A B2B Buyer’s Guide to Braided Rope: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for braided rope

Navigating the complexities of sourcing braided rope can pose significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a diverse array of braided rope types—ranging from 24-strand to diamond braid—buyers must carefully consider the specific applications, durability, and cost-effectiveness of each option. This guide aims to streamline your purchasing journey by providing detailed insights into the various braided rope types, their applications across industries, and practical tips for vetting suppliers.

Understanding the nuances of braided rope materials, such as nylon and polyester, is crucial for making informed decisions that meet your business needs. Additionally, we will explore price ranges and market trends that affect procurement strategies in different regions, including key considerations for negotiating with suppliers in countries like Nigeria and Vietnam.

Empowering B2B buyers with the knowledge necessary to navigate this global market, this comprehensive guide will help you maximize value while minimizing risk. By leveraging these insights, you can confidently select the right braided rope solutions that enhance your operations and meet your project requirements efficiently.

Understanding braided rope Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Double Braid Nylon Rope | High strength, shock-absorbing, flexible | Marine, climbing, general utility | Pros: Excellent elasticity and durability. Cons: Higher cost compared to other types. |

| Diamond Braid Polypro Rope | Economical, lightweight, floats on water | Fishing, camping, general outdoor use | Pros: Cost-effective and versatile. Cons: Less durable than nylon. |

| Solid Braid Polyester Rope | Low stretch, high abrasion resistance | Industrial, marine, towing | Pros: Strong and UV resistant. Cons: Limited elasticity may not suit all applications. |

| Hollow Braid Polypropylene | Lightweight, floats, economical | Water sports, anchoring, utility | Pros: Very affordable and buoyant. Cons: Less strength compared to solid braids. |

| Static Climbing Rope | Designed for minimal stretch, high durability | Rock climbing, rescue operations | Pros: Ideal for safety applications. Cons: Not suitable for dynamic loads. |

What Are the Key Features of Double Braid Nylon Rope?

Double braid nylon rope is renowned for its shock-absorbing properties and high tensile strength, making it suitable for demanding applications such as marine use and climbing. Its unique construction allows for flexibility while maintaining a smooth surface, reducing wear on pulleys. B2B buyers should consider its higher cost but can expect exceptional durability and performance, particularly in environments where elasticity is crucial.

How Does Diamond Braid Polypro Rope Stand Out?

Diamond braid polypro rope is characterized by its lightweight and economical design, making it an excellent choice for various outdoor applications like fishing and camping. Its ability to float is a significant advantage in water-related activities. Buyers should note that while it is cost-effective, it may not offer the same level of durability as nylon options, making it less suitable for heavy-duty tasks.

Why Choose Solid Braid Polyester Rope for Industrial Applications?

Solid braid polyester rope is ideal for industrial and marine applications due to its low stretch and high abrasion resistance. This type of rope excels in environments exposed to UV rays and chemicals, offering long-lasting performance. B2B buyers should consider its strength and durability, although they may find its limited elasticity a disadvantage in applications requiring flexibility.

What Are the Benefits of Using Hollow Braid Polypropylene Rope?

Hollow braid polypropylene rope is lightweight and floats, making it a popular choice for water sports and utility tasks. Its economical pricing makes it accessible for various applications, including anchoring. However, buyers should be aware that while it is cost-effective, it does not match the strength of solid braids, which could limit its use in more demanding environments.

When Is Static Climbing Rope the Best Option?

Static climbing ropes are designed specifically for minimal stretch, providing high durability and safety for rock climbing and rescue operations. Their construction ensures reliability under static loads, making them indispensable in life-threatening situations. B2B buyers should prioritize this type of rope when safety is paramount, although it is not suitable for dynamic climbing scenarios where flexibility is needed.

Key Industrial Applications of braided rope

| Industry/Sector | Specific Application of braided rope | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine | Dock Lines and Mooring | Enhanced safety and durability in marine environments | UV resistance, shock absorption, and length options |

| Construction | Lifting and Rigging | Increased safety and efficiency during heavy lifting | Load capacity, material strength, and abrasion resistance |

| Agriculture | Fencing and Animal Restraint | Secure containment of livestock and equipment | Weather resistance, tensile strength, and flexibility |

| Outdoor Recreation | Climbing and Camping Gear | Safety and reliability in high-stakes activities | Weight, tensile strength, and resistance to elements |

| Automotive | Towing and Recovery | Reliable performance under extreme conditions | Load ratings, elasticity, and resistance to wear |

How is Braided Rope Used in the Marine Industry?

In the marine sector, braided rope is essential for applications like dock lines and mooring. These ropes offer superior strength and durability, crucial for securing vessels against harsh weather conditions and strong tides. International buyers, particularly from coastal regions in Africa and South America, should prioritize ropes with high UV resistance and shock absorption properties to ensure longevity and safety. Sourcing ropes that meet specific maritime standards can prevent costly accidents and improve operational efficiency.

Illustrative image related to braided rope

What Role Does Braided Rope Play in Construction?

In construction, braided rope is frequently used for lifting and rigging tasks. The strength and flexibility of braided ropes allow for secure lifting of heavy materials, enhancing safety on job sites. Buyers in regions with significant construction activities, such as the Middle East, should consider ropes with high load capacities and excellent abrasion resistance to withstand the rigors of construction environments. Proper sourcing ensures compliance with safety regulations and reduces the risk of equipment failure.

