A B2B Buyer’s Guide to Coil Valves: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for coil valves

In the ever-evolving landscape of industrial automation, sourcing reliable coil valves poses a significant challenge for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The complexity of choosing the right valve for specific applications—whether in oil and gas, manufacturing, or HVAC systems—demands a thorough understanding of various types, specifications, and suppliers. This comprehensive guide is designed to empower you with the knowledge necessary to navigate the global market for coil valves effectively.

We delve into the diverse types of coil valves available, their applications across various industries, and the critical factors to consider when vetting suppliers. Additionally, we provide insights into cost considerations and market trends that can impact your purchasing decisions. By equipping you with actionable insights and a clear framework for evaluation, this guide aims to enhance your procurement strategies and ensure that you select the most suitable coil valves for your operational needs.

Whether you are looking to optimize performance, ensure compliance with international standards, or reduce operational costs, understanding the nuances of coil valves will enable you to make informed decisions that drive efficiency and reliability in your projects. Explore the intricacies of this vital component and position your business for success in the global market.

Understanding coil valves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Acting Solenoid Valves | Operate directly on the valve mechanism; require minimal pressure to function. | Water treatment, HVAC systems, industrial automation. | Pros: Fast response time, simple design. Cons: Limited to lower pressure applications. |

| Pilot Operated Solenoid Valves | Use system pressure to assist in valve operation; more complex design. | Oil and gas, chemical processing, high-pressure systems. | Pros: Suitable for high-pressure applications, energy-efficient. Cons: Slower response time, more components can lead to maintenance issues. |

| Latching Solenoid Valves | Retain their position without continuous power; ideal for battery-operated systems. | Remote control systems, irrigation, and security applications. | Pros: Energy-efficient, ideal for applications requiring infrequent actuation. Cons: More complex circuitry required. |

| Two-Way Solenoid Valves | Control flow in one direction; can be normally open or normally closed. | Pneumatic systems, fluid control in manufacturing. | Pros: Versatile, easy installation. Cons: Limited to on/off control, not suitable for throttling. |

| Three-Way Solenoid Valves | Allow for flow control between three ports; can redirect flow. | HVAC systems, pneumatic control, automotive applications. | Pros: Flexible flow management, compact design. Cons: More complex installation and control logic. |

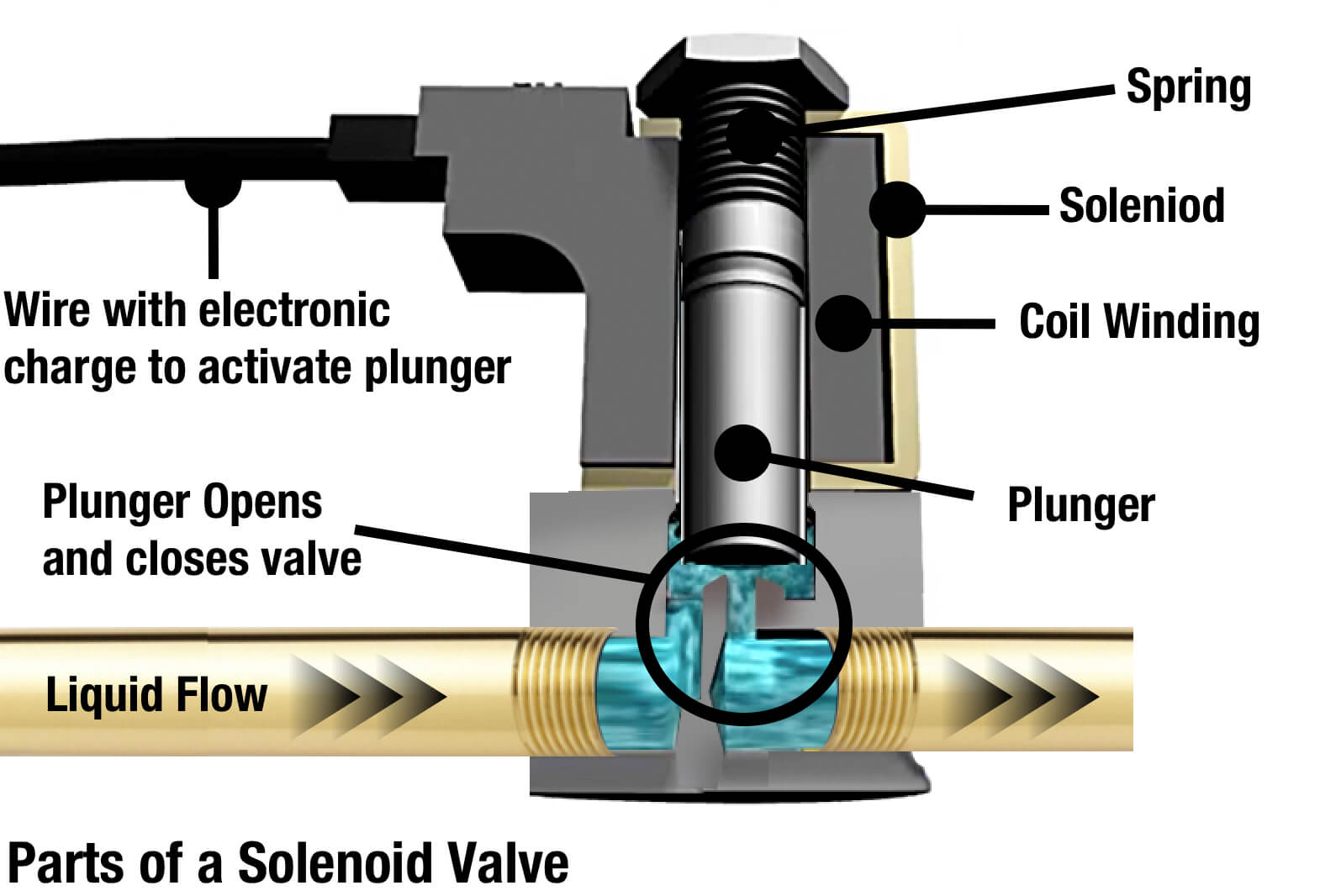

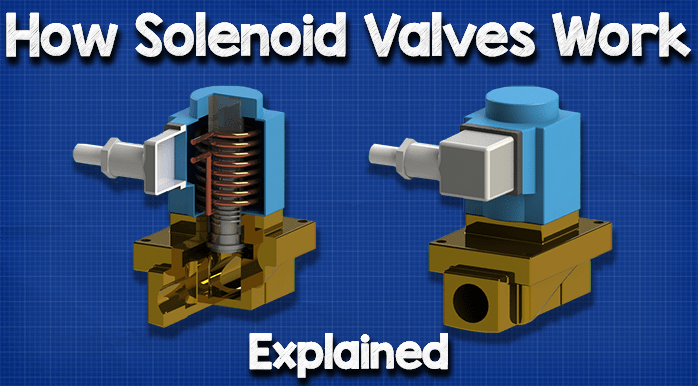

What are Direct Acting Solenoid Valves and Their B2B Suitability?

