A B2B Buyer’s Guide to Diagram Cooling Tower: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for diagram cooling tower

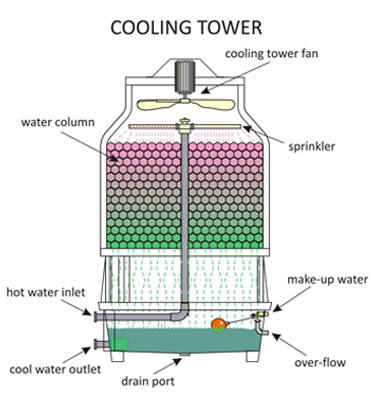

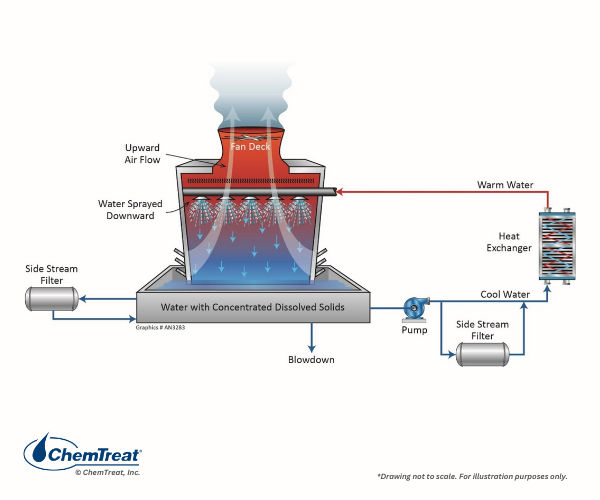

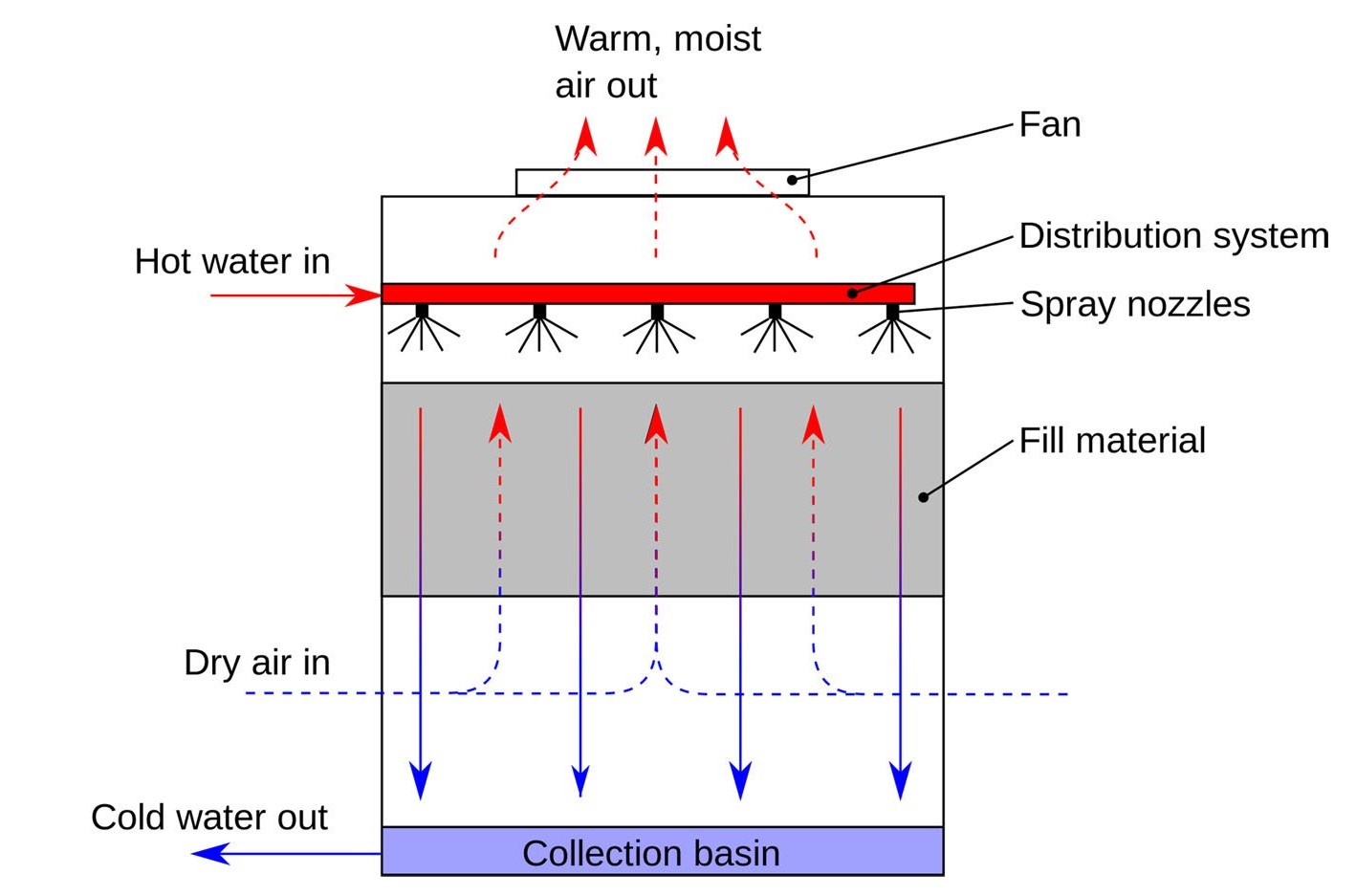

The global market for diagram cooling towers presents a significant challenge for B2B buyers seeking efficient and cost-effective solutions to manage industrial heat. Understanding the intricacies of cooling tower technology, including its various types and applications, is crucial for making informed purchasing decisions. This guide serves as a comprehensive resource, exploring the operational principles of cooling towers, such as evaporative cooling, and detailing the differences between crossflow and counterflow systems.

With a focus on supplier vetting, cost considerations, and maintenance practices, this guide equips international buyers—particularly those from Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Vietnam—with the knowledge needed to navigate this complex landscape. Buyers will gain insights into selecting the right cooling tower based on their specific industrial needs, ensuring optimal performance and compliance with local regulations.

By addressing key challenges and providing actionable insights, this guide empowers B2B buyers to confidently engage with suppliers, streamline their procurement processes, and ultimately enhance the efficiency of their operations. Understanding the market dynamics and technology behind diagram cooling towers will not only facilitate better purchasing decisions but also drive operational excellence in various industrial applications.

