A B2B Buyer’s Guide to Bolt Anatomy: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for bolt anatomy

Navigating the complexities of bolt anatomy is a critical challenge for international B2B buyers who seek to ensure the reliability and longevity of their fastening solutions. Understanding the intricate details of bolts—including their various types, applications, and the materials from which they are made—can significantly influence purchasing decisions. This comprehensive guide delves into the essential components of bolts, exploring their anatomy, from heads and threads to finishes and materials. It also covers the different types of fasteners available, their specific applications across diverse industries, and best practices for supplier vetting.

For buyers from regions like Africa, South America, the Middle East, and Europe—such as Brazil and Germany—this guide serves as an indispensable resource. It empowers stakeholders to make informed decisions by providing insights into cost considerations, sourcing strategies, and the significance of quality standards. By understanding bolt anatomy, B2B buyers can better assess their needs and select the right fasteners that will not only meet technical specifications but also enhance operational efficiency and safety. Whether you are involved in construction, manufacturing, or automotive sectors, mastering bolt anatomy is key to optimizing your fastening solutions and achieving long-term success.

Understanding bolt anatomy Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Bolt | Hexagonal head, often used with a nut | Construction, automotive, machinery | Pros: Versatile, strong connection. Cons: Requires tools for installation. |

| Carriage Bolt | Rounded head, square neck to prevent spinning | Wood fastening, outdoor furniture | Pros: Easy to install, prevents loosening. Cons: Limited to specific applications. |

| Lag Bolt | Large diameter, coarse threads for wood | Heavy timber construction, decking | Pros: High load capacity, robust. Cons: Requires pre-drilling, can be overkill for lighter applications. |

| Socket Head Cap Screw | Cylindrical head, internal hex drive | Machinery assembly, automotive | Pros: Low-profile, can be used in tight spaces. Cons: Requires specific tools, less common. |

| Self-Drilling Screw | Drill point for direct installation into materials | Metal sheeting, roofing | Pros: Eliminates pre-drilling, quick installation. Cons: Can create debris, not suitable for all materials. |

What are the Key Characteristics of Hex Bolts?

Hex bolts are characterized by their hexagonal heads, which allow for easy gripping with a wrench. This type of bolt is widely used in construction and machinery due to its strength and versatility. Buyers should consider the material and grade of the hex bolt, as these factors influence its tensile strength and corrosion resistance. The ability to use nuts with hex bolts also enhances their utility in various applications.

How Do Carriage Bolts Stand Out?

Carriage bolts are identified by their rounded heads and square necks, which prevent them from turning once installed. They are particularly suited for fastening wood, making them popular in outdoor furniture and construction projects. When purchasing carriage bolts, buyers should ensure they select the appropriate length and diameter to match their application needs, as well as consider the material to ensure durability against weathering.

What Makes Lag Bolts Ideal for Heavy-Duty Applications?

Lag bolts are designed with a large diameter and coarse threads, providing a strong grip in wood. They are ideal for heavy timber construction and decking applications where high load capacity is required. Buyers should be aware that lag bolts often necessitate pre-drilling, which can add time to the installation process. Choosing the right length and thread type is crucial for achieving optimal holding power.

Why Choose Socket Head Cap Screws?

Socket head cap screws feature a cylindrical head with an internal hex drive, allowing for a low-profile installation in tight spaces. They are commonly used in machinery assembly and automotive applications. When sourcing these screws, buyers should focus on the thread size and material, as these factors affect compatibility with existing components and overall performance.

What are the Advantages of Self-Drilling Screws?

Self-drilling screws are designed with a drill point that allows them to penetrate materials directly without pre-drilling. This feature makes them particularly efficient for metal sheeting and roofing applications. Buyers should consider the material and coating of self-drilling screws to ensure they are suited for the specific environment and application, as improper selection can lead to reduced performance or corrosion issues.

Key Industrial Applications of bolt anatomy

| Industry/Sector | Specific Application of bolt anatomy | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural connections in buildings | Ensures safety and stability of structures | Material specifications, load capacity, and corrosion resistance |

| Automotive | Engine and chassis assembly | Enhances vehicle durability and performance | Compliance with industry standards, weight considerations, and temperature resistance |

| Aerospace | Fastening components in aircraft | Critical for safety and reliability | Aerospace-grade materials, precision tolerances, and regulatory compliance |

| Renewable Energy | Mounting systems for solar panels | Supports sustainability initiatives and cost savings | Environmental resistance, ease of installation, and compatibility with existing systems |

| Heavy Machinery | Assembly of industrial equipment | Increases operational efficiency and safety | Strength ratings, thread types, and availability of bulk orders |

How is Bolt Anatomy Utilized in the Construction Industry?

In the construction industry, bolt anatomy is crucial for creating secure structural connections. Bolts are used to join beams, columns, and other structural elements, ensuring safety and stability in buildings. Buyers in this sector need to focus on the material properties of bolts, such as strength and corrosion resistance, as they must withstand various environmental conditions. Additionally, understanding the specific requirements for load capacity and installation methods is vital, especially for international projects in regions like Africa and South America, where construction standards may vary.

What Role Does Bolt Anatomy Play in Automotive Applications?

In the automotive sector, bolt anatomy is integral to engine and chassis assembly. High-strength bolts are used to secure critical components, enhancing vehicle durability and performance. Buyers must consider compliance with automotive industry standards and specifications, as well as factors like weight and temperature resistance. As global automotive markets evolve, sourcing bolts that meet these requirements while also being cost-effective is essential for manufacturers in Europe and South America.

Why is Bolt Anatomy Important in Aerospace Engineering?

The aerospace industry relies heavily on bolt anatomy for fastening components in aircraft, where safety and reliability are paramount. Aerospace-grade bolts must meet stringent quality standards and are often made from specialized materials to withstand extreme conditions. Buyers should prioritize precision tolerances and regulatory compliance when sourcing these fasteners, especially as they navigate international supply chains. Understanding these requirements is critical for businesses operating in the Middle East and Europe, where aerospace regulations can be particularly rigorous.

How Does Bolt Anatomy Support Renewable Energy Initiatives?

In renewable energy, particularly solar power, bolt anatomy is essential for mounting systems that secure solar panels. The durability and environmental resistance of bolts are critical to ensuring long-term performance and minimizing maintenance costs. Buyers should consider the ease of installation and compatibility with existing systems when sourcing these fasteners. As sustainability becomes increasingly important in regions like Africa and South America, businesses must ensure that their sourcing strategies align with environmental goals.

What is the Significance of Bolt Anatomy in Heavy Machinery?

