A B2B Buyer’s Guide to Connector And Backshell: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for connector and backshell

In the ever-evolving landscape of global commerce, sourcing reliable connectors and backshells poses a significant challenge for international B2B buyers. These critical components play a pivotal role in ensuring the integrity and performance of electronic systems across various sectors, including aerospace, military, telecommunications, and industrial applications. As the demand for high-quality, durable, and environmentally resilient connectors increases, navigating the complexities of product specifications, supplier reliability, and cost-effectiveness becomes essential for businesses aiming to maintain a competitive edge.

This comprehensive guide delves into the multifaceted world of connectors and backshells, offering insights into various types, applications, and the latest innovations in the field. Buyers will find valuable information on how to effectively vet suppliers, understand pricing structures, and assess product compatibility based on environmental conditions and operational requirements. By addressing these key areas, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—such as Brazil and Germany—to make informed purchasing decisions that align with their unique business needs and challenges.

With a focus on actionable insights and expert recommendations, this resource is designed to streamline the sourcing process, reduce risks, and foster successful partnerships in the global market for connectors and backshells.

Understanding connector and backshell Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Circular Connector Backshells | Offers strain relief and EMI/RFI shielding; available in various angles. | Aerospace, military, telecommunications | Pros: Robust protection, versatile designs. Cons: Can be expensive. |

| D-Sub Backshells | Typically rectangular; provides strain relief and environmental sealing. | Industrial automation, data communication | Pros: Cost-effective, easy installation. Cons: Limited shielding. |

| Ruggedized Backshells | Designed for extreme conditions; high durability and environmental resistance. | Defense, oil & gas, outdoor applications | Pros: Exceptional reliability. Cons: Heavier and bulkier. |

| Environmental Backshells | Seals against moisture and dust; often used with grommets. | Automotive, consumer electronics, industrial | Pros: Enhances lifespan of connectors. Cons: May require specific installation techniques. |

| Shrink Boot Backshells | Flexible, low-profile solution; provides strain relief and sealing. | Telecommunications, medical devices | Pros: Lightweight, compact. Cons: Less durable than metal options. |

What are Circular Connector Backshells and Their Applications?

Circular connector backshells are essential in providing strain relief and protecting against electromagnetic and radio frequency interference (EMI/RFI). These backshells are available in various angled configurations, making them adaptable for different installation scenarios. They are widely used in aerospace and military applications, where reliability is critical. When purchasing, consider the environmental conditions and the specific EMI/RFI shielding requirements, as these factors will influence the choice of material and design.

How Do D-Sub Backshells Differ from Other Types?

D-Sub backshells are rectangular in shape and are primarily used in applications that require reliable data communication, such as industrial automation. They provide strain relief and can offer some degree of environmental sealing, though they are typically less robust than circular counterparts in terms of EMI/RFI protection. Buyers should evaluate the installation environment and the level of protection required, as D-Sub backshells may be more cost-effective but offer limited shielding capabilities.

What Makes Ruggedized Backshells Ideal for Harsh Environments?

Ruggedized backshells are specifically engineered for extreme environments, featuring high durability and environmental resistance. They are commonly used in defense and oil & gas sectors, where equipment is exposed to harsh conditions. While they offer exceptional reliability, buyers should be mindful that these backshells can be heavier and bulkier than standard options, which may impact overall system design and weight constraints.

Why Choose Environmental Backshells?

Environmental backshells are designed to seal connectors against moisture, dust, and other contaminants, thereby enhancing the longevity and reliability of electrical connections. They are particularly suitable for automotive and consumer electronics applications. When selecting environmental backshells, consider the specific sealing requirements and whether individual wire sealing grommets or cable glands are necessary for your application.

What are the Advantages of Using Shrink Boot Backshells?

Shrink boot backshells provide a flexible, low-profile alternative for applications that require strain relief and environmental sealing, such as telecommunications and medical devices. They are lightweight and compact, making them ideal for space-constrained installations. However, buyers should be aware that shrink boots may not offer the same level of durability as metal backshells, so it’s essential to assess the specific environmental conditions they will face.

Key Industrial Applications of connector and backshell

| Industry/Sector | Specific Application of Connector and Backshell | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Use in avionics for connecting sensors and control systems | Ensures reliable performance under extreme conditions | Compliance with aerospace standards, weight considerations, and EMI shielding |

| Automotive | Integration in electric vehicles for battery management systems | Enhances safety and efficiency in high-voltage environments | Resistance to vibration and temperature variations, environmental sealing |

| Telecommunications | Connection of base stations and antennas for signal transmission | Facilitates robust communication networks | Durability, weather resistance, and compatibility with existing systems |

| Industrial Automation | Wiring in robotic systems for control and feedback loops | Increases operational efficiency and reliability | Compatibility with various industrial standards and ease of installation |

| Military and Defense | Utilization in ruggedized equipment for field communication systems | Provides resilience in hostile environments | Compliance with military specifications and environmental protection features |

How Are Connectors and Backshells Used in Aerospace Applications?

