A B2B Buyer’s Guide to Bush Rubber: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for bush rubber

In the ever-evolving landscape of industrial components, sourcing bush rubber presents a formidable challenge for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. The intricacies involved in selecting the right type, size, and material can significantly impact the performance and longevity of machinery and equipment. This comprehensive guide delves into the various types of bush rubber available, exploring their applications in automotive, industrial, and mechanical sectors. Additionally, it covers essential aspects such as supplier vetting processes, pricing strategies, and market trends, equipping buyers with the insights needed to make informed purchasing decisions.

By understanding the nuances of bush rubber—from the differences between rubber/metal bushes to the benefits of custom moulding options—international buyers can navigate the complexities of the global market with confidence. This guide serves as a vital resource, empowering companies to identify reliable suppliers, optimize their procurement strategies, and ultimately enhance operational efficiency. As industries increasingly prioritize durability and performance, investing in the right bush rubber solutions becomes critical for maintaining competitive advantage. With this guide, B2B buyers will not only streamline their sourcing processes but also ensure they are making choices that align with their specific operational needs and market demands.

Understanding bush rubber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rubber/Metal Bush | Bonded rubber and metal construction | Automotive, industrial machinery | Pros: High durability, excellent vibration isolation. Cons: Limited flexibility compared to pure rubber. |

| EPDM Rubber Bush | Excellent weather resistance and durability | Construction, automotive | Pros: UV and ozone resistant, versatile. Cons: Higher cost compared to standard rubber. |

| Neoprene Rubber Bush | Good oil and chemical resistance | Marine, automotive, industrial | Pros: Effective in harsh environments. Cons: Less cost-effective for non-specialized applications. |

| Silicone Rubber Bush | High-temperature resistance and flexibility | Aerospace, food processing | Pros: Non-toxic, excellent thermal stability. Cons: Not suitable for heavy load applications. |

| Nitrile Rubber Bush | Superior oil and fuel resistance | Automotive, industrial machinery | Pros: Ideal for oil exposure, durable. Cons: Limited temperature range compared to other materials. |

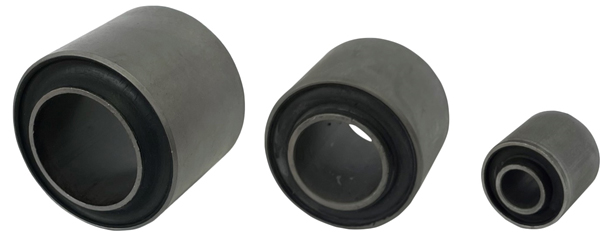

What are the Characteristics and Suitability of Rubber/Metal Bushes?

Rubber/metal bushes are designed to offer robust support in mechanical applications. Their construction combines the durability of metal with the shock-absorbing qualities of rubber, making them ideal for automotive and industrial machinery. When considering these bushes, buyers should evaluate the required load-bearing capacity and environmental conditions, as they excel in vibration isolation but may have limitations in flexibility.

How Do EPDM Rubber Bushes Stand Out?

EPDM (Ethylene Propylene Diene Monomer) rubber bushes are known for their exceptional weather resistance, making them suitable for outdoor applications in construction and automotive sectors. Their ability to withstand UV rays and ozone degradation allows them to perform well in harsh climates. B2B buyers should consider the longevity and maintenance costs associated with EPDM, especially for projects requiring prolonged exposure to the elements.

What Makes Neoprene Rubber Bushes Unique?

Neoprene rubber bushes are favored in marine and industrial applications due to their excellent resistance to oils and chemicals. This makes them particularly suitable for environments where exposure to harsh substances is common. When purchasing neoprene bushes, buyers should assess the specific chemical exposure risks and ensure that the selected product meets their operational requirements.

