A B2B Buyer’s Guide to Cantilever Canopy: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for cantilever canopy

In the quest for effective outdoor solutions, sourcing the right cantilever canopy can present a significant challenge for businesses across various sectors. These versatile structures not only enhance the aesthetic appeal of commercial spaces but also provide essential protection against the elements, improving customer experiences in retail, hospitality, and transportation environments. This comprehensive guide is designed to navigate the complexities of the global cantilever canopy market, offering insights into the various types available, their diverse applications, and practical considerations for sourcing high-quality products.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Saudi Arabia—will find this guide invaluable. It covers critical aspects such as supplier vetting processes, cost analysis, and installation considerations, empowering businesses to make informed purchasing decisions. By understanding the unique benefits and potential challenges of cantilever canopies, buyers can optimize their investments, ensuring that their chosen structures align with both functional needs and brand aesthetics.

With this guide, you will be equipped to select the ideal cantilever canopies that not only meet regulatory standards but also resonate with your brand’s vision, enhancing your outdoor spaces while driving customer engagement. Prepare to elevate your projects with strategic insights that pave the way for successful installations and lasting partnerships with reliable suppliers.

Understanding cantilever canopy Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cantilever Bracket Canopy | Utilizes support brackets for a minimalistic aesthetic; versatile in design | Retail storefronts, shopping centers | Pros: Clean design, high load capacity; Cons: Installation may require precise engineering. |

| Curved Cantilever Canopy | Features a smooth, arched design that enhances architectural appeal | Parks, bus stops, outdoor venues | Pros: Aesthetic appeal, good weather resistance; Cons: May have higher fabrication costs. |

| Post Supported Canopy | Supported by vertical posts, providing stability for larger spans | Parking lots, warehouses, event spaces | Pros: Strong and durable; Cons: More intrusive design may limit space utilization. |

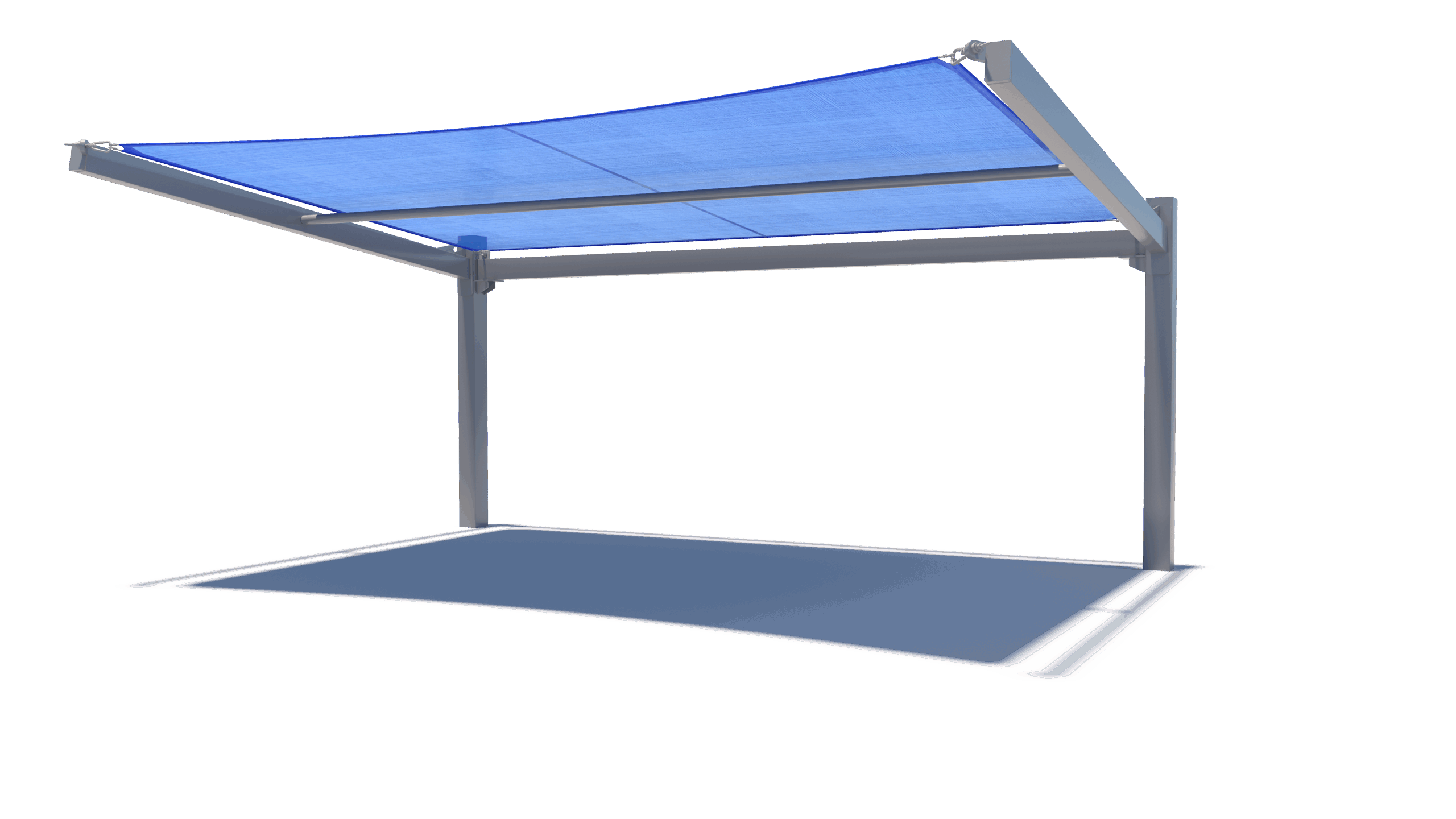

| Cantilever Shade Structure | Offers shade with unobstructed space beneath, often used in outdoor settings | Playgrounds, sports fields, outdoor dining | Pros: Versatile, enhances outdoor comfort; Cons: Requires regular maintenance to retain appearance. |

| Custom Cantilever Canopy | Tailored designs to meet specific project requirements and aesthetics | Specialty retail, unique architectural projects | Pros: Fully customizable, meets unique needs; Cons: Longer lead times and potentially higher costs. |

What are the Characteristics of Cantilever Bracket Canopies?