In the aerospace sector, connectors and backshells are critical for ensuring the reliable operation of avionics systems, which include sensors and control mechanisms. These components must withstand extreme temperatures, vibrations, and other challenging environmental factors. B2B buyers in this sector need to prioritize suppliers that comply with stringent aerospace standards and can provide effective electromagnetic interference (EMI) shielding. The reliability of these connections is paramount, as failures can lead to severe safety risks.

What Role Do Connectors and Backshells Play in Automotive Applications?

In the automotive industry, particularly with the rise of electric vehicles (EVs), connectors and backshells are essential for battery management systems. They facilitate connections that manage high-voltage power while ensuring safety and efficiency. Buyers must consider sourcing components that offer robust strain relief and environmental sealing to protect against moisture and contaminants. Compatibility with existing systems and standards is also crucial for seamless integration into new vehicle designs.

How Are Connectors and Backshells Essential for Telecommunications?

In telecommunications, connectors and backshells are vital for establishing reliable connections between base stations and antennas. These components must endure harsh weather conditions and provide durability to maintain signal integrity. Buyers should focus on sourcing products that offer high resistance to environmental factors while ensuring compatibility with various telecommunication standards. The effectiveness of these connections directly influences network reliability and performance.

Why Are Connectors and Backshells Important in Industrial Automation?

Within industrial automation, connectors and backshells are used extensively in robotic systems for control and feedback loops. Their role is crucial in enhancing operational efficiency and ensuring reliable communication between components. Buyers in this sector must seek connectors that meet industrial standards and provide ease of installation, as well as those that can withstand the rigors of industrial environments. The ability to manage cable routing effectively also contributes to system longevity.

What Are the Military Applications of Connectors and Backshells?

In military and defense applications, connectors and backshells are employed in ruggedized equipment designed for field communication systems. These components must perform reliably in hostile environments, making durability and environmental protection key considerations for buyers. It is essential to source connectors that comply with military specifications and provide features such as EMI shielding and moisture resistance. The operational readiness of military equipment hinges on the reliability of these connections.

3 Common User Pain Points for ‘connector and backshell’ & Their Solutions

Scenario 1: Strain Relief Failure in Harsh Environments

The Problem: A manufacturer in the aerospace sector faces significant challenges with connector reliability. In high-vibration environments, their connectors are frequently experiencing failure due to inadequate strain relief. This issue leads to costly downtime, production delays, and potential safety hazards, as connections become loose or fail entirely under stress. The manufacturer finds that standard backshell solutions are insufficient, leaving them vulnerable to operational risks and increased maintenance costs.

The Solution: To address this problem, the manufacturer should invest in high-performance strain relief backshells specifically designed for harsh conditions. These backshells should feature robust clamping mechanisms that securely grip the cable, minimizing movement at the junction point. Additionally, selecting backshells with integrated strain relief features tailored for high-vibration applications can significantly enhance connector reliability. Buyers should consult with suppliers to source backshells that meet relevant military specifications (MIL-Spec), ensuring they are engineered to withstand the operational demands of aerospace environments. Regular training and guidelines on proper installation techniques can further ensure that the strain relief is effectively utilized, thereby preventing future failures.

Scenario 2: Inadequate Environmental Protection

The Problem: A telecommunications company operating in coastal regions struggles with connectors that are not adequately sealed against moisture and salt exposure. Frequent corrosion leads to connectivity issues, resulting in poor performance and service interruptions. The company is concerned about the long-term reliability of their equipment, particularly in critical applications where downtime is unacceptable.

The Solution: The company should prioritize sourcing backshells that provide comprehensive environmental sealing features. Look for backshells that offer IP67 or higher ratings, which guarantee protection against dust and water ingress. Implementing backshells equipped with individual wire sealing grommets or cable glands can create a watertight seal, ensuring that moisture does not compromise the electrical connections. Additionally, using corrosion-resistant materials, such as anodized aluminum or marine-grade stainless steel, will enhance durability against harsh coastal conditions. Collaborating with a supplier who understands local environmental challenges can yield customized solutions that cater specifically to the company’s operational needs, thereby extending the life of the connectors.

Scenario 3: Electromagnetic Interference (EMI) Disruption

The Problem: An automotive electronics manufacturer is facing interference issues that affect the performance of their sensitive electronic components. The connectors in use are susceptible to electromagnetic interference, leading to erratic behavior in the devices, which can result in customer dissatisfaction and warranty claims. The manufacturer realizes that their existing connectors lack the necessary shielding to mitigate these issues effectively.