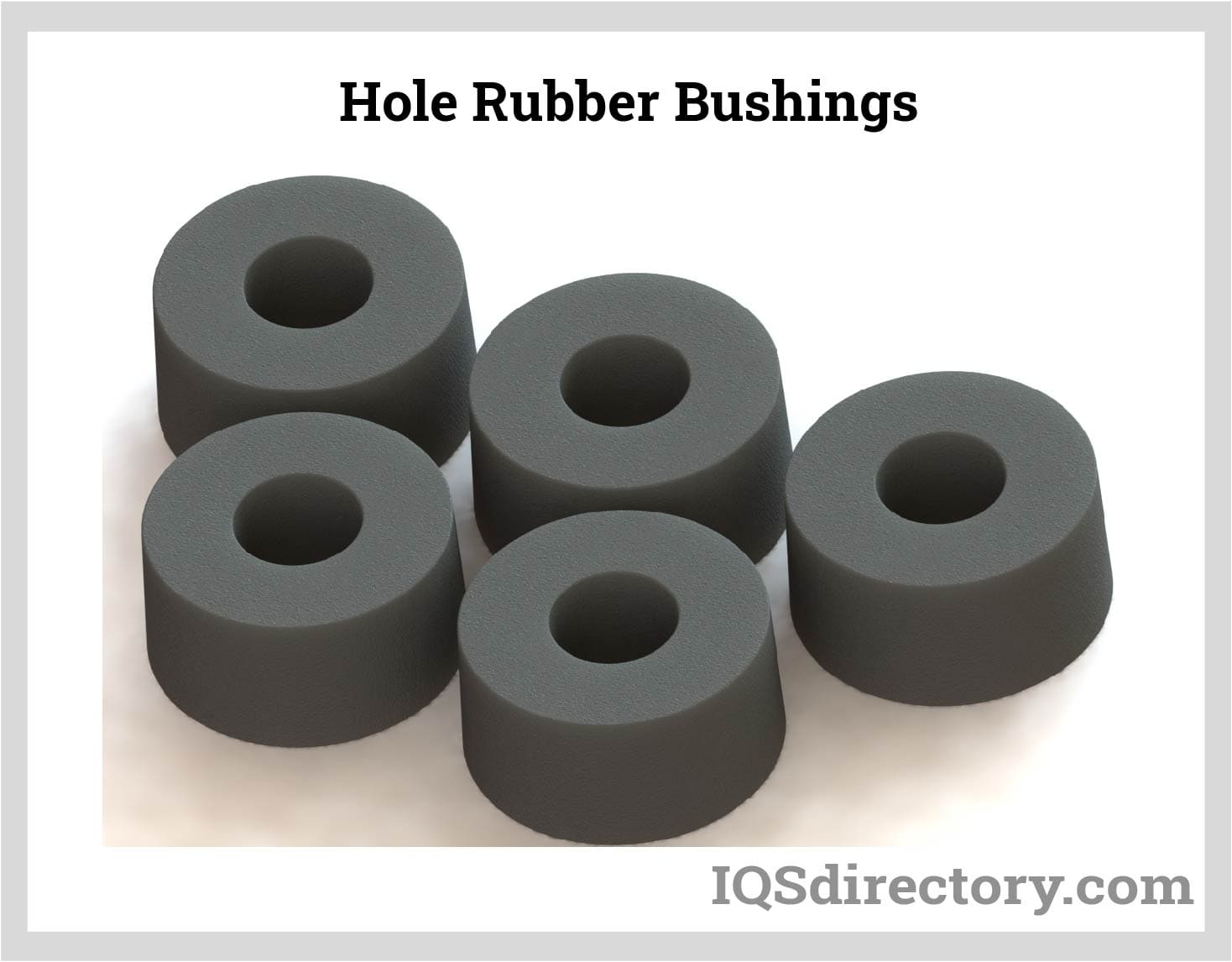

Illustrative image related to bush rubber

Why Choose Silicone Rubber Bushes for Specialized Applications?

Silicone rubber bushes are recognized for their high-temperature resistance and flexibility, making them ideal for aerospace and food processing industries. Their non-toxic nature is a significant advantage in applications requiring hygiene and safety. Buyers should weigh the benefits of silicone’s thermal stability against its higher cost and ensure it aligns with their application needs.

What are the Benefits of Nitrile Rubber Bushes?

Nitrile rubber bushes are particularly effective in applications where oil and fuel exposure is a concern, such as in automotive and industrial machinery. Their durability under such conditions makes them a reliable choice for B2B buyers looking for longevity in performance. However, it is crucial to consider their limited temperature range, which may affect their suitability for specific applications.

Key Industrial Applications of bush rubber

| Industry/Sector | Specific Application of bush rubber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems and chassis components | Enhanced vehicle stability and reduced noise/vibration levels | Ensure compliance with international automotive standards; consider durability under various climate conditions. |

| Construction | Machinery vibration dampening | Prolonged equipment lifespan and improved worker safety | Look for high-quality, weather-resistant materials suitable for outdoor use. |

| Agriculture | Agricultural machinery and equipment | Increased operational efficiency and reduced wear on machinery | Sourcing should focus on materials that can withstand exposure to chemicals and moisture. |

| Aerospace | Aircraft landing gear and components | Improved safety and performance during takeoff and landing | Consider the need for lightweight materials that meet stringent aviation regulations. |

| Mining and Heavy Industry | Equipment shock absorption systems | Enhanced machinery performance and reduced maintenance costs | Ensure sourcing from reliable suppliers that provide customizable options for specific machinery needs. |

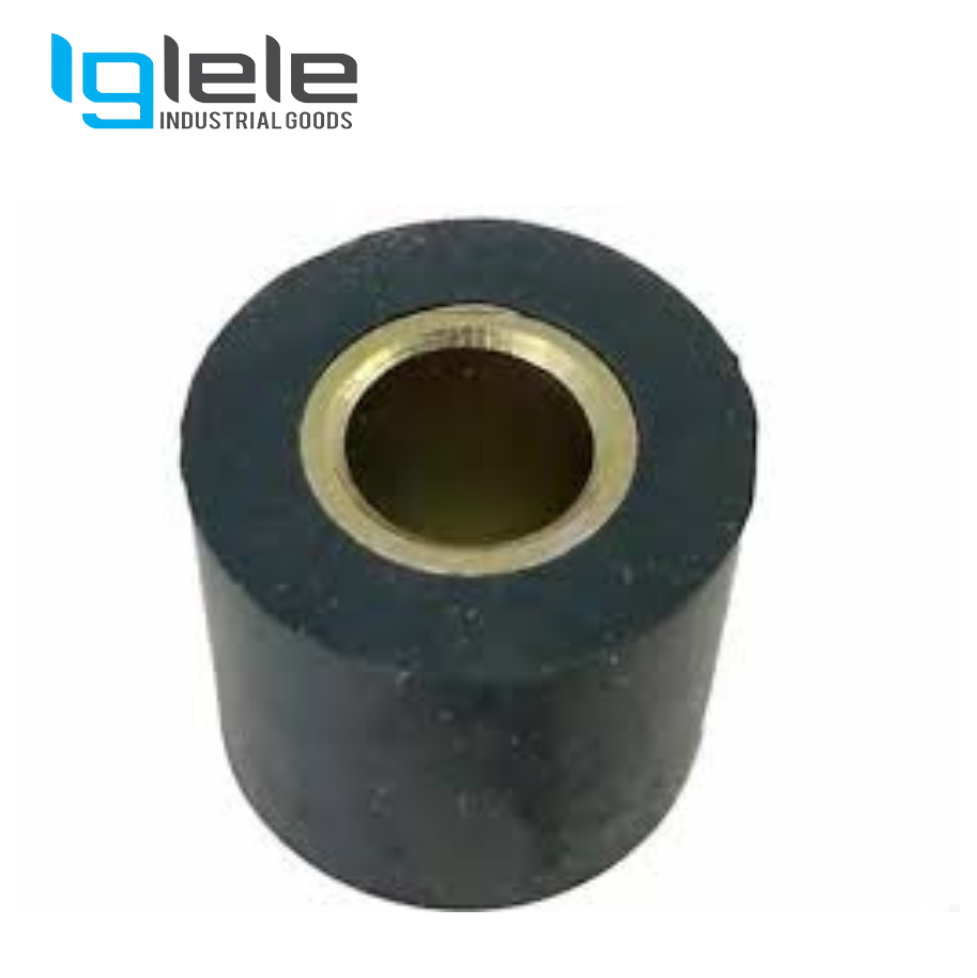

How is ‘bush rubber’ Used in the Automotive Sector?

