A B2B Buyer’s Guide to Bucket Conveyor System: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for bucket conveyor system

In today’s competitive landscape, sourcing an efficient bucket conveyor system poses a significant challenge for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany. As industries strive for operational efficiency and cost-effectiveness, the right conveyor solution can dramatically impact productivity, material handling, and overall business success. This comprehensive guide delves into the diverse types of bucket conveyor systems available, their various applications across multiple sectors, and key considerations for supplier vetting and cost analysis.

By providing detailed insights into the functionalities and benefits of different bucket conveyor designs, this guide empowers decision-makers to make informed purchasing choices. Readers will learn how to assess their unique operational needs, evaluate potential suppliers, and understand the total cost of ownership associated with these systems. Additionally, we will explore best practices in installation and maintenance, ensuring that buyers can optimize their investment over time.

Equipped with this knowledge, B2B buyers can navigate the global market with confidence, selecting the right bucket conveyor systems that meet their specific requirements and drive operational excellence.

Understanding bucket conveyor system Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Elecon™ | Multi-axis capability, can move materials in any direction | Food processing, pharmaceuticals | Pros: Space-efficient, versatile design. Cons: Higher initial investment. |

| Swinglink® | Robust construction, overlapping bucket lips | Heavy industrial, bulk material handling | Pros: Durable, gentle handling. Cons: May require more maintenance. |

| Econ-O-Lift™ | Collapsing chain, multiple discharge points | Food and delicate product applications | Pros: Flexible and sanitary design. Cons: Complexity may increase costs. |

| Standard Bucket Elevators | Simple vertical lift mechanism, fixed bucket design | Agriculture, mining, and construction | Pros: Cost-effective, straightforward installation. Cons: Limited flexibility in layout. |

| Pneumatic Bucket Conveyors | Utilizes air pressure for material transport | Powder and granule handling | Pros: Minimal product degradation, suitable for sensitive materials. Cons: Requires compressed air source, may be costly to operate. |

What are the Key Characteristics of the Elecon™ Bucket Conveyor System?

The Elecon™ bucket conveyor stands out due to its unique multi-axis capability, enabling it to transport materials not only vertically and horizontally but also in turns. This flexibility allows it to be integrated into complex production layouts, making it ideal for industries such as food processing and pharmaceuticals where space efficiency is crucial. When considering the Elecon™, buyers should evaluate their layout requirements, as its versatility can lead to significant operational efficiencies, although the initial investment may be higher than traditional systems.

How Does the Swinglink® Bucket Elevator Benefit Heavy Industrial Applications?

The Swinglink® bucket elevator is designed for heavy-duty applications, featuring a continuous chain and overlapping bucket lips that enhance its durability and adaptability. This system is particularly suited for industries that deal with bulk materials, such as mining and construction. Buyers should focus on the material handling capabilities and environmental conditions of their operations, as the Swinglink® is engineered to withstand harsh environments, although it may require more maintenance compared to lighter systems.

What Makes the Econ-O-Lift™ Ideal for Food and Delicate Products?

The Econ-O-Lift™ bucket elevator is engineered with a collapsing chain design and multiple discharge points, making it particularly effective for food and delicate product applications. Its design minimizes product spillage and allows for compliance with stringent sanitation standards. Buyers in the food industry should consider the regulatory requirements and the need for gentle handling of products, as this system provides a balance between flexibility and adherence to hygiene standards, albeit with potentially higher costs due to its complexity.

Why Choose Standard Bucket Elevators for Simplicity and Cost-Effectiveness?

Standard bucket elevators are characterized by their straightforward vertical lift mechanism, making them a cost-effective choice for applications in agriculture, mining, and construction. Their simplicity allows for easy installation and maintenance, which is appealing for businesses looking to minimize operational disruptions. However, buyers should recognize the limitations in flexibility and layout options, as these systems are best suited for straightforward vertical applications without complex routing needs.

How Can Pneumatic Bucket Conveyors Enhance Material Handling?

Pneumatic bucket conveyors utilize air pressure to move bulk materials, making them ideal for handling powders and granules. This system minimizes product degradation and is suitable for sensitive materials, such as those in the pharmaceutical and food sectors. Buyers should assess their operational requirements, particularly the need for a compressed air source, as this can lead to increased operational costs. However, the benefits of reduced product damage and improved efficiency can outweigh these considerations for many applications.

Key Industrial Applications of bucket conveyor system

| Industry/Sector | Specific Application of bucket conveyor system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Transporting grains and powders for packaging | Ensures gentle handling, minimizing product degradation | Compliance with food safety standards, material type |

| Mining and Minerals | Elevating bulk minerals from extraction sites | Increases efficiency in material handling operations | Durability against harsh environments, maintenance needs |

| Pharmaceuticals | Moving delicate ingredients in production lines | Maintains product integrity and reduces contamination | Cleanability, compatibility with sensitive materials |

| Agriculture | Handling seeds and fertilizers for distribution | Enhances operational efficiency and reduces spillage | Material compatibility, environmental conditions |

| Recycling and Waste Management | Transporting sorted recyclables for processing | Improves sorting efficiency and reduces manual handling | Robust design for heavy loads, adaptability in layout |

How is a Bucket Conveyor System Used in Food Processing?

In the food processing industry, bucket conveyor systems are essential for transporting grains, powders, and other ingredients from one point to another, such as from storage silos to packaging lines. These systems are designed to handle materials gently to prevent degradation and contamination, addressing key concerns in food safety. Buyers in this sector must consider compliance with strict food safety regulations, selecting materials that are easy to clean and resistant to corrosion, such as stainless steel.