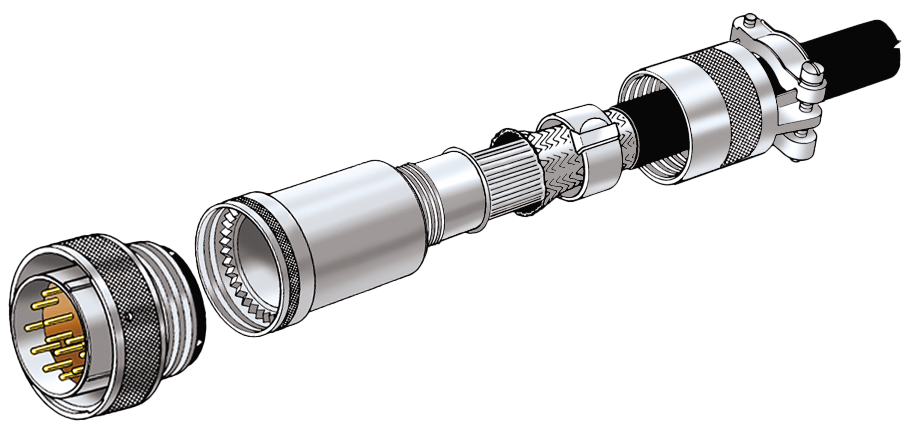

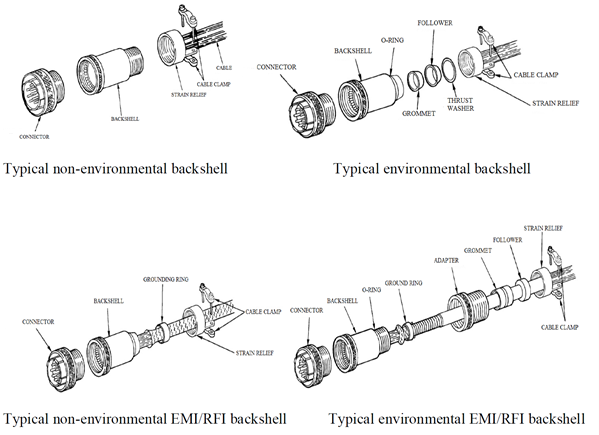

Illustrative image related to connector and backshell

The Solution: To combat EMI disruptions, the manufacturer should consider sourcing EMI/RFI environmental backshells that are compatible with their existing connectors. These backshells should be designed to work in conjunction with shielded cables, providing a comprehensive approach to electromagnetic shielding. When specifying backshells, it is crucial to ensure they feature a conductive interface to maintain continuity of the shield, thus minimizing interference. Furthermore, conducting a thorough assessment of the manufacturing process to identify potential sources of EMI can help in designing a more robust shielding solution. Engaging with engineering teams to validate the selection and installation of these specialized backshells can lead to improved reliability and performance in automotive electronics, ultimately safeguarding the brand’s reputation.

Strategic Material Selection Guide for connector and backshell

What Are the Key Properties of Common Materials Used in Connectors and Backshells?

When selecting materials for connectors and backshells, understanding the unique properties of each material is crucial for ensuring optimal performance in various applications. Here, we analyze four common materials: aluminum, stainless steel, plastic, and brass.

How Does Aluminum Perform in Connector and Backshell Applications?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically has a temperature rating of up to 150°C and is suitable for applications where weight reduction is essential, such as aerospace and automotive sectors.

Illustrative image related to connector and backshell

Pros: Its low density makes it cost-effective for mass production, and it can be anodized for additional corrosion resistance.

Cons: While aluminum is durable, it may not withstand extreme temperatures as well as other metals. Additionally, it can be prone to galvanic corrosion when in contact with dissimilar metals.

Impact on Application: Aluminum is compatible with various media, including air and non-corrosive fluids, making it versatile for numerous applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is critical. Buyers should ensure that aluminum components meet specific industry requirements, particularly in sectors like aerospace where safety is paramount.

What Are the Advantages of Using Stainless Steel for Connectors and Backshells?

Stainless steel is renowned for its exceptional corrosion resistance and mechanical strength, making it ideal for harsh environments. It can withstand temperatures up to 300°C and is often used in applications exposed to moisture or chemicals.

Pros: Its durability ensures a long lifespan, and it is less likely to corrode compared to aluminum.

Cons: The higher cost of stainless steel can be a limiting factor for budget-sensitive projects. Additionally, its weight can be a disadvantage in applications where lightweight materials are preferred.

Impact on Application: Stainless steel is suitable for applications involving exposure to corrosive media, such as in marine or chemical processing industries.

Considerations for International Buyers: Buyers should verify compliance with standards like JIS and ASTM to ensure quality and reliability, particularly in regulated industries.

How Do Plastics Compare in Terms of Cost and Performance for Connectors and Backshells?

Plastics, particularly thermoplastics like polycarbonate and nylon, offer a lightweight and cost-effective alternative for connectors and backshells. They generally have a temperature rating of around 85°C and are suitable for applications where electrical insulation is critical.

Pros: Plastics are resistant to corrosion and can be molded into complex shapes, allowing for innovative designs.

Cons: They may not perform well under high temperatures or mechanical stress compared to metals. Additionally, their environmental resistance can vary widely based on the specific type of plastic used.

Impact on Application: Plastics are often used in consumer electronics and automotive applications where weight and cost are significant considerations.

Considerations for International Buyers: Buyers should ensure that the selected plastic meets relevant standards for flame resistance and environmental impact, especially in regions with stringent regulations.

Illustrative image related to connector and backshell

What Role Does Brass Play in Connector and Backshell Design?

Brass is an alloy of copper and zinc, known for its excellent electrical conductivity and machinability. It typically has a temperature rating of around 200°C, making it suitable for high-performance applications.

Pros: Brass is highly durable and resistant to corrosion, particularly in marine environments. It also provides good EMI shielding when used in connectors.

Cons: The cost can be higher than aluminum and plastics, and it may not be suitable for applications requiring lightweight materials.