In the automotive industry, bush rubber is primarily utilized in suspension systems and chassis components. These rubber bushings serve to absorb vibrations and reduce noise, thereby enhancing vehicle stability and comfort. For international buyers, especially those in regions with varying climates, sourcing high-quality bush rubber that can withstand temperature extremes and road conditions is critical. Additionally, compliance with automotive standards is essential to ensure safety and performance.

Illustrative image related to bush rubber

What Role Does Bush Rubber Play in Construction Machinery?

Bush rubber is extensively used in construction machinery to dampen vibrations and shock, protecting both the machinery and operators. This application improves equipment longevity and worker safety by minimizing wear and tear on critical components. Buyers in the construction sector should prioritize sourcing durable, weather-resistant rubber that can endure harsh outdoor conditions, ensuring consistent performance over time.

How is Bush Rubber Beneficial in Agricultural Equipment?

In agriculture, bush rubber is crucial for machinery and equipment, where it helps absorb shocks and vibrations during operation. This leads to increased efficiency and reduced wear on machinery, ultimately lowering maintenance costs. For B2B buyers in agriculture, it’s important to source bush rubber that is resistant to chemicals and moisture, ensuring that it can handle the rigors of farming environments.

Why is Bush Rubber Important in Aerospace Applications?

In the aerospace sector, bush rubber is used in aircraft landing gear and various components, providing essential vibration dampening and shock absorption. This application is vital for improving safety and performance during takeoff and landing. International buyers in aerospace must consider lightweight materials that comply with stringent aviation regulations, ensuring that the bush rubber meets safety and performance standards.

How Does Bush Rubber Enhance Equipment Performance in Mining and Heavy Industry?

In the mining and heavy industry, bush rubber is employed in equipment shock absorption systems, which are crucial for enhancing machinery performance and reducing maintenance costs. By mitigating vibrations, bush rubber helps to prolong the life of heavy machinery, which is often subjected to harsh operating conditions. Buyers in this sector should focus on sourcing customizable bush rubber solutions from reputable suppliers to meet specific machinery requirements and ensure operational efficiency.

3 Common User Pain Points for ‘bush rubber’ & Their Solutions

Scenario 1: Ensuring Compatibility with Existing Equipment

The Problem: One of the most significant challenges B2B buyers face when sourcing bush rubber is ensuring compatibility with existing machinery and equipment. Many suppliers offer a wide range of sizes and materials, but without precise specifications, buyers often find themselves with products that don’t fit or function as intended. This can lead to costly downtime and the frustration of having to return or exchange parts, which can disrupt operational flow and affect service delivery.

The Solution: To mitigate this risk, buyers should conduct a thorough assessment of their current equipment and its specifications before making a purchase. This includes measuring the dimensions of existing bushings, understanding the load-bearing requirements, and identifying the specific environmental conditions the rubber will be exposed to, such as temperature extremes or chemical exposure. When sourcing bush rubber, choose suppliers who provide detailed product specifications and customization options. Utilizing a vendor that allows for customized orders can ensure that the bushings meet precise requirements, thus eliminating compatibility issues and ensuring a smoother integration into existing systems.

Scenario 2: Addressing Durability Concerns in Harsh Environments

The Problem: Buyers in industries such as mining, construction, or heavy manufacturing often contend with the harsh conditions that can rapidly degrade rubber components. Factors like extreme temperatures, abrasive materials, and exposure to chemicals can lead to premature wear and failure of bush rubber, resulting in frequent replacements and increased maintenance costs. This not only impacts budget but can also compromise safety and operational efficiency.

The Solution: To address durability concerns, it’s essential for buyers to select bush rubber that is specifically formulated for high-stress environments. This involves choosing materials like EPDM or Nitrile rubber, which are known for their resilience against temperature fluctuations and chemical exposure. Engaging with manufacturers who offer extensive testing data and performance metrics can help buyers make informed decisions. Furthermore, implementing a regular maintenance schedule that includes inspections of bush rubber can help identify wear early, allowing for timely replacements before failures occur. This proactive approach ensures longevity and reliability, reducing unexpected downtime.

Scenario 3: Managing Inventory and Supply Chain Challenges

The Problem: Global supply chain disruptions can significantly impact the availability of bush rubber, making it difficult for buyers to maintain adequate inventory levels. Delays in shipments or fluctuations in pricing can create uncertainty, forcing businesses to either overstock in anticipation of future shortages or risk running low on critical components. This balancing act can strain budgets and lead to operational inefficiencies.

The Solution: To effectively manage inventory and mitigate supply chain risks, buyers should consider establishing long-term relationships with reliable suppliers who can provide consistent quality and availability. Implementing a just-in-time inventory system can also help maintain optimal stock levels without overcommitting financial resources. Buyers should leverage technology, such as inventory management software, to track usage patterns and predict future needs accurately. Additionally, diversifying the supplier base can safeguard against disruptions; having multiple suppliers for bush rubber can provide alternatives in case of shortages from a primary vendor. This strategic approach enables businesses to maintain continuity in operations and adapt swiftly to changing market conditions.

Illustrative image related to bush rubber

Strategic Material Selection Guide for bush rubber

What Are the Key Properties of Common Materials for Bush Rubber?

When selecting bush rubber materials, it’s essential to consider various properties that impact product performance. The most common materials used in bush rubber applications include EPDM, Neoprene, Nitrile, and Natural Rubber. Each material has unique characteristics that can affect durability, cost, and suitability for specific applications.

How Does EPDM Rubber Benefit Bush Applications?

EPDM (Ethylene Propylene Diene Monomer) rubber is known for its excellent weather resistance and durability. It performs well in extreme temperatures, ranging from -40°C to +120°C, making it suitable for outdoor applications. EPDM is also resistant to ozone, UV radiation, and various chemicals, which enhances its longevity in harsh environments.