Cantilever bracket canopies are designed with support brackets that create a sleek, unobtrusive look. This type is particularly suitable for retail environments where aesthetics matter, as it provides a clean sightline that enhances the overall building façade. B2B buyers should consider the engineering requirements for installation, as precise calculations are essential to ensure safety and functionality. The ability to customize colors and designs makes it a popular choice for branding purposes.

Illustrative image related to cantilever canopy

How Do Curved Cantilever Canopies Enhance Outdoor Spaces?

Curved cantilever canopies feature an elegant arch that not only provides shelter but also enhances the visual appeal of outdoor areas. These canopies are ideal for applications such as parks and bus stops, where they can contribute to a welcoming atmosphere. When purchasing, businesses should assess the durability of materials used, as the canopy must withstand varying weather conditions. The investment in aesthetic design can significantly boost brand image and customer experience.

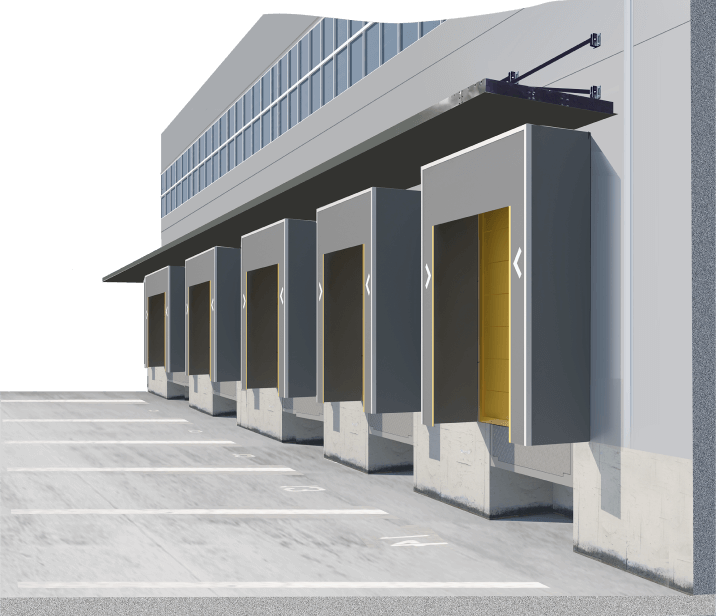

What Are the Benefits of Post Supported Canopies?

Post supported canopies are characterized by vertical posts that provide robust support for larger spans, making them suitable for environments like parking lots and warehouses. While they offer exceptional durability, the presence of posts can limit space utilization. Buyers should evaluate the balance between stability and design needs, especially in high-traffic areas. This type is often favored for its straightforward installation and long-lasting performance.

Why Choose Cantilever Shade Structures for Outdoor Comfort?

Cantilever shade structures are designed to create shaded areas while maintaining unobstructed space beneath. They are particularly useful in settings like playgrounds and sports fields, where comfort and sun protection are essential. B2B buyers should consider the maintenance requirements, as regular cleaning is necessary to preserve their appearance and functionality. The versatility of these structures makes them an attractive option for enhancing customer experiences in outdoor environments.

How Do Custom Cantilever Canopies Meet Unique Business Needs?

Custom cantilever canopies offer tailored solutions that align with specific project requirements and design preferences. This type is ideal for specialty retail or unique architectural projects, allowing businesses to create a distinctive presence. However, buyers should be aware of the potentially longer lead times and higher costs associated with custom designs. Collaborating closely with manufacturers during the design phase can ensure that the final product meets both functional and aesthetic expectations.

Key Industrial Applications of cantilever canopy

| Industry/Sector | Specific Application of cantilever canopy | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Storefronts and Entryways | Enhances brand visibility and provides weather protection for customers. | Customization options for colors and materials to match branding; durability against local weather conditions. |

| Transportation | Bus Stops and Train Stations | Offers shelter for passengers, improving comfort and safety during wait times. | Consideration for local regulations and safety standards; ease of installation and maintenance. |

| Automotive | Parking Lots and Car Washes | Protects vehicles from sun damage while maximizing space efficiency. | High load capacity to withstand environmental stress; modular designs for easy expansion. |

| Hospitality | Outdoor Dining Areas | Creates inviting outdoor spaces that attract more customers. | Aesthetic compatibility with existing architecture; options for shade fabrics that resist fading. |

| Sports and Recreation | Bleachers and Spectator Areas | Provides shade for spectators, enhancing their experience during events. | Structural integrity to withstand dynamic loads; easy maintenance protocols to ensure safety. |

How is Cantilever Canopy Used in Retail Settings?

In the retail sector, cantilever canopies are often installed at storefronts and entryways to enhance brand visibility while providing protection from the elements. These canopies create a welcoming environment for customers, encouraging foot traffic and improving the shopping experience. For international buyers, particularly in regions with extreme weather, selecting durable materials that can withstand local conditions is crucial. Customization options, such as colors and styles, allow businesses to align the canopy design with their brand identity, making it an effective marketing tool.

Illustrative image related to cantilever canopy

What Role Do Cantilever Canopies Play in Transportation?

Cantilever canopies serve a vital function in transportation hubs like bus stops and train stations. They provide essential shelter for passengers, improving comfort and safety during wait times. For B2B buyers in this sector, it is important to consider local regulations regarding public structures, as well as the need for materials that can endure heavy use and harsh weather conditions. The ease of installation and maintenance is also a key factor, ensuring that the structures remain functional and visually appealing over time.

How Do Cantilever Canopies Benefit Automotive Businesses?