How is Braided Rope Utilized in Agriculture?

Agricultural applications for braided rope include fencing and animal restraint. These ropes provide a secure means to contain livestock and manage equipment effectively, which is vital for productivity in farming operations. Buyers from rural areas in Africa and South America should focus on weather-resistant options that can withstand harsh environmental conditions. Ensuring the rope has high tensile strength will minimize the risk of breakage and ensure reliable performance over time.

Why is Braided Rope Important for Outdoor Recreation?

In outdoor recreation, braided rope is critical for climbing and camping gear. Its lightweight yet strong characteristics make it ideal for safety in high-altitude or wilderness activities. Buyers from Europe and other regions with active outdoor communities should prioritize ropes that offer excellent tensile strength and resistance to environmental elements. This ensures safety and reliability, crucial for both amateur and professional climbers, thereby enhancing the overall recreational experience.

How Does Braided Rope Support the Automotive Sector?

In the automotive industry, braided rope is often used for towing and recovery operations. Its ability to withstand extreme conditions and heavy loads makes it an invaluable tool for roadside assistance and off-road recovery scenarios. Buyers from regions with challenging terrains, such as parts of Africa and South America, should look for ropes with high load ratings and elasticity to ensure effective performance. Selecting the right braided rope can significantly improve recovery operations and reduce vehicle damage during towing.

3 Common User Pain Points for ‘braided rope’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: Many B2B buyers of braided rope encounter significant challenges with inconsistent quality when sourcing from different suppliers. This can lead to performance issues in critical applications, especially in industries such as construction, shipping, or outdoor recreation. For instance, a company in Nigeria might receive a batch of rope that appears strong but fails under stress due to inferior materials or manufacturing processes. Such discrepancies can jeopardize safety, project timelines, and ultimately, customer satisfaction.

The Solution: To mitigate quality inconsistencies, B2B buyers should prioritize sourcing from established suppliers with a strong reputation for quality assurance. Conduct thorough due diligence by reviewing supplier certifications, such as ISO 9001, and asking for samples before placing large orders. Implementing a quality control protocol, including on-site inspections or third-party testing, can further ensure that the braided rope meets the required specifications. Additionally, establishing long-term relationships with reliable suppliers can lead to better consistency over time, as they become familiar with your quality expectations and application needs.

Scenario 2: Lack of Understanding of Material Properties

The Problem: Buyers often struggle with selecting the appropriate type of braided rope due to a lack of understanding regarding the material properties and their implications for specific applications. For instance, a company in South America might choose a low-cost polyester rope for heavy-duty marine applications, only to discover that it lacks the necessary elasticity and shock absorption characteristics, leading to catastrophic failures in high-stress situations.

Illustrative image related to braided rope

The Solution: To address this knowledge gap, B2B buyers should invest time in understanding the material properties of various braided ropes, such as nylon, polyester, and polypropylene. Each material offers different strengths, weaknesses, and environmental resistances. Buyers can benefit from consulting with manufacturers or technical experts who can provide tailored advice based on their specific applications. Additionally, creating a comprehensive guide that outlines the properties and recommended uses of each type of rope can serve as a valuable reference for future purchases, reducing the likelihood of costly mistakes.

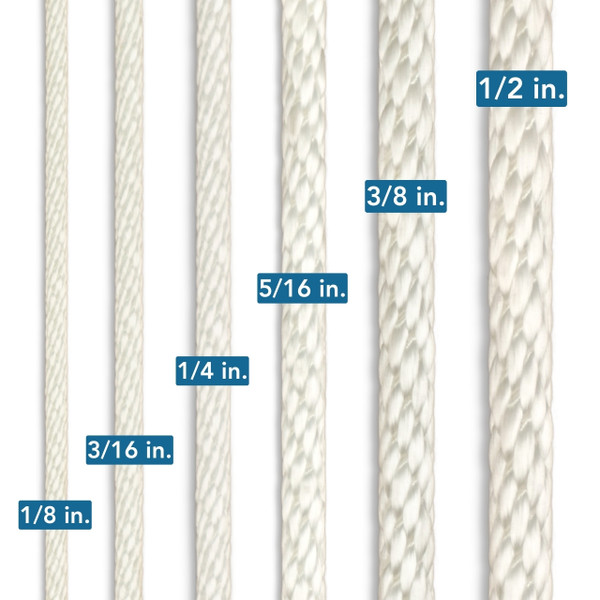

Scenario 3: Difficulty in Sizing and Specifications

The Problem: Another common pain point for B2B buyers is the confusion surrounding sizing and specifications when ordering braided rope. Misunderstandings about the diameter, tensile strength, and load capacities can lead to purchasing ropes that are either inadequate for the intended use or unnecessarily over-engineered, resulting in wasted resources. For example, a Middle Eastern company may order a rope that is too thin for lifting heavy equipment, risking failure and injury.

The Solution: To overcome sizing and specification challenges, B2B buyers should adopt a systematic approach to evaluating their requirements. This includes conducting a thorough assessment of the intended use, environmental conditions, and the specific loads the rope will need to handle. It is advisable to consult the manufacturer’s guidelines on load ratings and safety factors. Creating a detailed specification sheet that includes desired characteristics—such as diameter, length, and strength—can streamline the ordering process. Additionally, working closely with suppliers during the selection process can ensure that the right rope is sourced for the application, enhancing safety and efficiency.