Direct acting solenoid valves are characterized by their straightforward mechanism, allowing them to operate with minimal pressure. This makes them ideal for applications in water treatment, HVAC systems, and various industrial automation processes. When considering procurement, B2B buyers should evaluate the response time and simplicity of the design, which can lead to lower maintenance costs. However, these valves are generally limited to lower pressure applications, which may not meet the needs of all industrial environments.

How Do Pilot Operated Solenoid Valves Function in High-Pressure Applications?

Pilot operated solenoid valves are designed to use system pressure to assist in their operation, making them suitable for high-pressure applications commonly found in oil and gas and chemical processing industries. Their energy efficiency and ability to handle larger flow rates are significant advantages for B2B buyers. However, the complexity of their design can lead to slower response times and potential maintenance challenges, making it crucial for buyers to consider these factors in their purchasing decisions.

What are the Advantages of Latching Solenoid Valves for B2B Buyers?

Latching solenoid valves stand out for their ability to maintain their position without continuous power, making them particularly advantageous in battery-operated systems such as remote controls and irrigation systems. This energy efficiency is a key consideration for B2B buyers looking to reduce operational costs. However, the complexity of their circuitry can pose challenges in installation and maintenance, necessitating thorough supplier evaluations to ensure compatibility with existing systems.

Why Choose Two-Way Solenoid Valves for Fluid Control?

Two-way solenoid valves are designed to control fluid flow in one direction and can be configured as normally open or normally closed. Their versatility and ease of installation make them a popular choice in pneumatic systems and fluid control applications across manufacturing sectors. While they provide straightforward on/off control, B2B buyers should be aware that they are not suitable for throttling, which may limit their application in more complex fluid management scenarios.

How Do Three-Way Solenoid Valves Enhance Flow Management?

Three-way solenoid valves offer enhanced flow management by allowing control between three ports, making them ideal for HVAC systems, pneumatic control, and automotive applications. Their compact design and flexibility are significant advantages for B2B buyers seeking efficient solutions for space-constrained environments. However, the complexity of installation and required control logic can pose challenges, making it essential for buyers to work closely with suppliers to ensure proper integration into their systems.

Key Industrial Applications of coil valves

| Industry/Sector | Specific Application of coil valves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Control of fluid flow in drilling operations | Enhances safety and efficiency in operations | Ensure compatibility with high-pressure systems and corrosive fluids |

| Manufacturing | Automation in assembly lines | Increases production speed and reduces labor costs | Look for durable coils suitable for continuous operation |

| Water Treatment | Regulation of water flow in treatment plants | Improves water quality and compliance with regulations | Consider environmental standards and material compatibility |

| HVAC Systems | Temperature control in heating and cooling systems | Optimizes energy usage and enhances comfort | Evaluate energy efficiency ratings and installation requirements |

| Agriculture | Irrigation control in agricultural applications | Maximizes water usage efficiency and crop yield | Assess voltage requirements and durability in outdoor environments |

How Are Coil Valves Used in the Oil and Gas Industry?

In the oil and gas sector, coil valves play a critical role in controlling the flow of fluids during drilling operations. These valves can manage high-pressure environments and provide precise control, enhancing both safety and operational efficiency. International buyers must consider the compatibility of coil valves with specific drilling fluids and the environmental conditions they will face, particularly in remote locations in Africa and the Middle East.

What Role Do Coil Valves Play in Manufacturing Automation?

Coil valves are integral to automation in manufacturing, particularly on assembly lines where they control the flow of air or fluids to pneumatic tools. This automation not only speeds up production but also reduces labor costs by minimizing manual intervention. Buyers should look for robust and durable valves that can withstand continuous operation and consider the ease of integration with existing systems to ensure seamless functionality.

How Are Coil Valves Used in Water Treatment Facilities?

In water treatment plants, coil valves regulate the flow of water through various treatment processes, ensuring that the water meets safety and quality standards. By optimizing flow rates, these valves help maintain compliance with environmental regulations, ultimately protecting public health. Buyers from South America and Europe should prioritize valves that can handle varying water qualities and comply with regional regulatory requirements.

What Benefits Do Coil Valves Provide in HVAC Systems?

In HVAC systems, coil valves are essential for regulating temperatures by controlling the flow of refrigerants or heating fluids. This regulation leads to optimized energy usage and improved comfort levels in residential and commercial buildings. Buyers should evaluate the energy efficiency ratings of these valves and ensure they meet the specific requirements of their HVAC systems, especially in regions with extreme temperatures.

How Are Coil Valves Applied in Agricultural Irrigation?

In agriculture, coil valves are used to automate irrigation systems, allowing farmers to efficiently manage water usage based on crop needs. This application maximizes water efficiency and can significantly enhance crop yields. Buyers should consider the durability of these valves in outdoor environments and assess their voltage requirements to ensure compatibility with existing irrigation systems, particularly in regions facing water scarcity challenges.

3 Common User Pain Points for ‘coil valves’ & Their Solutions

Scenario 1: Struggling with Coil Valve Compatibility Issues

The Problem: Many B2B buyers face significant challenges in ensuring that the coil valves they purchase are compatible with their existing systems. This often arises from a lack of standardized specifications across manufacturers, leading to confusion about voltage requirements, connection types, and physical dimensions. For example, a company in the oil and gas sector may find that the solenoid coil they ordered does not fit their existing valve setup, causing delays and increased costs as they scramble to find a suitable replacement.

