A B2B Buyer’s Guide to Cal Drop Forge: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for cal drop forge

In the fast-evolving landscape of global manufacturing, sourcing high-quality closed die forgings—especially for applications in aerospace, automotive, and medical sectors—poses significant challenges for international B2B buyers. The quest for reliable suppliers of cal drop forge components requires not only understanding the intricacies of the forging process but also navigating complex supplier networks across diverse markets. This guide offers a comprehensive resource tailored to empower businesses in Africa, South America, the Middle East, and Europe, including key markets like Vietnam and Germany.

Within this guide, you will explore various types of cal drop forge products, their applications across multiple industries, and the critical factors to consider when vetting potential suppliers. We delve into essential topics such as manufacturing standards, material specifications, and cost considerations, ensuring that your purchasing decisions are informed and strategic. By equipping you with actionable insights and expert recommendations, this guide aims to streamline your procurement process, mitigate risks, and ultimately enhance the quality and performance of your projects. Embrace the opportunity to make educated sourcing decisions that align with your business goals in the competitive global market.

Understanding cal drop forge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Closed Die Forging | Utilizes precision dies to shape metal under high pressure. | Aerospace components, medical devices | Pros: High accuracy, excellent surface finish. Cons: Higher initial tooling costs. |

| Open Die Forging | Metal is shaped without a closed die, allowing for larger parts. | Heavy machinery, automotive components | Pros: Flexibility in size and shape. Cons: Less precision compared to closed die. |

| Hot Forging | Involves shaping metal at high temperatures, enhancing ductility. | Structural components, automotive parts | Pros: Improved material properties. Cons: Limited to certain alloys. |

| Cold Forging | Metal is shaped at or near room temperature, enhancing strength. | Fasteners, precision parts | Pros: Increased strength, no heating costs. Cons: Limited to softer materials. |

| Precision Forging | Combines advanced technology for high tolerance requirements. | Aerospace, defense, high-performance applications | Pros: Exceptional precision, repeatability. Cons: Higher costs due to technology. |

What Are the Characteristics of Closed Die Forging?

Closed die forging is characterized by the use of precision dies that shape metal under high pressure, resulting in parts with excellent dimensional accuracy and surface finish. This method is particularly suitable for producing complex shapes, making it ideal for aerospace components and medical devices. B2B buyers should consider the initial tooling costs, which can be higher, but the long-term benefits include reduced machining time and improved material properties.

How Does Open Die Forging Differ from Other Types?

Open die forging allows for the shaping of larger metal parts without the constraints of a closed die, making it suitable for heavy machinery and automotive components. The flexibility in size and shape is a significant advantage, but this method generally offers less precision compared to closed die forging. Buyers should assess their specific requirements for size and tolerances, as open die forging may not meet stringent accuracy demands.

Why Choose Hot Forging for Structural Components?

Hot forging involves shaping metal at elevated temperatures, which enhances ductility and allows for the use of various alloys. This method is commonly used for structural components and automotive parts due to its ability to improve mechanical properties. However, buyers should note that the process is limited to specific alloys that can withstand the heat, which may restrict options for certain applications.

What Are the Benefits of Cold Forging?

Cold forging shapes metal at or near room temperature, which can significantly enhance the strength of the final product. This method is ideal for producing fasteners and precision parts where dimensional accuracy is critical. While cold forging reduces energy costs since no heating is required, it is generally limited to softer materials. Buyers must evaluate their material options and strength requirements when considering cold forging.

Illustrative image related to cal drop forge

How Does Precision Forging Enhance Aerospace Applications?

Precision forging employs advanced technology to achieve high tolerance requirements, making it particularly valuable in aerospace and defense sectors where performance is paramount. The exceptional precision and repeatability of this method come at a higher cost, but for buyers requiring critical components, the investment is often justified. Understanding the technological capabilities and cost implications is essential for B2B buyers in these high-stakes industries.

Key Industrial Applications of cal drop forge

| Industry/Sector | Specific Application of cal drop forge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Closed die forgings for aircraft landing gear components | High strength, lightweight materials enhance aircraft safety | Certification standards (e.g., AS9100), material traceability, and lead times. |

| Medical Devices | Forged components for surgical instruments and implants | Precision and reliability in critical medical applications | Compliance with medical regulations, quality assurance processes, and material specifications. |

| Power Generation | Components for gas and steam turbines | Improved efficiency and durability in energy production | Material selection (high-temperature alloys), performance testing, and global shipping logistics. |

| Automotive | Forged parts for high-performance vehicles | Enhanced performance and reduced weight for better fuel efficiency | Compliance with automotive standards (IATF 16949), cost-effectiveness, and delivery schedules. |

| Marine | Closed die forgings for ship components | Corrosion resistance and strength in harsh environments | Material certifications, environmental regulations, and supply chain reliability. |

How is California Drop Forge Used in Aerospace Applications?

In the aerospace sector, California Drop Forge produces closed die forgings for critical components like landing gear and structural elements. These parts are essential for ensuring safety and performance in aircraft operations. Buyers in this industry must consider stringent certification standards, such as AS9100, ensuring that materials are traceable and meet exacting specifications. The lightweight yet strong materials used in these forgings contribute significantly to overall aircraft efficiency, making sourcing from reliable manufacturers vital for international buyers.

