A B2B Buyer’s Guide to Can You Nickel Plate Aluminum: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for can you nickel plate aluminum

In today’s competitive manufacturing landscape, the question of whether you can nickel plate aluminum presents both a challenge and an opportunity for international B2B buyers. Nickel plating not only enhances the appearance of aluminum components but also significantly improves their durability and resistance to corrosion. However, navigating the complexities of this process, including selecting the right plating method and ensuring optimal surface preparation, can be daunting for businesses across Africa, South America, the Middle East, and Europe, such as Brazil and Vietnam.

This comprehensive guide aims to demystify the nickel plating process for aluminum by exploring various types of plating techniques—such as electroplating and electroless nickel plating—and their specific applications. We will provide insights into supplier vetting, highlighting key considerations to ensure you partner with reputable manufacturers who meet international standards. Additionally, the guide will delve into cost factors, helping you understand pricing structures based on surface area, thickness, and specific requirements.

By equipping you with essential knowledge and actionable insights, this guide empowers B2B buyers to make informed purchasing decisions. Whether you are looking to enhance the functionality of aluminum parts or seeking to elevate your product’s aesthetic appeal, understanding the nuances of nickel plating will position your business for success in the global marketplace.

Understanding can you nickel plate aluminum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nickel Electroplating | Requires electrical current; produces bright finishes. | Automotive, aerospace, decorative items. | Pros: Excellent aesthetic finish, good corrosion resistance. Cons: Requires meticulous surface preparation. |

| Electroless Nickel Plating | No electrical current; chemically deposits nickel. | Electronics, engineering components. | Pros: Uniform coating, good for complex shapes. Cons: Slower process, higher cost. |

| Black Nickel Plating | Offers a matte, dark finish; typically used for aesthetics. | Decorative applications, jewelry. | Pros: Unique appearance, good corrosion resistance. Cons: Limited to specific applications; may require additional finishing steps. |

| Nickel Sulfamate Plating | Provides better dimensional control and corrosion resistance. | Engineering parts, sublayer for chrome. | Pros: Strong and durable, suitable for heavy-duty applications. Cons: More expensive than standard nickel plating. |

| Hard Coat Anodizing | Provides a thick, durable layer; often used as an alternative to nickel plating. | Aerospace, military, industrial. | Pros: Exceptional wear resistance, non-conductive. Cons: Limited aesthetic appeal compared to nickel finishes. |

What Are the Key Characteristics of Nickel Electroplating?

Nickel electroplating involves applying a nickel layer through an electrolytic process, requiring both the part and the coating to be metallic. This method is favored for its bright finishes and excellent corrosion resistance, making it ideal for automotive and aerospace applications. However, the surface must be meticulously prepared to avoid imperfections, which can significantly impact the final appearance. B2B buyers should consider the cost associated with preparation and the potential for aesthetic enhancement in their applications.

How Does Electroless Nickel Plating Differ from Other Methods?

Electroless nickel plating is a chemical process that does not require electrical current, allowing for uniform coating on complex geometries. This method is particularly suitable for electronic components where precision and consistency are crucial. While it offers advantages in terms of coating uniformity, the process can be slower and more costly than traditional electroplating. B2B buyers should weigh the benefits of enhanced coating properties against the increased time and financial investment.

What Are the Benefits of Black Nickel Plating?

Black nickel plating provides a distinctive matte finish, often chosen for decorative purposes in items such as jewelry and consumer electronics. This finish not only enhances the aesthetic appeal but also offers good corrosion resistance. However, its application is somewhat limited, and additional finishing steps may be necessary to achieve the desired look. Buyers should assess whether the unique appearance aligns with their branding and product requirements.

Why Choose Nickel Sulfamate Plating for Engineering Applications?

Nickel sulfamate plating is known for its superior dimensional control and enhanced corrosion resistance, making it ideal for engineering components that require high durability. This type of plating is often used as a sublayer for chrome plating, providing a robust foundation. While it is more expensive than standard nickel plating, its performance in heavy-duty applications justifies the investment for B2B buyers focused on longevity and reliability.

When Should Hard Coat Anodizing Be Considered Instead of Nickel Plating?

Hard coat anodizing offers a thick, durable layer that excels in wear resistance, making it a preferred choice for aerospace and military applications. Unlike nickel plating, which can provide a shiny finish, hard anodizing typically lacks aesthetic appeal but compensates with its strength and non-conductive properties. Buyers should consider this option when durability and functionality take precedence over appearance, especially in demanding environments.

Key Industrial Applications of can you nickel plate aluminum

| Industry/Sector | Specific Application of can you nickel plate aluminum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Component manufacturing for aircraft | Enhances corrosion resistance and durability of lightweight parts | Compliance with aerospace standards and specifications |

| Automotive | Engine parts and exterior components | Improves wear resistance and aesthetic appeal | Precision in plating thickness and surface finish requirements |

| Electronics | Housing for electronic devices | Provides electromagnetic shielding and thermal management | Ensuring compatibility with electronic components and thermal needs |

| Medical Devices | Surgical instruments and implants | Increases biocompatibility and reduces oxidation | Adherence to medical standards and quality control |

| Oil & Gas | Equipment and pipeline components | Protects against harsh environmental conditions and corrosion | Consideration of material compatibility and environmental impact |

How is Nickel Plating Aluminum Used in the Aerospace Industry?

In the aerospace sector, nickel plating aluminum is crucial for manufacturing components that require both lightweight properties and high durability. The process enhances corrosion resistance, which is vital for parts exposed to harsh atmospheric conditions. Buyers must ensure that the plating meets stringent aerospace standards and specifications, particularly regarding thickness and surface finish, to guarantee safety and performance.

What Role Does Nickel Plating Aluminum Play in the Automotive Sector?

Automotive manufacturers utilize nickel plating on engine parts and exterior components to improve wear resistance and aesthetic appeal. This process not only protects parts from corrosion but also provides a shiny finish that enhances the vehicle’s appearance. Buyers in this sector should focus on precision in plating thickness and surface finish, as these factors directly impact the performance and longevity of automotive components.

How is Nickel Plating Beneficial for Electronics?

In electronics, nickel plating aluminum is used for housings and connectors, providing essential electromagnetic shielding and thermal management. This application is critical for maintaining device performance and longevity. B2B buyers should consider the compatibility of the nickel plating with electronic components and ensure that thermal conductivity meets the specific needs of their devices, which is especially important in regions with varying climate conditions.

Why is Nickel Plating Important for Medical Devices?

