A B2B Buyer’s Guide to Cold Header: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for cold header

In today’s competitive landscape, sourcing high-quality cold headers can pose significant challenges for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. The complexities of global supply chains, fluctuating material costs, and varying manufacturing standards can complicate the procurement process, making it essential to navigate these waters with a strategic approach. This comprehensive guide on cold headers aims to demystify the sourcing process, providing insights into different types of cold headers, their applications across various industries, and the key factors to consider when vetting suppliers.

Buyers will discover how cold heading technology enhances efficiency, reduces waste, and improves the physical properties of metal parts, translating to significant cost savings. The guide also emphasizes the importance of understanding production capabilities, tolerances, and secondary operations that may be required to meet specific project needs. By offering actionable advice on supplier evaluation and negotiation strategies, this resource empowers B2B buyers to make informed decisions that align with their operational goals. Whether you are based in Vietnam or Nigeria, this guide equips you with the knowledge needed to confidently engage in the global market for cold headers, ensuring you secure the best products for your business needs.

Understanding cold header Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Cold Headers | Common shapes, high-speed production, and tight tolerances | Fasteners, automotive parts, construction | Pros: Cost-effective, widely available; Cons: Limited customization options |

| Custom Cold Headers | Tailored designs and specifications based on client needs | Specialized machinery, unique fastener shapes | Pros: Fully customized; Cons: Longer lead times, potentially higher costs |

| Upset Headers | Involves increasing diameter while reducing height | Structural components, heavy machinery | Pros: Stronger parts, less waste; Cons: Complexity in design and production |

| Extrusion Headers | Material is forced through a die to create specific shapes | Plumbing fittings, aerospace components | Pros: Versatile applications, efficient material use; Cons: Requires precise tooling |

| Secondary Operation Headers | Involves additional processes after cold heading | Complex fasteners, intricate components | Pros: Enhanced functionality; Cons: Increased production time and costs |

What Are Standard Cold Headers and Their Applications?

Standard cold headers are the most commonly produced fasteners, characterized by their ability to be manufactured at high speeds while maintaining tight tolerances. They are widely used in industries such as automotive, construction, and electronics. Buyers should consider their volume requirements, as these headers are cost-effective for large orders but may lack the customization needed for specialized applications.

How Do Custom Cold Headers Differ from Standard Options?

Custom cold headers are designed specifically to meet the unique requirements of a project. These headers allow for intricate designs and specifications, making them ideal for specialized machinery and unique fastener shapes. While they offer significant advantages in customization, buyers must weigh the longer lead times and potentially higher costs against the benefits of tailored solutions.

What Are Upset Headers and Their Key Benefits?

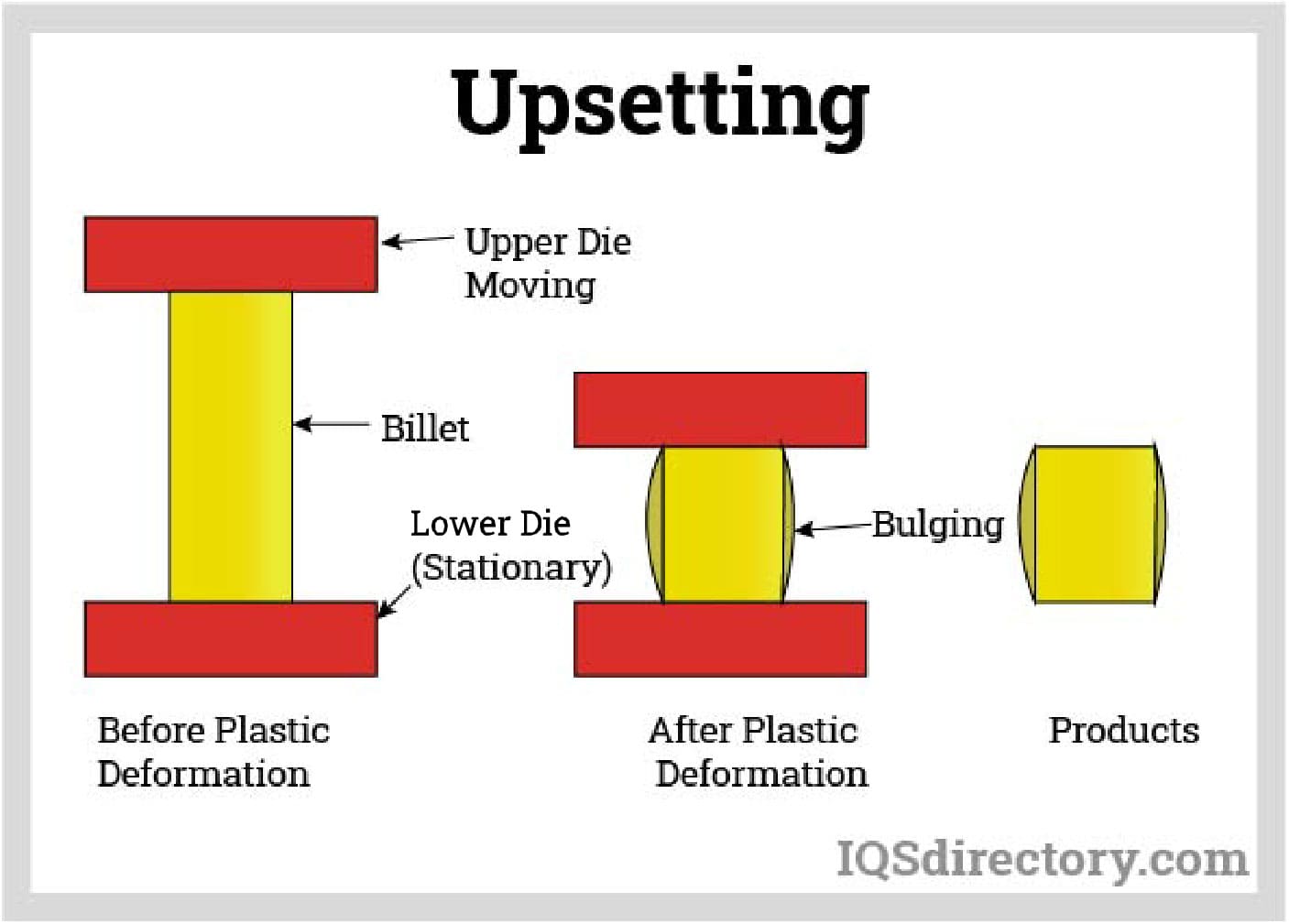

Upset headers are a fundamental type of cold header where the diameter of the material increases while its height decreases. This technique is especially beneficial for creating structural components used in heavy machinery and construction. The primary advantages include reduced waste and enhanced strength of the finished product. However, the complexity of the design may present challenges during production.