Impact on Application: Brass is often used in electrical applications where conductivity and durability are crucial, such as in military and aerospace sectors.

Considerations for International Buyers: Compliance with industry standards like ASTM and DIN is essential for ensuring the quality and reliability of brass components.

Summary Table of Material Selection for Connectors and Backshells

| Material | Typical Use Case for connector and backshell | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace and automotive applications | Lightweight and cost-effective | Prone to galvanic corrosion | Medium |

| Stainless Steel | Marine and chemical processing | Exceptional corrosion resistance | Higher cost and weight | High |

| Plastic | Consumer electronics and automotive | Lightweight and moldable | Limited high-temperature performance | Low |

| Brass | Military and aerospace applications | Excellent conductivity and durability | Higher cost, not lightweight | Medium to High |

This material selection guide provides actionable insights for B2B buyers, ensuring informed decisions that align with both performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for connector and backshell

What Are the Main Stages in the Manufacturing Process of Connectors and Backshells?

The manufacturing of connectors and backshells involves several critical stages that ensure the final products meet the required standards of quality and performance. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The process begins with the selection of high-quality raw materials, typically metals such as aluminum or brass, and plastics for insulative components. Material properties are assessed to ensure they meet specifications for strength, conductivity, and resistance to environmental factors. This stage may also involve the application of protective coatings, such as anodizing, to enhance corrosion resistance. -

Forming:

Once materials are prepared, they undergo various forming techniques. Common methods include stamping, machining, and extrusion. Stamping is often used for producing metal parts in bulk, while machining allows for precise dimensions in smaller batches. The forming process must adhere to tolerances that are crucial for the functionality of connectors and backshells, ensuring that parts fit together seamlessly. -

Assembly:

After individual components are formed, they are assembled. This can involve manual assembly or automated processes, depending on the complexity and volume of production. Key considerations during assembly include ensuring correct alignment and secure connections, particularly for components that will experience strain or environmental exposure. -

Finishing:

The final stage involves surface finishing treatments that enhance performance and durability. Techniques such as plating, painting, or applying protective films are common. Finishing not only affects aesthetic appeal but also contributes to properties like EMI/RFI shielding and environmental resistance.

How Is Quality Assurance Implemented in Connector and Backshell Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of connectors and backshells, ensuring that each product meets both international standards and specific industry requirements.

-

What International Standards Should B2B Buyers Be Aware Of?

Compliance with international standards such as ISO 9001 is essential for manufacturers. This standard provides a framework for consistent quality management systems, focusing on customer satisfaction and continuous improvement. In addition, industry-specific certifications like CE marking for safety and performance in the European market or API standards for oil and gas applications may also be relevant. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These include:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): Regular checks during production help identify and rectify any deviations from standards in real-time.

– Final Quality Control (FQC): Once production is complete, a thorough inspection of finished products is conducted. This includes functional testing, dimensional checks, and environmental resistance tests. -

What Common Testing Methods Are Used?

Various testing methods are employed to validate the performance and reliability of connectors and backshells:

– Electrical Testing: Ensures conductivity and signal integrity through methods like continuity tests and insulation resistance tests.

– Mechanical Testing: Assesses the physical durability of connectors under stress, including tensile strength and strain relief tests.

– Environmental Testing: Products are subjected to conditions such as temperature extremes, humidity, and exposure to dust or moisture to evaluate their resilience.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should adopt several strategies to ensure that their suppliers adhere to stringent quality control measures.

-

Supplier Audits:

Conducting on-site audits can provide insights into a manufacturer’s quality control practices. Audits should assess the manufacturing environment, equipment maintenance, and adherence to QA protocols. -

Requesting Quality Reports:

Suppliers should be able to provide documentation related to quality control processes, including test results, inspection reports, and certifications. Reviewing these documents can help buyers gauge the reliability of the supplier. -

Third-Party Inspections:

Engaging third-party inspection services can add an additional layer of assurance. These independent bodies can conduct thorough evaluations of the manufacturing process and product quality before shipment.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification that can affect their procurement process.

-

Regional Compliance Requirements:

Different regions may have unique compliance requirements. For instance, EU buyers must ensure that products meet CE marking standards, while buyers in the Middle East might need to consider local certifications. -

Cultural Differences in Business Practices:

Understanding cultural differences in business practices is crucial. Some regions may prioritize personal relationships and trust, while others may focus more on documented processes and certifications. -

Logistical Considerations:

International shipping and customs regulations can impact the delivery of certified products. Buyers should work closely with suppliers to ensure that all necessary documentation accompanies shipments to avoid delays.

In conclusion, the manufacturing processes and quality assurance measures for connectors and backshells are multifaceted and critical for ensuring product reliability and performance. B2B buyers must conduct thorough due diligence in selecting suppliers, focusing on their quality control practices and compliance with international standards to ensure successful procurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘connector and backshell’

To ensure a successful procurement process for connectors and backshells, this guide provides a structured checklist designed for B2B buyers. By following these steps, you can navigate the complexities of sourcing these essential components effectively.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of any successful sourcing strategy. Clearly define the types of connectors and backshells needed based on your application—consider factors like size, material, environmental conditions, and compliance with military specifications if relevant. This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational demands.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in connector and backshell technology. The industry is evolving, with new materials and designs that offer better performance and reliability. Review trade publications, attend industry conferences, and participate in relevant forums to gather insights that could influence your procurement decisions.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Look for manufacturers with a proven track record in the industry; request company profiles, case studies, and references from other buyers in similar sectors. Pay attention to their production capabilities, quality assurance processes, and lead times to ensure they can meet your demands.