Nickel plating is applied to surgical instruments and implants to enhance biocompatibility and reduce oxidation. This is essential for ensuring the safety and efficacy of medical devices. Buyers must prioritize adherence to rigorous medical standards and quality control processes, as any defect could compromise patient safety. Additionally, sourcing from suppliers who understand the medical device regulations is crucial for compliance and reliability.

How Does Nickel Plating Protect Equipment in Oil & Gas?

In the oil and gas industry, nickel plating aluminum components is essential for protecting against harsh environmental conditions and corrosion. This is particularly important for equipment and pipeline components that are exposed to aggressive substances. B2B buyers should consider the compatibility of the nickel plating with various materials and the environmental impact, ensuring that the plating process aligns with industry regulations and sustainability goals.

3 Common User Pain Points for ‘can you nickel plate aluminum’ & Their Solutions

Scenario 1: Inconsistent Quality in Nickel Plating Aluminum Parts

The Problem: B2B buyers often encounter issues with the quality of nickel plating on aluminum parts. Variability in plating thickness, adhesion, and surface finish can lead to parts that do not meet specifications or perform as required. This inconsistency can result in increased production costs, project delays, and dissatisfaction from end customers. Buyers may feel frustrated, especially when they have invested time and resources into sourcing and preparing their aluminum components for plating.

The Solution: To mitigate quality issues, it is essential to partner with a reputable nickel plating service that specializes in aluminum. Before committing to a vendor, request samples of their previous work and verify adherence to industry standards. Specify the desired plating thickness and finish, and ensure that the vendor understands the importance of consistent quality. In addition, consider implementing a quality assurance process that includes inspection of the plated parts upon receipt. This can involve measuring the thickness of the plating and visually inspecting for defects. By taking these steps, buyers can enhance their confidence in the nickel plating process and ensure they receive high-quality products.

Scenario 2: High Costs of Nickel Plating Aluminum Components

The Problem: Many B2B buyers are surprised by the costs associated with nickel plating aluminum parts. The pricing structure can be complex, often based on surface area, thickness, and the specific processes used (e.g., electroless vs. electroplating). Buyers may struggle to understand the breakdown of costs, leading to budget overruns and unexpected expenses. Additionally, if the aluminum parts are not adequately prepared, this can further inflate costs due to additional surface treatment requirements.

The Solution: To control costs, buyers should engage in thorough upfront discussions with their plating service providers to clarify pricing structures. Request detailed quotes that outline the costs associated with each aspect of the plating process. This includes surface preparation, masking, and any additional treatments required. Buyers can also explore bulk pricing options if they have large volumes of parts to plate. By ensuring that the aluminum components are properly cleaned, polished, and prepared before plating, buyers can avoid extra charges related to inadequate preparation. This proactive approach will streamline the plating process and help maintain budgetary goals.