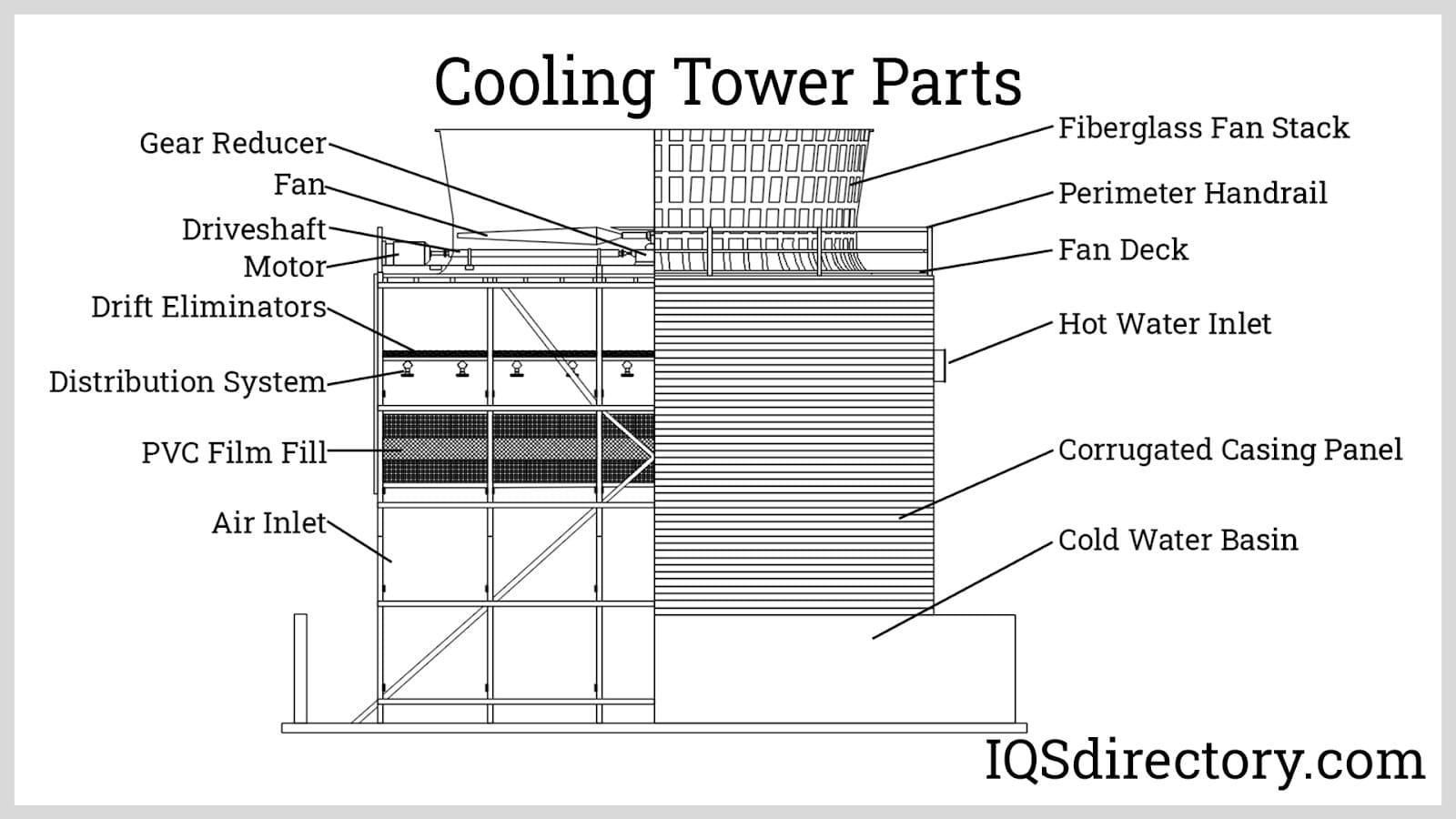

Understanding diagram cooling tower Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Crossflow Cooling Tower | Water flows vertically, air flows horizontally; gravity-fed water distribution. | HVAC systems, petrochemical plants, and industrial processes. | Pros: Efficient heat transfer; simple maintenance. Cons: Requires more space; may have lower cooling efficiency in high temperatures. |

| Counterflow Cooling Tower | Air flows upwards against the downward water flow; uses pressurized spray systems. | Power plants, large industrial facilities, and HVAC systems. | Pros: Higher cooling efficiency; compact design. Cons: More complex installation and maintenance; higher initial costs. |

| Induced Draft Cooling Tower | Utilizes fans to pull air through the fill media; promotes evaporation. | Large industrial applications, thermal power plants. | Pros: Effective in high-load conditions; improved performance in humid climates. Cons: Higher energy consumption; potential noise issues. |

| Forced Draft Cooling Tower | Fans push air into the cooling tower; suitable for smaller applications. | Light industrial applications, HVAC. | Pros: Compact design; easier to install. Cons: Lower efficiency in high ambient temperatures; limited capacity. |

| Natural Draft Cooling Tower | Relies on natural convection; no mechanical fans required. | Power generation, large cooling requirements. | Pros: Low operational costs; minimal energy use. Cons: Size and height limitations; less effective in low-wind conditions. |

What Are the Characteristics of Crossflow Cooling Towers?

Crossflow cooling towers are characterized by their unique design where water flows vertically through fill media while air moves horizontally across it. This configuration allows for gravity-fed water distribution, making maintenance relatively straightforward. Crossflow towers are particularly suitable for HVAC systems and petrochemical applications due to their effective heat exchange capabilities. Buyers should consider the space availability, as these towers typically require a larger footprint, and assess their efficiency based on the specific temperature conditions of their processes.

How Do Counterflow Cooling Towers Stand Out?

Counterflow cooling towers feature a design where air flows upward against the downward movement of water. This design enhances cooling efficiency, making them ideal for power plants and large industrial facilities. The use of pressurized spray systems allows for a more compact design compared to crossflow towers. However, buyers should be aware of the higher initial costs and the complexity of installation and maintenance. Understanding the operational demands of their facilities will help in making an informed decision.

What Are the Benefits of Induced Draft Cooling Towers?

Induced draft cooling towers utilize fans to draw air through the fill media, promoting evaporation and enhancing cooling effectiveness, especially under high-load conditions. These towers are commonly used in large industrial applications and thermal power plants. While they offer improved performance in humid climates, buyers should consider the higher energy consumption and potential noise issues associated with fan operation. Evaluating the operational costs versus performance benefits will be crucial for buyers in this category.

Why Choose Forced Draft Cooling Towers?

Forced draft cooling towers push air into the cooling system using fans, making them well-suited for light industrial applications and HVAC systems. Their compact design allows for easier installation, which can be advantageous for space-constrained environments. However, buyers should note that these towers may exhibit lower efficiency in high ambient temperatures and have limited cooling capacity. A thorough analysis of the specific cooling needs and environmental conditions will guide buyers in selecting the right solution.

What Makes Natural Draft Cooling Towers Unique?

Natural draft cooling towers operate without mechanical fans, relying instead on natural convection to circulate air. This design results in low operational costs and minimal energy use, making them an attractive option for power generation and large cooling requirements. However, their size and height can pose limitations, and they may be less effective in low-wind conditions. Buyers must consider site-specific factors such as wind patterns and cooling demands to determine if a natural draft tower aligns with their operational goals.

Key Industrial Applications of diagram cooling tower

| Industry/Sector | Specific Application of Diagram Cooling Tower | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Cooling steam in thermal power plants | Increases efficiency of turbines, reducing operational costs | Reliability of components and maintenance support |

| Petrochemical | Heat rejection in refining processes | Enhances operational efficiency and product yield | Material compatibility with corrosive environments |

| HVAC Systems | Temperature regulation in large buildings | Improves energy efficiency and indoor air quality | Energy consumption rates and noise levels |

| Food and Beverage | Cooling in processing plants | Ensures product safety and compliance with health standards | Hygiene certifications and ease of maintenance |

| Mining | Cooling water used in mineral processing | Reduces downtime by maintaining optimal processing temperatures | Durability and resistance to harsh environmental conditions |

How is the Diagram Cooling Tower Used in Power Generation?

