A B2B Buyer’s Guide to Bolt With Lock Washer: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for bolt with lock washer

In today’s fast-paced industrial landscape, sourcing high-quality bolts with lock washers presents a significant challenge for international B2B buyers. The need for reliable fastening solutions that can withstand vibrations and environmental stresses is paramount, especially in sectors ranging from automotive to construction. This guide serves as a comprehensive resource, addressing the complexities of selecting the right bolt with lock washer combination for your specific applications. We will delve into various types of lock washers, their applications in different industries, and essential factors to consider when vetting suppliers and evaluating costs.

Understanding the nuances of bolt and lock washer specifications is crucial for making informed purchasing decisions. As businesses from Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia, navigate the global supply chain, this guide empowers you with actionable insights. You will learn how to assess product quality, negotiate effectively, and identify reliable suppliers that align with your operational needs. By equipping yourself with this knowledge, you can enhance your procurement strategy, ensuring that your fastening solutions are not only cost-effective but also meet the stringent performance criteria required in today’s competitive markets.

Understanding bolt with lock washer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Split Lock Washer | Helical shape, exerts spring tension | Automotive, machinery | Pros: Effective against vibration; Cons: Limited load capacity. |

| Internal Tooth Lock Washer | Teeth bite into nut/screw head, compact design | Electrical connections, small fastenings | Pros: Secure grip; Cons: May scratch surfaces. |

| External Tooth Lock Washer | Teeth bite into bearing surface, larger contact area | Heavy machinery, structural applications | Pros: Strong hold; Cons: Can leave marks on surfaces. |

| High-Collar Lock Washer | Increased height for added friction | Railways, heavy-duty applications | Pros: Enhanced grip; Cons: Bulkier design. |

| Tab Washer | Includes a tab for securing against rotation | Harsh environments, critical assemblies | Pros: Excellent stability; Cons: Requires additional installation steps. |

What Are Split Lock Washers and Their Uses in B2B Transactions?

Split lock washers are characterized by their helical shape, which creates a spring effect when tightened. This design helps maintain a secure connection by counteracting loosening due to vibration and torque, making them ideal for automotive and machinery applications. When purchasing split lock washers, consider the load capacity and material type, as these factors impact performance and durability.

How Do Internal Tooth Lock Washers Enhance Electrical Connections?

Internal tooth lock washers feature teeth designed to bite into the nut or screw head. This compact design is particularly useful in electrical connections and small fastenings where space is limited. Buyers should consider the size and material of the washer to ensure compatibility with their fasteners, as well as the potential for surface scratching due to the teeth.

What Advantages Do External Tooth Lock Washers Offer for Heavy Machinery?

External tooth lock washers have teeth that grip the bearing surface, providing a larger contact area for enhanced holding power. These washers are commonly used in heavy machinery and structural applications, where secure fastening is critical. When selecting external tooth lock washers, buyers should account for the potential for surface damage and the overall strength required for their specific application.

Why Choose High-Collar Lock Washers for Heavy-Duty Applications?

High-collar lock washers are designed with an increased height to provide additional friction and grip. They are particularly suited for railway and heavy-duty applications, where the risk of loosening is high. Buyers should assess the compatibility of the high-collar design with existing fasteners, as well as the load-bearing requirements of their projects.

In What Scenarios Are Tab Washers Most Effective?

Tab washers include a tab that can be bent against the nut or fastener head, providing a secure hold in harsh environments. They are often used in critical assemblies where reliability is paramount. Buyers should consider the additional steps required for installation and the specific environmental conditions the washers will face, such as exposure to moisture or vibration.

Key Industrial Applications of bolt with lock washer

| Industry/Sector | Specific Application of bolt with lock washer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Securing engine components and chassis parts | Enhances durability and vibration resistance, reducing maintenance costs | Ensure compatibility with specific vehicle models and environmental standards |

| Construction | Joining structural steel beams and frames | Provides structural integrity and safety in buildings and infrastructure | Look for corrosion-resistant materials suitable for local climates |

| Aerospace | Fastening aircraft components and assemblies | Ensures safety and performance under extreme conditions | Compliance with aviation standards and certification requirements |

| Marine | Attaching deck fittings and hull components | Prevents loosening due to harsh marine environments and vibrations | Sourcing from suppliers familiar with marine-grade materials |

| Renewable Energy | Securing wind turbine components and solar panel mounts | Increases reliability and reduces downtime in energy production | Consider sourcing from manufacturers with experience in energy sector standards |

How is ‘bolt with lock washer’ utilized in the automotive industry?

In the automotive sector, bolts with lock washers are critical for securing engine components and chassis parts. These fasteners help withstand vibrations and dynamic forces that can cause traditional fasteners to loosen over time. For international buyers, particularly in regions like Africa and South America, sourcing must ensure that the materials meet local regulations and automotive standards. Additionally, buyers should consider compatibility with specific vehicle models to avoid costly errors during assembly or repairs.

What role does ‘bolt with lock washer’ play in construction projects?