Illustrative image related to braided rope

Strategic Material Selection Guide for braided rope

What Are the Key Properties of Common Materials Used in Braided Rope?

When selecting braided rope for various applications, understanding the properties of the materials involved is crucial. Here, we will analyze four common materials: nylon, polyester, polypropylene, and natural fibers. Each material presents unique characteristics that can significantly impact performance, durability, and application suitability.

How Does Nylon Perform as a Material for Braided Rope?

Nylon is renowned for its high strength and elasticity, making it a popular choice for applications requiring shock absorption. It has a melting point of approximately 490°F and can withstand significant loads, which is essential in marine and climbing applications. However, nylon is susceptible to UV degradation and can lose strength when exposed to high temperatures over time.

Pros: High strength, excellent shock absorption, and good flexibility.

Cons: Prone to UV damage, less abrasion-resistant compared to polyester, and can shrink under heat.

Impact on Applications: Ideal for marine applications, such as anchor lines, where shock loading is a concern.

Considerations for International Buyers: Compliance with standards like ASTM for safety and performance is critical, especially in regions with varying environmental conditions.

What Advantages Does Polyester Offer for Braided Rope?

Polyester is favored for its durability and resistance to UV light and abrasion. With a lower stretch than nylon, it provides excellent dimensional stability, making it suitable for applications that require minimal elongation. Polyester ropes typically have a melting point of around 450°F, providing a good balance of heat resistance and strength.

Pros: Superior UV and abrasion resistance, low stretch, and excellent dimensional stability.

Cons: Lower elasticity compared to nylon, which can be a disadvantage in applications requiring shock absorption.

Impact on Applications: Commonly used in outdoor and industrial applications where durability is paramount.

Considerations for International Buyers: Polyester ropes often meet international standards like DIN and JIS, which can be advantageous for compliance in various markets.

Why Choose Polypropylene for Braided Rope?

Polypropylene is a lightweight and economical option that is resistant to moisture and chemicals. It has a lower melting point of about 320°F and is often used in applications where buoyancy is essential, as it floats on water. However, it is less durable than nylon and polyester, making it less suitable for high-stress applications.

Illustrative image related to braided rope

Pros: Lightweight, cost-effective, and floats on water.

Cons: Lower strength and durability compared to nylon and polyester, and can degrade under UV exposure.

Impact on Applications: Ideal for marine applications like fishing lines or floating buoys.

Considerations for International Buyers: Cost-effectiveness makes it appealing in developing markets, but buyers should be aware of its limitations in high-stress environments.

What Role Do Natural Fibers Play in Braided Rope?

Natural fibers, such as cotton and jute, are biodegradable and offer a traditional aesthetic. While they provide decent strength and flexibility, they are less durable than synthetic options and can be susceptible to rot and mildew. Natural fibers typically have lower melting points and are not suitable for high-temperature applications.

Pros: Eco-friendly, biodegradable, and aesthetically pleasing.

Cons: Lower strength, susceptible to moisture damage, and not suitable for harsh environments.

Impact on Applications: Often used in decorative applications or where environmental impact is a concern.

Considerations for International Buyers: Compliance with environmental regulations may be more favorable for natural fibers in certain regions, appealing to eco-conscious buyers.

Summary Table of Material Selection for Braided Rope

| Material | Typical Use Case for braided rope | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Marine applications, climbing ropes | High strength and elasticity | UV degradation and heat sensitivity | Medium |

| Polyester | Industrial and outdoor applications | Superior UV and abrasion resistance | Lower elasticity compared to nylon | Medium |

| Polypropylene | Fishing lines, floating buoys | Lightweight and economical | Lower strength and UV sensitivity | Low |

| Natural Fibers | Decorative applications, eco-friendly uses | Biodegradable and aesthetically pleasing | Susceptible to rot and moisture | Low |

This guide provides a strategic overview of material selection for braided rope, enabling B2B buyers to make informed decisions tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for braided rope

What Are the Key Stages in the Manufacturing Process of Braided Rope?

The manufacturing of braided rope involves several critical stages that ensure the final product is robust, reliable, and suitable for various applications. Understanding these stages is essential for B2B buyers looking to ensure quality in their supply chain.

Material Preparation: What Materials Are Used in Braided Rope?

The first stage in the manufacturing process involves selecting high-quality raw materials. Common materials include nylon, polyester, polypropylene, and natural fibers like cotton. Each material has unique properties that influence the rope’s strength, elasticity, and resistance to environmental factors. For instance, nylon is favored for its elasticity and strength, making it ideal for applications requiring shock absorption. Polyester, on the other hand, offers superior UV resistance and abrasion resistance, making it suitable for outdoor use.

Before production begins, these fibers are prepared by being twisted, dyed, or treated to enhance their performance characteristics. This preparation is crucial as it directly impacts the rope’s durability and functionality.

How Are Braided Ropes Formed?

Once the materials are prepared, the next step is forming the rope. This process typically involves braiding or twisting the fibers together. Braided ropes can be categorized into different styles, including double braid, diamond braid, and solid braid, each offering distinct advantages.

