A B2B Buyer’s Guide to Ceramic Magnetics: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for ceramic magnetics

In the ever-evolving landscape of global manufacturing, sourcing high-quality ceramic magnetics presents unique challenges for B2B buyers. With their exceptional properties, ceramic magnets—known for their cost-effectiveness and resistance to demagnetization—are essential in various applications, from automotive sensors to medical imaging. However, navigating the complexities of material specifications, supplier reliability, and pricing can be daunting, particularly for international buyers in regions such as Africa, South America, the Middle East, and Europe.

This comprehensive guide aims to demystify the world of ceramic magnetics, equipping buyers with the knowledge needed to make informed purchasing decisions. We will delve into the different types of ceramic magnets, including MnZn and NiZn ferrites, and explore their applications across industries. Additionally, we will provide insights on vetting suppliers to ensure quality and compliance with international standards, alongside an analysis of cost factors to help optimize your procurement strategy.

By consolidating vital information and actionable insights, this guide empowers B2B buyers to confidently navigate the global market for ceramic magnetics. Whether you are looking to enhance product performance or streamline your supply chain, understanding the nuances of ceramic magnetics will be crucial in achieving your business objectives and maintaining a competitive edge in your respective markets.

Understanding ceramic magnetics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MnZn Ferrite | High magnetic permeability and low cost | DC motors, transformers, inductors | Pros: Cost-effective; Cons: Lower thermal stability |

| NiZn Ferrite | Higher frequency performance and improved temperature stability | RF applications, microwave devices | Pros: Better performance at high frequencies; Cons: Higher cost than MnZn |

| Ultra Dense Ferrite | Exceptional density and magnetic strength | Magnetic resonance imaging, high-performance motors | Pros: Superior performance; Cons: More brittle and expensive |

| Controlled Curie Temperature Ferrite | Tailored Curie temperature for specific applications | Particle accelerators, scientific research | Pros: Customizable for specific needs; Cons: Longer lead times for production |

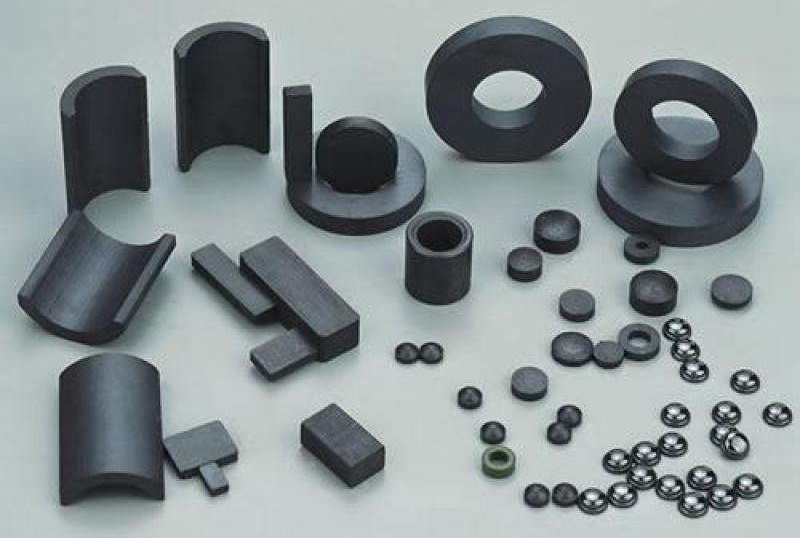

| Pressed Ceramic Magnets | Versatile shapes and sizes through pressing techniques | General industrial applications, consumer products | Pros: Custom shapes available; Cons: Limited to applications needing lower energy density |

What are the Characteristics of MnZn Ferrite Magnets?

MnZn ferrite magnets are characterized by their high magnetic permeability and affordability, making them a popular choice in various B2B applications. They are particularly suitable for use in DC motors, transformers, and inductors due to their efficient magnetic properties. Buyers should consider their cost-effectiveness, which appeals to budget-conscious projects, but note that they may not perform well under high-temperature conditions, limiting their application in more demanding environments.

How Does NiZn Ferrite Stand Out in High-Frequency Applications?

NiZn ferrite magnets excel in high-frequency applications and offer improved thermal stability compared to their MnZn counterparts. This makes them ideal for use in RF applications and microwave devices, where performance is critical. B2B buyers should weigh the benefits of enhanced performance against the higher costs associated with these magnets. Their ability to maintain functionality under varying temperatures adds value for industries requiring reliability in challenging environments.

What Makes Ultra Dense Ferrite an Ideal Choice for Advanced Applications?

Ultra dense ferrite magnets are known for their exceptional density and magnetic strength, making them indispensable in high-performance settings such as magnetic resonance imaging and advanced motor applications. While they provide superior performance, buyers must be mindful of their brittleness and higher price point. This type of magnet is best suited for specialized applications where performance justifies the investment.

How Can Controlled Curie Temperature Ferrite Benefit Scientific Research?

Controlled Curie temperature ferrite magnets are tailored for specific applications, particularly in scientific research and particle accelerators. Their customizable Curie temperatures allow for precise control of magnetic properties, which is crucial in experimental setups. However, the need for customization may lead to longer production lead times, which buyers must consider when planning their projects.

Why Choose Pressed Ceramic Magnets for Versatile Applications?

Pressed ceramic magnets offer versatility in shapes and sizes, making them suitable for a wide range of industrial and consumer applications. Their ability to be manufactured in various forms allows for customization to meet specific project requirements. However, they are best suited for applications that do not require high energy density. Buyers should evaluate their needs for custom shapes against potential limitations in performance.

