A B2B Buyer’s Guide to Bolt Square: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for bolt square

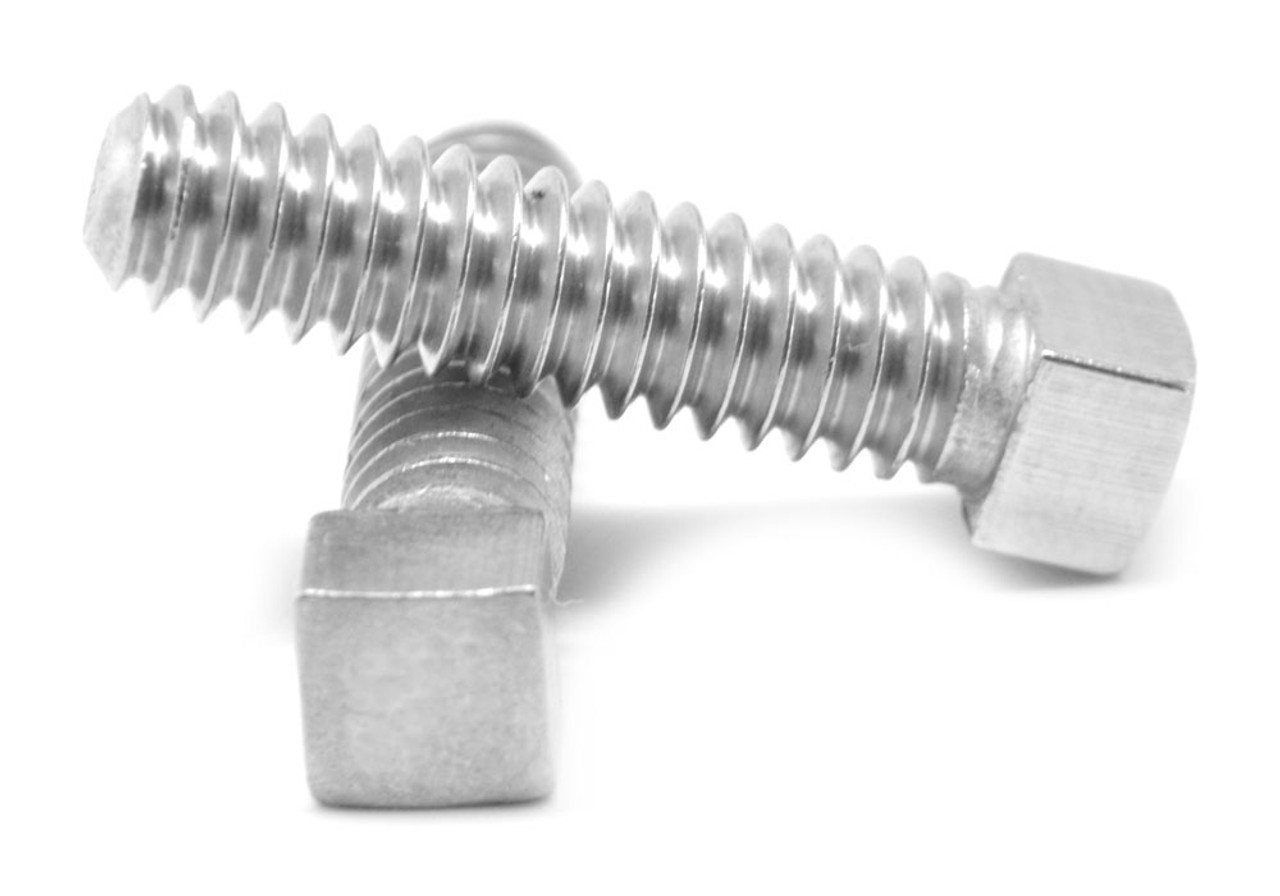

Navigating the intricate landscape of the global market for square head bolts presents a significant challenge for B2B buyers, particularly those seeking reliable suppliers and high-quality products across diverse regions such as Africa, South America, the Middle East, and Europe. As businesses increasingly prioritize efficiency and cost-effectiveness, the need for actionable insights into sourcing square head bolts becomes paramount. This comprehensive guide serves as a vital resource, exploring various types of square head bolts, their applications in industries ranging from construction to manufacturing, and strategies for vetting suppliers effectively.

In addition to detailing the specifications and characteristics of square head bolts, including material options and finishes, this guide will provide critical information on pricing structures, volume discounts, and best practices for international shipping. By equipping buyers with the knowledge to make informed purchasing decisions, this resource aims to bridge the gap between product needs and supplier capabilities, ensuring that businesses can confidently navigate their procurement processes. Whether you are in Vietnam, Germany, or any point in between, understanding the nuances of square head bolts and the global market landscape will empower your business to secure the most suitable and cost-effective solutions for your operational requirements.

Understanding bolt square Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Square Head Lag Bolts | Designed for heavy-duty applications, often partially threaded. | Timber framing, construction, restoration | Pros: High strength; suitable for outdoor use. Cons: Limited thread length may require custom orders. |

| Plain Square-Head Bolts | Simple design, often without finish, ideal for rustic aesthetics. | Vintage restorations, architectural projects | Pros: Cost-effective; versatile in applications. Cons: May require additional corrosion protection. |

| Fully Threaded Square Bolts | Entirely threaded for maximum grip, enhancing fastening security. | Machinery, equipment assembly | Pros: Strong grip; suitable for various materials. Cons: May not be necessary for all applications. |

| Decorative Square Head Bolts | Available in unique styles (hammered, pyramid) for aesthetic appeal. | Furniture, artistic installations | Pros: Enhances visual appeal; available in various finishes. Cons: Higher cost compared to standard bolts. |

| Hot-Dip Galvanized Square Bolts | Coated for superior corrosion resistance, suitable for outdoor use. | Marine, agricultural equipment | Pros: Long-lasting; excellent for harsh environments. Cons: Heavier than untreated options, affecting transport. |