In the braiding process, multiple strands are interlaced in a specific pattern to create a strong, flexible rope. Advanced braiding machines are used to ensure precision and consistency in the braiding process. The use of automation in this stage enhances production efficiency and maintains quality standards.

What Does the Assembly Process Entail?

After the braiding process, the rope undergoes assembly, which may include adding features like end fittings, splicing, or securing knots for specific applications. This stage is crucial for ensuring that the rope performs as intended, especially in critical applications like climbing, marine use, or industrial rigging.

Quality during assembly is paramount; any faults in this stage can compromise the rope’s integrity. Skilled technicians typically oversee this process to ensure that all components are correctly attached and meet performance specifications.

Illustrative image related to braided rope

How Is the Finishing Process Conducted?

The final stage of manufacturing is finishing, where the braided rope is treated to improve its performance characteristics. This may involve coating the rope with protective substances to enhance its water resistance, UV stability, and overall durability. Additionally, ropes may be cut to specific lengths and packaged for distribution.

Quality control during finishing ensures that the ropes not only meet aesthetic standards but also conform to performance specifications. Proper labeling and documentation are essential for B2B buyers to trace the product’s compliance with industry standards.

What Quality Assurance Measures Are Essential for Braided Rope?

Quality assurance is a critical aspect of the braided rope manufacturing process. International and industry-specific standards guide the quality control measures that suppliers must adhere to.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should look for compliance with international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications are crucial. These certifications indicate that the rope meets safety and performance standards essential for various applications.

What Are the Key Quality Control Checkpoints?

Quality control typically involves several checkpoints throughout the manufacturing process, including:

Illustrative image related to braided rope

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards. Any non-compliant materials are rejected to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to identify any deviations from quality standards. This proactive approach allows for immediate corrective actions.

-

Final Quality Control (FQC): Before packaging, a thorough inspection of the finished product is performed. This includes testing for strength, flexibility, and other performance metrics to ensure compliance with specifications.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to assess the quality of braided ropes. Common methods include tensile strength tests, abrasion resistance tests, UV exposure tests, and knot strength tests. Each test provides valuable data on the rope’s performance and durability in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to stringent quality standards, B2B buyers can take several steps:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insight into their manufacturing processes, quality control measures, and compliance with industry standards. This helps buyers assess whether the supplier can meet their quality requirements consistently.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline testing results and compliance with relevant standards. This transparency builds trust and allows buyers to make informed decisions.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can conduct audits, review documentation, and perform product tests to verify compliance.

What Nuances Should International Buyers Consider in Quality Control?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional standards and certifications is crucial. Each market may have different requirements for quality and safety, which can affect import regulations and compliance.

Buyers should also be aware of cultural differences in business practices and communication styles. Establishing clear expectations and open lines of communication with suppliers can help mitigate misunderstandings and ensure that quality standards are met consistently.

By understanding the manufacturing processes and quality assurance measures for braided rope, B2B buyers can make informed decisions that align with their operational needs and ensure the reliability of their supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘braided rope’

To effectively source braided rope for your business needs, follow this comprehensive checklist designed for international B2B buyers. Each step is crucial for ensuring you select the right product and supplier to meet your specific requirements.

Step 1: Define Your Technical Specifications

Before starting the procurement process, clearly outline your technical requirements. Consider factors such as the type of braided rope (e.g., double braid, diamond braid), material (nylon, polyester, polypropylene), diameter, and intended use (marine, climbing, industrial). This clarity will help you communicate your needs effectively to potential suppliers and ensure you receive suitable products.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing is essential to making informed purchasing decisions. Investigate average costs per foot for various types of braided rope and compare prices among different suppliers. This knowledge will equip you to negotiate better deals and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and certifications to assess their credibility. Look for reviews and testimonials from other businesses in your industry to gauge reliability and quality. Ensure the supplier has experience in international shipping, especially if you’re sourcing from regions like Africa or South America.

Step 4: Verify Quality Standards and Certifications

Quality assurance is paramount when sourcing braided rope. Confirm that the products meet industry standards and certifications relevant to your application (e.g., ISO, ASTM). This verification process minimizes the risk of defects and ensures compliance with safety regulations, particularly for ropes used in critical applications like climbing or marine use.

Step 5: Request Samples for Testing

Before placing a bulk order, always request samples of the braided rope. Testing samples allows you to assess the quality, strength, and suitability for your specific applications. Pay attention to aspects such as flexibility, knot retention, and resistance to abrasion and UV damage, which are crucial for performance in diverse environments.

Illustrative image related to braided rope

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clarify the terms of warranty and return policies to protect your investment. Ensure that both parties have a clear understanding of expectations to avoid potential disputes later.

Step 7: Establish a Long-Term Relationship

After a successful transaction, consider building a long-term relationship with your supplier. Frequent communication can lead to better pricing, priority service, and insights into new products or technologies. Establishing trust can also facilitate smoother transactions in future procurements, enhancing your supply chain efficiency.

By following this checklist, you can streamline your procurement process for braided rope, ensuring that your business obtains high-quality products tailored to your specific needs.

Comprehensive Cost and Pricing Analysis for braided rope Sourcing

What Are the Key Cost Components in Braided Rope Manufacturing?