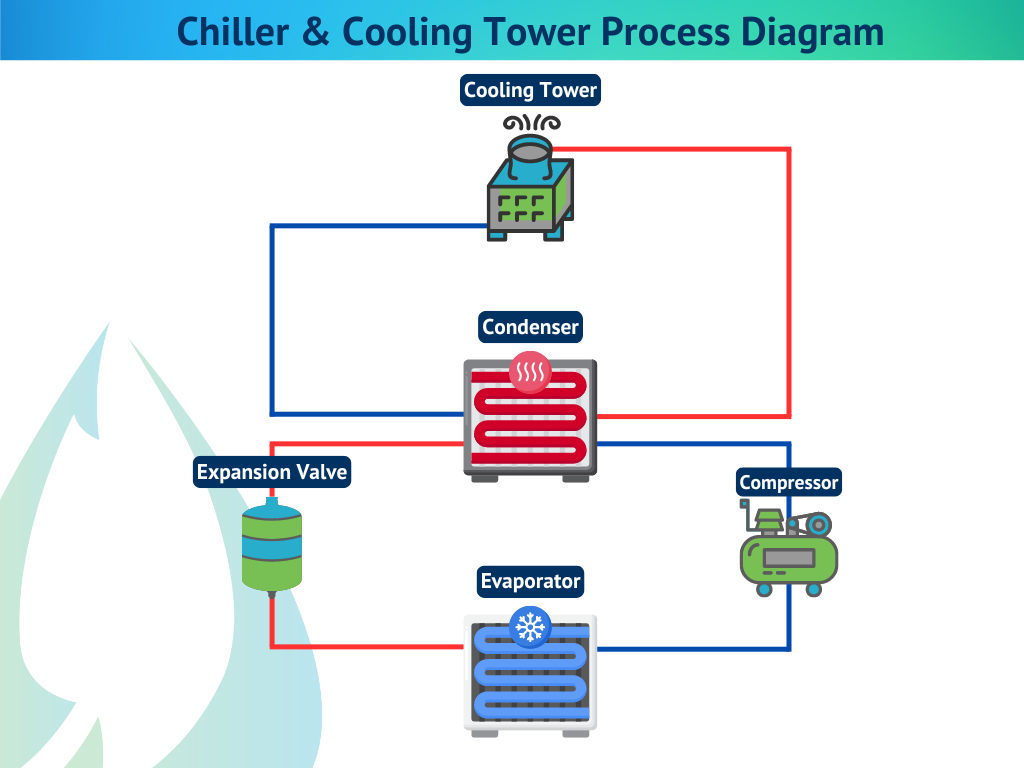

In the power generation sector, diagram cooling towers are vital for cooling steam produced in thermal power plants. The heated water is circulated through the cooling tower, where it cools down before being reused in the cooling cycle. This process enhances the efficiency of turbines, leading to reduced operational costs and increased energy output. Buyers should consider the reliability of components, as well as the availability of maintenance support, to ensure uninterrupted operations in regions where power demands are high, such as in Saudi Arabia and parts of Africa.

What Role Does the Diagram Cooling Tower Play in Petrochemical Industries?

In petrochemical facilities, diagram cooling towers are employed to manage heat rejection during refining processes. The cooling tower helps maintain optimal temperatures, which is crucial for maximizing product yield and ensuring the efficiency of chemical reactions. Buyers in this sector must consider material compatibility due to the presence of corrosive substances, as well as the cooling tower’s ability to handle varying thermal loads, which can differ significantly across different geographical regions.

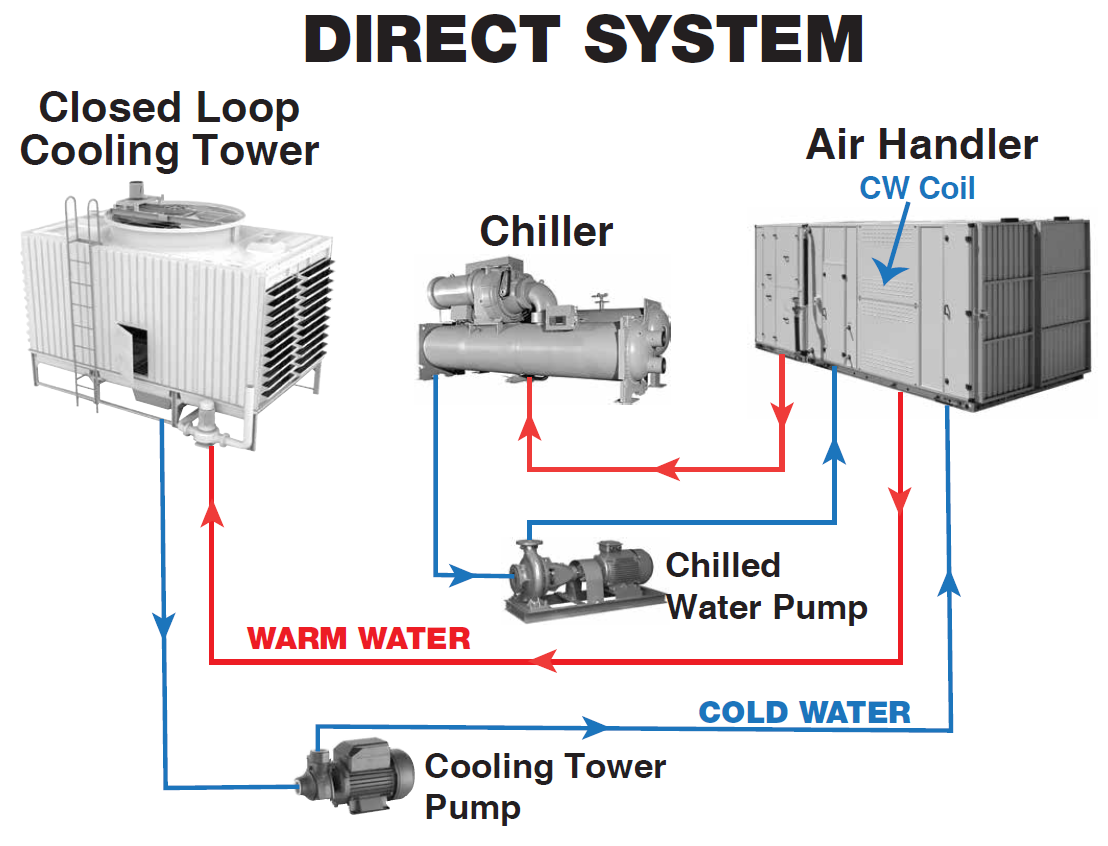

How Do HVAC Systems Benefit from Diagram Cooling Towers?

