pressure transmitters serve a similar function to digital pressure transducers but often excel in industrial environments where precision and stability are crucial. They convert pressure measurements into standardized electrical signals, allowing for integration with automated control systems. While transmitters can be more expensive and complex to set up, they provide enhanced accuracy and continuous data monitoring. This makes them ideal for industries such as oil and gas, chemical processing, and water treatment, where pressure control is vital for safety and efficiency.

Conclusion: How to Choose the Right Pressure Measurement Solution?

Selecting the appropriate pressure measurement solution depends on specific operational needs and environmental conditions. Digital pressure transducers are ideal for applications requiring high accuracy and advanced features, while analog gauges may suffice for simpler, cost-sensitive applications. Pressure transmitters offer a robust alternative for automated systems needing reliable data transmission. B2B buyers should assess their unique requirements, including performance expectations, budget constraints, and integration capabilities, to make an informed decision that aligns with their operational objectives.

Essential Technical Properties and Trade Terminology for digital pressure transducer

What Are the Key Technical Properties of Digital Pressure Transducers?

Digital pressure transducers are critical components in various industrial applications, providing precise measurements of pressure. Understanding their technical properties can significantly impact operational efficiency and reliability.

1. Pressure Range

The pressure range defines the span of pressures the transducer can accurately measure. This specification is crucial for ensuring that the transducer is suitable for the intended application, whether it involves low-pressure environments or high-pressure systems up to 20,000 PSI. Choosing a transducer with the appropriate pressure range prevents equipment failure and optimizes safety.

2. Output Signal

Digital pressure transducers typically provide output signals in formats like 4-20 mA, 0-5 VDC, or wireless signals. The output signal type affects how data is transmitted to control systems or monitoring devices. For B2B buyers, understanding the output signal compatibility with existing systems is essential for seamless integration and data accuracy.

3. Accuracy and Tolerance

Accuracy is a measure of how closely the transducer’s readings align with the actual pressure. Tolerance, often expressed as a percentage, indicates the allowable deviation from the true value. High accuracy (e.g., ±0.25% BFSL) is vital in applications like chemical processing or oil and gas, where precision can impact safety and compliance. B2B buyers should prioritize transducers with the required accuracy for their specific industry needs.

4. Material Composition

The materials used in the construction of digital pressure transducers, such as 316L stainless steel or specialized polymers, determine their durability and resistance to corrosive environments. Selecting the right material is crucial for applications in harsh conditions, such as oil fields or chemical plants, where equipment longevity can significantly reduce operational costs.

5. Response Time

Response time refers to how quickly a transducer can react to changes in pressure. A fast response time is important in dynamic systems where pressure fluctuates rapidly. B2B decision-makers must consider this property to ensure that their processes remain stable and responsive.

What Trade Terms Should B2B Buyers Know When Purchasing Digital Pressure Transducers?

Familiarity with industry terminology is essential for effective communication and negotiation in the procurement of digital pressure transducers.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for businesses looking to integrate transducers into their systems or develop new products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budgeting strategies effectively, especially when dealing with custom transducer configurations.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers. This process is vital for B2B buyers to compare options and ensure they are getting competitive pricing for the necessary specifications.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping, insurance, and delivery responsibilities, which is particularly important in global sourcing.

5. HART Protocol

HART (Highway Addressable Remote Transducer) is a communication protocol used in industrial automation. It allows for two-way communication between field devices and control systems, providing added functionality and diagnostics. Familiarity with HART can enhance a buyer’s ability to integrate digital pressure transducers into automated systems.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that align with their operational requirements and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the digital pressure transducer Sector

What Are the Key Trends Driving the Digital Pressure Transducer Market?

The digital pressure transducer market is experiencing significant growth, driven by several global factors. The increasing demand for automation across industries such as oil and gas, chemical processing, and water treatment is a major driver. These sectors require precise pressure control to ensure operational efficiency and safety, leading to a surge in the adoption of digital pressure transducers that offer real-time data transmission and enhanced accuracy compared to traditional gauges.

Emerging technologies, including IoT and wireless communication, are transforming sourcing trends within this sector. B2B buyers are increasingly seeking transducers that integrate with smart systems, enabling remote monitoring and data analytics. This shift not only enhances operational efficiency but also supports predictive maintenance strategies, which are critical for minimizing downtime. Moreover, as industries worldwide prioritize sustainability, there is a growing preference for transducers that utilize eco-friendly materials and manufacturing processes.

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. Economic growth in these regions is spurring investment in infrastructure and manufacturing, thus increasing demand for reliable pressure measurement solutions. Buyers must also navigate varying regulatory requirements and standards, which can influence sourcing decisions. Additionally, competitive pricing and lead times are essential factors, as suppliers who can deliver custom solutions quickly are likely to gain a competitive edge.