Pros: EPDM is highly durable and has excellent resistance to heat and weathering. Its cost is relatively low compared to other synthetic rubbers, making it an economical choice for bulk purchases.

Cons: While EPDM is resistant to many chemicals, it may not perform well with petroleum-based products. This limitation can affect its suitability in certain industrial applications.

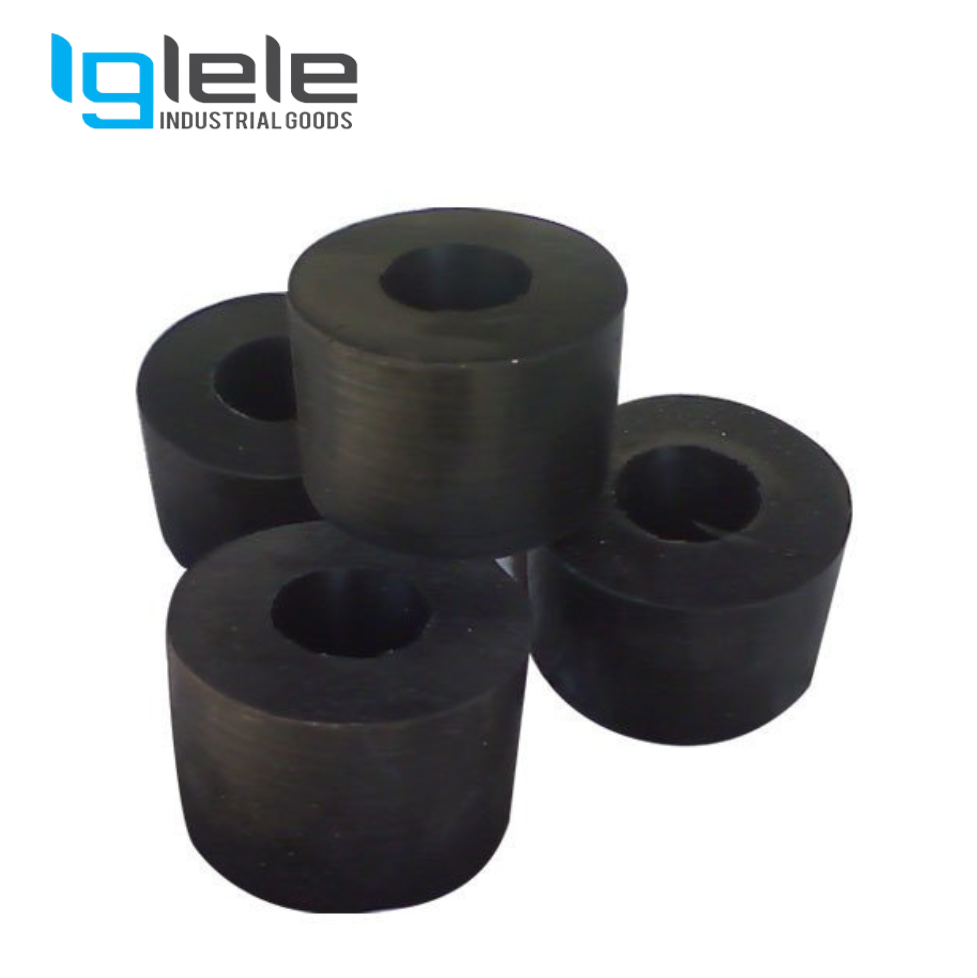

Illustrative image related to bush rubber

Impact on Application: EPDM is ideal for automotive and construction applications, where exposure to the elements is a concern. It is commonly used in seals and gaskets, providing reliable performance over time.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN, as EPDM’s performance can vary based on manufacturing practices.

What Advantages Does Neoprene Offer for Bush Rubber?

Neoprene rubber is recognized for its versatility and resilience. It offers good temperature resistance, typically from -30°C to +100°C, and is also known for its excellent resistance to oil, chemicals, and weathering.

Pros: Neoprene’s chemical resistance makes it suitable for applications in automotive and industrial sectors where exposure to oils and solvents is common. Its flexibility and durability contribute to a longer service life.

Illustrative image related to bush rubber

Cons: Neoprene tends to be more expensive than EPDM and may require more complex manufacturing processes, which can increase overall costs.

Impact on Application: Neoprene is particularly effective in environments where oil and chemicals are prevalent, making it a preferred choice for bushings in machinery and automotive applications.

Considerations for International Buyers: Compliance with international standards is crucial for Neoprene products, especially in Europe, where stringent regulations may apply.

Why Choose Nitrile Rubber for Bush Applications?

Nitrile rubber, or NBR, is well-known for its excellent oil resistance and is often used in applications requiring exposure to fuels and oils. It operates effectively in temperatures ranging from -40°C to +100°C.

Pros: The primary advantage of Nitrile is its outstanding resistance to petroleum products, making it ideal for automotive and industrial applications. Its durability and flexibility also enhance performance in dynamic applications.

Cons: Nitrile may not perform well in extreme heat or ozone exposure, which limits its use in outdoor applications. Additionally, it can be more costly than EPDM.

Impact on Application: Nitrile is commonly used in automotive seals and gaskets, where oil resistance is critical. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Buyers should verify that Nitrile products meet local compliance standards, especially in regions with strict environmental regulations.

What Are the Benefits of Using Natural Rubber in Bush Applications?

Natural rubber is prized for its excellent elasticity and tensile strength. It operates effectively in temperatures ranging from -20°C to +70°C and is known for its superior shock absorption capabilities.

Pros: Natural rubber is cost-effective and has excellent mechanical properties, making it suitable for a wide range of applications. Its shock-absorbing qualities are particularly beneficial in bushings.

Cons: However, natural rubber is less resistant to oils, chemicals, and UV light, which may limit its application in harsh environments.

Impact on Application: Natural rubber is often used in applications where flexibility and resilience are paramount, such as in automotive bushings and vibration dampers.

Considerations for International Buyers: Buyers should be aware of the sourcing and sustainability of natural rubber, as well as compliance with international labor and environmental standards.