In large commercial buildings, diagram cooling towers are integral to HVAC systems, facilitating effective temperature regulation. By cooling the water used in chillers, these towers improve energy efficiency and enhance indoor air quality. For international buyers, especially in hot climates like those in the Middle East and South America, it’s essential to evaluate energy consumption rates and noise levels to ensure compliance with local regulations and standards.

Why are Diagram Cooling Towers Important in the Food and Beverage Industry?

In the food and beverage sector, diagram cooling towers are used to maintain safe processing temperatures, which is critical for product safety and compliance with health standards. They help regulate the temperature of water used in various processing stages, ensuring that products are kept at safe temperatures. Buyers should prioritize suppliers that offer hygiene certifications and easy maintenance solutions to meet stringent health regulations, particularly in regions with diverse regulatory environments like Europe and Africa.

How Do Mining Operations Utilize Diagram Cooling Towers?

Mining operations leverage diagram cooling towers to manage the cooling water used in mineral processing. Maintaining optimal temperatures is essential to reduce downtime and enhance the efficiency of extraction processes. Buyers in this sector must focus on the durability of cooling towers, ensuring they can withstand harsh environmental conditions and heavy operational loads, particularly in remote locations where resource availability might be limited.

3 Common User Pain Points for ‘diagram cooling tower’ & Their Solutions

Scenario 1: Inefficient Cooling Leading to Equipment Overheating

The Problem: A common issue faced by industrial buyers is the inefficiency of their cooling towers, resulting in inadequate cooling of process water. This inefficiency often leads to overheating of equipment, which can cause production delays, increase maintenance costs, and even lead to equipment failure. This problem is particularly acute in industries where cooling demands fluctuate significantly, such as in petrochemical plants or during peak summer months in regions like the Middle East or Africa.

The Solution: To combat inefficiency, it is essential to conduct a thorough assessment of the cooling tower system. Begin by analyzing the cooling load requirements specific to your industrial process. This includes considering factors such as the temperature of incoming water, the desired outlet temperature, and environmental conditions. Once you have this data, consult with a cooling tower manufacturer to select a diagram cooling tower that matches these specifications closely. Investing in advanced cooling tower technologies, such as variable speed fans or enhanced fill media, can also optimize performance. Regular maintenance and periodic performance evaluations are crucial; ensure your team is trained to clean and inspect the cooling tower regularly to prevent fouling and scaling, which can significantly hamper cooling efficiency.

Scenario 2: High Operational Costs Due to Water Waste

The Problem: Water scarcity is a pressing issue in many regions, particularly in Africa and parts of the Middle East. B2B buyers often face high operational costs due to excessive water usage in cooling processes. Traditional cooling towers can lead to significant evaporation losses, resulting in increased water procurement costs and regulatory challenges related to water usage.

The Solution: To mitigate water waste, consider implementing a closed-loop cooling system integrated with your diagram cooling tower. This system minimizes evaporation losses by recirculating water more effectively. Additionally, explore the use of advanced water treatment solutions to enhance water quality and reduce the need for makeup water. Technologies such as conductivity monitoring and automated blowdown controls can optimize water use and minimize waste. It’s also beneficial to collaborate with suppliers who can provide innovative solutions tailored to your specific needs, ensuring compliance with local regulations while managing operational costs effectively.

Scenario 3: Lack of Understanding of Cooling Tower Types

The Problem: Many B2B buyers encounter confusion regarding the various types of cooling towers and their respective applications. This lack of understanding can lead to poor decision-making when selecting a cooling tower system, resulting in inefficient performance and increased capital expenditures. This issue is especially prevalent in regions like South America and Europe, where diverse industrial processes require tailored cooling solutions.

The Solution: To overcome this knowledge gap, it is critical to educate your team on the different types of cooling towers—such as crossflow, counterflow, and induced draft systems—and their specific applications. Organize training sessions or workshops with industry experts to discuss the benefits and limitations of each type. Additionally, developing a decision matrix that outlines the requirements for your specific processes can assist in selecting the most suitable cooling tower. Collaborate with experienced cooling tower manufacturers who can provide customized solutions based on your operational needs. This proactive approach not only ensures the selection of the right cooling tower but also enhances overall operational efficiency and cost-effectiveness in the long run.

Strategic Material Selection Guide for diagram cooling tower

What Materials Are Commonly Used in Diagram Cooling Towers?

When selecting materials for diagram cooling towers, it is essential to consider their properties, advantages, and limitations. The right choice can significantly impact performance, durability, and overall cost-effectiveness, particularly for international buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

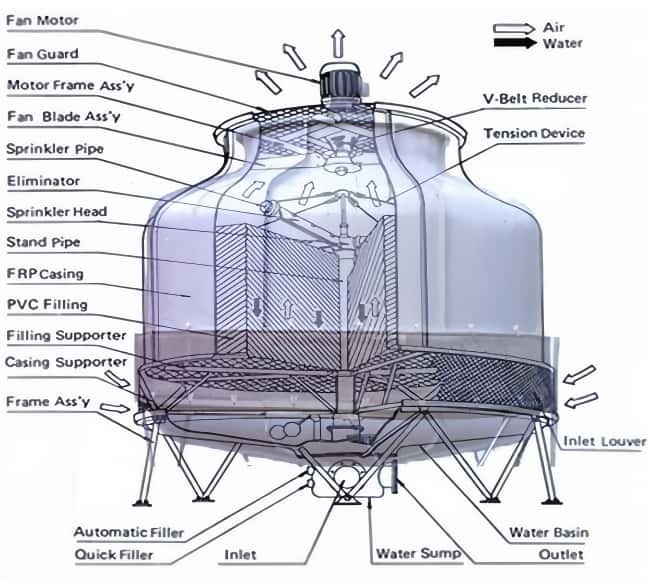

Illustrative image related to diagram cooling tower

Which Materials Are Suitable for Diagram Cooling Towers?

-

Fiberglass Reinforced Plastic (FRP)

Key Properties: FRP is known for its excellent corrosion resistance and high strength-to-weight ratio. It can withstand temperatures up to 150°C and pressures up to 2 bar, making it suitable for various cooling applications.

Pros & Cons: FRP is lightweight and easy to install, reducing labor costs. However, it can be more expensive than traditional materials and may require specialized manufacturing techniques.

Impact on Application: FRP is compatible with a wide range of cooling media, including saline and acidic waters, making it ideal for coastal and industrial applications.

Considerations for International Buyers: Compliance with ASTM standards for FRP is crucial. Buyers in regions like the Middle East may prefer FRP due to its resistance to corrosion from high salinity environments. -

Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, particularly against chlorides, and can handle high temperatures (up to 400°C) and pressures (up to 10 bar).

Pros & Cons: It is highly durable and has a long lifespan, making it a reliable choice. However, it is heavier than other materials and typically comes with a higher price tag.

Impact on Application: Stainless steel is suitable for applications involving aggressive cooling media, such as wastewater or chemical processes.

Considerations for International Buyers: Buyers should ensure that the stainless steel grades comply with international standards like DIN or JIS. In regions like Europe, the preference for high-quality materials may drive demand for stainless steel cooling towers. -

Galvanized Steel

Key Properties: Galvanized steel is coated with zinc to enhance corrosion resistance and can withstand temperatures up to 200°C. It is a cost-effective option for many cooling tower applications.