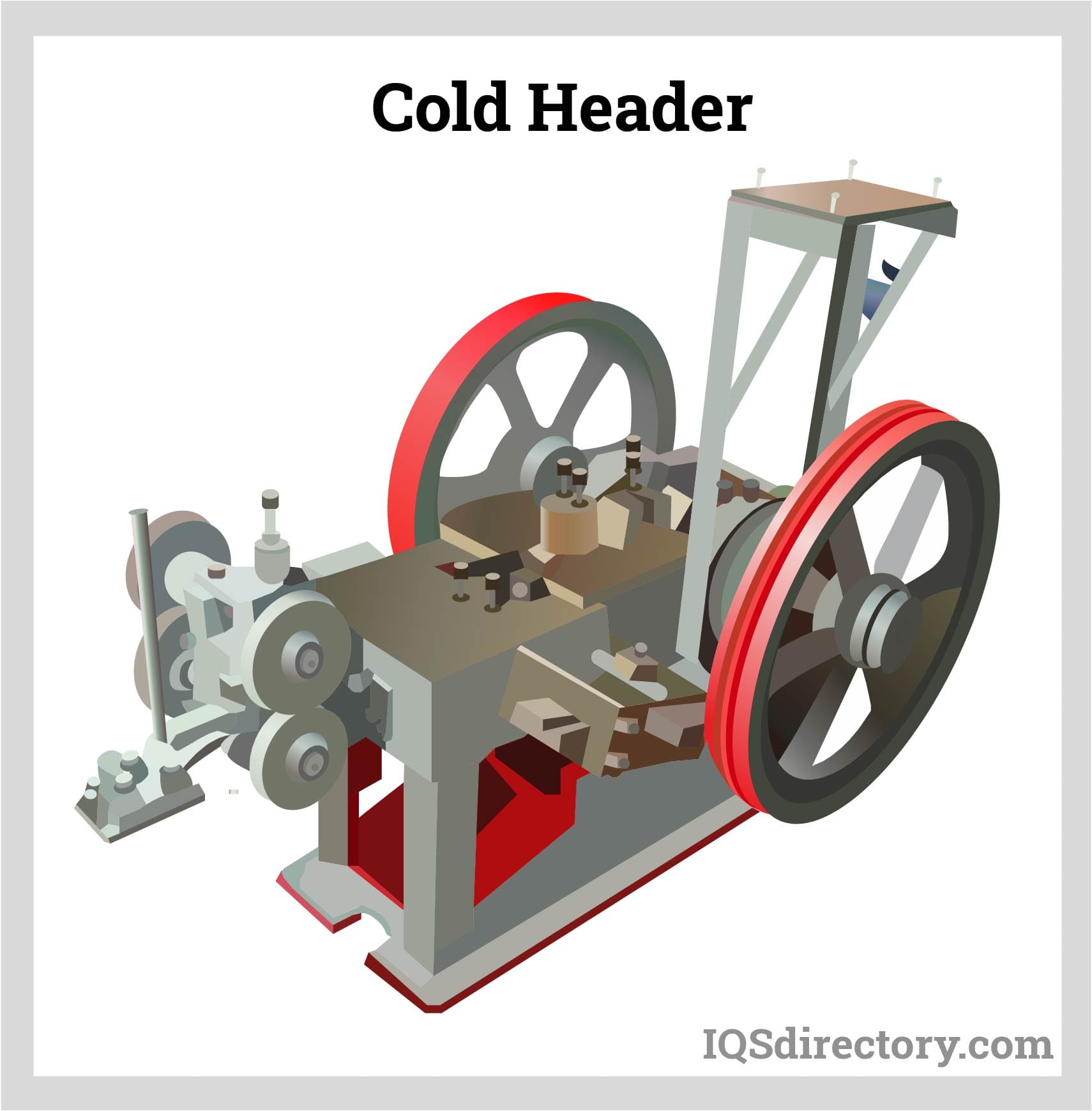

Illustrative image related to cold header

What Are Extrusion Headers and Their Versatile Uses?

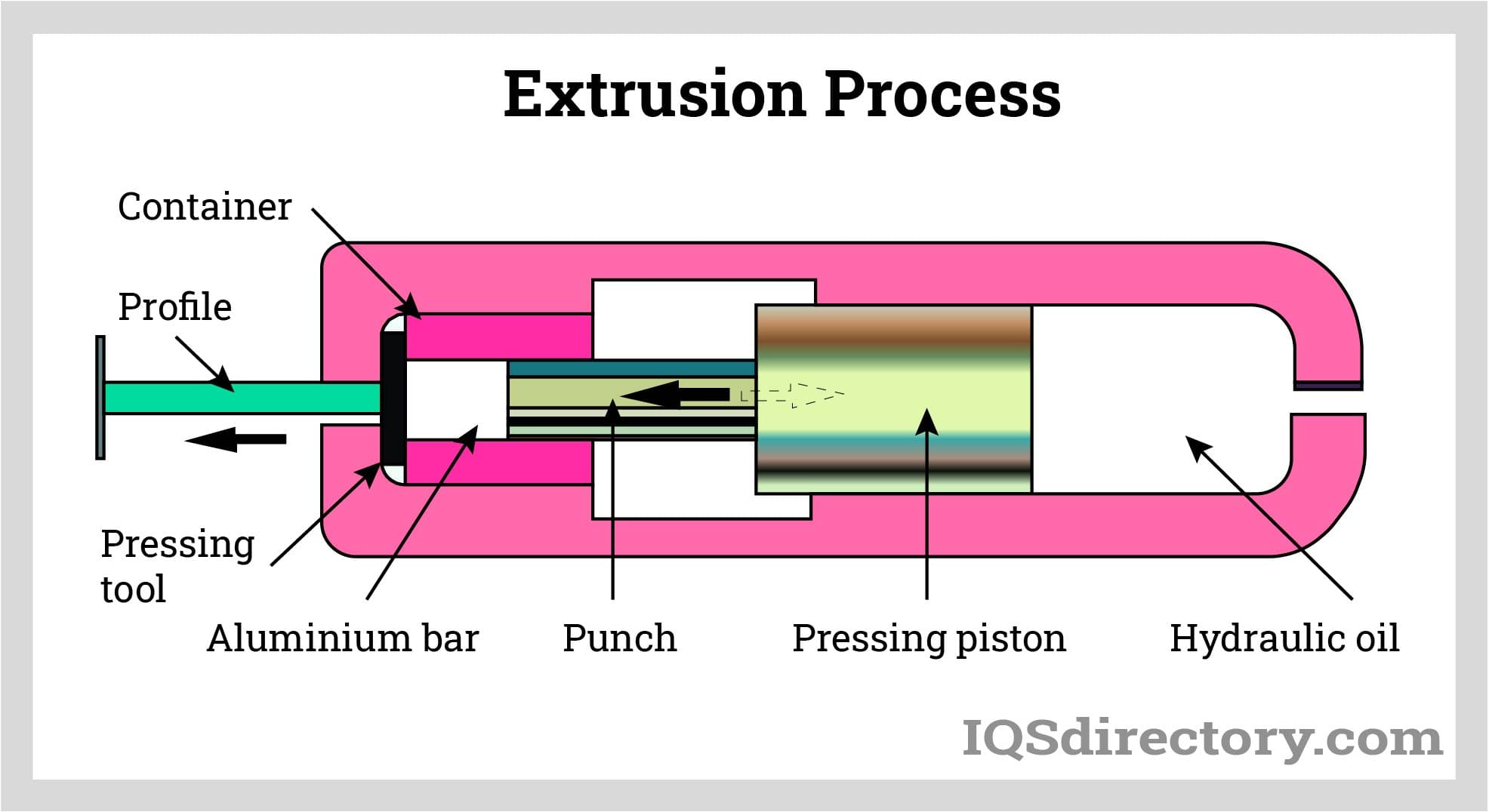

Extrusion headers utilize a process where material is forced through a die to achieve specific shapes, making them versatile for applications in plumbing fittings and aerospace components. This method is efficient in terms of material usage and allows for a variety of shapes. Buyers should consider the precision required in tooling, as any discrepancies can affect the final product’s integrity.

How Do Secondary Operation Headers Enhance Functionality?

Secondary operation headers refer to parts that undergo additional processes after the cold heading phase, such as threading or plating. These operations are crucial for producing complex fasteners and intricate components used in specialized applications. While they enhance the functionality and performance of the final product, buyers should be mindful of the increased production time and costs associated with these additional processes.

Key Industrial Applications of cold header

| Industry/Sector | Specific Application of cold header | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of fasteners and brackets | High precision and reduced production costs | Quality of materials, lead times, and customization options |

| Aerospace | Production of structural components | Lightweight, strong parts with tight tolerances | Certifications, compliance with industry standards, and material specifications |

| Construction | Fabrication of anchors and connectors | Enhanced durability and reduced material waste | Availability of custom designs and rapid prototyping capabilities |

| Electronics | Creation of specialized screws and pins | Improved assembly efficiency and cost savings | Supplier reliability, delivery schedules, and MOQ flexibility |

| Industrial Machinery | Production of specialized bolts and fittings | High-volume production with minimal waste | Material selection, precision engineering capabilities, and after-sales support |

How is Cold Header Used in the Automotive Industry?

In the automotive sector, cold heading is crucial for producing fasteners and brackets that require high precision and durability. The process allows manufacturers to create complex geometries with minimal waste, which is essential for meeting stringent safety and performance standards. International buyers should focus on sourcing suppliers that can ensure tight tolerances and provide quality materials to withstand the automotive environment.

Illustrative image related to cold header

What Role Does Cold Heading Play in Aerospace Manufacturing?

Aerospace applications rely heavily on cold heading for producing lightweight yet strong structural components. These parts must meet rigorous industry standards for safety and performance. Suppliers need to provide detailed certifications and compliance documentation, ensuring that materials meet specific aerospace requirements, particularly for international buyers who may have different regulatory landscapes.

How is Cold Heading Beneficial in Construction Applications?

In construction, cold heading is used for fabricating anchors and connectors that enhance the structural integrity of buildings and infrastructure. The process minimizes raw material waste while producing parts that can withstand significant loads. Buyers in this sector should prioritize suppliers that offer custom designs and rapid prototyping services to meet project-specific needs.

Why is Cold Header Important for Electronics Manufacturing?

The electronics industry utilizes cold heading to create specialized screws and pins that facilitate efficient assembly processes. The ability to produce these components quickly and cost-effectively is vital for maintaining competitive pricing and ensuring product reliability. Buyers should consider the supplier’s reliability, delivery schedules, and flexibility in minimum order quantities to align with their production timelines.

Illustrative image related to cold header

How Does Cold Heading Enhance Industrial Machinery Production?

In the industrial machinery sector, cold heading is employed to manufacture specialized bolts and fittings that require high-volume production with minimal waste. This efficiency translates into cost savings and improved product quality. When sourcing these components, businesses should evaluate the material selection and precision engineering capabilities of suppliers, as well as their after-sales support to ensure ongoing operational success.