Bolt anatomy plays a vital role in the assembly of industrial equipment within the heavy machinery sector. High-strength bolts are necessary to maintain operational efficiency and safety in demanding environments. Buyers need to focus on strength ratings and thread types to ensure compatibility with machinery specifications. Additionally, sourcing bolts in bulk can be a key consideration for companies in Europe and South America, where production scales can significantly impact costs and lead times.

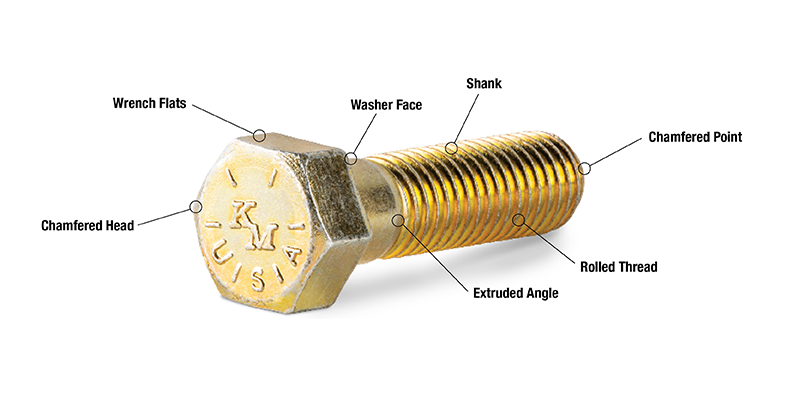

Illustrative image related to bolt anatomy

3 Common User Pain Points for ‘bolt anatomy’ & Their Solutions

Scenario 1: Misalignment of Bolt Specifications with Application Needs

The Problem: A B2B buyer in the construction sector often encounters issues when the bolts sourced do not meet the specific application requirements. For instance, they may purchase high-strength bolts, believing they are suitable for heavy structural connections, only to find out later that the thread type or material does not align with the intended load-bearing capacity or environmental conditions. This misalignment can lead to project delays, increased costs due to reordering, and potential safety risks.

The Solution: To mitigate this issue, buyers should engage in a thorough analysis of application requirements before sourcing bolts. This includes understanding the load specifications, environmental factors (like corrosion potential), and the type of materials being joined. Buyers should consult with engineers or technical experts to develop a clear specification sheet that includes bolt type, material grade, thread standards, and finish requirements. Additionally, utilizing standardized bolts that are commonly recognized in the industry can help ensure compatibility and reduce sourcing errors.

Scenario 2: Inconsistent Quality and Sourcing Challenges

The Problem: A buyer responsible for procurement in a manufacturing facility often faces challenges with inconsistent quality from different bolt suppliers. This inconsistency may manifest as variations in material strength, finishes, or even dimensions, which can lead to assembly problems and ultimately affect the performance of the final product. These quality issues not only disrupt production schedules but also erode trust in the supply chain.

The Solution: To address this pain point, it is crucial for buyers to establish strong relationships with reputable suppliers who have a proven track record in quality assurance. Implementing a rigorous supplier evaluation process that includes certifications (like ISO or ASTM), product testing, and regular audits can help ensure consistent quality. Additionally, buyers should consider leveraging technology, such as digital tracking systems, to monitor batch quality and maintain records of supplier performance over time. This proactive approach enables buyers to anticipate quality issues and take corrective actions before they impact production.

Scenario 3: Lack of Knowledge on Bolt Types and Their Applications

The Problem: International buyers, particularly those new to the fastener market, often struggle with the vast array of bolt types and their specific applications. This confusion can lead to the selection of inappropriate bolts for their projects, resulting in underperformance or failure. For instance, a buyer might opt for standard bolts when a specialized bolt type, such as a self-tapping or shoulder bolt, would be more effective for their application.

The Solution: To overcome this knowledge gap, buyers should invest in training sessions or workshops focused on bolt anatomy and application. Collaborating with fastener manufacturers or industry experts to conduct educational seminars can provide valuable insights into different bolt types, their attributes, and suitable applications. Furthermore, creating a comprehensive reference guide that outlines the characteristics, uses, and benefits of various bolts can serve as an ongoing resource for buyers. This educational approach empowers buyers to make informed decisions and optimize their fastener selections for specific applications, ultimately enhancing product reliability and performance.

Strategic Material Selection Guide for bolt anatomy

What Are the Key Properties of Common Bolt Materials?

When selecting the appropriate material for bolts, it is essential to consider the unique properties that affect performance in various applications. Below are analyses of four common materials used in bolt manufacturing: carbon steel, stainless steel, brass, and titanium.

How Does Carbon Steel Perform in Bolt Applications?

Key Properties: Carbon steel bolts offer high tensile strength and are suitable for applications requiring significant load-bearing capabilities. They typically have a temperature rating up to 300°F (150°C) and exhibit moderate corrosion resistance when treated with protective coatings.

Illustrative image related to bolt anatomy

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for general-purpose applications. However, its susceptibility to corrosion without proper finishing can limit its use in environments exposed to moisture or chemicals. Manufacturing complexity is relatively low, allowing for mass production.

Impact on Application: Carbon steel bolts are ideal for construction, automotive, and machinery applications. However, they may not be suitable for marine or chemical environments where corrosion resistance is critical.

Considerations for International Buyers: Compliance with standards such as ASTM A307 or DIN 933 is essential. Buyers from regions like Europe may prefer certified materials that meet stringent quality controls.

What Advantages Does Stainless Steel Offer for Bolt Manufacturing?

Key Properties: Stainless steel bolts are known for their excellent corrosion resistance and can withstand temperatures ranging from -200°F to 1,200°F (-129°C to 649°C). They are also non-magnetic and maintain strength in high-temperature applications.

Pros & Cons: The major advantage of stainless steel is its durability and resistance to rust and corrosion, making it suitable for harsh environments. However, it is more expensive than carbon steel and may require specialized manufacturing techniques, which can increase lead times.

Impact on Application: These bolts are commonly used in marine, food processing, and chemical industries due to their resistance to corrosion and staining. They are compatible with a wide range of media, including saltwater and acidic substances.

Considerations for International Buyers: Buyers should look for compliance with ASTM A193 or JIS B 1180 standards. In regions like the Middle East, where high humidity is prevalent, stainless steel is often preferred for its longevity.

How Does Brass Compare as a Bolt Material?

Key Properties: Brass bolts exhibit moderate strength and excellent corrosion resistance, particularly against saltwater. They can withstand temperatures up to 300°F (150°C) but are not suitable for high-load applications.