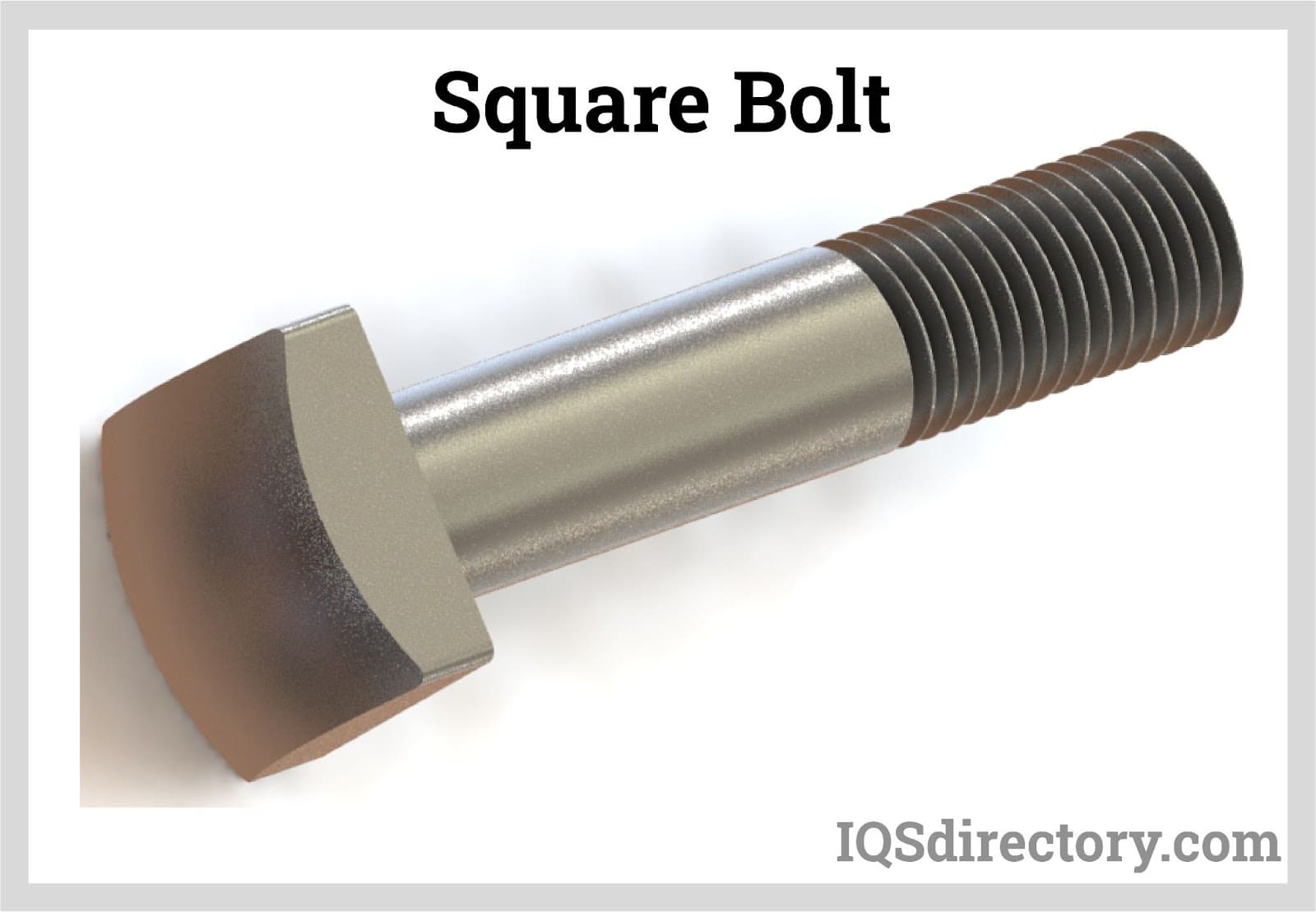

What Are Square Head Lag Bolts and Their Applications?

Square head lag bolts are specifically designed for heavy-duty applications, making them ideal for timber framing and construction projects. Their partially threaded design allows for a strong grip and effective load-bearing capabilities. When sourcing these bolts, buyers should consider the required length and diameter, as well as any specific environmental factors that may affect performance, such as exposure to moisture or chemicals.

How Do Plain Square-Head Bolts Differ from Other Variants?

Plain square-head bolts feature a straightforward design, often without any protective finish, which makes them suitable for vintage restoration projects and architectural applications. Their cost-effectiveness and versatility make them appealing to B2B buyers, but it is essential to consider the need for additional corrosion protection, especially in outdoor settings. Buyers should evaluate the aesthetic requirements of their projects when choosing this type.

Why Choose Fully Threaded Square Bolts?

Fully threaded square bolts provide maximum grip and fastening security, making them a preferred choice for machinery and equipment assembly. These bolts ensure that the fastening is secure, minimizing the risk of slippage during operation. Buyers should assess whether the application requires the added security of fully threaded bolts versus partially threaded options, which may suffice in less demanding environments.

What Are Decorative Square Head Bolts Used For?

Decorative square head bolts are available in various styles, including hammered and pyramid designs, which cater to aesthetic requirements in furniture and artistic installations. While they enhance the visual appeal of projects, these bolts typically come at a higher price point than standard options. Buyers should weigh the importance of aesthetics against functionality when considering these bolts for their projects.

How Do Hot-Dip Galvanized Square Bolts Perform in Harsh Environments?

Hot-dip galvanized square bolts are coated to provide superior corrosion resistance, making them suitable for use in marine and agricultural equipment applications. Their durability ensures a longer lifespan, even in harsh environmental conditions. Buyers should consider the weight of these bolts, as the added coating can increase transport costs, but the benefits of longevity often outweigh the downsides in demanding applications.

Key Industrial Applications of bolt square

| Industry/Sector | Specific Application of bolt square | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Timber framing and structural support | Provides strong, reliable connections in structural applications, ensuring safety and durability. | Ensure compliance with local building codes and material standards. |

| Manufacturing | Heavy machinery assembly | Enhances assembly efficiency and product longevity by providing secure fastening solutions. | Assess load requirements and choose appropriate material grades. |

| Restoration & Renovation | Historical building renovations | Maintains aesthetic integrity while providing robust structural support for vintage projects. | Source authentic styles and finishes that match historical specifications. |

| Agriculture & Farming | Equipment assembly and repair | Increases equipment reliability and reduces maintenance costs by securing critical components. | Evaluate corrosion resistance for outdoor use and choose appropriate finishes. |

| Marine & Offshore | Shipbuilding and repair | Ensures high-strength connections that withstand harsh marine environments, enhancing vessel safety. | Consider sourcing materials with exceptional corrosion resistance for longevity. |

How is ‘bolt square’ Used in the Construction Industry?

