A B2B Buyer’s Guide to Cord And Plug: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for cord and plug

In today’s global marketplace, sourcing reliable cord and plug solutions can be a daunting task for international B2B buyers. The challenge lies not only in identifying products that meet specific electrical standards but also in ensuring compatibility across various regions, particularly for markets in Africa, South America, the Middle East, and Europe. This guide aims to demystify the complexities associated with cord and plug procurement by providing an extensive overview of types, applications, and crucial factors to consider when selecting suppliers.

Our comprehensive resource will delve into the diverse range of cord and plug options available, including NEMA configurations widely used in North America and various international standards that cater to different electrical specifications. We will also explore essential criteria for supplier vetting, helping you assess reliability, compliance, and cost-effectiveness. Understanding these components is vital to making informed purchasing decisions that enhance operational efficiency and safety.

By equipping international B2B buyers with the knowledge to navigate the intricate landscape of cord and plug products, this guide empowers you to streamline your sourcing process. Whether you are looking to fulfill specific project requirements or seeking to optimize your supply chain, the insights provided here will enable you to engage with confidence in the global market.

Understanding cord and plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Blade | Simple design, commonly used, available in various amperages | General appliances, lighting, tools | Pros: Easy to use, widely available. Cons: Less secure connection. |

| Twist Lock | Requires a twisting motion to lock into place | Industrial equipment, generators, outdoor use | Pros: Secure connection, prevents accidental disconnection. Cons: More expensive, bulkier. |

| Pin & Sleeve | Features pins and sleeves for secure connection | Heavy machinery, high-power applications | Pros: High durability, ideal for heavy loads. Cons: Requires specific receptacles. |

| NEMA | Standardized plug types used primarily in North America | Commercial and residential electrical systems | Pros: Wide compatibility, standardized safety ratings. Cons: Limited to North American standards. |

| IEC | International standard for electrical connectors | Data centers, IT equipment, appliances | Pros: Versatile, used globally, compact design. Cons: May require adapters for non-IEC equipment. |

What Are the Characteristics of Straight Blade Cords and Plugs?

Straight blade plugs are the most common type of electrical connectors, typically featuring two or three flat pins. They are widely used in residential and commercial settings for general appliances, lighting, and power tools. When purchasing straight blade connectors, buyers should consider the amperage ratings, compatibility with existing systems, and whether grounding is necessary. Their simplicity and availability make them a cost-effective choice, but they may not provide the same level of security as other types.

How Do Twist Lock Plugs Enhance Safety in Industrial Applications?

Twist lock plugs are designed to securely connect to their receptacles through a twisting motion. This feature makes them ideal for industrial applications where equipment may be frequently moved or subject to vibration. Commonly used with generators and outdoor equipment, twist lock plugs prevent accidental disconnections. Buyers should evaluate the specific amperage and voltage requirements, as well as the environment in which the plugs will be used. While they offer enhanced safety, their complexity and higher cost may be considerations for some businesses.

What Makes Pin & Sleeve Connectors Suitable for Heavy Machinery?

Pin and sleeve connectors are robust and designed for high-power applications, such as heavy machinery and industrial equipment. They consist of multiple pins and sleeves that provide a secure and durable connection. When sourcing pin and sleeve connectors, B2B buyers should focus on the amperage ratings and ensure compatibility with existing systems. These connectors are ideal for environments where high durability is essential, but the need for specific receptacles can limit their flexibility.

Why Are NEMA Plugs Important for North American Businesses?

NEMA (National Electrical Manufacturers Association) plugs are standardized connectors primarily used in North America. They come in various configurations that cater to different voltage and amperage requirements, making them suitable for both commercial and residential applications. Buyers should consider the specific NEMA type that meets their equipment needs and ensure compliance with local electrical codes. While these plugs offer wide compatibility and safety, their limitation to North American standards may pose challenges for international operations.

How Do IEC Connectors Support Global Electrical Needs?

IEC (International Electrotechnical Commission) connectors are widely used for electrical devices across the globe, particularly in data centers and IT applications. Their compact design and versatility make them suitable for a range of appliances. B2B buyers should assess the compatibility of IEC connectors with their equipment and consider the need for adapters when interfacing with non-IEC systems. While these connectors are favored for their international applicability, businesses may face challenges in sourcing specific types depending on regional standards.

Key Industrial Applications of cord and plug

| Industry/Sector | Specific Application of cord and plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and equipment | Ensures continuous operation and reduces downtime | Compliance with local electrical standards and ratings |

| Construction | Temporary power supply for tools and equipment | Enhances site efficiency and worker safety | Durability and weather resistance for outdoor use |

| Telecommunications | Connecting network devices and infrastructure | Supports high-speed data transfer and connectivity | Compatibility with varying voltage and amperage needs |

| Hospitality | Powering appliances and equipment in hotels | Improves guest experience and operational efficiency | Energy efficiency and safety features |

| Agriculture | Connecting irrigation systems and machinery | Optimizes resource management and increases yield | Resistance to environmental factors and corrosion |

How is ‘cord and plug’ utilized in the manufacturing sector?

In the manufacturing sector, cord and plug systems are essential for powering various machinery and equipment. These connections enable seamless operation of production lines, which is crucial for maintaining productivity. Buyers in this sector must ensure that the cords and plugs meet local electrical standards, particularly in regions like Africa and South America, where compliance can vary significantly. Additionally, the ability to handle high amperage and voltage ratings is critical to prevent overheating and potential equipment failure.

What role does ‘cord and plug’ play in construction sites?

On construction sites, cord and plug configurations are used to provide temporary power to tools and machinery. This flexibility allows construction teams to set up equipment quickly and efficiently, enhancing overall site productivity. Given the outdoor nature of construction work, sourcing durable and weather-resistant plugs is vital to withstand harsh conditions. International buyers should prioritize suppliers who can guarantee compliance with safety standards to minimize the risk of accidents and ensure worker safety.