- Check Certifications: Ensure the supplier holds relevant industry certifications (e.g., ISO, RoHS) that demonstrate compliance with quality and environmental standards.

Step 4: Request Samples and Technical Data

Always request samples of the connectors and backshells you intend to purchase. This allows you to assess their quality and compatibility with your existing systems. Additionally, obtain technical datasheets that provide detailed specifications, including mechanical and electrical properties, to ensure they align with your requirements.

Step 5: Consider Customization Options

In many cases, off-the-shelf solutions may not meet all your needs. Discuss customization possibilities with suppliers, such as unique configurations or finishes that may enhance performance in your specific environment. This could be particularly important in sectors like aerospace or military applications, where stringent requirements exist.

Step 6: Evaluate Pricing and Terms of Sale

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Look beyond just the unit cost; consider factors like shipping, bulk order discounts, and warranty provisions. Understanding the total cost of ownership will help you make a more informed decision.

Step 7: Finalize the Purchase Agreement

Before concluding your purchase, ensure that all terms are clearly outlined in the agreement. Confirm delivery timelines, payment terms, and return policies. A well-documented agreement can help prevent misunderstandings and ensure that both parties are aligned on expectations.

By following this checklist, B2B buyers can streamline their procurement process for connectors and backshells, ensuring they acquire the right products from reputable suppliers that meet their operational requirements.

Comprehensive Cost and Pricing Analysis for connector and backshell Sourcing

When analyzing the cost structure and pricing for connectors and backshells, several critical components and influencers come into play, particularly for B2B buyers in international markets like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Connector and Backshell Manufacturing?

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for backshells include aluminum, stainless steel, and plastic, each offering different cost, weight, and durability characteristics. Higher-grade materials may incur higher costs but provide enhanced performance, especially in harsh environments.

-

Labor: Labor costs can vary widely based on geographical location. In regions with higher labor costs, such as parts of Europe, the manufacturing expense will be elevated. Conversely, sourcing from countries with lower labor costs can yield savings but may come with trade-offs in quality and lead time.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and maintenance of equipment. Efficient factories with advanced manufacturing technologies can reduce overhead costs, leading to more competitive pricing.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom designs. Depending on the complexity of the connector or backshell, tooling costs can vary significantly. Buyers should inquire about tooling costs and whether they will be amortized over future orders.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specified standards, especially for military and aerospace applications. While comprehensive QC increases costs, it can prevent costly failures in the field, thus representing a valuable investment.

-

Logistics: Shipping and handling costs can add a significant burden to the overall price, especially for international orders. Factors like distance, shipping method, and urgency will influence these costs. Understanding Incoterms can help buyers navigate logistics more effectively.

-

Margin: Suppliers typically build a profit margin into their pricing. This margin can vary based on market competition, brand reputation, and the complexity of the product. Buyers should be aware of typical industry margins to assess fair pricing.

How Do Price Influencers Impact Connector and Backshell Costs?

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing significantly. Higher volumes often lead to discounts, as they justify the production setup and reduce per-unit costs.

-

Specifications and Customization: Custom designs and specific performance requirements can drive up costs. Buyers should consider whether standard products can meet their needs, as customization can lead to increased material and labor costs.

-

Quality and Certifications: Products that meet military specifications (Mil-Spec) or industry certifications often come at a premium. These certifications ensure reliability and performance, critical for mission-critical applications.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge higher prices due to perceived quality and service, while emerging suppliers may offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can affect who bears the cost of shipping and insurance, impacting the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices?

-

Negotiate Volume Discounts: Always inquire about discounts for larger orders. If your business model allows for it, consolidating orders can lead to significant savings.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with purchasing, including shipping, customs duties, and potential failures due to poor quality. A lower initial price may lead to higher costs down the line if quality is compromised.

-

Investigate Regional Suppliers: For buyers in Africa and South America, local suppliers may offer lower shipping costs and shorter lead times. Investigating regional options can yield cost efficiencies.

-

Be Aware of Pricing Nuances: International markets may have varying pricing structures due to currency fluctuations, tariffs, and trade agreements. Staying informed about these factors can help in negotiations.

-

Request Samples: Before committing to a large order, request samples to ensure product quality. This step can prevent future costs associated with returns or replacements.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of connectors and backshells is essential for B2B buyers. By focusing on key cost components, recognizing price influencers, and employing strategic negotiation tactics, buyers can optimize their sourcing strategies and enhance their bottom line.