In the construction sector, square head bolts are primarily employed in timber framing and structural support applications. Their design allows for a secure grip, facilitating installation in tight spaces. These bolts provide reliable connections that meet stringent safety standards, which is critical in construction projects. For international buyers, particularly in regions like Africa and South America, it is essential to ensure that the bolts comply with local building codes and material standards, which may vary significantly.

What Role Does ‘bolt square’ Play in Manufacturing?

In manufacturing, square head bolts are integral to the assembly of heavy machinery. Their robust design allows them to withstand high levels of stress and wear, ensuring longevity and operational efficiency. By using square head bolts, manufacturers can streamline assembly processes and reduce the likelihood of equipment failure. Buyers should assess load requirements and select the appropriate material grades to meet specific operational demands, particularly in regions with diverse industrial regulations.

Why Are ‘bolt square’ Important for Restoration and Renovation?

Square head bolts are commonly utilized in historical building renovations, where maintaining aesthetic integrity is as crucial as structural reliability. These bolts offer an old-world charm that aligns with vintage architectural styles, making them ideal for restoration projects. For B2B buyers in Europe and the Middle East, sourcing authentic styles and finishes that adhere to historical specifications is vital. This ensures that the restoration not only meets modern safety standards but also preserves the original character of the building.

How Do ‘bolt square’ Enhance Agricultural Equipment?

In agriculture, square head bolts are essential for assembling and repairing farming equipment. Their durability and strength ensure that critical components remain securely fastened, reducing the risk of equipment failure during operations. This reliability translates into lower maintenance costs and increased productivity on farms. Buyers should consider the corrosion resistance of the bolts, especially in regions with harsh weather conditions, to ensure optimal performance and longevity.

What Are the Benefits of ‘bolt square’ in Marine Applications?

In the marine and offshore industries, square head bolts play a crucial role in shipbuilding and repair. They provide high-strength connections that are essential for maintaining the integrity and safety of vessels operating in harsh marine environments. For international buyers, particularly those in Europe and the Middle East, sourcing materials with exceptional corrosion resistance is critical to ensure the longevity of marine applications. Ensuring compliance with maritime regulations and standards is also necessary for successful sourcing.

3 Common User Pain Points for ‘bolt square’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Square Head Bolts for Specialized Projects

The Problem: B2B buyers often encounter challenges when trying to find square head bolts that meet specific project requirements. This can be particularly frustrating for industries focused on restoration, vintage construction, or unique architectural designs where standard sizes and styles do not suffice. The lack of availability in desired materials, finishes, or sizes can lead to project delays and increased costs, as buyers may have to compromise on quality or aesthetics.

The Solution: To effectively source square head bolts tailored to specialized needs, B2B buyers should establish relationships with multiple suppliers that offer customizable options. Look for manufacturers or distributors that provide a broad range of sizes, materials (like ASTM A307 Grade A steel), and finishes (such as hot-dip galvanization or black oxide). Furthermore, buyers can benefit from engaging in direct communication with suppliers to inquire about custom orders or bulk purchasing options. This proactive approach not only ensures that the right components are procured but can also yield cost savings through volume discounts, enhancing overall project efficiency.

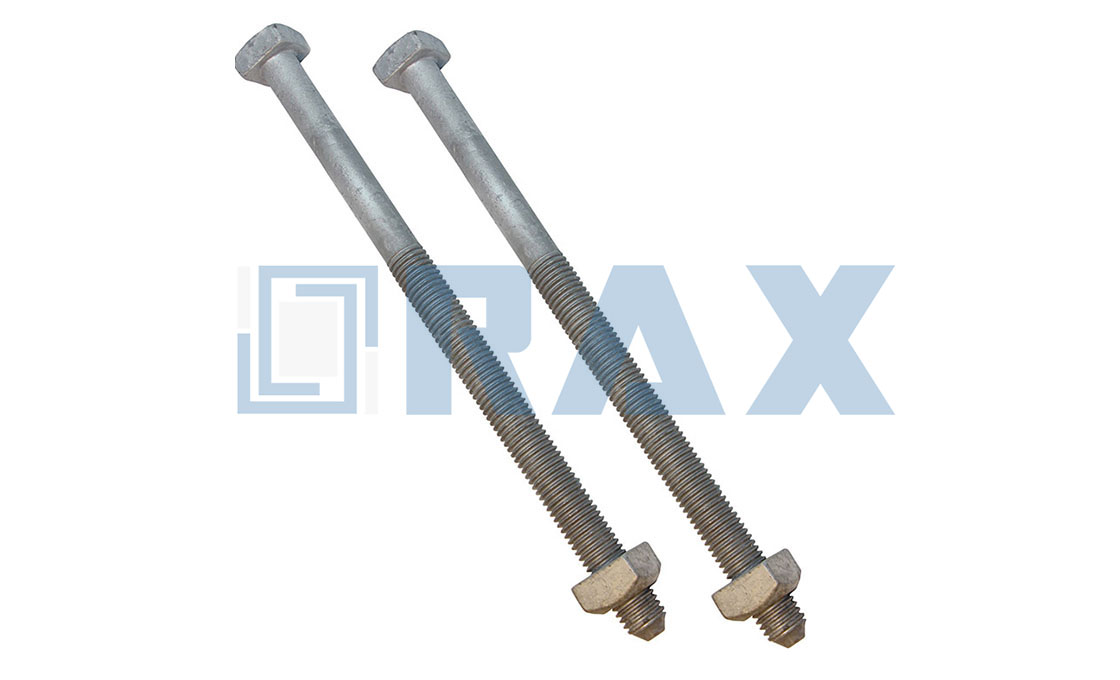

Illustrative image related to bolt square

Scenario 2: Ensuring Corrosion Resistance for Outdoor Applications

The Problem: When using square head bolts in outdoor settings, such as in construction or agricultural equipment, buyers often face the risk of corrosion. Exposure to elements like moisture, salt, and varying temperatures can significantly degrade the integrity of the bolts, leading to safety hazards and increased maintenance costs. Many buyers may not be aware of the best practices for selecting bolts that can withstand these conditions, leading to premature failure.