What Role Does California Drop Forge Play in Medical Device Manufacturing?

California Drop Forge is instrumental in the medical device industry by providing high-precision forged components for surgical instruments and implants. These components require rigorous quality assurance processes to ensure reliability in life-critical applications. Buyers must prioritize suppliers who comply with medical regulations and can demonstrate robust quality control measures. The use of advanced materials in these applications also helps in reducing the risk of device failure, which is paramount for healthcare providers.

Illustrative image related to cal drop forge

How Does California Drop Forge Contribute to Power Generation?

In the power generation sector, California Drop Forge supplies components for gas and steam turbines, enhancing energy production efficiency. The closed die forging process allows for the creation of parts that can withstand extreme temperatures and pressures, crucial for operational reliability. Buyers should focus on sourcing materials that meet high-temperature alloy specifications and ensure performance testing is conducted. Additionally, understanding global shipping logistics is essential for timely project execution, particularly for international buyers in regions like Africa and South America.

What Advantages Do Automotive Manufacturers Gain from California Drop Forge?

Automotive manufacturers leverage the capabilities of California Drop Forge to produce high-performance forged parts that improve vehicle efficiency and performance. The lightweight nature of forged components contributes to better fuel economy and overall vehicle dynamics. Buyers in this sector should ensure compliance with automotive standards such as IATF 16949 and consider the cost-effectiveness of sourcing from established manufacturers. Timely delivery schedules are also crucial, given the fast-paced nature of automotive production.

How is California Drop Forge Essential for Marine Applications?

California Drop Forge plays a critical role in the marine industry by providing closed die forgings for various ship components, which must resist corrosion and endure harsh environmental conditions. The strength and durability of these forged parts are vital for maintaining vessel integrity and performance. Buyers should focus on suppliers that can provide material certifications and demonstrate compliance with environmental regulations. Reliability in the supply chain is also a key consideration, especially for international marine projects.

Illustrative image related to cal drop forge

3 Common User Pain Points for ‘cal drop forge’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Forged Components

The Problem: B2B buyers often face challenges related to the quality assurance of forged components, especially when sourcing from international suppliers. Inconsistent quality in closed-die forgings can lead to production delays, increased costs, and, ultimately, product failures. This is particularly critical in sectors like aerospace, where stringent standards must be met. Buyers may struggle to verify the quality control processes of suppliers like California Drop Forge, leading to uncertainty about whether the parts will meet their specifications.

The Solution: To mitigate quality assurance issues, buyers should prioritize establishing a robust communication channel with California Drop Forge. Request detailed documentation of their quality control processes, including certifications, testing methodologies, and inspection reports. Engaging in collaborative product development discussions can also help align expectations. Consider scheduling visits to the manufacturing facility to observe processes firsthand. This proactive approach allows buyers to assess quality measures in real-time and build trust with the supplier, ensuring that the forged components meet industry standards.

Scenario 2: Delays Due to Complex Supply Chains

The Problem: Many B2B buyers experience frustration with delays stemming from complex supply chains, particularly when sourcing specialized components like those produced by California Drop Forge. The intricacies of international shipping, customs clearance, and potential disruptions can significantly extend lead times. This can jeopardize project timelines and result in costly penalties or missed opportunities.

Illustrative image related to cal drop forge

The Solution: To combat supply chain delays, buyers should engage in strategic planning with California Drop Forge early in the procurement process. Develop a clear timeline that accounts for production lead times and shipping durations. Utilize tools such as supply chain management software to gain real-time insights into order status and potential bottlenecks. Additionally, consider establishing local warehousing solutions to stock essential components, thus reducing reliance on just-in-time deliveries. By working collaboratively with the supplier to create a contingency plan, buyers can minimize the risk of delays and maintain smoother project execution.

Scenario 3: Technical Expertise Gaps in Material Selection

The Problem: Selecting the right materials for forged components can be a daunting task for B2B buyers, especially when dealing with high-performance applications in industries like aerospace and medical. Buyers may lack the technical expertise needed to specify the appropriate alloys or processes required for their projects, leading to suboptimal performance or increased costs.

The Solution: To address this expertise gap, buyers should leverage the engineering and metallurgical assistance offered by California Drop Forge. Initiate discussions about specific project requirements and ask for recommendations on material selection based on performance criteria, environmental factors, and budget constraints. California Drop Forge’s extensive experience with a variety of metals, including titanium and exotic alloys, can provide invaluable insights. Additionally, consider developing prototype components to test material performance before full-scale production. This iterative approach not only enhances product quality but also builds confidence in the materials chosen for critical applications.

Strategic Material Selection Guide for cal drop forge

What Are the Key Materials Used in California Drop Forge Applications?

In the realm of drop forging, selecting the appropriate material is crucial for ensuring product performance and longevity. California Drop Forge specializes in closed-die forgings, utilizing various materials tailored to specific applications. Below, we analyze four common materials used in their manufacturing processes, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Titanium Perform in Drop Forging Applications?

Titanium is renowned for its exceptional strength-to-weight ratio, making it an ideal choice for aerospace components. It exhibits excellent corrosion resistance and can withstand high temperatures, which is critical for applications like jet engine parts and structural components.