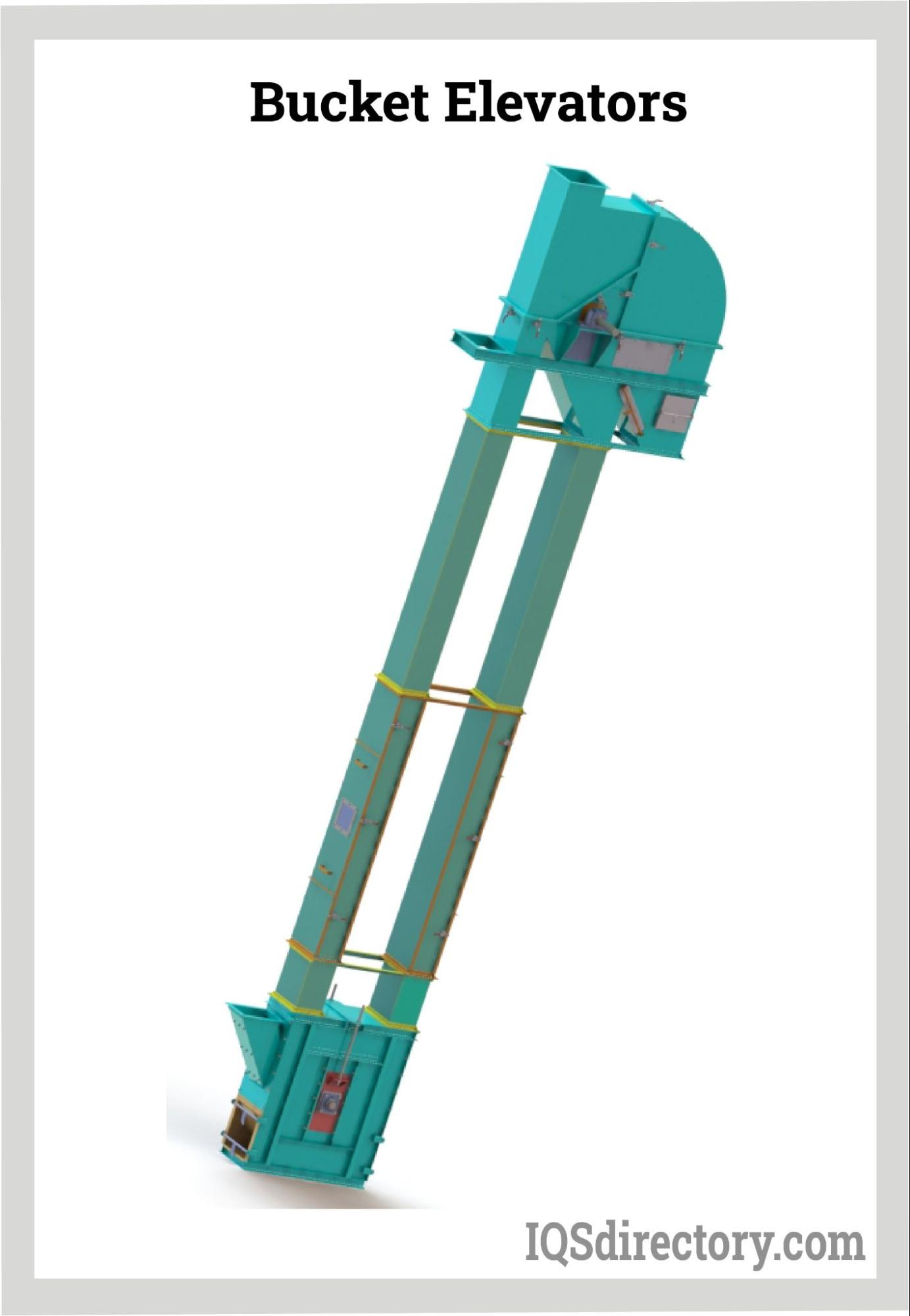

Illustrative image related to bucket conveyor system

What Role Does a Bucket Conveyor System Play in Mining and Minerals?

In mining and minerals, bucket conveyor systems are employed to elevate bulk materials from extraction sites to processing areas. This application enhances operational efficiency by facilitating continuous material flow and reducing downtime. For international buyers, especially in regions like Africa and South America, sourcing considerations include the durability of the conveyor systems against harsh mining environments and the ease of maintenance to minimize operational interruptions.

How Do Bucket Conveyors Benefit the Pharmaceutical Industry?

Bucket conveyor systems are pivotal in the pharmaceutical sector for moving delicate ingredients throughout production lines. These systems ensure that products remain uncontaminated and maintain their integrity during transport. Buyers need to focus on the cleanability of the equipment, as well as the materials used in construction to comply with stringent health regulations. Custom designs that allow for easy disassembly and cleaning are often a priority.

How are Bucket Conveyor Systems Used in Agriculture?

In agriculture, bucket conveyor systems efficiently handle seeds and fertilizers, optimizing the distribution process. These systems minimize spillage and ensure that products are delivered to the right location without degradation. Buyers should consider the compatibility of the conveyor system with various agricultural materials and the environmental conditions in which they will operate, ensuring that the equipment can withstand exposure to moisture and chemicals.

What Advantages Do Bucket Conveyors Offer in Recycling and Waste Management?

In the recycling and waste management sectors, bucket conveyor systems are utilized to transport sorted recyclables to processing facilities. This application significantly improves sorting efficiency and reduces the need for manual handling, which can pose safety risks. When sourcing these systems, businesses should prioritize robust designs that can handle heavy loads and consider the adaptability of the conveyor layout to fit existing processing operations.

3 Common User Pain Points for ‘bucket conveyor system’ & Their Solutions

Scenario 1: Inefficient Material Handling Processes

The Problem: In many manufacturing environments, B2B buyers encounter challenges with their material handling systems that lead to inefficiencies. For instance, a food processing company may struggle with outdated conveyor systems that cannot adapt to varying product sizes and weights. This results in bottlenecks, increased labor costs, and, ultimately, product degradation due to mishandling. Furthermore, these inefficiencies can lead to increased downtime as teams are forced to manually intervene in the process, disrupting the overall workflow.

The Solution: To combat inefficiencies in material handling, buyers should consider investing in a versatile bucket conveyor system designed for flexibility and adaptability. When sourcing a bucket conveyor, it is crucial to assess the specific requirements of the operation, such as the types of materials being handled and the desired throughput rates. Working with manufacturers who offer custom solutions, like Gough Econ’s Elecon™, can help ensure the system is tailored to meet unique operational needs. This system not only provides vertical and horizontal movement but can also make turns, minimizing the footprint of the conveyor layout. By implementing such a tailored solution, companies can significantly enhance workflow efficiency, reduce labor costs, and maintain product integrity throughout the handling process.

Scenario 2: High Maintenance Costs and Downtime

The Problem: Many B2B buyers experience high maintenance costs associated with their bucket conveyor systems, leading to unexpected downtime. For example, a mining company may find that their heavy-duty bucket conveyors require frequent repairs due to the harsh operating conditions and the abrasive nature of the materials being transported. This not only results in direct costs for repairs but also indirect costs from lost productivity and delayed project timelines.

The Solution: To mitigate maintenance costs and reduce downtime, businesses should focus on selecting bucket conveyor systems built with durability in mind. When considering options, buyers should inquire about the materials and construction of the conveyor components. For instance, opting for bucket conveyors made from high-strength steel or engineered plastics can provide enhanced durability against wear and tear. Additionally, implementing a preventive maintenance schedule can further reduce the likelihood of unexpected breakdowns. Regular inspections and proactive replacements of wear parts can extend the lifespan of the equipment and ensure consistent operation. Collaborating with manufacturers who provide robust warranty options and support can also lead to peace of mind and lower long-term operational costs.