3 Common User Pain Points for ‘cold header’ & Their Solutions

Scenario 1: Difficulty in Achieving Tight Tolerances

The Problem:

B2B buyers often face challenges in achieving the tight tolerances required for their components, especially when dealing with complex designs or high-performance applications. This issue can lead to product failures, increased scrap rates, and ultimately, higher costs. For instance, a manufacturer in the automotive sector may need fasteners that must fit precisely within a defined space. Any deviation can result in assembly issues, reduced performance, and potential safety hazards.

The Solution:

To mitigate the challenge of achieving tight tolerances, buyers should work closely with their cold header suppliers to specify the exact requirements upfront. It’s crucial to communicate the specific tolerances needed for each component, along with the material type and design specifications. Suppliers can provide insights into the capabilities of their cold heading processes, ensuring that the correct tooling and techniques are employed. Additionally, buyers should consider conducting initial test runs to validate tolerances before scaling up production. This proactive approach not only ensures the parts meet specifications but also minimizes costly revisions down the line.

Scenario 2: Inconsistent Quality Across Batches

The Problem:

Another common pain point for B2B buyers is the inconsistency in quality across different batches of cold-headed components. Variations in material quality, machine calibration, or operator skill can lead to parts that do not meet the required specifications, resulting in additional inspection costs and potential production delays. For example, a construction firm relying on fasteners for structural integrity may find that some batches are subpar, risking both project timelines and safety standards.

The Solution:

To ensure consistent quality, buyers should implement a robust quality assurance process that includes regular inspections and material testing. Establishing a long-term partnership with a reputable cold header supplier that adheres to strict quality control standards can also enhance consistency. Buyers should request documentation of the supplier’s quality management systems, including certifications like ISO 9001, to ensure adherence to industry standards. Furthermore, engaging in routine communication with the supplier about production processes and any observed variations can foster collaboration and improvements, leading to higher overall quality in the components received.

Scenario 3: High Production Costs and Waste

The Problem:

High production costs and excessive waste during manufacturing can significantly impact a buyer’s bottom line. In sectors where margins are tight, such as electronics or consumer goods, the inefficiency of traditional machining methods can lead to wasted materials and inflated costs. A company may find that its current machining processes generate up to 60% waste, which not only increases material expenses but also extends lead times and complicates inventory management.

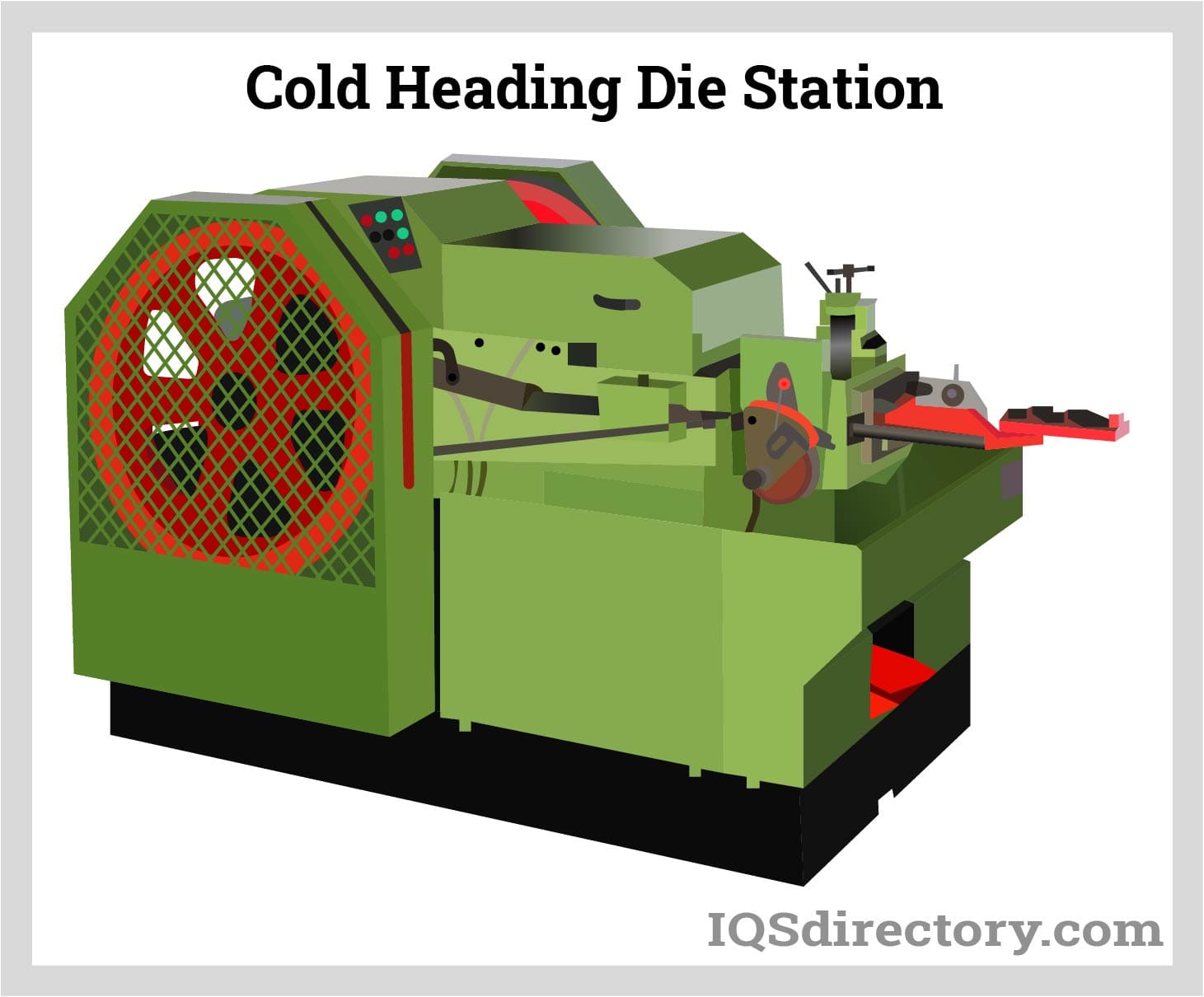

Illustrative image related to cold header

The Solution:

Adopting cold heading as a manufacturing solution can dramatically reduce production costs and waste. Buyers should evaluate their current manufacturing processes and consider transitioning to cold heading for suitable components. Cold heading is known for its material efficiency, producing near-net shapes with minimal waste. When sourcing cold-headed parts, buyers should provide detailed specifications and collaborate with suppliers to optimize designs for the cold heading process, potentially incorporating features that enhance manufacturability. Additionally, leveraging advanced technologies such as computer simulations during the design phase can help identify and eliminate waste before production begins, ensuring a more streamlined manufacturing operation.

Strategic Material Selection Guide for cold header

What Are the Best Materials for Cold Header Applications?

When selecting materials for cold heading applications, it is crucial to consider the properties and performance characteristics that best align with the intended use. Here, we analyze four common materials used in cold heading: carbon steel, stainless steel, aluminum, and brass. Each material has unique properties that influence its suitability for various applications.

How Does Carbon Steel Perform in Cold Heading?

Key Properties: Carbon steel is known for its high tensile strength and durability. It typically exhibits good wear resistance and can withstand moderate temperatures and pressures. However, it is susceptible to corrosion if not properly treated.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and ease of machining. It is widely available and can be heat-treated to enhance its mechanical properties. On the downside, its susceptibility to rust can limit its use in corrosive environments, necessitating additional coatings or treatments.

Illustrative image related to cold header

Impact on Application: Carbon steel is suitable for a wide range of applications, including automotive and construction fasteners. However, in environments with high humidity or exposure to chemicals, its longevity may be compromised.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM A36 or DIN 17100. In regions like Africa and South America, sourcing reliable suppliers who adhere to these standards is crucial for ensuring product quality.

What Benefits Does Stainless Steel Offer in Cold Heading?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It maintains its integrity in harsh environments, making it ideal for demanding applications.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to oxidation. However, it is more expensive than carbon steel and can be more challenging to machine, which may increase manufacturing complexity.

Impact on Application: Ideal for applications in the food, pharmaceutical, and chemical industries, stainless steel components are compatible with corrosive media. Its long-term performance often justifies the higher initial cost.

Considerations for International Buyers: Compliance with standards like ASTM A276 or JIS G4303 is essential. Buyers should also consider the availability of specific grades, such as 304 or 316, which may vary by region.

Why Choose Aluminum for Cold Heading?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can be easily shaped, making it a popular choice for various applications.

Pros & Cons: The primary advantage of aluminum is its low density, which reduces overall weight in applications. However, it has lower tensile strength compared to steel, which may limit its use in high-stress environments.

Illustrative image related to cold header

Impact on Application: Aluminum is commonly used in the aerospace and automotive industries, where weight savings are critical. It is also suitable for applications requiring good corrosion resistance, such as marine environments.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B211 or EN AW-6060. In regions like the Middle East, where aluminum is prevalent, understanding local sourcing options can streamline procurement.

What Role Does Brass Play in Cold Heading?

Key Properties: Brass, an alloy of copper and zinc, offers excellent corrosion resistance and good machinability. It has a moderate strength and is known for its aesthetic appeal.