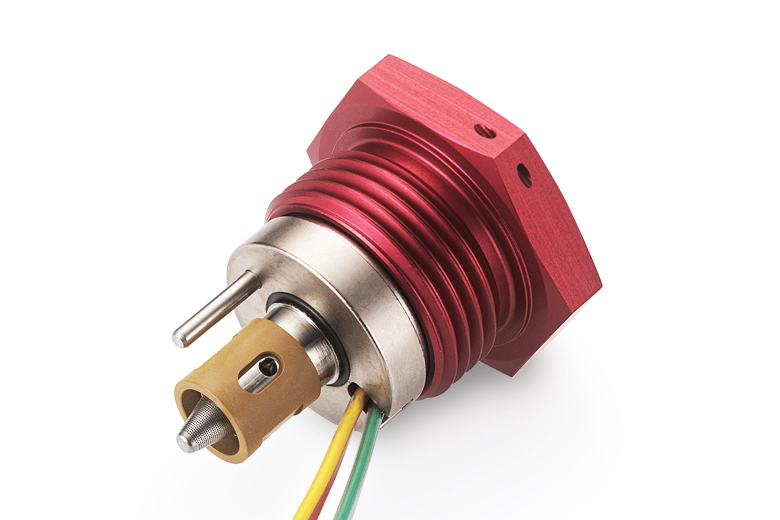

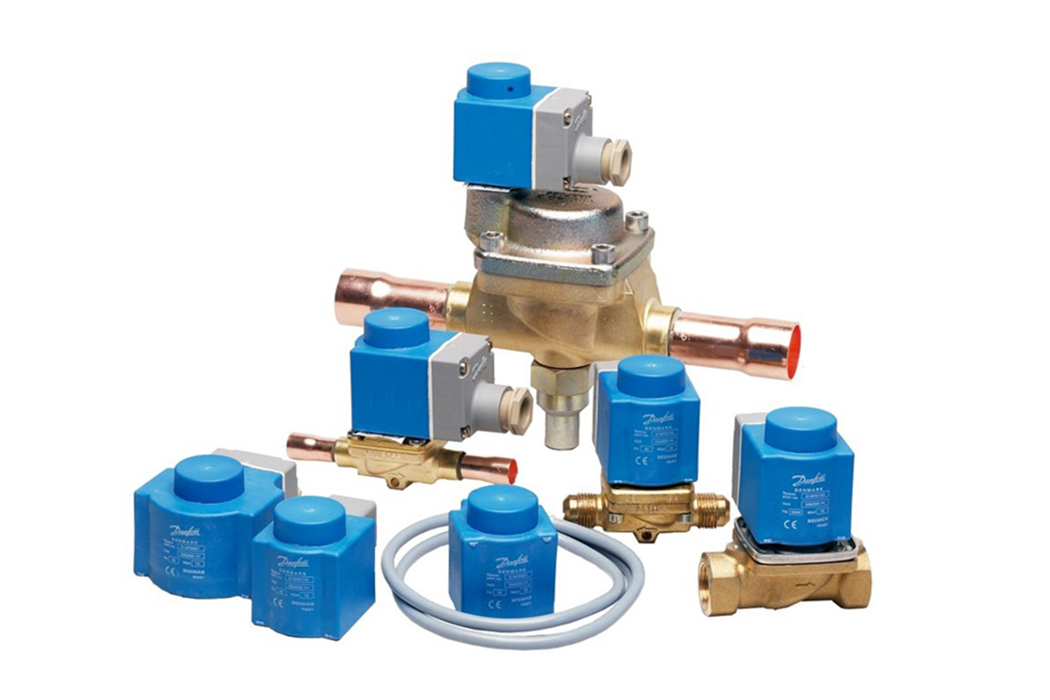

Illustrative image related to coil valves

The Solution: To avoid compatibility issues, buyers should conduct thorough research before making a purchase. Begin by clearly documenting the specifications of the existing valves, including voltage, connection types (like DIN or Deutsch), and any other relevant dimensions. When sourcing new coils, always request detailed product datasheets from suppliers that specify these attributes. Additionally, consider establishing relationships with reputable suppliers who can provide technical assistance in matching coils to your current systems. This proactive approach not only saves time but also mitigates the risk of operational disruptions.

Scenario 2: Facing Coil Valve Performance Reliability Concerns

The Problem: Performance reliability is a critical concern for industries that rely on coil valves to manage fluid control. Buyers often report issues such as overheating, inconsistent response times, or complete valve failure, which can lead to significant operational downtime. In sectors like manufacturing or chemical processing, where precision is paramount, these performance issues can have cascading effects on productivity and safety.

The Solution: To enhance performance reliability, buyers should prioritize sourcing high-quality solenoid coils from established manufacturers known for rigorous testing and quality control. It’s advisable to check for certifications such as ISO and industry-specific approvals. Furthermore, consider investing in coils with built-in protection features, such as thermal overload protection or integrated diodes, which can prevent damage due to electrical spikes. Regular maintenance, including routine inspections and testing of the coils, will also help identify potential issues before they escalate, ensuring consistent operational performance.

Scenario 3: Navigating Supply Chain Delays for Coil Valves

The Problem: Global supply chain disruptions have made it increasingly difficult for businesses to obtain coil valves in a timely manner. B2B buyers often face extended lead times, which can halt production lines and lead to significant financial losses. This is particularly problematic in regions such as Africa and South America, where logistics infrastructure may be less developed, exacerbating the issue.

Illustrative image related to coil valves

The Solution: To mitigate the impact of supply chain delays, buyers should adopt a strategic approach to inventory management. Implementing a just-in-time inventory system can help balance stock levels with demand, reducing the risk of over-ordering and waste. Additionally, consider diversifying your supplier base to include multiple manufacturers across different regions, which can provide alternatives in case of localized disruptions. Establishing strong communication channels with suppliers can also ensure better visibility into lead times and potential delays, allowing for more effective planning. Finally, investing in local suppliers where possible can significantly reduce lead times and shipping complexities, ensuring a more reliable supply chain.