Alternatives Analysis: Comparing connector and backshell With Other Solutions

Understanding Alternative Solutions for Connectors and Backshells

In the realm of industrial and military applications, connectors and backshells play a pivotal role in ensuring robust and reliable electrical connections. However, buyers may also consider alternative solutions that can achieve similar objectives. This section provides a comparative analysis of connectors and backshells against other viable solutions, such as shrink boots and integrated cable assemblies. This analysis will help international B2B buyers make informed decisions based on their specific needs and operational environments.

| Comparison Aspect | Connector And Backshell | Shrink Boots | Integrated Cable Assemblies |

|---|---|---|---|

| Performance | High durability, EMI/RFI shielding, environmental protection | Good for strain relief and sealing but limited EMI protection | Excellent for specific applications with pre-defined requirements |

| Cost | Moderate to high, depending on specifications | Generally lower cost | Higher upfront investment, but cost-effective in large-scale applications |

| Ease of Implementation | Requires proper installation and expertise | Easier to install, often requiring only heat application | Complex assembly process; requires specific design and manufacturing |

| Maintenance | Moderate; periodic checks needed for integrity | Low; minimal maintenance required | High; may require full replacement if issues arise |

| Best Use Case | Military, aerospace, and harsh environments requiring high reliability | Light-duty applications where low-profile is preferred | Custom applications where specific cable lengths and configurations are needed |

What Are the Advantages and Disadvantages of Shrink Boots?

Shrink boots serve as a low-profile alternative to traditional backshells, providing effective strain relief and environmental sealing. One of their primary advantages is ease of installation; they can simply be heated to shrink around the cable and connector, offering a quick solution for less demanding applications. However, shrink boots do not provide the same level of electromagnetic interference (EMI) or radio frequency interference (RFI) protection as backshells, making them less suitable for critical military and aerospace applications.

How Do Integrated Cable Assemblies Compare?

Integrated cable assemblies combine connectors and cables into a single unit, streamlining the installation process. They are particularly beneficial for custom applications where specific lengths and configurations are required. This solution can save time in assembly and reduce the number of potential failure points. However, the initial cost is generally higher compared to connectors and backshells, and once an integrated assembly is deployed, it may require complete replacement if there are issues, leading to increased maintenance costs over time.

Illustrative image related to connector and backshell

How to Choose the Right Solution for Your Needs

When selecting between connectors and backshells, shrink boots, and integrated cable assemblies, B2B buyers should carefully consider their specific operational requirements. For applications demanding high reliability and protection from environmental factors, connectors and backshells may be the best choice. Conversely, for more straightforward applications where cost and ease of installation are paramount, shrink boots could be sufficient. Integrated cable assemblies are ideal for custom projects that require specific configurations but may come at a higher price point. By evaluating performance, cost, ease of implementation, maintenance needs, and the best use case for each solution, buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for connector and backshell

What Are the Key Technical Properties of Connectors and Backshells?

When evaluating connectors and backshells, understanding essential technical properties is vital for ensuring reliability and performance. Below are several critical specifications that influence your purchasing decisions:

1. Material Grade

Connectors and backshells are commonly made from materials such as aluminum, stainless steel, or plastic composites. The material grade affects durability, corrosion resistance, and weight. For instance, aluminum offers a lightweight solution ideal for aerospace applications, while stainless steel is preferred for its strength and resistance to harsh environmental conditions. Choosing the right material grade can significantly impact the lifespan and reliability of the connection in demanding applications.

2. Tolerance

Tolerance refers to the allowable deviation from a specified dimension. Precise tolerances are crucial in ensuring that connectors fit correctly and function as intended. For example, a connector with a tolerance of ±0.01 mm will perform better in high-precision applications, such as military or aerospace environments. Understanding tolerances helps buyers assess the compatibility of connectors and backshells with existing systems, thereby reducing the risk of failure.

3. IP Rating (Ingress Protection)

The IP rating indicates the degree of protection provided against dust and moisture. An IP67 rating, for example, signifies that the connector can withstand immersion in water up to 1 meter for 30 minutes. This specification is essential for applications in harsh environments, such as outdoor or industrial settings. Buyers should prioritize connectors and backshells with appropriate IP ratings to ensure operational reliability.

4. EMI/RFI Shielding

Electromagnetic interference (EMI) and radio frequency interference (RFI) can disrupt the performance of electronic devices. Connectors and backshells with built-in EMI/RFI shielding protect sensitive electronics by preventing interference from external sources. This property is particularly important in military and aerospace applications, where signal integrity is critical. Understanding shielding options can help buyers select the right products for their specific operational needs.

5. Strain Relief

Strain relief features in backshells help to manage cable stress at the junction where wires connect to the contacts. This is crucial for preventing damage to the wires and ensuring a long-lasting connection. Strain relief is especially important in high-vibration environments, where cable movement can lead to premature failure. Buyers should look for backshells designed with effective strain relief mechanisms to enhance reliability.

Which Trade Terms Are Commonly Used in the Connector and Backshell Industry?

Familiarity with industry jargon can streamline communication and enhance the purchasing process. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is crucial for buyers looking to source components for their own products. Establishing relationships with reputable OEMs can lead to higher quality and more reliable products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Knowing the MOQ helps businesses plan their inventory and budgeting. Buyers should inquire about MOQs to avoid overstocking or facing shortages.

Illustrative image related to connector and backshell

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to request pricing and terms from suppliers. This process is essential for comparing costs and ensuring competitive pricing. Buyers should prepare detailed RFQs to receive accurate and comprehensive quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with these terms helps clarify shipping costs, risk, and delivery responsibilities, reducing potential disputes during the procurement process.