Illustrative image related to digital pressure transducer

How Is Sustainability Influencing Sourcing Decisions for Digital Pressure Transducers?

Sustainability is becoming a focal point for B2B buyers in the digital pressure transducer market. The environmental impact of manufacturing processes and product lifecycle is increasingly scrutinized, prompting companies to seek suppliers committed to ethical sourcing and sustainable practices. This trend is particularly relevant for industries facing regulatory pressures to reduce their carbon footprint and enhance environmental responsibility.

Buyers are now more inclined to partner with manufacturers that prioritize sustainable materials, such as recyclable components and eco-friendly packaging. Certifications like ISO 14001 or RoHS compliance are becoming essential criteria for procurement decisions, as they demonstrate a commitment to environmental management and safety standards. Furthermore, companies are exploring the use of renewable energy sources in production to minimize environmental impact.

Investing in suppliers that practice ethical sourcing not only aligns with corporate social responsibility goals but also enhances brand reputation. As global consumers increasingly favor environmentally conscious brands, B2B buyers can leverage these partnerships to differentiate themselves in competitive markets. Ultimately, sustainability in sourcing is not just a trend but a strategic imperative that can drive long-term business success.

How Has the Digital Pressure Transducer Market Evolved Over Time?

The evolution of digital pressure transducers has been marked by technological advancements and changing industry demands. Initially, pressure measurement relied heavily on mechanical gauges, which offered limited accuracy and real-time data capabilities. The introduction of electronic sensors in the late 20th century marked a significant shift, allowing for improved precision and the ability to transmit data to control systems.

As industries embraced automation, the need for smart pressure measurement solutions became apparent. The integration of digital technology in pressure transducers led to the development of devices capable of wireless communication and data logging, enabling real-time monitoring and analysis. Today, digital pressure transducers are not only more accurate but also more versatile, with applications spanning various sectors, including healthcare, automotive, and manufacturing.

This evolution reflects a broader trend towards the Internet of Things (IoT), where interconnected devices enhance operational efficiency and data-driven decision-making. As the market continues to innovate, buyers can expect further advancements in sensor technology, including enhanced durability and integration with advanced analytics platforms, paving the way for smarter industrial operations.

Frequently Asked Questions (FAQs) for B2B Buyers of digital pressure transducer

-

How do I choose the right digital pressure transducer for my application?

Choosing the right digital pressure transducer depends on several factors, including the pressure range you need to measure, the type of fluid (liquid or gas), environmental conditions, and the required accuracy. Consider whether you need features like wireless connectivity or specific output signals (e.g., 4-20 mA, 0-10 V). It’s also essential to assess the compatibility of materials with the media being measured, especially in harsh environments. Engaging with technical sales specialists can help you narrow down options based on your specific application requirements. -

What are the key specifications to look for in a digital pressure transducer?

Key specifications include pressure range, accuracy, output signal type, and environmental ratings. Look for transducers with high overpressure protection and durability ratings if used in demanding conditions. Additionally, consider the response time, as faster response times are crucial for real-time applications. Ensure that the materials used are suitable for the measured medium to prevent corrosion or damage, which could lead to inaccuracies or failures. -

What is the minimum order quantity (MOQ) when sourcing digital pressure transducers?

Minimum order quantities can vary by supplier, often ranging from single units for custom orders to bulk quantities for standard models. If you are purchasing for larger projects or ongoing needs, many suppliers offer discounts on higher volumes. It’s advisable to discuss your specific requirements with suppliers to understand their MOQ policies and explore potential flexibility, especially for international buyers. -

What customization options are available for digital pressure transducers?

Many manufacturers offer customization options such as pressure range adjustments, output signal configurations, and housing material selections. Customization can also extend to specific connectors or interfaces tailored to your system’s needs. When discussing your requirements, provide detailed specifications to ensure the manufacturer can deliver a product that meets your application criteria. Custom solutions typically have longer lead times, so plan accordingly. -

How do I ensure quality assurance when sourcing digital pressure transducers internationally?

To ensure quality, choose suppliers with established reputations and certifications (e.g., ISO 9001). Request samples for testing before placing a large order to evaluate performance and reliability. Additionally, inquire about the supplier’s quality control processes and any testing they conduct on their products. Engaging with third-party inspection services can provide an added layer of assurance, especially when sourcing from regions with different manufacturing standards. -

What payment terms are typically offered for international B2B purchases of digital pressure transducers?

Payment terms can vary significantly among suppliers. Common options include upfront payments, net 30/60/90 days after delivery, or a letter of credit for larger transactions. Discussing terms upfront is essential to ensure alignment on expectations. Be mindful of potential currency exchange fluctuations and additional fees related to international transactions. Establishing a good rapport with your supplier can also facilitate more favorable payment conditions. -

What logistical considerations should I keep in mind when importing digital pressure transducers?