Pros & Cons: It is relatively inexpensive and widely available. However, its lifespan is shorter than stainless steel, especially in harsh environments.

Impact on Application: Galvanized steel is suitable for freshwater cooling applications but may not be ideal for corrosive environments.

Considerations for International Buyers: Compliance with local standards for galvanized coatings is essential. In regions like Africa, where budget constraints are common, galvanized steel may be a preferred option. -

Concrete

Key Properties: Concrete is robust and can withstand high temperatures and pressures. It is often used for large, field-erected cooling towers.

Pros & Cons: Its durability and low maintenance make it an attractive option. However, the initial construction cost can be high, and it requires significant lead time for curing.

Impact on Application: Concrete is suitable for large-scale industrial applications, particularly in power generation.

Considerations for International Buyers: Buyers must consider local building codes and standards when selecting concrete. In regions like South America, where construction practices vary, understanding these regulations is critical.

Summary Table of Material Selection for Diagram Cooling Towers

| Material | Typical Use Case for diagram cooling tower | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fiberglass Reinforced Plastic | Coastal and industrial applications | Excellent corrosion resistance | Higher initial cost | High |

| Stainless Steel | Aggressive cooling media applications | High durability and lifespan | Heavier and more expensive | High |

| Galvanized Steel | Freshwater cooling applications | Cost-effective and widely available | Shorter lifespan in harsh environments | Low |

| Concrete | Large-scale industrial applications | Robust and low maintenance | High initial construction cost | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers looking to optimize their cooling tower investments. By understanding the properties, advantages, and limitations of various materials, buyers can make informed decisions that align with their operational needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for diagram cooling tower

What Are the Main Stages of Manufacturing a Diagram Cooling Tower?

The manufacturing process for a diagram cooling tower involves several critical stages that ensure the final product meets industry standards and performs efficiently. Below is a detailed breakdown of these stages:

1. Material Preparation

The first step in manufacturing a cooling tower is the selection and preparation of materials. Common materials used include galvanized steel, stainless steel, and fiberglass-reinforced plastic (FRP). Each material has its own advantages in terms of durability, weight, and resistance to corrosion.

- Material Selection: B2B buyers should focus on suppliers that utilize high-quality materials, as this directly impacts the cooling tower’s longevity and efficiency.

- Pre-Treatment: Materials often undergo treatments such as galvanization or coating to enhance corrosion resistance, especially important in humid or saline environments.

2. Forming Techniques

Once the materials are prepared, they undergo various forming techniques to create the structural components of the cooling tower.

- Cutting and Shaping: Advanced CNC machines are typically used for precise cutting and shaping of metal sheets and components. This ensures that parts fit together seamlessly during assembly.

- Bending and Welding: After cutting, parts may be bent to form the desired shapes. Welding techniques, including MIG and TIG welding, are employed to join metal components securely.

3. Assembly Process

The assembly stage is where the individual components come together to form the cooling tower structure.

- Component Integration: The assembly process includes integrating the fill media, nozzles, fans, and distribution systems. Proper alignment is crucial for optimal airflow and water distribution.

- Use of Jigs and Fixtures: These tools are utilized to maintain precision during assembly, allowing for consistent quality across multiple units.

4. Finishing Touches

Finishing processes are essential for both aesthetics and functionality.

- Surface Treatment: Coatings, such as epoxy paints, are applied to enhance corrosion resistance and improve the tower’s lifespan.

- Final Assembly: This includes installing electrical components, such as fans and motors, and ensuring all parts are secure and operational.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is paramount in the manufacturing of cooling towers. B2B buyers should look for suppliers who adhere to international quality standards and implement robust QA processes.

Relevant International Standards

The manufacturing of cooling towers should comply with various international standards to ensure quality and reliability:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: Particularly important for European markets, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: For cooling towers used in oil and gas industries, compliance with American Petroleum Institute (API) standards is critical.

Key Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process. Here are the main checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor compliance with design specifications.

- Final Quality Control (FQC): Before the product is shipped, a comprehensive final inspection is performed to ensure the cooling tower meets all quality and performance standards.

What Common Testing Methods Are Employed in Cooling Tower Manufacturing?

Testing methods play a crucial role in verifying the performance and safety of cooling towers. B2B buyers should be aware of the following common testing procedures:

- Hydrostatic Testing: This test checks for leaks by filling the cooling tower with water and monitoring for any drop in pressure.

- Performance Testing: Conducted to evaluate the cooling efficiency of the tower under operating conditions, ensuring it meets specified thermal performance criteria.

- Vibration Analysis: This is important for assessing the operational stability of fans and motors, which can affect overall performance.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing cooling towers, B2B buyers should establish a method to verify the quality control measures of potential suppliers.

Audits and Inspections

- Supplier Audits: Conducting regular audits of the supplier’s manufacturing facility can provide insights into their quality management practices.

- Third-Party Inspections: Engaging independent third-party inspectors can add an extra layer of assurance regarding compliance with industry standards.

Quality Assurance Documentation

B2B buyers should request documentation that demonstrates the supplier’s commitment to quality:

- Quality Assurance Reports: These should detail the results of testing and inspections conducted during the manufacturing process.

- Certification Copies: Buyers should verify that suppliers hold the necessary certifications, such as ISO 9001, CE, or API.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be cognizant of specific nuances in quality control:

- Local Regulations: Understanding local regulations and standards for cooling towers is essential, as these can vary significantly between regions.

- Supply Chain Reliability: Ensure that suppliers have a robust supply chain capable of meeting international shipping standards to avoid delays.

- Cultural Considerations: Be aware of cultural differences in business practices that may influence the quality assurance process, particularly in communication and expectations.

Conclusion

In summary, the manufacturing processes and quality assurance measures for diagram cooling towers are critical to ensuring their performance and reliability. B2B buyers should prioritize suppliers that adhere to international standards, implement comprehensive quality control measures, and can provide verifiable documentation. This diligence not only protects investment but also ensures that cooling towers function optimally in diverse industrial applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diagram cooling tower’

To streamline the procurement process of a cooling tower, this guide provides a comprehensive checklist tailored for international B2B buyers. It emphasizes critical steps to ensure that you select the right equipment for your industrial needs while navigating the complexities of sourcing in various regions.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your cooling tower. Consider factors such as the type of cooling needed (crossflow, counterflow, etc.), the expected cooling capacity, and the specific application (e.g., HVAC systems, industrial processes). Documenting these specifications will help you communicate your needs effectively to suppliers and ensure you receive tailored solutions.

Illustrative image related to diagram cooling tower

Step 2: Research Regulatory Compliance

Understanding the regulatory environment in your target market is crucial. Different regions may have varying standards for cooling towers, including environmental regulations and safety codes. Ensure that the suppliers you consider are compliant with local regulations and can provide relevant certifications that verify their products meet necessary standards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. Look for companies with a proven track record in the cooling tower industry, particularly those with experience in your specific application. Request case studies, client testimonials, and references from other businesses in similar sectors to assess their reliability and quality of service.

- Tip: Pay attention to suppliers who have local presence or partnerships in your region, as this can facilitate support and maintenance.