5. Lead Time

Lead time is the amount of time between placing an order and receiving it. Understanding lead times is critical for effective inventory management and project planning. Buyers should always consider lead times when negotiating contracts to ensure timely deliveries.

In conclusion, a solid grasp of technical properties and trade terminology is essential for B2B buyers in the connector and backshell market. By understanding these factors, businesses can make informed purchasing decisions that enhance operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the connector and backshell Sector

What Are the Key Market Dynamics and Trends Affecting the Connector and Backshell Sector?

The global connector and backshell market is experiencing significant growth, driven by the increasing demand for reliable interconnect solutions across various industries, including telecommunications, aerospace, automotive, and industrial automation. A notable trend is the rise of miniaturization in electronic components, which requires connectors and backshells that can provide robust performance in increasingly compact designs. Additionally, the proliferation of IoT devices is creating a surge in demand for connectors capable of handling high-speed data transmission while maintaining environmental protection and EMI/RFI shielding.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should also be aware of the shift towards digital sourcing platforms. These platforms streamline the procurement process, allowing buyers to access a broader range of suppliers and products. Furthermore, there is a growing emphasis on customization, with buyers seeking tailored solutions that meet specific application requirements. Adapting to these dynamics can enhance competitiveness and ensure that businesses remain aligned with technological advancements.

How Does Sustainability Influence B2B Sourcing for Connectors and Backshells?

Sustainability is becoming a critical consideration for B2B buyers in the connector and backshell sector. The environmental impact of manufacturing processes, particularly in terms of waste and energy consumption, is under scrutiny. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recyclable materials and reducing carbon footprints. Certifications like ISO 14001 for environmental management systems are becoming essential for suppliers looking to build trust with environmentally-conscious clients.

Ethical sourcing is equally important. Buyers are encouraged to vet their supply chains for compliance with labor standards and environmental regulations. This not only mitigates risks but also enhances brand reputation in markets where consumers are increasingly aligned with sustainability. The use of ‘green’ materials and processes can also be a differentiator in competitive bids, as companies strive to meet regulatory standards and consumer expectations for eco-friendly products.

What Is the Historical Context of the Connector and Backshell Industry?

The connector and backshell industry has evolved significantly since its inception in the early 20th century. Initially, connectors were primarily used in military applications, where reliability and durability were paramount. Over the decades, advancements in materials science and manufacturing techniques have expanded the applications of connectors and backshells to various commercial sectors.

The introduction of standardized military specifications, such as MIL-DTL-38999, has further shaped the industry by establishing benchmarks for performance and interoperability. This standardization has facilitated international trade and has allowed manufacturers to innovate while ensuring compatibility across different systems. As the demand for high-performance, environmentally resistant connectors continues to grow, the industry is poised for further transformation, driven by technological advancements and the increasing complexity of electronic systems.

Conclusion

Navigating the connector and backshell sector requires a keen understanding of market dynamics and emerging trends. By focusing on sustainability and ethical sourcing, B2B buyers can enhance their procurement strategies, ensuring that they are not only meeting technical specifications but also aligning with broader corporate responsibility goals. The historical evolution of this industry underscores the importance of adaptability and innovation in meeting the challenges of a rapidly changing technological landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of connector and backshell

-

How do I choose the right backshell for my connectors?

Choosing the right backshell involves considering several factors: the type of connector you are using, the environmental conditions (such as moisture, dust, and temperature), and the specific application requirements (like EMI/RFI protection). Ensure compatibility with the connector’s material and finish for optimal performance. Additionally, evaluate the need for strain relief and whether a straight or angled configuration is more suitable for your installation. Consulting product specifications and expert recommendations can guide you in making the best choice. -

What are the key benefits of using connector backshells?

Connector backshells provide multiple benefits, including strain relief, environmental sealing, and electromagnetic interference (EMI) shielding. They protect the cable-connector junction from mechanical stress, moisture, and contaminants, enhancing the longevity and reliability of electrical connections. In demanding applications, such as military or aerospace, backshells ensure compliance with industry standards while safeguarding sensitive electronics from external interferences. -

What customization options are available for connector backshells?

Many manufacturers offer customization options for connector backshells, including material selection, angle configurations, and specific finishes to match your connectors. You can also request unique features such as integrated strain relief or custom sealing solutions to meet environmental specifications. When placing an order, discuss your specific requirements with suppliers to explore available options and ensure compatibility with your existing systems. -

What are the typical minimum order quantities (MOQs) for backshells?

Minimum order quantities for connector backshells can vary significantly based on the supplier, product type, and customization requirements. Standard parts may have lower MOQs, while customized solutions often require larger orders. It’s advisable to communicate your needs directly with suppliers to negotiate MOQs that fit your project and budget. Additionally, some suppliers may offer samples or trial orders to facilitate initial assessments. -

What payment terms should I expect when purchasing connector backshells internationally?

Payment terms for international orders can differ widely among suppliers. Common options include payment in advance, letters of credit, or payment upon delivery. Factors influencing payment terms include order size, relationship with the supplier, and country-specific regulations. It’s essential to clarify payment conditions during negotiations and consider using secure payment methods to protect your transaction. -

How can I ensure quality assurance (QA) for my backshell orders?

