A B2B Buyer’s Guide to Column Bracket: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for column bracket

Navigating the complexities of sourcing column brackets can pose significant challenges for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia. The right column brackets are crucial for ensuring the structural integrity and longevity of various construction projects, yet the multitude of options available can make decision-making overwhelming. This guide aims to simplify the process by providing a comprehensive overview of column brackets, including their types, applications, and the critical factors to consider when selecting suppliers.

In this guide, you will find detailed insights into the various types of column brackets, such as those designed for different materials and construction methods, as well as their specific applications across diverse industries. Additionally, we will cover essential aspects of supplier vetting, including quality assurance, compliance with international standards, and cost considerations. By equipping you with this knowledge, we empower you to make informed purchasing decisions that align with your project requirements and budget constraints.

Whether you are a contractor in Johannesburg, a builder in São Paulo, or a procurement manager in Riyadh, this guide serves as a valuable resource to navigate the global market for column brackets, ensuring that your investments lead to successful project outcomes.

Understanding column bracket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sturdi-Wall Drill Set Brackets | Heavy-duty steel construction, available in multiple sizes | Post-frame structures, agricultural buildings | Pros: Durable, suitable for various column sizes. Cons: Requires specific tools for installation. |

| Sturdi-Wall Plus Wet Set Brackets | Designed for wet set applications, robust anchoring system | Permanent foundations, commercial structures | Pros: Excellent for new concrete, strong hold. Cons: Limited to new construction projects. |

| Simpson Strong-Tie Post Bases | Versatile designs for wood to concrete, adjustable height options | Residential and commercial decks, patios | Pros: Easy installation, customizable. Cons: May require additional hardware for optimal use. |

| Adjustable Post Bases | Features adjustable heights and standoff capabilities | Decks, fences, and outdoor structures | Pros: Flexible for various applications. Cons: Potentially higher cost compared to standard bases. |

| Decorative Column Caps | Aesthetic designs for architectural appeal, various materials | Residential homes, gardens, commercial facades | Pros: Enhances visual appeal. Cons: Primarily decorative, may lack structural support. |

What Are Sturdi-Wall Drill Set Brackets and Their Applications?

Sturdi-Wall Drill Set Brackets are known for their heavy-duty steel construction, making them ideal for post-frame structures and agricultural buildings. They come in various sizes, allowing for compatibility with different column dimensions. Buyers looking for reliable support in environments subject to substantial loads will find these brackets advantageous. However, installation requires specific tools, which may present a challenge for some buyers.

How Do Sturdi-Wall Plus Wet Set Brackets Differ from Other Options?

The Sturdi-Wall Plus Wet Set Brackets are engineered for wet set applications, providing robust anchoring capabilities for new concrete installations. They are particularly suited for permanent foundations and commercial structures where a solid and lasting hold is essential. While they offer superior strength and stability, their use is limited to new construction projects, making them less versatile than other types.

What Makes Simpson Strong-Tie Post Bases a Popular Choice?

Simpson Strong-Tie Post Bases are versatile, designed to connect wood to concrete with adjustable height options. They are widely used in both residential and commercial applications such as decks and patios. Their ease of installation and customization options appeal to many buyers. However, it’s important to note that they may require additional hardware to achieve optimal results.

Why Consider Adjustable Post Bases for Your Projects?

Adjustable Post Bases offer flexibility with their height adjustment features and standoff capabilities. They are ideal for decks, fences, and various outdoor structures where adaptability is essential. While they provide a practical solution for many applications, their cost may be higher compared to standard bases, which could be a consideration for budget-conscious buyers.

How Do Decorative Column Caps Enhance Structural Aesthetics?

Decorative Column Caps are designed to enhance the visual appeal of structures, available in various materials and designs. They are commonly used in residential homes, gardens, and commercial facades to add a touch of elegance. Although they primarily serve a decorative purpose and may not provide significant structural support, they are an excellent choice for projects where aesthetics are a priority.

Key Industrial Applications of column bracket

| Industry/Sector | Specific Application of column bracket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Supporting wooden posts in residential and commercial buildings | Enhances structural integrity and safety of buildings | Ensure compatibility with various post sizes and materials |

| Agriculture | Anchoring posts for agricultural structures like barns and greenhouses | Provides stable support for essential farming infrastructure | Durability against environmental factors and load-bearing capacity |

| Renewable Energy | Mounting structures for solar panel installations | Optimizes energy production by securely positioning panels | Corrosion resistance and adaptability to different terrains |

| Infrastructure Development | Securing columns for bridges and overpasses | Ensures longevity and safety of vital transportation routes | Compliance with local regulations and load specifications |

| Manufacturing & Warehousing | Supporting shelving and racking systems | Maximizes space utilization and efficiency in storage areas | Load capacity and material strength to handle heavy inventory |

How Are Column Brackets Used in Construction & Building Projects?

In the construction and building sector, column brackets are essential for supporting wooden posts in both residential and commercial structures. They provide a reliable anchoring solution that enhances the structural integrity of buildings, ensuring they can withstand various loads and stresses. For international buyers, particularly from regions with diverse climates like Africa and Europe, sourcing brackets made from durable materials is crucial. Buyers should consider the compatibility of the brackets with different post sizes and the specific requirements of local building codes.

What Role Do Column Brackets Play in Agriculture?

In agriculture, column brackets are commonly used to anchor posts for essential structures such as barns, greenhouses, and fencing. This application ensures that these structures remain stable, which is vital for protecting crops and livestock. For B2B buyers in South America or Africa, where agricultural practices can vary widely, it is important to select brackets that can withstand local weather conditions and heavy loads. Additionally, sourcing options should prioritize durability to minimize maintenance costs over time.

How Are Column Brackets Utilized in Renewable Energy Projects?