Pros & Cons: The key advantage of brass is its aesthetic appeal and resistance to tarnishing, making it ideal for decorative applications. However, its lower tensile strength compared to steel limits its use in structural applications, and it is generally more expensive.

Impact on Application: Brass is commonly used in plumbing, electrical, and decorative applications. It is particularly effective in environments where corrosion resistance is vital.

Considerations for International Buyers: Compliance with standards such as ASTM B16 is crucial. Buyers in Europe may prefer brass bolts that meet specific alloy compositions for quality assurance.

Why Choose Titanium for High-Performance Bolts?

Key Properties: Titanium bolts are known for their high strength-to-weight ratio and exceptional corrosion resistance, withstanding temperatures up to 800°F (427°C). They are also non-magnetic and biocompatible, making them suitable for specialized applications.

Illustrative image related to bolt anatomy

Pros & Cons: The primary advantage of titanium is its lightweight nature combined with high strength, making it ideal for aerospace and medical applications. However, titanium is significantly more expensive than other materials, and its manufacturing complexity can lead to longer production times.

Impact on Application: Titanium bolts are used in aerospace, military, and medical applications where weight savings and corrosion resistance are paramount. They are particularly effective in extreme environments.

Considerations for International Buyers: Compliance with ASTM F136 or ISO 5832 standards is essential. Buyers from regions like Africa may need to consider the availability and cost implications of sourcing titanium bolts.

Summary Table of Bolt Materials

| Material | Typical Use Case for bolt anatomy | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General-purpose applications | Cost-effective and strong | Susceptible to corrosion | Low |

| Stainless Steel | Marine and chemical industries | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Plumbing and electrical applications | Aesthetic appeal and tarnish resistance | Lower tensile strength | Med |

| Titanium | Aerospace and medical applications | High strength-to-weight ratio | Very high cost and complex manufacturing | High |

This guide provides B2B buyers with critical insights into material selection for bolts, ensuring informed decisions that align with application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bolt anatomy

What Are the Key Stages of Bolt Manufacturing Processes?

The manufacturing process of bolts involves several critical stages that ensure the final product meets the required specifications and performance standards. Understanding these stages is essential for B2B buyers to evaluate suppliers effectively.

How Is Material Prepared for Bolt Production?

The first step in the manufacturing process is material preparation. Typically, bolts are made from high-strength steel, stainless steel, or other alloys. The raw materials are often purchased in bulk form, such as rods or coils. These materials must undergo various treatments, including heat treatment or annealing, to enhance their mechanical properties.

Quality control begins at this stage, where suppliers should provide material certifications that verify the chemical composition and mechanical properties of the raw materials. B2B buyers should look for documentation that adheres to international standards, ensuring the material’s integrity before proceeding to the next manufacturing phase.

What Forming Techniques Are Commonly Used in Bolt Manufacturing?

After material preparation, the next stage involves forming the bolts. This is primarily achieved through processes like cold heading, hot forging, or machining.

-

Cold Heading: This technique involves shaping the bolt by applying high pressure to the material at room temperature. It is energy-efficient and produces precise dimensions, making it a preferred method for high-volume production.

-

Hot Forging: In this process, the material is heated to a plastic state and then formed into the desired shape. This method is beneficial for producing larger bolts or those requiring complex geometries.

Each forming technique has its advantages, and the choice often depends on the specific requirements of the bolts, such as size, material, and intended application. B2B buyers should inquire about the forming methods used by suppliers and their implications on the final product’s strength and durability.

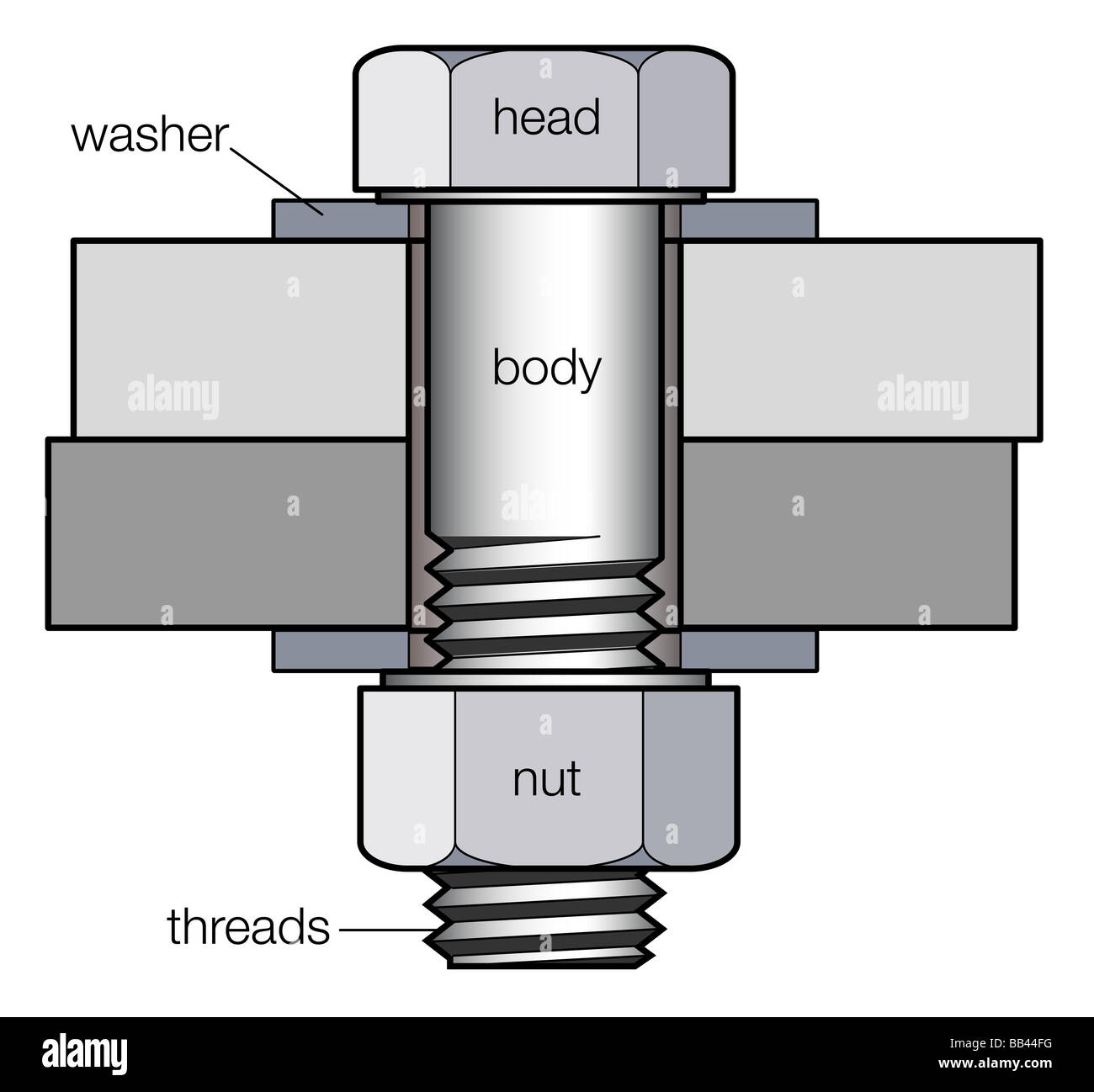

How Are Bolts Assembled and Finished?