In construction, bolts with lock washers are extensively used for joining structural steel beams and frames. Their design provides enhanced structural integrity, ensuring that buildings and infrastructure can withstand various loads and environmental conditions. Buyers in Europe, particularly in Germany, must focus on sourcing high-quality, corrosion-resistant materials to meet stringent safety regulations. Additionally, understanding the local construction codes is essential to ensure compliance and project success.

Why are ‘bolt with lock washer’ essential in the aerospace industry?

In aerospace applications, bolts with lock washers are vital for fastening aircraft components and assemblies. These fasteners must withstand extreme conditions, including high vibrations and temperature fluctuations, making their reliability crucial for safety. International buyers from the Middle East and Europe should prioritize suppliers who comply with aviation standards and possess the necessary certifications. This ensures that the components will perform reliably throughout the aircraft’s lifecycle.

How does ‘bolt with lock washer’ benefit marine applications?

In the marine industry, bolts with lock washers are used to attach deck fittings and hull components, providing a secure hold in environments subject to harsh conditions and vibrations. These fasteners help prevent loosening, which can lead to catastrophic failures at sea. Buyers should seek suppliers familiar with marine-grade materials to ensure durability against corrosion and saltwater exposure. Understanding local maritime regulations can also guide sourcing decisions.

What advantages does ‘bolt with lock washer’ offer in renewable energy installations?

Bolts with lock washers are crucial in securing wind turbine components and solar panel mounts, providing reliability in energy production systems. These fasteners help maintain structural integrity against wind loads and vibrations, minimizing downtime and maintenance costs. Buyers in the renewable energy sector should consider sourcing from manufacturers experienced in energy sector standards to ensure compliance and quality. Additionally, understanding the environmental conditions of installation sites is key to selecting the right materials.

3 Common User Pain Points for ‘bolt with lock washer’ & Their Solutions

Scenario 1: Ensuring Consistent Quality in Fasteners

The Problem: B2B buyers often struggle with inconsistent quality in bolts with lock washers, especially when sourcing from multiple suppliers. Variations in material strength, dimensions, and finishes can lead to premature failures, resulting in costly downtime and safety risks. This inconsistency can stem from different manufacturing processes or quality control standards, making it challenging for buyers to trust the reliability of the products they receive.

The Solution: To mitigate quality issues, it is crucial to establish strong relationships with reputable suppliers who adhere to international quality standards, such as ISO 9001. Before placing bulk orders, conduct thorough evaluations of potential suppliers, including requesting samples and certifications that validate their manufacturing processes. Additionally, consider implementing a quality control protocol upon receipt of goods, which includes checking for compliance with specified standards like ASTM or DIN for bolts and washers. Utilizing a standardized checklist can help ensure that every batch meets your organization’s expectations for performance and durability.

Scenario 2: Addressing Vibration-Induced Loosening in Applications

The Problem: In industries such as automotive and construction, bolts with lock washers are essential for maintaining secure connections in environments subjected to significant vibration. However, buyers often encounter the issue of fasteners loosening over time, which can lead to structural failures and safety hazards. This problem is particularly prevalent in applications involving machinery or transport vehicles where constant movement is a factor.

The Solution: To effectively combat vibration-induced loosening, it’s essential to select the right type of lock washer for the application. For high-vibration environments, split lock washers are typically recommended due to their spring action that creates additional friction. Moreover, consider using high-strength bolts made from materials such as stainless steel or high-carbon steel, which offer better resistance to fatigue. Training your assembly teams on proper installation techniques, including the correct torque specifications, can further enhance the reliability of the connections. Implementing periodic inspections can also help identify any loosening early, allowing for timely maintenance before failures occur.

Scenario 3: Sizing and Compatibility Challenges in Diverse Applications

The Problem: A common pain point for B2B buyers is ensuring that the bolts with lock washers they purchase are the right size and compatible with existing components. Miscommunication regarding sizing standards—metric versus imperial—can lead to mismatched parts, causing delays and additional costs. This issue is compounded when working with international suppliers, where specifications may vary.

The Solution: To prevent sizing and compatibility issues, it is essential to establish a clear specification guide that includes detailed measurements for every application. This guide should outline the required bolt sizes, lock washer types, and any specific material properties needed for durability. Additionally, consider leveraging digital tools or platforms that allow for easy conversion between metric and imperial measurements, which can simplify the ordering process. Engaging in collaborative discussions with suppliers about your specific needs can also ensure they understand your requirements, reducing the likelihood of errors in orders. Furthermore, maintaining a small inventory of commonly used sizes can provide flexibility and minimize downtime when unexpected needs arise.

Strategic Material Selection Guide for bolt with lock washer

What Are the Key Properties of Common Materials for Bolts with Lock Washers?

When selecting bolts with lock washers, the choice of material is crucial to ensure optimal performance and longevity in various applications. Here, we analyze four common materials used in the manufacturing of these fasteners: carbon steel, stainless steel, brass, and titanium.

Carbon Steel: A Cost-Effective Option

Key Properties: Carbon steel bolts are known for their strength and hardness. They typically have a tensile strength ranging from 400 to 1200 MPa, making them suitable for high-stress applications. However, their corrosion resistance is limited, which can be a concern in humid or corrosive environments.