In the automotive industry, cantilever canopies are strategically used in parking lots and car washes to protect vehicles from sun damage and environmental elements. Their design maximizes space efficiency, allowing for more vehicles to be parked without obstructing views. Buyers should prioritize high load capacity structures that can withstand environmental stressors, especially in regions with high temperatures or severe weather. Modular designs that allow for easy expansion can also be beneficial as businesses grow.

How Can Cantilever Canopies Enhance Hospitality Venues?

Cantilever canopies are increasingly popular in the hospitality industry, particularly for outdoor dining areas. They create inviting spaces that attract customers, enhancing the overall dining experience. For international buyers, aesthetic compatibility with existing architecture is essential, as is the selection of shade fabrics that resist fading and wear. These canopies can also be customized to align with the venue’s theme or branding, adding to the establishment’s visual appeal.

What Are the Advantages of Cantilever Canopies in Sports and Recreation?

In sports and recreation settings, cantilever canopies are used to provide shade for bleachers and spectator areas. This enhances the viewing experience for fans, especially in hot climates. Key considerations for B2B buyers in this sector include ensuring the structural integrity of the canopies to withstand dynamic loads from crowds and weather conditions. Additionally, easy maintenance protocols are necessary to ensure safety and longevity, providing a reliable solution for outdoor sporting events.

3 Common User Pain Points for ‘cantilever canopy’ & Their Solutions

Scenario 1: Concerns Over Weather Resistance and Longevity

The Problem: B2B buyers, particularly in regions with extreme weather conditions, often worry about the durability of cantilever canopies. Many canopies may not withstand heavy winds, rain, or snow, leading to potential damage, safety hazards, and costly replacements. This concern is amplified when considering the installation of canopies in public spaces or commercial environments where liability could be an issue.

The Solution: To ensure that a cantilever canopy can withstand harsh weather, buyers should prioritize sourcing products made from high-quality materials such as extruded aluminum, which is known for its strength and resistance to rust and corrosion. When specifying a cantilever canopy, buyers should request detailed specifications, including load capacity and wind resistance ratings. Engaging with manufacturers who offer custom solutions can also help in tailoring canopies to meet specific environmental conditions. Furthermore, consider selecting canopies with internal drainage systems to prevent water accumulation, thereby enhancing longevity. Regular maintenance checks after severe weather events can help identify potential issues early, ensuring safety and durability.

Illustrative image related to cantilever canopy

Scenario 2: Design and Aesthetic Compatibility

The Problem: Many buyers face the challenge of integrating cantilever canopies into existing architectural designs without compromising aesthetic appeal. In competitive markets, the visual impact of a business’s exterior can significantly influence customer perceptions and brand image. A poorly designed canopy can detract from the overall look of a building, leading to dissatisfaction and potential revenue loss.

The Solution: To address aesthetic concerns, buyers should work closely with manufacturers who offer customizable design options. Look for canopies that can be tailored in terms of color, shape, and materials to match the building’s existing style. Utilizing CAD (Computer-Aided Design) and BIM (Building Information Modeling) tools can facilitate visual planning and help visualize how different designs will fit into the overall architecture. Consider consulting with architects or design professionals who specialize in commercial structures to ensure that the canopy complements the brand’s image and enhances the overall customer experience. Leveraging modular designs can also provide flexibility for future expansions or modifications while maintaining visual coherence.

Scenario 3: Installation Complexity and Time Constraints

The Problem: Installation of cantilever canopies can often be complex and time-consuming, leading to project delays and increased labor costs. Buyers may face challenges in coordinating installation schedules, particularly when working with multiple contractors or during peak construction seasons. Delays can disrupt business operations, particularly in busy commercial environments where timely installation is critical.

The Solution: To streamline the installation process, buyers should seek manufacturers that provide comprehensive support, including detailed installation instructions, training for on-site personnel, and access to installation videos. Pre-engineered cantilever canopies can significantly reduce installation time, as they come with standardized components that are easier to assemble. Additionally, establishing clear communication channels with the manufacturer and contractors involved can facilitate better project management. When negotiating contracts, include timelines and milestones to ensure accountability. Finally, consider conducting a pre-installation meeting to address any potential issues and ensure everyone is aligned on the project’s scope, which can help mitigate delays and enhance efficiency during the installation phase.

Illustrative image related to cantilever canopy

Strategic Material Selection Guide for cantilever canopy

What Are the Key Materials for Cantilever Canopies?

When selecting materials for cantilever canopies, it is crucial to consider their properties, advantages, and limitations. Here, we analyze four common materials used in the construction of cantilever canopies: aluminum, steel, fiberglass, and polycarbonate. Each material presents unique characteristics that can significantly affect performance, cost, and suitability for various applications.

How Does Aluminum Perform as a Material for Cantilever Canopies?

Aluminum is a popular choice for cantilever canopies due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 300°F (149°C) and can withstand moderate pressure, making it suitable for a variety of climates.

Pros: Aluminum’s durability and low maintenance requirements make it an attractive option. It is also highly customizable and can be finished in various colors, enhancing aesthetic appeal.

Cons: The primary drawback is its relatively higher cost compared to other materials. Additionally, while aluminum is strong, it may not be as robust as steel in high-stress applications.

Illustrative image related to cantilever canopy

Impact on Application: Aluminum is ideal for urban environments where aesthetics and lightweight structures are essential. It is compatible with various media, including signage and lighting.

Considerations for International Buyers: In regions like Europe and the Middle East, compliance with standards such as ASTM and EN is essential. Buyers should also consider local climatic conditions to ensure the material’s performance.

What Are the Advantages of Steel for Cantilever Canopies?

Steel is known for its exceptional strength and load-bearing capacity, making it suitable for large cantilever canopies. It can withstand extreme temperatures and pressures, with a typical temperature rating exceeding 1,000°F (538°C).

Pros: Steel’s durability is unmatched, offering a long lifespan with minimal maintenance. It is also cost-effective for large-scale projects due to its availability and ease of fabrication.

Cons: The main limitation is its susceptibility to corrosion, requiring protective coatings or treatments, especially in humid or coastal environments. Additionally, its weight can complicate installation.