Summary Table of Material Selection for Bush Rubber

| Material | Typical Use Case for bush rubber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EPDM | Automotive seals, construction gaskets | Excellent weather and UV resistance | Poor oil resistance | Low |

| Neoprene | Industrial machinery bushings | Good oil and chemical resistance | Higher cost, complex manufacturing | Med |

| Nitrile | Automotive seals and gaskets | Outstanding oil resistance | Limited performance in extreme heat | Med |

| Natural Rubber | Vibration dampers, automotive bushings | High elasticity and shock absorption | Poor chemical and UV resistance | Low |

This guide provides a comprehensive overview of material options for bush rubber, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bush rubber

What Are the Key Stages in the Manufacturing Process of Bush Rubber?

The manufacturing of bush rubber involves several critical stages, each essential for producing high-quality products that meet the demands of various industrial applications. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to bush rubber

-

Material Preparation: The first step involves selecting the appropriate rubber compounds. Common materials for bush rubber include natural rubber, EPDM, Neoprene, and Nitrile. Each material is chosen based on its specific properties, such as temperature resistance, flexibility, and durability. The selected rubber is then mixed with additives like curing agents, fillers, and pigments to enhance its performance characteristics.

-

Forming: Once the rubber compound is prepared, it is subjected to various forming techniques. Common methods include compression molding, injection molding, and extrusion. Compression molding is often used for larger bushings, while injection molding allows for more complex shapes and tighter tolerances. Extrusion is utilized to create continuous profiles that can be cut into specific lengths as needed.

-

Assembly: In this stage, the rubber components may be bonded to metal parts or other substrates. This is crucial for applications where bushings are used in mechanical assemblies, such as automotive and industrial machinery. The bonding process can involve adhesive applications or vulcanization, where heat and pressure are applied to create a strong bond between the rubber and metal.

-

Finishing: The final stage includes trimming, surface treatment, and quality checks. Components may be trimmed to exact specifications, and additional treatments, such as coating for enhanced durability or resistance to environmental factors, can be applied. This stage is critical for ensuring that the bushings meet the specific requirements of end-users.

What Quality Assurance Standards Are Relevant for Bush Rubber Manufacturing?

Quality assurance is a vital aspect of the bush rubber manufacturing process, ensuring that products meet international and industry-specific standards. Key standards include:

-

ISO 9001: This widely recognized standard outlines the criteria for a quality management system. Manufacturers certified under ISO 9001 demonstrate their commitment to quality and customer satisfaction through systematic processes and continuous improvement.

-

CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly important for bush rubber used in automotive and industrial applications.

-

API Standards: The American Petroleum Institute (API) sets standards for products used in the oil and gas industry. Compliance with API standards can be critical for bush rubber used in these high-stakes environments.

How Is Quality Control Implemented in Bush Rubber Manufacturing?

Quality control (QC) in bush rubber manufacturing involves multiple checkpoints to ensure that products meet the required specifications and standards. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection stage assesses raw materials upon delivery. Manufacturers verify that materials meet specified requirements before they are used in production.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, quality checks are performed at various stages. This includes monitoring the conditions of molding and bonding processes to ensure consistency and adherence to specifications.

-

Final Quality Control (FQC): After manufacturing, the finished products undergo comprehensive testing. This may include dimensional checks, tensile strength tests, and environmental resistance assessments to ensure that they perform as expected under operational conditions.

What Testing Methods Are Commonly Used for Bush Rubber Quality Assurance?

Various testing methods are employed to verify the quality and performance of bush rubber products. Common tests include:

-

Tensile Strength Testing: This test measures the maximum amount of tensile stress that a material can withstand before failure, providing insights into the durability of the rubber.

-

Hardness Testing: Often conducted using a durometer, this test assesses the material’s hardness, which is crucial for applications requiring specific levels of flexibility and resistance.

-

Compression Set Testing: This evaluates how much a rubber material can deform under a load and how well it returns to its original shape once the load is removed, indicating its resilience.

-

Environmental Resistance Testing: Products are subjected to various environmental conditions (e.g., temperature extremes, UV exposure, chemical exposure) to ensure they can withstand operational stresses.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should conduct due diligence to ensure that their suppliers maintain rigorous quality control practices. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing process and quality control systems in place. This firsthand assessment can reveal the supplier’s commitment to quality.

-

Reviewing Quality Reports: Requesting and reviewing quality assurance reports can provide insights into the supplier’s performance history, including compliance with standards and any past quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product quality. This is particularly useful for international transactions where distance may complicate direct oversight.

-

Certifications Verification: Buyers should verify that suppliers hold relevant certifications (e.g., ISO 9001, CE marking) and understand the implications of these certifications for product quality and safety.

What Are the Key Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, several nuances should be considered:

Illustrative image related to bush rubber

-

Regulatory Compliance: Understanding the regulatory landscape in the buyer’s country is essential. Different regions may have unique standards that suppliers must meet, impacting product acceptance.

-

Cultural Considerations: Cultural differences can influence communication and expectations regarding quality. Buyers should be aware of these nuances to foster effective partnerships.

-

Logistical Challenges: Shipping and handling can affect product quality. Buyers should work with suppliers who have robust logistics capabilities to ensure products arrive in excellent condition.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing bush rubber products, ensuring they select suppliers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bush rubber’

Introduction

In the competitive landscape of industrial procurement, sourcing bush rubber effectively is essential for ensuring operational efficiency and product quality. This guide provides a step-by-step checklist tailored for B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe. By following these actionable steps, you can streamline your sourcing process and make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in sourcing bush rubber. Consider factors such as size, material composition (e.g., EPDM, Neoprene, or Nitrile), and performance requirements, including temperature resistance and anti-vibration properties. Establishing these parameters upfront will help you filter suppliers and ensure that the products meet your operational standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in bush rubber. Look for companies with a solid reputation in the industry, focusing on their experience, certifications, and client testimonials. Utilize platforms like trade directories and industry forums to gather insights and reviews from other buyers.

Step 3: Evaluate Supplier Certifications

Before moving forward, it’s crucial to verify that your shortlisted suppliers have the necessary certifications and compliance with industry standards. Check for ISO certifications and any specific certifications relevant to your sector, as these indicate a commitment to quality and safety. This step helps mitigate risks associated with substandard products.