Key Industrial Applications of ceramic magnetics

| Industry/Sector | Specific Application of ceramic magnetics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | DC Motors and Sensors | Reliable performance in challenging conditions | Ensure high temperature resistance and corrosion protection. |

| Healthcare | Magnetic Resonance Imaging (MRI) | Enhanced imaging quality and safety | Verify compliance with medical standards and material purity. |

| Manufacturing and Automation | Magnetic Separation Systems | Improved efficiency in material handling | Focus on custom shapes and sizes for specific applications. |

| Renewable Energy | Wind Turbine Generators | Increased energy efficiency and reliability | Consider sourcing options for high-volume production and durability. |

| Electronics | Consumer Electronics (e.g., speakers, microphones) | Cost-effective solutions with good performance | Assess the need for various shapes and sizes, and ensure consistent quality. |

How Are Ceramic Magnetics Used in the Automotive Industry?

In the automotive sector, ceramic magnetics are primarily utilized in DC motors and automotive sensors. These magnets provide reliable performance under extreme conditions, such as high temperatures and vibrations, which are common in vehicle operation. For international buyers, especially in regions like Africa and South America, sourcing ceramic magnets that meet stringent quality standards is crucial. Buyers should prioritize suppliers who can offer high-temperature resistance and corrosion protection to ensure longevity and reliability in automotive applications.

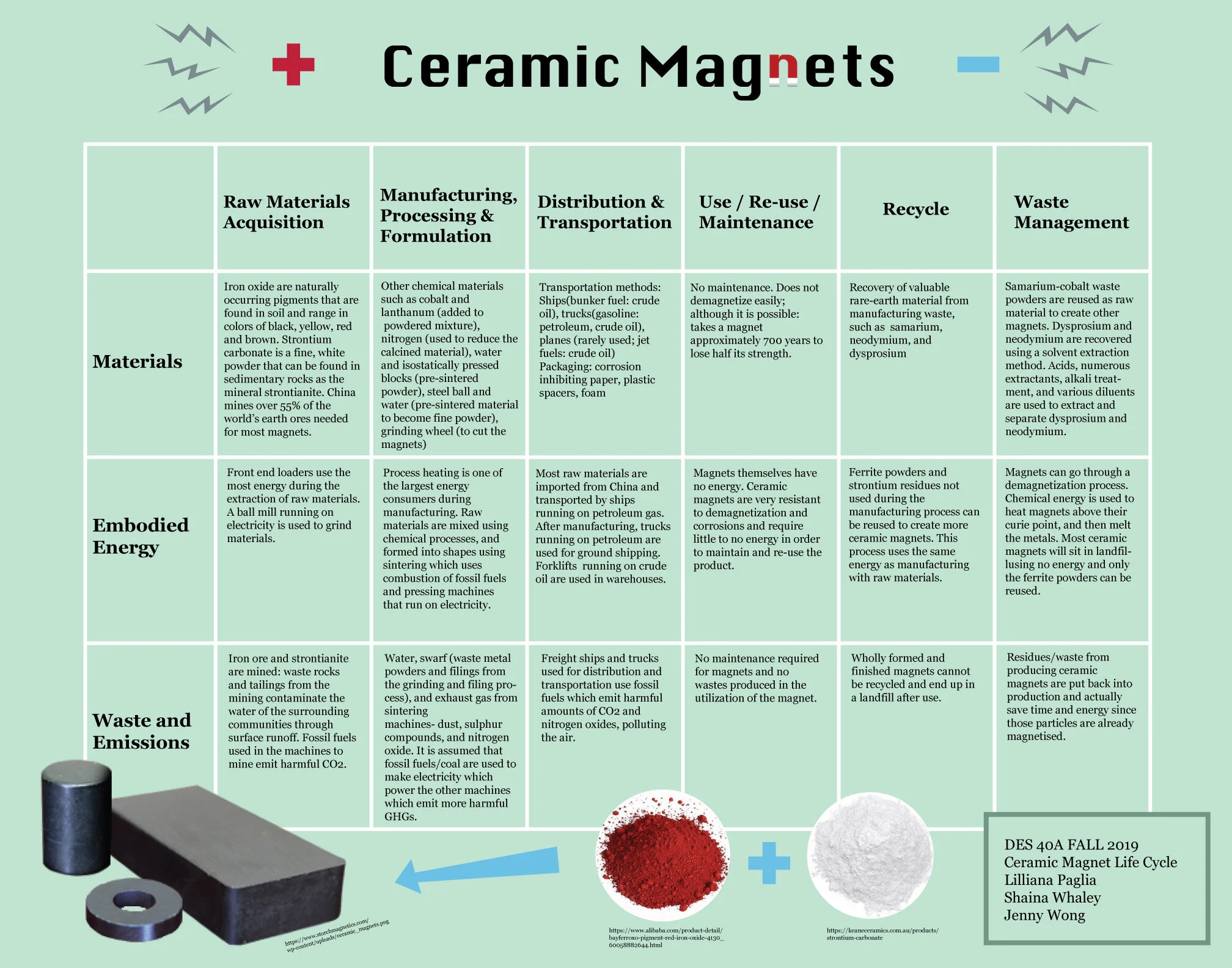

Illustrative image related to ceramic magnetics

What Role Do Ceramic Magnetics Play in Healthcare?

Ceramic magnets are essential in healthcare, particularly in Magnetic Resonance Imaging (MRI) systems. Their unique properties enhance imaging quality while ensuring patient safety. Buyers from the Middle East and Europe need to ensure that the sourced materials comply with medical standards, as any deviation can lead to significant risks. It’s vital to work with suppliers who can guarantee material purity and reliability, as these factors directly impact the quality of medical imaging.

How Are Ceramic Magnetics Applied in Manufacturing and Automation?

In manufacturing, ceramic magnetics are often used in magnetic separation systems, which are crucial for material handling. These systems improve efficiency by effectively separating ferrous materials from non-ferrous ones. B2B buyers should look for suppliers that can provide custom shapes and sizes to fit specific applications, as this can greatly enhance operational efficiency. Additionally, ensuring that the magnets are durable and able to withstand the rigors of manufacturing environments is key to maintaining productivity.

Why Are Ceramic Magnetics Important for Renewable Energy?

Ceramic magnets are increasingly being used in wind turbine generators to enhance energy efficiency and reliability. These magnets contribute to the overall performance of the turbines, which is essential for maximizing energy production. Buyers in the renewable energy sector should consider sourcing options that allow for high-volume production while ensuring that the magnets are durable enough to withstand outdoor conditions. This ensures that the energy systems remain operational and cost-effective over time.