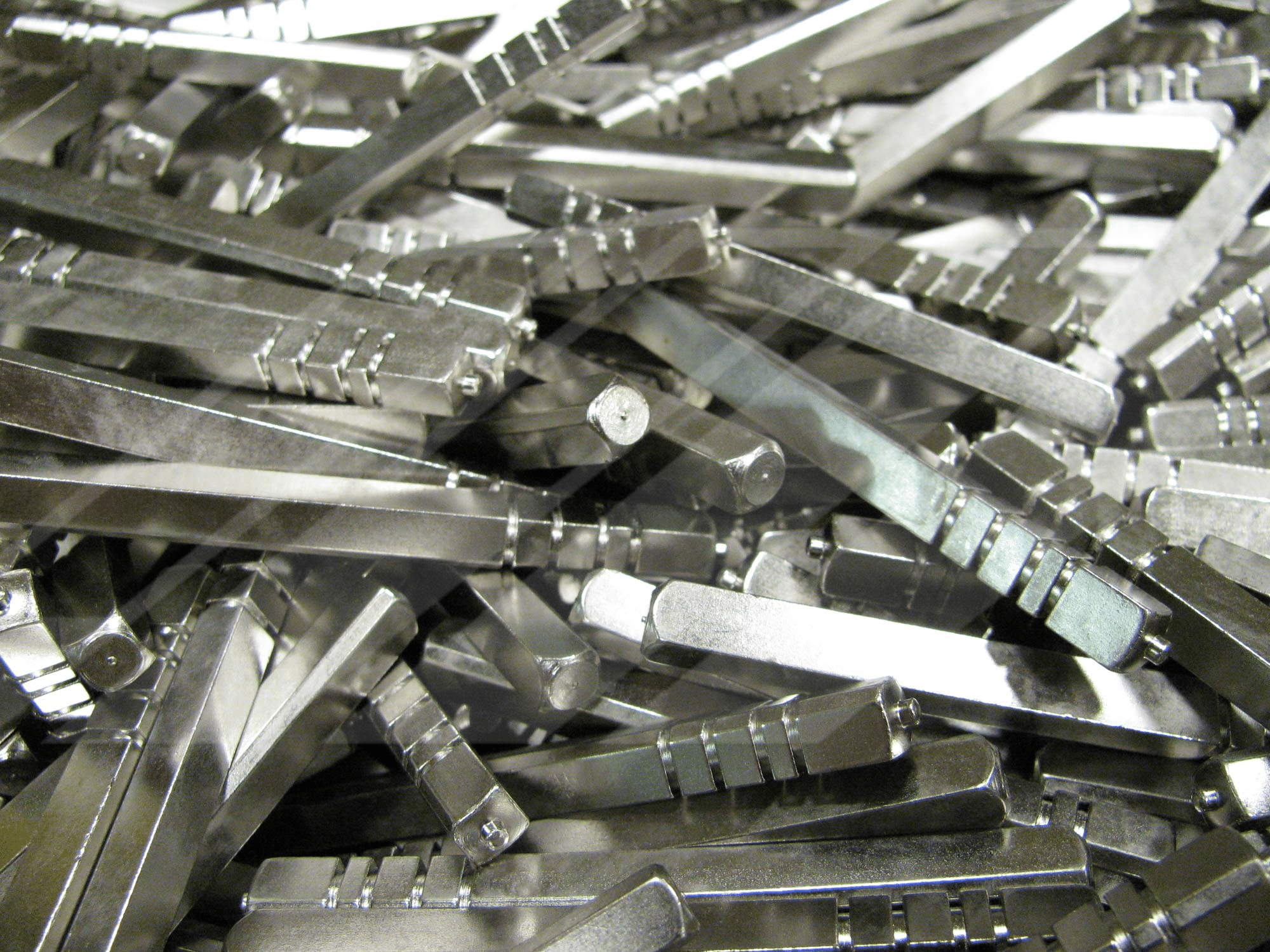

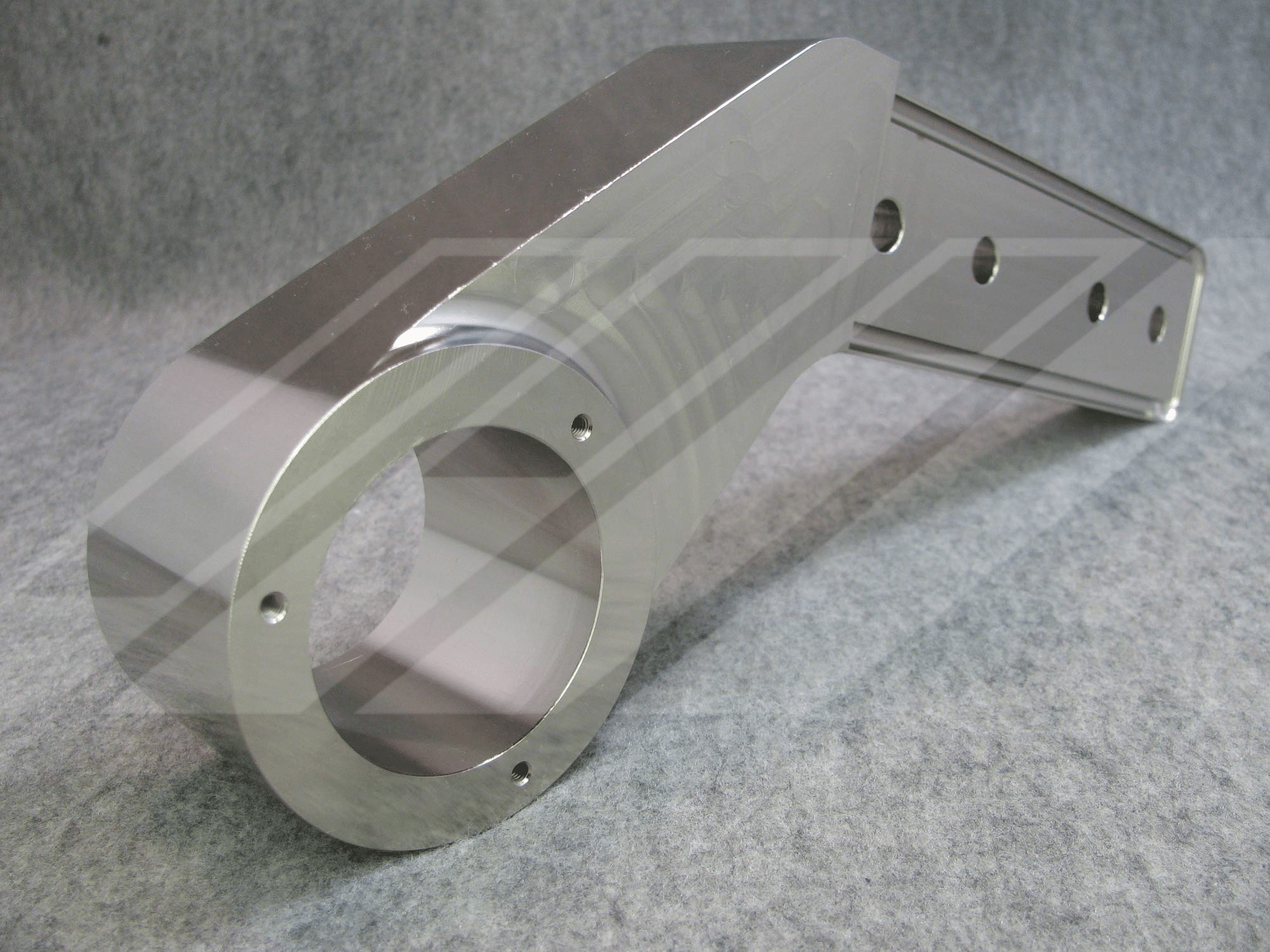

Illustrative image related to can you nickel plate aluminum

Scenario 3: Limited Knowledge on Nickel Plating Processes

The Problem: B2B buyers may lack comprehensive knowledge about the various nickel plating processes available for aluminum, such as electroless nickel plating and traditional electroplating. This can lead to improper material selection, resulting in suboptimal performance and potential failures in the end application. Furthermore, buyers may struggle to communicate their needs effectively to plating service providers, which can result in misunderstandings and mismatched expectations.

The Solution: To bridge the knowledge gap, buyers should invest time in understanding the differences between nickel plating processes. Conduct research or attend workshops that focus on surface finishing techniques. Additionally, when engaging with plating service providers, come prepared with specific questions regarding their processes, such as the type of nickel used, the required surface preparation, and the expected performance characteristics of the finished product. Establishing a collaborative relationship with the plating provider can also facilitate better communication and ensure that the buyer’s needs are met effectively. By becoming more informed about nickel plating, buyers can make better decisions that align with their project requirements and improve overall outcomes.

Strategic Material Selection Guide for can you nickel plate aluminum

What Are the Key Materials for Nickel Plating Aluminum?

When considering nickel plating for aluminum components, several materials are commonly involved in the process. Each material offers distinct properties and implications for performance, cost, and suitability for various applications. Below are analyses of three key materials used in nickel plating aluminum.