Step 4: Request Product Samples

Request samples from your potential suppliers to assess the quality of their bush rubber products. Evaluate these samples for durability, flexibility, and overall performance in your application context. Testing samples can provide you with practical insights into how the products will perform under real-world conditions.

Step 5: Compare Pricing and Terms

Once you have gathered samples, compare pricing and payment terms from different suppliers. Ensure that you are not only looking at the upfront costs but also considering long-term value, including warranty options and after-sales support. This comparative analysis will help you make a cost-effective decision while ensuring quality.

Step 6: Engage in Negotiations

Initiate negotiations with your preferred suppliers to discuss pricing, lead times, and delivery schedules. Be transparent about your needs and expectations, and don’t hesitate to ask for discounts on bulk orders or favorable payment terms. Effective negotiation can lead to significant cost savings and a stronger supplier relationship.

Illustrative image related to bush rubber

Step 7: Establish a Long-term Partnership

After finalizing your supplier, focus on establishing a long-term partnership. Regular communication and feedback can enhance collaboration and ensure that the supplier understands your evolving requirements. A solid partnership often leads to better pricing, priority service, and improved product offerings over time.

By following this checklist, you can confidently navigate the complexities of sourcing bush rubber, ensuring that you secure high-quality products that meet your business needs.

Comprehensive Cost and Pricing Analysis for bush rubber Sourcing

What Are the Key Cost Components of Bush Rubber Sourcing?

When sourcing bush rubber, understanding the cost structure is vital for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of rubber material significantly impacts the cost. Common materials include EPDM, Neoprene, Nitrile, and Silicone. Each material has different properties and price points, affecting overall costs.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Countries with lower labor costs may offer more competitive pricing, but this can also impact quality.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient production processes can lower overhead costs, which may be passed on to buyers.

-

Tooling: Initial tooling investments are critical for custom bush rubber products. The complexity and specificity of molds can lead to higher upfront costs, particularly for custom designs.

-

Quality Control: Ensuring that products meet industry standards and certifications can incur additional costs. Buyers should consider the implications of quality on longevity and performance.

-

Logistics: Transportation costs can fluctuate based on distance, shipping method, and weight. International shipping may involve tariffs and customs duties, adding to the total cost.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This can vary widely based on market demand and competition.

How Do Price Influencers Affect Bush Rubber Costs?

Several factors can influence the price of bush rubber, making it essential for buyers to understand these dynamics.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit prices due to economies of scale. Negotiating MOQ can yield significant savings.

-

Specifications and Customization: Custom specifications can raise costs due to additional tooling and materials. However, customized products may provide better performance and longevity, justifying the expense.

-

Materials: The choice of rubber material impacts durability and price. High-quality materials may result in higher upfront costs but can lead to lower Total Cost of Ownership (TCO) through reduced maintenance and replacement rates.

-

Quality and Certifications: Products meeting higher quality standards or certifications (e.g., ISO) may command premium prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence pricing. Engaging with reputable suppliers may result in better quality and service, albeit at a potentially higher cost.

-

Incoterms: Understanding shipping terms is crucial. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total cost of procurement.

What Are the Best Buyer Tips for Negotiating Bush Rubber Prices?

To secure favorable pricing and terms, B2B buyers should consider the following strategies:

-

Effective Negotiation: Leverage volume and long-term partnerships to negotiate better pricing. Clear communication about expectations can lead to more favorable terms.

-

Cost-Efficiency: Analyze the entire supply chain to identify areas for cost reduction. This includes considering local suppliers to minimize shipping and customs fees.

-

Total Cost of Ownership: Evaluate the long-term costs associated with bush rubber products, including maintenance, replacement, and operational efficiency. Sometimes a higher initial price can lead to lower overall costs.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and international trade regulations. Building relationships with local representatives can provide insights into market trends and pricing strategies.

-

Disclaimer for Indicative Prices: Always remember that prices for bush rubber can fluctuate based on market conditions, material availability, and other factors. Request quotes that reflect current pricing and consider the context of your specific needs.

By understanding these components and strategies, B2B buyers can make informed decisions, ensuring they source bush rubber effectively while optimizing costs.

Alternatives Analysis: Comparing bush rubber With Other Solutions

Understanding Alternatives in Bush Rubber Applications

In the realm of industrial applications, especially in sectors like automotive and manufacturing, choosing the right material for vibration dampening and support is crucial. Bush rubber is a popular choice, but it’s essential to explore viable alternatives that may offer different advantages or suit specific operational needs. This analysis compares bush rubber with two alternative solutions: polyurethane bushings and metal bushings.

Comparison Table

| Comparison Aspect | Bush Rubber | Polyurethane Bushings | Metal Bushings |

|---|---|---|---|

| Performance | Excellent vibration dampening; flexible | High load-bearing capacity; durable | Very rigid; limited vibration dampening |

| Cost | Moderate cost per unit | Higher initial cost | Generally lower cost |

| Ease of Implementation | Easy to install; requires minimal tools | Moderate installation complexity | Requires precise machining for fit |

| Maintenance | Low maintenance; resistant to wear | Moderate maintenance; may degrade over time | Low maintenance; highly durable |

| Best Use Case | Automotive applications, machinery support | Heavy-duty applications, off-road vehicles | Structural applications, high-load situations |

Pros and Cons of Each Alternative

What Are the Advantages and Disadvantages of Polyurethane Bushings?

Polyurethane bushings are renowned for their high load-bearing capacity and durability, making them suitable for heavy-duty applications. They offer superior performance in high-stress environments, such as off-road vehicles, where traditional rubber may fail. However, they come at a higher initial cost compared to bush rubber, which may deter some buyers. Additionally, while they require a more complex installation process, their long-term performance can justify the investment.

How Do Metal Bushings Compare to Bush Rubber?

Metal bushings provide exceptional rigidity and can support substantial loads, making them ideal for structural applications. They are generally more cost-effective than both bush rubber and polyurethane options. However, metal bushings have limited vibration dampening capabilities, which can lead to increased wear and tear on connected components. Their installation requires precise machining, which can complicate the implementation process and increase labor costs.