Following the forming process, bolts undergo assembly if they are part of a more complex fastening system. For instance, some bolts may require the addition of nuts or washers, which necessitates precise alignment and threading.

Illustrative image related to bolt anatomy

Once assembled, bolts are finished through various processes, including surface treatment and coating. Common finishes include zinc plating, black oxide, and hot-dip galvanizing, each providing different levels of corrosion resistance and aesthetic appeal. The choice of finish should align with the bolt’s intended environment; for example, zinc-coated bolts are ideal for indoor use, while hot-dip galvanized bolts are better suited for outdoor applications.

B2B buyers should evaluate the finishing processes employed by suppliers, as these can significantly impact the longevity and performance of the bolts in challenging environments.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical aspect of bolt manufacturing, as it ensures that the products meet international and industry-specific standards. B2B buyers should familiarize themselves with the following key quality assurance frameworks:

Which International Standards Are Relevant for Bolt Quality Assurance?

ISO 9001 is the most recognized quality management standard globally. It focuses on consistent quality and customer satisfaction. Manufacturers who comply with ISO 9001 demonstrate a commitment to quality processes, which is crucial for B2B buyers looking for reliable suppliers.

Additionally, industry-specific standards such as the CE marking for products sold in Europe or API standards for oil and gas applications are vital. Compliance with these standards indicates that the bolts have undergone rigorous testing and meet specific safety and performance criteria.

What Are the Key QC Checkpoints in Bolt Manufacturing?

Quality control in bolt manufacturing typically includes several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are conducted to ensure that the processes are functioning correctly and that the bolts are being produced to specification.

-

Final Quality Control (FQC): After production, bolts undergo final inspections to verify dimensions, mechanical properties, and surface finishes. This stage is critical for identifying defects before the product reaches the customer.

B2B buyers should ask suppliers for detailed QC processes and documentation, including inspection reports and test results, to ensure the bolts meet their specific requirements.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps:

What Methods Can Buyers Use to Validate Supplier QC Practices?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control practices, and overall capabilities of the supplier. This direct engagement provides valuable insights into the supplier’s commitment to quality.

-

Quality Reports: Requesting regular quality reports can help buyers stay informed about the supplier’s performance, including any non-conformities and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes. This is particularly important for international transactions, where buyers may not have the resources to conduct on-site assessments.

-

Certification Verification: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001, and check their validity through official channels.

What Are the Unique QC Considerations for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Differences in regulations, standards, and market expectations can significantly impact product quality.

-

Local Standards Compliance: Buyers must ensure that suppliers comply with local regulations and standards in their respective markets. This is particularly relevant for industries like construction and automotive, where safety regulations can vary widely.

-

Cultural and Communication Barriers: Language differences and cultural nuances can affect the quality assurance process. Establishing clear communication channels and expectations is vital for maintaining quality across borders.

-

Supply Chain Transparency: Ensuring transparency in the supply chain can help mitigate risks associated with quality assurance. Buyers should seek suppliers who provide clear visibility into their sourcing, manufacturing, and QC processes.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing bolts, ensuring they receive high-quality products that meet their specifications and performance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bolt anatomy’

When sourcing bolts, understanding their anatomy is crucial for making informed procurement decisions. This guide provides a step-by-step checklist to help B2B buyers navigate the complexities of bolt anatomy, ensuring that you select the right fasteners for your specific applications.

1. Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing bolts effectively. Identify the exact requirements based on your application, including dimensions, thread type, and material. Consider factors like load-bearing capacity and environmental conditions that may affect performance.

- Key Considerations:

- Thread standards (metric vs. imperial).

- Required strength grades (e.g., ASTM standards).