Impact on Application: Steel is ideal for commercial applications, such as parking garages and warehouses, where heavy loads are common. It can support various media, including heavy signage and lighting systems.

Considerations for International Buyers: Buyers in South America and Africa should be aware of local standards and corrosion protection requirements. Compliance with ASTM and JIS standards can enhance reliability.

How Does Fiberglass Compare as a Material for Cantilever Canopies?

Fiberglass is a composite material known for its lightweight and high strength-to-weight ratio. It is resistant to corrosion and can typically withstand temperatures up to 250°F (121°C).

Pros: Fiberglass offers excellent design flexibility and can be molded into various shapes. It is also low maintenance and resistant to UV radiation, making it suitable for outdoor applications.

Cons: The primary disadvantage is its higher manufacturing complexity, which can lead to increased costs. Additionally, fiberglass can be less durable than metal options in high-stress applications.

Impact on Application: Fiberglass is often used in recreational settings, such as poolside canopies, where aesthetics and UV protection are essential. It is compatible with various outdoor media.

Considerations for International Buyers: In regions like the Middle East, buyers should ensure compliance with local building codes and standards. The availability of fiberglass may vary, impacting project timelines.

Illustrative image related to cantilever canopy

What Role Does Polycarbonate Play in Cantilever Canopy Construction?

Polycarbonate is a thermoplastic material known for its high impact resistance and transparency. It can withstand temperatures ranging from -40°F to 240°F (-40°C to 116°C).

Pros: Polycarbonate is lightweight and offers excellent UV protection, making it ideal for outdoor canopies. It is also easy to install and can be manufactured in various colors and finishes.

Cons: While it is durable, polycarbonate can be prone to scratching and may not be as structurally sound as metal options. Its lifespan may be shorter than that of aluminum or steel.

Illustrative image related to cantilever canopy

Impact on Application: Polycarbonate is commonly used in applications where light transmission is desired, such as walkways and bus stops. It is compatible with various media, including signage and lighting.

Considerations for International Buyers: Buyers in Europe should ensure compliance with EU standards for safety and performance. The availability of polycarbonate may vary by region, affecting project timelines.

Summary of Material Selection for Cantilever Canopies

| Material | Typical Use Case for cantilever canopy | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Urban environments, signage | Lightweight, corrosion-resistant | Higher cost | Medium |

| Steel | Parking garages, warehouses | Exceptional strength | Susceptible to corrosion | Low |

| Fiberglass | Recreational settings, poolside | Design flexibility | Higher manufacturing complexity | Medium |

| Polycarbonate | Walkways, bus stops | UV protection, lightweight | Prone to scratching | Medium |

This guide provides a comprehensive overview of material options for cantilever canopies, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

Illustrative image related to cantilever canopy

In-depth Look: Manufacturing Processes and Quality Assurance for cantilever canopy

What Are the Key Stages in the Manufacturing Process of Cantilever Canopies?

The manufacturing process of cantilever canopies involves several critical stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages is essential for B2B buyers looking to partner with reliable suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process is material preparation, where high-quality raw materials, such as extruded aluminum and durable fabrics, are selected. Aluminum is favored for its strength-to-weight ratio and resistance to rust and corrosion, making it ideal for outdoor structures. Suppliers often source materials that comply with international standards, ensuring consistency and reliability.

Once the materials are sourced, they undergo cutting and shaping to meet specific project requirements. This may involve advanced techniques like CNC machining, which allows for precision in shaping components that will later be assembled into the final product.

Forming: What Techniques Are Used to Shape Cantilever Canopies?

In the forming stage, the processed materials are shaped into their final forms. Techniques such as extrusion and bending are commonly employed to create the aluminum components of the cantilever canopies. Extrusion allows for the production of complex shapes that can be tailored to meet architectural designs, while bending techniques ensure that the structural integrity is maintained.

Illustrative image related to cantilever canopy

Additionally, the fabric components may undergo processes like sewing and welding, ensuring that the canopies are both functional and aesthetically pleasing. The choice of fabric, often weather-resistant and UV-protected, is crucial for the longevity of the canopy.

Assembly: How Is the Canopy Constructed for Optimal Durability?

Assembly is a critical phase where all components come together. This process is typically done in a controlled environment to minimize the risks of contamination and defects. Skilled technicians use welding rather than through-fastening techniques, which enhances the structural integrity and reduces the likelihood of corrosion points.

During assembly, manufacturers also incorporate features such as internal drainage systems and custom detailing, which add to the functionality and aesthetic appeal of the canopies. Modular designs allow for flexibility in construction, enabling suppliers to cater to various project specifications.

Finishing: What Steps Are Taken to Enhance Aesthetics and Protection?

The finishing stage involves applying protective coatings and treatments to enhance the durability and appearance of the cantilever canopies. Anodizing or powder coating aluminum components provides a robust finish that resists fading and corrosion, vital for canopies exposed to harsh weather conditions.

For fabric components, treatments are applied to improve water resistance and UV protection, ensuring longevity and minimal maintenance. This stage not only adds to the aesthetic appeal but also extends the lifespan of the canopies, making them a worthwhile investment for businesses.

What Are the Quality Assurance Practices for Cantilever Canopies?

Quality assurance is paramount in the manufacturing of cantilever canopies, especially for B2B buyers who prioritize reliability and safety in their procurement processes.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 play a significant role in ensuring that manufacturers adhere to quality management principles. This certification indicates that the manufacturer has established a consistent quality management system, which is essential for maintaining product quality throughout the manufacturing process.

In addition to ISO standards, industry-specific certifications like CE marking for European markets and API standards for certain applications are crucial. These certifications ensure that the products meet specific safety and performance criteria relevant to their intended use.

Illustrative image related to cantilever canopy

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in cantilever canopy manufacturing typically involves several key checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to monitor compliance with quality standards. This includes checking dimensions, structural integrity, and finish quality.