How does ‘cord and plug’ support telecommunications infrastructure?

In the telecommunications industry, cord and plug systems are crucial for connecting network devices, such as routers, switches, and servers. These connections facilitate high-speed data transfer and reliable communication networks, which are fundamental for business operations. Buyers should consider the compatibility of plugs with different voltage and amperage requirements, particularly in regions with varying electrical standards, like Europe and the Middle East. Ensuring that cords can handle surge protection is also essential to safeguard sensitive equipment.

In what ways does ‘cord and plug’ improve hospitality operations?

Within the hospitality sector, cord and plug systems power various appliances and equipment, from kitchen tools to guest room amenities. Reliable power connections enhance guest experiences and operational efficiency, making it vital for hotels and restaurants to invest in high-quality products. Buyers should look for energy-efficient options with safety features, such as surge protection and tamper-resistant designs, especially in European markets where energy regulations are stringent. This focus not only supports guest satisfaction but also reduces operational costs.

How is ‘cord and plug’ utilized in agricultural applications?

In agriculture, cord and plug systems are used to connect irrigation systems and machinery, facilitating efficient water management and crop production. This application is particularly beneficial in maximizing yield and conserving resources. Buyers must source products that are resistant to environmental factors, such as moisture and corrosion, to ensure longevity and reliability in the field. Additionally, understanding the specific voltage and amperage needs of agricultural equipment is crucial for effective sourcing, especially for international buyers in diverse climates.

3 Common User Pain Points for ‘cord and plug’ & Their Solutions

Scenario 1: Ensuring Compliance with International Standards

The Problem: A B2B buyer sourcing electrical components for their manufacturing facility in Brazil faces the challenge of ensuring that all cord and plug connections comply with local safety standards and international regulations. Many suppliers may provide products that seem suitable but do not meet the specific requirements set by Brazilian electrical standards, leading to potential safety hazards, legal repercussions, and costly delays in production. This issue is compounded by the diversity of plug types and voltage requirements across different regions, making it difficult to find a consistent solution.

The Solution: To mitigate this risk, buyers should conduct thorough research on local compliance standards, such as the Brazilian Association of Technical Standards (ABNT) regulations. Collaborating with suppliers who specialize in international markets can provide access to products specifically designed to meet these standards. It is advisable to request certification documentation for all cord and plug products to ensure that they adhere to local and international safety protocols. Additionally, buyers should consider working with a knowledgeable local distributor who can offer insights into specific requirements for their region and assist with sourcing compliant products.

Scenario 2: Managing Inventory and Reducing Downtime

The Problem: A company in South Africa operates multiple production lines that rely heavily on various cord and plug configurations. When a plug fails, the downtime can be costly, leading to delays in production and loss of revenue. Maintaining a diverse inventory of spare plugs and connectors can be a logistical nightmare, especially when dealing with different voltage and amperage requirements across equipment. Furthermore, the lack of standardized connections can complicate repairs and lead to inconsistencies in maintenance procedures.

The Solution: Implementing a standardized approach to cord and plug specifications across the production lines can significantly enhance efficiency. Buyers should analyze the equipment used and identify common plug types and configurations. By consolidating the variety of plugs into a few standardized types, the company can simplify inventory management. Additionally, creating a strategic partnership with a supplier that offers a range of standardized plugs and connectors can ensure quick access to replacements. Regular training sessions for maintenance staff on these standard plugs will also improve repair times and reduce the likelihood of using incorrect components during fixes.

Scenario 3: Addressing Environmental Concerns and Sustainability

The Problem: A European B2B buyer is increasingly concerned about the environmental impact of their electrical components, particularly regarding the materials used in cord and plug manufacturing. Many traditional plugs are made from non-recyclable plastics and contain hazardous materials, raising ethical concerns and potentially harming the company’s reputation. Sourcing sustainable alternatives can be difficult, especially when balancing cost and performance requirements.

The Solution: Buyers should prioritize sourcing from manufacturers that focus on sustainability and offer eco-friendly cord and plug options. This involves researching suppliers that utilize recyclable materials, such as biodegradable plastics or sustainable sourcing methods, and possess certifications like RoHS (Restriction of Hazardous Substances). Engaging with suppliers who demonstrate a commitment to environmental responsibility can also open up opportunities for collaboration on innovative products that meet both performance and sustainability goals. Furthermore, buyers can consider bulk purchasing agreements to lower costs while investing in a more sustainable supply chain, ensuring that their operations align with corporate social responsibility goals.