Column brackets play a significant role in renewable energy, particularly in mounting solar panel installations. By securely positioning panels, these brackets optimize energy production, making them a critical component in green energy projects. Buyers in the Middle East, where solar energy is rapidly growing, should focus on sourcing brackets that offer corrosion resistance and can adapt to various terrains. Ensuring that the brackets meet the required specifications for load-bearing capacity is also essential for long-term performance.

Why Are Column Brackets Important in Infrastructure Development?

In infrastructure development, column brackets are vital for securing columns used in bridges and overpasses. They contribute to the safety and longevity of these critical transportation routes. For buyers in Europe, particularly Germany, adherence to strict engineering standards is paramount. This requires sourcing brackets that not only comply with local regulations but also meet specific load specifications to ensure structural stability over time.

How Do Column Brackets Enhance Efficiency in Manufacturing & Warehousing?

Within manufacturing and warehousing, column brackets support shelving and racking systems, maximizing space utilization and efficiency. This is particularly important for businesses looking to optimize their storage solutions. B2B buyers should consider the load capacity and material strength of the brackets to handle heavy inventory. Additionally, sourcing brackets that can be easily installed and adjusted will enhance operational efficiency in dynamic warehouse environments.

3 Common User Pain Points for ‘column bracket’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Column Brackets

The Problem: Many B2B buyers, especially those in emerging markets across Africa and South America, face challenges in sourcing high-quality column brackets that meet international standards. Often, local suppliers may offer lower-quality options that lack durability or compliance with building codes. This can lead to costly project delays and safety concerns, as inferior brackets might not adequately support structural loads, potentially compromising the integrity of post-frame buildings.

The Solution: To overcome sourcing challenges, buyers should prioritize working with reputable manufacturers who provide detailed product specifications and certifications. Consider establishing relationships with suppliers that offer a transparent supply chain, allowing for quality inspections and testing. Engaging in direct communication with manufacturers can help clarify the materials used, such as the specific grades of steel and finishing processes, ensuring that the products meet local regulatory requirements. Moreover, utilizing online platforms to compare different suppliers and their offerings can help buyers make informed decisions while ensuring that they obtain high-quality brackets suitable for their specific applications.

Scenario 2: Incompatibility with Existing Structures

The Problem: Buyers often encounter issues when the column brackets they select are not compatible with existing structures or materials. This is particularly common in renovation projects where older buildings may have unique dimensions or materials that standard brackets do not accommodate. This incompatibility can lead to unexpected project delays and increased costs as additional modifications are needed to fit the brackets.

The Solution: Before purchasing column brackets, it is crucial for buyers to conduct a thorough assessment of the existing structures. Detailed measurements and material evaluations should be performed to identify any unique requirements. When specifying brackets, opt for customizable options that can accommodate various sizes and configurations. Engaging with a knowledgeable supplier who understands the nuances of structural compatibility can provide insights into which products are best suited for specific applications. Additionally, considering adjustable or universal brackets can significantly enhance flexibility, allowing for more straightforward installations without the need for extensive modifications.

Scenario 3: Installation Challenges Leading to Increased Labor Costs

The Problem: Another common pain point is the complexity of installing column brackets, which can lead to increased labor costs and extended timelines. In regions with a shortage of skilled labor, such as parts of the Middle East and Africa, the lack of experienced personnel can result in improper installations, further complicating projects. Buyers may find themselves facing additional costs due to the need for rework or hiring specialized contractors.

The Solution: To mitigate installation challenges, buyers should invest in brackets that come with comprehensive installation guides and support. Look for products that are designed for ease of installation, such as those that do not require specialized tools or extensive skills. Additionally, consider seeking suppliers that offer training sessions or installation support services to educate the workforce on best practices. Utilizing pre-fabricated or modular systems can also streamline the installation process, reducing the reliance on skilled labor. Furthermore, investing in adequate planning and preparation can ensure that all necessary tools and materials are on-site before the installation begins, minimizing potential delays and associated costs.

Strategic Material Selection Guide for column bracket

When selecting materials for column brackets, it is essential to consider the specific requirements of your application, including environmental conditions, structural integrity, and cost-effectiveness. Below, we analyze four common materials used in the manufacturing of column brackets: steel, aluminum, plastic, and composite materials. Each material has unique properties, advantages, and limitations that can significantly impact the performance and suitability of the column bracket in various applications.

What Are the Key Properties of Steel for Column Brackets?

Steel is a widely used material for column brackets due to its high strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for heavy-load applications. Steel also offers good corrosion resistance when treated with protective coatings, such as galvanization or powder coating.

Pros and Cons: The primary advantage of steel is its superior strength-to-weight ratio, which allows for the construction of robust structures. However, steel can be more expensive than other materials, and its weight may require additional support during installation. Additionally, unprotected steel is susceptible to rust, particularly in humid or coastal environments.

Impact on Application: Steel column brackets are ideal for applications requiring high load-bearing capacity, such as in industrial or commercial buildings. However, buyers must ensure compliance with international standards, such as ASTM or DIN, particularly in regions like Europe and the Middle East, where stringent regulations apply.

How Does Aluminum Compare as a Material for Column Brackets?

Aluminum is another popular choice for column brackets, known for its lightweight nature and resistance to corrosion. Its thermal and electrical conductivity can also be beneficial in specific applications.

Pros and Cons: The key advantage of aluminum is its lightweight property, which simplifies installation and reduces labor costs. However, it is generally not as strong as steel, which may limit its use in high-load applications. Additionally, aluminum can be more expensive than steel, particularly when considering the cost of manufacturing and finishing processes.

Impact on Application: Aluminum brackets are suitable for applications where weight is a concern, such as in residential or light commercial structures. International buyers should consider the specific alloy grades, as different grades offer varying levels of strength and corrosion resistance.