-

Final Quality Control (FQC): Once the canopy is fully assembled, a comprehensive inspection is carried out to verify that the final product meets all design specifications and quality standards. This includes testing for structural stability and weather resistance.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should implement a thorough vetting process to ensure that their suppliers adhere to stringent quality control measures. This can include:

-

Audits: Conducting on-site audits to review the manufacturing processes and quality control practices. This provides insights into the supplier’s operational efficiency and adherence to standards.

-

Quality Reports: Requesting detailed quality control reports that outline the results of inspections and tests conducted at various stages of the manufacturing process.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These inspectors can verify compliance with international standards and provide certification where applicable.

What Are the Quality Control Nuances for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Import regulations may differ significantly across countries, affecting how products are certified and what standards are recognized.

Buyers should also be aware of the potential for variations in manufacturing practices based on local standards and regulations. Collaborating closely with suppliers who have experience in international trade can mitigate risks associated with quality discrepancies.

In conclusion, comprehensively understanding the manufacturing processes and quality assurance practices for cantilever canopies enables B2B buyers to make informed decisions. By focusing on key stages of manufacturing and implementing rigorous quality control measures, buyers can ensure they partner with suppliers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cantilever canopy’

To streamline your procurement process for cantilever canopies, this guide provides actionable steps that international B2B buyers can follow. Each step is designed to enhance decision-making, ensuring that you select the right canopy solution for your business needs.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your project requirements. This includes dimensions, load capacity, materials, and design aesthetics. A detailed specification helps ensure that suppliers understand your needs and can provide suitable options.

- Consider the environment: Evaluate weather conditions in your area to select materials that can withstand local climates.

- Think about usage: Determine the primary function of the canopy, whether for shading, branding, or structural support.

Step 2: Research and Shortlist Suppliers

Begin by identifying potential suppliers who specialize in cantilever canopies. Conduct online research, attend industry trade shows, and seek recommendations from peers.

- Check regional capabilities: Focus on suppliers with experience in your target regions, such as Africa, South America, the Middle East, and Europe, to ensure they understand local regulations and market demands.

- Review portfolios: Examine previous projects to gauge the supplier’s expertise and creativity.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This process not only confirms their reliability but also provides insight into their customer service levels.

- Assess certifications: Verify if the supplier meets international quality standards and holds relevant certifications.

- Inquire about warranties: Understand the warranty terms for both materials and workmanship to safeguard your investment.

Step 4: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotes that outline all costs associated with the cantilever canopies. This includes manufacturing, shipping, installation, and any additional services.

- Compare inclusions: Ensure that all quotes provide comparable details, including material specifications and lead times.

- Check for hidden costs: Be aware of potential extra charges that may arise during installation or maintenance.

Step 5: Assess Customization Options

Many projects require unique designs or specifications that standard products may not meet. Discuss customization options with potential suppliers to see how they can accommodate your specific needs.

- Explore design flexibility: Inquire about variations in colors, sizes, and additional features such as integrated lighting or signage.

- Understand the process: Clarify the timeline and processes for custom orders to avoid delays.

Step 6: Review Installation and Maintenance Support

The ease of installation and ongoing maintenance is critical for the longevity of your cantilever canopies. Confirm whether the supplier offers installation services and what kind of maintenance support is available.

- Ask about training: If you plan to handle installation in-house, ensure the supplier provides adequate training and documentation.

- Evaluate maintenance plans: Check if they offer maintenance contracts or guidance to prolong the lifespan of the canopies.

Step 7: Finalize Your Purchase Agreement

Once you are satisfied with your supplier and their offerings, finalize the purchase agreement. Ensure that it includes all agreed-upon terms, specifications, and timelines.

- Review the contract thoroughly: Pay close attention to clauses regarding delivery, installation, and warranties.

- Establish communication protocols: Set up clear lines of communication for ongoing project updates and support.

By following this checklist, you can make informed decisions that align with your business goals and project requirements when sourcing cantilever canopies.

Illustrative image related to cantilever canopy

Comprehensive Cost and Pricing Analysis for cantilever canopy Sourcing

What Are the Key Cost Components for Sourcing Cantilever Canopies?

When sourcing cantilever canopies, several cost components need to be considered to develop a comprehensive pricing analysis. These components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The primary cost driver in cantilever canopies is the materials used. Common materials include extruded aluminum, steel, and specialized fabrics for shade. The choice of material affects not just the initial cost but also the durability and maintenance requirements of the canopy.

-

Labor: Labor costs encompass the wages for skilled workers involved in the design, fabrication, and installation of the canopies. Higher labor costs can arise in regions with stricter labor regulations or where skilled labor is scarce.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help minimize overhead costs, which in turn can affect pricing.

-

Tooling: Tooling costs refer to the expenses incurred in the creation of molds and dies for production. Custom designs typically require more specialized tooling, which can increase upfront costs.

-

Quality Control (QC): Implementing stringent QC measures ensures that canopies meet safety and durability standards. However, this can also add to the overall cost, particularly if extensive testing is required.

-

Logistics: Transportation costs for shipping canopies to their final destination are significant, particularly for international orders. Factors such as distance, shipping method, and the complexity of the delivery can influence logistics costs.

-

Margin: Supplier margins vary based on competition, brand reputation, and the complexity of the product. Understanding the margin structure can provide insights into potential negotiation points.

How Do Pricing Influencers Impact Cantilever Canopy Costs?

Several factors can influence the pricing of cantilever canopies, including order volume, specifications, material quality, and supplier factors.

-

Volume/MOQ: Bulk orders generally lead to lower per-unit costs due to economies of scale. Minimum Order Quantities (MOQ) set by suppliers can also impact the overall cost if the buyer cannot meet these requirements.

-

Specifications and Customization: Custom designs tailored to specific applications often incur higher costs due to additional design and tooling expenses. Standardized designs may offer cost savings.

-

Material Quality and Certifications: Higher-quality materials that meet international certifications can command a premium price. Buyers should assess whether the added cost aligns with their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality may charge more, but they often provide better service and product assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they dictate the responsibilities of buyers and sellers regarding shipping costs, risk, and insurance. Choosing the right Incoterm can significantly affect total costs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Cantilever Canopies?