What Are the Applications of Ceramic Magnetics in Electronics?

In the electronics industry, ceramic magnets are widely used in consumer electronics, such as speakers and microphones. Their cost-effectiveness combined with good performance makes them a preferred choice for manufacturers. International buyers need to assess the need for various shapes and sizes, as well as ensure consistent quality across their orders. This is particularly important in competitive markets, where product reliability can significantly impact brand reputation and customer satisfaction.

3 Common User Pain Points for ‘ceramic magnetics’ & Their Solutions

Scenario 1: Struggling with Material Specifications for Unique Applications

The Problem: Many B2B buyers face challenges in specifying the right type of ceramic magnetics for unique applications, particularly when dealing with custom or non-standard production shapes. For instance, a manufacturer in the automotive industry might require ceramic magnets that can withstand high temperatures and maintain performance under varying environmental conditions. Without a thorough understanding of material properties such as Curie temperature, coercivity, and magnetization, buyers risk sourcing unsuitable products that may lead to operational failures or increased costs.

The Solution: To overcome this challenge, buyers should engage directly with manufacturers that offer customized ceramic magnetics solutions. It’s crucial to provide detailed specifications about the application, including the operating environment, required dimensions, and performance criteria. Collaborating with engineers during the design phase can ensure that the selected materials, such as MnZn or NiZn ferrites, are tailored to meet specific needs. Furthermore, utilizing suppliers with a strong quality assurance process can mitigate risks associated with material inconsistencies, ensuring that the magnets perform reliably in their intended applications.

Scenario 2: Concerns Over Cost-Effectiveness in Bulk Purchases

The Problem: B2B buyers often grapple with the challenge of cost-effectiveness when ordering ceramic magnets in bulk. Factors such as fluctuating raw material costs, shipping expenses, and the potential for waste during the manufacturing process can quickly inflate the overall expenditure. For companies in regions like Africa or South America, where import costs can be significant, the pressure to maintain a balanced budget while ensuring product quality becomes even more pronounced.

The Solution: To optimize costs, buyers should consider establishing long-term relationships with suppliers who offer volume discounts or loyalty programs. Additionally, it is beneficial to conduct a thorough market analysis to understand price trends for ceramic magnet materials. Negotiating contracts that lock in prices for a set period can protect against fluctuations in raw material costs. Implementing a Just-In-Time (JIT) inventory system can also minimize waste and reduce storage costs, allowing companies to order exactly what they need when they need it, thus further enhancing cost-effectiveness.

Scenario 3: Navigating Quality Assurance and Compliance Issues

The Problem: Ensuring the quality and compliance of ceramic magnets with international standards can be a daunting task for B2B buyers, especially those exporting products to diverse markets in Europe and the Middle East. Variations in quality assurance practices and compliance regulations can lead to significant headaches, including production delays, costly rework, or even legal ramifications if products fail to meet required standards.

The Solution: Buyers should prioritize partnering with manufacturers that adhere to recognized international quality certifications, such as ISO 9001. Conducting audits of potential suppliers can also help ensure that their quality control processes align with the buyer’s standards. It is advisable to request documentation verifying compliance with relevant industry standards, such as RoHS or REACH, which govern the use of hazardous substances in manufacturing. Additionally, establishing a rigorous testing protocol before full-scale production can identify potential issues early, ensuring that the final products meet both quality and compliance requirements, thus safeguarding the buyer’s reputation and minimizing risks associated with non-compliance.

Strategic Material Selection Guide for ceramic magnetics

What Are the Key Properties of Ceramic Magnetics Materials?

Ceramic magnetics primarily consist of ferrite materials, which can be classified into various types based on their composition and intended applications. The most common types include MnZn (Manganese-Zinc) ferrite and NiZn (Nickel-Zinc) ferrite. Each of these materials has distinct properties that make them suitable for specific applications in various industries.

Illustrative image related to ceramic magnetics

MnZn Ferrite: A Versatile Choice for High Performance

MnZn ferrite is widely used in applications requiring high magnetic permeability and low losses at high frequencies. It typically operates effectively in temperatures up to 150°C. This material exhibits excellent corrosion resistance, making it suitable for environments prone to moisture and chemicals.

Pros: MnZn ferrite offers high magnetic saturation and is relatively cost-effective. It is also easier to manufacture in complex shapes, which is beneficial for custom applications.

Cons: However, its performance diminishes at higher temperatures, limiting its use in high-temperature applications. Additionally, it can be brittle, which may pose challenges during handling and installation.

Impact on Application: MnZn ferrite is ideal for inductors, transformers, and magnetic sensors, particularly in automotive and consumer electronics.

NiZn Ferrite: Optimized for High-Frequency Applications

NiZn ferrite is known for its high electrical resistivity, making it suitable for high-frequency applications. It can operate effectively at temperatures up to 200°C and is particularly useful in telecommunications and RF applications.

Pros: The high resistivity of NiZn ferrite reduces eddy current losses, making it efficient for high-frequency operations. It is also lightweight, which can be advantageous in applications where weight is a concern.

Cons: The main drawback is its lower saturation magnetization compared to MnZn ferrite, which may limit its use in certain high-power applications. It is also more expensive to manufacture due to the complexity of its production process.

Impact on Application: NiZn ferrite is often used in RF transformers, antennas, and EMI suppression applications, making it a preferred choice in the telecommunications sector.

Ultra-Dense Ferrite: For Specialized Applications

Ultra-dense ferrite materials are engineered for applications requiring exceptional density and magnetic performance. These materials can withstand high temperatures and are often used in scientific applications, such as particle accelerators.

Pros: Their high density allows for better magnetic performance and stability, making them suitable for precision applications. They also exhibit excellent thermal stability.

Cons: The manufacturing process is complex and can be costly. Additionally, the brittleness of these materials may limit their use in certain environments.