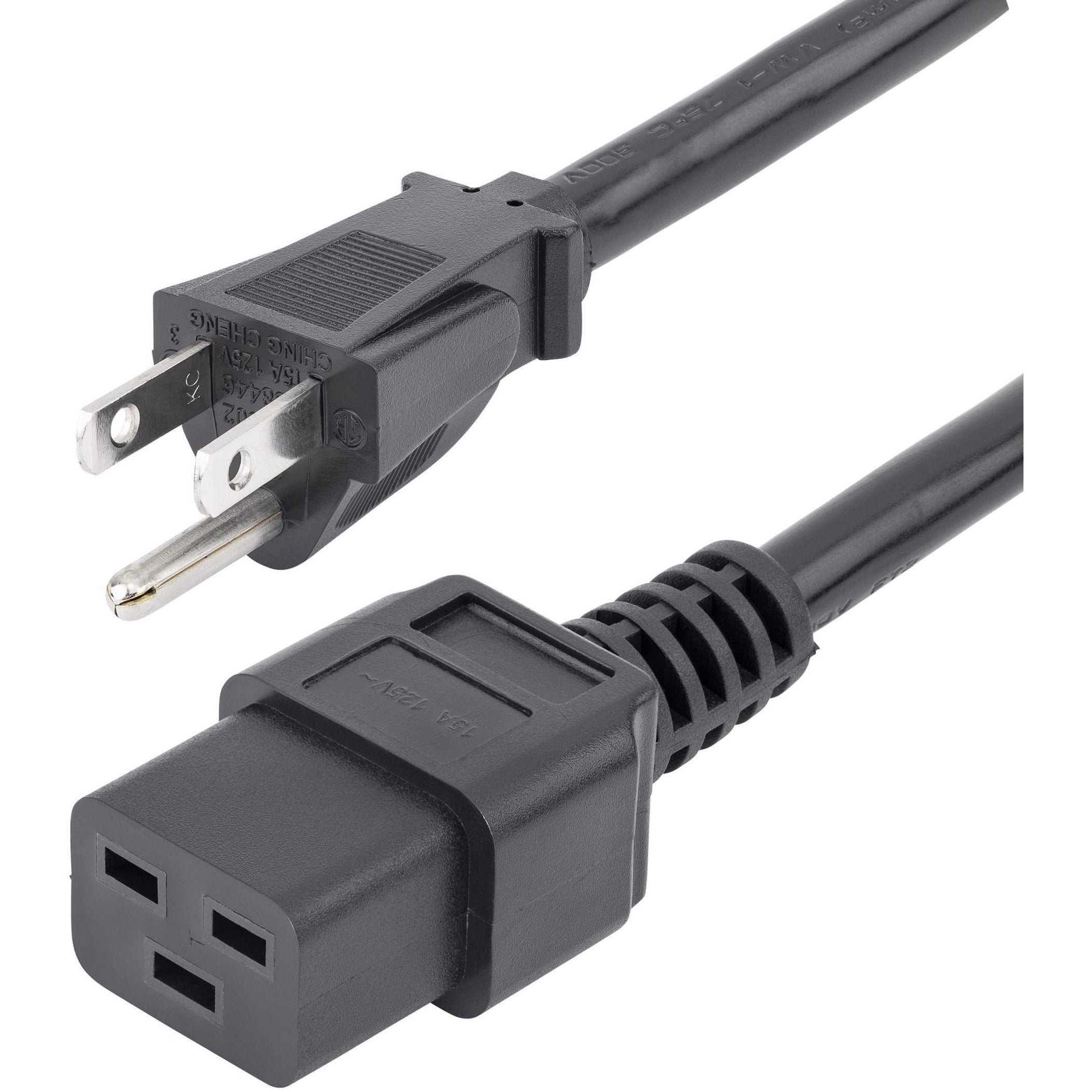

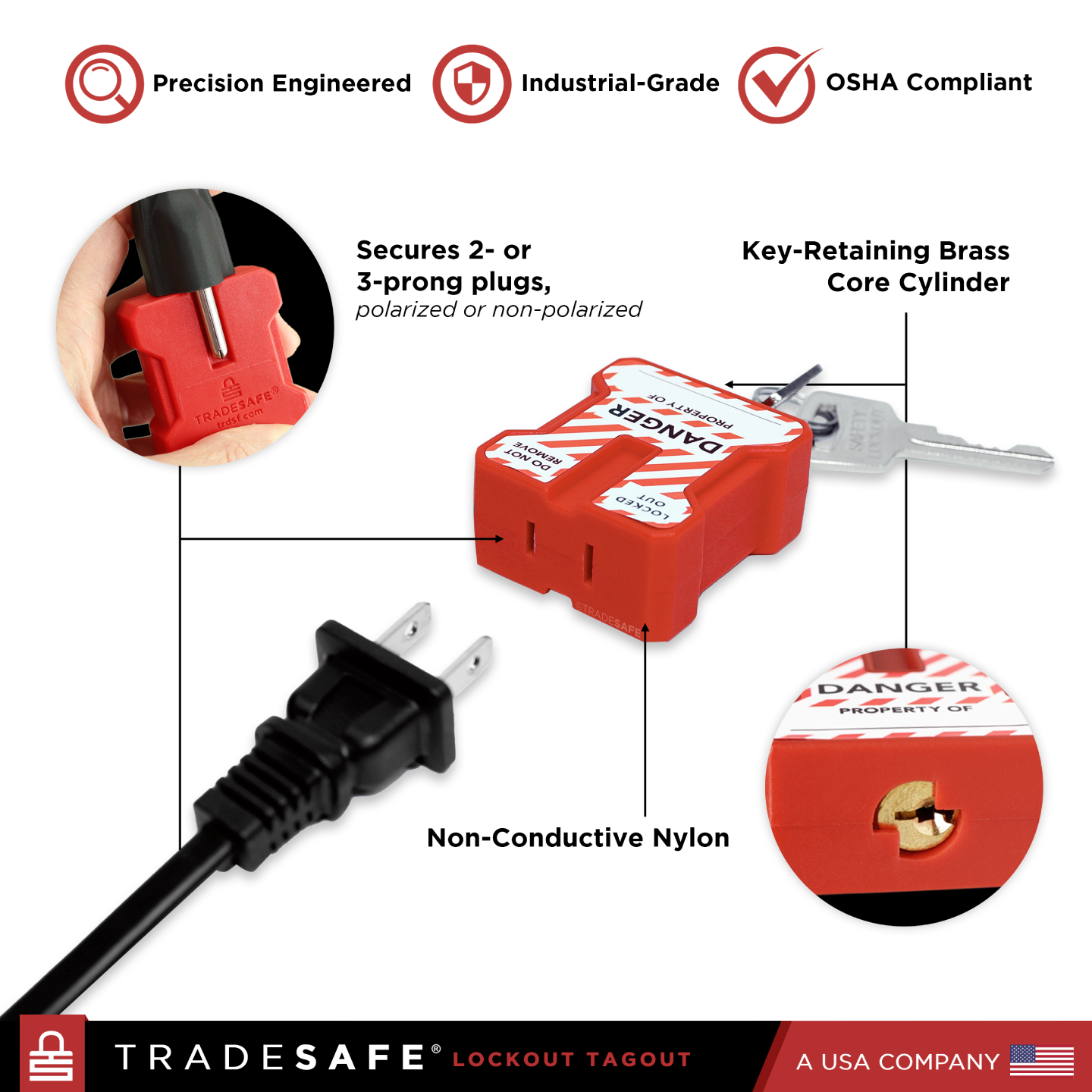

Illustrative image related to cord and plug

Strategic Material Selection Guide for cord and plug

What are the Key Materials Used in Cord and Plug Manufacturing?