What Are the Benefits of Using Plastic for Column Brackets?

Plastic materials, such as PVC or high-density polyethylene (HDPE), are increasingly being used for column brackets, particularly in environments where corrosion is a significant concern.

Pros and Cons: The primary advantage of plastic is its excellent resistance to moisture, chemicals, and UV radiation, making it suitable for outdoor applications. However, plastic typically has lower strength compared to metal options, which may limit its use in load-bearing scenarios. Furthermore, the manufacturing process can be less complex, leading to lower production costs.

Impact on Application: Plastic column brackets are ideal for applications in humid or corrosive environments, such as in coastal regions or agricultural settings. International buyers should verify that the plastic materials meet relevant standards for durability and environmental safety.

How Do Composite Materials Perform in Column Bracket Applications?

Composite materials, which often combine polymers with reinforcing fibers, offer a unique blend of properties that can be advantageous for column brackets.

Pros and Cons: Composites are known for their high strength-to-weight ratio and excellent resistance to environmental factors, including moisture and chemicals. However, they can be more expensive than traditional materials and may require specialized manufacturing techniques.

Impact on Application: Composite column brackets are suitable for specialized applications, such as in marine environments or where weight savings are critical. Buyers should ensure that the composites used comply with international standards and are suitable for the specific loads and stresses expected in their applications.

Summary Table of Material Selection for Column Brackets

| Material | Typical Use Case for column bracket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-load industrial structures | High strength and durability | Heavier and susceptible to rust | High |

| Aluminum | Residential and light commercial | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Plastic | Outdoor and corrosive environments | Excellent moisture and UV resistance | Lower load-bearing capacity | Low |

| Composite | Marine and specialized applications | High strength-to-weight ratio | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides a comprehensive overview of the key materials used in column brackets, enabling international B2B buyers to make informed decisions based on their specific requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for column bracket

The manufacturing and quality assurance processes for column brackets are crucial for ensuring that these components meet the structural integrity and performance standards required in various construction applications. This section provides a comprehensive overview of the typical manufacturing stages, quality control measures, and international standards relevant to B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Stages in the Manufacturing Process of Column Brackets?

The manufacturing process of column brackets generally comprises several key stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets the necessary specifications and durability requirements.

How Is Material Prepared for Column Bracket Manufacturing?

The first step involves selecting the appropriate raw materials, typically high-grade steel or aluminum, which are known for their strength and durability. For steel brackets, the material is often sourced in sheets or coils, which are then cut to size based on specific designs. Advanced techniques like laser cutting or plasma cutting may be employed for precision.

Once the materials are cut, they undergo a thorough inspection to ensure they meet the specified chemical and mechanical properties. This inspection is critical to avoid defects that could compromise the bracket’s performance.

What Forming Techniques Are Used in Column Bracket Production?

After material preparation, the next stage is forming. This can involve processes such as bending, stamping, or welding, depending on the design of the column bracket.

- Bending: For brackets that require specific angles, CNC bending machines are utilized to achieve precise shapes.

- Stamping: This technique is often used for mass production, where a die is used to stamp out the bracket shape from the sheet metal.

- Welding: For assemblies requiring multiple parts, welding techniques such as MIG or TIG welding are employed to join components securely.

Each forming technique must be monitored closely to ensure accuracy and consistency, as even minor deviations can affect the load-bearing capacity of the bracket.

What Assembly Processes Are Involved in Column Bracket Manufacturing?

Assembly involves bringing together various components, including the bracket, fasteners, and any additional hardware. Automated assembly lines may be utilized for efficiency, especially in high-volume production. Workers or robotic systems perform tasks such as attaching bolts, nuts, or other connecting elements to create the final product.

Quality checks are typically integrated into the assembly process to catch any errors before the product moves to the finishing stage.