Pros & Cons: The primary advantage of carbon steel is its low cost, making it a popular choice for many industrial applications. However, its susceptibility to rust and corrosion can limit its use in outdoor or marine environments, necessitating protective coatings that may increase manufacturing complexity.

Impact on Application: In applications where exposure to moisture or chemicals is minimal, carbon steel bolts with lock washers can perform effectively. However, in harsher conditions, their performance may degrade, leading to potential failures.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the local climate and environmental conditions. Compliance with standards such as ASTM A307 for carbon steel fasteners is essential to ensure quality and safety.

Stainless Steel: Durability and Corrosion Resistance

Key Properties: Stainless steel bolts, particularly those made from grades 304 and 316, offer excellent corrosion resistance and can withstand temperatures up to 870°C. They are ideal for applications that require both strength and resistance to rust.

Pros & Cons: The durability and aesthetic appeal of stainless steel make it a preferred choice for many industries, including automotive and marine. However, it is more expensive than carbon steel and can be more challenging to machine, which may increase production costs.

Impact on Application: Stainless steel bolts with lock washers are suitable for environments exposed to moisture, chemicals, and high temperatures. Their resistance to corrosion ensures a longer lifespan, reducing maintenance costs.

Considerations for International Buyers: Buyers in Europe, particularly in Germany, often prefer stainless steel due to stringent quality standards. Compliance with EN 10088 and ISO 3506 standards is crucial for ensuring that the fasteners meet required specifications.

Brass: A Unique Choice for Specific Applications

Key Properties: Brass bolts are known for their excellent machinability and corrosion resistance, particularly in marine environments. They typically have a tensile strength of around 300 MPa and can withstand moderate temperatures.

Pros & Cons: The primary advantage of brass is its resistance to corrosion and tarnishing, making it suitable for decorative applications. However, brass is softer than steel, which limits its use in high-stress applications. Additionally, it is generally more expensive than carbon steel.

Impact on Application: Brass bolts with lock washers are ideal for electrical applications and environments where corrosion is a concern. However, their lower strength may not be suitable for heavy-duty applications.

Considerations for International Buyers: In regions like the Middle East, where humidity can be high, brass fasteners are often preferred. Compliance with standards such as ASTM B16 for brass fasteners is important for ensuring reliability.

Titanium: The Premium Choice for Extreme Conditions

Key Properties: Titanium bolts are known for their exceptional strength-to-weight ratio and excellent corrosion resistance, even in extreme environments. They can withstand temperatures up to 600°C and are highly resistant to saltwater corrosion.

Pros & Cons: The main advantage of titanium is its lightweight and high strength, making it ideal for aerospace and military applications. However, it is significantly more expensive than other materials, and its machining can be complex, leading to higher production costs.

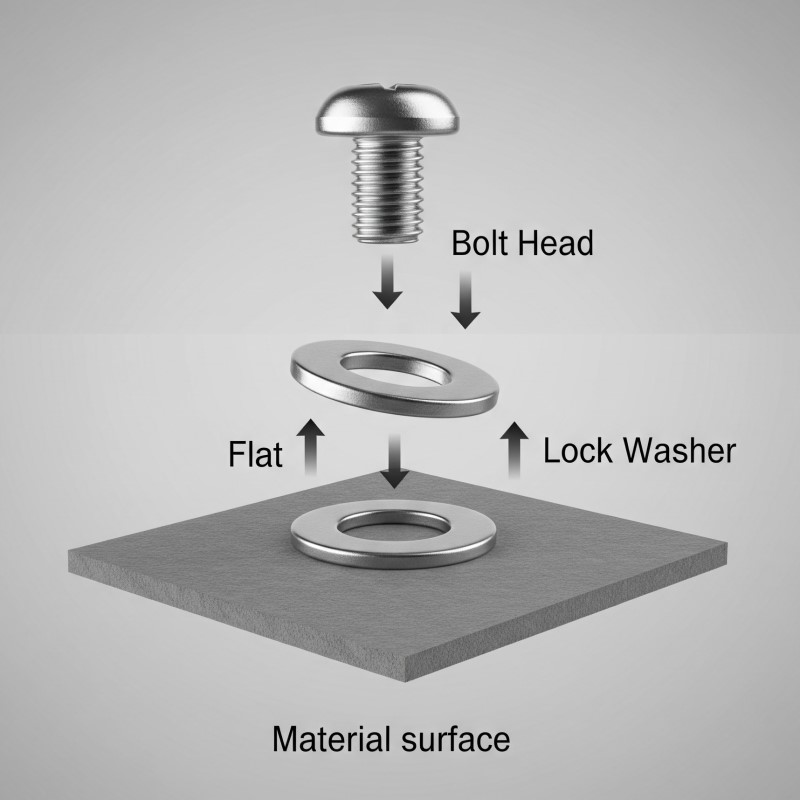

Illustrative image related to bolt with lock washer

Impact on Application: Titanium bolts with lock washers are best suited for high-performance applications where weight and corrosion resistance are critical. Their durability ensures long-term reliability in extreme conditions.