To ensure quality assurance for your backshell orders, request detailed product specifications and certifications from suppliers. Implementing a quality control process that includes inspections, testing, and compliance checks can mitigate risks. Additionally, consider suppliers that offer warranties or guarantees on their products. Regular communication and feedback during the procurement process can help maintain quality standards. -

What logistics considerations should I keep in mind when sourcing backshells internationally?

When sourcing backshells internationally, consider shipping methods, delivery times, and customs regulations in your destination country. Evaluate the logistics capabilities of your supplier to ensure they can meet your timelines and provide tracking information. Understanding import duties and taxes will help you calculate total costs. Collaborating with logistics providers experienced in international shipping can also streamline the process and minimize delays. -

How do I vet suppliers for connector backshells effectively?

Vetting suppliers for connector backshells involves assessing their industry reputation, experience, and customer reviews. Verify their certifications and compliance with international standards, particularly if you operate in regulated sectors. Request references from previous clients and inquire about their manufacturing processes and quality control measures. Engaging with suppliers through trade shows or industry forums can also provide insights into their reliability and expertise.

Top 7 Connector And Backshell Manufacturers & Suppliers List

1. TE – Backshell Solutions

Domain: te.com

Registered: 1992 (33 years)

Introduction: This company, TE – Backshell Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Milnec – Backshells for Mil-Spec Connectors

Domain: milnec.com

Registered: 2007 (18 years)

Introduction: Backshells for Mil-Spec Connectors enhance operational characteristics by providing strain relief, environmental protection, and EMI/RFI protection. They come in various finishes, materials, and angle configurations (straight, 45°, and 90°). Strain relief backshells protect wire-contact junctions in clean environments, while EMI/RFI environmental backshells offer complete IP67 protection for milit…

3. Glenair – Connector Backshells and Accessories

Domain: glenair.com

Registered: 1995 (30 years)

Introduction: Connector Backshells and Accessories: M85049 and Glenair Signature Environmental and EMI Backshells for Circular Mil-Spec Connectors including Strain-Relief Clamps, Shield Termination Adaptors, Environmental-Sealing Accessories, Shrink Boot Adapters, and more. Complete selection with same-day availability for AS85049 (M85049), D38999, MIL-DTL-26500, MIL-DTL-28840, MIL-DTL-83513, MIL-DTL-83538, MIL…

4. Apollo Aerospace – Connector Backshells & Accessories

Domain: apollo-aerospace.com

Registered: 2022 (3 years)

Introduction: Connector backshells, adapters, protective covers, cable clamps, and accessories from OEMs including EMCA, Amphenol, Glenair, Compaero, Telason, and TE. Adapters range from simple strain reliefs to submersible EMI/RFI shielded backshells for harsh environments. Protective covers with lanyards, eyelets, and security rings for customization. MS3057 cable clamps available in multiple finishes for aut…

5. Peigenesis – Connector Backshells

Domain: peigenesis.com

Registered: 2000 (25 years)

Introduction: Connector backshells are essential accessories threaded onto the rear of circular or rectangular connectors for additional support and protection, enhancing aesthetic appeal. They intermate with connector rear end geometries and are available for military and commercial applications. Key selection factors include angle/profile (straight, 90°, or 45°), coupling style (spin, self-lock, or direct), c…

6. Arrow – Backshell Ordering Guide

Domain: arrow.com

Registered: 1991 (34 years)

Introduction: This company, Arrow – Backshell Ordering Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. JRH Electronics – EMI/RFI Backshells

Domain: jrhelec.com

Registered: 1997 (28 years)

Introduction: Connector Backshells and Accessories – JRH Electronics Authorized Distributor, AS9100 Certified. Key products include: 90° EMI/RFI Environmental Backshell, 90° Strain Relief (Self-Locking or Non-Self-Locking), AS85049 Qualified Backshells and Connector Accessories, AS85049/8 and MS3188A 90° EMI/RFI Environmental Backshell, AS85049/80 Sealing Plug for MIL-DTL-38999 Connectors (Contact Sizes 8, 12, …

Strategic Sourcing Conclusion and Outlook for connector and backshell

How Can Strategic Sourcing Enhance Your Connector and Backshell Procurement?

In today’s competitive landscape, strategic sourcing of connectors and backshells is essential for businesses aiming to optimize supply chains and enhance operational efficiency. By partnering with reliable suppliers, buyers can ensure access to high-quality products that provide strain relief, environmental protection, and EMI/RFI shielding. The right sourcing strategy not only mitigates risks associated with supply chain disruptions but also enables companies to leverage innovative technologies and materials tailored to their specific industry needs.

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial. This insight allows for informed decisions that align with local regulations and industry standards. Furthermore, establishing strong supplier relationships can foster collaboration on product development, ensuring that your organization remains at the forefront of technological advancements.

As you contemplate your sourcing strategy, consider exploring partnerships that prioritize sustainability and innovation. In doing so, you can enhance your competitive edge while contributing to a more resilient global supply chain. Engage with suppliers who understand your unique requirements and invest in solutions that meet the challenges of tomorrow. Start your strategic sourcing journey today to secure the best connectors and backshells for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.