The Solution: To mitigate corrosion risks, B2B buyers should prioritize square head bolts that come with robust protective coatings, such as hot-dip galvanization or specialized black chromate finishes. These coatings provide an additional layer of defense against environmental factors. It’s advisable to consult with suppliers about the specific environmental conditions the bolts will face and request technical data on the corrosion resistance of the products. Additionally, implementing a regular maintenance schedule that includes inspections and touch-ups of the protective finishes can prolong the life of the bolts and ensure safety in outdoor applications.

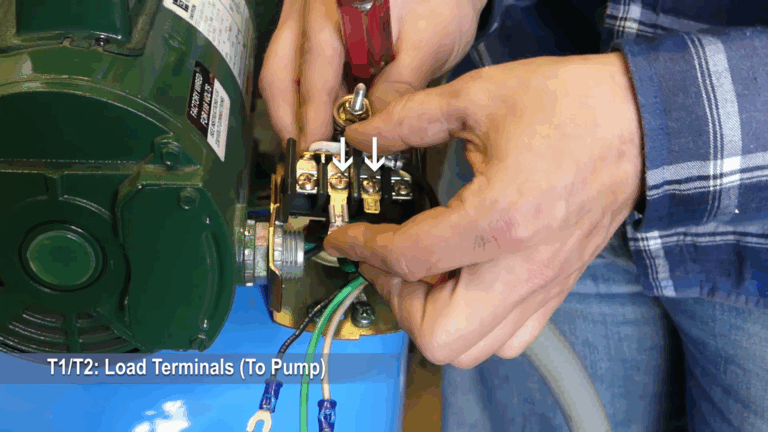

Scenario 3: Challenges with Installation in Confined Spaces

The Problem: Installation of square head bolts in tight or awkward spaces can pose significant difficulties, particularly in heavy-duty applications or when equipment does not allow for easy access. This can result in time-consuming adjustments, potential damage to surrounding components, and increased labor costs. Buyers may find themselves frustrated with the inefficiencies caused by using fasteners that do not accommodate their specific installation scenarios.

The Solution: To address installation challenges, it’s crucial for B2B buyers to select square head bolts that are designed for ease of use in confined spaces. Bolts with a partially threaded design can provide the necessary grip while minimizing the risk of snapping during installation. Additionally, investing in the right tools—such as socket wrenches or square drive bits—can enhance the installation process. Buyers should also consider pre-assembly or employing techniques such as using extension bars to reach difficult areas. Collaborating with suppliers who understand these installation challenges can lead to tailored recommendations that improve efficiency and reduce installation-related costs.

Strategic Material Selection Guide for bolt square

What Are the Common Materials Used for Square Head Bolts?

When selecting square head bolts for international B2B applications, understanding the material properties is crucial for ensuring optimal performance and compatibility with specific environments. Here, we analyze four common materials used in the manufacturing of square head bolts: carbon steel, stainless steel, alloy steel, and brass.

Illustrative image related to bolt square

How Does Carbon Steel Perform in Square Head Bolts?

Key Properties: Carbon steel square head bolts are known for their high tensile strength and toughness. They typically have a temperature rating up to 300°F (150°C) and can withstand significant mechanical stress.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and availability, making it a popular choice for general applications. However, it has limited corrosion resistance unless treated with coatings like zinc plating. This treatment can add to the manufacturing complexity and cost.

Impact on Application: Carbon steel bolts are suitable for indoor applications and environments where exposure to moisture is minimal. However, they may not be ideal for outdoor use without appropriate protective coatings.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM A307. Additionally, understanding the local climate’s impact on corrosion resistance is essential for selecting the right treatment.

What Are the Advantages of Stainless Steel for Square Head Bolts?

Key Properties: Stainless steel square head bolts exhibit excellent corrosion resistance due to their chromium content, which forms a passive layer on the surface. They can withstand temperatures up to 1500°F (815°C), making them suitable for high-heat applications.

Pros & Cons: The primary advantage is their durability and resistance to rust and corrosion, making them ideal for outdoor and marine applications. However, stainless steel bolts are generally more expensive than carbon steel, which may impact budget considerations for large projects.

Impact on Application: These bolts are particularly well-suited for environments exposed to harsh chemicals or saline conditions. Their longevity reduces the need for frequent replacements, making them a cost-effective option in the long run.

Considerations for International Buyers: Compliance with standards such as ASTM A193 or DIN 931 is crucial for ensuring quality. Buyers in Europe, particularly Germany, may prefer stainless steel due to stringent regulations on corrosion resistance.

How Do Alloy Steel Bolts Compare?

Key Properties: Alloy steel square head bolts are engineered for enhanced strength and hardness, often rated for high-stress applications. They can handle temperatures up to 600°F (315°C) and are often used in heavy machinery and automotive applications.

Pros & Cons: The key advantage is their superior strength-to-weight ratio, making them suitable for demanding applications. However, they can be more expensive than carbon steel and may require specialized manufacturing processes.

Impact on Application: Alloy steel bolts are ideal for high-pressure environments, such as in oil and gas industries. Their enhanced properties ensure reliability in critical applications.

Considerations for International Buyers: Buyers should check for compliance with standards like ASTM A574 or JIS B 1180, particularly in regions with stringent industrial regulations, such as the Middle East.

What Role Does Brass Play in Square Head Bolts?

Key Properties: Brass square head bolts are characterized by their excellent corrosion resistance and aesthetic appeal. They are suitable for applications where electrical conductivity is required, and they can withstand temperatures up to 400°F (204°C).

Pros & Cons: The primary advantage of brass is its resistance to corrosion and tarnishing, making it ideal for decorative applications. However, brass is softer than steel, which limits its use in high-stress environments.

Impact on Application: These bolts are commonly used in plumbing and electrical applications, where corrosion resistance is critical. Their aesthetic appeal also makes them suitable for visible installations.

Illustrative image related to bolt square

Considerations for International Buyers: Compliance with local standards, such as ASTM B16 or DIN 17660, is essential for ensuring quality. Buyers in Europe may prefer brass for its aesthetic qualities in architectural applications.