Strategic Material Selection Guide for coil valves

What Are the Key Materials Used in Coil Valves?

When selecting coil valves for various applications, the choice of material is crucial as it directly influences performance, durability, and compatibility with different media. Here, we analyze four common materials used in the manufacturing of coil valves: brass, stainless steel, plastic, and aluminum. Each material presents unique properties, advantages, and limitations that international B2B buyers must consider, especially those operating in diverse environments such as Africa, South America, the Middle East, and Europe.

How Does Brass Perform in Coil Valve Applications?

Brass is a popular choice for coil valves due to its excellent corrosion resistance and good thermal conductivity. It typically withstands pressures up to 150 psi and operates effectively in temperatures ranging from -20°F to 250°F.

Illustrative image related to coil valves

Pros: Brass is durable and has a relatively low cost compared to other metals, making it a cost-effective solution for many applications. Its machinability allows for complex designs, which can be advantageous in custom applications.

Cons: However, brass can be susceptible to dezincification in certain environments, which can lead to premature failure. Additionally, its weight may be a consideration for applications where minimizing weight is crucial.

Impact on Application: Brass is compatible with a variety of media, including water, air, and some oils. However, it is not suitable for aggressive chemicals, which could corrode the material.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B36 for brass materials. In regions like Europe, adherence to EN standards is also essential.

What Are the Benefits of Stainless Steel in Coil Valves?

Stainless steel is renowned for its superior corrosion resistance and strength, making it ideal for harsh environments. It can handle higher pressures (up to 300 psi) and operates effectively at temperatures ranging from -40°F to 400°F.

Illustrative image related to coil valves

Pros: The durability of stainless steel ensures a long service life, reducing the need for frequent replacements. Its resistance to corrosion makes it suitable for applications involving aggressive chemicals and extreme conditions.

Cons: The primary drawback is the higher cost compared to brass and plastic. Additionally, the manufacturing process can be more complex, which may lead to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive fluids, steam, and gases. Its robustness allows it to perform well in demanding applications.

Illustrative image related to coil valves

Considerations for International Buyers: Compliance with standards such as ASTM A276 for stainless steel is crucial. Buyers in the Middle East and Europe should also consider the specific grades of stainless steel suitable for their applications.

How Does Plastic Compare for Coil Valve Manufacturing?

Plastic materials, such as polyamide and PVC, are increasingly used in coil valves due to their lightweight and corrosion-resistant properties. They typically handle pressures up to 100 psi and temperatures from -40°F to 180°F.

Pros: The low cost and ease of manufacturing make plastic an attractive option for many applications. Additionally, plastic valves can be molded into complex shapes, allowing for versatile designs.

Cons: However, plastic is less durable than metal options and may not withstand high-pressure applications. Its thermal stability can also be a concern in high-temperature environments.

Impact on Application: Plastic coil valves are suitable for water and air but may not be compatible with oils or aggressive chemicals, limiting their application scope.

Considerations for International Buyers: Buyers should ensure that the chosen plastic complies with relevant standards such as ASTM D638. In regions like Africa, where temperatures can be extreme, selecting the right plastic grade is crucial.

What Role Does Aluminum Play in Coil Valve Design?

Aluminum is another viable option for coil valves, known for its lightweight and good corrosion resistance. It typically operates effectively under pressures up to 150 psi and temperatures from -40°F to 300°F.

Pros: The lightweight nature of aluminum makes it ideal for applications where weight reduction is critical. It is also relatively inexpensive compared to stainless steel.

Cons: However, aluminum can be prone to corrosion in certain environments, especially when exposed to saltwater. Its strength is also lower than that of stainless steel.

Impact on Application: Aluminum is suitable for applications involving water and air but may not be ideal for aggressive chemicals.

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum is essential. Buyers in Europe should also consider the EN standards that may apply to aluminum products.

Summary Table of Material Selection for Coil Valves

| Material | Typical Use Case for coil valves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General industrial applications | Cost-effective and durable | Susceptible to dezincification | Low |

| Stainless Steel | Harsh chemical environments | Superior corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Lightweight applications | Low cost and versatile design | Less durable and lower pressure rating | Low |

| Aluminum | Applications requiring weight reduction | Lightweight and inexpensive | Prone to corrosion in harsh environments | Medium |

This strategic material selection guide provides B2B buyers with a comprehensive overview of the key materials used in coil valves, facilitating informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to coil valves

In-depth Look: Manufacturing Processes and Quality Assurance for coil valves

What Are the Main Stages of Manufacturing Coil Valves?

The manufacturing process for coil valves is complex, involving several critical stages that ensure the final product meets stringent performance and reliability standards. Understanding these stages is vital for B2B buyers aiming to source high-quality coil valves for various applications.

How Is Material Prepared for Coil Valve Manufacturing?

The first stage involves material preparation, where raw materials such as metals and plastics are sourced. Common materials include brass, stainless steel, and aluminum, selected for their durability and resistance to corrosion.

Once the materials are procured, they undergo various treatments, such as annealing or heat treatment, to enhance their mechanical properties. Quality checks are essential at this stage to verify that the materials meet industry standards and specifications, preventing costly errors in later stages.

What Forming Techniques Are Used in Coil Valve Production?

After material preparation, the forming stage begins. This typically includes processes such as machining, stamping, and molding, depending on the design specifications of the coil valve.

Machining is often used for precision components, ensuring that each part meets tight tolerances. Stamping can be employed for creating components like valve bodies, where speed and efficiency are paramount. Advanced techniques, such as CNC (Computer Numerical Control) machining, are increasingly utilized to enhance precision and reduce waste.

How Are Coil Valves Assembled?

The assembly stage is where the individual components come together to form the complete coil valve. This process may be manual or automated, depending on the manufacturer’s capabilities and the complexity of the valve design.

Illustrative image related to coil valves

During assembly, components such as solenoid coils, valve bodies, and actuator mechanisms are fitted together. Proper alignment and secure fastening are critical to ensure functionality and longevity. Manufacturers often utilize specialized jigs and fixtures to maintain consistency and accuracy during this stage.

What Finishing Techniques Are Commonly Applied to Coil Valves?