Pros: Titanium’s lightweight nature enhances fuel efficiency in aerospace applications. It also resists corrosion, extending the lifespan of components in harsh environments.

Cons: The primary drawback is its high cost and manufacturing complexity, which can lead to increased production expenses. Additionally, titanium requires specialized tooling and techniques, which may not be readily available in all regions.

Impact on Application: Titanium is compatible with various media, including aggressive chemicals, making it suitable for aerospace and medical applications.

International Considerations: Buyers must consider compliance with international standards such as ASTM B348 for titanium products. Regions like Europe and the Middle East often have stringent regulations regarding material specifications and certifications.

What Advantages Do Stainless Steels Offer in Forging?

Stainless steel is widely used in drop forging due to its excellent corrosion resistance and mechanical properties. It is available in various grades, allowing for flexibility in applications ranging from automotive to medical devices.

Pros: Stainless steel is durable and offers good mechanical strength, making it suitable for high-stress applications. Its resistance to rust and staining enhances the longevity of components.

Cons: While generally more affordable than titanium, stainless steel can still be costly, particularly for high-grade alloys. Additionally, it may not perform as well as titanium in extreme temperature conditions.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and various chemicals, making it versatile for many industries.

International Considerations: Compliance with standards like ASTM A276 is essential for buyers in regions such as Africa and South America, where quality assurance is paramount.

Illustrative image related to cal drop forge

How Does Carbon Steel Compare in Forging Applications?

Carbon steel is a staple in the forging industry due to its balance of strength, ductility, and cost-effectiveness. It is commonly used for structural components and machinery parts.

Pros: Carbon steel is relatively inexpensive and easy to manufacture, making it a popular choice for many applications. It also offers good tensile strength and hardness.

Cons: Its corrosion resistance is lower than that of stainless steel or titanium, requiring protective coatings in certain environments. Additionally, it may not perform well in high-temperature applications.

Illustrative image related to cal drop forge

Impact on Application: Carbon steel is suitable for applications where high strength is required, but exposure to corrosive environments may limit its use.

International Considerations: Buyers should be aware of compliance with standards such as ASTM A36. In regions like Europe, adherence to EN standards is also critical.

What Role Do Exotic Alloys Play in Drop Forging?

Exotic alloys, which include materials like Inconel and Monel, are used in specialized applications where extreme conditions are present. These alloys provide superior performance in high-temperature and corrosive environments.

Illustrative image related to cal drop forge

Pros: Exotic alloys offer exceptional resistance to heat and corrosion, making them ideal for aerospace and chemical processing applications.

Cons: The cost of exotic alloys is significantly higher than that of more common materials, and their manufacturing processes can be complex and time-consuming.

Impact on Application: These materials are compatible with aggressive media and can withstand extreme temperatures, making them essential for critical applications.

International Considerations: Buyers must ensure compliance with specific industry standards, such as ASTM B168 for Inconel. Understanding regional preferences and certifications is vital for successful procurement.

Summary Table of Material Selection

| Material | Typical Use Case for cal drop forge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Aerospace components | Excellent strength-to-weight ratio | High cost and complex manufacturing | High |

| Stainless Steel | Automotive and medical devices | Good corrosion resistance | Higher cost for premium grades | Medium |

| Carbon Steel | Structural components | Cost-effective and easy to manufacture | Lower corrosion resistance | Low |

| Exotic Alloys | Aerospace and chemical processing | Superior heat and corrosion resistance | Very high cost and complex processes | High |

This strategic material selection guide serves as a comprehensive resource for international B2B buyers, helping them make informed decisions when sourcing materials for their drop forging needs. Understanding the properties and implications of each material is essential for optimizing performance and compliance in global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for cal drop forge

What Are the Main Stages of the Manufacturing Process for Closed Die Forging?

The manufacturing process for closed die forgings, such as those produced by California Drop Forge, typically involves several critical stages: material preparation, forming, assembly, and finishing. Each of these stages is essential to ensure that the final product meets the stringent requirements of various industries, including aerospace, medical, and military applications.

Material Preparation

The first step involves selecting the appropriate metal alloy, often titanium, stainless steel, or other exotic materials. These materials are then cut into specific sizes to facilitate efficient forging. Material preparation is crucial because the quality of the raw material directly impacts the integrity of the final product.