B2B buyers can adopt several strategies to maximize cost-efficiency when sourcing cantilever canopies:

-

Negotiate Terms: Engage in discussions with suppliers to negotiate pricing, payment terms, and bulk discounts. Understanding market conditions can provide leverage during negotiations.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess long-term costs, including maintenance, durability, and potential energy savings. A higher upfront cost may be justified by lower lifetime costs.

-

Be Aware of Pricing Nuances for International Purchases: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should account for currency fluctuations, import duties, and taxes, which can all influence final pricing.

-

Request Detailed Quotes: Obtain comprehensive quotes that break down costs into components. This transparency helps identify areas for potential savings and assists in comparing different suppliers.

-

Evaluate Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and priority service. Regular communication and feedback can foster loyalty and improve collaboration.

Disclaimer on Indicative Prices

Prices for cantilever canopies can vary widely based on the factors discussed above. The information provided is meant for guidance only, and actual costs should be confirmed with suppliers.

Alternatives Analysis: Comparing cantilever canopy With Other Solutions

Exploring Alternatives to Cantilever Canopies

In the quest for effective shading and shelter solutions, B2B buyers often encounter various options. While cantilever canopies provide a sleek and functional design, alternative solutions may offer different benefits that align more closely with specific project needs. This section compares cantilever canopies against two viable alternatives: traditional awnings and tensile fabric structures.

| Comparison Aspect | Cantilever Canopy | Traditional Awning | Tensile Fabric Structure |

|---|---|---|---|

| Performance | Excellent for creating shaded areas; unobstructed space underneath; robust against harsh weather. | Good for moderate shading; may sag over time; limited durability against strong winds. | Highly effective in sun and rain protection; flexible design allows for various shapes. |

| Cost | Moderate initial investment; lower long-term maintenance costs due to durability. | Generally lower upfront cost; potential for higher maintenance costs over time. | Higher initial cost; however, offers durability and long-term savings on maintenance. |

| Ease of Implementation | Requires professional installation but can be customized easily. | Easy to install; often available in pre-fabricated sizes. | Installation can be complex, requiring specialized knowledge for tensioning. |

| Maintenance | Low maintenance; periodic inspections recommended. | Moderate maintenance required; fabric may need replacement. | Low maintenance; regular inspections and cleaning needed. |

| Best Use Case | Ideal for commercial spaces needing aesthetic appeal and functionality, such as storefronts and parking lots. | Best suited for residential applications or smaller commercial spaces. | Excellent for large public spaces like parks, stadiums, and outdoor events where flexibility is key. |

What Are the Pros and Cons of Traditional Awnings?

Traditional awnings are a popular choice due to their affordability and ease of installation. They provide decent shade and can enhance the aesthetic appeal of a building. However, they may sag over time, especially if made from less durable materials. This can lead to a compromised appearance and reduced functionality. Awnings are best suited for smaller applications, such as residential homes or cafes, where lower upfront costs are prioritized over long-term durability.

How Do Tensile Fabric Structures Compare?

Tensile fabric structures are an innovative alternative that offers impressive versatility and aesthetic appeal. They can be designed in various shapes and sizes, allowing for unique architectural elements. Their ability to withstand harsh weather conditions makes them suitable for outdoor events and public spaces. However, the initial cost can be higher, and installation requires specialized knowledge to ensure proper tensioning and stability. These structures are ideal for large-scale projects where visual impact and flexibility are paramount.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate shading solution, B2B buyers should consider the specific requirements of their projects, including budget constraints, desired aesthetics, and functionality. Cantilever canopies are excellent for commercial settings requiring durability and a modern look. In contrast, traditional awnings may appeal to those looking for cost-effective, smaller-scale options, while tensile fabric structures cater to those seeking unique designs for larger spaces. By carefully assessing these factors, businesses can make informed decisions that align with their operational needs and brand identity.

Essential Technical Properties and Trade Terminology for cantilever canopy

What Are the Key Technical Properties of a Cantilever Canopy?

1. Material Grade

Cantilever canopies are typically constructed from high-grade materials such as aluminum or steel. Aluminum is favored for its lightweight and corrosion-resistant properties, making it ideal for outdoor applications. Steel, particularly galvanized or stainless steel, offers enhanced strength and durability. Selecting the right material grade is crucial for ensuring the canopy’s longevity and ability to withstand environmental stresses, such as heavy winds or rain. For B2B buyers, understanding material specifications can lead to informed decisions regarding maintenance and lifecycle costs.

2. Load Capacity

Load capacity refers to the maximum weight the canopy can support without compromising structural integrity. This specification is vital for applications like parking lots or walkways, where additional weight from snow, rain, or even pedestrian traffic must be considered. A canopy with a high load capacity ensures safety and functionality, reducing the risk of structural failure. Buyers should assess load capacity in relation to their specific installation environment and expected use to ensure compliance with safety standards.

3. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. For cantilever canopies, this can pertain to the fabrication of components, ensuring that parts fit together correctly during installation. Tight tolerances are essential for maintaining the aesthetic and functional qualities of the canopy. In a B2B context, understanding tolerance specifications helps buyers anticipate installation challenges and ensures that contractors can execute projects efficiently.

Illustrative image related to cantilever canopy

4. Customization Options

Customization options include the ability to tailor the design, color, and dimensions of the cantilever canopy to meet specific project requirements. This flexibility is particularly beneficial for branding purposes, allowing businesses to enhance their visual identity. For B2B buyers, recognizing the extent of customization available enables them to align the canopy design with their corporate branding and aesthetic preferences, potentially increasing customer engagement.

5. Installation Method

The installation method can vary based on the design of the cantilever canopy, with options including wall-mounted or freestanding configurations. A streamlined installation process is essential for minimizing downtime and project costs. Understanding the installation method also allows buyers to evaluate potential logistical challenges and the need for specialized labor or equipment.