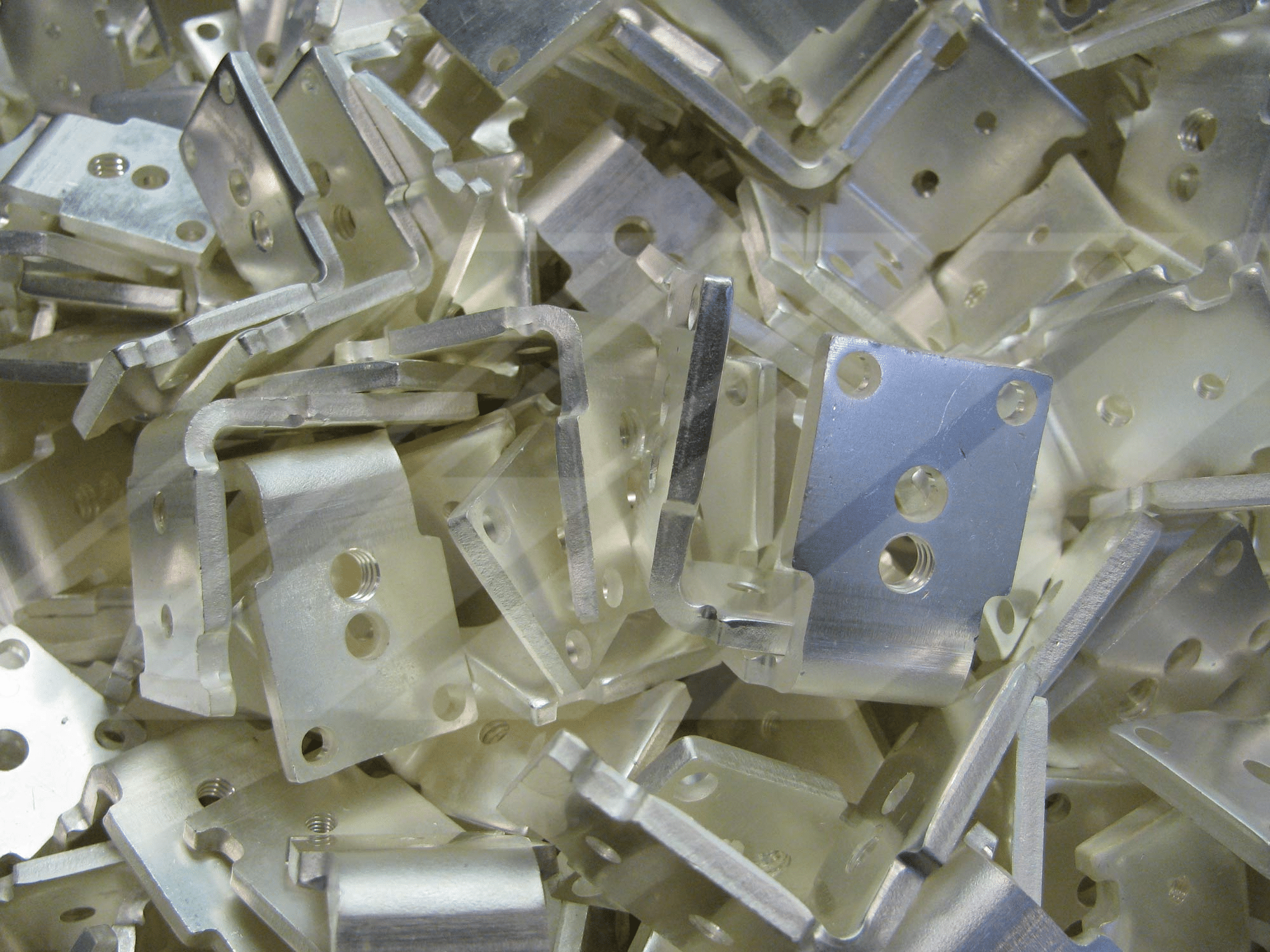

Illustrative image related to can you nickel plate aluminum

1. Nickel Sulfamate

Key Properties:

Nickel sulfamate is a widely used electrolyte in nickel electroplating processes. It provides excellent corrosion resistance and wear properties, making it suitable for engineering applications. Its ability to offer better dimensional control is crucial for precision components.

Pros & Cons:

The primary advantage of nickel sulfamate is its superior ability to produce a smooth, uniform coating that enhances the aesthetic appeal and durability of aluminum parts. However, the process can be more complex and costlier than other nickel plating methods due to the need for specialized equipment and careful handling of chemicals.

Impact on Application:

Nickel sulfamate is particularly effective in environments where corrosion resistance is critical, such as automotive and aerospace applications. Its compatibility with various media makes it a preferred choice for high-performance components.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local regulations regarding chemical handling and waste disposal. Familiarity with international standards such as ASTM and JIS can facilitate smoother transactions and quality assurance.

2. Electroless Nickel Plating (EN)

Key Properties:

Electroless nickel plating involves a chemical reaction that deposits nickel without the need for electrical current. This process allows for uniform coating on complex geometries, ensuring that even hard-to-reach areas are effectively plated.

Illustrative image related to can you nickel plate aluminum

Pros & Cons:

The main advantage of electroless nickel plating is its ability to provide a consistent thickness across all surfaces, which is essential for parts with intricate designs. However, the process can be slower than electroplating and may require additional surface preparation to eliminate impurities.

Impact on Application:

EN is particularly beneficial in applications requiring high wear resistance and corrosion protection, such as in the oil and gas industry. Its versatility makes it suitable for a wide range of components, from small fasteners to large structural parts.

Considerations for International Buyers:

International buyers should be aware of the varying quality standards across regions. Ensuring that suppliers adhere to recognized standards can mitigate risks associated with performance and compliance.

3. Copper Flashing

Key Properties:

Copper flashing is often used as a preparatory step before nickel plating aluminum. It serves as a conductive layer that improves adhesion between the aluminum substrate and the nickel coating.

Pros & Cons:

The advantage of using copper flashing is that it allows for better surface preparation, which can significantly enhance the final appearance of the nickel plating. However, the additional step can increase manufacturing complexity and cost.

Illustrative image related to can you nickel plate aluminum

Impact on Application:

Copper flashing is particularly useful in applications where aesthetic appeal is important, such as decorative components. It also improves the overall durability of the final product by providing a robust base for the nickel layer.

Considerations for International Buyers:

Buyers should consider the availability of copper and the associated costs in their regions. Understanding local market dynamics can help in making informed decisions regarding material selection.

Summary Table of Material Options for Nickel Plating Aluminum

| Material | Typical Use Case for can you nickel plate aluminum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nickel Sulfamate | Automotive and aerospace components | Excellent corrosion resistance and wear properties | Higher complexity and cost | High |

| Electroless Nickel | Oil and gas industry components | Uniform thickness on complex geometries | Slower process and requires careful surface prep | Medium |

| Copper Flashing | Decorative aluminum components | Enhances adhesion and final appearance | Increases manufacturing complexity and cost | Medium |

This analysis provides a comprehensive overview of the materials involved in nickel plating aluminum, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers. Understanding these factors can help businesses make informed decisions that align with their operational needs and market conditions.

Illustrative image related to can you nickel plate aluminum

In-depth Look: Manufacturing Processes and Quality Assurance for can you nickel plate aluminum

What Are the Key Stages in the Manufacturing Process of Nickel Plating Aluminum?

Nickel plating aluminum involves a meticulous manufacturing process that encompasses several crucial stages, ensuring that the final product meets the desired specifications for both functionality and aesthetics. Understanding these stages is vital for B2B buyers, particularly when sourcing from international suppliers.

1. Material Preparation: How Is Aluminum Prepared for Nickel Plating?

Before aluminum parts can be nickel plated, they must undergo thorough preparation. This process typically includes:

- Cleaning: The aluminum surface is cleaned to remove any contaminants, oils, or residues that could affect plating adhesion. Common cleaning methods involve alkaline cleaning solutions and ultrasonic cleaning.