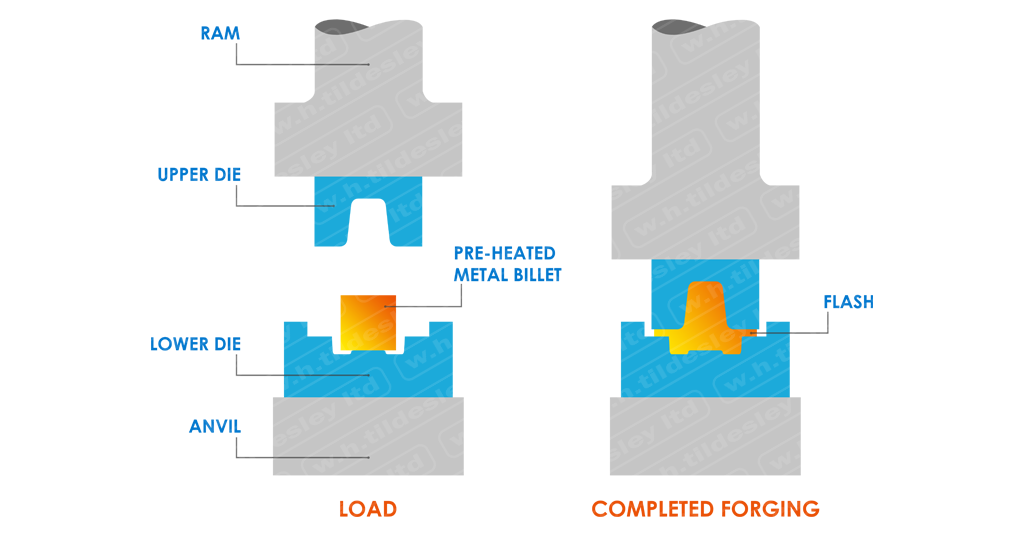

Forming

Once the materials are prepared, they undergo the forming process. This is where the actual forging takes place, typically using hydraulic presses or hammers to shape the metal into a pre-defined die. The closed die method allows for complex shapes and high precision, making it ideal for applications such as landing gear components and structural elements in aircraft.

Illustrative image related to cal drop forge

Assembly

In some cases, forged components may require assembly with other parts. This stage might involve welding, machining, or other joining techniques to ensure that the components fit together perfectly. The assembly process is critical for maintaining the structural integrity and performance of the final product.

Finishing

The last stage is finishing, which includes processes like machining, surface treatment, and inspection. This ensures that all components meet the required tolerances and surface quality. Finishing is vital for products intended for high-stress applications, as it can significantly affect their performance and longevity.

What Quality Control Measures Are Implemented in Drop Forging?

Quality control (QC) is a cornerstone of the manufacturing process at California Drop Forge. Ensuring that products meet international standards and industry-specific requirements is vital for maintaining customer trust and safety.

Illustrative image related to cal drop forge

Relevant International Standards

California Drop Forge adheres to several quality standards, including ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO 9001 ensures a consistent approach to quality across all manufacturing processes. Additionally, industry-specific standards such as CE marking for the European market and API (American Petroleum Institute) standards for oil and gas applications are also followed.

Quality Control Checkpoints

Quality control is integrated at various stages of the manufacturing process through specific checkpoints:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival to ensure they meet specified standards before they enter production.

-

In-Process Quality Control (IPQC): During the forging process, continuous monitoring is conducted to catch any deviations from quality standards early. This includes checking dimensions and material properties at various stages of production.

-

Final Quality Control (FQC): After the finishing stage, final inspections are performed to ensure that each product meets the required specifications and quality standards before shipment.

Which Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to verify the quality of forged components, each serving a specific purpose in ensuring product reliability and safety.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and magnetic particle inspection are used to detect internal and surface defects without damaging the components. These methods are crucial for aerospace applications where safety is paramount.

-

Destructive Testing: While less common for finished products, some prototypes may undergo tensile testing, impact testing, and fatigue testing to determine their mechanical properties and ensure they can withstand operational stresses.

-

Dimensional Inspection: Precision measuring tools are employed to verify that components meet the specified dimensions and tolerances. This is particularly important in applications requiring high precision, such as aerospace and medical devices.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control systems, and adherence to industry standards. This firsthand assessment can provide valuable insights into the supplier’s commitment to quality.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can help buyers understand their testing methods, results, and any corrective actions taken in case of deviations from quality standards.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. This is especially beneficial for buyers who may not have the resources to conduct their audits.

What Are the Quality Control Nuances for International Buyers?

When engaging with suppliers from different regions, international buyers must consider various nuances related to quality control.

-

Understanding Local Standards: Different countries may have distinct quality standards and regulatory requirements. Buyers should familiarize themselves with these standards to ensure compliance and avoid potential issues during importation.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary across regions. Buyers should communicate their specific quality requirements clearly to avoid misunderstandings.

-

Documentation and Traceability: Ensure that suppliers maintain proper documentation and traceability for all materials and processes. This is crucial for accountability and resolving any quality-related disputes that may arise.

In conclusion, understanding the manufacturing processes and quality assurance measures for closed die forgings is essential for B2B buyers seeking reliable suppliers. By focusing on the intricacies of manufacturing stages, implementing rigorous quality control measures, and verifying supplier practices, buyers can mitigate risks and ensure they receive high-quality products that meet their industry-specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cal drop forge’

Introduction

This practical sourcing guide aims to assist B2B buyers in the effective procurement of closed die forgings from California Drop Forge or similar suppliers. The checklist provides actionable steps to ensure you select a provider that meets your technical specifications and business needs, particularly for industries such as aerospace, medical, and power generation.

Illustrative image related to cal drop forge

Step 1: Define Your Technical Specifications

Before initiating contact with suppliers, clearly outline your technical requirements. This includes material types (e.g., titanium, stainless steel), dimensions, tolerances, and any specific industry standards that need to be met. Defining these specifications upfront helps in streamlining communications and ensuring potential suppliers can meet your needs.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers specializing in closed die forgings. Look for companies with a solid reputation, such as California Drop Forge, which has a long history in the industry. Pay attention to their capabilities, past projects, and industries served to ascertain if they align with your requirements.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold relevant industry certifications, such as ISO 9001 or AS9100 for aerospace components. Certifications indicate a commitment to quality management and compliance with industry standards, which is crucial for ensuring the reliability of your sourced products.