Understanding the cost structure of braided rope is essential for B2B buyers looking to optimize their sourcing strategies. The primary components of cost include:

-

Materials: The type of fiber used significantly impacts the cost. Common materials include nylon, polyester, and polypropylene. Nylon is generally more expensive due to its strength and elasticity, while polypropylene offers a budget-friendly option but with less durability. Each material has its own cost implications based on market demand and availability.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs, such as those in Southeast Asia, can offer more competitive pricing. However, this should be balanced against quality assurance to ensure that lower labor costs do not compromise product quality.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can help minimize these costs, leading to better pricing for buyers.

-

Tooling: The initial investment in tooling can be significant, especially for custom designs. Buyers should consider whether they require standard products or custom solutions, as this will affect the overall cost structure.

-

Quality Control (QC): Implementing robust QC measures is crucial for ensuring product reliability. The cost of QC can vary, but it is a necessary investment to maintain quality standards, especially for ropes used in critical applications like climbing or marine activities.

-

Logistics: Shipping costs can vary widely based on the distance from the manufacturer to the buyer, the mode of transport, and current fuel prices. Incoterms play a crucial role in defining who bears these costs, so understanding them is essential for accurate cost forecasting.

-

Margin: Finally, the supplier’s profit margin will impact the final price. This can vary based on competition, brand reputation, and the perceived value of the product.

What Factors Influence Pricing in Braided Rope Sourcing?

Several key factors influence the pricing of braided rope, which international buyers must consider:

Illustrative image related to braided rope

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers with high-volume needs.

-

Specifications and Customization: Custom specifications, such as specific lengths, colors, or additional features, can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications, such as ISO or safety standards, can raise prices but may provide added value through enhanced durability and performance.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may charge more for their products but often provide better service and quality assurance.

-

Incoterms: Understanding the terms of shipping is crucial. Different Incoterms can shift the responsibility and costs of transport, insurance, and customs clearance between the buyer and seller, influencing the total cost of acquisition.

What Are the Best Practices for Negotiating Braided Rope Prices?

To achieve cost-efficiency in braided rope sourcing, buyers should adopt several strategic approaches:

-

Negotiate Terms: Engage suppliers in discussions about pricing, delivery times, and payment terms. Being open about your needs can lead to more favorable conditions.

-

Consider Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, assess the total cost, which includes shipping, maintenance, and potential replacements. This holistic view can lead to better long-term savings.

-

Research Market Trends: Understanding market dynamics, such as material prices and demand fluctuations, can empower buyers during negotiations, allowing them to make informed decisions.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and service over time. Loyalty can be rewarded with discounts and priority service.

-

Stay Informed About Regional Differences: For buyers from regions like Africa, South America, the Middle East, and Europe, being aware of regional pricing differences can aid in identifying the best sourcing opportunities.

Conclusion

In summary, a comprehensive understanding of the cost structure and pricing influencers in braided rope sourcing is crucial for international B2B buyers. By leveraging this knowledge and employing effective negotiation strategies, businesses can optimize their procurement processes and achieve significant savings. Always remember that indicative prices can fluctuate based on various market conditions, so maintaining flexibility in sourcing strategies is essential.

Alternatives Analysis: Comparing braided rope With Other Solutions

In the competitive landscape of industrial applications, selecting the right type of rope is crucial for efficiency and safety. Braided rope, known for its durability and flexibility, has various alternatives that may suit specific needs better depending on the application. This analysis will explore braided rope in comparison to twisted nylon rope and solid braid polyester rope, both of which offer distinct advantages and drawbacks.

| Comparison Aspect | Braided Rope | Twisted Nylon Rope | Solid Braid Polyester Rope |

|---|---|---|---|

| Performance | High tensile strength; flexible | Strong but less flexible; stretches under load | Low stretch; excellent abrasion resistance |

| Cost | Moderate ($0.30 – $3.24/ft) | Generally lower ($0.25 – $3.96/ft) | Competitive ($0.45 – $1.99/ft) |

| Ease of Implementation | Easy to handle; ties knots well | Moderate; can tangle easily | Easy to handle; torque-free design |

| Maintenance | Low; resistant to wear and UV | Moderate; can degrade with exposure | Low; resistant to UV and chemicals |

| Best Use Case | General-purpose and marine use | Heavy-duty applications requiring elasticity | Applications needing low stretch and high durability |

What Are the Pros and Cons of Twisted Nylon Rope?

Twisted nylon rope is a strong alternative that excels in applications requiring elasticity. Its primary advantage is its high stretch capacity, making it ideal for shock absorption in heavy-duty scenarios like towing or anchoring. However, this elasticity can also be a disadvantage, leading to potential issues with stability in certain applications. Twisted ropes can tangle more easily than braided ropes, complicating their use in dynamic environments.

How Does Solid Braid Polyester Rope Compare?

Solid braid polyester rope presents a compelling option, particularly for applications requiring low stretch and high abrasion resistance. Its resistance to UV degradation and chemicals makes it suitable for outdoor and marine environments. The torque-free design allows it to run smoothly over pulleys, which can enhance operational efficiency. However, solid braid polyester lacks the elasticity of nylon, making it less suitable for applications where shock absorption is necessary.

How Should B2B Buyers Choose the Right Rope Solution?