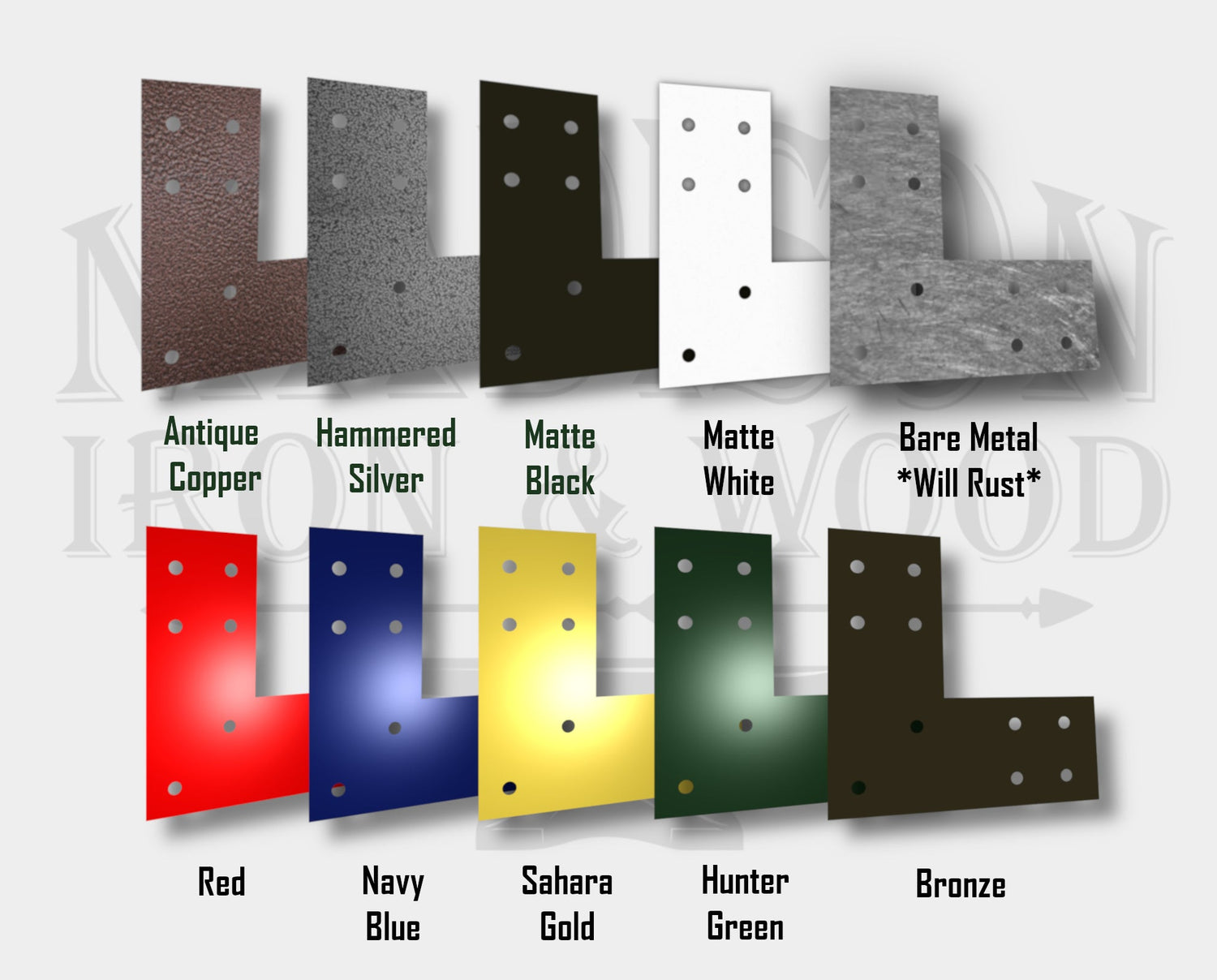

How Are Finishing Processes Applied to Column Brackets?

The finishing stage is essential for enhancing the durability and aesthetics of column brackets. Common finishing processes include:

- Coating: Brackets are often coated with protective layers such as powder coating or galvanization to prevent corrosion and improve longevity.

- Painting: For aesthetic purposes, brackets may be painted in various colors, which can also serve to provide additional protection against environmental factors.

Finishing not only enhances the appearance of the brackets but also ensures they can withstand the conditions they will face in their intended applications.

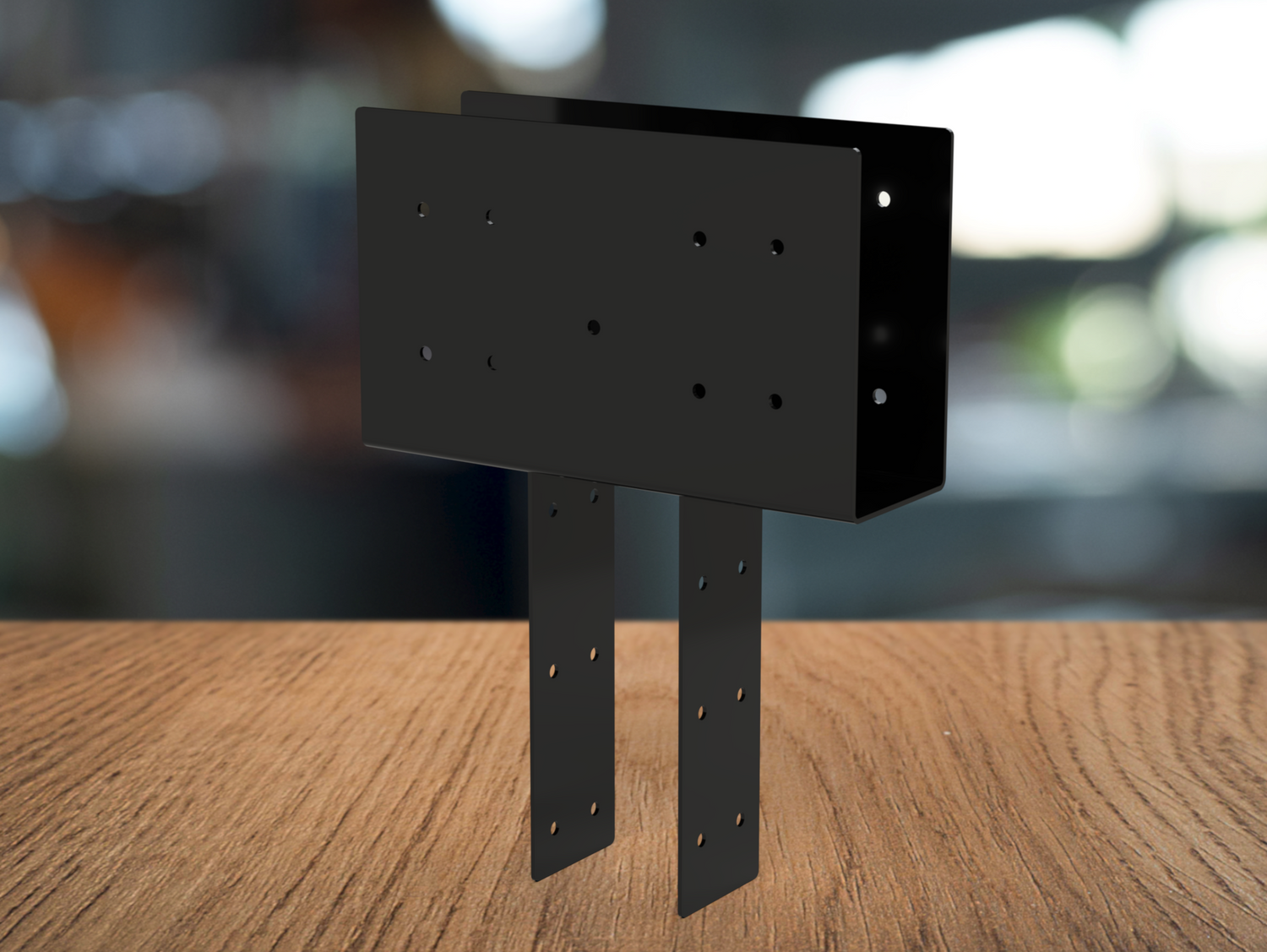

Illustrative image related to column bracket

What Are the Quality Control Measures in Column Bracket Manufacturing?