Scenario 3: Product Integrity and Contamination Risks

The Problem: In industries such as food and pharmaceuticals, maintaining product integrity is paramount. B2B buyers often face challenges with traditional bucket conveyor systems that can lead to contamination risks and product spills. For example, a bakery might use a standard bucket conveyor that causes delicate baked goods to tumble and break, leading to waste and potential contamination from unclean equipment.

Illustrative image related to bucket conveyor system

The Solution: To address product integrity and contamination concerns, buyers should prioritize bucket conveyor systems designed specifically for sensitive materials. Systems like the Swinglink bucket elevator, which features gentle handling and clean-in-place capabilities, can significantly reduce the risk of product damage and contamination. When sourcing these systems, buyers should ensure that the equipment meets industry hygiene standards and has easily cleanable surfaces to maintain sanitary conditions. Additionally, investing in a system with enclosed buckets can prevent spillage and contamination from external sources. By focusing on specialized equipment designed for delicate handling, companies can safeguard their products, reduce waste, and comply with strict regulatory standards.

Strategic Material Selection Guide for bucket conveyor system

What Are the Key Materials Used in Bucket Conveyor Systems?

When selecting materials for bucket conveyor systems, it is essential to consider various factors such as durability, cost, and compatibility with the materials being handled. Below, we analyze four common materials used in bucket conveyor systems, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Carbon Steel Perform in Bucket Conveyor Systems?

Key Properties: Carbon steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It typically has a temperature rating of up to 400°F (204°C) and can withstand moderate corrosive environments when properly coated.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength. However, it is prone to rust and corrosion if not adequately protected, which can lead to increased maintenance costs over time. Manufacturing complexity is relatively low, making it a popular choice for many industries.

Impact on Application: Carbon steel is ideal for handling bulk materials such as grains and aggregates. However, it may not be suitable for applications involving corrosive substances without additional protective coatings.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that carbon steel components meet local standards for corrosion resistance, especially in humid environments. Compliance with standards such as ASTM A36 or equivalent is critical.

What Role Does Stainless Steel Play in Bucket Conveyor Systems?

Key Properties: Stainless steel offers excellent corrosion resistance and can operate effectively at temperatures up to 800°F (427°C). It is also non-reactive, making it suitable for food and pharmaceutical applications.

Pros & Cons: The main advantage of stainless steel is its longevity and hygiene, making it perfect for sensitive applications. However, it comes at a higher cost compared to carbon steel and may require more complex manufacturing processes.

Impact on Application: Stainless steel is highly effective for handling food products, chemicals, and pharmaceuticals. Its resistance to corrosion ensures that it maintains product integrity.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure compliance with food safety standards such as FDA or EU regulations, particularly when used in food processing. The material should also meet standards like ASTM A304 or A316.

How Do Plastic Materials Enhance Bucket Conveyor Systems?

Key Properties: Plastics, such as polyethylene and polypropylene, are lightweight and resistant to corrosion and chemicals. They can typically handle temperatures up to 180°F (82°C) and are flexible in design.

Pros & Cons: The advantages of plastic materials include low weight, corrosion resistance, and lower costs. However, they may not be suitable for high-temperature applications and can wear out faster than metal options.

Impact on Application: Plastic is ideal for conveying lightweight materials, including food items and powders. Its non-corrosive nature makes it suitable for various industries, including food and pharmaceuticals.

Considerations for International Buyers: Buyers should verify that plastic materials comply with relevant safety and health regulations, particularly in food applications. Standards such as FDA compliance or EU regulations are essential.

What Are the Advantages of Using Aluminum in Bucket Conveyor Systems?

Key Properties: Aluminum is lightweight, resistant to corrosion, and can withstand temperatures up to 400°F (204°C). Its strength-to-weight ratio makes it suitable for various applications.

Illustrative image related to bucket conveyor system

Pros & Cons: The key advantage of aluminum is its lightweight nature, which reduces energy consumption during operation. However, it is more expensive than carbon steel and may require specialized manufacturing techniques.

Impact on Application: Aluminum is well-suited for applications that require frequent cleaning and maintenance, such as food processing and pharmaceuticals. Its resistance to corrosion ensures long-term durability.

Considerations for International Buyers: Buyers in regions like Germany and Vietnam should ensure that aluminum components meet industry standards such as DIN or JIS, particularly for food and pharmaceutical applications.

Summary Table of Material Selection for Bucket Conveyor Systems

| Material | Typical Use Case for bucket conveyor system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Bulk materials like grains and aggregates | Cost-effective and strong | Prone to rust without protective coatings | Medium |

| Stainless Steel | Food and pharmaceutical applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Lightweight materials, food items | Lightweight and corrosion-resistant | Limited high-temperature applications | Low |

| Aluminum | Food processing and pharmaceuticals | Lightweight, energy-efficient | More expensive and requires special manufacturing | Medium |

By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bucket conveyor system

What Are the Main Stages of Manufacturing a Bucket Conveyor System?

The manufacturing process of a bucket conveyor system involves several critical stages, ensuring the final product meets the operational and quality requirements of diverse industries. These stages include material preparation, forming, assembly, and finishing, each employing specific techniques tailored to the unique demands of bucket conveyors.

Illustrative image related to bucket conveyor system

How Is Material Prepared for Bucket Conveyor Manufacturing?

Material preparation is the foundational stage where raw materials are selected and processed to meet the design specifications. Common materials for bucket conveyors include various grades of steel, stainless steel, and plastics, chosen for their durability and resistance to wear and corrosion.

In this stage, the materials undergo cutting, shaping, and surface treatment. Advanced cutting techniques, such as laser cutting or water jet cutting, ensure precision in the dimensions of components like buckets and frames. Surface treatments, including galvanization or powder coating, are applied to enhance corrosion resistance and improve the lifespan of the conveyor system.

What Techniques Are Used in Forming Components of Bucket Conveyors?

Once the materials are prepared, the next step is forming the individual components of the bucket conveyor system. This includes fabricating buckets, frames, and chains.

Key techniques in this stage include:

- Stamping: Used for creating bucket shapes from flat metal sheets, ensuring uniformity and reducing waste.

- Welding: This is critical for assembling various components together. Automated welding processes, such as robotic welding, enhance precision and repeatability.

- Injection Molding: For plastic components, injection molding is utilized to produce lightweight and durable buckets, allowing for intricate designs and shapes that facilitate material handling.

These forming techniques ensure that each component meets the necessary specifications for strength, durability, and functionality.

How Is the Assembly of Bucket Conveyors Executed?

Assembly is where all formed components come together to create the complete bucket conveyor system. This stage typically involves both manual and automated processes, depending on the complexity and scale of production.