Step 4: Request Sample Products

Before making a bulk order, ask for sample products to evaluate the quality of the forgings. This step allows you to assess the supplier’s manufacturing capabilities and ensure that their products meet your technical specifications. Look for consistency in quality, finish, and adherence to tolerances in the samples provided.

Illustrative image related to cal drop forge

Step 5: Assess Production Capabilities and Lead Times

Inquire about the supplier’s production capabilities and lead times. Understanding their manufacturing processes, including the availability of machinery and workforce, helps determine whether they can handle your order size and delivery schedule. Ensure they can meet your timeline without compromising quality.

Step 6: Review Pricing and Terms of Sale

Request detailed pricing information, including any additional costs for tooling, shipping, and handling. Compare quotes from different suppliers, but consider not just the price but also the value offered, such as warranties, after-sales support, and payment terms. This will help you make an informed decision based on total cost of ownership.

Step 7: Establish Communication and Support Channels

Ensure that the supplier provides clear channels for communication and support. It’s essential to have a dedicated point of contact for any inquiries or issues that may arise during the sourcing process. Effective communication can prevent misunderstandings and foster a better working relationship.

By following these steps, B2B buyers can navigate the sourcing process for closed die forgings more effectively, ensuring they partner with suppliers who can deliver quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for cal drop forge Sourcing

What Are the Key Cost Components in Sourcing California Drop Forge Products?

When sourcing closed die forgings from California Drop Forge, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. California Drop Forge utilizes a range of metals, including titanium, stainless steel, and exotic alloys. Prices can fluctuate based on market conditions and material availability, so it’s vital to confirm current rates with suppliers.

-

Labor: Labor costs encompass skilled artisans and engineers involved in the forging process. Given the specialized nature of drop forging, these costs may be higher than conventional manufacturing processes. Labor rates can also vary by region, affecting total expenses.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, equipment maintenance, and other indirect expenses. A well-managed operation may offer more competitive pricing, so evaluating a supplier’s operational efficiency can provide insights into potential cost savings.

-

Tooling: Tooling expenses are incurred for the creation and maintenance of molds and dies essential for closed die forging. These costs can be substantial, especially for custom designs, and should be factored into the overall pricing model.

-

Quality Control (QC): Ensuring that products meet stringent industry standards—especially in aerospace and medical applications—requires investment in quality control measures. This includes testing and certification processes that can influence the final cost.

-

Logistics: Shipping and handling costs can vary widely, especially for international shipments. Factors such as distance, shipping method, and customs duties should be considered when evaluating total costs.

-

Margin: Suppliers typically add a margin to cover profit and risk. Understanding the typical margins within the industry can help buyers gauge whether a quoted price is reasonable.

How Do Price Influencers Affect the Cost of California Drop Forge Products?

Several factors can influence the pricing of California Drop Forge products:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounts, making it advantageous to consolidate orders. Conversely, lower quantities may result in higher per-unit costs.

-

Specifications and Customization: Custom designs and specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: The demand for high-quality materials and specific certifications (e.g., AS9100 for aerospace) can elevate prices. Buyers should assess the required standards before finalizing their orders.

-

Supplier Factors: Supplier reputation, production capabilities, and location can all impact pricing. A well-established supplier may charge more but offer better reliability and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can affect shipping costs and responsibilities. Understanding these terms is crucial for international buyers to avoid unforeseen expenses.

What Are Some Effective Buyer Tips for Sourcing California Drop Forge Products?

-

Negotiation: Engage in open discussions with suppliers about pricing, especially if you have a long-term partnership in mind. Suppliers may be willing to negotiate on price based on order volume or contract length.

-

Cost-Efficiency: Assess the total cost of ownership (TCO) rather than just the upfront price. Consider factors like durability, maintenance, and lifecycle costs to make informed purchasing decisions.

-

Pricing Nuances for International Buyers: For buyers from regions such as Africa, South America, the Middle East, and Europe, be mindful of currency fluctuations and import tariffs, which can impact overall costs. Additionally, consider the logistical implications of long-distance shipping.

-

Supplier Diversification: To mitigate risks associated with supply chain disruptions, consider diversifying your supplier base. This approach can also foster competitive pricing among suppliers.

-

Request Detailed Quotes: Always ask for detailed quotes that break down costs into components. This transparency will aid in better understanding the pricing structure and identifying areas for potential savings.

Disclaimer on Pricing

Prices for California Drop Forge products can vary widely based on the factors outlined above. It is advisable to contact suppliers directly for the most accurate and up-to-date pricing information tailored to your specific needs.