- Surface Etching: After cleaning, etching is performed using acidic solutions to enhance the surface roughness, improving the mechanical bonding of the nickel layer.

- Pickling: This step involves treating the aluminum with a mild acid to remove any oxide layers that may have formed, further preparing the surface for plating.

- Masking: For parts with areas that should not be plated, masking with lacquer or other protective materials is essential to avoid unwanted coverage during the plating process.

2. Forming: What Techniques Are Used in the Nickel Plating Process?

The nickel plating itself can be performed using two primary techniques: electroplating and electroless plating.

- Electroplating: This method requires electrical current to deposit nickel ions from a solution onto the aluminum substrate. The process involves immersing the aluminum part in an electrolyte bath where nickel salts are dissolved. The part acts as a cathode, attracting the nickel ions, which deposit onto its surface.

- Electroless Nickel Plating: Unlike electroplating, this method does not require electrical current. Instead, nickel ions are deposited through a chemical reaction, allowing for uniform coating even on complex geometries. This process often includes an additional step to manage “smut” (black soot) that may form on aluminum during plating.

What Quality Control Standards Should B2B Buyers Look for in Nickel Plating?

Quality assurance is a critical aspect of the nickel plating process. Buyers should be aware of relevant international standards and industry-specific certifications that suppliers must adhere to, ensuring the reliability and quality of plated parts.

1. What International Standards Are Essential for Nickel Plating Quality Assurance?

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring that suppliers maintain consistent quality in their processes.

- ISO 14001: Environmental management standards are also relevant, as they ensure that the plating process adheres to environmental regulations.

- Industry-Specific Standards: Depending on the application, certifications such as CE marking for European markets or API specifications for oil and gas applications may also be pertinent.

2. What Are the Key Quality Control Checkpoints in the Nickel Plating Process?

Quality control is generally structured around several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified requirements before processing begins.

- In-Process Quality Control (IPQC): During the nickel plating process, real-time monitoring is essential. Parameters such as temperature, pH levels of the plating solution, and current density are regularly checked.

- Final Quality Control (FQC): After plating, parts undergo a final inspection to assess the thickness and adhesion of the nickel layer, using techniques such as micrometers or X-ray fluorescence (XRF) for precise measurement.

How Can B2B Buyers Verify Supplier Quality Control Measures?

Ensuring that suppliers maintain robust quality control measures is crucial for B2B buyers, particularly when sourcing from diverse international markets.

Illustrative image related to can you nickel plate aluminum

1. What Are Effective Methods for Conducting Supplier Audits?

Buyers can employ several strategies to verify supplier quality control:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate manufacturing processes, quality control systems, and adherence to international standards firsthand.

- Quality Control Reports: Requesting regular quality reports can provide insights into the supplier’s quality management practices and any corrective actions taken in response to issues.

- Third-Party Inspections: Engaging independent inspection services can validate the quality of the plating process and the final products, providing an unbiased evaluation of the supplier’s capabilities.

2. What Are the Unique Quality Control Considerations for International Buyers?

International buyers must navigate specific nuances when dealing with suppliers from different regions:

- Regulatory Compliance: Understanding regional regulations, such as REACH in Europe or environmental laws in South America, is essential for compliance.

- Cultural Differences: Different regions may have varying approaches to quality and inspection processes. Establishing clear communication and expectations is vital.

- Logistical Challenges: Shipping and transportation can introduce risks that may affect product quality. Buyers should ensure that suppliers have robust packaging and handling procedures.

Conclusion

The manufacturing processes and quality assurance protocols for nickel plating aluminum are intricate yet essential for ensuring high-quality outputs. B2B buyers must be vigilant in assessing suppliers, focusing on preparation techniques, plating methods, and quality control measures aligned with international standards. By leveraging these insights, businesses can make informed decisions when sourcing nickel-plated aluminum products across global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you nickel plate aluminum’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure nickel plating services for aluminum parts. Nickel plating enhances the durability and aesthetic appeal of aluminum, making it a popular choice in various industries. By following these steps, you will ensure a successful sourcing process and find a reliable supplier that meets your technical and budgetary requirements.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the nickel plating process, including dimensions, coating thickness, and finish type. This step is critical as it helps suppliers provide accurate quotes and ensures that the final product meets your quality standards. Consider factors such as:

– Surface area: Measure the total square inches of the parts you need plated.

– Coating type: Determine whether you need electroless nickel plating or traditional electroplating based on your application.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers specializing in nickel plating aluminum. Look for companies with a proven track record in your industry to ensure they understand your specific needs. Key aspects to consider include:

– Experience: Assess how long they have been in the plating business and their expertise with aluminum.

– Capabilities: Ensure they can handle your order volume and specific requirements.

Step 3: Evaluate Supplier Certifications and Compliance

Before finalizing any agreements, verify that your shortlisted suppliers have the necessary certifications, such as ISO 9001, which indicates quality management systems. Compliance with environmental regulations is also essential, especially when dealing with hazardous materials. Consider checking:

– Certifications: Request documentation that proves their adherence to industry standards.

– Environmental practices: Inquire about their waste management and pollution control measures.

Step 4: Request Detailed Quotations

Once you have identified potential suppliers, request detailed quotations that outline pricing, lead times, and terms of service. This step is vital to compare offers effectively. Look for:

– Pricing structure: Understand whether they charge based on weight, surface area, or part complexity.

– Turnaround times: Confirm how quickly they can deliver your parts after plating.

Step 5: Assess Quality Control Processes

Inquire about the quality control measures the supplier has in place to ensure consistent results. A robust quality assurance process will minimize defects and ensure the coating meets your specifications. Key questions to ask include:

– Inspection methods: What techniques do they use to assess the quality of the plating?

– Rework policies: How do they handle issues with defects or non-conformance?

Step 6: Review Customer References and Case Studies

Seek testimonials and case studies from previous clients, especially those in similar industries or regions. This feedback can provide insights into the supplier’s reliability and service quality. Focus on:

– Success stories: Look for examples where the supplier delivered exceptional results under similar conditions.

– Client feedback: Assess overall satisfaction regarding communication, delivery, and product quality.

Step 7: Finalize Agreements and Place Orders

After thorough evaluation, finalize contracts with your chosen supplier, ensuring all terms are clearly defined. Pay attention to details such as payment terms, delivery schedules, and warranty conditions. This final step is crucial to establishing a successful partnership and ensuring smooth project execution.

Comprehensive Cost and Pricing Analysis for can you nickel plate aluminum Sourcing

What Are the Key Cost Components in Nickel Plating Aluminum?