Finishing processes are crucial for ensuring that coil valves are not only functional but also visually appealing and resistant to environmental factors. Common finishing techniques include surface treatment, painting, and coating.

Surface treatments, such as anodizing or galvanizing, enhance corrosion resistance, particularly for valves used in harsh environments. Painting provides an additional protective layer and can also be used for branding purposes. Quality control checks are performed post-finishing to verify that the coatings meet specified thickness and adhesion standards.

What Quality Assurance Measures Are Necessary for Coil Valves?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that coil valves meet both international standards and customer expectations.

Which International Standards Should Coil Valve Manufacturers Comply With?

Internationally recognized standards, such as ISO 9001, play a crucial role in maintaining quality throughout the manufacturing process. This standard focuses on a quality management system (QMS) that helps organizations improve processes, ensure customer satisfaction, and maintain consistent quality.

In addition to ISO standards, industry-specific certifications such as CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications are vital. These certifications indicate compliance with safety and performance requirements, which is particularly important for B2B buyers in regulated industries.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early.

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to catch issues as they arise, ensuring that each component is manufactured to specifications.

-

Final Quality Control (FQC): Once assembly is complete, a thorough inspection of the finished product is conducted. This may include functional testing, pressure testing, and dimensional checks to ensure the valve operates correctly and meets all specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks associated with procurement.

What Audit Processes Should Buyers Implement?

Conducting audits of potential suppliers can reveal their commitment to quality assurance. Buyers should consider both on-site audits and reviewing documentation that demonstrates compliance with international standards.

Requesting certificates of compliance, quality assurance reports, and records of past inspections can provide insight into a supplier’s operational integrity.

How Do Third-Party Inspections Enhance Quality Assurance?

Utilizing third-party inspection services can add an additional layer of assurance. Independent inspectors can verify that manufacturing processes adhere to specified standards and that the final products are free from defects.

This is particularly important in international transactions, where language barriers and differing standards can complicate quality assurance. Third-party inspections can help build trust and ensure that the product delivered meets the buyer’s expectations.

Illustrative image related to coil valves

What Quality Control Nuances Should International Buyers Consider?

International B2B buyers must navigate various quality control nuances specific to their regions. For instance, buyers in the Middle East may need to comply with local regulations that differ from European or African standards.

Understanding these regional variations in quality standards is crucial for successful procurement. Buyers should also be aware of potential cultural differences in business practices, which can affect supplier communication and quality expectations.

Conclusion

Manufacturing coil valves involves meticulous processes and rigorous quality assurance measures that are essential for ensuring product reliability and performance. By understanding these processes and implementing thorough verification methods, B2B buyers can make informed decisions and select suppliers that align with their quality standards and operational needs. This knowledge not only helps mitigate risks but also fosters long-term partnerships with manufacturers committed to excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘coil valves’

In the competitive landscape of international procurement, sourcing coil valves requires a strategic approach. This guide offers a step-by-step checklist to help B2B buyers effectively navigate the complexities of purchasing coil valves, ensuring they make informed decisions that meet their operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is paramount. Identify the type of coil valve required, including parameters such as voltage, connection type, and body material. Consider the application environment—will it be exposed to extreme temperatures or corrosive substances? Defining these aspects upfront will streamline the selection process and ensure compatibility with existing systems.

Step 2: Research Market Trends and Technologies

Stay updated on the latest trends in coil valve technology. This includes understanding advancements in energy efficiency, automation compatibility, and materials used in manufacturing. Engaging with industry publications, webinars, and trade shows can provide valuable insights into emerging technologies that could enhance your operational efficiency.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, product specifications, and case studies that demonstrate their expertise in coil valves. Look for references from businesses in similar industries or regions to gain insights into their reliability and service quality. This step is crucial to minimize risks associated with procurement.

Step 4: Check Certifications and Compliance Standards

Verify that suppliers adhere to relevant industry standards and certifications, such as ISO 9001 or specific regional compliance regulations. These certifications ensure that the products meet quality and safety standards, which is particularly important in industries such as oil and gas or food processing. A supplier with robust compliance can significantly reduce the risk of operational disruptions.

Step 5: Request Samples and Conduct Performance Testing

Obtaining samples before finalizing an order can be a game-changer. Conduct performance testing under conditions that mimic your operational environment. Evaluate factors such as response time, durability, and energy consumption. This hands-on approach allows you to assess the valve’s suitability for your specific needs, ensuring you make an informed decision.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations to secure favorable pricing and terms. Consider factors such as bulk purchasing discounts, warranty provisions, and delivery timelines. Effective negotiation can lead to significant cost savings while establishing a mutually beneficial partnership.

Illustrative image related to coil valves

Step 7: Establish a Follow-Up and Support Plan

After procurement, establish a follow-up plan to monitor the performance of the coil valves and the supplier’s ongoing support. Ensure that you have access to technical assistance and replacement parts as needed. A reliable support system is essential for maintaining operational efficiency and addressing any issues that may arise post-purchase.

By following this checklist, B2B buyers can enhance their sourcing strategy for coil valves, ensuring they select the right products and suppliers to meet their specific needs.

Comprehensive Cost and Pricing Analysis for coil valves Sourcing

What Are the Key Cost Components for Sourcing Coil Valves?

Understanding the cost structure of coil valves is crucial for international B2B buyers. The primary components contributing to the total cost include:

-

Materials: The choice of materials significantly influences the pricing of coil valves. Common materials such as aluminum, stainless steel, and various plastics affect durability and performance. High-quality materials, while more expensive, can reduce maintenance costs over time.

-

Labor: Labor costs encompass the workforce required for manufacturing, assembly, and quality control. Regions with higher labor costs may lead to elevated pricing. However, investing in skilled labor can enhance product quality and reduce defects.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can minimize overhead and ultimately lower prices.

-

Tooling: Initial tooling costs can be significant, especially for custom valves. These costs are often amortized over large production runs, making it essential for buyers to consider their order volume.

-

Quality Control (QC): Ensuring product reliability involves rigorous testing and inspection processes. Higher QC standards can increase costs, but they also mitigate the risk of failures in critical applications.