Impact on Application: Ultra-dense ferrites are ideal for high-precision instruments and scientific equipment, where performance and reliability are critical.

Considerations for International B2B Buyers

When selecting ceramic magnetics, international buyers from regions like Africa, South America, the Middle East, and Europe should consider compliance with local standards such as ASTM, DIN, and JIS. Understanding the specific requirements of their target markets, including temperature ratings and corrosion resistance, is crucial. Additionally, buyers should evaluate the availability of materials and manufacturing capabilities in their region to ensure timely delivery and cost-effectiveness.

Summary Table of Ceramic Magnetics Materials

| Material | Typical Use Case for ceramic magnetics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| MnZn Ferrite | Inductors, transformers, magnetic sensors | High magnetic saturation and cost-effective | Performance diminishes at high temperatures | Medium |

| NiZn Ferrite | RF transformers, antennas, EMI suppression | High resistivity reduces eddy current losses | Lower saturation magnetization limits power use | High |

| Ultra-Dense Ferrite | High-precision instruments, scientific equipment | Exceptional density and thermal stability | Complex manufacturing process and cost | High |

This strategic material selection guide provides a comprehensive overview of ceramic magnetics materials, ensuring that B2B buyers can make informed decisions tailored to their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic magnetics

What Are the Key Stages in the Manufacturing Process of Ceramic Magnetics?

The manufacturing of ceramic magnets, also known as ferrite magnets, involves a series of precise and controlled stages that ensure the production of high-quality products suitable for various applications. The main stages of the manufacturing process include material preparation, forming, assembly, and finishing.

How is Material Prepared for Ceramic Magnet Production?

The foundation of ceramic magnets lies in the raw materials, primarily iron oxide and strontium carbonate. These materials are initially mixed in specific ratios to achieve desired magnetic properties. The blend is then subjected to high temperatures ranging from 1800 to 2000 degrees Fahrenheit, facilitating a chemical conversion into ferrite. This process is critical, as the quality of the ferrite directly affects the performance of the final magnet.

Once the ferrite is produced, it undergoes wet milling to achieve a fine particle size. This fine powder is crucial for ensuring uniformity in the magnetic properties of the finished magnets. Following milling, the material is either dried for dry pressing or prepared as a slurry for wet pressing, which is performed in hydraulic presses equipped with carbide-lined, non-magnetic steel dies.

What Techniques Are Used in Forming Ceramic Magnets?

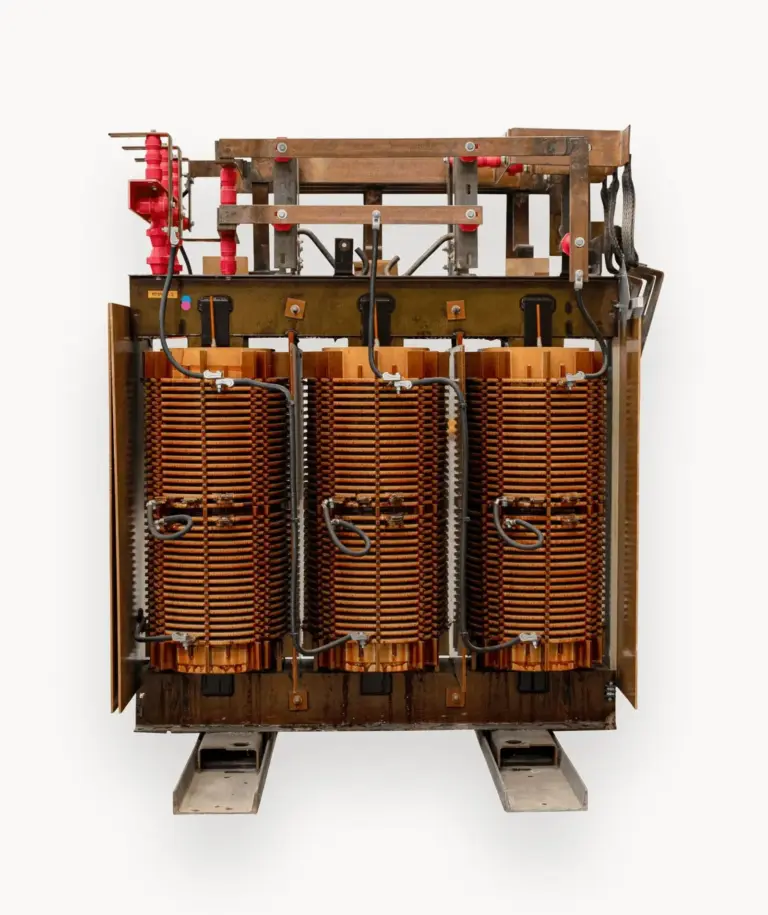

The forming stage is where the ferrite powder is compacted into the desired shape. In wet pressing, the slurry is compacted under a magnetic field, allowing the flat ferrite particles to align optimally for enhanced magnetic properties. This alignment is pivotal for achieving the required performance characteristics in applications such as DC motors, magnetic resonance imaging, and automotive sensors.

After compaction, the next step is sintering, where the compacted ferrite is heated again, typically around 2000 degrees Fahrenheit. This process densifies the material, ensuring it achieves its final strength and magnetic performance. The hard and brittle nature of the material necessitates that any subsequent grinding or finishing be done with diamond wheels to maintain the integrity of the magnets.

Illustrative image related to ceramic magnetics

How is Quality Assurance Implemented in Ceramic Magnet Manufacturing?

Quality assurance (QA) is a critical component of the ceramic magnet manufacturing process, ensuring that products meet specific international standards and customer requirements. Manufacturers often adhere to ISO 9001 standards, which outline a quality management system aimed at enhancing customer satisfaction through consistent quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically structured around several key checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they are used in production. Suppliers are evaluated based on their compliance with specified material standards, ensuring that only high-quality inputs are utilized.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing assessments are conducted to monitor critical parameters such as temperature, pressure, and material consistency. This real-time monitoring helps identify any deviations from standards early in the process.