Step 4: Request Detailed Proposals

Once you’ve shortlisted potential suppliers, request detailed proposals that include technical specifications, pricing, delivery timelines, and warranty information. A comprehensive proposal will enable you to compare options more effectively and understand the overall value each supplier offers.

Step 5: Consider After-Sales Support

Assess the level of after-sales support that suppliers provide. This includes installation services, maintenance plans, and availability of spare parts. A supplier that offers robust support can significantly reduce downtime and ensure the longevity of your cooling tower.

- Tip: Inquire about training programs for your staff to ensure they can operate and maintain the cooling tower efficiently.

Step 6: Negotiate Contract Terms

When you have selected a supplier, carefully negotiate the terms of the contract. Pay attention to payment terms, delivery schedules, and penalties for non-compliance. Ensuring clear, mutually agreed-upon terms will help mitigate risks and prevent misunderstandings in the future.

Step 7: Plan for Logistics and Installation

Finally, develop a logistics plan that accounts for the transportation and installation of the cooling tower. This is especially important for international buyers, as customs regulations and shipping times can vary. Work closely with your supplier to coordinate the delivery and ensure that installation is scheduled at a time that minimizes disruption to your operations.

By following this checklist, B2B buyers can confidently navigate the procurement of cooling towers, ensuring they make informed decisions that align with their operational needs and regional requirements.

Comprehensive Cost and Pricing Analysis for diagram cooling tower Sourcing

What Are the Key Cost Components in Sourcing Diagram Cooling Towers?

When sourcing diagram cooling towers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The selection of materials significantly impacts the overall cost. Cooling towers are typically constructed from fiberglass, steel, or concrete. Each material has a different cost profile, durability, and maintenance requirements. For instance, fiberglass towers may be more expensive initially but often require less maintenance than steel counterparts, which can rust or corrode over time.

-

Labor: Labor costs encompass both the assembly of the cooling towers and the installation at the site. Depending on the complexity of the design and the geographical location, labor costs can vary significantly. Regions with skilled labor shortages may incur higher labor costs, while areas with abundant skilled workers may benefit from lower rates.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, impacting the final pricing of cooling towers.

-

Tooling: Custom designs often require specific tooling, which can add to the initial costs. Buyers should consider whether they need standard models or custom solutions, as custom tooling can significantly increase upfront expenses.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that the cooling towers meet industry standards and function effectively. Higher QC standards may lead to increased costs, but they ultimately contribute to the longevity and efficiency of the cooling system.

-

Logistics: Transportation costs are critical, especially for international shipments. Factors such as distance, shipping method, and customs duties can all affect logistics expenses. Buyers must account for these costs when evaluating total pricing.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on market conditions, competition, and perceived value. Understanding the market landscape helps buyers negotiate better pricing.

How Do Price Influencers Affect Cooling Tower Sourcing?

Several factors can influence the pricing of cooling towers, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders may qualify for volume discounts, significantly reducing the per-unit cost. Conversely, low-volume purchases may not be eligible for these savings, making it essential for buyers to evaluate their needs carefully.

-

Specifications and Customization: Customized cooling towers designed for specific applications or environments may incur higher costs due to the additional engineering and materials required. Buyers should weigh the benefits of customization against the associated costs.

-

Material Quality and Certifications: The quality of materials used and relevant certifications (e.g., ISO standards) can influence pricing. Suppliers offering higher-quality, certified products may charge a premium, but these investments often lead to lower maintenance costs and longer lifespans.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality and service may charge more but offer peace of mind. Newer or less-known suppliers may offer lower prices but could come with risks related to quality and support.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define responsibilities regarding shipping, insurance, and tariffs, which can significantly affect the total cost. Buyers should clarify these terms to avoid unexpected expenses.

What Are Effective Buyer Tips for Cost-Efficiency in Cooling Tower Procurement?

-

Negotiation: Always negotiate pricing with suppliers. Understanding the cost components allows buyers to engage in informed discussions about pricing flexibility and potential discounts.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but the long-term costs associated with operation, maintenance, and energy efficiency. A slightly higher upfront cost may result in lower operational costs over time.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and trade agreements that may affect pricing. Conducting thorough market research can provide insights into competitive pricing and supplier options.

-

Request for Proposals (RFPs): When sourcing cooling towers, issuing RFPs to multiple suppliers can foster competition and lead to better pricing. Clearly outline specifications and expectations to ensure accurate quotes.

-

Stay Informed on Market Trends: Keeping abreast of industry trends, technological advancements, and shifts in material costs can help buyers make timely purchasing decisions and secure favorable pricing.

Disclaimer for Indicative Prices

Prices for cooling towers can vary widely based on the factors outlined above. It’s crucial for buyers to obtain detailed quotes from multiple suppliers and consider all cost components to determine a fair and competitive price for their specific needs.

Illustrative image related to diagram cooling tower

Alternatives Analysis: Comparing diagram cooling tower With Other Solutions

Exploring Alternatives to Diagram Cooling Towers

In the quest for effective cooling solutions, B2B buyers often find themselves evaluating various technologies that serve similar functions to diagram cooling towers. These alternatives can vary significantly in terms of performance, cost, ease of implementation, maintenance, and ideal applications. Understanding these differences is crucial for making informed purchasing decisions.

Comparison Table

| Comparison Aspect | Diagram Cooling Tower | Air-Cooled Chiller | Heat Exchanger |

|---|---|---|---|

| Performance | High thermal efficiency; ideal for large-scale industrial applications. | Moderate efficiency; best for smaller systems. | Very effective for specific applications, especially in closed-loop systems. |

| Cost | Higher upfront costs; long-term savings on energy and water. | Lower initial investment; higher operational costs due to energy consumption. | Mid-range costs; depends on the application and materials used. |

| Ease of Implementation | Requires significant space and infrastructure setup. | Easier to install; often requires less space. | Installation complexity varies; generally requires skilled labor. |

| Maintenance | Regular maintenance needed to prevent algae and scale buildup. | Lower maintenance needs; periodic checks are sufficient. | Maintenance depends on the system but can be more complex if fouling occurs. |

| Best Use Case | Ideal for large industrial processes like power plants and refineries. | Suitable for commercial buildings and smaller industrial applications. | Best for heat recovery applications and specific process cooling needs. |

Detailed Breakdown of Alternatives

Air-Cooled Chiller

Air-cooled chillers operate by using ambient air to cool refrigerants. They are generally more compact and easier to install compared to diagram cooling towers. However, their cooling efficiency can be lower, especially in hot climates where they may struggle to maintain optimal temperatures. While the initial investment is lower, operational costs can rise due to their reliance on electricity, particularly during peak usage times. Businesses looking for a quick and cost-effective solution in smaller applications may find air-cooled chillers appealing.

Heat Exchanger

Heat exchangers transfer heat between two or more fluids without mixing them. They can be highly efficient in specific applications, such as in closed-loop systems or where heat recovery is essential. The initial cost can vary widely based on materials and design, but they often fall in the mid-range compared to other cooling solutions. However, heat exchangers can require more complex maintenance and may not be suitable for all industrial applications. They are best for companies looking to optimize energy use and reduce waste in processes that already have a heat component.