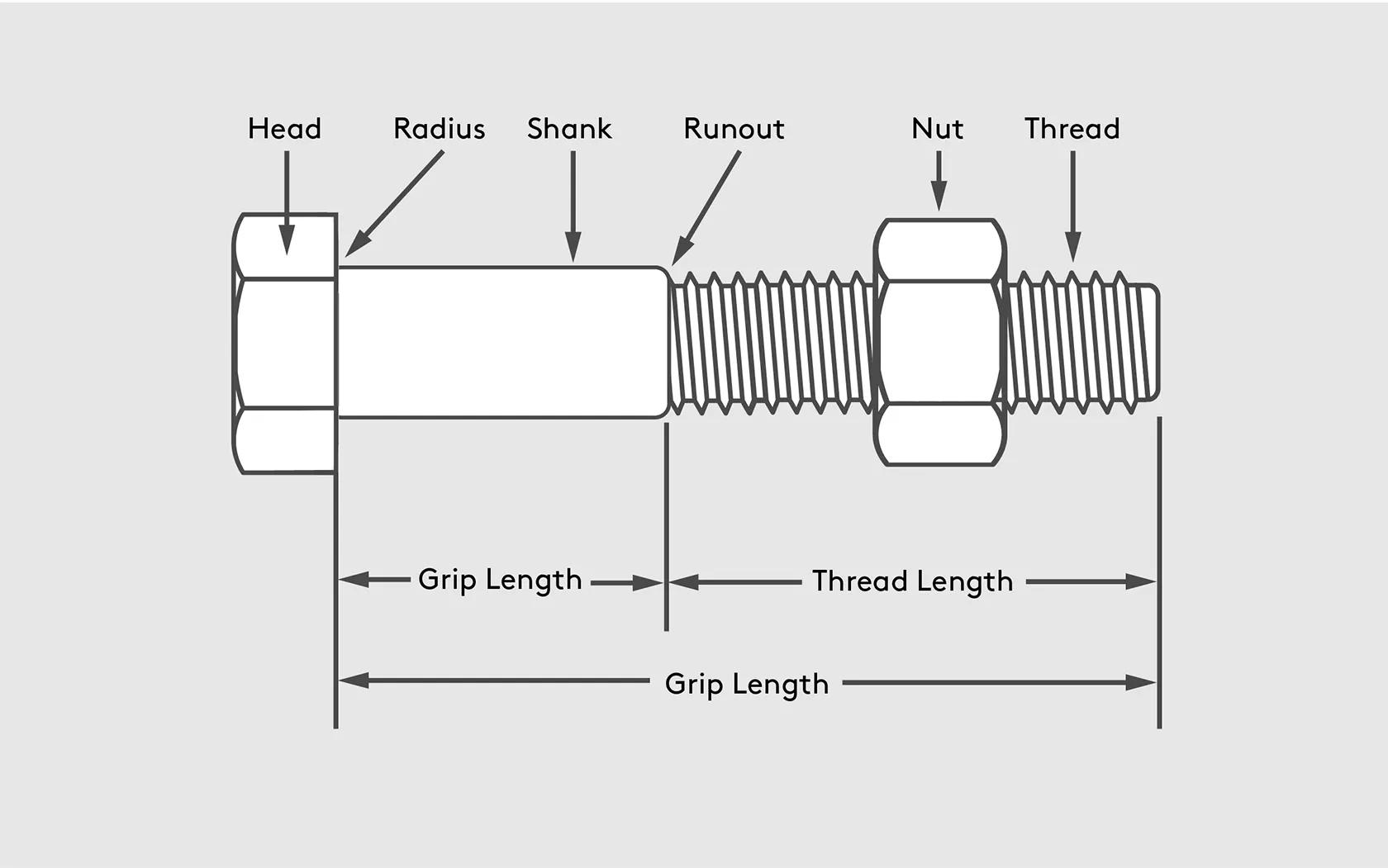

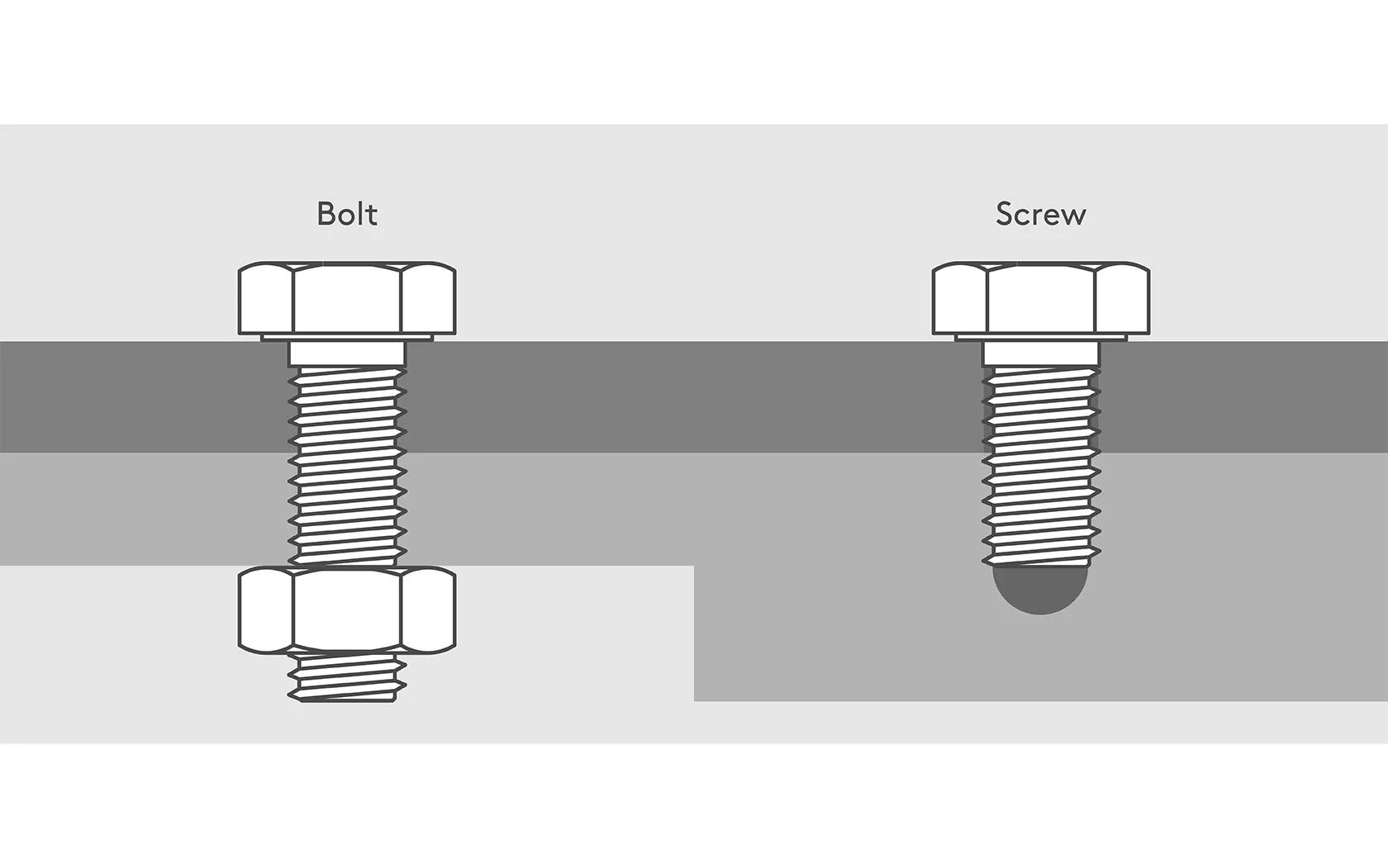

2. Step 2: Understand Bolt Anatomy

Familiarize yourself with the different parts of a bolt, including the head, body, shank, threads, and point. Each component plays a vital role in how the bolt functions within an assembly.

- Important Features:

- Head type: Determines the tool used for fastening (e.g., hex, socket).

- Thread pitch: Affects compatibility with nuts and other components.

3. Step 3: Evaluate Material and Finish Options

The material and finish of a bolt significantly influence its durability and suitability for specific environments. Common materials include steel and stainless steel, while finishes can provide corrosion resistance.

- Material Considerations:

- Choose stainless steel for outdoor applications or corrosive environments.

- Opt for coated bolts (e.g., zinc plating) to enhance lifespan.

4. Step 4: Assess Supplier Capabilities

Before making a purchase, assess potential suppliers for their manufacturing capabilities and quality assurance processes. Request documentation that demonstrates compliance with international standards.

- Verification Steps:

- Check for ISO certifications or equivalent.