When sourcing nickel plating services for aluminum, understanding the cost structure is crucial for international B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The cost of nickel itself, along with any additional chemicals required for the electroplating process, forms a significant part of the total expenses. The type of nickel plating—electrolytic versus electroless—also affects material costs due to differing chemical requirements.

-

Labor: Skilled labor is necessary for the preparation, plating, and finishing processes. The complexity of the job, including pre-treatment and post-treatment steps, can influence labor costs. Regions with higher labor costs may lead to increased pricing for the service.

-

Manufacturing Overhead: This includes facility costs, utilities, and equipment maintenance. The efficiency of the plating operation can vary significantly based on the technology and processes used, influencing overhead expenses.

-

Tooling: Custom tooling may be required for specific parts, particularly if unique geometries or features are involved. Tooling costs can add a substantial amount to the overall pricing, especially for low-volume orders.

-

Quality Control (QC): Ensuring that the nickel plating meets specified standards involves rigorous quality checks. The costs associated with QC processes, including testing for thickness and adhesion, should be factored into the pricing.

-

Logistics: Shipping costs can vary based on the distance and methods used. For international buyers, understanding Incoterms is essential to assess which party bears these costs.

-

Margin: Finally, suppliers will add a margin to cover their profit, which can vary widely based on market competition and the perceived value of their service.

How Do Price Influencers Impact Nickel Plating Costs?

Numerous factors can influence the pricing of nickel plating services:

-

Volume and Minimum Order Quantity (MOQ): Higher volume orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk orders, making it advantageous for buyers with consistent needs.

-

Specifications and Customization: Custom requirements, such as specific thicknesses or finishes, can increase costs. Standardized parts typically incur lower costs, while bespoke solutions may involve additional processing and materials.

-

Materials and Quality Certifications: The choice of nickel type (e.g., low, medium, or high phosphorus) can affect both the price and performance characteristics of the plating. Additionally, suppliers with industry certifications may charge a premium for their assurance of quality.

-

Supplier Factors: The reputation and capabilities of the supplier play a crucial role. Established suppliers with advanced technology may command higher prices but offer greater reliability and quality assurance.

What Negotiation and Cost-Efficiency Tips Should International Buyers Consider?

For B2B buyers, particularly in Africa, South America, the Middle East, and Europe, there are several strategies to maximize cost-efficiency in sourcing nickel plating services:

-

Leverage Volume Discounts: If your business has the capacity, consolidating orders can yield significant savings. Discuss potential volume commitments with suppliers to secure better pricing.

-

Clarify Specifications: Be explicit about your requirements to avoid unexpected costs. Ensure that you communicate any specific quality standards or certifications needed for your project.

-

Explore Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times. This is particularly beneficial for businesses in regions with high import tariffs or complex customs processes.

-

Understand Total Cost of Ownership (TCO): Evaluate not only the upfront costs but also the long-term implications of your choices. Consider factors such as durability, maintenance, and performance to assess the true value of the plating service.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms and delivery schedules. Flexible terms can enhance cash flow and reduce financial strain on your operations.

Are There Pricing Nuances for International B2B Buyers?

International buyers should be aware of certain nuances when sourcing nickel plating services. Currency fluctuations, import duties, and shipping costs can significantly affect overall pricing. Furthermore, cultural differences in negotiation practices can influence the purchasing process. Understanding these factors can empower buyers to make informed decisions and foster successful supplier relationships.

Disclaimer on Indicative Prices

Pricing for nickel plating services can vary widely based on the aforementioned factors. Buyers are encouraged to seek quotes from multiple suppliers and conduct thorough due diligence to obtain the best value for their specific needs.

Illustrative image related to can you nickel plate aluminum

Alternatives Analysis: Comparing can you nickel plate aluminum With Other Solutions

Introduction to Alternatives in Surface Finishing for Aluminum

When considering surface finishing options for aluminum, nickel plating is a popular choice due to its ability to enhance both appearance and durability. However, B2B buyers should be aware of alternative methods that may offer different benefits depending on their specific application needs. This section compares nickel plating with other viable solutions, including anodizing and powder coating, to help manufacturers make informed decisions.

Comparison Table of Surface Finishing Options

| Comparison Aspect | Can You Nickel Plate Aluminum | Anodizing | Powder Coating |

|---|---|---|---|

| Performance | Excellent corrosion resistance and wear protection; enhances aesthetic appeal. | Superior corrosion resistance; maintains surface integrity. | Good durability and impact resistance; wide color range. |

| Cost | Moderate; varies based on surface area and thickness. | Generally lower; costs depend on part size and finish type. | Cost-effective for large volumes; initial setup may be higher. |

| Ease of Implementation | Requires surface preparation and expertise; time-consuming. | Relatively simple; requires specific conditions for best results. | Easy to apply on large surfaces; requires curing time. |

| Maintenance | Low maintenance; durable finish. | Requires periodic inspection for wear; can be damaged by harsh chemicals. | Low maintenance; finish can chip or scratch under heavy use. |

| Best Use Case | Applications needing both aesthetic appeal and protection (e.g., automotive parts). | Suitable for components exposed to harsh environments (e.g., aerospace, marine). | Ideal for high-volume production with diverse color options (e.g., appliances, furniture). |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Anodizing Aluminum?

Anodizing involves an electrochemical process that thickens the natural oxide layer on aluminum, enhancing its corrosion resistance and surface hardness. This method is particularly effective for applications in harsh environments, such as aerospace and marine industries. Anodized surfaces can be dyed for color, offering aesthetic flexibility. However, while anodizing provides excellent protection, it may not have the same decorative finish as nickel plating, and the surface can be more susceptible to scratches if not properly maintained.

How Does Powder Coating Compare to Nickel Plating?

Powder coating is a dry finishing process that applies a powdered paint to a surface, which is then cured under heat to form a hard, protective layer. This method is highly efficient for large-scale production and offers a wide array of colors and finishes. While powder coating is generally more cost-effective for high volumes, it may not provide the same level of corrosion resistance as nickel plating or anodizing, particularly in extreme conditions. Additionally, the finish can be less durable under heavy mechanical stress, making it more suitable for decorative applications rather than heavy-duty uses.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting a surface finishing method for aluminum components, B2B buyers should evaluate their specific requirements, including performance, cost, ease of implementation, and maintenance. Nickel plating excels in providing a balance of aesthetic appeal and protection, making it ideal for applications where appearance is crucial. In contrast, anodizing is preferred for environments requiring high corrosion resistance, while powder coating is advantageous for cost-effective, large-scale production with diverse color needs. By carefully assessing these factors, buyers can make informed decisions that align with their operational goals and budget constraints.