Alternatives Analysis: Comparing cal drop forge With Other Solutions

When considering the procurement of closed-die forgings, it is essential for B2B buyers to evaluate multiple options to ensure they select the best solution for their specific manufacturing needs. This analysis compares California Drop Forge with two notable alternatives in the closed-die forging industry: Forge Resources Group and Canton Drop Forge. Each solution offers distinct advantages and disadvantages that can influence a buyer’s decision based on performance, cost, and application suitability.

| Comparison Aspect | ‘Cal Drop Forge’ | Forge Resources Group | Canton Drop Forge |

|---|---|---|---|

| Performance | High-quality closed-die forgings; precision engineered for aerospace and medical applications. | Customizable forgings in various materials; suitable for both lightweight and heavy-duty applications. | Specializes in high-volume production; efficient for mass production of standard components. |

| Cost | Premium pricing due to high-quality materials and specialized engineering capabilities. | Competitive pricing with a focus on value for custom orders. | Generally lower cost for standard forgings; may lack customization options. |

| Ease of Implementation | Established processes and robust supply chain, but longer lead times for custom orders. | Flexible manufacturing processes; quick turnaround on custom designs. | Streamlined production processes for standard parts, but less flexibility for customization. |

| Maintenance | Requires adherence to strict quality standards; ongoing support for maintenance and inspection. | Offers maintenance support and guidance for custom products. | Minimal maintenance required for standard components; limited support for specialized parts. |

| Best Use Case | Ideal for aerospace and medical industries needing precision and reliability. | Best for clients needing custom solutions across various industries, including automotive and industrial sectors. | Suitable for high-volume production where cost-efficiency is crucial. |

What Are the Pros and Cons of Forge Resources Group as an Alternative?

Forge Resources Group provides a strong alternative to California Drop Forge by offering a wide range of customizable forgings across different materials. One of the main advantages of Forge Resources Group is its competitive pricing, which appeals to businesses looking for cost-effective solutions without sacrificing quality. Additionally, their flexible manufacturing capabilities allow for quick turnarounds on custom designs, making them suitable for clients with specific requirements. However, potential downsides include variability in quality for custom orders and possible limitations in precision compared to California Drop Forge’s specialized offerings.

How Does Canton Drop Forge Compare in Terms of Production Efficiency?

Canton Drop Forge stands out for its efficiency in high-volume production, making it a viable choice for businesses that require large quantities of standard forgings at a lower cost. The streamlined production processes allow for quicker lead times, which can be advantageous for companies with tight schedules. However, the trade-off is a lack of flexibility in customization, meaning that companies needing specific designs or materials might find this option less suitable. Additionally, while the cost savings are significant, the overall precision and quality may not match the higher standards set by California Drop Forge.

How Can B2B Buyers Choose the Right Forging Solution for Their Needs?

When selecting the right closed-die forging solution, B2B buyers should carefully assess their specific requirements, including the intended application, production volume, and budget constraints. Understanding the unique advantages of each provider—such as California Drop Forge’s focus on high-quality precision parts versus Forge Resources Group’s customizable options or Canton Drop Forge’s cost efficiency—will enable buyers to make informed decisions. Engaging in discussions with potential suppliers about their capabilities and support services can further clarify which solution aligns best with their operational needs and quality standards.

Essential Technical Properties and Trade Terminology for cal drop forge

What Are the Key Technical Properties of California Drop Forgings?

When considering closed die forgings from California Drop Forge, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are several critical specifications:

Illustrative image related to cal drop forge

1. Material Grade

The material grade refers to the specific type of metal used in the forging process, such as titanium, stainless steel, or exotic alloys. Each material grade possesses unique mechanical properties, such as strength, ductility, and corrosion resistance. Selecting the appropriate material grade is vital for ensuring the end product meets the required performance standards in demanding applications like aerospace or medical equipment.

2. Tolerance

Tolerance defines the allowable variation in dimensions for a forged part. It is typically expressed in terms of +/- measurements (e.g., ±0.005 inches). Tight tolerances are essential in industries where precision is critical, such as aviation and medical devices. A well-defined tolerance ensures parts fit correctly, reducing the likelihood of assembly issues and enhancing overall product reliability.

3. Heat Treatment

Heat treatment is a controlled process used to alter the physical and sometimes chemical properties of a metal. Common heat treatments include annealing, quenching, and tempering. This process is crucial for optimizing the strength and durability of forged components, particularly in high-stress environments. Understanding the heat treatment specifications helps buyers ensure the parts will perform under expected operational conditions.

4. Surface Finish

Surface finish refers to the texture of a surface after processing, which can range from rough to polished. In the context of drop forgings, a specific surface finish may be required for aesthetic purposes or to enhance performance characteristics, such as reducing friction in moving parts. Buyers should specify their surface finish requirements to ensure compatibility with assembly and operational needs.

5. Yield Strength

Yield strength indicates the maximum stress that a material can withstand without permanent deformation. This property is particularly important in applications where components are subjected to heavy loads or stress. Knowing the yield strength helps buyers select materials that can handle the operational demands of their specific applications, thereby ensuring safety and reliability.

Illustrative image related to cal drop forge

What Are Common Trade Terms in the Drop Forging Industry?

Familiarizing oneself with industry jargon can facilitate smoother transactions and clearer communication. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is crucial for buyers looking to source components that will be integrated into larger systems, as OEM parts often adhere to specific quality and performance standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is particularly relevant for international buyers, as it can significantly impact inventory management and cost calculations. Knowing the MOQ helps in planning purchases and managing budgets effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and terms from suppliers. It is essential for buyers looking to compare prices and terms from different manufacturers. Issuing an RFQ can streamline the procurement process and ensure that buyers receive competitive offers tailored to their specifications.