-

Logistics: Transportation and shipping costs vary based on distance and mode of transport. Choosing efficient logistics partners can help manage these expenses.

-

Margin: Supplier profit margins can vary widely, influenced by market demand and competition. Understanding the supplier’s pricing strategy can aid in negotiation.

What Influences the Pricing of Coil Valves?

Several factors can affect the pricing of coil valves, particularly for international buyers:

-

Volume/MOQ: Bulk purchases often lead to discounts. Establishing a minimum order quantity (MOQ) that aligns with supplier capabilities can yield cost benefits.

-

Specifications and Customization: Custom specifications, such as voltage ratings and connection types, can increase costs. Standardized products generally have lower prices due to economies of scale.

-

Materials and Quality Certifications: High-grade materials and certifications (such as ISO or CE) can command premium pricing. Buyers should assess whether these certifications align with their project requirements.

-

Supplier Factors: The reputation, reliability, and location of the supplier influence pricing. Established suppliers may charge more, but their reliability can offset potential risks associated with cheaper alternatives.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining responsibilities in shipping and handling costs. They can significantly impact the total landed cost of products.

How Can Buyers Optimize Costs When Sourcing Coil Valves?

International buyers can adopt several strategies to optimize their sourcing costs:

-

Negotiation: Engage in open discussions with suppliers about pricing, volume discounts, and payment terms. Highlighting long-term relationships can foster better terms.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes purchase price, operational costs, and maintenance expenses over the valve’s lifespan. A higher initial cost might be justified by lower operational expenses.

-

Understanding Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have higher costs due to stricter regulations, while those in Africa or South America might offer more competitive pricing but may lack certifications.

-

Market Research: Conduct thorough research on market trends and competitor pricing. This knowledge can empower buyers to make informed decisions and negotiate effectively.

Conclusion

The pricing of coil valves is influenced by a myriad of factors ranging from material choice to supplier reputation. For international B2B buyers, understanding these elements is key to making informed purchasing decisions. While indicative prices can vary, strategic sourcing practices can lead to significant cost savings and enhanced supply chain efficiency. Always consider the total cost of ownership and leverage negotiation to optimize your procurement strategy.

Alternatives Analysis: Comparing coil valves With Other Solutions

Exploring Alternatives to Coil Valves in Industrial Applications

In the landscape of industrial automation and fluid control, coil valves represent a popular choice due to their reliability and efficiency. However, various alternatives exist that can also fulfill similar roles in controlling fluid flow and pressure. Understanding these alternatives is crucial for B2B buyers who are evaluating the best fit for their specific applications.

Comparison Table

| Comparison Aspect | Coil Valves | Pneumatic Valves | Electric Actuated Valves |

|---|---|---|---|

| Performance | High precision and responsiveness | Moderate precision; suitable for high flow | High precision; slow response compared to coil valves |

| Cost | Moderate initial investment; low operational cost | Lower initial cost; higher operational costs due to air supply | Higher initial investment; operational cost varies |

| Ease of Implementation | Generally straightforward installation | Requires compressed air system; may need additional setup | Requires electrical setup; can be complex |

| Maintenance | Low maintenance; easy to replace coils | Moderate maintenance; air filter checks necessary | Low maintenance; electronic components may require updates |

| Best Use Case | Automated systems needing precise flow control | High-flow applications; where rapid actuation is needed | Applications needing remote control and automation |

Detailed Breakdown of Alternatives

Pneumatic Valves

Pneumatic valves utilize compressed air to operate, making them a viable alternative to coil valves. They offer rapid actuation and are well-suited for high-flow applications. One of their primary advantages is their lower initial cost, which can be appealing for budget-conscious buyers. However, they do come with higher operational costs due to the need for a compressed air supply, and their performance can suffer in terms of precision when compared to coil valves. Maintenance is moderate as regular checks on air filters and pressure systems are required.

Electric Actuated Valves

Electric actuated valves operate via an electric motor or actuator, providing a high degree of precision and control. They are particularly advantageous for applications that require remote operation, allowing for automation in systems where manual control is impractical. While the initial investment for electric actuated valves is typically higher, their operational costs can vary depending on the complexity of the electrical system. Maintenance is generally low, but the electronic components may necessitate occasional updates or replacements.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between coil valves and their alternatives, B2B buyers must consider various factors, including performance requirements, cost constraints, and maintenance capabilities. Coil valves are ideal for applications that demand precise control and low maintenance. In contrast, pneumatic valves may be suitable for high-flow needs with a lower initial investment, while electric actuated valves excel in automation and remote control scenarios. Ultimately, the best choice will depend on the specific operational needs and budget considerations of your business.

Essential Technical Properties and Trade Terminology for coil valves

What Are the Key Technical Properties of Coil Valves?

When selecting coil valves for industrial applications, understanding their technical specifications is crucial. Here are some essential properties to consider:

Illustrative image related to coil valves

-

Material Grade

The material grade of a coil valve directly affects its durability and resistance to environmental factors. Common materials include brass, stainless steel, and aluminum. For example, stainless steel offers excellent corrosion resistance, making it ideal for harsh environments. In B2B contexts, choosing the right material ensures longevity and reduces maintenance costs. -

Voltage Rating

Coil valves operate at specific voltage ratings, typically 12V DC or 24V DC. This specification is vital for compatibility with existing electrical systems. Selecting a valve with the correct voltage prevents operational failures and enhances safety. Buyers should confirm voltage requirements to avoid costly mismatches. -

Connection Type

Connection types, such as 3 Prong DIN or Deutsch DT-06, determine how the coil valve integrates with other components. Proper connection types ensure secure fittings and reliable electrical performance. In B2B transactions, specifying the correct connection type can streamline installation and reduce downtime. -

Power Consumption

Measured in watts, power consumption indicates how much energy the coil valve requires to operate effectively. Lower power consumption can lead to cost savings over time, especially in large-scale operations. For buyers, understanding power requirements can influence overall energy efficiency and operational costs. -

Temperature Range

Coil valves are designed to function within specific temperature ranges. Knowing the operational temperature limits is essential for applications in extreme conditions. Using valves outside their temperature range can result in failures or decreased performance, leading to potential financial losses. -

Duty Cycle

The duty cycle refers to the amount of time a coil can operate continuously before needing a rest period. This specification is crucial for applications that require frequent cycling. B2B buyers must assess their operational needs to choose valves that can handle the required duty cycle without overheating or failing.