When selecting materials for cords and plugs, several factors including durability, cost, and application suitability must be considered. Below is an analysis of four common materials used in the manufacturing of cords and plugs, along with their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. PVC (Polyvinyl Chloride)

Key Properties: PVC is known for its excellent electrical insulation properties and resistance to moisture, chemicals, and abrasion. It can operate effectively in temperatures ranging from -10°C to 70°C.

Pros & Cons: The primary advantage of PVC is its low cost and ease of manufacturing, making it a popular choice for budget-conscious applications. However, PVC is less durable than some alternatives, particularly in extreme temperatures or environments, which can lead to cracking or degradation over time.

Impact on Application: PVC is suitable for general-purpose applications where flexibility and insulation are required. However, it may not be ideal for high-temperature environments or heavy-duty industrial applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and REACH is essential, especially for buyers in Europe. PVC is widely accepted, but buyers should ensure that it meets local regulations regarding environmental impact and safety.

2. Rubber

Key Properties: Rubber offers excellent elasticity, flexibility, and resistance to extreme temperatures, ranging from -40°C to 100°C. It also provides good electrical insulation and is resistant to moisture and chemicals.

Pros & Cons: The primary advantage of rubber is its durability and flexibility, making it suitable for outdoor and industrial applications. However, rubber can be more expensive than PVC and may require more complex manufacturing processes.

Impact on Application: Rubber is ideal for heavy-duty applications, such as construction and outdoor equipment, where flexibility and durability are critical. Its resistance to weathering makes it suitable for outdoor plugs and connectors.

Considerations for International Buyers: Buyers in regions with harsh climates, such as parts of Africa and the Middle East, should prioritize rubber for outdoor applications. Compliance with local safety and environmental standards is crucial, particularly in Europe and South America.

3. Thermoplastic Elastomers (TPE)

Key Properties: TPE combines the properties of rubber and plastic, offering excellent flexibility, durability, and resistance to extreme temperatures (-50°C to 90°C). It is also resistant to UV light and ozone.

Pros & Cons: TPE is highly versatile and can be molded into complex shapes, making it suitable for various applications. However, it tends to be more expensive than PVC and rubber, which may deter cost-sensitive buyers.

Impact on Application: TPE is ideal for applications requiring high flexibility and durability, such as in medical devices and automotive connectors. Its resistance to environmental factors makes it a preferred choice for outdoor use.

Considerations for International Buyers: TPE products must comply with specific standards, such as DIN and JIS, depending on the region. Buyers should be aware of the higher costs associated with TPE and evaluate whether the benefits justify the investment.

Illustrative image related to cord and plug

4. Nylon

Key Properties: Nylon is known for its high strength, abrasion resistance, and thermal stability, with operating temperatures ranging from -40°C to 120°C. It is also resistant to chemicals and UV light.

Pros & Cons: The strength and durability of nylon make it suitable for heavy-duty applications. However, nylon can be more expensive than PVC and may require specialized manufacturing techniques.

Impact on Application: Nylon is ideal for industrial applications where strength and resistance to wear are critical, such as in machinery and automotive components. Its thermal stability also makes it suitable for high-temperature environments.

Considerations for International Buyers: Buyers should consider the specific performance requirements of their applications and ensure that nylon components meet international standards. The higher cost may be justified in applications requiring superior performance.

Summary Table

| Material | Typical Use Case for cord and plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General-purpose electrical applications | Low cost and easy to manufacture | Less durable in extreme conditions | Low |

| Rubber | Heavy-duty outdoor and industrial use | Excellent durability and flexibility | Higher cost and complex manufacturing | Med |

| Thermoplastic Elastomers | Medical devices, automotive connectors | Versatile with high flexibility | More expensive than PVC and rubber | High |

| Nylon | Industrial machinery and automotive parts | High strength and abrasion resistance | Higher cost and specialized manufacturing | High |

This material selection guide serves as a foundational resource for international B2B buyers, enabling informed decisions that align with operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cord and plug

What Are the Main Stages of Cord and Plug Manufacturing Processes?

The manufacturing of cords and plugs involves several critical stages that ensure the final products meet stringent quality and safety standards. The typical manufacturing process can be divided into four main stages: material preparation, forming, assembly, and finishing.

How Are Materials Prepared for Cord and Plug Production?

The first step in manufacturing is material preparation, where high-quality raw materials are sourced. Common materials include copper for conductors, thermoplastic or thermoset materials for insulation, and metal alloys for the connectors. The selection of materials is crucial as it directly impacts the durability, conductivity, and safety of the final product.

Once materials are sourced, they undergo rigorous testing to ensure they meet specific mechanical and electrical properties. This step often involves checking for conductivity, tensile strength, and resistance to environmental factors such as heat and moisture.

What Techniques Are Used in the Forming Stage?

During the forming stage, the prepared materials are shaped into their required forms. This can involve processes such as extrusion for the insulation and injection molding for the plugs. Advanced techniques like CNC machining may also be employed for precision components.