-

Final Quality Control (FQC): Once the ceramic magnets are finished, they undergo rigorous testing to verify their magnetic properties, dimensions, and overall quality. This final inspection is essential for ensuring that the products meet the performance specifications required by customers.

What Testing Methods Are Commonly Used in Ceramic Magnet Quality Control?

Several testing methods are employed to ensure the quality of ceramic magnets, including:

-

Magnetic Testing: This involves measuring the magnetic strength and performance characteristics using gauss meters and other magnetic testing devices.

-

Dimensional Testing: Precision measurement tools are used to ensure that the dimensions of the magnets align with customer specifications.

-

Durability Testing: Conducting tests for thermal and corrosion resistance helps determine the longevity and reliability of the magnets in various environments.

How Can B2B Buyers Verify Supplier Quality Control Standards?

For B2B buyers, particularly those from diverse international markets such as Africa, South America, the Middle East, and Europe, verifying the quality assurance practices of potential suppliers is crucial. Here are some actionable steps:

-

Supplier Audits: Conducting audits of the manufacturing facility can provide insight into the supplier’s quality management practices. This allows buyers to assess adherence to international standards and the effectiveness of their QC processes.

-

Requesting Documentation: Buyers should request detailed reports on quality control measures, including IQC, IPQC, and FQC results. Such documentation can demonstrate the supplier’s commitment to maintaining high standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality practices and product quality. This is especially valuable for international buyers who may not be able to conduct on-site evaluations.

What Are the Quality Certification Nuances for International B2B Buyers?

Quality certifications can vary significantly across regions and industries. For instance, European buyers may prioritize CE marking, which indicates compliance with EU safety standards, while buyers in other regions might focus on certifications like API for specific applications. Understanding these nuances is essential for B2B buyers to ensure that the products they purchase not only meet their requirements but also comply with local regulations.

Additionally, international buyers should consider the logistics of quality assurance, including potential language barriers in documentation and the need for localized support. Establishing clear communication channels with suppliers can help mitigate these challenges and foster a more effective partnership.

Conclusion

The manufacturing processes and quality assurance practices for ceramic magnetics are integral to ensuring that these products meet the diverse needs of international B2B buyers. By understanding the stages of production, quality control checkpoints, and verification methods, businesses can make informed decisions when sourcing ceramic magnets. This knowledge not only enhances the purchasing process but also fosters stronger supplier relationships and ensures compliance with industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ceramic magnetics’

Introduction

This guide provides a step-by-step checklist for B2B buyers looking to source ceramic magnetics effectively. Ceramic magnets, known for their cost-effectiveness and wide application across various industries, require careful consideration during the procurement process. By following these steps, you can ensure that you select the right materials and suppliers to meet your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to define your technical specifications for ceramic magnetics. This includes determining the required size, shape, magnetic strength, and material composition. Understanding these parameters helps streamline your search and ensures that the products meet your application requirements, whether for automotive sensors or magnetic resonance imaging.

- Key Considerations:

- Identify the type of ferrite material (e.g., MnZn or NiZn).

- Specify any unique characteristics, such as controlled Curie temperature or ultra-dense properties.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in ceramic magnetics. Look for companies with a strong reputation in the industry and experience in producing the specific types of magnets you require. A well-established supplier is likely to provide better quality assurance and support.

- Action Items:

- Check online directories and industry associations for reputable manufacturers.

- Review customer testimonials and case studies to gauge their reliability.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and quality assurance processes. This step is vital to ensure that the products you receive will meet international standards and regulatory requirements. Certifications such as ISO 9001 can indicate a commitment to quality management.

- What to Look For:

- Documentation of quality control processes.

- Evidence of compliance with industry standards relevant to your region.

Step 4: Request Samples for Testing

Always request samples of ceramic magnets before placing a large order. Testing samples allows you to assess the product’s performance in real-world applications. This step can help prevent costly errors and ensure that the magnets meet your specifications.

- Testing Criteria:

- Magnetic strength and durability.

- Performance under varying environmental conditions.

Step 5: Compare Pricing and Delivery Options

Once you have narrowed down your supplier options, compare pricing and delivery timelines. While cost is an important factor, consider the total value, including quality, service, and reliability. Be aware of any additional costs, such as shipping or customs duties, especially when sourcing internationally.

- Cost Considerations:

- Assess bulk order discounts.

- Factor in lead times and availability for timely production schedules.

Step 6: Negotiate Terms and Finalize Contracts

After selecting a supplier, negotiate terms that align with your business needs. This includes pricing, payment terms, delivery schedules, and warranties. A clear contract can help prevent misunderstandings and ensure a smooth transaction.

- Contract Essentials:

- Outline quality assurance expectations.

- Include clauses for potential disputes and resolution processes.

Step 7: Establish a Relationship for Future Sourcing

Building a strong relationship with your chosen supplier can yield benefits for future sourcing needs. Regular communication and feedback can foster collaboration, leading to better product offerings and services over time.

- Relationship Management:

- Schedule periodic reviews to discuss product performance and improvements.

- Explore opportunities for custom formulations or new product developments.

By following this checklist, B2B buyers can navigate the sourcing process for ceramic magnetics with confidence, ensuring that they select the best products and suppliers for their needs.

Comprehensive Cost and Pricing Analysis for ceramic magnetics Sourcing

When sourcing ceramic magnetics, understanding the cost structure and pricing dynamics is crucial for B2B buyers. This section outlines the key components influencing costs and provides actionable insights for effective negotiation and purchasing strategies.

What Are the Key Cost Components in Ceramic Magnetics?

The cost structure of ceramic magnets includes several essential components:

-

Materials: The primary raw materials, iron oxide and strontium carbonate, are relatively inexpensive, but costs can fluctuate based on global supply and demand. High-grade materials that enhance performance, such as controlled Curie temperature ferrites, may incur higher costs.

-

Labor: Labor costs can vary significantly based on geographic location and the skill level required for manufacturing. Automated processes can reduce labor costs, but skilled technicians are necessary for quality assurance and custom production.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, energy, equipment depreciation, and administrative costs. Efficient manufacturing processes can help mitigate these expenses.