Illustrative image related to cold header

Pros & Cons: The advantage of brass lies in its ability to resist corrosion and its attractive finish, making it suitable for decorative applications. However, it is generally more expensive than carbon steel and may not perform as well under high-stress conditions.

Impact on Application: Brass is often used in plumbing fittings, electrical connectors, and decorative items. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Compliance with standards such as ASTM B16 or JIS H3250 is important. Buyers in Europe and South America should also consider the availability of brass components, as sourcing can vary significantly by region.

Summary Table of Material Selection for Cold Header

| Material | Typical Use Case for cold header | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive fasteners | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Food and pharmaceutical components | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Aerospace and automotive parts | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Brass | Plumbing fittings and connectors | Corrosion resistance and aesthetics | Higher cost and stress limitations | Medium |

This strategic material selection guide equips international B2B buyers with the insights needed to make informed decisions when sourcing materials for cold heading applications, ensuring compliance and suitability for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for cold header

What Are the Main Stages in the Cold Header Manufacturing Process?

The manufacturing process for cold headers involves several critical stages, each designed to ensure efficiency and precision. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Cold Heading?

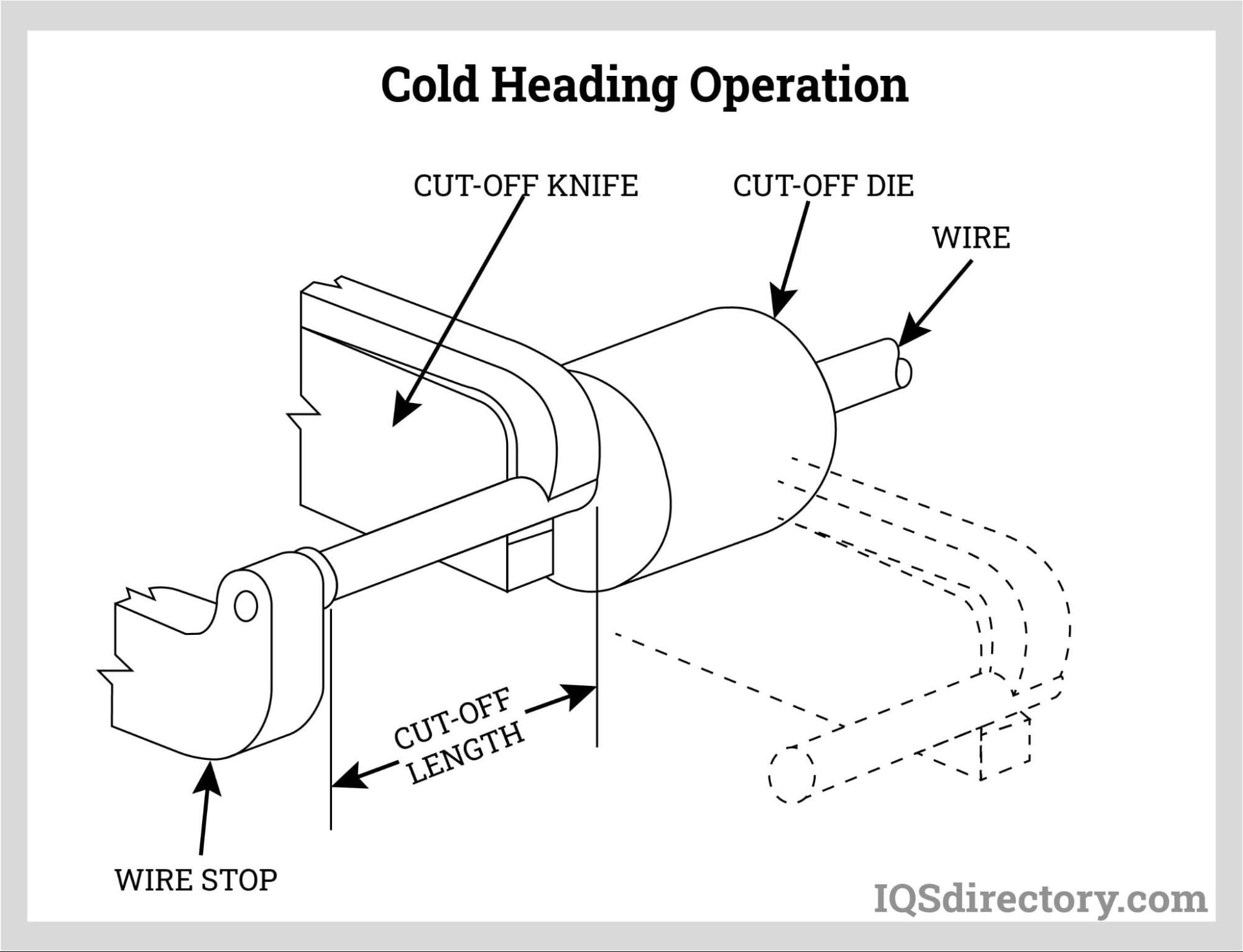

Material preparation is the foundational step where raw materials, typically high-quality steel or other alloys, are sourced and processed. The wire is drawn to the required diameter, ensuring it meets specific mechanical properties. Quality control checks at this stage may include verifying the chemical composition and tensile strength of the wire to ensure it is suitable for cold heading. This is crucial for maintaining tight tolerances and achieving the desired physical properties in the final product.

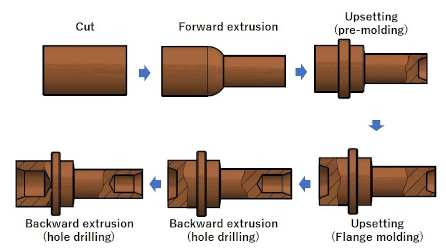

What Techniques Are Used in the Forming Process?