Considerations for International Buyers: Buyers in aerospace and defense sectors, particularly in Europe and the Middle East, often require titanium fasteners. Compliance with aerospace standards such as AMS 4928 is essential for ensuring quality and safety.

Summary Table of Material Selection for Bolts with Lock Washers

| Material | Typical Use Case for bolt with lock washer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General industrial applications | Low cost | Poor corrosion resistance | Low |

| Stainless Steel | Marine and high-temperature applications | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Brass | Electrical and decorative applications | Good corrosion resistance | Lower strength | Med |

| Titanium | Aerospace and military applications | Lightweight and strong | Very high cost and complex machining | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in bolts with lock washers, enabling informed purchasing decisions tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bolt with lock washer

What Are the Main Stages of Manufacturing a Bolt with Lock Washer?

The manufacturing process for bolts with lock washers is intricate, involving several key stages that ensure both the functionality and quality of the final product. This process typically includes material preparation, forming, assembly, and finishing.

How Is Material Prepared for Bolts and Lock Washers?

The first stage involves selecting high-quality raw materials suitable for fasteners. Common materials include carbon steel, stainless steel, and alloy steels, which are chosen based on the application requirements. The selected materials undergo processes like cutting and heat treatment to enhance their strength and durability. For instance, stainless steel is often used for applications requiring corrosion resistance, while carbon steel may be used for general-purpose applications.

What Forming Techniques Are Used in Bolt and Lock Washer Production?

Once the materials are prepared, they are subjected to various forming techniques. The most common methods include:

- Cold Heading: This technique is used for forming the bolt head and shank. It involves deforming the metal at room temperature, which increases its strength through work hardening.

- Thread Rolling: After forming the bolt, threads are rolled onto the shank. This method enhances the durability of the threads compared to cutting, which can create weak points.

- Washer Forming: Lock washers are typically produced using stamping or laser cutting. The material is cut into the desired shape, and for split or tooth washers, specific geometries are achieved to provide the locking mechanism.

How Is the Assembly Process Conducted for Bolts and Lock Washers?

In the assembly stage, bolts and lock washers are paired together, ensuring that they meet the specifications required for their intended application. This might involve:

- Manual Assembly: For small batches or specialized products, workers may manually assemble the components.

- Automated Systems: In high-volume production, automated machinery is used to efficiently pair bolts with the appropriate lock washers, reducing labor costs and improving consistency.

What Quality Assurance Measures Are Essential in Bolt Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of bolts with lock washers, ensuring that the products meet international standards and industry-specific requirements.

Which International Standards Apply to Bolt Manufacturing?

B2B buyers should be familiar with several key international standards:

- ISO 9001: This standard outlines the requirements for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial for ensuring product integrity under extreme conditions.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) in the manufacturing process involves several checkpoints:

- Incoming Quality Control (IQC): This stage checks the quality of raw materials before they enter the production line. Suppliers are often required to provide material certificates to verify compliance with specified standards.

- In-Process Quality Control (IPQC): During production, periodic checks are performed to ensure that the manufacturing processes are within specified tolerances. This may include monitoring dimensions, material properties, and surface finishes.

- Final Quality Control (FQC): After production, finished products undergo final inspections to verify that they meet all specifications and standards. This may involve functional testing, dimensional checks, and visual inspections.

What Testing Methods Are Commonly Used to Ensure Product Quality?

Various testing methods are employed to verify the quality and performance of bolts with lock washers:

- Tensile Testing: This method measures the strength of the bolt by applying a tensile load until it fails. This helps determine the maximum load the bolt can withstand.

- Hardness Testing: Hardness tests assess the resistance of the bolt material to deformation, which is critical for ensuring durability under load.

- Corrosion Resistance Testing: For stainless steel and coated products, tests such as salt spray tests evaluate the material’s resistance to corrosion in harsh environments.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is essential. Here are some effective methods:

- Supplier Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards.

- Quality Reports: Requesting detailed quality reports, including test results and certifications, can help verify that the supplier meets the necessary quality standards.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices and product compliance.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must be aware of specific nuances in quality control when sourcing bolts with lock washers. These may include:

- Cultural Differences: Understanding the local manufacturing culture can impact communication and expectations regarding quality standards.

- Import Regulations: Familiarizing oneself with the import regulations in the buyer’s country is crucial, as these may impose additional requirements on product quality and documentation.

- Logistics and Supply Chain Considerations: International shipping can affect product quality, particularly in terms of handling and storage conditions. Ensuring that suppliers have robust logistics practices is vital.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing bolts with lock washers, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bolt with lock washer’

When sourcing bolts with lock washers, a systematic approach is essential for ensuring quality, reliability, and suitability for your specific application. This checklist provides a step-by-step guide to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it is crucial to clearly define the technical specifications of the bolts and lock washers you need. Consider factors such as size, material (e.g., stainless steel, carbon steel), grade, and any specific standards (e.g., ISO or ASTM) that must be met. Detailed specifications will streamline the sourcing process and help you communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in fasteners and locking mechanisms. Look for companies with a proven track record in your region or industry. Utilize platforms like industry directories, trade shows, and online marketplaces to compile a list of candidates. It is essential to consider suppliers with experience in international shipping to avoid delays and compliance issues.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and quality assurance processes. Certifications such as ISO 9001 indicate a commitment to quality management systems, which is crucial in maintaining product consistency. Additionally, inquire about their compliance with international standards that may apply to your industry, such as those related to safety or environmental impact.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of their bolts with lock washers. Testing samples allows you to evaluate the quality, durability, and compatibility of the products with your applications. Ensure that the samples meet your specifications and conduct any necessary performance tests, particularly for applications subject to vibration or dynamic loads.