Illustrative image related to bush rubber

How Can B2B Buyers Choose the Right Solution?

When selecting the right solution, B2B buyers should consider their specific operational requirements and constraints. If vibration dampening and flexibility are paramount, bush rubber remains a strong choice. For applications demanding high load capacity and durability, polyurethane bushings may be more appropriate, despite their higher cost. In contrast, metal bushings can be beneficial for structural applications where rigidity is critical, but users must be aware of their limitations regarding vibration absorption.

Ultimately, understanding the unique advantages and disadvantages of each alternative enables buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for bush rubber

What Are the Key Technical Properties of Bush Rubber?

When sourcing bush rubber, understanding its technical specifications is crucial for ensuring compatibility and performance in various applications. Here are some essential properties to consider:

1. Material Grade

Bush rubber can be manufactured from various materials, including natural rubber, EPDM, Neoprene, and Nitrile. Each material offers unique benefits, such as resistance to heat, chemicals, and abrasion. Selecting the right material grade is vital for ensuring the longevity and durability of the bushings in their specific operating environments.

2. Tolerance

Tolerance refers to the allowable variation in dimensions during manufacturing. In bush rubber applications, precise tolerances are critical to ensure proper fit and function within machinery. Tight tolerances reduce the risk of wear and tear, enhancing performance and minimizing the need for frequent replacements, which is particularly important for B2B buyers focused on operational efficiency.

3. Hardness (Shore A)

Hardness is measured using the Shore A scale, indicating the rubber’s resistance to indentation. Softer rubbers provide better shock absorption, while harder rubbers offer increased support and load-bearing capacity. Buyers must assess the hardness of bush rubber to ensure it meets the demands of their applications, particularly in automotive and industrial contexts.

4. Dynamic and Static Load Capacity

This property defines the maximum load that bush rubber can withstand under dynamic (moving) and static (stationary) conditions. For B2B buyers, understanding load capacity is crucial for selecting the right bushings that can handle the expected stresses in their specific applications, thereby preventing premature failure.

5. Temperature Resistance

Bush rubber must perform effectively across a range of temperatures. The ability to withstand extreme heat or cold is essential for applications in automotive, aerospace, and industrial machinery. Buyers should consider the operational temperature range when selecting bush rubber to ensure reliability and safety.

6. Vibration Damping Properties

Bush rubber serves as a vibration damper, reducing the transmission of vibrations from machinery to other components. Effective vibration damping can lead to improved performance and extended lifespan for both the bushings and the machinery. Understanding the damping properties is crucial for industries where vibration reduction is a priority.

What Are Common Trade Terms Related to Bush Rubber?

Familiarity with industry jargon can streamline communication and enhance negotiations. Here are some essential trade terms related to bush rubber:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of bush rubber, knowing if a supplier is an OEM can assure buyers of quality and compatibility with existing machinery.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers to plan their purchases effectively, ensuring they meet their operational needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Issuing an RFQ for bush rubber can help buyers compare offers and negotiate better terms, ensuring cost-effectiveness in their procurement processes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers. Familiarity with these terms is crucial for B2B transactions involving bush rubber, as they dictate shipping responsibilities, risk management, and costs.

5. Lead Time

Lead time refers to the duration from placing an order to its delivery. Understanding lead times is vital for B2B buyers to manage inventory and production schedules effectively, ensuring they have the necessary components when needed.

6. Certification Standards

Certification standards (such as ISO or ASTM) ensure that products meet specific quality and safety requirements. Buyers should verify that their bush rubber suppliers comply with relevant certification standards to ensure product reliability and safety in their applications.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing bush rubber, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the bush rubber Sector

What Are the Key Trends Driving the Bush Rubber Market?

The bush rubber sector is witnessing dynamic changes influenced by several global drivers. One of the primary factors is the increasing demand for high-performance materials across various industries, including automotive, construction, and manufacturing. This trend is driven by technological advancements that enhance product durability and efficiency. Moreover, the growing emphasis on reducing total cost of ownership is pushing companies to seek reliable and cost-effective sourcing options.

Emerging B2B technologies, such as digital marketplaces and supply chain management platforms, are transforming how international buyers source bush rubber products. These technologies facilitate real-time data sharing, improve visibility across the supply chain, and allow for more informed decision-making. As a result, buyers from regions like Africa, South America, the Middle East, and Europe can effectively identify and engage with suppliers that meet their specific needs.

Market dynamics are also shifting due to geopolitical factors and supply chain disruptions, which have underscored the importance of diversifying sourcing strategies. International buyers must now consider alternative supply chains to mitigate risks associated with reliance on single sources or regions. This diversification trend is particularly relevant for buyers in countries like Germany and Nigeria, where local industries are rapidly evolving and require adaptable sourcing solutions.

How Does Sustainability Influence Sourcing Trends in the Bush Rubber Sector?

Sustainability has become a cornerstone of modern sourcing strategies within the bush rubber sector. The environmental impact of rubber production is increasingly scrutinized, prompting businesses to adopt ethical sourcing practices. This shift is crucial not only for compliance with regulations but also for meeting consumer demand for environmentally friendly products.

International buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices, such as responsible harvesting and the use of eco-friendly materials. Certifications like Forest Stewardship Council (FSC) and Global Organic Latex Standard (GOLS) are becoming essential criteria in the procurement process. These certifications assure buyers that the bush rubber is sourced sustainably, aligning with broader corporate social responsibility goals.

Furthermore, the incorporation of recycled materials and innovative manufacturing processes that reduce waste is gaining traction. Buyers who engage with suppliers focused on sustainability can enhance their brand reputation and appeal to a growing demographic of environmentally conscious consumers.

What Is the Historical Context of the Bush Rubber Market?

The bush rubber industry has evolved significantly over the decades. Initially, bush rubber was primarily used in niche applications, but advancements in manufacturing technology have expanded its applications across various sectors. The introduction of synthetic alternatives in the mid-20th century posed challenges for natural rubber sourcing; however, the unique properties of bush rubber, such as its flexibility and durability, have ensured its continued relevance.