What Are Common Trade Terms Used in Coil Valve Transactions?

Familiarity with industry jargon can enhance communication and decision-making during procurement. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the coil valve industry, knowing if a supplier is an OEM can indicate the quality and reliability of the products being offered. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for budget-conscious buyers; it helps manage inventory costs and ensures that purchasing aligns with operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price estimates for specific products. This term is crucial for B2B buyers looking to compare costs and secure the best deal for coil valves. A well-prepared RFQ can streamline the procurement process. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms is critical for B2B transactions, as they clarify shipping, insurance, and delivery obligations, thereby minimizing disputes. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times helps buyers plan their inventory and production schedules more effectively, reducing the risk of operational delays. -

Certification Standards

Certification standards, such as ISO or CE marking, indicate compliance with safety and quality regulations. B2B buyers should look for these certifications to ensure that coil valves meet industry standards, which can prevent potential legal and safety issues.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring the selection of the right coil valves for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the coil valves Sector

What are the Current Market Dynamics and Key Trends in the Coil Valves Sector?

The coil valves market is experiencing significant evolution driven by technological advancements, increasing industrial automation, and a growing emphasis on efficiency. Major global drivers include the rising demand for energy-efficient systems and the proliferation of smart technologies. Industries across Africa, South America, the Middle East, and Europe are increasingly adopting IoT-enabled devices, which enhances operational efficiency and enables predictive maintenance. This shift is particularly pronounced in sectors like oil and gas, manufacturing, and HVAC, where the integration of solenoid valves with automation technologies is becoming standard.

Emerging trends in sourcing include a focus on digital platforms for procurement, allowing international buyers to access a broader range of products and suppliers. Enhanced visibility in the supply chain through real-time tracking systems is facilitating better decision-making. Moreover, the demand for customized solutions is on the rise, as companies seek to optimize their operations for specific applications. Buyers are advised to consider suppliers that offer comprehensive technical support and after-sales service, which are critical in maintaining operational continuity.

How is Sustainability Impacting the Coil Valves Supply Chain?

Sustainability is increasingly influencing the procurement strategies of B2B buyers in the coil valves sector. The environmental impact of manufacturing processes is under scrutiny, prompting many companies to adopt more sustainable practices. As a result, ethical sourcing has become a priority, with businesses seeking suppliers who adhere to environmental regulations and demonstrate a commitment to reducing their carbon footprint.

Buyers should look for products that are certified green or made from recyclable materials. Certifications such as ISO 14001 can help in identifying suppliers who prioritize environmental management. Moreover, companies are exploring alternative materials that reduce waste and enhance product longevity. By aligning with suppliers focused on sustainability, businesses can not only fulfill regulatory requirements but also enhance their brand reputation in an increasingly eco-conscious market.

What is the Historical Context of Coil Valves in the B2B Sector?

The coil valve industry has evolved significantly since its inception. Initially, valves were simple mechanical devices, but with the advent of electrical and electronic technologies, solenoid valves emerged as a reliable solution for automation in various industries. Over the decades, innovations in materials and design have improved the performance and efficiency of coil valves.

The introduction of smart valves equipped with sensors and IoT capabilities marks a critical shift, allowing for real-time monitoring and control. This evolution reflects a broader trend towards automation and efficiency in industrial processes, positioning coil valves as essential components in modern manufacturing and process control systems. For B2B buyers, understanding this historical context is crucial for making informed sourcing decisions that align with current technological advancements and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of coil valves

-

How do I solve issues with solenoid valve coils that fail prematurely?

To address premature failures in solenoid valve coils, first evaluate the operating conditions. Ensure the voltage and current specifications match the coil’s requirements. Excessive heat can also lead to failure; consider installing cooling mechanisms or ensuring proper ventilation. Additionally, check for moisture ingress, which can cause electrical shorts. Regular maintenance and inspections can help identify potential problems before they escalate, and selecting high-quality coils from reputable suppliers can mitigate the risk of early failures. -

What is the best solenoid coil for high-temperature applications?

For high-temperature applications, look for solenoid coils specifically designed with heat-resistant materials, such as those with a NEMA rating suitable for elevated temperatures. Coils made from materials like aluminum or those featuring thermal protection circuits are ideal. Additionally, consider coils with built-in cooling capabilities or those designed for continuous duty, as they are engineered to perform optimally under stress. Always consult with manufacturers to ensure the coil meets the specific temperature requirements of your application. -

What should I consider when vetting suppliers for solenoid coils?

When vetting suppliers for solenoid coils, assess their reputation in the industry through reviews and testimonials. Verify their compliance with international standards and certifications, such as ISO or CE, which indicate quality and safety. Investigate their product range to ensure they can meet your specific needs, including customization options. Finally, inquire about their after-sales support and warranty policies, as reliable customer service can be crucial for long-term partnerships. -

What are common minimum order quantities (MOQs) for solenoid coils?

Minimum order quantities for solenoid coils can vary significantly depending on the supplier and the specific product. Generally, MOQs range from 50 to 500 units for standard products. However, for custom or specialized coils, suppliers may require higher MOQs due to the additional costs involved in production. It’s essential to communicate your needs upfront and negotiate terms that align with your inventory management strategy. -

What payment terms should I expect when purchasing solenoid coils internationally?

Payment terms for international purchases of solenoid coils typically include options such as advance payment, letter of credit, or payment upon delivery. Terms may vary based on the supplier’s policies and your relationship with them. It is common for new buyers to encounter stricter terms, such as partial upfront payment. Always clarify these terms before finalizing any transactions to ensure they align with your financial capabilities and risk tolerance. -

How can I ensure quality assurance (QA) for my solenoid coils?

To ensure quality assurance for solenoid coils, request detailed product specifications and certifications from suppliers. Conduct regular inspections during production and upon receipt to verify compliance with your quality standards. Establish a clear QA process that includes testing for functionality, durability, and performance under specified conditions. Collaborating with suppliers who have robust QA processes in place can also enhance your confidence in the products you purchase. -

What logistics considerations should I keep in mind when importing solenoid coils?