For cord manufacturing, the conductors are typically twisted together and covered with insulation to create a durable and flexible product. The forming stage is essential for ensuring that each component fits precisely, which is critical for maintaining electrical integrity and safety.

How Is Assembly Conducted in Cord and Plug Manufacturing?

In the assembly phase, the formed components are brought together. This stage often involves mechanical fastening, soldering, or crimping to ensure a secure connection between the plug and the cord. Automated assembly lines are increasingly common, allowing for faster production times and reducing the potential for human error.

Quality checks are integrated into this stage, with operators inspecting connections and ensuring that components meet specifications. This proactive approach helps to catch any potential issues before the product moves to the next stage.

What Finishing Techniques Are Applied to Ensure Quality?

Finishing is the final stage in the manufacturing process. This stage often includes applying coatings for protection against corrosion, abrasion, and environmental damage. Additionally, plugs and connectors may undergo further testing to ensure they meet industry standards.

Common finishing techniques include surface treatment, painting, and the application of labels or certifications. This step not only enhances the product’s durability but also provides information necessary for end users, such as voltage ratings and safety certifications.

What Quality Assurance Practices Are Critical in Cord and Plug Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of cords and plugs, particularly in a B2B context where reliability is paramount. Various international and industry-specific standards guide the QA process.

Which International Standards Should B2B Buyers Be Aware Of?

For manufacturers, adhering to international standards such as ISO 9001 is crucial. This standard outlines requirements for a quality management system (QMS), ensuring that products consistently meet customer and regulatory requirements. Additionally, certifications like CE mark (for European markets) and UL certification (for North America) are often mandatory.

These certifications not only enhance the credibility of the manufacturer but also reassure buyers about the quality and safety of the products. Buyers should prioritize suppliers who can provide evidence of compliance with these standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process. Key QC stages include:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections are performed to monitor quality and adherence to specifications. This can include checking dimensions, electrical properties, and overall assembly integrity.

- Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to ensure they meet all regulatory and quality standards.

Implementing these checkpoints helps manufacturers catch defects early and reduce waste, ultimately saving costs and improving product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are some strategies:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits can provide insights into a manufacturer’s processes and quality control measures. Buyers should consider:

- On-Site Audits: Visiting the manufacturing facility allows buyers to observe production processes, quality control measures, and compliance with international standards firsthand.

- Documentation Review: Requesting and reviewing quality control reports, inspection records, and certification documentation can provide assurance of a supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices.

What Testing Methods Are Commonly Used in Quality Control?

Common testing methods used in quality control for cords and plugs include:

- Electrical Testing: This includes continuity testing, insulation resistance testing, and dielectric strength testing to ensure electrical safety and performance.

- Mechanical Testing: Tensile strength and flexibility tests help assess the durability of the cords and plugs under various conditions.

- Environmental Testing: Products may undergo exposure to extreme temperatures, humidity, or corrosive environments to ensure they meet performance standards in real-world conditions.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control:

- Regulatory Compliance: Different regions have varying regulatory requirements. Understanding local standards is crucial for compliance and market entry.

- Cultural Considerations: The approach to quality assurance can vary significantly across regions. Building strong relationships with suppliers can facilitate better communication and understanding of quality expectations.

- Logistics and Shipping: Quality control does not end at the manufacturing facility. Ensuring products are handled correctly during shipping and storage is vital for maintaining quality upon arrival.

By understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting suppliers for cords and plugs. This knowledge not only helps in ensuring product quality but also fosters long-term business relationships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cord and plug’

Introduction

This sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure cords and plugs. It outlines essential steps to ensure a successful purchasing process, focusing on quality, compliance, and supplier reliability. By following this checklist, buyers can make informed decisions that align with their operational needs and regional standards.

1. Define Your Technical Specifications

Understanding the specific technical requirements of the cords and plugs you need is critical. This includes voltage ratings, amperage, and connector types (e.g., NEMA, IEC). Clearly defined specifications help in narrowing down suitable products that meet safety and performance standards relevant to your industry.

- Consider the environments in which the cords will be used (e.g., indoor vs. outdoor).

- Identify any specific features required, such as weather resistance or surge protection.

2. Research Compliance Standards

Different regions have distinct regulations governing electrical products. Verify that the cords and plugs comply with applicable standards such as IEC for Europe, NEMA for North America, and local regulations in your target markets. Compliance ensures safety and reliability, minimizing the risk of legal issues.

Illustrative image related to cord and plug

- Look for certifications like CE, UL, or RoHS, which indicate adherence to safety and environmental standards.

- Check if the supplier provides documentation confirming compliance.

3. ✅ Verify Supplier Certifications

Before engaging with a supplier, ensure they possess the necessary certifications and quality management systems. This step is vital to avoid potential pitfalls associated with substandard products. A reputable supplier should be transparent about their certifications and quality control processes.

- Request documentation of ISO certifications or other relevant quality assurance frameworks.

- Investigate their production processes to ensure they meet international quality standards.

4. Evaluate Potential Suppliers

Thoroughly vet potential suppliers to establish reliability and quality. Look for suppliers with a proven track record in the industry and positive reviews from other businesses. This diligence can save you from costly mistakes and delays.

- Ask for case studies or references from similar industries or regions.

- Evaluate their customer service responsiveness, which can be crucial for ongoing support.

5. Request Samples for Testing

Before finalizing a bulk order, request samples of the cords and plugs. Testing samples allows you to assess the quality, durability, and compatibility with your existing systems. This hands-on evaluation can prevent future issues related to performance.

- Conduct thorough testing under real operational conditions to ensure reliability.

- Analyze the samples for any defects or inconsistencies.

6. Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Clear agreements are essential to prevent misunderstandings that could disrupt your supply chain.

- Discuss bulk purchase discounts or long-term contract incentives.