Key considerations during assembly include:

- Alignment and Integration: Ensuring that all components fit together correctly is crucial for operational efficiency. This often requires specialized jigs and fixtures to hold parts in place during assembly.

- Quality Checks: At various points in the assembly process, inspections are conducted to confirm that components meet design specifications. This can include visual inspections as well as measurements using calipers and gauges.

The assembly process is designed to facilitate easy maintenance and flexibility, allowing for quick adjustments to accommodate different material types and sizes.

What Finishing Processes Are Applied to Bucket Conveyors?

The finishing stage enhances the appearance and performance of the bucket conveyor system. This may involve:

- Surface Finishing: Techniques such as sanding, polishing, or additional coating applications improve aesthetics and functionality, providing resistance to abrasion and chemical exposure.

- Testing: Before the final product is shipped, it undergoes rigorous testing to ensure it meets operational standards. This includes load testing and operational trials to simulate real-world conditions.

Finishing processes are essential for ensuring that the bucket conveyor system is not only visually appealing but also capable of performing effectively in its intended environment.

What Quality Assurance Measures Are Essential for Bucket Conveyor Systems?

Quality assurance (QA) is critical in manufacturing bucket conveyor systems, ensuring that products meet both international and industry-specific standards. This process involves several checkpoints and testing methods, which are vital for maintaining high-quality manufacturing standards.

Illustrative image related to bucket conveyor system

Which International Standards Are Relevant for Quality Assurance?

For bucket conveyor systems, adherence to international quality standards is paramount. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements, leading to enhanced customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE marking (for products sold in the European Economic Area) and API standards (for equipment used in the petroleum and natural gas industries) are also critical. These certifications affirm that the products meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are essential in the manufacturing process of bucket conveyor systems. These checkpoints typically include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified standards before being used in production.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to identify any deviations from quality standards, allowing for immediate corrective actions.

- Final Quality Control (FQC): Before shipment, the completed bucket conveyor systems undergo thorough testing to confirm they meet all operational and safety requirements.

What Common Testing Methods Are Utilized in Quality Assurance?

Common testing methods employed in the QA process for bucket conveyor systems include:

- Load Testing: Assessing the system’s ability to handle the maximum load it will encounter in operation.

- Functional Testing: Verifying that all components operate as intended, including the movement of buckets and the integrity of the conveyor system.

- Durability Testing: Subjecting the system to simulated operational conditions to evaluate wear and tear over time.

These testing methods ensure that the final product is reliable and capable of performing under the expected operational conditions.

Illustrative image related to bucket conveyor system

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers must take proactive steps to ensure that their suppliers maintain robust quality assurance practices. Here are several ways to verify supplier QC:

- Supplier Audits: Conducting on-site audits of manufacturing facilities allows buyers to assess the supplier’s quality management systems, production processes, and adherence to standards.

- Requesting Quality Reports: Buyers should request documentation that outlines the supplier’s quality control processes, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices, ensuring compliance with international standards.

What Quality Control Nuances Should International Buyers Be Aware Of?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. These may include:

- Regulatory Compliance: Understanding the regulatory requirements in both the supplier’s and buyer’s country is crucial. This may involve certifications specific to the industry or region.

- Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality. Buyers should ensure that suppliers understand and can meet their specific quality standards.

- Logistical Considerations: International shipping can introduce variables that impact product quality. Buyers should consider how suppliers manage packaging and shipping to minimize the risk of damage during transport.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when selecting suppliers for bucket conveyor systems, ensuring they receive high-quality, reliable products tailored to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bucket conveyor system’

Introduction

When sourcing a bucket conveyor system, a structured approach can streamline the procurement process and ensure that you select the right equipment for your operational needs. This checklist serves as a practical guide for B2B buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can make informed decisions that enhance productivity and meet your business objectives.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring the bucket conveyor system meets your operational requirements. Consider the types of materials you will be handling, their physical characteristics (e.g., size, weight, and abrasiveness), and the throughput rates needed for your production processes. This step lays the foundation for evaluating suppliers and their products effectively.

Step 2: Assess Your Space and Layout Requirements

Understanding the space constraints and layout of your facility is essential for selecting a compatible bucket conveyor system. Measure available areas, accounting for height and width, to ensure the system can be integrated without operational disruption. Additionally, consider the flow of materials and how the conveyor will fit into your existing processes.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they can meet your specific needs. Request company profiles, detailed product catalogs, and case studies that showcase their experience with similar projects. Look for references from other clients in your industry or region to gauge their reliability and performance.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your selected suppliers hold the necessary certifications and comply with industry standards. This includes ISO certifications, safety standards, and regulatory compliance specific to your sector. Verifying these credentials not only assures quality but also mitigates risks related to equipment performance and safety.

Step 5: Request Customization Options

In many cases, a one-size-fits-all approach may not be sufficient. Engage with suppliers to discuss customization options that align with your operational requirements. This could include modifications to bucket sizes, materials, or additional features such as variable speed drives or specialized discharge systems, enhancing the efficiency and effectiveness of your conveyor system.

Step 6: Analyze Total Cost of Ownership (TCO)

When evaluating different systems, consider the total cost of ownership rather than just the initial purchase price. TCO encompasses installation costs, maintenance, operational energy consumption, and potential downtime. A system with a higher upfront cost may offer lower long-term expenses, providing better value for your investment.

Step 7: Plan for Maintenance and Support

Finally, ensure that you have a clear plan for ongoing maintenance and technical support. Inquire about the supplier’s service offerings, including warranty terms, availability of spare parts, and training for your staff. A reliable support system can significantly extend the lifespan of your bucket conveyor and minimize operational disruptions.

By following these steps, you can effectively navigate the procurement process for a bucket conveyor system, ensuring that you select the right solution to meet your business needs.

Comprehensive Cost and Pricing Analysis for bucket conveyor system Sourcing

What Are the Key Cost Components of a Bucket Conveyor System?

When sourcing a bucket conveyor system, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

Illustrative image related to bucket conveyor system

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials such as stainless steel or specialized polymers can increase initial expenses but may reduce maintenance costs and enhance durability.

-

Labor: Labor costs encompass both manufacturing and installation. Skilled labor is often required for custom installations, particularly in complex environments. This can lead to higher costs but may ensure better performance and longevity.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can minimize overhead, influencing the final pricing of the system.

-

Tooling: Custom tooling may be necessary for specific designs or configurations. These costs should be factored into the overall budget, particularly for bespoke systems tailored to unique operational requirements.

-

Quality Control (QC): Implementing rigorous quality control measures ensures that the bucket conveyor system meets industry standards and client specifications. However, this adds to the cost, especially if third-party certifications are required.