-

Tooling: The initial investment in tooling can be substantial, especially for custom shapes and sizes. Buyers should consider this when evaluating the overall cost, as high tooling costs can be offset by lower unit prices in large production runs.

-

Quality Control (QC): Ensuring that ceramic magnets meet specific standards requires rigorous quality control processes. This adds to the cost but is essential for maintaining product integrity, especially in critical applications like automotive and medical devices.

-

Logistics: Transportation and handling costs are crucial, particularly for international shipments. Factors such as distance, shipping methods, and customs duties can significantly impact overall expenses.

-

Margin: Suppliers will factor in their desired profit margin, which can vary based on competition and market conditions. Understanding these dynamics helps buyers negotiate better prices.

How Do Price Influencers Impact Ceramic Magnetics Sourcing?

Several factors influence the pricing of ceramic magnetics:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Higher volumes often lead to reduced per-unit costs, making bulk purchasing a cost-effective strategy.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized tooling and additional QC measures. Buyers should assess the necessity of custom features against budget constraints.

-

Material Quality and Certifications: Premium materials and certifications (e.g., ISO compliance) can drive up costs but may be essential for specific applications. Buyers should weigh the importance of these factors against potential risks.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a history of quality may charge more, but the assurance of product reliability can justify the higher cost.

-

Incoterms: The terms of sale (Incoterms) dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Understanding these terms is critical for calculating the total landed cost.

What Negotiation Strategies Can Buyers Employ?

For international buyers, particularly in Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings:

-

Leverage Volume Discounts: Combining orders with other buyers or committing to long-term contracts can enhance negotiating power for better pricing.

-

Total Cost of Ownership (TCO): Focus on TCO rather than just the purchase price. Consider factors like longevity, reliability, and maintenance costs when evaluating suppliers.

-

Explore Local Suppliers: Engaging with local suppliers can reduce logistics costs and delivery times, enhancing overall value.

-

Request Samples: Before committing to large orders, request samples to assess quality, performance, and adherence to specifications.

Final Thoughts on Pricing Nuances for International Buyers

When sourcing ceramic magnetics, especially from regions with varying economic conditions like Vietnam and Germany, buyers should remain aware of the complexities of international trade. Currency fluctuations, trade tariffs, and local regulations can all influence final costs.

Disclaimer: Prices for ceramic magnetics can vary widely based on the aforementioned factors. Buyers are encouraged to conduct thorough market research and consider multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing ceramic magnetics With Other Solutions

Introduction: Understanding Alternatives to Ceramic Magnetics

When considering magnetic solutions for various applications, it’s crucial to explore viable alternatives to ceramic magnetics. Ceramic magnets, also known as ferrite magnets, are widely recognized for their cost-effectiveness and resistance to corrosion. However, depending on specific requirements such as performance, application, and budget, other magnetic solutions may offer advantages. This analysis will compare ceramic magnetics with two notable alternatives: neodymium magnets and powdered iron magnets.

Comparison Table

| Comparison Aspect | Ceramic Magnetics | Neodymium Magnets | Powdered Iron Magnets |

|---|---|---|---|

| Performance | Moderate strength; good for low-energy applications | High strength; excellent energy density | Lower strength; suitable for magnetic shielding |

| Cost | Low cost per pound | Higher cost due to material scarcity | Moderate cost; varies by application |

| Ease of Implementation | Easy to manufacture in various shapes | Requires specialized manufacturing | Simple production process |

| Maintenance | Low maintenance; durable | Moderate; susceptible to corrosion | Low; can require periodic replacement |

| Best Use Case | DC motors, sensors, general applications | High-performance applications like electronics | Magnetic shielding, transformers |

Detailed Breakdown of Alternatives

Neodymium Magnets

Neodymium magnets are composed of an alloy of neodymium, iron, and boron. They are known for their exceptional strength and energy density, making them suitable for high-performance applications such as electric motors, magnetic resonance imaging (MRI), and advanced electronics. The primary drawback of neodymium magnets is their higher cost, which can limit their use in budget-sensitive projects. Additionally, they are more susceptible to corrosion, necessitating protective coatings to maintain their integrity in harsh environments.

Powdered Iron Magnets

Powdered iron magnets offer a different approach, utilizing iron powder to create magnetic fields. These magnets are particularly useful in applications requiring magnetic shielding and can effectively reduce electromagnetic interference. While their strength is lower compared to ceramic and neodymium magnets, they are cost-effective and can be produced using relatively simple manufacturing processes. However, powdered iron magnets may require more frequent replacements due to wear and tear, especially in demanding environments.

Conclusion: Choosing the Right Magnetic Solution

When selecting the appropriate magnetic solution for a specific application, B2B buyers should consider the unique requirements of their projects. Ceramic magnetics are a solid choice for cost-sensitive applications requiring moderate performance and durability. However, if the application demands high strength and energy efficiency, neodymium magnets may be the better option despite their higher cost. For projects focused on magnetic shielding, powdered iron magnets can provide effective solutions at a moderate price point. Ultimately, understanding the trade-offs between these alternatives will enable buyers to make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for ceramic magnetics

What Are the Key Technical Properties of Ceramic Magnetics?

Understanding the essential technical properties of ceramic magnetics is crucial for B2B buyers looking to make informed decisions. Here are some critical specifications that should be considered:

1. Material Grade

Material grade refers to the specific formulation and composition of the ceramic magnet, typically categorized as strontium ferrite (SrFeO3) or barium ferrite (BaFeO3). The grade affects the magnet’s performance, including its magnetic strength and resistance to demagnetization. For B2B buyers, selecting the appropriate material grade ensures optimal performance for applications such as DC motors and magnetic resonance imaging.

Illustrative image related to ceramic magnetics

2. Magnetic Energy Product (BHmax)

The magnetic energy product, expressed in Mega Gauss Oersteds (MGOe), measures the strength of the magnetic field a magnet can produce. Higher BHmax values indicate stronger magnets. For international buyers, understanding this specification is vital when determining the magnet’s suitability for applications requiring high magnetic forces, such as in automotive sensors and magnetic separation systems.