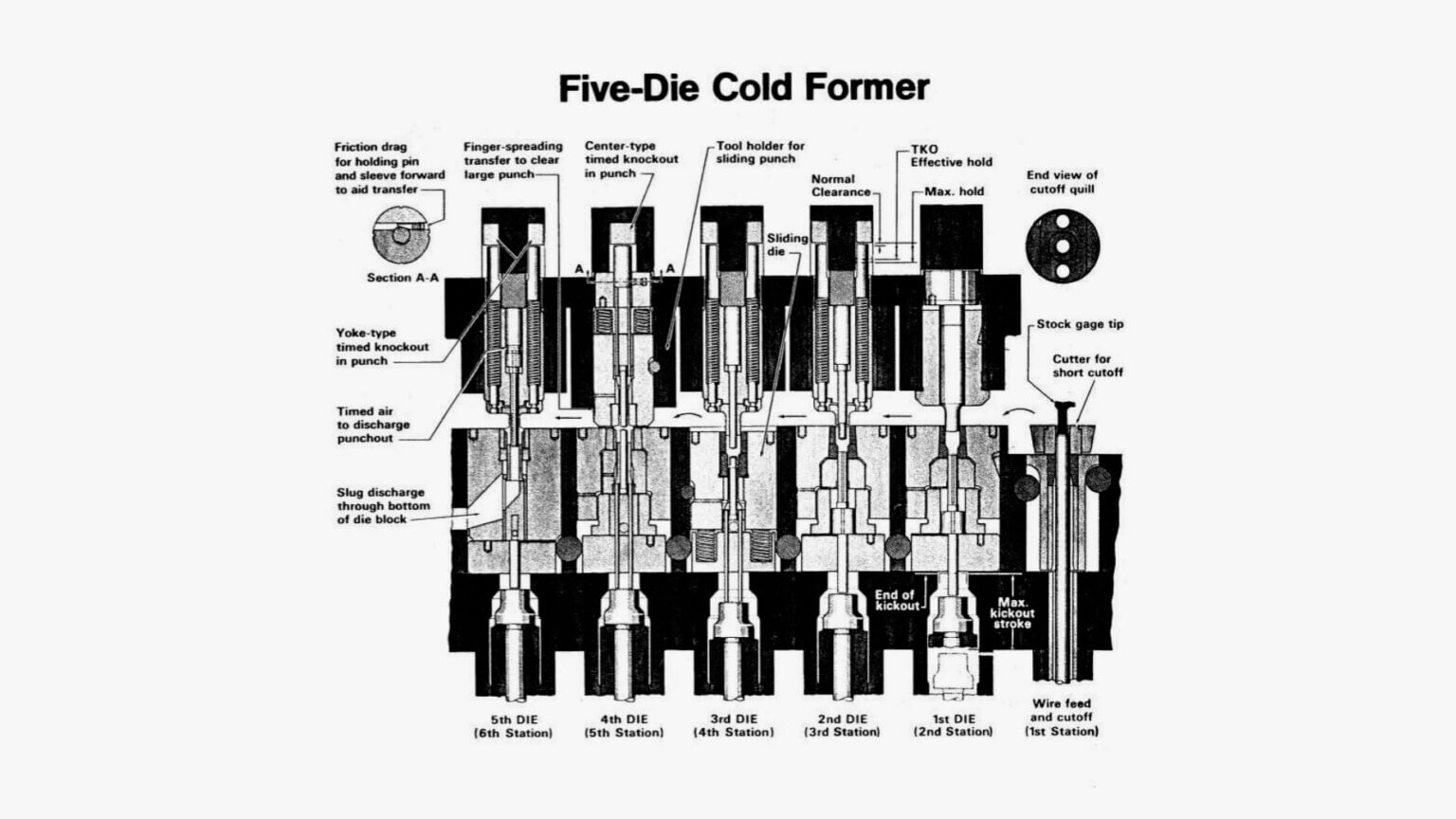

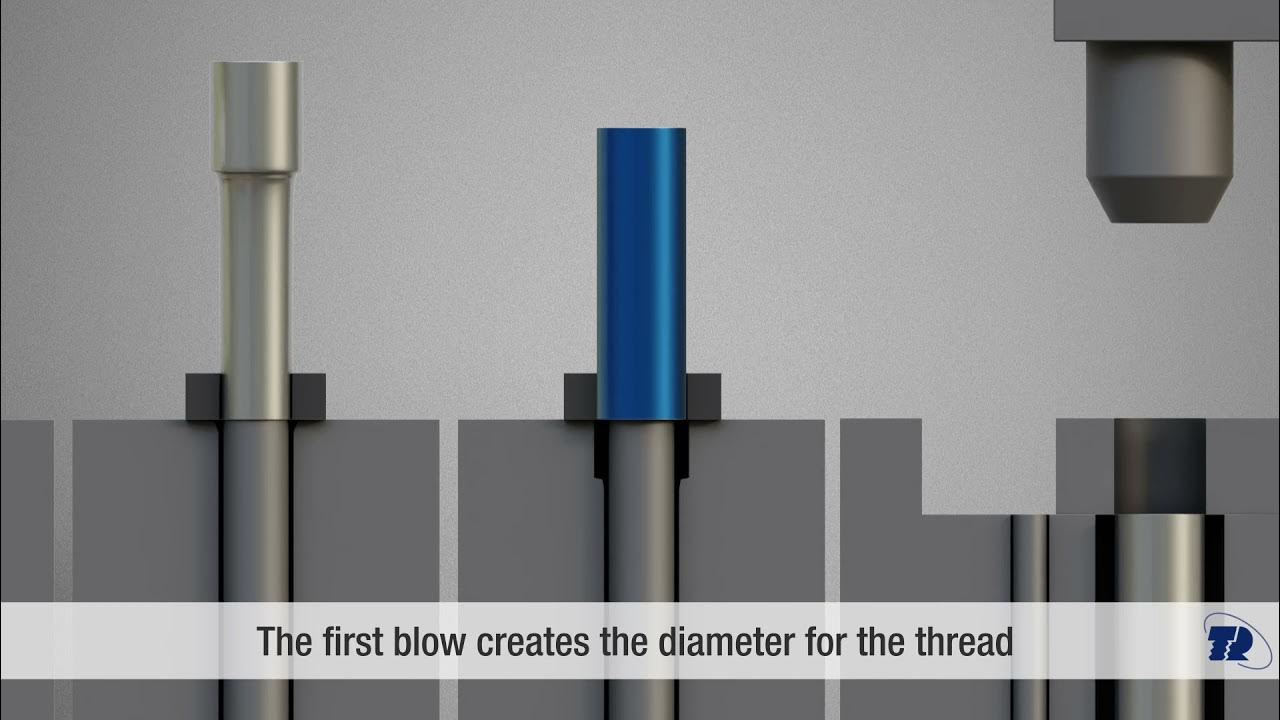

Once the material is prepared, the forming process begins. Cold heading machines utilize a series of dies and hammers to shape the wire into the desired form without applying heat. The main techniques employed include:

- Upsetting: This is the most common technique where the wire slug is reduced in height while increasing in diameter to form heads or other shapes.