Quality assurance is a fundamental aspect of the manufacturing process, especially for structural components like column brackets. It involves multiple checkpoints and adherence to international standards to ensure product reliability and safety.

Which International Standards Are Relevant to Column Bracket Quality Control?

For B2B buyers, understanding the applicable international standards is crucial. Common standards include:

- ISO 9001: This standard outlines requirements for a quality management system, ensuring consistent quality in manufacturing processes.

- CE Marking: Particularly relevant in Europe, CE marking indicates that the product complies with EU safety, health, and environmental protection standards.

- API Standards: For brackets used in oil and gas applications, compliance with API standards ensures they can withstand the extreme conditions often present in these environments.

By ensuring that suppliers adhere to these standards, buyers can mitigate risks associated with product failures.

What Are the Key Quality Control Checkpoints in Column Bracket Production?

Quality control in column bracket manufacturing typically involves several key checkpoints:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications before production begins.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor processes and identify defects early. This may include dimensional checks, visual inspections, and functional tests.

- Final Quality Control (FQC): After assembly and finishing, a final inspection is conducted to ensure that the product meets all design and performance criteria before shipping.

These checkpoints help ensure that any issues are caught early, reducing waste and enhancing overall product quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is vital to ensure the reliability of the products they are sourcing. Here are some effective strategies:

What Audit and Inspection Practices Should Buyers Consider?

- Supplier Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insights into their quality control processes and adherence to standards. This includes reviewing documentation, inspecting production lines, and assessing quality management systems.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control practices. These inspections can cover various aspects, including raw material quality, manufacturing processes, and final product testing.

What Documentation Should Buyers Request from Suppliers?

Buyers should also request relevant documentation that demonstrates compliance with quality standards. This may include:

- Certificates of Compliance: Documentation proving that the product meets international standards.

- Quality Control Reports: Detailed reports from quality checks conducted during the manufacturing process.

- Test Results: Results from any testing performed on the brackets, such as load-bearing tests or corrosion resistance tests.

This documentation serves as a valuable tool for buyers to ensure that they are sourcing high-quality products.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers must also navigate various nuances related to quality control, particularly when sourcing from different regions.

Illustrative image related to column bracket

How Do Regional Standards Impact Quality Control for Column Brackets?

Different regions may have unique standards and regulations that affect manufacturing and quality assurance. For instance, buyers in Europe may prioritize CE compliance, while those in the Middle East might focus on specific local certifications.

Understanding these regional differences is critical for buyers to ensure compliance and facilitate smooth transactions.

How Can Buyers Address Language and Cultural Barriers?

Language and cultural differences can pose challenges in communication regarding quality expectations. Engaging local representatives or translators can help bridge these gaps and ensure that quality standards are clearly communicated and understood.

In conclusion, the manufacturing processes and quality assurance measures for column brackets are intricate and essential for ensuring the reliability and performance of these structural components. By understanding these processes and implementing rigorous quality control measures, B2B buyers can make informed decisions that align with their project requirements and regulatory standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘column bracket’

Introduction

Navigating the procurement process for column brackets can be complex, especially for international B2B buyers from diverse regions like Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to help you source high-quality column brackets effectively, ensuring that you meet your project requirements while also maximizing value.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. Consider factors such as the type of material (steel or aluminum), size, weight capacity, and compatibility with existing structures.

– Material Strength: Evaluate whether the brackets need to withstand specific loads or environmental conditions, particularly if they will be used in outdoor applications.

Step 2: Identify Suitable Suppliers

Research potential suppliers who specialize in column brackets and related products. Look for manufacturers with a strong reputation and proven track record.

– Geographical Considerations: Given your location, prioritize suppliers who have experience shipping to your region and understand local building codes and standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Quality Certifications: Check if they possess relevant certifications (e.g., ISO, CE) that indicate adherence to quality and safety standards.

Step 4: Request Samples and Specifications

Once you have shortlisted potential suppliers, request samples of the column brackets along with detailed specifications. This step allows you to assess the quality and durability of the products firsthand.

– Test for Compatibility: Ensure that the samples fit your project requirements, and test them under simulated load conditions if possible.

Step 5: Negotiate Pricing and Terms

Engage in discussions regarding pricing, bulk order discounts, and payment terms. Understand the total cost of ownership, which includes shipping, duties, and any potential import taxes.

– Long-term Relationships: Consider negotiating terms that allow for future orders, which may lead to better pricing or preferential treatment in the long run.

Step 6: Review Shipping and Delivery Options

Discuss shipping methods and timelines with your chosen supplier to ensure that they align with your project schedules. Confirm that they can handle customs clearance and any other logistics needed for international shipping.

– Tracking and Support: Opt for suppliers who provide tracking information and responsive customer support throughout the shipping process.

Step 7: Implement Quality Control Measures

Upon receiving the brackets, conduct a thorough inspection to verify that they meet your specifications and quality standards. Implement a quality control process to monitor future shipments.

– Feedback Loop: Establish a communication channel with your supplier for ongoing feedback, which can help improve future orders and resolve any issues swiftly.

By following these steps, you can streamline your sourcing process for column brackets, ensuring that you select the best products for your needs while also fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for column bracket Sourcing

What Are the Key Cost Components in Column Bracket Sourcing?