6. Weather Resistance

Weather resistance is a critical property, ensuring that the canopy can withstand various environmental conditions, including UV exposure, rain, and extreme temperatures. This property is especially important for international buyers in regions prone to harsh weather. A canopy designed with high weather resistance can reduce maintenance costs and extend the structure’s lifespan, making it a wise investment.

Illustrative image related to cantilever canopy

What Common Trade Terms Should B2B Buyers Know Regarding Cantilever Canopies?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of cantilever canopies, buyers may work with OEMs to source specific components that meet their project specifications. Understanding OEM relationships can help buyers secure quality materials and ensure compatibility with existing structures.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For cantilever canopies, this can affect pricing and inventory management. B2B buyers should inquire about MOQs to gauge the feasibility of bulk purchasing and understand potential cost savings when ordering larger quantities.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. When considering cantilever canopies, an RFQ can help buyers compare costs, materials, and delivery timelines from multiple suppliers. This process is essential for budgeting and ensuring the best value for investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers, especially those sourcing cantilever canopies from international suppliers, as they clarify shipping costs and liability during transport.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times for cantilever canopies is essential for project planning and scheduling. Buyers should account for production, shipping, and potential delays to ensure timely project completion.

Illustrative image related to cantilever canopy

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions regarding cantilever canopies, ultimately enhancing project success and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the cantilever canopy Sector

What Are the Current Market Dynamics and Key Trends Influencing the Cantilever Canopy Sector?

The cantilever canopy market is experiencing significant growth driven by urbanization, increased commercial development, and a rising demand for functional outdoor spaces. In regions like Africa and South America, rapid urban expansion creates opportunities for businesses to enhance their physical presence through aesthetically pleasing and functional structures. In the Middle East and Europe, where architectural innovation is prioritized, cantilever canopies are becoming a staple for enhancing building facades and providing shade in public spaces.

Emerging trends include the integration of advanced materials and design technologies. For instance, the use of extruded aluminum for durability and lightweight structures is gaining traction, ensuring longevity even in harsh weather conditions. Additionally, the demand for customizable solutions that accommodate unique architectural styles is on the rise. International buyers are increasingly looking for suppliers who can offer modular designs that are easy to install and maintain, reducing overall project timelines and costs.

Another trend is the adoption of digital tools in the sourcing process. CAD and BIM technologies are enabling buyers to visualize and customize their projects before purchase, streamlining decision-making. This is particularly relevant for buyers in markets like Brazil and Saudi Arabia, where the focus on smart building solutions is intensifying. The combination of these factors is shaping a competitive landscape where flexibility, innovation, and efficiency are paramount.

How Is Sustainability and Ethical Sourcing Affecting the Cantilever Canopy Industry?

Sustainability has become a core consideration for B2B buyers in the cantilever canopy sector. The environmental impact of construction materials and practices is under scrutiny, prompting companies to adopt greener alternatives. Many manufacturers are now using recyclable materials and eco-friendly coatings that minimize environmental harm. This shift not only appeals to environmentally conscious consumers but also aligns with global sustainability goals.

Ethical sourcing is equally important. Buyers are increasingly demanding transparency in supply chains, seeking suppliers who adhere to fair labor practices and responsible sourcing. Certifications such as LEED (Leadership in Energy and Environmental Design) are gaining importance, providing assurance that the products meet specific sustainability criteria. This trend is particularly relevant in regions where regulatory frameworks are evolving to support sustainable construction practices.

Illustrative image related to cantilever canopy

Investing in green materials and ethical supply chains not only enhances a company’s brand reputation but can also lead to cost savings in the long run. As energy efficiency becomes a priority, opting for materials that offer better insulation or durability can reduce operational costs. Buyers who prioritize sustainability and ethics in their sourcing decisions are likely to find more favorable partnerships and a competitive edge in their markets.

What Is the Brief Evolution and Historical Context of Cantilever Canopies?

The concept of cantilever structures dates back to ancient architecture but gained prominence in modern construction during the 20th century. Originally used in bridges and large buildings, the cantilever design’s inherent strength and versatility have allowed it to expand into various applications, including canopies. The integration of new materials and technologies in the late 20th century further propelled the cantilever canopy’s development, allowing for innovative designs that blend functionality with aesthetic appeal.

In recent decades, the rise of urban landscapes has increased the demand for cantilever canopies as businesses seek to create inviting outdoor spaces. This evolution reflects broader architectural trends favoring minimalism and functionality, making cantilever canopies a popular choice for commercial and public buildings alike. Today, they serve not only as protective structures but also as essential elements in branding and enhancing customer experiences.

Frequently Asked Questions (FAQs) for B2B Buyers of cantilever canopy

-

How do I choose the right cantilever canopy for my business needs?

Selecting the appropriate cantilever canopy involves assessing your specific requirements, such as the intended use (e.g., shading, branding), location, and weather conditions. Consider factors like the size, style, and materials that align with your aesthetic preferences and functional needs. Collaborate with suppliers who offer customization options to tailor the canopy to your brand and operational needs. Additionally, review any applicable local regulations regarding structural installations to ensure compliance. -

What are the benefits of cantilever canopies for commercial spaces?

Cantilever canopies provide numerous advantages, including aesthetic appeal, improved customer comfort, and enhanced brand visibility. They create shaded areas without obstructing walkways, making them ideal for outdoor seating, entrances, and parking lots. Furthermore, these structures can protect vehicles and outdoor equipment from harsh weather, thereby prolonging their lifespan. The minimalistic design can also complement modern architecture, making your establishment more inviting to clients. -

What customization options are available for cantilever canopies?

Many manufacturers offer extensive customization options for cantilever canopies, including various colors, materials, sizes, and designs to match your branding and functional requirements. You can select from different fascia styles, deck profiles, and support configurations. Discuss your specific needs with potential suppliers to explore their capabilities and ensure they can provide a solution that aligns with your vision. -

What are the typical minimum order quantities (MOQ) for cantilever canopies?