4. Incoterms

Incoterms (International Commercial Terms) are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC). These terms clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international buyers to avoid misunderstandings and ensure smooth logistics.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the finished products. Understanding lead times is essential for effective supply chain management, particularly in industries that rely on just-in-time inventory practices. Buyers should consider lead times when planning production schedules and inventory levels.

These properties and terms are fundamental for B2B buyers engaging with California Drop Forge or similar manufacturers, aiding in clearer communications and better decision-making in the procurement process.

Illustrative image related to cal drop forge

Navigating Market Dynamics and Sourcing Trends in the cal drop forge Sector

What Are the Current Market Dynamics and Key Trends in the Cal Drop Forge Sector?

The global drop forge market is witnessing significant transformation driven by technological advancements and increased demand across various industries, including aerospace, automotive, and medical. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek high-quality forged components, the emphasis on precision and customization has never been higher. The rise of Industry 4.0 technologies, such as automation and data analytics, is enabling manufacturers to improve production efficiency and reduce lead times, making it easier for buyers to source tailored solutions.

Furthermore, the demand for closed-die forgings is increasing due to their superior mechanical properties, which are essential in high-stress applications such as aerospace landing gear and structural components. Buyers are also looking for suppliers that can provide value-added services, such as engineering support and metallurgical expertise, to ensure optimal component performance. Additionally, the ongoing recovery from the pandemic has intensified competition, prompting companies to adopt digital sourcing platforms and enhance their supply chain transparency, facilitating smoother transactions for international buyers.

How Is Sustainability and Ethical Sourcing Impacting the Cal Drop Forge Sector?

Sustainability is becoming a critical factor in the sourcing decisions of B2B buyers, particularly in the cal drop forge sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under increasing scrutiny. As a result, companies are actively seeking suppliers who prioritize sustainable practices. Ethical sourcing is not merely a trend but a necessity, as buyers demand transparency in their supply chains. This includes understanding the origin of materials, labor practices, and environmental certifications.

In response to these demands, manufacturers are investing in green technologies and processes. Utilizing eco-friendly materials and obtaining certifications such as ISO 14001 for environmental management systems can enhance a supplier’s appeal. Furthermore, adopting practices that reduce carbon footprints, such as recycling scrap metal and using renewable energy sources, positions companies as responsible and forward-thinking partners. For buyers, sourcing from suppliers committed to sustainability not only aligns with corporate social responsibility goals but can also enhance brand reputation in increasingly eco-conscious markets.

What Is the Historical Context of the Cal Drop Forge Sector for B2B Buyers?

The cal drop forge sector has a rich history that dates back to the early 20th century. Established in 1901, California Drop Forge, Inc. began as a producer of oil tool forgings before evolving into a leader in closed-die forging. This evolution was driven by a growing demand for high-performance components in critical sectors like aerospace and medical technology. Over the decades, the company has adapted to industry changes and technological advancements, solidifying its reputation for quality and reliability.

This historical context is essential for B2B buyers as it highlights the experience and expertise that established companies bring to the table. The longevity of firms like California Drop Forge reflects their ability to innovate and meet the changing needs of global markets. For international buyers, partnering with a company steeped in history can provide confidence in the quality and reliability of the products sourced, ensuring they meet stringent industry standards. Understanding this background can help buyers make informed decisions when selecting suppliers that not only meet current needs but also align with future trends in manufacturing and sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of cal drop forge

-

How do I ensure quality when sourcing cal drop forge products?

To guarantee quality when sourcing from California Drop Forge, request detailed information about their quality assurance processes. Inquire about certifications, such as ISO 9001, and their experience with non-destructive testing methods. Additionally, consider arranging visits to their facility or requesting samples of their forgings to evaluate their craftsmanship firsthand. Establishing clear specifications and quality standards in your purchase agreement can also help ensure that the products meet your needs. -

What are the customization options available for cal drop forge products?

California Drop Forge offers extensive customization options for their closed die forgings. Buyers can collaborate with their engineering team to develop tailored solutions that meet specific design requirements, including material selection, dimensions, and finishes. Be prepared to provide detailed specifications and prototypes to facilitate the customization process. Early engagement in the design phase can lead to more efficient production and better alignment with your project needs. -

What is the minimum order quantity (MOQ) for cal drop forge products?

The minimum order quantity for products from California Drop Forge can vary based on the complexity and specifications of the forging. Typically, larger orders may yield better pricing and lead times. It’s advisable to discuss your project requirements directly with their sales team to understand the MOQ that applies to your specific needs and to explore potential flexibility based on your order size. -

What payment terms can I expect when sourcing from California Drop Forge?

Payment terms at California Drop Forge are generally negotiable and can vary depending on the size of the order and the relationship with the buyer. Common practices include upfront deposits, net 30, or net 60 terms. It’s essential to clarify payment expectations in the initial discussions to avoid misunderstandings. Additionally, consider discussing the option for letters of credit or other secure payment methods, especially in international transactions. -

How does California Drop Forge handle logistics for international shipping?