Understanding the cost structure is vital for international B2B buyers sourcing column brackets. The primary components of cost include:

-

Materials: The quality of materials used significantly influences cost. Steel, for instance, is a common choice due to its durability and strength, but variations in grade, such as galvanized or powder-coated finishes, can lead to price fluctuations. Sourcing locally can mitigate costs associated with import duties and tariffs.

-

Labor: Labor costs vary widely depending on geographic location. Regions with lower labor costs may offer competitive pricing but could compromise on quality or turnaround time. It’s essential to assess the labor market of the supplier’s location to gauge potential costs accurately.

-

Manufacturing Overhead: This includes expenses like utilities, rent, and administrative costs incurred during production. Suppliers with efficient processes and automation may achieve lower overhead costs, allowing them to offer more competitive pricing.

-

Tooling: The initial investment in tooling and equipment necessary for production can also impact pricing. Custom tools for unique designs may increase costs, while standard tooling can help keep prices lower.

-

Quality Control (QC): Ensuring product quality can add to costs. Rigorous QC processes can lead to higher initial pricing but reduce the risk of returns and warranty claims, ultimately benefiting buyers in the long run.

-

Logistics: Shipping costs can vary based on distance, weight, and chosen Incoterms. Buyers should consider both freight costs and potential customs duties when calculating total expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding this margin can provide leverage in negotiations.

What Factors Influence the Pricing of Column Brackets?

Several factors can impact the pricing of column brackets, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ is crucial, as ordering just below this threshold can significantly increase per-unit costs.

-

Specifications and Customization: Custom brackets tailored to specific project needs typically come at a premium. Standardized products are generally more cost-effective, so assessing whether customization is necessary can save money.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or ASTM) can increase costs but also enhance durability and reliability. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Established suppliers with proven track records may charge higher prices due to their reliability and quality assurance.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is essential. These terms dictate who bears the risk and costs during transportation, significantly affecting the total landed cost.

What Are Some Tips for Negotiating Column Bracket Prices?

To maximize value while sourcing column brackets, consider the following strategies:

-

Negotiate Terms: Don’t just focus on the price; negotiate terms such as payment schedules, delivery timelines, and warranties. A supplier willing to be flexible on terms might offer better overall value.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price. Consider installation costs, potential maintenance, and the lifespan of the product to assess the true value of the investment.

-

Research Market Prices: Familiarize yourself with current market prices for similar products. This information can empower your negotiations and help you identify fair pricing.

-

Assess Supplier Stability: Work with suppliers who demonstrate financial stability and reliability. This can minimize risks associated with delays or product failures.

-

Consider Local Sourcing: For buyers in Africa, South America, and the Middle East, local suppliers may offer significant cost savings on logistics and tariffs, as well as shorter lead times.

Disclaimer on Pricing Information

The prices referenced in this guide are indicative and may vary based on supplier, order volume, and market conditions. Always confirm with suppliers for the most accurate and up-to-date pricing when sourcing column brackets.

Alternatives Analysis: Comparing column bracket With Other Solutions

When it comes to securing structural elements like columns, various solutions can be utilized beyond traditional column brackets. Understanding these alternatives is crucial for B2B buyers who seek to optimize their construction projects, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will compare column brackets with two viable alternatives: post bases and wet set anchors, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Column Bracket | Post Base | Wet Set Anchor |

|---|---|---|---|

| Performance | Provides robust support for vertical loads and lateral forces. | Excellent for supporting wooden posts in various applications. | Ideal for permanent installations in concrete, offering strong stability. |

| Cost | Moderate cost, varies by model and specifications. | Generally lower cost, depending on material and brand. | Higher initial investment but provides long-term durability. |

| Ease of Implementation | Requires precise measurements and drilling into concrete. | Simple installation with basic tools; can be adjusted post-installation. | Installation requires concrete work, can be more complex initially. |

| Maintenance | Low maintenance; occasional checks recommended. | Minimal maintenance; check for rust in metal bases. | Very low maintenance once installed. |

| Best Use Case | Suitable for post-frame buildings and heavy-duty applications. | Best for temporary structures and lighter applications. | Optimal for permanent installations where maximum stability is required. |

What Are the Benefits and Drawbacks of Using Post Bases as an Alternative?

Post bases are designed to support wooden posts, making them a popular choice in residential and light commercial applications. Their ease of installation is a significant advantage; they typically require only basic tools and can be adjusted after installation to ensure proper alignment. Additionally, post bases are generally more affordable than column brackets, making them attractive for budget-conscious projects. However, they may not provide the same level of structural integrity as column brackets in heavy-duty applications, limiting their use in more demanding environments.

How Do Wet Set Anchors Compare to Column Brackets?

Wet set anchors are another alternative that offers a robust solution for securing columns to concrete. Their design allows them to be embedded directly in wet concrete, providing a permanent anchor that can withstand significant loads and lateral forces. This makes them an excellent choice for permanent installations, such as commercial buildings and heavy structures. While wet set anchors can be more expensive and require more complex installation than column brackets, they offer exceptional durability and stability once in place, leading to lower long-term maintenance costs.

Illustrative image related to column bracket

How Should B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate solution for securing columns ultimately depends on the specific requirements of the project. Buyers should consider factors such as the intended use of the structure, budget constraints, and the level of expertise available for installation. For projects requiring maximum stability and longevity, investing in column brackets or wet set anchors may be beneficial. Conversely, for lighter applications or temporary structures, post bases could provide a cost-effective and efficient alternative. By carefully evaluating these aspects, B2B buyers can make informed decisions that align with their project goals and operational needs.

Essential Technical Properties and Trade Terminology for column bracket

What Are the Key Technical Properties of Column Brackets?