Step 5: Review Pricing and Terms

After evaluating product quality, review the pricing structures and payment terms offered by each supplier. Consider bulk pricing options, discounts, and the total cost of ownership, which includes shipping and import duties. Transparent pricing models will help you make informed decisions and maintain budget control.

Step 6: Assess Customer Support and Communication

Effective communication is vital throughout the sourcing process. Evaluate each supplier’s responsiveness and willingness to provide support. Good customer service can be a significant factor in resolving any issues that may arise post-purchase, such as product defects or delivery delays.

Illustrative image related to bolt with lock washer

Step 7: Finalize the Order and Establish a Relationship

After selecting a supplier, finalize your order by confirming all details, including specifications, pricing, and delivery timelines. Establishing a good relationship with your supplier can lead to better terms in the future, including priority service and potential discounts. Regular communication post-purchase can also provide valuable insights into product performance and supplier reliability.

By following this checklist, B2B buyers can ensure a thorough and effective sourcing process for bolts with lock washers, leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for bolt with lock washer Sourcing

What Are the Key Cost Components of Sourcing Bolts with Lock Washers?

When sourcing bolts with lock washers, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The type of materials used significantly impacts cost. Common materials for bolts and lock washers include carbon steel, stainless steel, and specialized alloys. Stainless steel options, while more expensive, offer superior corrosion resistance, which can be critical in certain environments.

-

Labor: Labor costs encompass the wages paid to workers involved in manufacturing, assembling, and packaging the products. In regions with higher labor costs, such as Western Europe, the overall price may be affected compared to sourcing from areas with lower labor costs.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be beneficial when negotiating bulk orders.

-

Tooling: The initial setup and tooling costs for custom bolts and washers can be substantial. If specific designs or sizes are required, these costs should be factored into the total price.

-

Quality Control (QC): Ensuring that products meet quality standards involves additional costs related to testing and inspection. Certifications such as ISO can increase costs but also provide assurance of quality to buyers.

-

Logistics: This encompasses shipping, warehousing, and distribution expenses. Costs can vary widely depending on the shipping method, distance, and any customs duties applicable when importing goods.

-

Margin: Suppliers will add a profit margin to the total cost of production. This margin can vary based on market demand, competition, and supplier relationships.

What Influences the Pricing of Bolts with Lock Washers?

Several factors influence the pricing of bolts and lock washers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs. Suppliers often offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Customized products often come at a premium. Clearly defining specifications upfront can help in receiving accurate quotes and avoid unexpected costs later.

-

Material Selection: As previously mentioned, the choice of materials directly affects pricing. Buyers should weigh the benefits of high-quality materials against cost considerations.

-

Quality and Certifications: Products that meet specific industry standards or certifications may command higher prices. Buyers should consider whether such certifications are necessary for their applications.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding the delivery terms agreed upon (e.g., FOB, CIF) is essential, as they dictate who bears the shipping costs and risks, affecting the total landed cost.

What Tips Can Help Buyers Negotiate Better Pricing?

To achieve cost efficiency when sourcing bolts with lock washers, buyers should consider the following strategies:

Illustrative image related to bolt with lock washer

-

Negotiate: Don’t hesitate to negotiate prices, especially for larger orders. Suppliers may have flexibility in their pricing, particularly if they are keen to secure a long-term relationship.

-

Assess Total Cost of Ownership (TCO): Consider all costs associated with the product, including maintenance, replacement, and disposal. Sometimes, investing in higher-quality items can result in lower TCO due to reduced failure rates and longer lifespans.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local market conditions, tariffs, and exchange rates. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these factors.

-

Request Samples: Before placing large orders, request samples to evaluate quality. This can help prevent costly mistakes and ensure that the product meets specifications.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can provide leverage in negotiations and help identify the best value for the required specifications.