- Ensure that delivery schedules align with your operational needs to avoid delays.

7. Establish a Continuous Relationship

Building a long-term relationship with your supplier can lead to better pricing, priority service, and access to new products. Regular communication and feedback help to foster a partnership that benefits both parties.

Illustrative image related to cord and plug

- Schedule periodic reviews to assess performance and address any issues.

- Stay informed about new products or technologies that may enhance your operations.

By following this checklist, B2B buyers can enhance their sourcing strategies for cords and plugs, ensuring they meet their specific requirements while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for cord and plug Sourcing

What Are the Key Cost Components in Cord and Plug Manufacturing?

In the manufacturing of cords and plugs, several cost components contribute to the overall pricing structure. These include:

-

Materials: The choice of materials significantly impacts cost. High-quality plastics and metals, such as copper and brass, are often used for durability and conductivity. The price of these raw materials can fluctuate based on global supply and demand, affecting the final product cost.

-

Labor: Labor costs are influenced by the location of manufacturing. Regions with lower labor costs may provide competitive pricing, but this can sometimes come at the expense of quality. Skilled labor is essential for tasks such as assembly and quality assurance, which can increase costs.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can help minimize overhead costs, which in turn can lower product prices.

-

Tooling: Initial tooling costs for molds and dies can be substantial, particularly for custom designs. This investment is typically spread over the production run, making it essential for buyers to consider their order volume.

-

Quality Control (QC): Ensuring product safety and compliance with international standards (e.g., UL, CE certifications) requires robust QC processes. The costs associated with testing and certification can influence pricing, especially for products aimed at regulated markets.

-

Logistics: Transportation costs play a crucial role in the total pricing structure. Factors such as distance, mode of transport, and shipping terms (Incoterms) can significantly impact the final cost to the buyer.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market dynamics, competition, and the buyer’s negotiation skills.

How Do Price Influencers Affect Cord and Plug Sourcing?

Several factors influence pricing in the cord and plug market, particularly for international B2B buyers:

Illustrative image related to cord and plug

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often attract discounts, making it economically advantageous for buyers to purchase larger quantities. Understanding the supplier’s MOQ can help negotiate better pricing.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers should assess whether the added expense aligns with their operational needs.

-

Materials: The type and quality of materials used in the manufacturing process directly affect pricing. High-performance materials may incur higher costs but offer better durability and safety.

-

Quality and Certifications: Products that meet stringent quality standards and certifications typically command higher prices. Buyers should weigh the benefits of certified products against their costs.

-

Supplier Factors: Supplier reputation, reliability, and experience can influence pricing. Established suppliers may charge a premium for their quality assurance, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is critical for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect total costs.

What Are Effective Buyer Tips for Cost-Efficiency in Cord and Plug Sourcing?

To maximize cost-efficiency when sourcing cords and plugs, buyers should consider the following strategies:

-

Negotiate Effectively: Leverage volume commitments and long-term partnerships to negotiate better terms and pricing. Building a strong relationship with suppliers can lead to favorable deals.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. TCO includes maintenance, replacement, and operational costs, which can vary significantly based on product quality and durability.

-

Research Market Prices: Stay informed about market trends and pricing benchmarks in your region. This knowledge can empower negotiations and ensure that you are not overpaying.

-

Evaluate Supplier Options: Diversify your supplier base to mitigate risks and find the best pricing. Different suppliers may offer unique advantages, whether in cost, quality, or delivery capabilities.

-

Be Aware of Pricing Nuances: International buyers should be cautious of currency fluctuations and tariffs that may impact final costs. Understanding these factors can aid in better budgeting and planning.

Disclaimer on Indicative Prices

Prices for cords and plugs can vary widely based on the factors discussed above. The information provided is for indicative purposes only and should be verified through direct supplier quotations and market research.

Alternatives Analysis: Comparing cord and plug With Other Solutions

Introduction: What Alternatives Exist to Cord and Plug Solutions?

As businesses explore electrical connection solutions, understanding the alternatives to traditional cord and plug systems becomes critical. Various methods and technologies can serve similar functions, offering distinct advantages and drawbacks depending on specific operational requirements. This analysis will compare cord and plug systems with two viable alternatives: hardwired connections and wireless power transmission.

Comparison Table

| Comparison Aspect | Cord And Plug | Hardwired Connection | Wireless Power Transmission |

|---|---|---|---|

| Performance | Reliable, consistent power delivery | Excellent, no disconnection risk | Limited range, efficiency varies |

| Cost | Generally low initial cost | Higher installation cost | High initial investment |

| Ease of Implementation | Simple installation, user-friendly | Requires skilled labor for installation | Requires specialized equipment |

| Maintenance | Low maintenance required | Moderate, depends on installation quality | Minimal, but technology-dependent |

| Best Use Case | Portable devices, temporary setups | Permanent installations, fixed equipment | Mobile applications, dynamic environments |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Hardwired Connections?

Hardwired connections involve directly connecting equipment to electrical circuits, eliminating the need for plugs and sockets. The primary advantage of hardwired systems is their reliability; they provide stable power without the risk of disconnection, making them ideal for permanent installations in factories or commercial buildings. However, the installation process can be costly and time-consuming, requiring skilled electricians. Additionally, once installed, modifications can be complex and may necessitate significant downtime.

How Does Wireless Power Transmission Compare to Cord and Plug Systems?