3. Coercivity

Coercivity is the measure of a magnet’s ability to withstand demagnetization. It is defined by the amount of external magnetic field required to reduce the magnet’s magnetization to zero. For B2B buyers, selecting magnets with adequate coercivity is essential for ensuring long-term stability in environments with fluctuating magnetic fields, such as in electronic devices and industrial machinery.

4. Curie Temperature

The Curie temperature indicates the temperature at which a magnet loses its magnetic properties. Ceramic magnets typically have high Curie temperatures, making them suitable for high-temperature applications. B2B buyers in industries such as aerospace and automotive must consider this property to ensure reliability and performance under thermal stress.

5. Tolerance

Tolerance refers to the permissible deviation from specified dimensions and properties during manufacturing. High precision in tolerances is crucial for applications requiring exact fit and function. In B2B transactions, understanding tolerance specifications can help buyers avoid compatibility issues in assembly processes.

What Are Common Trade Terms Used in the Ceramic Magnetics Industry?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation. Here are some common trade terms relevant to ceramic magnetics:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are then marketed by another company under its brand name. In the context of ceramic magnetics, OEMs typically require custom magnet solutions that fit their specific application needs. Understanding this term is critical for buyers looking to partner with manufacturers for tailored solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the ceramic magnetics industry, MOQs can vary based on the complexity of the magnet design and production costs. Buyers should be aware of MOQs to plan their inventory and procurement strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. B2B buyers should use RFQs to solicit competitive bids for ceramic magnets, ensuring they receive the best value for their purchases.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, risk, and costs associated with the delivery of ceramic magnets, particularly in cross-border transactions.

5. Sintering

Sintering is a manufacturing process that involves heating powdered materials to form a solid mass without melting them. This process is crucial in producing ceramic magnets, affecting their density and magnetic properties. Buyers should be aware of the implications of sintering on the quality and performance of the final product.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring ceramic magnetics, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the ceramic magnetics Sector

What Are the Key Market Dynamics in the Ceramic Magnetics Sector?

The ceramic magnetics sector is experiencing significant growth driven by a variety of global factors. One of the primary drivers is the increasing demand for low-cost, high-performance materials across various industries, including automotive, electronics, and renewable energy. With ceramic magnets, also known as ferrite magnets, comprising over 75% of global magnet consumption, their affordability and durability make them the go-to choice for applications ranging from DC motors to magnetic resonance imaging.

Emerging trends in B2B sourcing highlight the rise of customized solutions. Manufacturers are increasingly focusing on producing non-standard shapes and sizes to meet specific customer needs, which is particularly relevant for international buyers from regions like Africa and South America, where tailored products can enhance operational efficiency. Furthermore, technological advancements in manufacturing processes, such as improved powder technology and sintering techniques, are enabling higher precision and quality in ceramic magnets.

Another crucial aspect for B2B buyers is the shift towards digital sourcing platforms. These platforms facilitate easier comparisons of materials, suppliers, and prices, streamlining the procurement process. Buyers from Europe and the Middle East are particularly benefiting from enhanced transparency and accessibility, allowing them to make informed decisions that align with their business strategies.

How Can B2B Buyers Address Sustainability and Ethical Sourcing in Ceramic Magnetics?

Sustainability and ethical sourcing have become paramount in the ceramic magnetics sector. The environmental impact of manufacturing processes, particularly those involving ferrite materials, necessitates a focus on sustainable practices. For B2B buyers, this means seeking suppliers who are committed to reducing carbon footprints and minimizing waste.

Illustrative image related to ceramic magnetics

Ethical supply chains are increasingly being prioritized, with a growing emphasis on certifications that demonstrate responsible sourcing. Buyers should look for suppliers that adhere to international standards, such as ISO 14001 for environmental management and certifications related to ethical labor practices.

Additionally, there is a rising demand for ‘green’ materials in the ceramic magnetics sector. Suppliers are responding by developing eco-friendly alternatives and production methods that limit harmful emissions and waste. Buyers should actively inquire about the sustainability practices of their suppliers, ensuring that their sourcing decisions not only meet performance criteria but also align with corporate social responsibility goals.

What Is the Historical Context of Ceramic Magnetics for Today’s B2B Landscape?

Ceramic magnets, or ferrite magnets, were first developed in the 1960s as a cost-effective alternative to metallic magnets. Their composition primarily includes iron oxide and strontium carbonate, which undergo a transformation through high-temperature processes to become ferrite. This innovation marked a significant evolution in magnet technology, leading to widespread adoption across various industries due to their corrosion resistance and stability in high-temperature applications.

As the demand for efficient and durable materials has grown, so too has the sophistication of ceramic magnet production techniques. Today, manufacturers can offer a range of customized options, ensuring that businesses can find solutions tailored to their specific operational needs. This historical context not only illustrates the evolution of ceramic magnetics but also highlights the importance of understanding supply chain dynamics for international B2B buyers looking to leverage these materials effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic magnetics

-

How do I choose the right ceramic magnet for my application?

Selecting the appropriate ceramic magnet depends on several factors, including the intended application, required magnetic strength, size, and environmental conditions. Consider the specific performance requirements such as resistance to temperature fluctuations, corrosion, and demagnetization. It’s advisable to consult with suppliers to discuss your application in detail. They can provide insights into material compositions, such as MnZn or NiZn ferrites, and recommend the best options based on your needs. -

What are the advantages of ceramic magnets over other types of magnets?

Ceramic magnets, or ferrite magnets, are favored for their cost-effectiveness and resistance to corrosion and demagnetization. They are ideal for applications requiring large surface areas, such as in DC motors or magnetic separators. Their ability to operate at elevated temperatures makes them suitable for automotive sensors and other demanding environments. Additionally, they represent over 75% of global magnet consumption by weight, indicating widespread acceptance in various industries. -

What customization options are available for ceramic magnets?