Summary Table of Material Selection for Square Head Bolts

| Material | Typical Use Case for bolt square | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General construction applications | Cost-effective and widely available | Limited corrosion resistance | Low |

| Stainless Steel | Marine and chemical environments | Excellent corrosion resistance | Higher cost compared to carbon steel | High |

| Alloy Steel | Heavy machinery and automotive | Superior strength and hardness | More expensive and complex to manufacture | Med |

| Brass | Plumbing and decorative fixtures | Corrosion resistant and aesthetically pleasing | Softer material limits high-stress use | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, assisting them in making informed decisions tailored to their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for bolt square

What Are the Key Stages in the Manufacturing Process of Square Head Bolts?

The manufacturing process of square head bolts is a systematic approach that ensures high-quality output suitable for various applications. The process generally consists of four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation

The manufacturing journey begins with the selection of high-quality steel or alloy materials, which are critical for the performance and durability of the finished product. Common materials include carbon steel, stainless steel, and alloy steel, chosen based on the desired strength and corrosion resistance. The raw materials undergo cutting to specific lengths, followed by heat treatment processes to enhance their mechanical properties. -

Forming

The forming stage involves several techniques, including forging and machining. In forging, the steel is heated and shaped under high pressure to create the bolt’s head and shank. This method increases the material’s density and strength. For bolts that require intricate designs or precise dimensions, machining processes like turning and milling are employed. These processes ensure that the bolts meet exact specifications, such as thread dimensions and head shape. -

Assembly

After forming, the components are assembled. This stage may involve threading the bolts, which is often done using automated machines to maintain consistency and accuracy. For square head bolts, the threading can be either partial or full, depending on the intended application. The assembly process may also include the installation of washers or nuts, especially for applications requiring additional fastening security. -

Finishing

The final stage is finishing, which enhances the aesthetic appeal and protects the bolts from environmental factors. Various finishing techniques are applied, including galvanization, powder coating, or black oxide treatments. Galvanization, for instance, provides excellent corrosion resistance, making the bolts suitable for outdoor applications. The choice of finish will depend on the end-use requirements and customer specifications.

How Is Quality Assurance Implemented in Square Head Bolt Manufacturing?

Quality assurance (QA) is critical in the manufacturing of square head bolts to ensure they meet international standards and customer specifications. The QA process typically adheres to several recognized standards, such as ISO 9001 and industry-specific certifications like CE and API.

-

International Standards and Certifications

ISO 9001 is a widely recognized standard for quality management systems, focusing on continuous improvement and customer satisfaction. Compliance with such standards assures B2B buyers that the manufacturing processes are systematic and reliable. Additionally, certifications like CE indicate compliance with European safety standards, which can be crucial for buyers in the European market. -

Quality Control Checkpoints

The QA process is integrated into the production stages through various checkpoints, including:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the quality of the forming and assembly processes. This includes checking dimensions, tolerances, and thread quality.

- Final Quality Control (FQC): After finishing, the final products undergo thorough testing and inspection to ensure they meet all specifications and standards before shipment.

- Common Testing Methods for Square Head Bolts

Various testing methods are employed to ensure the integrity and performance of square head bolts. These may include:

- Tensile Testing: Measures the strength and ductility of the bolt material.

- Hardness Testing: Assesses the hardness of the finished product, which correlates with wear resistance.

- Corrosion Testing: Evaluates the effectiveness of protective coatings against environmental factors.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential for ensuring product reliability.

Illustrative image related to bolt square

-

Supplier Audits

Conducting on-site audits can provide valuable insights into the supplier’s manufacturing processes and quality control measures. Buyers should assess the supplier’s adherence to international standards, the state of their equipment, and their quality management practices. -

Quality Control Reports

Requesting detailed quality control reports from suppliers can help buyers evaluate the consistency of product quality over time. These reports typically include data from IQC, IPQC, and FQC stages, detailing any defects or non-conformities identified during production. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes. These inspections often include verification of compliance with industry standards and testing of sample products to ensure they meet specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control is vital for B2B buyers operating in different regions. Each market may have specific regulations and expectations regarding product quality, which can influence purchasing decisions.

-

Regional Standards Compliance

Buyers should be aware of local standards and regulations that may apply to square head bolts in their region. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may focus on API standards for applications in oil and gas sectors. -

Cultural Differences in Quality Expectations

Cultural perceptions of quality may vary between regions. For instance, buyers from Europe might expect stricter compliance with quality standards compared to those from emerging markets. Understanding these differences can help suppliers tailor their offerings to meet the expectations of diverse buyers. -

Logistics and Supply Chain Considerations

Quality assurance does not end at manufacturing; it extends to logistics and supply chain management. Buyers should ensure that suppliers have robust processes for handling, packaging, and transporting square head bolts to prevent damage or deterioration during transit.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for square head bolts is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions that align with their quality standards and operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bolt square’

To assist B2B buyers in sourcing square head bolts effectively, this guide provides a structured checklist to streamline the procurement process. Following these steps will ensure that you select the right products and suppliers, maximizing value and minimizing risks.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the square head bolts meet your project requirements. Consider factors such as material grade (e.g., ASTM A307), dimensions (diameter and length), and thread type. This clarity will help you communicate effectively with suppliers and avoid costly mistakes.

Illustrative image related to bolt square

- Material considerations: Determine whether you need steel, stainless steel, or a specific finish (e.g., hot-dipped galvanized for corrosion resistance).

- Thread requirements: Decide between fully or partially threaded options based on your application needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for manufacturers or distributors that specialize in fasteners and have a proven track record in your target markets, such as Africa, South America, the Middle East, or Europe.

- Supplier reputation: Check online reviews, testimonials, and case studies to gauge supplier reliability.

- Product range: Ensure the supplier offers a variety of square head bolts to meet your specifications.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, confirm their certifications and compliance with industry standards. This step is vital for ensuring product quality and safety.

- Quality certifications: Look for ISO certifications or other relevant industry standards that indicate a commitment to quality control.

- Material certifications: Ensure that the materials used meet the necessary specifications for your application, particularly if they will be exposed to harsh environments.

Step 4: Request Samples and Conduct Testing

Once you’ve narrowed down potential suppliers, request samples of the square head bolts. Testing the samples helps verify that they meet your technical specifications and quality expectations.

- Physical inspection: Check for defects, finish quality, and overall workmanship.

- Performance testing: If applicable, conduct stress tests to ensure they can withstand your project demands.