Wireless power transmission is an innovative solution that allows power to be transferred without physical connections. This technology is particularly beneficial in environments where traditional wiring is impractical, such as in mobile devices or for charging electric vehicles. The major advantage is flexibility; devices can be charged or powered without being tethered to a socket. However, the technology is still developing and can be expensive. Efficiency can also be a concern, as the distance between the transmitter and receiver can significantly impact performance.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate electrical connection solution, B2B buyers should carefully evaluate their specific needs. Cord and plug systems offer a cost-effective and versatile option, particularly for applications that require mobility or temporary setups. In contrast, hardwired connections may be more suitable for permanent installations where reliability is paramount. Wireless power transmission presents a cutting-edge alternative that caters to modern mobility demands, though it may require a larger upfront investment. Ultimately, the choice should align with operational requirements, budget constraints, and long-term strategic goals.

Essential Technical Properties and Trade Terminology for cord and plug

What Are the Key Technical Properties of Cord and Plug Products?

Understanding the critical specifications of cord and plug products is essential for making informed purchasing decisions in the B2B landscape. Here are several key properties that buyers should consider:

1. Material Grade

The material used in cord and plug manufacturing significantly affects durability, flexibility, and resistance to environmental factors. Common materials include PVC (Polyvinyl Chloride) for insulation and thermoplastic elastomers for flexibility. High-grade materials ensure longevity, making them vital for businesses that rely on consistent performance under various conditions.

2. Amperage Rating

This specification indicates the maximum current a cord or plug can handle safely. Common ratings range from 10A to 50A, depending on the application. Selecting a product with an appropriate amperage rating is critical to prevent overheating and potential hazards, ensuring safety and compliance with industry standards.

Illustrative image related to cord and plug

3. Voltage Rating

Voltage ratings indicate the maximum voltage a cord or plug can carry, typically ranging from 110V to 600V. Understanding the voltage requirements of your equipment is crucial to avoid electrical failures. This knowledge allows B2B buyers to ensure compatibility with their power sources, especially in international markets with varying electrical standards.

4. Connector Type

Connectors are categorized based on their design and application, such as NEMA (National Electrical Manufacturers Association) configurations in North America or IEC (International Electrotechnical Commission) standards globally. Familiarity with connector types is essential for ensuring compatibility with existing systems, especially for international buyers who may encounter different standards.

5. Durability Features

Durability features such as weather resistance, waterproofing, and corrosion resistance are critical for applications in harsh environments. For example, cords used outdoors or in industrial settings should have enhanced durability to withstand elements. This property impacts maintenance costs and the overall lifespan of the product.

What Are Common Trade Terms in the Cord and Plug Industry?

Familiarity with industry jargon can streamline communications and negotiations. Here are several key terms relevant to the cord and plug sector:

Illustrative image related to cord and plug

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the cord and plug industry, understanding OEM relationships can help buyers identify quality standards and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers who need to understand purchasing limits, especially when managing inventory or budgeting for larger projects.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products. This process is essential for buyers to compare costs, assess supplier capabilities, and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers for the delivery of goods. Familiarity with these terms helps international buyers understand shipping costs, risks, and obligations, facilitating smoother transactions.

5. Certification Standards

Certification standards such as UL (Underwriters Laboratories) or CE (Conformité Européenne) indicate that a product meets specific safety and quality requirements. Buyers should prioritize products that comply with relevant certifications to ensure safety and legal compliance in their markets.

By grasping these essential technical properties and trade terminology, B2B buyers can make more informed decisions, ensuring they select the right cord and plug solutions for their specific needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the cord and plug Sector

What are the Key Market Trends Influencing the Cord and Plug Sector?

The cord and plug sector is experiencing dynamic shifts driven by several global factors. The increasing demand for electronic devices and appliances in emerging markets, particularly in Africa and South America, is propelling growth. With urbanization and rising disposable incomes, consumers are increasingly reliant on technology, leading to a surge in demand for reliable electrical solutions. In parallel, the Middle East and Europe are witnessing a shift towards enhanced connectivity and smart home technologies, necessitating high-quality, durable cord and plug solutions.

B2B buyers are increasingly prioritizing products that are compliant with international standards such as NEMA (National Electrical Manufacturers Association) in the U.S. and IEC (International Electrotechnical Commission) in Europe. Additionally, the trend towards customization is gaining traction, as businesses seek solutions tailored to their specific operational needs. This includes the integration of IoT (Internet of Things) capabilities in plugs and connectors, which facilitate smarter energy management and monitoring.

Emerging technologies such as wireless charging are also reshaping the landscape, prompting manufacturers to innovate their product lines to remain competitive. As supply chains become more globalized, international buyers must navigate complex logistics and compliance requirements, making it essential to partner with suppliers who possess a robust understanding of local regulations.

How is Sustainability Shaping the Sourcing of Cord and Plug Products?

Sustainability has become a cornerstone of sourcing strategies in the cord and plug sector. With growing awareness of environmental issues, B2B buyers are increasingly seeking suppliers who prioritize sustainable practices. The use of eco-friendly materials and manufacturing processes can significantly reduce the environmental impact of cord and plug products.

Ethical sourcing is paramount; companies are expected to ensure that their supply chains are transparent and that they adhere to fair labor practices. Certifications such as RoHS (Restriction of Hazardous Substances) and UL (Underwriters Laboratories) signify a commitment to both safety and environmental responsibility, making these certifications critical for B2B buyers aiming to align with global sustainability standards.

Illustrative image related to cord and plug

Moreover, there is a marked shift towards recyclable and biodegradable materials in product design, which appeals to environmentally conscious consumers and businesses. Suppliers who can demonstrate their commitment to green practices are likely to gain a competitive advantage in the marketplace, making it essential for B2B buyers to evaluate their partners on these criteria.

What is the Historical Context of the Cord and Plug Market?

The cord and plug market has evolved significantly over the past century. Initially, the focus was primarily on basic functionality, with standard designs catering to limited electrical applications. However, as technology advanced, so did the complexity and variety of cord and plug solutions.