Many manufacturers offer customization options for ceramic magnets, including shape, size, and specific material compositions. This can include custom formulations to meet unique application requirements or specific magnetic properties. When sourcing, inquire about the supplier’s capabilities for prototyping and high-volume production. Understanding their manufacturing processes and lead times can help you align your project timelines with your needs. -

What is the minimum order quantity (MOQ) for ceramic magnets?

The minimum order quantity (MOQ) for ceramic magnets varies by supplier and depends on factors like production capabilities and material costs. Typically, MOQs can range from a few hundred to thousands of units. It’s essential to discuss your project requirements with potential suppliers to understand their MOQ policies and explore options for smaller orders if necessary. -

What payment terms should I expect when sourcing ceramic magnets internationally?

Payment terms for international orders of ceramic magnets can vary significantly by supplier and region. Common practices include advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). It’s crucial to negotiate these terms upfront and ensure they are clearly outlined in your purchase agreement. Additionally, consider currency fluctuations and any potential fees related to international transactions. -

How can I ensure quality assurance in my ceramic magnet purchases?

To ensure quality assurance in ceramic magnet purchases, request documentation of the supplier’s quality control processes and certifications. Look for compliance with international standards such as ISO 9001, which indicates a commitment to quality management. Additionally, consider requesting samples for testing before placing a larger order, and inquire about warranty policies and return processes in case of defects. -

What logistics considerations should I keep in mind when importing ceramic magnets?

When importing ceramic magnets, consider factors like shipping methods, customs duties, and local regulations in your country. Choose a reliable logistics partner familiar with international shipments to navigate these complexities efficiently. Additionally, be aware of lead times and potential delays, especially for larger orders or during peak shipping seasons. Properly understanding these logistics can help prevent unexpected costs and delays. -

What are the typical applications for ceramic magnets in various industries?

Ceramic magnets are widely used across multiple industries due to their versatility. They are commonly found in electric motors, magnetic separators, automotive sensors, and magnetic resonance imaging (MRI) systems. Their ability to withstand high temperatures makes them suitable for applications in the aerospace and industrial machinery sectors. Understanding the specific requirements of your industry will help in selecting the right type of ceramic magnet for your applications.

Top 6 Ceramic Magnetics Manufacturers & Suppliers List

1. Magnetics Group – Custom Ceramic Magnetics Solutions

Domain: magneticsgroup.com

Registered: 1998 (27 years)

Introduction: Ceramic Magnetics Division emphasizes custom and non-standard production shapes with unique forming techniques enabling the largest shapes in the industry. They offer a broad range of material compositions controlled to exacting standards for various applications, particularly focusing on cores for the scientific community, including large shapes used as pole pieces (kicker magnets) for particle a…

2. BuyMagnets – Ceramic Magnets

Domain: buymagnets.com

Registered: 2002 (23 years)

Introduction: Ceramic magnets are low cost, lightweight, and high energy, primarily made of iron oxide and strontium carbonate. They can withstand operating temperatures up to 480 °F. BuyMagnets.com offers various ceramic magnets in different sizes, shapes, and strengths, including: 1. Ceramic Holding Magnets, HW Series, Shallow, Thru-hole – $1.40 2. BMT Ceramic Holding Magnets – $6.56 3. Ceramic Channel Magnet…

3. MagnaVisual – Ceramic Magnets

Domain: magnavisual.com

Registered: 1998 (27 years)

Introduction: {“name”: “Ceramic Magnets”, “price_range”: “$22.18 – $77.34”, “pack_size”: “25 magnets or mixed pack of 6 magnets”, “dimensions”: {“height”: “7/8\””, “width”: “1 7/8\””, “thickness”: “3/8\””}, “features”: [“high-strength holding power”, “permanently coated in polystyrene”, “write-on/wipe-off surface using water soluble markers”], “colors_available”: [“Black”, “Blue”, “Green”, “Mixed”, “Red”, “Whit…

4. Ceramic Magnetics – Custom Ferrites

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Ceramic Magnetics – Custom Ferrites, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. MagnetShop – Ceramic Magnets

Domain: magnetshop.com

Registered: 1998 (27 years)

Introduction: Ceramic Magnets (Ferrite) are permanent magnets made from strontium carbonate and iron oxide. They are low-cost, medium-strength magnets that can withstand high temperatures, are corrosion-resistant, and easy to magnetize. Available shapes include discs, blocks (rectangular & square), rings, and round cups. Key specifications include:

– Grade: 5 (most commonly used) through 8

– Magnetization: Thro…

6. First4Magnets – Ceramic Magnets

Domain: first4magnets.com

Registered: 2007 (18 years)

Introduction: Ceramic magnets are a type of permanent magnet made from a mixture of iron oxide and strontium carbonate. They are known for their high resistance to demagnetization, making them ideal for various applications. Ceramic magnets are commonly used in motors, speakers, and magnetic assemblies. They are available in different shapes and sizes, including discs, blocks, and rings. These magnets are cost-…

Strategic Sourcing Conclusion and Outlook for ceramic magnetics

As the demand for ceramic magnets continues to rise, particularly in key industries such as automotive, electronics, and healthcare, strategic sourcing becomes increasingly vital for international B2B buyers. Understanding the unique properties and manufacturing processes of ceramic magnetics allows companies to make informed purchasing decisions that align with their operational needs. The cost-effectiveness and durability of ceramic magnets, particularly in high-temperature and corrosive environments, position them as an attractive option for various applications.

International buyers from regions like Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers that offer a diverse range of ceramic magnet products tailored to specific applications. This approach not only ensures access to high-quality materials but also fosters innovation through collaboration. Moreover, sourcing from manufacturers with robust quality assurance processes can mitigate risks associated with performance and reliability.

Looking ahead, the ceramic magnetics market is poised for growth, driven by advancements in technology and increasing demand for energy-efficient solutions. Buyers are encouraged to leverage strategic sourcing practices to optimize their supply chains and capitalize on emerging opportunities. Engage with reputable suppliers to explore customized solutions that can enhance your competitive edge in the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.