- Review their quality control procedures and testing methods.

5. Step 5: Request Samples

Always request samples before committing to a large order. This allows you to evaluate the quality and suitability of the bolts for your specific application.

- Sample Evaluation:

- Inspect samples for defects, thread quality, and finish.

- Test the bolts in your application to ensure compatibility.

6. Step 6: Review Pricing and Terms

Once you have identified a suitable supplier, review pricing structures and payment terms. Ensure that the costs align with your budget while considering the total cost of ownership.

- Cost Considerations:

- Factor in shipping costs and lead times.

- Inquire about bulk discounts or long-term contract options.

7. Step 7: Finalize the Order and Monitor Delivery

After agreeing on terms, finalize your order and establish clear communication regarding delivery timelines. Monitor the shipment to ensure that it arrives as scheduled and meets the agreed specifications.

- Delivery Management:

- Confirm tracking details and expected arrival dates.

- Prepare for inspection upon receipt to verify quality and quantity.

Following this checklist will empower you to make informed purchasing decisions regarding bolt anatomy, ensuring that your procurement process is efficient and effective.

Comprehensive Cost and Pricing Analysis for bolt anatomy Sourcing

What Are the Key Cost Components for Bolt Anatomy Sourcing?

When sourcing bolts, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of material significantly impacts pricing. Common materials include steel, stainless steel, and specialized alloys. Each material has its own price point, influenced by market conditions, availability, and the specific mechanical properties required for different applications.

-

Labor: Labor costs vary depending on the manufacturing location and the complexity of the bolt design. Regions with lower labor costs may provide savings, but this must be balanced against potential quality issues.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce these overhead costs, leading to better pricing for buyers.

-

Tooling: The cost of tooling (e.g., molds, dies) can be significant, particularly for custom bolt designs. High-quality tooling increases initial costs but can enhance production efficiency and product quality in the long run.

-

Quality Control (QC): Implementing rigorous QC measures ensures that bolts meet industry standards and specifications, which may involve additional costs. Certifications like ISO or ASTM can also affect pricing but are essential for guaranteeing product reliability.

-

Logistics: Transportation costs play a vital role, especially for international buyers. Factors such as shipping method, distance, and customs duties can add to the overall cost of sourcing bolts.

-

Margin: Suppliers typically add a markup to cover their costs and generate profit. Understanding the standard margins in different regions can help buyers negotiate better pricing.

What Factors Influence Bolt Pricing in B2B Transactions?

Several elements can influence bolt pricing, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to reduced per-unit costs. Suppliers may offer discounts for larger orders, making it beneficial for buyers to plan their inventory accordingly.

-

Specifications and Customization: Custom bolts tailored to specific applications may incur higher costs due to unique materials, designs, and production processes. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications can elevate pricing but are essential for ensuring safety and performance, particularly in critical applications.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers with a history of quality may charge more but offer peace of mind regarding product consistency.

-

Incoterms: Understanding international trade terms (Incoterms) is vital for buyers, as they dictate the responsibilities of buyers and sellers during shipping. These terms can affect overall costs, including transportation and insurance.

What Are Effective Buyer Tips for Cost-Efficient Bolt Sourcing?

To optimize costs while sourcing bolts, buyers should consider the following strategies:

-

Negotiate Pricing: Leverage the volume of purchases and long-term relationships to negotiate better pricing. Suppliers are often willing to provide discounts for loyal customers or larger orders.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes logistics, maintenance, and replacement costs. A lower upfront price may lead to higher long-term expenses if the quality is subpar.

-

Understand Pricing Nuances in International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and trade tariffs that can affect pricing. Building relationships with local suppliers may provide additional insights and cost-saving opportunities.

-

Research and Compare Suppliers: Conduct thorough research on potential suppliers, focusing on their pricing structures, quality standards, and customer reviews. This can help identify the best fit for specific needs.

-

Stay Informed on Market Trends: Keeping up with trends in the fastener industry can provide insights into pricing fluctuations and help buyers make informed purchasing decisions.

Conclusion

Sourcing bolts effectively requires a comprehensive understanding of cost components, pricing influencers, and strategic negotiation techniques. By considering these factors, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing bolt anatomy With Other Solutions

Introduction to Alternative Solutions for Fastening

In the world of fastening solutions, understanding bolt anatomy is crucial for making informed purchasing decisions. However, there are alternative fastening methods that can offer different advantages based on specific applications. This section explores how bolt anatomy compares to other solutions, helping B2B buyers identify the best option for their needs.

Comparison of Bolt Anatomy Against Alternative Fastening Solutions

| Comparison Aspect | Bolt Anatomy | Rivets | Adhesive Bonding |

|---|---|---|---|

| Performance | High strength and durability; mechanical advantage through threaded design | Excellent shear strength; permanent joint | Varies based on type; can be very strong |

| Cost | Moderate initial cost; ongoing maintenance can add to total cost | Generally low cost; minimal tooling required | Cost-effective for large applications but can vary widely |

| Ease of Implementation | Requires tools for installation; skilled labor needed for precision | Simple installation; often requires minimal training | Easy to apply; requires curing time |

| Maintenance | Regular checks needed for loosening; potential corrosion issues | Permanent once set; no maintenance required | Minimal maintenance; depends on environmental factors |

| Best Use Case | Mechanical assemblies requiring frequent disassembly | Structural applications where permanence is key | Applications needing flexibility or sealing properties |

Detailed Breakdown of Alternatives

Rivets

Rivets are a popular alternative to bolts, especially in applications where a permanent joint is needed. They excel in providing high shear strength and can be installed quickly with minimal tooling. However, once set, rivets cannot be disassembled, which limits their use in applications requiring maintenance or adjustments. While the initial cost is low, the inability to replace or adjust rivets can lead to higher long-term expenses in certain scenarios.

Adhesive Bonding

Adhesive bonding has gained traction as a versatile fastening solution, particularly in industries where weight reduction is a priority, such as aerospace and automotive. Adhesives can provide strong bonds that resist various environmental factors, making them suitable for diverse applications. The ease of application is a significant advantage, as it requires less specialized labor compared to traditional mechanical fasteners. However, the performance of adhesives can vary widely based on environmental conditions and the specific materials being bonded. Additionally, curing time can delay production processes.

Conclusion: Choosing the Right Fastening Solution for Your Needs

When selecting a fastening solution, B2B buyers must consider several factors, including performance requirements, cost implications, ease of implementation, and maintenance needs. Bolt anatomy offers robust mechanical advantages and is ideal for applications requiring frequent disassembly, while rivets provide permanence and strength in structural applications. Adhesive bonding presents a flexible option for lightweight and moisture-sensitive applications. By carefully evaluating these alternatives against their specific requirements, buyers can make informed decisions that enhance their operational efficiency and product reliability.