Disclaimer on Pricing

Prices for bolts with lock washers can fluctuate based on market conditions, material availability, and other external factors. The figures mentioned in this analysis are indicative and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing bolt with lock washer With Other Solutions

When considering the use of bolts with lock washers in fastening applications, it’s essential to evaluate alternative solutions that may offer comparable or enhanced performance. In the B2B sector, especially for international buyers from diverse regions like Africa, South America, the Middle East, and Europe, understanding these alternatives can help in making informed purchasing decisions that align with specific operational needs.

| Comparison Aspect | Bolt With Lock Washer | Alternative 1: Lock Nut | Alternative 2: Adhesive Fasteners |

|---|---|---|---|

| Performance | Provides secure fastening with spring tension to resist loosening. | High resistance to vibration; maintains tightness without additional components. | Strong bonding; ideal for static applications where movement is minimal. |

| Cost | Generally low-cost, especially in bulk purchases. | Slightly higher than standard bolts but cost-effective for high-stress applications. | Varies widely; can be expensive depending on the type and brand. |

| Ease of Implementation | Simple installation; requires basic tools for assembly. | Easy to install but may require specific torque settings for optimal performance. | Requires surface preparation and curing time; not as straightforward as mechanical fasteners. |

| Maintenance | Minimal maintenance; regular checks recommended in high-vibration environments. | Low maintenance; can be checked visually without disassembly. | Typically low maintenance once cured, but can be more challenging to remove if needed. |

| Best Use Case | Ideal for applications experiencing vibration, such as automotive and machinery. | Best suited for high-stress environments where loosening is a concern. | Effective for structural bonding in applications where traditional fasteners may not fit. |

What Are Lock Nuts and How Do They Compare?

Lock nuts, often used as an alternative to bolts with lock washers, provide a reliable solution for preventing loosening due to vibration. They are designed to grip the bolt threads tightly, ensuring a secure fit. The primary advantage of lock nuts is their ability to maintain tightness without the need for additional components, which simplifies assembly. However, they may require specific torque settings during installation to perform optimally, adding a layer of complexity compared to standard bolts with washers.

Illustrative image related to bolt with lock washer

How Do Adhesive Fasteners Work as Alternatives?

Adhesive fasteners are a modern solution that offers a strong bond between surfaces, making them ideal for applications where mechanical fasteners might be unsuitable, such as in thin materials or sensitive electronics. They excel in static applications where movement is minimal, providing a clean aesthetic without protruding hardware. However, they require proper surface preparation and curing time, which can complicate the installation process. Additionally, once set, they can be challenging to remove, limiting flexibility in assembly and disassembly.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between bolts with lock washers and alternative fastening solutions like lock nuts or adhesive fasteners, B2B buyers should consider the specific requirements of their applications. Factors such as performance needs, cost constraints, ease of installation, and maintenance capabilities play a crucial role in the decision-making process. By evaluating these aspects against the operational context—whether it be high vibration environments or static applications—buyers can make informed choices that enhance their overall project efficiency and effectiveness.

Essential Technical Properties and Trade Terminology for bolt with lock washer

What Are the Key Technical Properties of a Bolt with Lock Washer?

When sourcing bolts with lock washers, understanding critical specifications is essential for ensuring performance, reliability, and compliance with industry standards. Here are key technical properties to consider:

-

Material Grade

The material grade of a bolt and lock washer significantly impacts their strength and corrosion resistance. Common materials include stainless steel (like Grade 304 and 316), carbon steel, and various alloys. For instance, Grade 316 stainless steel is ideal for marine applications due to its high resistance to corrosion, while carbon steel is often used in less demanding environments. Buyers must select the appropriate material grade based on the application and environmental factors to ensure longevity and safety. -

Diameter and Length

The diameter and length of a bolt are critical specifications that determine its suitability for specific applications. Bolts are available in various sizes, and selecting the correct dimensions ensures proper fit and load distribution. For instance, a 1/2 inch diameter bolt may be appropriate for heavy-duty applications, while a 1/4 inch bolt might suffice for lighter tasks. Accurate measurements prevent overloading and potential failures. -

Tolerance

Tolerance refers to the allowable variation in the dimensions of a bolt. Tight tolerances are crucial in applications where precision is necessary, such as in machinery or structural components. Loose tolerances can lead to improper fitment, increased wear, and potential failure under load. Buyers should consult specifications to ensure the tolerance level meets the requirements of their specific application. -

Finish Type

The finish of bolts and washers affects their performance and durability. Common finishes include zinc plating, galvanization, and powder coating. Each finish provides varying levels of corrosion resistance and aesthetic appeal. For instance, zinc-plated bolts are suitable for indoor use, while galvanized options are better for outdoor or moisture-rich environments. Understanding the finish helps in making informed purchasing decisions that align with environmental conditions. -

Load Rating

Load rating indicates the maximum load a bolt can handle before failure. This specification is particularly important in construction and heavy machinery applications, where safety is paramount. Buyers should ensure that the load rating of the bolt and lock washer exceeds the expected loads in their specific applications to prevent failures and ensure safety.

What Are Common Trade Terms Associated with Bolts and Lock Washers?

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions. Here are common trade terms relevant to bolts with lock washers:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of bolts and lock washers, buyers often seek OEM parts to ensure compatibility and reliability in their specific applications. Understanding OEM standards helps buyers choose products that meet required specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is a crucial consideration for buyers, particularly for those sourcing bolts and washers in bulk. Understanding MOQ helps businesses plan their inventory and manage costs effectively, especially in large-scale operations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. It is essential for B2B buyers to provide detailed specifications when issuing an RFQ for bolts and lock washers to receive accurate quotes and ensure that the products meet their requirements. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for managing shipping costs and responsibilities when sourcing bolts and lock washers from international suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. It is a significant factor in supply chain management, affecting project timelines and inventory levels. Buyers should communicate their lead time requirements clearly to suppliers to ensure timely delivery of bolts and lock washers, especially in critical applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance procurement processes and ensure the reliability of their fastening solutions.