Step 5: Discuss Pricing and Terms

Engage in discussions about pricing, order quantities, and payment terms. Understanding the total cost of procurement, including shipping and potential discounts for bulk orders, is essential for budgeting.

- Volume discounts: Inquire about pricing breaks for larger orders, which can significantly reduce costs.

- Payment terms: Negotiate favorable payment terms that align with your cash flow and project timelines.

Step 6: Confirm Shipping and Delivery Options

Ensure that the supplier can meet your delivery requirements. This includes understanding their shipping methods, lead times, and any logistics considerations relevant to your location.

- Shipping methods: Confirm whether the supplier offers expedited shipping options if needed.

- Tracking and support: Ensure that you receive tracking information and support during the shipping process to manage expectations effectively.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your chosen supplier. This plan should outline key contacts, reporting structures, and how to address any issues that may arise during the procurement process.

- Regular updates: Schedule periodic check-ins to discuss order status and any potential concerns.

- Issue resolution: Establish a clear protocol for resolving discrepancies or quality issues to maintain a strong working relationship.

By following these steps, B2B buyers can confidently source square head bolts that meet their specifications while fostering strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for bolt square Sourcing

What Are the Key Cost Components in Sourcing Square Head Bolts?

Understanding the cost structure of square head bolts is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The type of steel and finish (e.g., hot-dipped galvanized, black oxide) significantly influence the material cost. High-grade materials tend to be more expensive but offer better corrosion resistance and longevity.

-

Labor: Labor costs vary by region and can be influenced by the complexity of the manufacturing process. Regions with higher wage standards may see increased costs, while countries with lower labor costs may offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and general factory operations. Efficient production processes can help minimize these overheads.

-

Tooling: The initial investment in tooling for specific bolt designs can be substantial. Custom tooling increases costs but is necessary for specialized applications.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the bolts meet specified standards and certifications, which can add to the overall cost. However, investing in QC can reduce the total cost of ownership by minimizing returns and replacements.

-

Logistics: Transportation costs depend on the distance from the manufacturer to the buyer, shipping method, and handling. Incoterms play a critical role in determining who bears these costs.

-

Margin: Suppliers typically add a margin to their costs to ensure profitability. This margin can vary based on market competition and the supplier’s positioning strategy.

How Do Price Influencers Affect the Cost of Square Head Bolts?

Several factors can influence the pricing of square head bolts:

-

Volume/MOQ: Buying in bulk often leads to significant discounts. Suppliers may offer tiered pricing where larger orders result in lower per-unit costs.

-

Specifications and Customization: Custom specifications such as thread length, finishes, and head styles can increase costs. Standardized products are generally more cost-effective.

-

Materials: The choice of raw materials directly affects pricing. Higher-quality materials may have a higher upfront cost but can result in lower maintenance and replacement costs over time.

-

Quality and Certifications: Products that meet specific industry standards or certifications may command a higher price. However, these investments in quality can enhance reliability and performance.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can impact costs. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: Understanding the chosen Incoterms is essential. They dictate responsibilities for shipping, insurance, and tariffs, affecting the overall cost.

What Buyer Tips Can Help in Negotiating Costs for Square Head Bolts?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Prices: Engage suppliers in discussions about pricing, especially for larger orders. Leverage potential future orders as a bargaining chip.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and potential downtime costs. Selecting higher-quality products may lead to long-term savings.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures. Understanding local market conditions and supplier dynamics can provide negotiation leverage.

-

Clarify Payment Terms: Discuss payment options that may provide cash flow benefits, such as deferred payments or discounts for early payment.

-

Research Multiple Suppliers: Don’t settle for the first quote. Comparing offers can reveal market standards and help identify the best deal.

By understanding these cost components, price influencers, and negotiation tips, B2B buyers can make informed decisions that enhance their sourcing strategies for square head bolts. Always remember that indicative prices can fluctuate based on market conditions, so continual market research and supplier engagement are essential.

Illustrative image related to bolt square

Alternatives Analysis: Comparing bolt square With Other Solutions

Exploring Alternatives to Bolt Square: A Comparative Analysis

In the realm of fasteners, selecting the right solution is crucial for efficiency and durability in various applications. While bolt square is a favored choice for its robust design and ease of use, there are alternative fastening solutions available. This section delves into a comparison between bolt square and two other popular fasteners: hex bolts and lag bolts. By examining their performance, cost, ease of implementation, maintenance requirements, and best use cases, B2B buyers can make informed decisions tailored to their specific needs.

| Comparison Aspect | Bolt Square | Hex Bolts | Lag Bolts |

|---|---|---|---|

| Performance | High gripping surface; ideal for heavy-duty applications. | Versatile; suitable for various applications, strong grip. | Excellent for wood; provides strong anchoring. |

| Cost | Moderately priced; bulk discounts available. | Generally lower cost; widely available. | Higher cost due to size and material. |

| Ease of Implementation | Easy to install with minimal tools; square head prevents slippage. | Requires standard tools; may slip in tight spaces. | Requires pre-drilling; installation can be challenging. |

| Maintenance | Minimal; can be treated for corrosion resistance. | Low maintenance; typically rust-resistant. | Moderate; may require regular checks for integrity. |

| Best Use Case | Restoration, timber framing, and applications with limited access. | General construction, automotive, and machinery. | Wood structures, heavy timber framing, and outdoor applications. |

An In-Depth Look at Alternatives

Hex Bolts: A Versatile Choice

Hex bolts are perhaps the most common fasteners used across various industries. Their hexagonal heads allow for a secure grip with standard wrenches, making them suitable for a wide range of applications. The primary advantage of hex bolts is their cost-effectiveness; they are generally less expensive than square bolts. However, they may not perform as well in tight or awkward spaces where tool access is limited. While hex bolts are reliable, they may require additional care in environments prone to rust unless treated with protective coatings.

Lag Bolts: The Heavy-Duty Option

Lag bolts, also known as lag screws, are designed for heavy-duty applications, particularly in wood construction. Their large, coarse threads provide superior holding power, making them ideal for securing beams and heavy timber. However, they typically require pre-drilling, which can complicate installation, especially in tighter spaces. Lag bolts are generally more expensive due to their size and strength, but their durability makes them a worthwhile investment for long-term projects. Regular maintenance is essential to ensure they remain secure over time, particularly in outdoor settings.