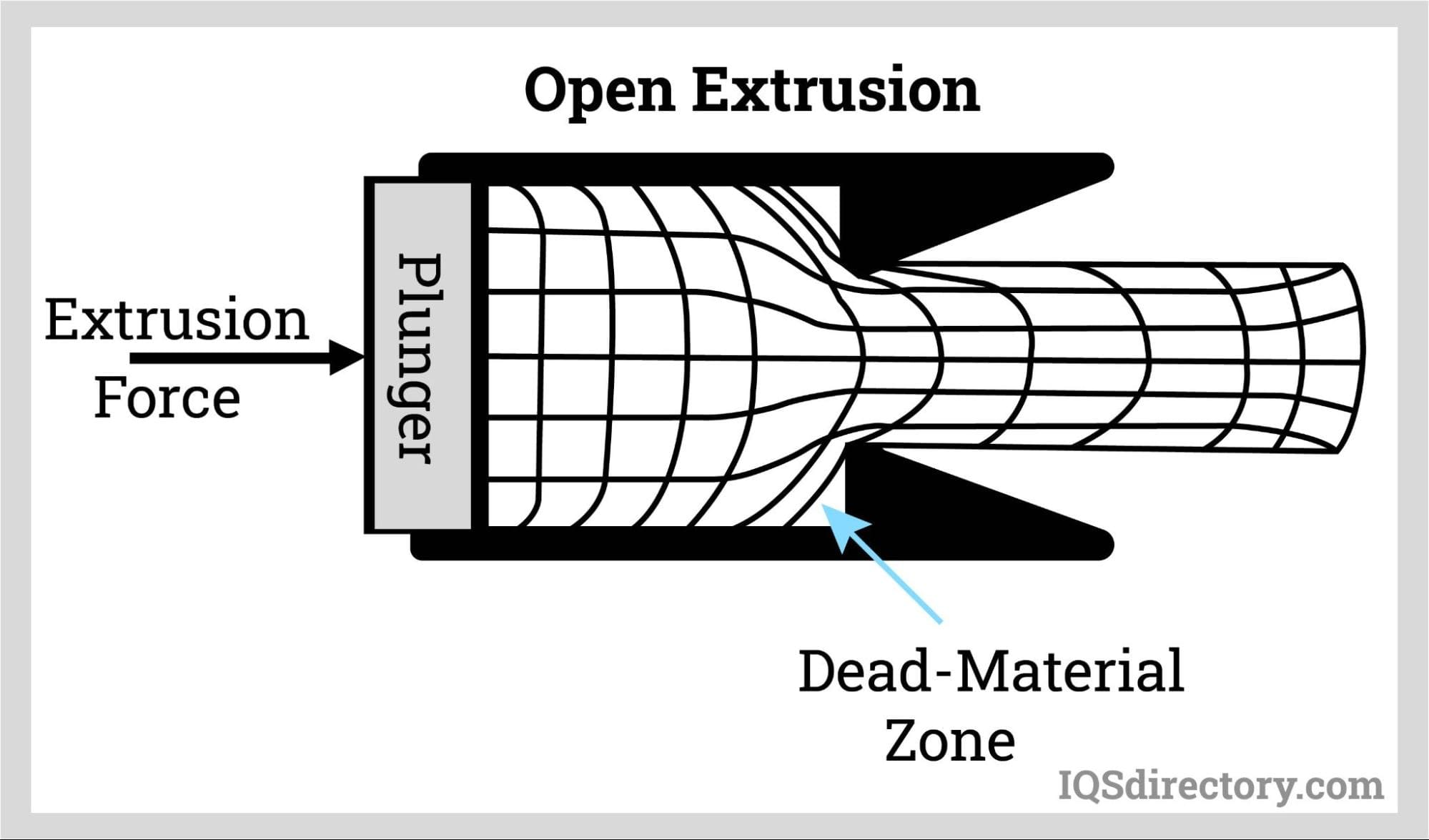

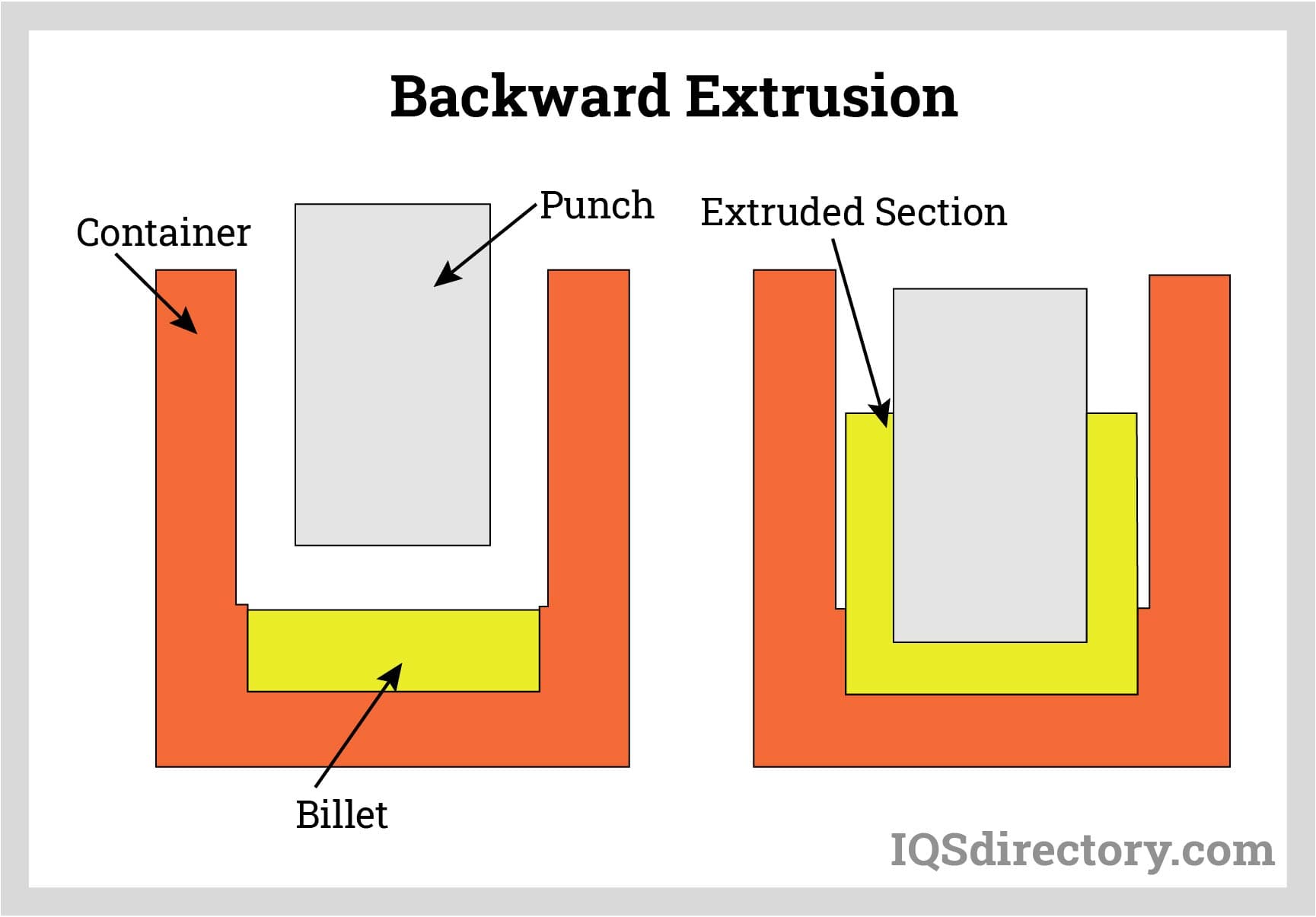

- Extrusion: This involves forcing the material through a die to create specific profiles or cavities. Both forward and backward extrusion techniques may be used, depending on the design requirements.

The forming process is characterized by high-speed production rates, making it suitable for large-volume orders while minimizing waste. This efficiency not only reduces costs but also enhances the mechanical properties of the finished parts due to improved grain flow.

How Is Assembly Performed in Cold Header Manufacturing?

Following the forming stage, assembly may be necessary for complex components that require additional features, such as threading or grooving. Secondary operations, often performed using specialized machinery, include:

- Thread Rolling: This technique is used to create threads on the formed part.

- Drilling and Tapping: For parts that require holes, drilling and tapping operations are executed.

- Heat Treatment: This process enhances strength and durability through controlled heating and cooling.

These assembly operations ensure that the final product meets specific customer specifications and industry standards.

What Finishing Processes Are Common in Cold Header Production?

Finishing processes are essential to achieve the desired surface quality and functionality of cold headers. These may include:

- Metal Finishing and Polishing: To enhance aesthetics and reduce friction.

- Plating: To provide corrosion resistance, particularly important for components used in harsh environments.

- CNC Machining: For any final adjustments to dimensions and tolerances.

The finishing stage not only improves the appearance of the components but also plays a critical role in their performance and longevity.

Which International Standards Govern Cold Header Quality Assurance?

Quality assurance is a vital component of the cold header manufacturing process, ensuring that products meet both customer expectations and regulatory requirements. International standards such as ISO 9001 provide a framework for quality management systems, guiding manufacturers in maintaining consistent quality across production processes.

Additionally, industry-specific certifications may be relevant depending on the application of the cold headers. For example:

Illustrative image related to cold header

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Certification: Relevant for components used in the oil and gas industry, ensuring adherence to quality standards established by the American Petroleum Institute.

What Are the Key Quality Control Checkpoints in Cold Header Manufacturing?

Quality control (QC) is integrated throughout the cold header manufacturing process, with several key checkpoints established to ensure compliance with standards:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to verify their quality and suitability for production.

- In-Process Quality Control (IPQC): During the forming and assembly stages, regular inspections are conducted to monitor dimensional accuracy and surface quality.

- Final Quality Control (FQC): At the end of the production process, finished products undergo rigorous testing to ensure they meet specified tolerances and performance criteria.

Common testing methods employed include dimensional checks, tensile strength testing, and surface finish evaluations. These checks are vital for identifying any defects early in the production cycle, reducing waste and ensuring customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies to ensure compliance and reliability:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, quality control measures, and adherence to international standards.

- Quality Assurance Reports: Requesting detailed reports on quality control processes and testing results can provide insights into a supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of product quality and compliance with relevant standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When dealing with suppliers from different regions, B2B buyers must be aware of the nuances in quality control and certification practices. For instance, certain certifications may be more prevalent or recognized in specific markets. Understanding these differences can help buyers make informed decisions and avoid potential compliance issues.

Illustrative image related to cold header

Moreover, language barriers and differing regulatory environments can complicate the verification process. Establishing clear communication channels and utilizing local experts can facilitate smoother transactions and ensure that quality standards are met consistently.

Conclusion: Ensuring Quality in Cold Header Manufacturing

In summary, the cold header manufacturing process involves meticulous attention to detail at every stage, from material preparation to finishing. By understanding the key techniques and quality assurance measures, B2B buyers can make informed decisions when selecting suppliers. Emphasizing quality control and compliance with international standards not only enhances product reliability but also fosters trust in supplier relationships, ultimately leading to successful business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cold header’

In the competitive landscape of B2B procurement, sourcing cold headers requires a strategic approach to ensure quality, efficiency, and cost-effectiveness. This checklist serves as a comprehensive guide for international buyers seeking to procure cold headers, particularly from diverse markets across Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for successful procurement. Determine the required dimensions, materials, and tolerances necessary for your application. This includes identifying whether you need standard or custom configurations, as well as the types of metals suitable for cold heading, such as copper, aluminum, or stainless steel.

Illustrative image related to cold header

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in cold heading. Look for manufacturers with a proven track record in producing high-quality fasteners and components. Utilize industry directories, trade shows, and online platforms to gather a list of candidates, focusing on those with experience in your specific market region.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to assess the capabilities of your shortlisted suppliers. Investigate their production processes, machinery, and technology used in cold heading. Pay particular attention to their ability to meet your volume requirements and production timelines, as well as their capacity for both standard and custom orders.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications that guarantee quality and compliance with international standards. Look for certifications such as ISO 9001, which demonstrates a commitment to quality management. This step is vital for mitigating risks associated with product defects and ensuring reliable supply chains.

Step 5: Request Samples and Prototypes

Before finalizing your supplier choice, request samples or prototypes of their cold headers. This allows you to evaluate the quality, fit, and functionality of their products. Pay attention to details like surface finish and dimensional accuracy, as these factors can significantly impact the performance of your final assembly.

Step 6: Assess Pricing Structures

Analyze the pricing structures provided by your shortlisted suppliers. While cost is an important factor, consider the total cost of ownership, which includes shipping, duties, and potential rework costs. Look for suppliers who offer competitive pricing without compromising on quality, and evaluate bulk order discounts or long-term partnership benefits.

Illustrative image related to cold header

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful procurement process. Establish clear channels for discussing technical requirements, order updates, and any potential issues that may arise. Ensure that the supplier is responsive and willing to collaborate, as this will foster a strong working relationship and facilitate smoother transactions.

By following these steps, B2B buyers can navigate the sourcing process for cold headers more effectively, ensuring they select the right suppliers to meet their manufacturing needs.

Comprehensive Cost and Pricing Analysis for cold header Sourcing

What Are the Key Cost Components for Cold Header Sourcing?

When sourcing cold headers, understanding the cost structure is essential for making informed decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Materials represent a significant portion of the cost, with prices varying based on the type of metal used—common choices include steel, aluminum, and specialized alloys. The choice of material can influence both the cost and the performance characteristics of the final product.

Labor costs depend on the complexity of the cold heading process and the expertise required. Skilled labor is essential for managing the machinery and ensuring the precision necessary for tight tolerances, which can affect overall production costs.

Manufacturing overhead encompasses utilities, equipment maintenance, and facility costs. Efficient production processes can help minimize these overheads, making the choice of a supplier with advanced technologies crucial.