-

Logistics: Shipping and handling costs can vary greatly based on the geographic location of the supplier and the destination. International shipments may incur additional duties and tariffs, impacting the total cost.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the industry standards for margins can help buyers negotiate better deals.

How Do Price Influencers Affect Bucket Conveyor System Costs?

Several factors can influence the pricing of bucket conveyor systems, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Buyers should assess their needs to determine if committing to a higher volume can yield cost savings.

-

Specifications and Customization: Customized solutions tailored to specific operational needs can drive up costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials: The choice of materials not only affects durability but also impacts cost. Buyers should consider long-term savings when investing in higher-quality materials.

-

Quality and Certifications: Systems that meet international standards and possess relevant certifications may come at a premium. However, they often provide assurance of reliability and compliance, making them worthwhile investments.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but often provide better support and warranty options.

-

Incoterms: The terms of sale can significantly affect the total cost. Understanding the implications of different Incoterms (like FOB, CIF) is crucial for budgeting shipping and handling expenses.

What Tips Can Help Buyers Optimize Their Bucket Conveyor System Investment?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Engaging in negotiations with suppliers can lead to better pricing. Be prepared to discuss volume discounts, payment terms, and other factors that may influence the final cost.

-

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis to understand the long-term expenses associated with the bucket conveyor system, including maintenance and operational costs. This can provide a clearer picture of the investment’s value.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and their impact on pricing. Additionally, consider the implications of local taxes and import duties when evaluating costs.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers allows for comparative analysis. Look for the best balance of price, quality, and service.

-

Focus on Lifecycle Costs: Consider the durability and maintenance needs of the conveyor system. Investing in a higher-quality system may lead to lower maintenance costs and fewer disruptions in the long run.

Disclaimer on Indicative Prices

Prices for bucket conveyor systems can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough research and obtain detailed quotes tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing bucket conveyor system With Other Solutions

Understanding Alternatives to Bucket Conveyor Systems

In the realm of material handling, businesses often seek efficient and cost-effective solutions tailored to their operational needs. While bucket conveyor systems are a popular choice for transporting bulk materials, several alternative technologies can also achieve similar objectives. This analysis compares bucket conveyor systems against belt conveyors and screw conveyors, exploring their respective strengths and weaknesses.

| Comparison Aspect | Bucket Conveyor System | Belt Conveyor | Screw Conveyor |

|---|---|---|---|

| Performance | High vertical lift capability; suitable for bulk materials | Good for long-distance transport; continuous operation | Effective for granular and powdery materials; limited vertical movement |

| Cost | Moderate initial investment; long-term savings on maintenance | Lower initial cost; potential high energy costs | Moderate cost; requires regular maintenance |

| Ease of Implementation | Requires precise installation; custom designs available | Quick installation and setup; standardized components | Moderate complexity; may need specific layout |

| Maintenance | Low maintenance; robust design | Moderate maintenance; belt wear is common | High maintenance; susceptible to wear and clogging |

| Best Use Case | Ideal for vertical transport of bulk solids and fragile materials | Best for horizontal and inclined transport of packages and bulk | Suitable for transporting powders, grains, and semi-solid materials |

In-Depth Analysis of Alternatives

Belt Conveyors: Are They a Cost-Effective Solution?

Belt conveyors are widely recognized for their versatility and ease of use. They are particularly effective for transporting materials over long distances horizontally or at slight inclines. The initial setup cost is generally lower than that of bucket conveyors, making them attractive for businesses on a budget. However, they can incur higher energy costs due to continuous operation and may require more frequent maintenance due to wear and tear on the belts. Their best use case lies in industries where the material is packaged or when materials can be easily conveyed in a flat position.

Screw Conveyors: When to Consider Them?

Screw conveyors excel in moving granular or powdery materials and are often used in agricultural and food processing industries. Their design allows for a controlled and continuous flow, making them effective for handling bulk solids. However, they have limitations when it comes to vertical lifting capabilities compared to bucket conveyors. While their moderate initial cost is appealing, the maintenance requirements can be significant, especially in harsh environments. They are ideal for applications where material flow needs to be carefully regulated but may not be the best choice for fragile products due to potential degradation during transport.

How to Choose the Right Solution for Your Needs

Selecting the right material handling solution hinges on various factors including the type of materials being transported, the required throughput rate, and the specific operational environment. Bucket conveyor systems offer unique advantages for vertical lifting and delicate material handling, making them suitable for industries such as food processing or pharmaceuticals. Conversely, belt and screw conveyors may present better options for horizontal transport or specific material types, respectively. Buyers should conduct a thorough analysis of their operational requirements, including cost considerations, maintenance capabilities, and performance needs to determine the best fit for their business.

Essential Technical Properties and Trade Terminology for bucket conveyor system

What Are the Key Technical Properties of Bucket Conveyor Systems?

When evaluating bucket conveyor systems, several technical properties play a crucial role in ensuring that the equipment meets the specific needs of various industries. Understanding these properties can help B2B buyers make informed decisions that optimize productivity and reduce operational costs.

1. Material Grade

The material grade of the bucket conveyor system is essential for durability and performance. Common materials include carbon steel, stainless steel, and plastic. Each material offers different advantages, such as corrosion resistance in stainless steel, which is ideal for food processing applications. Selecting the appropriate material grade can enhance the lifespan of the conveyor and minimize maintenance costs.

Illustrative image related to bucket conveyor system

2. Tolerance Levels

Tolerance levels refer to the allowable deviation from specified dimensions in the design and manufacturing of the conveyor system. Accurate tolerances are critical for ensuring proper fit and function, especially in applications where precision is necessary, such as packaging or food handling. High tolerance levels can lead to improved efficiency and reduced risk of material spillage or equipment failure.

3. Capacity and Throughput Rate

The capacity and throughput rate indicate the volume of material a bucket conveyor can handle within a given timeframe. These specifications are vital for aligning the conveyor’s capabilities with production goals. B2B buyers should consider their operational requirements to ensure that the selected system can meet demands without overloading or causing delays in material handling.

4. Drive Mechanism

The drive mechanism refers to the system that powers the conveyor, such as an electric motor or hydraulic system. This property affects the overall efficiency and energy consumption of the conveyor. Understanding the drive mechanism is crucial for B2B buyers to ensure that the equipment aligns with their energy efficiency goals and operational cost management.

5. Noise Levels

Noise levels generated by bucket conveyor systems can impact workplace environment and compliance with local regulations. Systems designed with noise reduction features can enhance operator comfort and safety. This property becomes increasingly important in settings where noise pollution could disrupt other operations or violate workplace standards.