Making the Right Choice for Your B2B Needs

When choosing between bolt square and its alternatives, B2B buyers should consider specific project requirements, such as the materials involved, the environment, and the level of accessibility. Bolt square offers unique advantages in tight spaces and aesthetic applications, while hex bolts provide cost-effective versatility for general use. Lag bolts, although more challenging to install, excel in heavy-duty wood applications.

Ultimately, understanding the strengths and limitations of each option will empower buyers to select the most appropriate fastener for their projects, ensuring both performance and cost-efficiency.

Illustrative image related to bolt square

Essential Technical Properties and Trade Terminology for bolt square

What Are the Key Technical Properties of Square Head Bolts?

When sourcing square head bolts, understanding their technical properties is crucial for ensuring that they meet specific application requirements. Here are some essential specifications to consider:

1. Material Grade

Square head bolts are typically made from various grades of steel, with common options including ASTM A307, which is a standard specification for carbon steel bolts. Higher-grade materials, such as ASTM A325, offer enhanced strength and corrosion resistance. Selecting the appropriate material grade is vital for ensuring that the bolts can withstand the mechanical stresses they will encounter in your application, particularly in heavy-duty environments.

2. Thread Type and Length

Threading can be either coarse or fine, impacting the bolt’s grip and suitability for different materials. Coarse threads are better for quick assembly and disassembly, while fine threads provide greater tensile strength. Additionally, thread length is critical; it should meet or exceed the material thickness being fastened. For instance, a standard rule is that the minimum thread length should be at least half the nominal screw length plus an additional half inch.

3. Finish and Coating

The finish on square head bolts serves both aesthetic and functional purposes. Common finishes include hot-dipped galvanizing for corrosion resistance and black oxide for a sleek appearance. The choice of finish can significantly affect the bolt’s longevity and performance in various environments, making it essential to match the finish with the application’s exposure to moisture and chemicals.

4. Diameter and Length Specifications

Square head bolts come in a range of diameters and lengths, typically from #10 to 3/4 inch in diameter and lengths from 3/4 inch to 12 inches. The size must align with the specifications of the project to ensure proper fit and load distribution. Incorrect sizes can lead to structural failure or increased maintenance costs.

5. Tolerance Levels

Manufacturers often specify tolerances for dimensions and thread pitches. These tolerances ensure that the bolts fit correctly with corresponding nuts and assemblies. Understanding the tolerance levels can help buyers avoid issues during installation and ensure optimal performance.

What Are Common Trade Terms Related to Square Head Bolts?

Familiarity with industry jargon can enhance communication and decision-making when sourcing square head bolts. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of square head bolts, buyers may work directly with OEMs for custom specifications or bulk orders, ensuring quality and compatibility with existing equipment.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and cost efficiency. For square head bolts, suppliers may offer discounts for larger MOQs, making it economically advantageous to purchase in bulk.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers. When sourcing square head bolts, submitting an RFQ can help businesses compare prices and terms from multiple vendors, ensuring the best deal for their specific requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers, especially when importing square head bolts from different countries, as they dictate who bears the costs and risks during shipping.

5. Lead Time

Lead time refers to the period between placing an order and receiving the products. For square head bolts, lead times can vary significantly based on the manufacturer’s location, production capacity, and whether the order is standard or custom. Knowing the lead time helps businesses plan their projects and manage inventory effectively.

Understanding these properties and terms can empower B2B buyers to make informed decisions when purchasing square head bolts, ultimately leading to successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the bolt square Sector

What Are the Current Market Dynamics and Key Trends in the Bolt Square Sector?

The global bolt square market is witnessing significant transformation driven by various factors, including industrial growth, infrastructure development, and technological advancements. As industries across Africa, South America, the Middle East, and Europe ramp up their manufacturing capabilities, the demand for reliable and durable fastening solutions like square head bolts is on the rise. Notably, countries such as Vietnam and Germany are leading the charge, leveraging their robust manufacturing sectors to meet both domestic and international needs.

Emerging B2B tech trends are reshaping sourcing practices, with the integration of digital platforms for procurement and inventory management becoming commonplace. Buyers are increasingly turning to e-commerce platforms that offer comprehensive catalogs, real-time inventory updates, and competitive pricing. This shift towards digitalization not only streamlines the purchasing process but also enhances transparency, allowing buyers to make informed decisions based on product specifications, availability, and supplier reliability.

Moreover, sustainability is becoming a central theme in sourcing strategies. B2B buyers are more inclined to partner with manufacturers who prioritize eco-friendly practices, including the use of recycled materials and sustainable production methods. This trend is particularly pertinent for international buyers who are navigating diverse regulatory environments and consumer expectations regarding sustainability.

How Important Is Sustainability and Ethical Sourcing for B2B Buyers in the Bolt Square Sector?

The environmental impact of production processes in the bolt square sector cannot be overstated. The extraction and processing of raw materials, such as steel, contribute significantly to carbon emissions and ecological degradation. As a result, the importance of ethical supply chains has become paramount. B2B buyers are increasingly scrutinizing their suppliers to ensure they adhere to ethical labor practices and environmental regulations.

Buyers are also seeking products that carry ‘green’ certifications, such as ISO 14001, which indicates a commitment to environmental management. Utilizing materials that are sustainably sourced or recycled is not just a compliance measure; it also enhances brand reputation and can lead to competitive advantages in the marketplace. For instance, square head bolts that are hot-dipped galvanized or treated with eco-friendly coatings not only offer durability but also align with sustainability goals.

Furthermore, the demand for transparency in the supply chain has led to the emergence of digital tools that track the lifecycle of products, ensuring that buyers can verify the ethical sourcing of materials. This trend is particularly relevant for international buyers who must navigate varying regulations and expectations in different regions.

Illustrative image related to bolt square

What Is the Brief Evolution and History of Square Head Bolts in the B2B Market?

Square head bolts have a rich history, dating back to the early days of industrialization. Originally designed for use in applications requiring robust fastening solutions, these bolts quickly became popular due to their practicality and ease of installation. Their design allows for a strong grip, making them ideal for challenging environments where access is limited.

Over the years, square head bolts have evolved in terms of materials and finishes. Initially made from iron, modern square head bolts are predominantly manufactured from high-strength steel, often treated for corrosion resistance. This evolution has made them suitable for a wider range of applications, from heavy-duty construction to aesthetic restorations in historical architecture.