When selecting the right rope solution, B2B buyers should first assess their specific application requirements. If flexibility and shock absorption are paramount, braided or twisted nylon ropes may be the best choice. Conversely, for applications demanding durability and low stretch, solid braid polyester is a superior option. Additionally, cost considerations should align with performance needs; while braided rope offers a balance of both, twisted nylon may be more budget-friendly for heavy-duty tasks. Ultimately, understanding the unique strengths and limitations of each alternative will empower buyers to make informed decisions that enhance operational efficiency and safety.

Essential Technical Properties and Trade Terminology for braided rope

What Are the Key Technical Properties of Braided Rope?

Understanding the technical specifications of braided rope is crucial for making informed purchasing decisions in a B2B context. Here are some essential properties to consider:

1. Material Grade

The most common materials for braided ropes include nylon, polyester, and polypropylene. Nylon is favored for its strength and elasticity, making it suitable for applications requiring shock absorption. Polyester offers superior UV resistance and is less elastic, making it ideal for applications where minimal stretch is required. Polypropylene is lightweight and resistant to moisture, which is advantageous for floating applications. Selecting the appropriate material grade ensures that the rope meets the specific needs of your application.

2. Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling) stress that a rope can withstand before breaking. It is typically measured in pounds or kilograms. A higher tensile strength indicates a more robust rope, which is essential for applications involving heavy loads or high-stress environments. Understanding tensile strength helps buyers assess whether a rope will perform adequately under specific conditions, minimizing the risk of failure.

3. Diameter

The diameter of braided rope significantly impacts its load-bearing capacity and flexibility. A thicker rope generally has a higher strength rating but may be less flexible, making it harder to handle. Conversely, thinner ropes are easier to manipulate but may not bear as much weight. Knowing the required diameter is essential for compatibility with pulleys, winches, or other equipment.

4. Construction Type

Braided ropes can be constructed in various ways, such as double braid or solid braid. Double braid ropes feature an inner core and an outer sheath, offering enhanced strength and durability. Solid braid ropes, on the other hand, are made from a single strand and are typically smoother, making them easier to handle. The construction type affects the rope’s performance, so selecting the right type based on the application is critical.

5. Abrasion Resistance

Abrasion resistance measures how well a rope can withstand wear and tear from friction and environmental conditions. Ropes with high abrasion resistance are essential for applications where the rope will be in constant contact with rough surfaces, such as in marine or industrial settings. This property is vital for ensuring longevity and reliability, reducing the frequency of replacements.

What Are Common Trade Terms Used in Braided Rope Transactions?

Familiarity with industry-specific terminology can facilitate smoother B2B transactions. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the braided rope industry, understanding whether a supplier is an OEM can help assess the quality and reliability of the products being offered.

Illustrative image related to braided rope

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers, especially when budgeting for inventory and ensuring that they can meet their operational needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. When considering braided rope purchases, issuing an RFQ can help buyers compare prices and terms from multiple vendors, facilitating better negotiation outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping logistics, costs, and risks associated with the procurement of braided rope from global suppliers.

Illustrative image related to braided rope

5. Lead Time

Lead time is the period between placing an order and receiving the goods. For braided rope, understanding lead times is critical for planning and ensuring that supply chain disruptions do not impact operational timelines.

6. Certification Standards

Certification standards, such as ISO or ASTM, indicate compliance with specific quality and safety regulations. Buyers should inquire about certification to ensure that the braided ropes meet industry standards and are suitable for their intended applications.

Being knowledgeable about these technical properties and trade terms will empower B2B buyers to make more informed decisions, ensuring they select the right braided rope for their needs.

Navigating Market Dynamics and Sourcing Trends in the braided rope Sector

What Are the Current Market Dynamics and Key Trends in the Braided Rope Sector?

The global braided rope market is witnessing significant growth, driven by increasing demand across various industries, including marine, construction, and sports. Factors such as urbanization, infrastructure development, and a surge in outdoor recreational activities have propelled the need for robust and reliable rope solutions. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focusing on high-performance materials that offer durability and versatility.

Emerging technologies, such as advanced synthetic fibers and manufacturing techniques, are reshaping the sourcing landscape. Buyers are now gravitating towards braided ropes that utilize materials like nylon and polyester for their superior strength and resistance to environmental factors. The integration of e-commerce platforms has also simplified procurement processes, allowing international buyers to access a broader range of products at competitive prices.

Moreover, the trend towards customization is gaining momentum, with manufacturers increasingly offering tailored solutions to meet specific industry needs. This adaptability is crucial for B2B buyers who require specialized products for unique applications. As global supply chains evolve, the emphasis on efficient logistics and transparent sourcing is becoming increasingly critical, influencing purchasing decisions among international buyers.

How Are Sustainability and Ethical Sourcing Shaping the Braided Rope Market?

Sustainability has emerged as a pivotal concern in the braided rope sector, reflecting broader environmental trends across industries. The production of braided ropes often involves synthetic materials, which can have significant environmental impacts. Consequently, buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials that are recyclable or derived from renewable resources, as well as adopting eco-friendly manufacturing processes.