In recent years, the focus has shifted towards sustainable practices and ethical sourcing, reflecting broader global trends in environmental consciousness. As businesses strive to meet regulatory standards and consumer expectations, the bush rubber market is poised for further transformation, emphasizing the importance of responsible sourcing and innovation in production methods.

Illustrative image related to bush rubber

Through understanding these trends, international B2B buyers can make informed decisions that not only meet their operational needs but also align with their corporate values and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of bush rubber

-

How do I solve issues with rubber bush wear in machinery?

To address rubber bush wear in machinery, start by assessing the operating environment and load conditions. Ensure that the bushings are made from suitable materials such as EPDM or Nitrile that offer better durability and resistance to environmental factors. Regular maintenance checks can help identify early signs of wear, allowing for timely replacements. Additionally, consider using customized bushings designed specifically for your application, which can enhance performance and longevity. -

What is the best rubber material for bushings in high-temperature applications?

For high-temperature applications, silicone rubber is often the best choice due to its excellent thermal stability and resistance to degradation. Silicone can maintain its properties at elevated temperatures, making it ideal for automotive and industrial settings. Other options include Viton® and EPDM, which also perform well under heat but may have specific temperature limits. Always consult with suppliers to ensure the selected material aligns with your operational requirements. -

How can I customize bush rubber products for my specific needs?

Customization of bush rubber products can be achieved by discussing your requirements with manufacturers or suppliers. Factors such as size, shape, material type, and specific performance characteristics can all be tailored. Many suppliers offer a range of materials, including Neoprene and SBR, allowing you to choose based on factors like chemical resistance and flexibility. Ensure to provide detailed specifications, including dimensions and operational conditions, to receive accurate prototypes and samples. -

What are the typical minimum order quantities (MOQs) for bush rubber products?

Minimum order quantities (MOQs) for bush rubber products can vary significantly by supplier, typically ranging from 100 to 1,000 units. Smaller suppliers might offer lower MOQs, while larger manufacturers may set higher thresholds to justify production costs. It’s advisable to discuss your needs directly with suppliers, as many are willing to negotiate MOQs for first-time orders or ongoing partnerships, especially if you express interest in bulk purchasing. -

What payment terms should I expect when sourcing bush rubber internationally?

Payment terms when sourcing bush rubber internationally typically include options such as letters of credit, wire transfers, or payment in advance. Many suppliers may request a deposit upfront, with the balance due upon shipment or delivery. It’s crucial to clarify these terms during negotiations and ensure they align with your financial processes. Additionally, consider the implications of currency exchange rates and international transaction fees when budgeting for your purchase. -

How do I ensure quality assurance when sourcing bush rubber?

To ensure quality assurance when sourcing bush rubber, request detailed product specifications and certifications from suppliers. Look for manufacturers that adhere to international standards such as ISO 9001, which indicates a commitment to quality management. Additionally, consider third-party inspections or quality audits, especially for large orders. Establishing a clear communication channel with the supplier regarding quality expectations can also prevent misunderstandings. -

What logistics considerations should I keep in mind when importing bush rubber?

When importing bush rubber, logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with rubber products to navigate potential import restrictions. Also, assess the shipping costs and delivery times for different modes of transport, such as sea or air freight. Planning for delays due to customs clearance is essential, especially in regions with strict import regulations. -

How can I vet suppliers when sourcing bush rubber internationally?

Vetting suppliers involves several steps: research their background, check references, and review their financial stability. Utilize platforms like Alibaba or Global Sources to find reputable manufacturers with positive reviews. Request samples to evaluate product quality firsthand and inquire about their production capabilities and lead times. It’s also beneficial to visit the supplier’s facility, if possible, or conduct virtual audits to ensure they meet your standards for quality and reliability.

Top 3 Bush Rubber Manufacturers & Suppliers List

1. The Rubber Company – Rubber Bushes

Domain: therubbercompany.com

Registered: 2013 (12 years)

Introduction: {“Item Code”: “RUBBER-BUSHES”, “Key Features”: [“Durable”, “Anti-vibration”, “Operable in high and low temperatures”, “Flexible and smooth-finish”], “Product Description”: “Our standard Rubber Bushes serve as invaluable and top-tier assets within the industrial sector, offering superior protection against potent vibrations for your machinery and assets. Our diverse selection of rubber metal bonded…

2. Gteek – Rubber Metal Bonded Bushings & Custom Moulded Polyurethane

Domain: gteek.com

Registered: 2017 (8 years)

Introduction: Rubber Metal Bonded Bushings, Vibration Dampers, Adjustable Leveling Feet, Screen Cleaning Balls, Custom Moulded Polyurethane.

3. Maedler – Heavy-Duty Steel Rubber Bushes PHO-V

Domain: maedlernorthamerica.com

Registered: 2020 (5 years)

Introduction: Heavy-Duty Steel Rubber Bushes PHO-V, Vulcanized Version

Strategic Sourcing Conclusion and Outlook for bush rubber

In today’s competitive landscape, strategic sourcing of bush rubber presents significant opportunities for international B2B buyers. By prioritizing quality, customization, and supplier relationships, companies can enhance their operational efficiency and product reliability. The diverse applications of bush rubber—from automotive to industrial sectors—underscore its importance as a versatile component in machinery and equipment.

Investing in durable, anti-vibration rubber bushes not only mitigates wear and tear on machinery but also ensures compliance with industry standards, particularly in regions like Europe and the Middle East where regulations are stringent. Buyers should focus on suppliers that offer a broad range of materials, such as EPDM, Neoprene, and Silicone, to tailor solutions to their specific needs.

Looking ahead, the demand for bush rubber is set to grow, driven by advancements in technology and increasing awareness of sustainability. B2B buyers across Africa, South America, and Europe should capitalize on this trend by forging strong partnerships with reliable manufacturers. By aligning with innovative suppliers, businesses can secure high-quality bush rubber products that support their operational goals and contribute to long-term success. Embrace the future of sourcing—invest in bush rubber today for a more resilient tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.