Conclusion

When considering the right cooling solution, B2B buyers should carefully assess their specific needs, including operational scale, budget constraints, and environmental conditions. Diagram cooling towers excel in large-scale applications with high thermal demands but may require more investment and maintenance. In contrast, alternatives like air-cooled chillers and heat exchangers provide viable options for smaller operations or specialized needs. By weighing the pros and cons of each option, buyers can make informed decisions that align with their operational goals and financial plans.

Illustrative image related to diagram cooling tower

Essential Technical Properties and Trade Terminology for diagram cooling tower

What Are the Key Technical Properties of a Diagram Cooling Tower?

When evaluating a diagram cooling tower, several critical technical properties must be considered to ensure optimal performance and suitability for specific industrial applications. Below are some essential specifications:

-

Material Grade

Cooling towers are typically constructed from materials such as fiberglass, stainless steel, or plastic. The material grade affects durability, corrosion resistance, and overall lifespan. For instance, stainless steel is preferred in environments where chemical exposure is high, while fiberglass offers lightweight properties and is resistant to corrosion. Understanding the material grade is vital for B2B buyers to assess the long-term viability and maintenance costs of the cooling tower. -

Thermal Capacity

This refers to the cooling tower’s ability to dissipate heat, often measured in tons. The thermal capacity is crucial for determining whether a cooling tower can handle the heat load generated by specific industrial processes. Buyers must accurately match the thermal capacity to their operational requirements to avoid inefficiencies or equipment failure. -

Water Flow Rate

Measured in gallons per minute (GPM), the water flow rate indicates how much water can be circulated through the cooling tower. A higher flow rate typically leads to more effective cooling but may require larger pumps and more energy. Understanding the required flow rate helps B2B buyers assess compatibility with existing systems and infrastructure. -

Noise Level

Noise generated by cooling towers can be a significant concern, particularly in urban or residential areas. Noise levels are measured in decibels (dB), and many regions have strict regulations regarding permissible sound levels. Choosing a cooling tower with an acceptable noise level is essential for compliance and maintaining good relations with surrounding communities. -

Drift Loss

Drift loss refers to the small amount of water that escapes from the cooling tower as vapor or droplets. It is typically expressed as a percentage of the total water flow. Minimizing drift loss is essential for water conservation and environmental compliance. B2B buyers should inquire about drift loss rates to ensure the cooling tower meets regulatory standards and operational sustainability goals. -

Plume Abatement

This refers to the control of visible vapor plumes that can form above cooling towers, particularly in cold weather. Plume abatement technologies can minimize environmental impact and improve the aesthetic appearance of installations. Understanding the plume characteristics helps buyers select cooling towers that comply with local regulations and community standards.

What Are Common Trade Terms Associated with Diagram Cooling Towers?

Familiarity with industry terminology is essential for B2B buyers to navigate the procurement process effectively. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of cooling towers, buyers may seek OEM components for replacements or upgrades, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage their budgets and inventory effectively, especially in large-scale projects where purchasing in bulk may lead to cost savings. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotations for specific products or services. For cooling towers, an RFQ helps buyers gather competitive pricing and evaluate potential vendors based on their offerings and terms. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for B2B buyers to clarify shipping, insurance, and delivery responsibilities, thereby reducing the risk of misunderstandings in cross-border transactions. -

Lead Time

This term refers to the amount of time it takes from placing an order until the product is delivered. For cooling towers, lead time can vary based on customization and production schedules. Buyers should factor in lead times when planning installations to ensure timely project completion. -

Field-Erected vs. Factory-Assembled Cooling Towers

This distinction highlights whether a cooling tower is constructed on-site (field-erected) or shipped pre-assembled (factory-assembled). Understanding these types helps buyers determine the best installation method based on project requirements, site conditions, and budget constraints.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting a diagram cooling tower that best fits their operational needs and compliance requirements.

Navigating Market Dynamics and Sourcing Trends in the diagram cooling tower Sector

What Are the Key Market Trends Impacting the Diagram Cooling Tower Sector?

The global cooling tower market is experiencing significant growth, driven by the increasing demand for energy-efficient solutions across various industries, particularly in manufacturing, power generation, and HVAC systems. As industries in regions like Africa, South America, the Middle East, and Europe seek to optimize operational efficiencies, the demand for advanced cooling technologies is on the rise. Key trends include the adoption of modular cooling tower designs, which allow for scalable solutions tailored to specific operational needs, and the integration of IoT technology for real-time monitoring and maintenance, enhancing reliability and performance.

Illustrative image related to diagram cooling tower

Emerging markets, particularly in Africa and South America, are witnessing increased investments in infrastructure, leading to a surge in industrial activities that necessitate efficient cooling solutions. Moreover, regulatory frameworks in the Middle East and Europe are becoming more stringent regarding environmental standards, pushing companies to invest in sustainable cooling technologies. As a result, international B2B buyers are focusing on sourcing cooling towers that not only meet operational requirements but also comply with these evolving regulations, ensuring long-term viability and cost-effectiveness.

How Does Sustainability Influence Sourcing Decisions in the Diagram Cooling Tower Sector?

Sustainability is becoming a crucial factor in the sourcing of cooling towers, as businesses increasingly recognize the environmental impact of their operations. The cooling tower sector is traditionally associated with significant water and energy consumption, which has led to a growing emphasis on sourcing practices that minimize these effects. Buyers are prioritizing manufacturers that demonstrate commitment to sustainable practices, such as using recycled materials and implementing energy-efficient technologies.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are now looking for suppliers who can provide transparency in their sourcing processes, ensuring that materials used in cooling towers are responsibly sourced and that labor practices adhere to ethical standards. Certifications such as LEED (Leadership in Energy and Environmental Design) and ENERGY STAR are becoming important benchmarks for B2B buyers when evaluating potential suppliers. By prioritizing sustainability and ethical sourcing, businesses can enhance their corporate social responsibility (CSR) profiles, appealing to environmentally conscious clients and stakeholders.

What is the Evolution of the Diagram Cooling Tower Sector and Its Relevance Today?

The cooling tower sector has evolved significantly since its inception in the early 20th century. Originally designed to facilitate the cooling of steam engines, cooling towers have transformed into complex systems integral to modern industrial processes. The development of more efficient designs, such as counterflow and crossflow cooling towers, has enabled industries to optimize their cooling operations while reducing water and energy usage.

Illustrative image related to diagram cooling tower

The relevance of this evolution is particularly pronounced today, as industries face mounting pressure to adopt sustainable practices and improve operational efficiencies. Innovations such as modular designs and IoT integration are not only enhancing the performance of cooling towers but also aligning with global trends toward digitalization and sustainability. For international B2B buyers, understanding the historical context of cooling tower technologies can provide valuable insights into current market dynamics and future sourcing opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of diagram cooling tower

-

How do I solve cooling efficiency issues with my existing cooling tower?

To improve cooling efficiency, first assess the operational parameters of your existing cooling tower. Check for debris in the fill media and ensure regular maintenance is conducted to prevent fouling. Adjust the water flow rates and inspect the fan operation, as inadequate airflow can significantly impact performance. Additionally, consider upgrading to a more efficient cooling tower design, such as a counterflow or induced draft system, which can provide superior cooling capabilities. Engaging with an experienced cooling tower supplier can also provide insights into optimizing your current setup. -

What is the best type of cooling tower for industrial applications in hot climates?