When sourcing column brackets, understanding their technical specifications is crucial for ensuring that they meet the demands of your structural projects. Here are some of the essential properties to consider:

-

Material Grade

The material grade of a column bracket determines its strength and durability. Common materials include galvanized steel, stainless steel, and powder-coated finishes. A higher material grade often translates to better resistance against environmental factors, making it essential for outdoor applications. For instance, galvanized steel is preferred for its corrosion resistance, particularly in humid or coastal climates. -

Weight Capacity

Each column bracket is designed to support a specific weight load, which is critical for structural integrity. This capacity is often tested and certified to ensure safety. Understanding the weight capacity helps in selecting the appropriate bracket based on the type of column (wood, steel, etc.) and the load it must bear, minimizing the risk of structural failure. -

Tolerance Levels

Tolerance refers to the allowable deviation from a specified dimension. In column brackets, this can impact the fit and function within a structural framework. Higher tolerance levels often mean that the brackets can accommodate slight variations in column dimensions, which is particularly important in custom or non-standard applications. -

Bracket Height and Pocket Size

The height of the bracket and the size of its pocket (the area where the column fits) are vital for ensuring a snug fit. Brackets come in various sizes to accommodate different column dimensions, such as 4×4, 6×6, or custom sizes. Proper sizing ensures that the load is distributed evenly, enhancing the stability of the overall structure. -

Installation Requirements

Understanding the installation requirements, including necessary tools and methods, is crucial for project planning. Some brackets may require specialized anchors or concrete drilling, while others might be more straightforward to install. Clear specifications help in budgeting and scheduling resources effectively. -

Finish Type

The finish of a column bracket can affect both aesthetics and performance. Options such as powder coating or hot-dip galvanizing provide additional protection against rust and wear. Choosing the right finish is important for projects exposed to harsh weather conditions, influencing the longevity of the installation.

What Are Common Trade Terms Used in Column Bracket Sourcing?

In the world of B2B procurement, familiarizing yourself with industry-specific jargon can enhance communication and streamline transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of column brackets, understanding whether a supplier is an OEM can assure you of the quality and compatibility of the product with your existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. For column brackets, this can impact your purchasing decisions, especially if you are a smaller contractor or buyer. Knowing the MOQ helps in budgeting and prevents overstocking. -

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. When sourcing column brackets, issuing an RFQ allows buyers to compare prices and specifications from various vendors, ensuring competitive pricing and better quality assurance. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. They clarify the responsibilities of buyers and sellers in global transactions, including who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for international buyers to avoid unexpected costs. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In construction projects, understanding lead times for column brackets is vital for project scheduling and ensuring that deadlines are met. -

Certification Standards

Certification standards indicate compliance with specific industry regulations and safety requirements. For column brackets, certifications like ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization) can provide assurance of quality and reliability.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when procuring column brackets, ultimately contributing to the success of their projects.

Navigating Market Dynamics and Sourcing Trends in the column bracket Sector

What Are the Current Market Dynamics and Key Trends in the Column Bracket Sector?

The global column bracket market is experiencing significant growth, driven by an increase in construction activities and the rising demand for durable, efficient building materials. Emerging economies in Africa and South America are witnessing a construction boom, fueled by urbanization and infrastructure development projects. In Europe, particularly in countries like Germany and Saudi Arabia, there is a strong emphasis on modernizing existing structures and enhancing energy efficiency. As a result, B2B buyers are increasingly seeking high-quality, reliable column brackets that can withstand varying climatic conditions and provide structural integrity.

Digital transformation is reshaping sourcing strategies, with a growing reliance on e-commerce platforms and digital marketplaces. International buyers are leveraging technology to compare prices, specifications, and supplier credentials. This trend is particularly prevalent in regions where traditional procurement methods may be less efficient. Furthermore, the integration of advanced manufacturing technologies such as robotics and automation is enhancing the production of column brackets, leading to better precision and reduced lead times. Buyers are also prioritizing suppliers that offer customization options, allowing them to meet specific project requirements.

How Does Sustainability and Ethical Sourcing Impact the Column Bracket Market?

Sustainability is becoming a pivotal factor in sourcing decisions for B2B buyers in the column bracket sector. With growing awareness of environmental issues, there is a marked shift towards products that minimize ecological impact. Buyers are increasingly looking for column brackets made from recycled materials or sourced from manufacturers that adhere to sustainable practices. The use of eco-friendly coatings and finishes, such as powder coatings that reduce VOC emissions, is also gaining traction.

Ethical sourcing is crucial, especially for international buyers who are keen on ensuring that their supply chains are transparent and socially responsible. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are becoming important criteria for evaluating suppliers. Buyers are encouraged to partner with manufacturers who demonstrate a commitment to ethical labor practices and environmental stewardship. This not only enhances brand reputation but also aligns with global sustainability goals.

What Is the Historical Context of Column Brackets in Construction?

The evolution of column brackets can be traced back to the early days of construction, where rudimentary methods were employed to secure wooden posts and beams. As architectural designs became more complex, so did the need for reliable anchoring solutions. The introduction of metal brackets in the mid-20th century revolutionized the industry, offering enhanced strength and durability. Over the years, advancements in materials science and engineering have led to the development of specialized brackets designed to accommodate various load requirements and environmental conditions.

Today, column brackets are a critical component in modern construction, with manufacturers continually innovating to meet the demands of contemporary architectural practices. The focus on safety, sustainability, and efficiency has driven the market towards more sophisticated solutions, ensuring that column brackets remain integral to structural integrity in both residential and commercial projects. As the industry continues to evolve, B2B buyers must stay informed about trends and innovations to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of column bracket

-

How do I ensure the quality of column brackets when sourcing internationally?