What Are Common Trade Terms Related to Bucket Conveyor Systems?

Familiarity with industry-specific terminology can facilitate smoother communication and negotiations between B2B buyers and suppliers. Here are several essential trade terms relevant to bucket conveyor systems.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of bucket conveyor systems, understanding whether a supplier is an OEM can influence the quality and reliability of the equipment offered, as OEMs often adhere to strict manufacturing standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for buyers to understand their purchasing limits and budget considerations. Knowing the MOQ helps companies plan their inventory and avoid unnecessary costs associated with overstocking.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. For B2B buyers, submitting an RFQ for bucket conveyor systems allows them to compare offers from multiple suppliers, facilitating better decision-making and cost management.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Understanding Incoterms is essential for B2B buyers to clarify shipping responsibilities, risk transfer, and cost allocation, ensuring that all parties are aligned on logistics and delivery.

5. Lead Time

Lead time is the duration from the order placement to the delivery of the product. In the context of bucket conveyor systems, shorter lead times can enhance operational efficiency and responsiveness to market demands. Buyers should consider lead times when planning their production schedules to minimize disruptions.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed choices regarding bucket conveyor systems, ultimately enhancing their operational efficiency and productivity.

Navigating Market Dynamics and Sourcing Trends in the bucket conveyor system Sector

What Are the Current Market Trends Driving the Bucket Conveyor System Sector?

The bucket conveyor system sector is experiencing significant transformation driven by several global factors. Increasing demand for automation in manufacturing and processing industries is leading to the adoption of advanced conveyor technologies that enhance efficiency and reduce labor costs. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly interested in systems that offer versatility, such as multi-directional capabilities, allowing for optimized space utilization and reduced operational footprint.

Emerging technologies like IoT-enabled sensors and predictive maintenance analytics are reshaping sourcing strategies. These innovations help organizations monitor equipment performance in real-time, thus minimizing downtime and enhancing operational reliability. Additionally, the rise of e-commerce is fueling demand for efficient material handling solutions, propelling the market for bucket conveyors, especially in industries such as food and beverage, pharmaceuticals, and mining.

The global market is also influenced by geopolitical dynamics, particularly in the supply chain context. Buyers are increasingly seeking local suppliers to mitigate risks associated with international logistics and tariffs, making regional sourcing a strategic priority. Sustainability is another pivotal trend; companies are increasingly prioritizing eco-friendly solutions that align with their corporate social responsibility goals, influencing their purchasing decisions.

How Is Sustainability Shaping Sourcing Decisions for Bucket Conveyor Systems?

Sustainability is becoming a critical consideration for international B2B buyers in the bucket conveyor system sector. The environmental impact of manufacturing and operating conveyor systems is under scrutiny, prompting companies to seek solutions that reduce their carbon footprint. This includes sourcing materials that are recyclable, energy-efficient, and produced through environmentally responsible processes.

Ethical sourcing is equally important, as businesses strive to ensure that their supply chains do not contribute to environmental degradation or social injustices. Certifications such as ISO 14001 for environmental management and adherence to sustainability standards are increasingly sought after by buyers. Additionally, manufacturers that utilize green materials—like biodegradable plastics or recycled metals—are more attractive to buyers aiming to enhance their sustainability credentials.

The shift towards sustainable practices is not just a regulatory requirement but also a competitive differentiator. Companies that invest in sustainable technologies, such as energy-efficient motors or systems that minimize waste, can offer more appealing solutions to environmentally conscious clients. As a result, the demand for bucket conveyor systems that prioritize sustainability is expected to grow, influencing sourcing strategies across various industries.

What Is the Historical Context of Bucket Conveyor Systems?

The bucket conveyor system has evolved significantly since its inception in the late 19th century. Originally designed for the transport of bulk materials in mining and agriculture, these systems have advanced to accommodate a wide array of industries, including food processing and pharmaceuticals. The introduction of powered bucket elevators in the early 20th century revolutionized material handling by enhancing efficiency and reducing manual labor.

Over the decades, technological advancements have led to the development of more sophisticated designs, such as the multi-directional capabilities of modern bucket conveyors. These innovations not only improve operational efficiency but also allow for greater flexibility in production processes. Today, the market continues to evolve with a focus on automation, sustainability, and smart technologies, reflecting the changing needs of international B2B buyers seeking reliable and efficient material handling solutions.

Illustrative image related to bucket conveyor system

Frequently Asked Questions (FAQs) for B2B Buyers of bucket conveyor system

-

How do I solve challenges with material handling in my facility?

To address material handling challenges, first assess the specific requirements of your operation, including the types of materials being conveyed, their physical characteristics, and the throughput rate needed. Next, consider implementing a bucket conveyor system designed for your unique application. This includes selecting systems that minimize product degradation and maximize efficiency. Consulting with manufacturers can provide insights into custom solutions that fit your operational constraints, ensuring a smooth integration into your existing processes. -

What is the best bucket conveyor system for fragile materials?

For fragile materials, a bucket conveyor system that emphasizes gentle handling is essential. Consider options like Swinglink bucket elevators, which are designed to maintain product integrity and minimize spillage. These systems often feature smooth bucket surfaces and clean-in-place capabilities that help prevent contamination and damage. Additionally, ensure that the selected system can accommodate the specific throughput and product characteristics required for your application. -

What are the customization options available for bucket conveyor systems?

Customization options for bucket conveyor systems can vary widely depending on the manufacturer. Common modifications include adjustments to bucket size and shape, conveyor speed, discharge configurations, and material compatibility. Some manufacturers also offer tailored designs for specific industries, such as food processing or pharmaceuticals, ensuring compliance with industry standards. Engaging with suppliers during the pre-engineering phase can help identify the best custom solutions to meet your operational needs. -

What are the minimum order quantities (MOQ) for bucket conveyor systems?

Minimum order quantities (MOQ) for bucket conveyor systems depend on the manufacturer and the complexity of the system. Generally, larger orders may yield better pricing and customization options, while smaller orders might incur higher per-unit costs. It’s advisable to discuss your requirements with potential suppliers to understand their MOQ policies and explore options that align with your budget and operational scale. -

What payment terms should I expect when sourcing bucket conveyor systems internationally?

Payment terms can vary significantly among suppliers and regions. Common terms include upfront deposits ranging from 30% to 50%, with the balance due upon completion or prior to shipment. In international transactions, options like letters of credit or escrow services may provide additional security. It’s crucial to clarify payment terms early in negotiations to ensure alignment with your financial processes and mitigate risks associated with cross-border transactions. -

How can I ensure quality assurance when purchasing a bucket conveyor system?