Illustrative image related to can you nickel plate aluminum

Essential Technical Properties and Trade Terminology for can you nickel plate aluminum

What Are the Key Technical Properties for Nickel Plating Aluminum?

When considering nickel plating for aluminum, several critical specifications come into play. Understanding these properties is essential for B2B buyers to ensure they make informed decisions.

-

Material Grade:

The most commonly used aluminum grades for nickel plating are 6061 and 7075. The choice of grade affects the plating process and the final product’s properties. For instance, 6061 is versatile and has good corrosion resistance, while 7075 is stronger but less corrosion-resistant. Buyers should select the appropriate grade based on the application requirements, such as strength and environmental exposure. -

Surface Finish and Preparation:

The surface finish of aluminum before plating is crucial. Parts must be polished or buffed to eliminate imperfections, as any flaws will be accentuated by the nickel layer. This preparation impacts adhesion and the aesthetic quality of the final product. Proper surface preparation can reduce rework costs and ensure a high-quality finish. -

Plating Thickness:

Nickel plating thickness is typically measured in mils (thousandths of an inch). Common thicknesses range from 0.0005 to 0.002 inches, depending on the application. Thicker coatings provide better wear and corrosion resistance but may increase costs. Buyers should specify their requirements based on the intended use—whether for decorative purposes or heavy-duty applications. -

Electroless vs. Electroplating:

Electroless nickel plating (EN) is a chemical process that deposits nickel without an external current, while electroplating uses electricity. EN is often preferred for aluminum as it provides uniform thickness and better corrosion resistance. Understanding the differences can help buyers select the appropriate method based on their specific needs. -

Hardness Rating:

Nickel coatings can vary in hardness, typically measured on the Rockwell scale (e.g., RC 50 to RC 72). Higher hardness ratings indicate better wear resistance, making them suitable for industrial applications. Buyers should assess the hardness requirements based on the working conditions of the plated components. -

Cost Factors:

The cost of nickel plating is influenced by various factors, including surface area, plating thickness, and the complexity of the parts. Buyers should expect quotes based on square inches of surface area and specified thickness. Understanding these cost factors helps in budgeting and selecting the right supplier.

What Are Common Trade Terms in Nickel Plating?

Familiarity with industry jargon can facilitate smoother transactions and communication among stakeholders in the nickel plating sector.

-

OEM (Original Equipment Manufacturer):

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of nickel plating, OEMs often require specific plating standards to ensure compatibility with their products. -

MOQ (Minimum Order Quantity):

This term denotes the smallest quantity of an item that a supplier is willing to sell. Understanding MOQ is vital for buyers, especially when dealing with suppliers in different regions, as it can affect procurement strategies and inventory management. -

RFQ (Request for Quotation):

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. For nickel plating, providing detailed specifications in an RFQ can lead to more accurate pricing and service expectations. -

Incoterms:

International Commercial Terms (Incoterms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping, risk, and cost responsibilities, which is critical for smooth cross-border operations. -

Smut:

This term refers to the black soot that can form on aluminum during the plating process. Proper cleaning and preparation are required to eliminate smut, which can adversely affect the adhesion and appearance of the nickel plating. -

Thickness Measurement (Mils):

A mil is a unit of measurement equivalent to one-thousandth of an inch. Understanding thickness measurement is essential for buyers to specify their requirements for nickel plating accurately, ensuring that the final product meets performance standards.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of nickel plating aluminum effectively, ensuring quality and cost-effectiveness in their procurement processes.

Illustrative image related to can you nickel plate aluminum

Navigating Market Dynamics and Sourcing Trends in the can you nickel plate aluminum Sector

What Are the Key Market Dynamics and Trends in Nickel Plating Aluminum?

The nickel plating aluminum sector is experiencing significant growth driven by diverse global factors. Increasing demand for lightweight materials in industries such as automotive, aerospace, and electronics is propelling the popularity of aluminum as a substrate for nickel plating. The need for enhanced corrosion resistance and improved surface properties is particularly crucial in regions with harsh environmental conditions, such as parts of Africa and the Middle East. International B2B buyers are also leveraging advancements in technology, such as automation and digitalization, to streamline sourcing processes and enhance quality control.

Emerging trends include the rise of electroless nickel plating, which offers superior uniformity and thickness control compared to traditional electroplating methods. This trend is particularly appealing to manufacturers in Europe and South America, where precision and durability are paramount. Furthermore, the integration of online platforms for sourcing and supplier management is reshaping the procurement landscape, allowing buyers to access a wider pool of suppliers and compare offerings more efficiently.

How Does Sustainability and Ethical Sourcing Impact the Nickel Plating Aluminum Sector?

Sustainability is becoming an essential consideration for B2B buyers in the nickel plating aluminum sector. The environmental impact of nickel plating processes, which often involve hazardous chemicals, necessitates a shift towards greener practices. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainability through the adoption of eco-friendly plating methods and responsible waste management.

Illustrative image related to can you nickel plate aluminum

Ethical sourcing is also gaining traction, with companies prioritizing suppliers that adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management systems and RoHS compliance for hazardous substances are becoming critical factors in supplier selection. By choosing suppliers with these certifications, B2B buyers can ensure that their sourcing practices align with global sustainability goals and enhance their brand reputation in an increasingly environmentally conscious market.

What Is the Historical Context of Nickel Plating Aluminum?

Nickel plating has a rich history dating back to the early 19th century, evolving from basic electroplating techniques to advanced methods used today. Initially developed for decorative purposes, the application of nickel plating to aluminum gained traction in the latter half of the 20th century as industries recognized its benefits for enhancing corrosion resistance and surface durability.

The advent of electroless nickel plating in the 1970s marked a significant milestone, allowing for uniform coating of complex shapes without the need for an electric current. This innovation opened new avenues for aluminum applications across various sectors, including aerospace and automotive, where performance and reliability are critical. As the industry continues to evolve, the focus on sustainability and technological advancements suggests that the future of nickel plating aluminum will be shaped by both environmental considerations and the need for high-performance materials.

Illustrative image related to can you nickel plate aluminum

Frequently Asked Questions (FAQs) for B2B Buyers of can you nickel plate aluminum

-

How can I ensure the quality of nickel plating on aluminum parts?

To ensure high-quality nickel plating on aluminum parts, it’s essential to partner with a reputable supplier who adheres to strict quality assurance protocols. Request detailed information on their plating processes, including surface preparation, cleaning methods, and any pre-treatment steps. Additionally, inquire about their certifications and compliance with international standards, such as ISO 9001. Regular quality checks, including visual inspections and thickness measurements, should be part of the process to confirm that the final product meets your specifications. -

What are the typical costs associated with nickel plating aluminum?