Illustrative image related to braided rope

Ethical supply chains are gaining traction, with buyers demanding transparency regarding the origin of materials and the working conditions of those involved in production. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX can enhance credibility and assure buyers of a product’s sustainability credentials. Additionally, the incorporation of biodegradable materials in braided ropes is an emerging trend that aligns with the growing consumer preference for environmentally friendly products.

By prioritizing sustainability, B2B buyers not only contribute to environmental conservation but also enhance their brand reputation in increasingly eco-conscious markets. Suppliers who align with these values may benefit from increased customer loyalty and market differentiation.

What Is the Historical Context of Braided Rope Development Relevant to B2B Buyers?

The evolution of braided rope can be traced back thousands of years, with its origins in ancient civilizations where natural fibers such as hemp and cotton were predominantly used. Over time, advancements in material science led to the development of synthetic fibers, revolutionizing the industry. The introduction of nylon in the mid-20th century marked a significant turning point, offering enhanced strength and durability compared to traditional materials.

Illustrative image related to braided rope

In recent decades, the focus has shifted towards high-performance braided ropes that cater to specialized applications, including climbing, fishing, and industrial uses. This historical context is essential for B2B buyers as it underscores the continuous innovation within the sector, emphasizing the importance of sourcing products that not only meet current demands but are also backed by a legacy of reliability and performance.

As the braided rope market continues to evolve, understanding its historical trajectory can provide B2B buyers with valuable insights into material properties, application suitability, and supplier reliability, ultimately aiding in informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of braided rope

-

How do I choose the right braided rope for my specific application?

Choosing the right braided rope involves understanding the specific requirements of your application, including load capacity, environmental conditions, and flexibility. Consider the material; nylon offers elasticity and strength, while polyester provides superior UV and abrasion resistance. Assess the rope’s diameter and construction type, such as double braid for strength or diamond braid for lightweight applications. Additionally, consult with suppliers for product specifications and recommendations based on your needs. -

What are the advantages of using braided rope over twisted rope?

Braided ropes typically offer enhanced strength, flexibility, and resistance to abrasion compared to twisted ropes. The interlocking fibers of braided ropes help distribute load evenly, reducing the risk of fraying and damage. They also tend to be torque-free, making them easier to handle and less prone to kinking. This makes braided ropes ideal for applications requiring consistent performance, such as marine use, climbing, and heavy-duty industrial tasks. -

What is the minimum order quantity (MOQ) for braided rope when sourcing internationally?

Minimum order quantities (MOQs) for braided rope can vary significantly between suppliers, often depending on the type of rope and the manufacturer’s policies. Typically, MOQs range from 100 to 1,000 meters or more. When sourcing internationally, it’s essential to clarify MOQs with suppliers early in the negotiation process, as lower MOQs may be available for established partnerships or bulk orders. Always consider how MOQs align with your project needs and budget. -

What payment terms should I expect when sourcing braided rope from international suppliers?

Payment terms can vary widely among suppliers and regions. Common terms include net 30, net 60, or payment in advance for first-time orders. Some suppliers may offer letters of credit or escrow services to ensure security for both parties. It’s advisable to negotiate favorable terms based on your purchasing volume and establish clear agreements to avoid misunderstandings. Always confirm accepted payment methods and consider currency fluctuations when dealing with international transactions. -

How can I verify the quality of braided rope before making a purchase?

To verify the quality of braided rope, request certifications and test results from the supplier, such as ISO certifications or compliance with international standards. Conducting sample testing can also be beneficial; ask for samples to evaluate the rope’s strength, flexibility, and durability. Additionally, consider supplier reviews, industry reputation, and previous client testimonials as indicators of reliability. Establishing a quality assurance process with your supplier can help maintain consistent standards. -

What are the logistics considerations for importing braided rope?

When importing braided rope, consider factors such as shipping methods, customs regulations, and import duties. Choose between sea freight for bulk orders or air freight for urgent needs, keeping in mind cost versus speed. Familiarize yourself with the customs requirements of your destination country to avoid delays, and ensure all paperwork, including invoices and shipping documents, is complete. Partnering with a logistics provider experienced in international trade can streamline the process and mitigate risks. -

Can I customize braided rope according to my specifications?

Many suppliers offer customization options for braided rope, including variations in diameter, color, length, and material composition. Customization can enhance the rope’s performance for specific applications, such as adding UV resistance or specific tensile strength. Discuss your requirements with potential suppliers, and inquire about their capabilities regarding custom orders. Be aware that customization may affect lead times and pricing, so plan accordingly. -

What are the common applications for braided rope in various industries?

Braided rope is widely used across various industries, including marine, construction, agriculture, and outdoor recreation. In marine applications, it serves as anchor lines and docking lines due to its durability and resistance to saltwater. In construction, it is often used for lifting and rigging. Agricultural operations utilize braided rope for fencing and securing equipment. Understanding the specific applications relevant to your industry can help you select the appropriate type of braided rope for your needs.

Top 9 Braided Rope Manufacturers & Suppliers List

1. Rope.com – Braided Rope Collection

Domain: rope.com

Registered: 1996 (29 years)

Introduction: Braided rope collection featuring interlocked fibers for strength and durability. Available in various diameters from 1/8″ to 2″ and multiple colors including Black, Blue, Brown, Green, Pink, Red, White, and more. Types include 3-Strand, 16-Strand, 24-Strand, Double Braid, Diamond Braid, Kernmantle, and Solid Braid. Materials include Cotton, Dyneema, Manila, Nylon, Polyester, Polypropylene, and Ec…

2. RightRope – Solid Braid Nylon Rope

Domain: rightrope.com

Registered: 2018 (7 years)

Introduction: Product Name: Solid Braid Nylon Rope

Material: 100% nylon

Design: Lock-stitch braided

Diameter Options: 1/8 in., 3/16 in., 1/4 in., 5/16 in., 3/8 in., 1/2 in.