Essential Technical Properties and Trade Terminology for bolt anatomy

In the world of fasteners, understanding the essential technical properties and terminology related to bolt anatomy is crucial for B2B buyers. This knowledge empowers decision-makers to select the right products for their specific applications, ensuring safety, reliability, and cost-effectiveness.

What Are the Key Technical Properties of Bolts That Influence Performance?

-

Material Grade

The material grade of a bolt determines its strength, ductility, and corrosion resistance. Common materials include carbon steel, stainless steel, and alloy steel. For instance, stainless steel bolts are ideal for environments prone to moisture, while carbon steel bolts offer high tensile strength for heavy-duty applications. Choosing the appropriate material grade is vital for ensuring the longevity and performance of the assembly. -

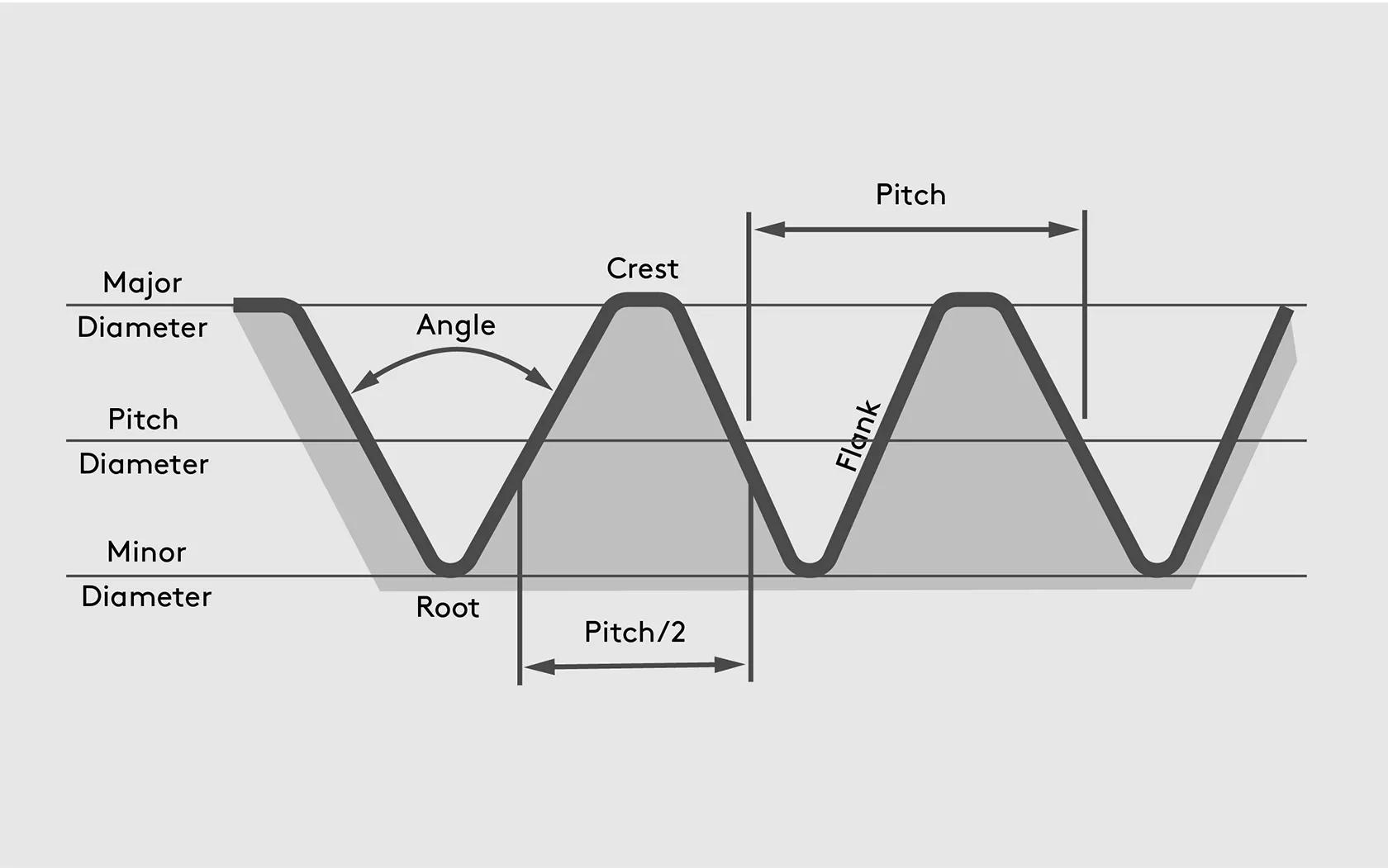

Thread Pitch

Thread pitch refers to the distance between threads and is critical for ensuring proper engagement with nuts or threaded holes. Coarse threads are typically used in softer materials, while fine threads offer better strength and resistance to vibration. Understanding thread pitch is essential for B2B buyers to ensure compatibility and reliability in mechanical assemblies. -

Tolerance

Tolerance specifies the allowable deviation from specified dimensions. It is crucial for ensuring that bolts fit properly in their intended applications. High tolerance levels can be necessary for precision machinery, while lower tolerances might suffice in less critical applications. This property is essential for maintaining quality control and preventing assembly failures. -

Finish

The finish of a bolt affects its resistance to corrosion and wear. Common finishes include zinc plating, black oxide, and galvanization. Each finish has its own durability and suitability for specific environments. Selecting the right finish can significantly extend the lifespan of bolts, making it a critical consideration for buyers in various industries. -

Load Capacity

Load capacity indicates the maximum load a bolt can handle before failure. It is determined by factors such as material, diameter, and thread design. Understanding load capacity is vital for engineers and procurement specialists to ensure safety and structural integrity in applications ranging from construction to automotive manufacturing.

What Are Common Trade Terms in the Bolt Industry That B2B Buyers Should Know?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, sourcing bolts from OEMs ensures that they receive high-quality, reliable products that meet industry standards, which is crucial for maintaining the integrity of their own products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory levels and costs effectively. Higher MOQs might lead to bulk savings, but they can also pose risks if demand fluctuates. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. Including specific details about bolt specifications, quantities, and delivery requirements can help buyers receive accurate and competitive pricing, facilitating better procurement decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping responsibilities, insurance, and costs, ultimately avoiding disputes and ensuring smooth logistics. -

Lead Time

Lead time is the time taken from placing an order to its delivery. For B2B buyers, understanding lead times is crucial for project planning and inventory management. Longer lead times can impact production schedules, making it essential to factor this into procurement strategies.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency, reduce costs, and improve product quality in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the bolt anatomy Sector

Market Overview & Key Trends: What Are the Current Dynamics in the Bolt Anatomy Sector?