Tooling costs are often overlooked but can be substantial, particularly for custom parts. The design and fabrication of dies and punches are significant investments, and these costs may be amortized over production runs.

Quality Control (QC) ensures that the cold headers meet required specifications and certifications. Implementing rigorous QC processes can increase upfront costs but can reduce long-term expenses related to defects or non-compliance.

Logistics include shipping and handling costs, which can vary widely based on the supplier’s location and the destination. Additionally, international shipping may involve tariffs and duties that add to the total cost.

Supplier margin is the final component and varies based on market competition, supplier reputation, and relationship dynamics. Understanding these margins can provide leverage during negotiations.

Illustrative image related to cold header

How Do Price Influencers Affect Cold Header Sourcing?

Several factors influence the pricing of cold headers, including volume or minimum order quantity (MOQ), specifications and customization, materials, quality certifications, supplier factors, and Incoterms.

Volume/MOQ plays a crucial role in pricing; larger orders typically result in lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk orders, making it beneficial for buyers to assess their needs carefully.

Specifications and customization can significantly impact costs. Custom designs often require specialized tooling and longer production times, which can elevate prices. Clear communication regarding specifications upfront can help avoid unexpected costs.

Illustrative image related to cold header

Material choices also affect pricing. For instance, high-strength alloys may be more expensive than standard steel, but they can provide enhanced performance and durability, which may justify the initial investment.

Quality and certifications are increasingly important in international markets. Suppliers that maintain high standards and can provide certifications may charge a premium, but this can be offset by the reduced risk of failures and returns.

Supplier factors include the supplier’s reputation, reliability, and service level. Established suppliers may command higher prices due to their proven track record, but they can also offer better support and reliability.

Illustrative image related to cold header

Incoterms influence the total cost of ownership by determining how risks and costs are shared between the buyer and supplier during shipping. Understanding these terms is essential for calculating the final landed cost.

What Negotiation Tips Can Enhance Cost-Efficiency for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe can adopt several strategies to negotiate effectively and achieve cost-efficiency in sourcing cold headers.

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes all expenses related to the product’s lifecycle. This approach helps in evaluating suppliers comprehensively.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Suppliers may be more willing to negotiate on pricing or offer favorable terms to loyal customers.

-

Request Multiple Quotes: Don’t hesitate to seek quotes from several suppliers. This practice not only provides a benchmark for pricing but also gives leverage during negotiations.

-

Clarify Specifications: Ensure all product specifications are clearly defined to avoid misunderstandings that could lead to additional costs. Well-defined requirements facilitate more accurate quotes.

-

Understand Payment Terms: Negotiate favorable payment terms that align with cash flow requirements. Extended payment terms may offer financial flexibility without affecting supplier relationships.

-

Be Aware of Pricing Nuances: Recognize that international suppliers may have different pricing structures based on regional economic factors, labor costs, and material availability. Understanding these nuances can aid in negotiations.

Disclaimer on Pricing

Prices for cold headers can vary significantly based on numerous factors, including market conditions, material costs, and supplier capabilities. The information provided in this analysis is indicative and should be validated with suppliers for accurate pricing tailored to specific requirements.

Alternatives Analysis: Comparing cold header With Other Solutions

Understanding Alternative Solutions to Cold Heading

When evaluating manufacturing processes, businesses often seek alternatives to traditional methods like cold heading. Cold heading is a highly efficient process for forming metal components without heating, but other methods may offer distinct advantages depending on specific project requirements. This section compares cold heading with alternative solutions to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Cold Header | CNC Machining | Hot Forging |

|---|---|---|---|

| Performance | High-speed production, tight tolerances | Moderate speed, high precision | High strength, good surface finish |

| Cost | Lower material waste, reduced costs | Higher operational costs due to waste | Moderate, but can vary with material |

| Ease of Implementation | Requires specialized tooling | More versatile, less specialized equipment | Requires heating equipment, more complex setup |

| Maintenance | Low maintenance with proper tooling | Moderate maintenance; regular calibration needed | High maintenance due to heating elements |

| Best Use Case | Large volume fasteners and components | Custom parts with intricate designs | Heavy-duty components needing high strength |

Detailed Breakdown of Alternatives

CNC Machining

CNC (Computer Numerical Control) machining is a versatile manufacturing process that uses computer-controlled tools to create parts from a solid block of material. It allows for high precision and can accommodate complex geometries that may be challenging for cold heading. However, CNC machining often results in higher material waste, as the process involves cutting away material rather than forming it. This method is ideal for custom parts requiring intricate designs but may not be cost-effective for large-scale production due to longer lead times and increased operational costs.

Illustrative image related to cold header

Hot Forging

Hot forging is a process that involves shaping metal using compressive forces at elevated temperatures. This method is excellent for producing strong and durable components, making it suitable for applications in industries like automotive and aerospace. While hot forging can yield high-quality parts, it requires significant investment in heating equipment and specialized tooling. Additionally, the complexity of setup and higher maintenance demands can deter some manufacturers. However, its ability to produce heavy-duty components efficiently makes it a viable alternative for specific applications.

Conclusion: Choosing the Right Manufacturing Solution

Selecting the right manufacturing method requires a thorough assessment of your specific needs, including production volume, part complexity, and budget constraints. Cold heading excels in high-speed production with minimal waste, making it ideal for large quantities of fasteners and components. In contrast, CNC machining offers precision for custom designs, while hot forging provides strength for demanding applications. By understanding the advantages and limitations of each method, B2B buyers can align their manufacturing choices with their operational goals and market demands, ensuring a strategic approach to their production processes.

Essential Technical Properties and Trade Terminology for cold header

What Are the Key Technical Properties of Cold Headers?

Understanding the technical specifications associated with cold headers is crucial for B2B buyers aiming to optimize their supply chain and manufacturing processes. Here are some essential properties to consider:

1. Material Grade

The choice of material grade directly influences the strength, durability, and corrosion resistance of cold-headed parts. Common materials include carbon steel, stainless steel, and alloy steels. Selecting the right grade ensures that the final product meets performance requirements while minimizing costs associated with material waste and failure.

2. Tolerance

Tolerance refers to the allowable variation in dimensions of the cold-headed part. Precise tolerances, often as tight as ±0.002 inches, are critical for ensuring that components fit correctly in assemblies. In industries like automotive and aerospace, where safety and performance are paramount, maintaining tight tolerances can significantly reduce rework and scrap rates, ultimately enhancing profitability.

3. Surface Finish

The surface finish of cold-headed components affects both aesthetics and functionality. A smooth finish can improve corrosion resistance and reduce friction in moving parts. Specifying the desired surface finish helps in meeting industry standards and customer expectations, which can enhance brand reputation and customer loyalty.

4. Production Volume

Cold heading is particularly advantageous for high-volume production due to its efficiency and reduced waste. Understanding the production volume capabilities allows buyers to align their manufacturing needs with the supplier’s capabilities. This insight is crucial for meeting market demand without incurring unnecessary costs.

5. Heat Treatment

Heat treatment processes can enhance the mechanical properties of cold-headed parts, such as hardness and tensile strength. Knowing whether heat treatment is needed for specific applications helps buyers make informed decisions about material selection and processing requirements, ensuring optimal performance of the final products.

What Are Common Trade Terms Used in the Cold Header Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or parts that are used in another company’s end product. In the context of cold headers, understanding OEM relationships helps buyers ensure that they are procuring parts that meet the specifications required for their applications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest order quantity that a supplier is willing to accept. For cold headers, knowing the MOQ is crucial for inventory management and cost control, particularly for businesses that may not need large quantities of specific components.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. Crafting a well-defined RFQ for cold headers enables buyers to compare offers efficiently and make informed purchasing decisions based on price, lead time, and quality.

Illustrative image related to cold header

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding Incoterms is vital for buyers to ensure clarity on shipping costs, risk, and insurance, ultimately facilitating smoother transactions across borders.

5. Secondary Operations

Secondary operations refer to additional processes that may be necessary after cold heading, such as threading, plating, or finishing. Recognizing the need for secondary operations helps buyers plan for the entire production cycle, ensuring that final products meet all specifications and quality standards.

By grasping these technical properties and industry terms, B2B buyers can navigate the cold header market more effectively, ensuring that they make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the cold header Sector

What Are the Global Drivers Influencing the Cold Header Market?

The cold header market is experiencing a significant transformation driven by multiple global factors. Increasing demand for high-strength fasteners across industries such as automotive, aerospace, and construction is propelling the adoption of cold heading technology. The ability to produce components with tight tolerances and minimal waste is making cold heading an attractive option for manufacturers looking to enhance efficiency and reduce costs. Emerging markets, particularly in Africa, South America, and the Middle East, are witnessing a surge in industrialization, further escalating the demand for cold-headed products.

Additionally, advancements in B2B technology, such as Industry 4.0, are reshaping sourcing trends. Automation and real-time data analytics enable manufacturers to optimize production processes and streamline supply chains. This is particularly crucial for international buyers who seek reliable suppliers that can deliver customized solutions quickly and efficiently. Moreover, the increasing emphasis on digital platforms for procurement is facilitating better communication and collaboration between buyers and suppliers globally.