Length Options: 100 ft., 150 ft., 200 ft., 300 ft., 500 ft. bulk, 1000 ft. bulk, Custom Length

Color Options: Standard colors are black and white; other colors available with lead times and minimums.

Best For: General utility rope, knot tyin…

3. Knot and Rope – Hollow Braid Rope

Domain: knotandrope.com

Registered: 2003 (22 years)

Introduction: Hollow Braid Rope is available in various sizes including 3/16″, 1/4″, 5/16″, 3/8″, 7/16″, 1/2″, 5/8″, 3/4″, 7/8″. It is made from materials such as Polyester and Polypropylene. The rope is categorized under 12-Strand type and has strength ratings ranging from 400lbs to 24999lbs. The product is offered in spool lengths of 1000′, 3000′, and 5000′. The Hollow Braid Polypropylene is noted for being e…

4. Memphis Net – Rope Braided

5. Rope and Cord – Solid Braid Nylon Rope

Domain: ropeandcord.com

Registered: 2017 (8 years)

Introduction: {‘name’: ‘Solid Braid Nylon Rope’, ‘SKU’: ‘RAC-SBN-‘, ‘weight’: ‘0.06 LBS’, ‘price’: ‘$0.09’, ‘colors’: [‘Black’, ‘White’, ‘Kelly Green’, ‘Hunter Green’, ‘Navy Blue’, ‘Orange’, ‘Pacific Blue’, ‘Red’, ‘Yellow’], ‘diameters’: [‘1/8 Inch’, ‘5/32 Inch’, ‘3/16 Inch’, ‘1/4 Inch’, ‘5/16 Inch’, ‘3/8 Inch’, ‘1/2 Inch’, ‘5/8 Inch’], ‘lengths’: [‘By the Foot’, ‘100 Feet’, ‘500 Foot Spool’, ‘1000 Foot Spool’]…

6. GMESupply – Double Braided Rope

Domain: gmesupply.com

Registered: 2004 (21 years)

Introduction: Double braided rope is a versatile tool used for various applications, especially in lifting and rigging. It features a braided core surrounded by a braided sheath, designed to share the load equally with low elongation. This type of rope remains round under tension, does not impart rotational force when loaded, and has a soft hand, making it ideal for use as a load rope. When selecting double bra…

7. Ibex Marina – Braided Ropes

Domain: ibexmarina.com

Registered: 2009 (16 years)

Introduction: Braided Ropes available in various materials including polyester, polypropylene, nylon, Dyneema, cotton, jute, and Aramid. Key features include: 8-plait construction for high-strength polyester braided cords, ideal for picture cords and industrial uses; matt polyester finish for grip and identification; 16-carrier polyester blind cords for window blinds; general-purpose cords for horticultural and…

8. WikiHow – Braiding Rope Techniques

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: Braiding rope enhances durability and versatility for various applications. Key methods include:

1. Three-Strand Braid: Commonly used, suitable for high-friction situations. Requires flexible rope material (synthetic, natural, or plastic). Ends can be fused or bound to prevent fraying.

2. Four-Strand Braid: Ideal for high-friction uses like winches and pulleys. Requires four flexible strands, whic…

9. Bulk Ropes – Double Braid Nylon Rope

Domain: bulkropes.com

Registered: 2007 (18 years)

Introduction: Double Braid Nylon Rope is favored by utility contractors, horse lovers, and crafters. It is manufactured with a high number of fibers for increased strength compared to twisted nylon ropes. All ropes are made in the USA and treated with a marine finish to reduce internal yarn abrasion and water absorption, enhancing durability. The rope is flexible, shock absorbent, and chemical resistant. Applic…

Strategic Sourcing Conclusion and Outlook for braided rope

What Are the Key Takeaways for Sourcing Braided Rope?

In the competitive landscape of braided rope procurement, understanding the nuances of material selection—be it nylon or polyester—can significantly impact operational efficiency and cost management. Buyers should prioritize suppliers that offer a range of products, including various strand counts and styles, to meet diverse applications from marine to industrial uses. The strategic sourcing of braided rope can enhance supply chain resilience, enabling businesses to adapt swiftly to market demands and mitigate risks associated with material shortages.

How Can Buyers Leverage Global Sourcing Opportunities?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, tapping into global supply chains can unlock competitive pricing and superior product quality. Establishing relationships with trusted manufacturers not only assures a steady supply of high-performance braided ropes but also opens avenues for innovation through customized solutions.

What’s Next for Your Sourcing Strategy?

As you navigate your sourcing strategy, consider the long-term benefits of investing in high-quality braided ropes that align with your operational needs. The future of braided rope sourcing looks promising, with advancements in materials and technology paving the way for even more durable and versatile options. Engage with suppliers now to secure the best deals and foster partnerships that can elevate your business in a dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to braided rope