When importing solenoid coils, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner familiar with international shipping to navigate these complexities efficiently. Ensure proper packaging to prevent damage during transit, and have clear documentation for customs clearance. Additionally, factor in lead times for shipping and potential delays, particularly if sourcing from regions with varying infrastructure capabilities. -

Can solenoid coils be customized for specific applications?

Yes, many manufacturers offer customization options for solenoid coils to meet specific application requirements. Customization can include adjustments in size, voltage, connection types, and materials used. When considering customization, communicate your precise needs, including any environmental factors the coil will encounter. Collaborating closely with the supplier during the design phase can ensure the final product aligns perfectly with your operational needs.

Top 8 Coil Valves Manufacturers & Suppliers List

1. Valveman – Solenoid Coils

Domain: valveman.com

Registered: 2009 (16 years)

Introduction: Solenoid coils designed for safe and efficient operation in solenoid valve actuating systems. Manufactured for both electric and pneumatic actuators, performing to a uniform performance specification across various industries. Offered in multiple voltages, configurations, and materials for a range of applications. Assistance available for sourcing the appropriate solenoid coil.

2. U-Line – Solenoid Valve Coil

Domain: u-line.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Solenoid Valve Coil”, “sku”: “80-55623-14”, “price”: “USD: $84.00”, “availability”: “In stock”, “shipping_dimensions”: {“depth”: “3 inches”, “height”: “2 inches”, “width”: “5 inches”, “weight”: “1 lb”}}

3. Solenoid Valve Coils – Grainger

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: Solenoid Valve Coils – 71 products available. These coils are wires wrapped around a metal core in a solenoid valve, which open or close the valve when an electric current is generated. Compatible brands include ASCO & REDHAT, Dayton, Parker, and Plast-O-Matic. Coil Insulation Class: F and H.

4. Danfoss – Industrial Solenoid Valves

Domain: danfoss.com

Registered: 1995 (30 years)

Introduction: Danfoss offers a wide range of high-performance industrial solenoid valves, including direct-operated, servo-operated, and assisted lift versions. Key features include:

– Valve bodies and electrical coils are typically supplied separately but can also be purchased as complete units.

– General B valve series for high capacity and A series for economic and compact solutions.

– Quick and tool-free as…

5. Century AC – Solenoid Coils for NC Valves

Domain: centuryac.com

Registered: 1998 (27 years)

Introduction: [{‘part_number’: ‘067718’, ‘description’: ‘PKC-1-24 24V SOLENOID COIL NC VALVES’}, {‘part_number’: ‘067722’, ‘description’: ‘PKC-1-120 120V SOLENOID COIL NC VALVES’}, {‘part_number’: ‘067724’, ‘description’: ‘PKC-1-208/240V SOLENID COIL NC VALVES’}, {‘part_number’: ‘067728’, ‘description’: ‘PKC-2 SOLENOID COIL 24V NC VALVES’}, {‘part_number’: ‘067732’, ‘description’: ‘PKC-2 SOLENOID COIL 120V NC V…

6. Copeland – Solenoid Valves and Coils

Domain: copeland.com

Registered: 1995 (30 years)

Introduction: Copeland offers a complete line of solenoid valves and coils for applications ranging from 1/2 to 100 tons, including normally closed and normally open valves. Key product details include:

– **200RE Series**: Pilot operated, 2-way, normally closed valve for liquid, discharge, and suction gas refrigerant service.

– **50RB Series**: Direct-acting, 2-way, normally closed valve for liquid or disch…

7. Connexion Developments – Solenoid Valve Coils

Domain: connexion-developments.com

Registered: 2013 (12 years)

Introduction: Solenoid Valve Coils convert electrical energy into lateral motion, consisting of copper wire wound around a hollow bobine. They are used to control various types of solenoid valves including direct acting, assisted lift, and servo/pressure assisted valves. Key specifications include:

– **Media Types**: Air, inert gases, light oil, natural gas, slightly aggressive media, steam, thick viscous liqu…

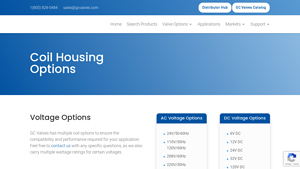

8. GC Valves – Solenoid Valve Coil Housing

Domain: gcvalves.com

Registered: 1997 (28 years)

Introduction: GC Valves offers a variety of solenoid valve coil housing options to ensure compatibility and performance for various applications. Voltage options include AC (24V/50-60Hz, 110V/50Hz, 120V/60Hz, 208V/60Hz, 220V/50Hz, 240V/60Hz, 440V/50Hz, 480V/60Hz) and DC (6V DC, 12V DC, 24V DC, 32V DC, 120V DC). Housing options include: S3 and S4 – Conduit G (NEMA 4/4X, fully encapsulated, 24 inch lead wires, 1/…

Strategic Sourcing Conclusion and Outlook for coil valves

What Are the Key Benefits of Strategic Sourcing for Coil Valves?

In conclusion, the strategic sourcing of coil valves is pivotal for international B2B buyers aiming to enhance operational efficiency and reduce costs. By carefully evaluating suppliers based on their technical expertise, product quality, and compliance with international standards, businesses can ensure they select the right partners. Additionally, leveraging local suppliers within regions such as Africa, South America, the Middle East, and Europe can lead to faster response times and lower shipping costs, enhancing overall supply chain resilience.

How Can Buyers Stay Ahead in the Coil Valve Market?

As we look to the future, the demand for advanced coil valves will continue to grow, driven by innovation in automation and the increasing complexity of industrial systems. Buyers are encouraged to stay informed about emerging technologies and market trends to adapt their sourcing strategies accordingly. Building long-term relationships with reliable suppliers can also provide access to exclusive products and competitive pricing.

What Steps Should Buyers Take Now?

Now is the time to assess your current sourcing strategies for coil valves. Evaluate your suppliers, consider diversification to mitigate risks, and invest in partnerships that align with your operational goals. By taking these proactive steps, you can position your organization for success in a rapidly evolving market, ensuring you have the right solutions to meet future challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.