As global markets continue to expand, square head bolts remain a staple in the toolkit of manufacturers and builders alike, combining durability, versatility, and a nod to traditional craftsmanship.

Frequently Asked Questions (FAQs) for B2B Buyers of bolt square

-

How do I choose the right square head bolt for my project?

When selecting a square head bolt, consider factors like material, size, thread type, and finish. For heavy-duty applications, opt for durable materials such as ASTM A307 Grade A steel or hot-dipped galvanized options to ensure corrosion resistance. Additionally, match the bolt diameter and length to your specific requirements, keeping in mind the threading type needed for your project. It’s also wise to consult with your supplier regarding the best practices for installation and maintenance to prolong the life of the fastener. -

What is the best finish for square head bolts used outdoors?

For outdoor applications, the best finish for square head bolts is typically hot-dip galvanization or black oxide. Hot-dip galvanized bolts provide superior corrosion resistance, making them ideal for environments exposed to moisture. Black oxide offers a sleek appearance with some level of rust protection, but may require periodic maintenance. Always verify that the chosen finish aligns with the environmental conditions and specific use cases of your project to ensure longevity. -

How can I verify the quality of square head bolts from a supplier?

To ensure quality, request certifications such as ISO 9001 or ASTM standards from your supplier. Ask for product samples to inspect the material and finish before placing a large order. Additionally, inquire about their manufacturing process and quality control measures. Engaging in direct communication with the supplier can also provide insights into their reliability and commitment to quality, which is crucial for international transactions. -

What are the typical minimum order quantities (MOQ) for square head bolts?

Minimum order quantities for square head bolts can vary significantly between suppliers, typically ranging from 100 to 1,000 units. Some suppliers may offer lower MOQs for specific product lines or during promotional periods. It’s essential to clarify the MOQ during negotiations to ensure it aligns with your project needs and budget. Bulk purchasing can often lead to discounts, so consider your long-term requirements when placing orders. -

What payment terms should I expect when sourcing square head bolts internationally?

Payment terms can vary based on the supplier and your negotiation. Common options include advance payment, letters of credit, or payment upon delivery. Some suppliers may offer net 30 or net 60 terms, especially for established business relationships. Always discuss payment options upfront and ensure that the terms are documented in your purchase agreement to avoid any misunderstandings later in the transaction process. -

What logistics considerations should I keep in mind when importing square head bolts?

When importing square head bolts, factor in shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with your target market to facilitate smooth logistics. Additionally, ensure that your supplier provides all necessary documentation, including invoices and certificates of origin, to avoid delays at customs. Planning for lead times and understanding local import regulations can significantly streamline the process. -

Are there customization options available for square head bolts?

Yes, many suppliers offer customization options for square head bolts, including specific sizes, thread types, and finishes. When requesting custom orders, be clear about your specifications and intended application to ensure the product meets your needs. Some manufacturers may also provide design services for unique requirements. Always verify the lead times and costs associated with custom orders to align with your project timeline and budget. -

What industries commonly use square head bolts, and what are their applications?

Square head bolts are widely used in construction, woodworking, automotive, and historical restoration projects. Their unique design allows for secure fastening in hard-to-reach areas, making them ideal for timber framing and structural applications. Additionally, their aesthetic appeal makes them popular in decorative projects and vintage reproductions. Understanding the industries and applications can help you determine if square head bolts are suitable for your specific project needs.

Top 4 Bolt Square Manufacturers & Suppliers List

1. GLFUS – Square Head Bolts

Domain: glfus.com

Registered: 2010 (15 years)

Introduction: Square Head Bolts are low or medium carbon steel, externally threaded mechanical devices with a diameter of 1/4″ or larger. They feature a trimmed square-shaped external wrenching head, providing greater bearing surface for wrenching compared to hex head bolts. Available specifications include various diameters (1/4, 5/16, 3/8, M10, 1/2, 5/8, 3/4, 7/8, 1, 1 1/8, 1 1/4, 1 1/2, 2), thread pitches (1…

2. Grainger – Square-Head Bolts

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Square-Head Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Blacksmith Bolt – Square Head Machine Bolts

Domain: blacksmithbolt.com

Registered: 2006 (19 years)

Introduction: Square Head Machine Bolts available in various sizes including #10-24, 1/4″-20, 5/16″-18, 3/8″-16, 7/16″-14, 1/2″-13, 5/8″-11, 3/4″-10, and 7/8″-9 & Up.

4. MISUMI – Square Head & Carriage Bolts

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Square Head Bolts & Carriage Bolts

– Head Shape: Square, Carriage

– Material Options: Stainless Steel 304 (18-8), Carbon Steel, Steel

– Material Details: JIS SWCH Equivalent Steel, JIS SUS304 Equivalent Stainless Steel

– Finish Options: Plain, Chrome Plated, Copper Plated, Nickel Plated, Dacrotized, Hot-Dip Galvanized, Parkerized, Temper Colored (Brown), various Zinc Platings (Hexavalent and Triva…

Strategic Sourcing Conclusion and Outlook for bolt square

What Are the Key Takeaways for International B2B Buyers of Square Head Bolts?

In summary, strategic sourcing of square head bolts can significantly enhance procurement efficiency and product quality for international buyers. The enduring demand for these robust fasteners, particularly in industries like construction, restoration, and manufacturing, underscores their value. Opting for suppliers that offer a variety of finishes—such as hot-dip galvanization or black oxide—can ensure durability and corrosion resistance, essential for applications in diverse climates.

How Can Strategic Sourcing Improve Your Supply Chain?

By leveraging strategic sourcing, companies can not only negotiate better pricing through bulk purchases but also ensure the consistency and reliability of their supply chains. Establishing relationships with reputable manufacturers or distributors is crucial, especially for those operating in Africa, South America, the Middle East, and Europe, where market dynamics may vary significantly.

What Does the Future Hold for Square Head Bolt Procurement?

As the global market continues to evolve, staying informed about the latest trends and innovations in fastener technology will be vital. Buyers are encouraged to explore diverse sourcing options and consider the integration of sustainable practices in their procurement strategies. By doing so, they can position themselves advantageously in a competitive landscape. Engage with suppliers today to secure quality square head bolts that meet your specific needs and ensure the success of your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to bolt square

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.