When importing, consider shipping methods, customs regulations, and potential tariffs that may apply. Choose a reliable freight forwarder familiar with your destination’s import laws to minimize delays. Ensure that all necessary documentation, such as invoices and certificates of origin, is correctly prepared. It’s also wise to track shipments to address any issues proactively and ensure timely delivery, especially for critical projects. -

How can I verify the reliability of a supplier for digital pressure transducers?

To verify a supplier’s reliability, research their business history, customer reviews, and case studies. Request references from other businesses that have purchased similar products. Evaluate their responsiveness and willingness to provide technical support and documentation. Engaging in direct communication can also help gauge their expertise and customer service commitment. Consider visiting their facility if feasible, or utilizing third-party audits to assess operational standards.

Top 6 Digital Pressure Transducer Manufacturers & Suppliers List

1. Transducers Direct – Pressure Transducers

Domain: transducersdirect.com

Registered: 1999 (26 years)

Introduction: Pressure Transducers: Measure pressure and convert it into continuous voltage output (V). Outputs include 0-5V, 0-10V, and unamplified millivolt outputs (mV). Measurement ranges include vacuum, absolute, compound, and above atmospheric pressure up to 10K PSI. Technologies used: piezoresistive sensing and patented digital sensing. Customization available for various applications. Quick shipping opt…

2. Kobold – Pressure Transmitters

Domain: koboldusa.com

Registered: 1996 (29 years)

Introduction: This company, Kobold – Pressure Transmitters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. AutomationDirect – Pressure Sensors

Domain: automationdirect.com

Registered: 1999 (26 years)

Introduction: Pressure sensors for process control and measurement, including various types such as piezoresistive, capacitive, and strain gauge. Features include different pressure ranges, output types (analog and digital), and compatibility with various applications. Suitable for industrial automation, HVAC, and other process control environments.

4. DwyerOmega – Differential Pressure Digital Gauge

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: Differential Pressure Digital Gauge from DwyerOmega. Price range: $200-$499.99 (2), $1,000-$9,999.99 (3). Measurement Pressure options include: 0.5 inH₂O, 0.25 inH₂O, 0.361 psi, 1 bar, 1 inH₂O, 1 psi, 2 bar, 2 inH₂O, 5 inH₂O, 10 inH₂O, 15 inH₂O, 25 inH₂O, 50 inH₂O, 100 inH₂O, 150 psi, 250 psi, 500 psi, 1000 psi, and more. Measurement Pressure Type: Absolute (1), Differential (5), Gauge (1), Vacuum…

5. KEYENCE – GP-M Series Heavy Duty Digital Pressure Sensor

Domain: keyence.com

Registered: 1996 (29 years)

Introduction: Pressure Sensors from KEYENCE include several series designed for various applications. The GP-M Series Heavy Duty Digital Pressure Sensor is suitable for hydraulic and pneumatic applications, with a detectable range from -14.50 to 5,802 PSI and simultaneous temperature monitoring. It features IO-Link compatibility, a step flush diaphragm structure for clog resistance, and an IP67 rating for envir…

6. Brooks Instrument – SolidSense II® Pressure Transducers

Domain: brooksinstrument.com

Registered: 1996 (29 years)

Introduction: {‘product_name’: ‘SolidSense II® Pressure Transducers’, ‘features’: [‘Accurate, stable, ultra-high purity control’, ‘Weld-free, corrosion-resistant materials’, ‘Outstanding zero stability and accuracy within 0.25% of full scale’, ‘Digital thermal compensation using multi-point temperature-compensation method’, ‘Proprietary micro-machined silicon strain gauges with very low zero drift’, ‘Smooth sur…

Strategic Sourcing Conclusion and Outlook for digital pressure transducer

What Are the Key Insights for B2B Buyers of Digital Pressure Transducers?

In conclusion, the strategic sourcing of digital pressure transducers presents a unique opportunity for international buyers to enhance operational efficiency and safety across diverse industries. By focusing on suppliers that offer advanced technology, such as piezoresistive and digital sensing, businesses can benefit from improved accuracy, lower power consumption, and customization options tailored to specific application needs.

Moreover, prioritizing suppliers with robust technical support and rapid turnaround times can significantly reduce lead times, allowing for swift responses to market demands. This agility is particularly crucial in regions like Africa, South America, the Middle East, and Europe, where project timelines and resource availability can be unpredictable.

Illustrative image related to digital pressure transducer

As we look to the future, the demand for high-performance digital pressure transducers will only increase. Companies that invest in strategic partnerships with reliable manufacturers will position themselves to capitalize on emerging market opportunities. We encourage B2B buyers to engage with reputable suppliers, explore innovative solutions, and leverage expert technical support to navigate the complexities of their sourcing needs effectively. Your next step is to connect with industry leaders and secure the best transducer solutions for your operations today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.