California Drop Forge has established logistics capabilities to facilitate international shipping. They typically work with freight forwarders to manage customs clearance and delivery timelines. As a buyer, you should provide shipping details early in the negotiation process to ensure smooth logistics. Inquire about their experience with shipping to your specific region, as this can affect lead times and costs. Ensure you understand the Incoterms being used to clarify responsibilities for shipping costs and risks. -

What industries does California Drop Forge primarily serve?

California Drop Forge primarily serves the aerospace, medical, and power generation industries. Their expertise includes manufacturing closed die forgings for components such as landing gear, jet engines, and medical devices. Understanding their industry focus can help you assess their capabilities and ensure they align with your project requirements. Consider discussing your specific application with their representatives to explore how their offerings can meet your needs. -

What quality control measures are in place at California Drop Forge?

California Drop Forge implements rigorous quality control measures throughout their manufacturing process. They utilize non-destructive testing, metallurgical analysis, and in-process inspections to ensure the integrity and performance of their products. Familiarize yourself with their quality standards and ask for documentation of their testing processes. This transparency can help build trust and confidence in the reliability of the products you are sourcing. -

How can I vet California Drop Forge as a reliable supplier?

To vet California Drop Forge as a reliable supplier, conduct thorough research on their reputation in the industry. Look for customer reviews, case studies, and testimonials from other international buyers. Additionally, consider requesting references or reaching out to their existing clients to gain insight into their experiences. Assess their certifications, years of operation, and responsiveness during initial communications to evaluate their professionalism and capability as a supplier.

Top 7 Cal Drop Forge Manufacturers & Suppliers List

1. California Drop Forge – Closed Die Forgings

Domain: marketplace.aviationweek.com

Registered: 1995 (30 years)

Introduction: California Drop Forge, Inc. specializes in producing closed die forgings for aircraft structural components, landing gear components, jet engines, and land-based turbines. The company has a manufacturing facility of 72,000 square feet that includes a die shop, layout inspection, non-destructive testing, and machining capabilities. Founded in 1901, it has a long history in the industry and has evol…

2. California Drop Forge, Inc. – Closed Die Forgings for Aircraft Programs

Domain: airframer.com

Registered: 2005 (20 years)

Introduction: California Drop Forge, Inc. specializes in closed die forgings for various aircraft programs, including:

– Airbus A320: Closed die forgings for landing gear & wings

– Airbus A330: Closed die forgings

– Airbus A380: Closed die forging landing gear components

– Bell Boeing V-22 Osprey: Closed die forgings for landing gear

– Boeing 737: Wing flap; landing gear parts

– Boeing 767: Closed die forgings …

3. California Drop Forge – Closed Die Forgings

Domain: mergr.com

Registered: 2010 (15 years)

Introduction: California Drop Forge, Inc. manufactures closed die forgings and machined components for aerospace, power generation, marine, commercial, and medical industries.

4. CalDrop – Chinatown Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, CalDrop – Chinatown Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. IQS Directory – California Drop Forging Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: California Drop Forging Companies offer a variety of products including:

– Close-tolerance forgings for medical, aerospace, and industrial applications (Precision Metal Products)

– Open-die forgings in titanium, aluminum, and stainless steel (American Handforge)

– Alloy, aluminum, carbon steel, nickel, titanium, and stainless steel forgings (Rickard Specialty Metals & Engineering)

– Open and close…

6. California Drop Forge – Employee Insights

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, California Drop Forge – Employee Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Forge Resources Group – Custom Closed-Die Forgings

Domain: forgeresourcesgroup.com

Registered: 2006 (19 years)

Introduction: We supply custom closed-die forgings in carbon, alloy and stainless steels, aluminum, and other non-ferrous grades from our forging cells. Carbon and Alloy Steels: 0.5-350 lbs; Aluminum/Non-Ferrous Forgings: 0.5-50 lbs/0.5-125 lbs; Stainless Steels: 0.5-100 lbs. Equipment capabilities include Hammers: 1,000-16,000 lbs; Mechanical Presses: 1,300-6,000 tons; Upsetters: 2-6 inch shaft, up to 11 inch …

Strategic Sourcing Conclusion and Outlook for cal drop forge

What Are the Key Takeaways for International Buyers Considering California Drop Forge?

California Drop Forge (CDF) stands out as a venerable player in the closed-die forging sector, with a legacy dating back to 1901. Its commitment to quality and innovation positions it as a leader in aerospace, medical, and power generation industries. By leveraging advanced capabilities in forging and machining, CDF offers tailored solutions that meet the rigorous standards of international markets.

Strategic sourcing from CDF not only ensures access to high-quality components but also fosters long-term partnerships that can enhance supply chain resilience. With its extensive experience and state-of-the-art facilities, CDF is well-equipped to support buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

How Can You Engage with California Drop Forge for Future Success?

As the global market evolves, engaging with established manufacturers like California Drop Forge can provide a competitive edge. International buyers are encouraged to explore collaboration opportunities that can lead to innovative solutions and improved operational efficiencies. With a focus on quality, reliability, and customer service, CDF is poised to meet the demands of modern industries.

Take the next step in your sourcing strategy by reaching out to California Drop Forge today to discuss how they can support your manufacturing needs and contribute to your success in a competitive global landscape.

Illustrative image related to cal drop forge

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.