To ensure quality assurance, select suppliers who adhere to recognized industry standards and certifications. Request documentation of quality control processes, such as ISO certifications, and inquire about testing procedures for the equipment. Additionally, consider arranging site visits or audits to evaluate manufacturing practices. Establishing clear communication about your quality expectations during the procurement process can also help ensure that the final product meets your specifications. -

What logistics considerations should I keep in mind when sourcing bucket conveyor systems?

Logistics play a critical role in the successful acquisition of bucket conveyor systems. Consider the shipping methods, lead times, and potential customs regulations that may affect delivery. Collaborate with suppliers to establish a clear timeline for production and shipment, and ensure that they provide documentation for customs clearance. Additionally, evaluate the shipping costs and options for installation or assembly at your facility to facilitate a smooth transition. -

How do I vet suppliers for bucket conveyor systems?

When vetting suppliers for bucket conveyor systems, consider their industry experience, customer reviews, and case studies of previous projects. Request references from existing clients to gauge their satisfaction with the products and services. Additionally, assess the supplier’s responsiveness and willingness to provide technical support. Evaluating their financial stability and production capabilities can also help ensure they can meet your long-term needs effectively.

Top 7 Bucket Conveyor System Manufacturers & Suppliers List

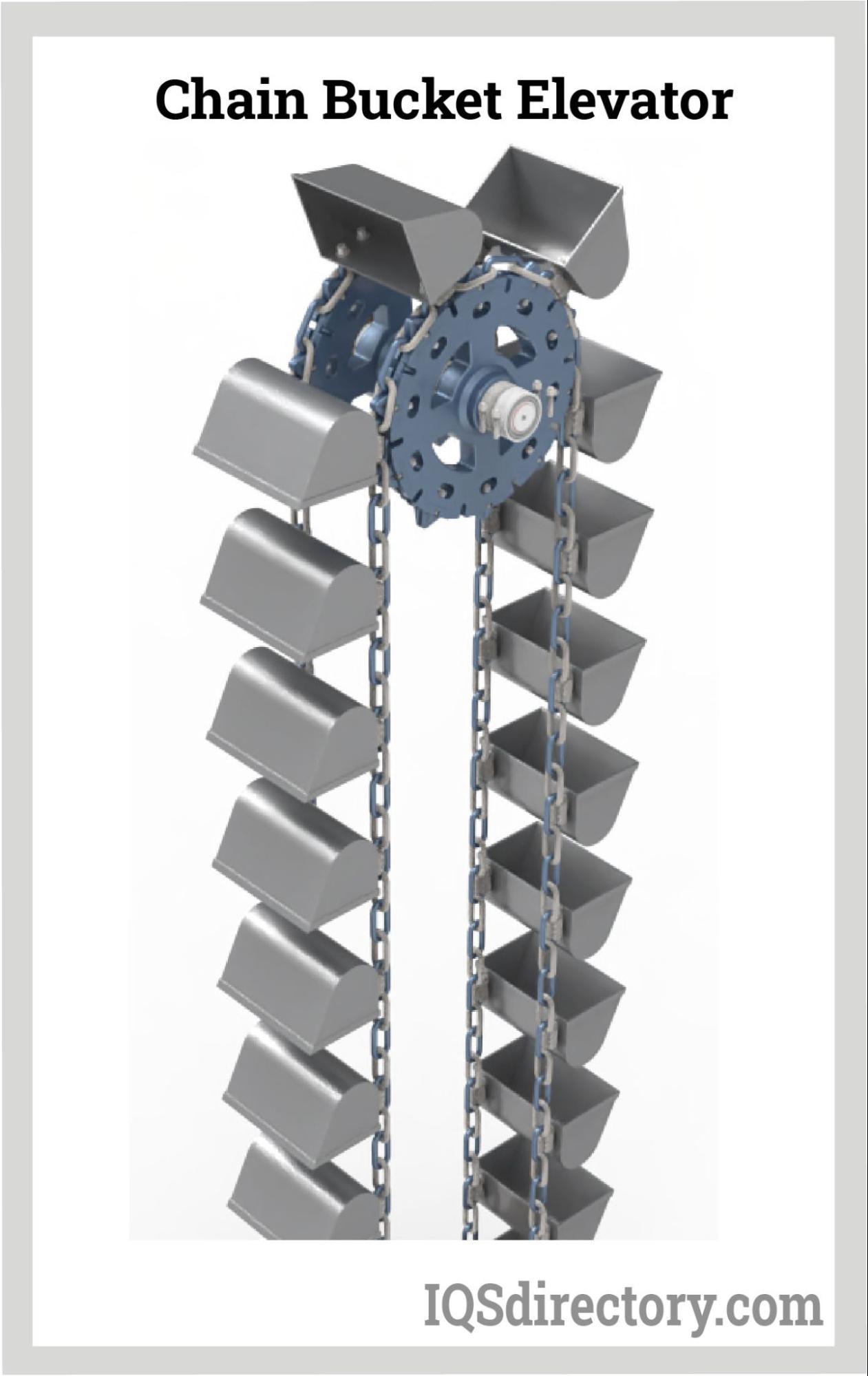

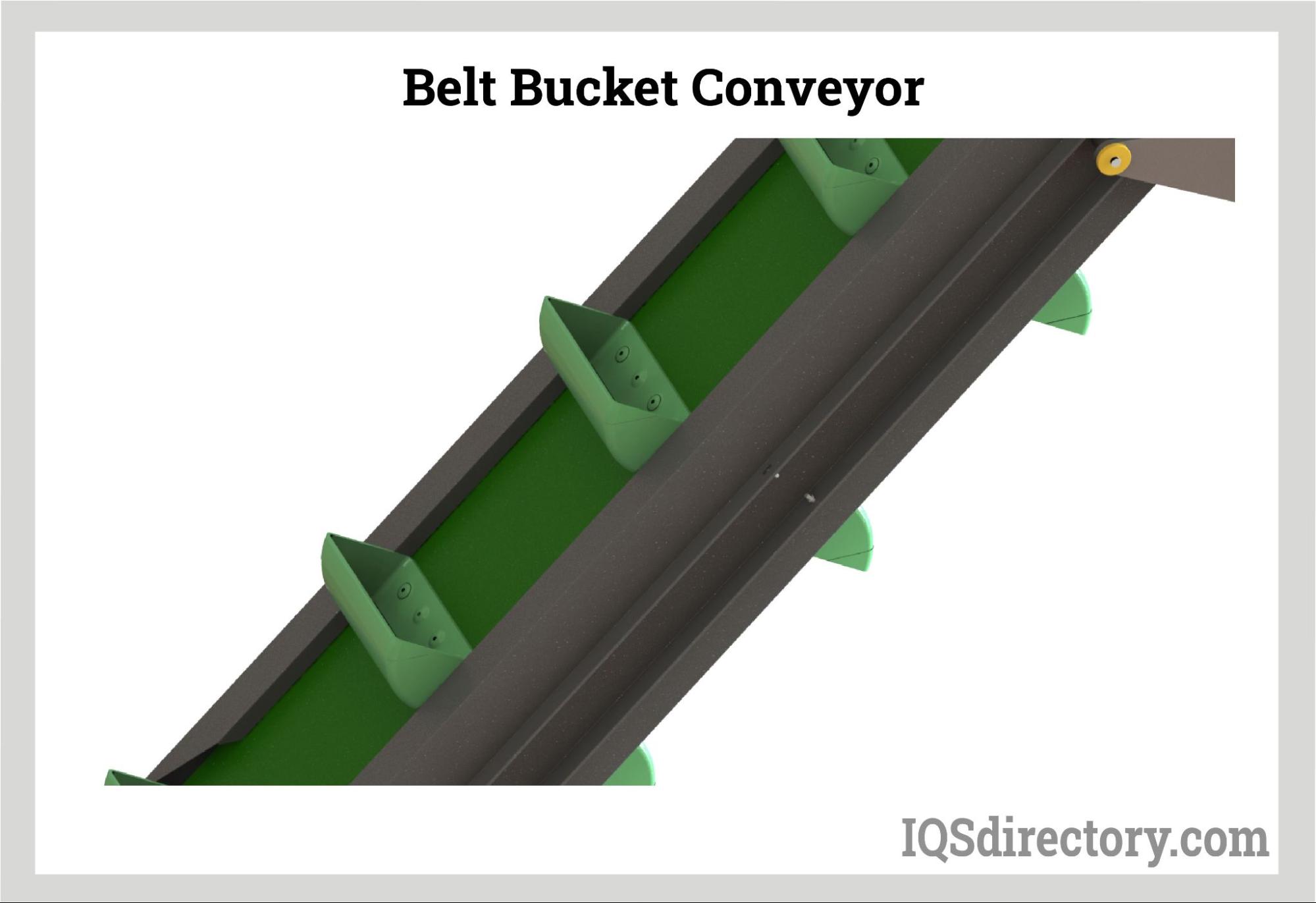

1. IQS Directory – Bucket Elevators and Conveyors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Bucket Elevators and Conveyors: Types, Applications and Advantages. Bucket elevators, also known as grain legs, transport bulk materials efficiently in industries like commercial agriculture and mining. Bucket conveyors use dual-strand roller chains for horizontal and inclined transport, handling hot and abrasive materials. Buckets maintain a stable position to prevent spillage. Types of buckets i…

2. Gough Econ – Elecon™ Bucket Conveyor

Domain: goughecon.com

Registered: 1997 (28 years)

Introduction: Gough Econ offers bucket elevators and conveyors designed for efficient product elevation and movement. Key products include: 1. Elecon™: The only bucket conveyor that can move materials in any direction, featuring a patented chain design and wedge-shaped buckets. Benefits include increased efficiency, improved safety, reduced maintenance, gentle material handling, and minimized footprint. 2. Swin…

3. Ryson – Bucket Elevators

Domain: ryson.com

Registered: 1996 (29 years)

Introduction: Bucket Elevator – Ryson International

Commonly used in: Industrial & Manufacturing, Consumer Packaged Goods, Food & Beverage

Bucket Widths: 9″, 15″, 2’4″

Max Capacity: 1,800 cubic feet/hr

Overview: Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one unit. They are known for their durability and effective design, featuring gentle handling, rugged cons…

4. Nerak Systems – Continuous Bucket Conveyors

Domain: nerak-systems.com

Registered: 1998 (27 years)