To ensure the quality of column brackets from international suppliers, start by verifying their certifications and industry standards compliance. Request samples to assess material quality and manufacturing techniques. Utilize third-party inspection services to evaluate production processes and finished products before shipment. Additionally, establish a clear quality assurance (QA) agreement outlining specifications, tolerances, and acceptable quality levels to mitigate risks associated with international sourcing. -

What is the best material for column brackets in different climates?

The best material for column brackets largely depends on the environmental conditions they will face. For humid or coastal regions, stainless steel or galvanized steel is ideal due to its corrosion resistance. In dry climates, powder-coated steel or aluminum can be effective, providing durability and aesthetic appeal. Always consider local building codes and environmental factors when selecting materials to ensure long-lasting performance. -

How can I vet potential suppliers for column brackets?

To vet potential suppliers for column brackets, conduct thorough research on their background, including years of experience and client testimonials. Request references from previous customers, especially those in your industry or region. Additionally, verify their manufacturing capabilities, quality control processes, and compliance with international standards. Visiting the supplier’s facilities or arranging virtual tours can also provide insights into their operations and reliability. -

What are the typical minimum order quantities (MOQs) for column brackets?

Minimum order quantities (MOQs) for column brackets can vary significantly depending on the supplier and the specific product. Generally, MOQs may range from 50 to 500 units for standard models, while custom designs may require higher quantities. Always discuss MOQs upfront during negotiations, as some suppliers may be flexible, especially for long-term partnerships or bulk orders. -

What payment terms should I expect when sourcing column brackets?

When sourcing column brackets, payment terms can vary by supplier and region. Common practices include a deposit of 30% to 50% upfront, with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or other financing options for larger orders. It’s crucial to clearly outline payment terms in the contract to avoid misunderstandings and ensure smooth transactions. -

How do I handle logistics for importing column brackets?

Managing logistics for importing column brackets involves coordinating with freight forwarders to determine the best shipping methods and routes. Consider factors such as shipping costs, lead times, and customs regulations in your destination country. Ensure all documentation, including invoices, packing lists, and certificates of origin, is accurate and complete to facilitate smooth customs clearance. Additionally, research local import duties and taxes to anticipate costs. -

Can column brackets be customized for specific applications?

Yes, many suppliers offer customization options for column brackets to meet specific project requirements. Customization can include alterations in size, material, finish, and design features. When seeking customization, provide detailed specifications and drawings to the supplier. Discuss lead times and any potential impact on pricing to ensure that the customized brackets align with your project timelines and budget. -

What are the best practices for installation of column brackets?

To ensure proper installation of column brackets, follow the manufacturer’s guidelines closely, including recommended tools and techniques. Use appropriate fasteners and ensure that the brackets are securely anchored to the substrate, whether concrete or wood. It’s advisable to conduct a load-bearing test post-installation to confirm structural integrity. Additionally, consider hiring professional installers if the project scope requires advanced skills or safety precautions.

Top 3 Column Bracket Manufacturers & Suppliers List

1. Midwest Perma-Column – Sturdi-Wall Drill Set Brackets

Domain: midwestpermacolumn.com

Registered: 2009 (16 years)

Introduction: {‘product_name’: ‘Sturdi-Wall Drill Set Brackets’, ‘manufacturer’: ‘Midwest Perma-Column’, ‘made_in’: ‘USA’, ‘features’: ‘Build stronger, longer-lasting post-frame structures’, ‘materials’: ‘100% American-made 1/4″ steel, robotically welded, finished with a tough powder coat’, ‘installation_tools’: ‘Masonry drill bit and concrete anchors’, ‘models’: [{‘model_id’: ‘SW46’, ‘type’: ‘4″ x 6″‘, ‘bracke…

2. Deslauriers – Scaffold Bracket

Domain: deslinc.com

Registered: 2001 (24 years)

Introduction: {“name”: “Scaffold Bracket”, “description”: “The Deslauriers Scaffold Bracket is designed and manufactured to install onto Deslauriers Column forms. This Scaffold Bracket provides the framework for 2 x 10 planks to make a comfortable working platform. The built-in guardrail receptacle makes it easy to install a safe and economical safety rail.”, “installation_requirements”: “Installation of each b…

3. AW Metal – Post Brackets

Domain: awmetal.net

Registered: 2012 (13 years)

Introduction: {“Post Brackets”: {“products”: [{“name”: “Sturdi-Wall”, “price_range”: “$64.50 – $132.25”, “variants”: “multiple”}, {“name”: “Sturdi-Wall Plus”, “price_range”: “$75.00 – $145.25”, “variants”: “multiple”}, {“name”: “Universal L Bracket”, “price_range”: “$28.50 – $75.75”, “variants”: “multiple”}, {“name”: “Perma-Columns”, “price_range”: “$118.10 – $199.20”, “variants”: “multiple”}]}}

Strategic Sourcing Conclusion and Outlook for column bracket

In today’s global marketplace, the strategic sourcing of column brackets is essential for ensuring the longevity and structural integrity of various construction projects. By prioritizing high-quality materials, such as those offered by brands like Sturdi-Wall, buyers can enhance their project outcomes. The emphasis on robust construction standards and innovative designs allows for greater adaptability in diverse applications—from residential builds in Europe to agricultural structures in Africa.

International buyers should also consider the importance of supplier relationships and the value of sourcing from manufacturers that prioritize sustainability and local compliance. This approach not only ensures product reliability but also fosters a more resilient supply chain. As construction demands evolve, leveraging strategic sourcing will be crucial for staying competitive in the market.

Looking ahead, it is vital for B2B buyers across Africa, South America, the Middle East, and Europe to engage with trusted suppliers who understand regional needs and regulations. By doing so, businesses can optimize their procurement processes and drive value through informed decisions. Begin your sourcing journey today—invest in quality column brackets and build a solid foundation for your future projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to column bracket

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.