How Is Sustainability Shaping Sourcing Practices in the Cold Header Sector?

Sustainability is becoming a cornerstone of sourcing practices in the cold header sector. The environmental impact of manufacturing processes, particularly in terms of resource consumption and waste generation, has prompted buyers to seek suppliers that prioritize sustainable practices. Cold heading inherently generates less waste compared to traditional machining, but the focus is expanding to include the sourcing of raw materials and energy-efficient production methods.

Ethical supply chains are gaining traction as businesses recognize the importance of transparency and accountability in their operations. Buyers are increasingly looking for suppliers who can provide certifications that demonstrate adherence to environmental standards, such as ISO 14001, and who utilize “green” materials. These may include recycled metals or materials sourced from sustainable suppliers. By aligning with environmentally conscious partners, international B2B buyers can enhance their own brand reputation and meet the growing consumer demand for sustainable products.

What Is the Historical Context of Cold Heading in B2B Manufacturing?

The evolution of cold heading technology dates back to the early 20th century when it was primarily used for producing fasteners. This method revolutionized manufacturing by enabling the mass production of high-quality components with reduced material waste and lower production costs. Over the decades, advancements in tooling and machinery have significantly improved the efficiency and capabilities of cold heading processes.

Today, cold heading is not limited to fasteners; it has expanded to include a variety of components across different industries. As technology continues to advance, the cold heading process is being refined further, leading to innovations such as multi-part assemblies and complex geometries. This evolution not only reflects the changing demands of the manufacturing sector but also underscores the potential for cold heading to adapt to emerging trends in sustainability and customization, making it a vital area of focus for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of cold header

-

How do I choose the right cold header supplier for my business?

Selecting the right cold header supplier involves evaluating their manufacturing capabilities, product range, and experience in your specific industry. Look for suppliers with a proven track record of producing high-quality products that meet your specifications. It’s also crucial to assess their ability to handle customization and volume requirements. Request samples and inquire about their quality assurance processes. Finally, consider their geographical location, as this can affect lead times and shipping costs, especially when dealing with international suppliers. -

What customization options are available for cold headers?

Cold header manufacturers typically offer a variety of customization options, including unique shapes, sizes, and materials. You can request specific head configurations, diameters, and finishes tailored to your needs. Additionally, many suppliers can accommodate complex designs requiring multiple upsets or secondary operations, such as threading or plating. When discussing customization, provide detailed specifications and examples to ensure that the supplier fully understands your requirements. -

What is the minimum order quantity (MOQ) for cold headers?

Minimum order quantities for cold headers can vary significantly based on the supplier’s production capabilities and the complexity of the parts required. Generally, larger orders can result in lower per-unit costs, while smaller orders may incur higher prices. It’s essential to communicate your needs upfront to understand the supplier’s MOQ policies. If your requirements fall below their standard MOQ, discuss potential options for flexibility, such as combining orders with other clients. -

What are typical payment terms for international cold header suppliers?

Payment terms can differ between suppliers and regions, but common practices include upfront deposits, net 30 or net 60 terms, and letters of credit for larger orders. When negotiating payment terms, consider the supplier’s reputation and your relationship with them. Ensure that the terms are mutually beneficial, and be aware of any currency fluctuations that may impact costs. Always confirm payment methods accepted by the supplier, as some may have specific preferences for international transactions. -

How can I ensure quality assurance for cold headers sourced internationally?

To ensure quality assurance, request certifications and quality control documentation from potential suppliers. Establish clear specifications and standards that the products must meet, and consider implementing a third-party inspection service to verify quality before shipment. Regular communication with the supplier throughout the manufacturing process can help address any issues early. Additionally, consider starting with a smaller order to evaluate product quality before committing to larger volumes. -

What logistics considerations should I keep in mind when sourcing cold headers?

Logistics play a crucial role in sourcing cold headers internationally. Consider shipping methods, transit times, and customs regulations in both the supplier’s and your country. Evaluate the total landed cost, which includes shipping, duties, and handling fees. It’s also wise to discuss the supplier’s shipping options and delivery timelines to avoid disruptions in your supply chain. Establishing a reliable logistics partner can further streamline the process. -

What are the advantages of cold heading over traditional machining methods?

Cold heading offers several advantages compared to traditional machining, including reduced raw material waste, lower production costs, and faster manufacturing speeds. The process allows for tight tolerances and can produce parts with enhanced physical properties due to the work-hardening effect. Additionally, cold heading is ideal for high-volume production runs, making it a cost-effective choice for businesses looking to scale. Understanding these benefits can help you make informed decisions when choosing manufacturing methods. -

What industries commonly use cold headers, and what applications do they serve?

Cold headers are widely used across various industries, including automotive, aerospace, electronics, and construction. Common applications include fasteners, bolts, nuts, and complex components requiring high strength and precision. The versatility of cold heading allows it to cater to both standard and custom parts, making it suitable for diverse manufacturing needs. When sourcing cold headers, consider the specific requirements of your industry to ensure compatibility and performance.

Top 6 Cold Header Manufacturers & Suppliers List

1. Grandeur Fasteners – Cold Headed Fasteners

Domain: grandeurfasteners.com

Registered: 1999 (26 years)

Introduction: Grandeur Fasteners specializes in cold headed fasteners, utilizing a process that forms metal wire into specified shapes without heat. Key features include:

– Custom tooling design and fabrication

– Manufacturing of various fastener forms including multiple upset configurations and customized head shapes

– Capabilities for tight tolerances (up to +/- .002″)

– High-speed production rates and la…

2. TFG USA – Cold Heading Solutions

Domain: tfgusa.com

Registered: 2008 (17 years)

Introduction: Cold heading is a high-speed metal forming process that shapes parts at room temperature without the need for heat. It is primarily used for forming the heads on fasteners like bolts, screws, rivets, and nails. Key advantages include minimal waste, faster production, stronger parts, reduced costs, and the ability to simplify multi-piece assemblies. Cold heading maximizes material usage by reshapin…

3. Cold Header – Supplier Locator

Domain: coldheader.com

Registered: 1997 (28 years)

Introduction: Cold Header is a domain intended to help users of heading, threading, and related equipment locate suppliers of equipment, tooling, and other products used in their manufacturing process. It offers resources for buying direct from suppliers, testing plates, completed auctions, and equipment sales agents. The site features specialized equipment dealers that focus on fastener manufacturing machines.

4. BCEPI – Specialty Fasteners Manufacturing

Domain: bcepi.com

Registered: 2005 (20 years)

Introduction: Cold heading is a forging process used in manufacturing specialty fasteners such as screws, bolts, and rivets. It involves cutting wire to a predetermined length, forming it into a desired shape using dies and tooling at room temperature, and does not remove any material. Key techniques include cutting the wire, heading to form the fastener head, extrusion or upsetting to shape the body, and final…

5. Surplus Record – Used Cold Headers for Sale

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: Used Cold Headers For Sale | Surplus Record

Manufacturers: National (50), Nakashimada (20), Waterbury-Farrel (18), Asahi (7), Hartford (7), Sacma (6), Asahi Okuma (5), Hilgeland (5), Carlo Salvi (4), Okuma (4), Ferracute (3), Sakamura (3), Asahi Sunac (2), Toko (2), Farrell (1), Greenbat (1), Hyodong (1), Itami (1), J.g. Kayser (1), Johns Manville (1), Morris (1), Roy (1), Shanghai Wuling (1), Si…

6. IQS Directory – Cold Heading Manufacturing

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Cold heading is a manufacturing process that produces the heads of small, simple parts without using heat, instead utilizing high pressure and force with a punch and die to shape metal. Key advantages include minimal scrap and waste, simultaneous operations like sizing and thread rolling, and high volume output with consistent parts. Common materials used include steel, stainless steel, aluminum, …

Strategic Sourcing Conclusion and Outlook for cold header

How Can Strategic Sourcing Enhance Your Cold Header Procurement?

In conclusion, strategic sourcing of cold headers presents significant advantages for international B2B buyers. The cold heading process offers enhanced efficiency, reduced waste, and the ability to produce high-quality components at scale. Key benefits include the capability to maintain tight tolerances, improved material properties, and cost savings compared to traditional machining methods. By leveraging these advantages, companies can optimize their supply chains and enhance their product offerings.

For businesses in Africa, South America, the Middle East, and Europe, understanding the nuances of cold heading is crucial. Collaborating with suppliers who specialize in this manufacturing process can lead to bespoke solutions tailored to unique specifications, ultimately driving innovation and competitiveness in the market.

As the demand for high-quality fasteners and components continues to grow globally, now is the time to evaluate your sourcing strategies. Embrace the opportunities that cold heading technology provides and consider partnerships with leading manufacturers. By doing so, you position your business for success in an increasingly competitive landscape. Reach out to experts in the field to explore how cold headers can meet your specific needs and propel your organization forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.