Introduction: Continuous Bucket Conveyors transport powder and bulk material from one or multiple feed points to one discharge point with high capacity on a small footprint. They offer smooth and continuous travel without the need for intermediate transfers. The design allows for ‘Z’ and ‘C’ type layouts, combining horizontal and vertical sections to fit unique plant layouts. Conveying capacities can reach up t…

5. Heat and Control – Modular Conveyor Solutions

Domain: heatandcontrol.com

Registered: 1996 (29 years)

Introduction: This company, Heat and Control – Modular Conveyor Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. PFI Conveyors – Incline Belt Conveyors

Domain: pficonveyors.com

Registered: 2022 (3 years)

Introduction: Incline Belt Conveyors: 1. Components: Conveyor belt, rollers, drive system, head and tail pulleys. 2. Operation Steps: Loading, inclined transport, discharge. 3. Benefits: Reliable operation, more sanitary design, flexible designs. 4. Ideal for: Raw/sticky products, bakery items, fruits, and vegetables. 5. Maximum Width: 72 inches. 6. Infeed Options: 1. 7. Discharge Options: 1. 8. Sanitary/Food-G…

7. Beumer Group – Belt Bucket Elevators

Domain: beumergroup.com

Registered: 2011 (14 years)

Introduction: Belt Bucket Elevators for Bulk Materials are designed for vertical transport of bulk materials across various industries including cement, fertilizers, mining, and power plants. Key features include:

– Lifting heights of up to 200 meters or more.

– Conveying capacities exceeding 2,000 m³/h.

– Cell widths ranging from 500 mm to 1,600 mm.

– Centre distances up to 250 m.

– Highly robust steel wi…

Strategic Sourcing Conclusion and Outlook for bucket conveyor system

What Are the Key Takeaways for Strategic Sourcing of Bucket Conveyor Systems?

In today’s competitive landscape, strategic sourcing of bucket conveyor systems is essential for optimizing operational efficiency and minimizing costs. By understanding the various types of bucket elevators and conveyors, businesses can tailor solutions to meet their specific material handling needs. The ability to design systems that accommodate different materials, throughput rates, and spatial constraints is crucial in enhancing productivity while ensuring product integrity.

How Can International Buyers Benefit from Advanced Bucket Conveyor Solutions?

International buyers from regions like Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers that offer customizable and innovative solutions, such as the versatile Elecon™ system, which allows for multi-directional movement. This flexibility can significantly reduce floor space requirements and improve overall system efficiency. Additionally, manufacturers focusing on sustainable practices and energy-efficient designs can help companies meet regulatory standards while also reducing operational costs.

What’s Next for Global Sourcing in Material Handling?

As the global market evolves, the demand for efficient and adaptable material handling solutions will only increase. Buyers are encouraged to leverage technological advancements and engage with suppliers who demonstrate a commitment to innovation and customer-centric designs. Taking proactive steps now will position businesses for success in an ever-changing market landscape. Reach out to reputable suppliers to explore how bucket conveyor systems can transform your operations and drive growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.