Minimum order quantities (MOQ) for cantilever canopies can vary significantly among suppliers. Some manufacturers may require a MOQ for custom designs, while others might offer flexibility for smaller orders, especially for standard models. It’s essential to inquire about MOQs upfront during your supplier discussions to ensure that your purchasing plans align with their production capabilities. -

What payment terms should I expect when sourcing cantilever canopies internationally?

Payment terms for international purchases of cantilever canopies often vary based on supplier policies, order size, and your business relationship. Common terms include a deposit upon order confirmation, followed by balance payment before shipping or upon delivery. It’s prudent to clarify payment methods (e.g., bank transfer, letter of credit) and any potential currency exchange implications during negotiations to avoid misunderstandings. -

How do I vet suppliers for cantilever canopies?

When vetting suppliers for cantilever canopies, consider their experience, reputation, and product quality. Request references from previous clients and review case studies of similar projects. Verify certifications and compliance with international standards, particularly regarding safety and durability. Additionally, assess their ability to provide after-sales support, warranty terms, and responsiveness to inquiries to ensure a reliable partnership. -

What quality assurance measures should I look for in cantilever canopies?

Quality assurance for cantilever canopies should encompass rigorous testing of materials and structural integrity. Look for suppliers that adhere to recognized industry standards and certifications, such as ISO or ASTM. Request documentation detailing their QA processes, including inspections, testing protocols, and warranties. A reputable supplier should be transparent about their quality control measures and willing to provide you with product specifications and testing results. -

What are the logistics considerations for importing cantilever canopies?

Importing cantilever canopies involves several logistics considerations, including shipping methods, customs regulations, and delivery timelines. Assess the supplier’s shipping options and whether they can handle international logistics. Understand the import duties and taxes applicable in your country, and ensure that the supplier provides all necessary documentation for customs clearance. Planning ahead for potential delays and ensuring proper packaging can also help mitigate risks during transportation.

Top 6 Cantilever Canopy Manufacturers & Suppliers List

1. Mapes – Cantilever Canopies

Domain: mapescanopies.com

Registered: 2005 (20 years)

Introduction: The Mapes line of Cantilever Canopies is engineered with support brackets for a clean streetscape sightline and minimalistic look. Available styles include Super Lumideck, Lumishade, and SuperShade. Features include: minimalism meets function, deck profiles combined with differing fascias, pre-engineered custom colors, modular design, internal drainage, economical custom details, and high load cap…

2. SKYSCAPE® – Cantilevered Canopies

Domain: skyscapecanopies.com

Registered: 2016 (9 years)

Introduction: Cantilevered canopies eliminate the need for hanger supports, allowing flexibility in multiple wall and building conditions. They provide a clean, streamlined look that enhances a building’s entry and façade, highlighting signage and brand awareness. SKYSCAPE® Canopies are made from extruded aluminum components, offering strength and durability, capable of withstanding harsh weather conditions wit…

3. SunGarden – Replacement Canopies

Domain: sungarden.us

Registered: 2006 (19 years)

Introduction: Replacement canopies for various umbrella models. Key products include: 1. 10.5′ Square Design Replacement Canopy (fits 86″ long rib & 62″ short rib) – Sale Price: $499.00 (Original Price: $599.00) – Colors: Java Brown, French Canvas, Indigo Blue, Modern Charcoal, Cafe Latte. 2. 11.5T Designer Series Replacement Canopy with Valance (fits 66″ 8 flat rib) – Sale Price: $499.00 (Original Price: $599….

4. Fenwalls – London Series Cantilevered Canopy™

Domain: fenwalls.com

Registered: 2014 (11 years)

Introduction: London Series Cantilevered Canopy™ is a pre-engineered water-control canopy featuring an integral ‘G’ shaped gutter main frame for optimal water management and an internal steel outrigger structure for support and rigidity. It has standard flashing between the canopy and the structure, with no visible exterior support. Customizable in style, color, and design for branding purposes. Available optio…

5. Greenville Awning – Cantilevered Canopies

Domain: greenvilleawning.com

Registered: 1997 (28 years)

Introduction: Cantilevered canopies utilize an internal support system for shade and a modern design aesthetic. Available in solid decking and louvered decking styles, with customizable fascia options. Canopy projections up to 5 feet. Constructed of aluminum to prevent corrosion, featuring a super durable powder-coated finish for excellent weather resistance. Job-specific engineering available. A wide variety o…

6. Brooklyn Solar – Cantilever Canopy Solutions

Domain: brooklynsolarcanopy.com

Registered: 2018 (7 years)

Introduction: Cantilever – Brooklyn Solar Canopy Solutions

– Type: Commercial Ground Mount Solution

– Material: American made aluminum (6061-GA)

– Weight: Lightweight and easy to install

– Configurations: Standardized modular configurations or custom engineered

– Size Constraints: No size constraints for projects

– Color Options: Black or White

– Finish Options: Matte or Mill Finish

– Panel Compatibility: Panel…

Strategic Sourcing Conclusion and Outlook for cantilever canopy

In navigating the competitive landscape of cantilever canopies, strategic sourcing emerges as a vital component for international B2B buyers. By selecting high-quality materials and reliable suppliers, businesses can ensure durability, aesthetic appeal, and functionality tailored to diverse applications, from retail environments to commercial spaces. The versatility of cantilever canopies, combined with their minimalistic design, enhances brand visibility and improves customer experience, making them an invaluable asset in various sectors.

Moreover, understanding regional market trends and preferences is essential for buyers from Africa, South America, the Middle East, and Europe. This knowledge allows for informed decisions that align with local architectural styles and environmental conditions.

Looking ahead, the demand for innovative cantilever solutions is set to rise, driven by the need for sustainable and aesthetically pleasing structures. We encourage international buyers to explore partnerships with reputable manufacturers who offer customizable options and robust support throughout the sourcing process. Investing in cantilever canopies today will position your business for success in an evolving marketplace, where functionality meets design.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.