The introduction of safety standards in the mid-20th century, such as the NEMA standards in the U.S., marked a turning point. These regulations ensured that products met safety and performance criteria, thereby enhancing consumer confidence. The rise of personal electronics in the late 20th century further accelerated innovation, leading to the development of specialized plugs and connectors designed for specific applications.

In recent years, the focus has shifted towards integration with smart technologies and sustainability, reflecting broader societal trends. As the market continues to evolve, it is crucial for B2B buyers to stay informed about these historical shifts to better understand current dynamics and future trends in the cord and plug sector.

Frequently Asked Questions (FAQs) for B2B Buyers of cord and plug

-

How do I ensure the quality of cord and plug products from suppliers?

To guarantee the quality of cord and plug products, conduct thorough supplier vetting. Request samples to assess materials and craftsmanship. Verify certifications such as ISO 9001 or specific electrical safety standards relevant to your region. It’s advisable to review the supplier’s production processes and quality control measures. Additionally, consider third-party inspections or audits to ensure compliance with international standards before placing large orders. -

What are the best practices for sourcing cord and plug in international markets?

Sourcing cord and plug internationally requires a strategic approach. Start by identifying reputable suppliers through trade platforms, industry exhibitions, or direct referrals. Understand regional standards and regulations to ensure compliance. Leverage trade agreements and local partnerships to mitigate tariffs and improve logistics. Finally, establish clear communication channels to discuss specifications, lead times, and payment terms, ensuring that both parties have aligned expectations. -

What customization options are available for cord and plug products?

Most manufacturers offer a range of customization options for cord and plug products, including length, color, and connector types. Discuss your specific requirements with potential suppliers, such as unique branding or specific technical specifications. Be clear about the desired certifications and compliance with local electrical standards. Customization may affect lead times and minimum order quantities (MOQ), so ensure these details are agreed upon before proceeding. -

What are typical minimum order quantities (MOQ) for cord and plug?

Minimum order quantities (MOQ) for cord and plug can vary significantly based on the supplier and customization requests. Generally, MOQs can range from 100 to 1,000 units for standard products, while custom specifications may have higher MOQs due to additional manufacturing costs. It’s essential to discuss MOQs upfront during negotiations to align your purchasing strategy with the supplier’s capabilities. -

What payment terms should I expect when sourcing cord and plug internationally?

Payment terms can vary widely depending on the supplier’s policies and your business relationship. Common terms include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. Consider using secure payment methods such as letters of credit or escrow services for larger transactions to protect your interests. Discuss and agree on payment terms in advance to avoid misunderstandings. -

How can I manage logistics when importing cord and plug products?

Effective logistics management for importing cord and plug products involves several key steps. Start by understanding the shipping regulations and customs requirements for your destination country. Collaborate with freight forwarders experienced in handling electrical components to ensure compliance. Track shipments closely and maintain open communication with suppliers to address potential delays. It’s also advisable to consider warehousing options if you anticipate high demand. -

What certifications should I look for when sourcing cord and plug products?

When sourcing cord and plug products, look for certifications that indicate compliance with safety and performance standards. Common certifications include CE marking for European markets, UL certification for the USA, and SANS standards for South Africa. Ensure that the supplier can provide documentation for these certifications, as they are crucial for regulatory compliance and market acceptance in your region. -

How do I handle disputes with suppliers over cord and plug orders?

To effectively handle disputes with suppliers, establish a clear contract outlining terms, conditions, and expectations from the outset. If a dispute arises, attempt to resolve it amicably through direct communication. Document all correspondence and agreements. If necessary, involve a neutral third party for mediation. Legal recourse may be an option, but it should be a last resort due to the time and costs involved. Always prioritize maintaining a professional relationship for future business opportunities.

Top 3 Cord And Plug Manufacturers & Suppliers List

1. Grand Brass – Lamp Cordsets and Power Cords

Domain: grandbrass.com

Registered: 1997 (28 years)

Introduction: This company, Grand Brass – Lamp Cordsets and Power Cords, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. ColorCord – Cord Plug End – Light Plug

Domain: colorcord.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Cord Plug End – Light Plug”, “sku”: “PPL-001-100”, “price”: “$5.00”, “color”: “White”, “rating”: 4.6, “reviews_count”: 35, “description”: “The Cord Plug End is a plastic 3-prong connector that is quick and easy to attach to our color cord. Made of hard plastic, the plug comes with a screw to open the plug for wiring. It is recommended to purchase a Barrel Cord Grip to secure the …

3. Eberbach Lab Tools – Cord and Plug 230V

Domain: eberbachlabtools.com

Registered: 1997 (28 years)

Introduction: Part #6669.2 – Cord and Plug, 230V Nema 6-15 to C-19; Price: $79.04; SKU: 6669.2; Refund Policy: 30 days return for a refund minus a 20% restocking fee; Must be unused and in original packaging.

Strategic Sourcing Conclusion and Outlook for cord and plug

As businesses navigate the complexities of sourcing cords and plugs, understanding market dynamics and supplier capabilities is paramount. Strategic sourcing not only ensures access to high-quality products but also fosters relationships with reliable manufacturers, which can significantly reduce lead times and costs. By focusing on regional standards, such as NEMA compliance in North America or IEC specifications in Europe and beyond, buyers can make informed decisions that align with their operational requirements.

Moreover, diversifying supply chains and considering local suppliers can enhance resilience, particularly in regions like Africa and South America, where infrastructure may pose challenges. Emphasizing sustainability and technological advancements in cord and plug design can also provide competitive advantages in an increasingly eco-conscious market.

Looking ahead, international buyers are encouraged to leverage digital platforms for sourcing, allowing for greater transparency and efficiency. By adopting a proactive approach in evaluating suppliers and keeping abreast of industry innovations, businesses can not only fulfill their immediate needs but also position themselves for future growth. Engage with your suppliers today to explore tailored solutions that meet your specific requirements and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to cord and plug

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.