Navigating Market Dynamics and Sourcing Trends in the bolt with lock washer Sector

What Are the Key Market Dynamics Affecting the Bolt with Lock Washer Sector?

The global market for bolts with lock washers is driven by the increasing demand for secure fastening solutions across diverse industries, including automotive, construction, and machinery. As businesses expand their operations internationally, particularly in regions like Africa, South America, and the Middle East, the need for reliable fasteners that can withstand vibration and environmental stress becomes paramount. Emerging technologies, such as 3D printing and advanced materials science, are reshaping sourcing strategies by enabling the production of more specialized and durable fasteners. Buyers are increasingly leveraging digital platforms for procurement, allowing for real-time comparison of suppliers and prices, which enhances competitiveness and transparency in sourcing.

Furthermore, the trend towards automation in manufacturing processes is driving the demand for high-quality fasteners that can meet stringent specifications. As industries push for efficiency and reduced operational costs, the use of standardized components, like bolts with lock washers, simplifies assembly and maintenance. International buyers must also navigate varying regulatory standards and certifications across regions, which can impact sourcing decisions and product selection.

How Can Sustainability and Ethical Sourcing Be Integrated into Bolt with Lock Washer Procurement?

Sustainability is becoming a critical consideration for B2B buyers in the bolt with lock washer sector. The environmental impact of manufacturing processes, particularly in metalworking, necessitates a focus on ethical sourcing practices. Companies are increasingly seeking suppliers that prioritize sustainability, including the use of recycled materials and environmentally friendly production techniques. This shift not only helps reduce the carbon footprint but also aligns with the growing consumer demand for responsible sourcing.

Buyers should look for suppliers that hold certifications such as ISO 14001 for environmental management systems or those that utilize green materials in their products. Additionally, the adoption of circular economy principles, where materials are reused and recycled, can enhance the sustainability profile of fastener products. By ensuring that their supply chains are ethically managed, companies can build brand loyalty and meet the expectations of increasingly environmentally conscious consumers.

What Is the Historical Context of Bolt with Lock Washer Development?

The evolution of bolts with lock washers dates back to the late 19th century when mechanical engineering advancements necessitated more reliable fastening solutions. Originally, standard bolts were prone to loosening due to vibration and torque, leading to mechanical failures. The introduction of lock washers provided an effective solution by increasing friction and resistance to motion, thus ensuring a more secure connection.

Over the decades, the design and material composition of lock washers have evolved, with modern variations such as split lock washers and external tooth washers becoming prevalent in industries that demand high performance under challenging conditions. This historical context underscores the importance of continuous innovation in the fastener industry, driving current trends toward enhanced durability and efficiency in bolt and lock washer applications.

Illustrative image related to bolt with lock washer

Conclusion

Understanding the market dynamics, sustainability considerations, and historical evolution of the bolt with lock washer sector is essential for international B2B buyers. As these factors shape the landscape of procurement, companies can make informed decisions that not only meet operational needs but also align with broader environmental and ethical goals.

Frequently Asked Questions (FAQs) for B2B Buyers of bolt with lock washer

-

How do I choose the right bolt with lock washer for my application?

Selecting the appropriate bolt with a lock washer depends on several factors, including load requirements, environmental conditions, and material compatibility. Assess the weight and type of load the bolt will support and consider whether the application will experience vibration or movement, which necessitates the use of a lock washer. Additionally, ensure that the materials of the bolt, washer, and the surfaces being joined are compatible to prevent corrosion or damage. It’s also advisable to consult with your supplier for specific recommendations based on your operational needs. -

What is the best type of lock washer for high-vibration applications?

For high-vibration environments, split lock washers are often the best choice due to their helical design, which creates spring tension to resist loosening. They are particularly effective in applications like automotive and industrial machinery where movement is constant. Alternatively, external tooth lock washers can also be beneficial, as their larger surface area provides additional grip. Always evaluate your specific application requirements and consider consulting with your supplier for tailored recommendations. -

What are the standard sizes available for bolts with lock washers?

Bolts with lock washers come in a variety of standard sizes, typically ranging from 1/4 inch to 1 inch in diameter, with varying lengths. The size you choose should correspond to the specifications of your project and the materials being joined. For specialized applications, some manufacturers may offer custom sizes or lengths, so it’s advisable to communicate your specific needs to your supplier to ensure you receive the correct product. -

What is the minimum order quantity (MOQ) for bolts with lock washers?

Minimum order quantities can vary significantly by supplier and the specific product being ordered. Generally, for standard bolts with lock washers, MOQs might range from 100 to 500 pieces. However, some suppliers may allow smaller orders, especially for customized or less common items. Always confirm the MOQ with your supplier before placing an order to avoid unexpected costs or delays. -

What payment terms should I expect when sourcing bolts with lock washers internationally?