For industrial applications in hot climates, counterflow cooling towers are often the best choice due to their higher efficiency in heat transfer. They are designed to handle high temperature variations and provide effective cooling even when ambient temperatures rise. Additionally, induced draft systems can help maintain lower water temperatures by enhancing airflow. Consider factors such as water quality, space availability, and specific cooling requirements of your processes when selecting the most suitable cooling tower type. -

How do I evaluate and vet suppliers for cooling towers?

When evaluating suppliers for cooling towers, consider their experience in the industry and the range of products they offer. Request references from previous clients, particularly those with similar needs to yours. Assess their manufacturing capabilities and quality control processes to ensure compliance with international standards. Additionally, inquire about their after-sales support and maintenance services, as well as their ability to provide customized solutions tailored to your specific cooling requirements. -

What customization options are available for cooling towers?

Customization options for cooling towers typically include modifications in size, materials, fan configurations, and design specifications to meet specific operational needs. Buyers can opt for corrosion-resistant materials for harsh environments or specific fill media for enhanced cooling efficiency. Many manufacturers also offer tailored solutions for noise reduction or energy efficiency improvements. Discuss your unique requirements with potential suppliers to explore the available customization options that fit your operational goals. -

What are the typical minimum order quantities (MOQ) for cooling towers?

Minimum order quantities (MOQ) for cooling towers can vary significantly by supplier and the type of cooling tower required. Generally, MOQs may range from a single unit for smaller, factory-assembled towers to several units for field-erected models, which are typically larger and more complex. It’s advisable to communicate directly with suppliers to understand their specific MOQs and explore potential flexibility, especially if you are a smaller company or are looking for pilot projects. -

What payment terms should I expect when purchasing cooling towers internationally?

Payment terms for international purchases of cooling towers can vary widely, but standard practices often include options such as 30% upfront payment with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or other financing options, particularly for larger orders. It’s crucial to clarify these terms before finalizing the purchase, ensuring that both parties are in agreement to avoid disputes. Always consider the implications of currency exchange rates and international transaction fees in your budgeting. -

How do I ensure quality assurance for my cooling tower purchase?

To ensure quality assurance for your cooling tower purchase, request detailed documentation regarding the manufacturing process, including material certifications and compliance with industry standards such as ASME or ISO. Conduct factory visits if possible, or request third-party inspections. Many reputable suppliers also provide warranties that cover defects and performance guarantees. Establishing clear communication about your quality expectations with the supplier at the outset can help mitigate any potential issues. -

What logistics considerations should I keep in mind when importing cooling towers?

When importing cooling towers, consider the logistics of shipping, including transportation modes, customs regulations, and import duties specific to your country. Engage a reliable logistics partner familiar with heavy industrial equipment to handle the complexities of international shipping. Ensure that your supplier can provide all necessary shipping documents, such as bills of lading and customs declarations. Additionally, plan for installation logistics, including site preparation and any specialized equipment needed for assembly.

Top 7 Diagram Cooling Tower Manufacturers & Suppliers List

1. Construct and Commission – Cooling Tower Piping Layout

Domain: constructandcommission.com

Registered: 2020 (5 years)

Introduction: Cooling Tower Piping Layout includes various systems connected for efficient operation. Key pipework connections: 1. Condenser water return 2. Condenser water supply 3. Cooling tower bypass 4. Equalization line / balance pipe 5. Make up water 6. Water sampling 7. Blow down / bleed water 8. Overflow 9. Filtration 10. Drainage 11. Plate Heat Exchanger. Standard equipment includes: Isolation valves, …

2. Chemtreat – Cooling Towers

Domain: chemtreat.com

Registered: 1996 (29 years)

Introduction: Cooling towers are specialized heat exchangers that remove waste heat by creating steam. They cool water used for various industrial and commercial processes. The cooling process involves heat transfer through sensible heat (related to changes in water temperature) and latent heat (related to changes in physical state). Most heat is transferred to the atmosphere through evaporating recirculating c…

3. Facebook – Cooling Tower Control System

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This schematic diagram illustrates a cooling tower system with integrated control and monitoring components. Key features include a basin with a float valve for water level regulation, water supply and return lines for condenser water flow, a basin heater contactor, temperature sensors for optimal operation, an adjustable speed drive (ASD) for fan speed control, and status indicators for start/sto…

4. Universal Tower Parts – Cooling Tower Components

Domain: universaltowerparts.com

Registered: 2010 (15 years)

Introduction: Universal Tower Parts offers a variety of cooling tower products including:

– Cooling Tower Nozzles

– Air Inlet Louvers

– Fill Media

– Drift Eliminators

– Float Valves

– Float Assemblies

– Individual Float Parts

– Solenoid Valves

– Water Meters

– Basin Heaters

– Fans

– Fan Belts

– Motors and Pumps

– Vibration Switches

– Coatings & Sealants

– Mechanical Parts

– Water Level Controls

– Dura Drift Eli…

5. Chardon Labs – Water Treatment Solutions

Domain: chardonlabs.com

Registered: 1997 (28 years)

Introduction: Chardon Labs offers a range of water treatment services and products for cooling towers and chillers, including:

– Cooling Tower Water Treatment

– Chemical Water Treatment Products for Cooling Towers

– Cooling Tower Chemicals

– Boiler Water Treatment

– Boiler Water Treatment Products

– Boiler Water Treatment Equipment

– Boiler Chemicals

– Closed Loop Water Treatment

– Closed Loop Chemical…

6. Pinterest – Cooling Tower Diagram

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: This company, Pinterest – Cooling Tower Diagram, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Advantage Engineering – Closed Loop Cooling Tower System

Domain: cooling-towers.net

Registered: 2003 (22 years)

Introduction: Advantage Engineering Closed Loop Cooling Tower System Diagram provides a visual representation of the closed loop cooling tower system, highlighting its components and functionality. The system is designed for efficient heat exchange, featuring a closed loop design that minimizes water loss and contamination. Key components include the cooling tower, pump, heat exchanger, and control system, all …

Strategic Sourcing Conclusion and Outlook for diagram cooling tower

As the demand for efficient cooling solutions continues to rise globally, strategic sourcing of cooling towers presents a unique opportunity for international buyers. Understanding the intricacies of cooling tower operations—from evaporative cooling principles to the distinctions between crossflow and counterflow designs—empowers businesses to select systems that best meet their specific industrial needs. This knowledge not only enhances operational efficiency but also contributes to significant cost savings in energy consumption and maintenance.

For companies in Africa, South America, the Middle East, and Europe, investing in high-quality cooling tower systems is crucial for optimizing processes in sectors such as manufacturing, petrochemicals, and HVAC. By establishing strong relationships with reliable suppliers, buyers can ensure access to innovative technologies and tailored solutions that address regional climate challenges and regulatory standards.

Looking forward, the evolution of cooling technology, including advancements in energy efficiency and environmental sustainability, will shape future sourcing strategies. B2B buyers are encouraged to stay informed about these developments and engage with trusted manufacturers to harness the benefits of modern cooling solutions. Begin your strategic sourcing journey today and position your business for success in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to diagram cooling tower

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.