The cost of nickel plating aluminum can vary widely based on several factors, including the size and complexity of the parts, the type of nickel plating used (electrolytic vs. electroless), and the required finish quality. Suppliers may quote prices based on surface area, thickness of the nickel layer, or per part. It’s advisable to obtain quotes from multiple suppliers and clarify all cost components, including any additional fees for masking, cleaning, or surface preparation, to get a comprehensive understanding of pricing. -

What should I look for when vetting a nickel plating supplier?

When vetting a nickel plating supplier, consider their experience and expertise in plating aluminum specifically. Check for customer reviews, case studies, and references to gauge their reliability. Ensure they have the necessary certifications and quality control measures in place. It’s also beneficial to assess their production capabilities, lead times, and flexibility in meeting your specific requirements. An on-site visit can further help you evaluate their operations and quality standards. -

Are there minimum order quantities (MOQ) for nickel plating services?

Minimum order quantities for nickel plating services can vary by supplier and project type. Some suppliers may have a low MOQ for prototype runs, while others might require larger quantities for production batches to optimize costs. When discussing your project, clearly communicate your needs and ask about any MOQs that may apply. This ensures you can find a supplier willing to accommodate your order size, whether it’s a small batch or a large-scale production run. -

What is the difference between electrolytic and electroless nickel plating?

Electrolytic nickel plating involves applying a nickel coating through an electrochemical process, where an electric current deposits nickel ions onto the aluminum surface. This method can offer a bright finish and is suitable for parts that require high precision. In contrast, electroless nickel plating relies on a chemical reaction to deposit nickel without electrical current, providing uniform thickness and excellent corrosion resistance. The choice between the two methods depends on your specific application, desired properties, and aesthetic requirements. -

How does surface preparation affect nickel plating on aluminum?

Surface preparation is crucial for successful nickel plating on aluminum. Proper cleaning, polishing, and etching remove contaminants and imperfections that could affect adhesion and finish quality. If the surface is not adequately prepared, defects such as pits or scratches may become visible after plating, compromising the aesthetic and functional performance. Suppliers should provide detailed guidelines on the necessary preparation steps to ensure optimal plating results, so it’s essential to discuss this aspect during the procurement process. -

What payment terms should I expect when sourcing nickel plating services internationally?

Payment terms for international sourcing of nickel plating services can vary widely based on the supplier’s policies and the nature of the agreement. Common terms include upfront payments, partial payments before shipment, or net payment terms post-delivery. It’s advisable to clarify these terms upfront and consider using secure payment methods, such as letters of credit or escrow services, to protect your interests. Additionally, factor in currency exchange rates and any potential tariffs that may apply to your transaction. -

What logistics considerations should I keep in mind when ordering nickel plated parts?

When ordering nickel plated parts, logistics considerations are vital for ensuring timely delivery and quality. Discuss shipping options with your supplier, including air freight for expedited delivery or sea freight for larger shipments. Ensure that the supplier packages the parts securely to prevent damage during transit. Additionally, consider customs regulations and duties in your country, as these can impact delivery times and overall costs. Establishing clear communication channels with your supplier can help address any logistics-related issues that may arise.

Top 6 Can You Nickel Plate Aluminum Manufacturers & Suppliers List

1. Nickel Plating – Key Factors and Processes

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: Nickel plating for aluminum involves two types: regular Nickel plating and Electroless Nickel (EN). EN requires additional processes to eliminate ‘smut’ from aluminum. Key factors affecting pricing include: 1) Surface area (square inches), 2) Thickness of plating (Flash Coat, Wear Coat, Build up), 3) Type of EN (Low Phos, Med. Phos, High Phos), 4) Need for masking, and 5) Cleanliness of parts. Pri…

2. Nickel Plating – Steel vs. Aluminum

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Nickel plating on steel and aluminum requires different processes. For aluminum, a zincate solution is necessary to ensure adhesion, while steel can be plated directly. The cleaning process involves using lacquer thinner, degreasing, electrocleaning, and acid dipping, with specific times for different metals. A 10A power supply is suitable for plating unless the surface area is large. Recommended …

3. Sunrise Metal – Nickel Plating Services

Domain: sunrise-metal.com

Registered: 2015 (10 years)

Introduction: Nickel plating is a surface finishing technique applied to aluminum parts for both decorative and engineering purposes. It is cost-effective and enhances appearance and durability. Sunrise Metal offers nickel plating as part of their full chain services in aluminum die casting. There are two main processes for nickel plating aluminum: Nickel Electroplating and Electroless Nickel Plating. Nickel El…

4. Advanced Plating Technologies – Aluminum Alloy Plating Solutions

Domain: advancedplatingtech.com

Registered: 2013 (12 years)

Introduction: Advanced Plating Technologies offers plating on aluminum alloys, including cast and wrought types, with finishes such as electroless nickel plating, tin plating, silver plating, and gold plating. The company employs barrel, vibratory, and rack methods based on component geometry and application. Their aluminum plating process has been refined over sixty years for industries like power transmission…

5. Caswell Plating – Electroless Nickel Plating Kits

Domain: caswellplating.com

Registered: 1997 (28 years)

Introduction: Electroless Nickel Plating Kits

6. eMasterCam – Nickel Plated Aluminum Milling Solutions

Domain: emastercam.com

Registered: 1999 (26 years)

Introduction: Milling nickel plated aluminum, 12µm thick plating, potential for flaking, recommended climb cutting, use of tools intended for aluminum, roughing and finishing cuts suggested, high tension plating, concerns about adhesion, masking challenges, alternative masking methods discussed (high temperature green tape, rubberized paint), preparation through bead blasting mentioned.

Strategic Sourcing Conclusion and Outlook for can you nickel plate aluminum

In summary, nickel plating aluminum presents a viable solution for enhancing both the appearance and durability of components across various industries. The process, whether through electroplating or electroless nickel plating, allows for significant customization based on specific engineering needs. Key considerations include surface preparation, the selection of the appropriate nickel type, and the thickness of the coating, all of which can influence both aesthetic appeal and performance.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of nickel plating services can lead to improved product quality and competitive advantage. Establishing partnerships with reputable plating providers ensures access to advanced technologies and expert knowledge, ultimately resulting in better end products.

Looking ahead, as the demand for high-performance materials continues to rise, investing in nickel plating will be crucial for companies aiming to enhance their offerings. Engage with reliable suppliers and consider the long-term benefits of nickel plating in your manufacturing processes. By prioritizing quality and strategic sourcing, your business can not only meet but exceed market expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.