Payment terms for international transactions can vary based on the supplier and the buyer’s relationship. Common terms include advance payment, net 30/60/90 days, or letters of credit for larger orders. It’s essential to discuss and agree upon payment terms before finalizing the order to ensure clarity and avoid payment disputes. Additionally, be mindful of currency exchange rates and potential transaction fees when dealing with international payments. -

How can I ensure the quality of bolts with lock washers from international suppliers?

To ensure quality, conduct thorough vetting of potential suppliers by checking their certifications, customer reviews, and production processes. Request samples before placing a large order to assess the quality firsthand. Furthermore, consider including quality assurance clauses in your purchase agreements, and if possible, arrange for third-party inspections to verify compliance with your specifications. Engaging with suppliers who have ISO certifications can also provide added confidence in their quality control measures. -

What logistics considerations should I keep in mind when importing bolts with lock washers?

When importing, consider shipping methods, customs regulations, and potential tariffs that might apply to your order. Choose a reliable freight forwarder familiar with your destination country’s import requirements. Plan for lead times that include production, shipping, and customs clearance. Additionally, ensure that your supplier provides all necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs processing. -

Can I customize bolts with lock washers to fit specific project requirements?

Yes, many manufacturers offer customization options for bolts with lock washers, including material selection, size, and coatings. When seeking customization, clearly communicate your project requirements, including load capacity, environmental factors, and any specific design features you need. Be prepared for potential minimum order quantities and longer lead times associated with custom products. Discussing your needs upfront with your supplier will help ensure that the final product meets your expectations.

Top 6 Bolt With Lock Washer Manufacturers & Suppliers List

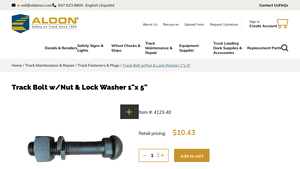

1. Aldonco – Track Bolt w/Nut & Lock Washer 1x 5

Domain: aldonco.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Track Bolt w/Nut & Lock Washer 1\”x 5\””, “Item Number”: “4123-40”, “Retail Price”: “$10.43”, “Quantity per Keg”: “100 Track Bolts”, “Size”: “1\” x 5\” Long”, “Weight per Track Bolt”: “1.80 lbs”, “Shipping Weight”: “3 lbs”, “Shipping Dimensions”: “9 × 9 × 7 in”}

2. Fastenere – Lock Washers

Domain: fastenere.com

Registered: 2016 (9 years)

Introduction: Lock Washers: Designed to stop fasteners from loosening and equipment from shaking apart. High-quality lock washers maintain tightness under heavy vibration and constant movement. Available in corrosion-resistant stainless steel. Types include: 1. External Tooth Lock Washers – feature sharp teeth for maximum holding power. 2. Internal Tooth Lock Washers – have teeth on the inside edge, preventing …

3. Reddit – Lock Washers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Lock Washers are fasteners that are used to prevent loosening of bolts and nuts in various applications. However, there is a debate about their effectiveness, with some users claiming they can make things worse in certain situations. Some users report having used lock washers for decades without failure, while others reference the NASA Fastener Design Manual, which suggests that once fully torqued…

4. McMaster – Lock Washers

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Lock Washers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Fastener Solutions – Washer Applications

Domain: engineering.stackexchange.com

Registered: 2009 (16 years)

Introduction: The discussion revolves around the use of a regular washer alongside a split lock washer in fastener applications. Key points include: 1. A regular washer can help distribute clamping forces and protect underlying materials. 2. Concerns exist that adding extra components may increase the risk of loosening. 3. Standard practice often includes using both types of washers, but effectiveness varies, e…

6. Nutty Company – Hi-Collar Split Lock Washers

Domain: nutty.com

Registered: 1996 (29 years)

Introduction: Hi-Collar Split Lock Washers from The Nutty Company, Inc. Free shipping on orders over $100. Available for purchase online. Customer service available Monday – Friday from 8:00 a.m. to 4:00 p.m. EST. Part of a larger product range including various types of nuts, washers, bolts, screws, and fasteners.

Strategic Sourcing Conclusion and Outlook for bolt with lock washer

In today’s competitive landscape, strategic sourcing of bolts with lock washers is crucial for ensuring product reliability and operational efficiency. By prioritizing high-quality materials such as stainless steel or galvanized options, businesses can mitigate risks associated with fastener failure, particularly in demanding environments prone to vibration. Understanding the specific applications for different types of lock washers—such as split, internal tooth, and external tooth—enables buyers to make informed decisions tailored to their operational needs.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, fostering strong supplier relationships is essential. It not only guarantees access to premium products but also enhances supply chain resilience. As industries continue to evolve, staying abreast of innovations and market trends will empower buyers to leverage strategic sourcing as a key driver of competitive advantage.

Looking ahead, businesses should consider engaging with suppliers who offer comprehensive solutions and support. By investing in quality fasteners and robust sourcing strategies, companies can secure their operations and position themselves for sustainable growth in the global marketplace. Embrace the opportunity to enhance your procurement strategy today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to bolt with lock washer