The global bolt anatomy market is witnessing significant transformations driven by technological advancements and evolving buyer expectations. As industries such as construction, automotive, and manufacturing expand, the demand for high-quality fasteners has surged. Buyers from regions like Africa, South America, the Middle East, and Europe (notably Germany and Brazil) are increasingly seeking suppliers that offer not only robust products but also innovative solutions tailored to specific applications.

Illustrative image related to bolt anatomy

Key trends shaping the market include the adoption of digital sourcing platforms, which facilitate easier access to a wider range of suppliers and products. These platforms allow B2B buyers to compare specifications, prices, and lead times efficiently. Moreover, the integration of Industry 4.0 technologies, such as IoT and AI, is enhancing supply chain transparency and operational efficiency. This is particularly relevant for international buyers who require real-time data to make informed purchasing decisions.

Another important trend is the customization of bolt designs to meet specific application needs. As different industries require varying standards of strength, flexibility, and resistance to environmental factors, suppliers are increasingly offering bespoke solutions. This not only improves product performance but also helps in reducing waste and optimizing inventory management.

Sustainability & Ethical Sourcing in B2B: How Are Environmental Considerations Shaping the Bolt Anatomy Market?

As global awareness of environmental issues rises, sustainability has become a critical factor in the sourcing of bolts and fasteners. B2B buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices and offer environmentally friendly materials. Fasteners made from recycled or sustainably sourced materials are gaining traction, as they align with corporate social responsibility initiatives and can enhance brand reputation.

The environmental impact of bolt production is also under scrutiny. Buyers are encouraged to seek suppliers who can provide certifications that demonstrate compliance with environmental standards. Certifications like ISO 14001 or the use of ‘green’ materials, such as eco-friendly coatings, not only mitigate ecological damage but also can lead to long-term cost savings through reduced waste and improved energy efficiency.

Moreover, the push for sustainability is influencing the design of bolt products. Manufacturers are developing innovative finishes that extend the lifespan of fasteners while minimizing the need for frequent replacements. This not only contributes to sustainability goals but also provides buyers with cost-effective solutions that enhance operational efficiency.

Brief Evolution/History: How Has the Bolt Anatomy Sector Developed Over Time?

The evolution of the bolt anatomy sector can be traced back to ancient civilizations, where rudimentary fastening methods were employed using wood and simple metal components. Over the centuries, the industrial revolution marked a significant turning point, leading to the mass production of bolts and screws with standardized measurements and materials.

The introduction of advanced metallurgy and manufacturing processes in the 20th century further enhanced the performance and reliability of bolts. Today, the market is characterized by a wide array of options, from traditional steel bolts to high-performance fasteners designed for specific applications in harsh environments. This evolution reflects a growing emphasis on quality, efficiency, and adaptability, which continues to drive innovation within the sector. For international B2B buyers, understanding this historical context is essential for making informed purchasing decisions that align with current technological and environmental trends.

Frequently Asked Questions (FAQs) for B2B Buyers of bolt anatomy

-

How do I identify the right bolt type for my application?

To select the appropriate bolt type for your application, begin by assessing the specific requirements, including load capacity, environmental conditions, and material compatibility. Consider the thread type and size, as these factors significantly impact performance. For critical applications, consult with suppliers who can provide detailed specifications and recommendations based on your operational needs. Additionally, reviewing industry standards can guide your choice, ensuring that the selected bolt meets the necessary safety and performance criteria. -

What materials are commonly used for bolts, and how do they affect performance?

Bolts are typically made from materials such as carbon steel, stainless steel, and alloy steel, each offering distinct advantages. Carbon steel provides strength but may corrode without proper finishing. Stainless steel offers excellent corrosion resistance, making it suitable for outdoor or humid environments. Alloy steel combines strength with ductility, ideal for high-stress applications. Understanding the mechanical properties of these materials will help you select bolts that align with your performance and durability requirements. -

What is the significance of bolt finishes, and how do they impact longevity?

Bolt finishes serve as protective coatings that prevent corrosion and enhance durability. Common finishes include zinc plating, which provides moderate corrosion resistance, and hot-dip galvanizing, which offers superior protection for outdoor applications. The choice of finish should align with the environmental conditions the bolt will face, as inadequate protection can lead to premature failure. Always inquire about the expected lifespan of the finish under specific conditions when sourcing bolts. -

How can I ensure the quality of bolts when sourcing from international suppliers?

To ensure quality when sourcing bolts internationally, conduct thorough supplier vetting. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Consider visiting manufacturing facilities or utilizing third-party inspection services for quality checks. Additionally, reviewing product samples and testing them in your application can help confirm that they meet your specifications. Establishing clear communication regarding quality expectations is crucial for maintaining standards. -

What are the typical minimum order quantities (MOQs) for bolts?

Minimum order quantities (MOQs) for bolts can vary widely depending on the supplier and the specific type of bolt. Common MOQs range from 1,000 to 10,000 pieces for standard products, while custom orders may have higher MOQs. It’s essential to clarify MOQs during negotiations to ensure they align with your procurement strategy. Some suppliers may be flexible with MOQs, especially for long-term partnerships or larger contracts, so it’s worth discussing your needs directly. -

What payment terms should I expect when purchasing bolts internationally?

Payment terms for international bolt purchases can vary, typically ranging from full payment in advance to 30, 60, or even 90 days after delivery. It’s common to negotiate terms based on your relationship with the supplier and order size. Letter of Credit (LC) or escrow services may be advisable for larger transactions to mitigate risks. Always ensure that payment terms are clearly outlined in the contract to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing bolts?

When importing bolts, consider logistics factors such as shipping methods, customs duties, and delivery timelines. Air freight is faster but more expensive, while sea freight is cost-effective for large orders but requires longer transit times. Be aware of import regulations and tariffs in your country, as these can impact overall costs. Collaborating with a freight forwarder can streamline the shipping process and ensure compliance with all regulatory requirements. -

How can I customize bolts to meet specific application needs?

Customization options for bolts can include variations in size, thread type, material, and finishing. When seeking custom solutions, communicate your precise requirements to suppliers, including any industry standards that must be met. Many manufacturers offer design services to help you develop a bolt tailored to your application. Be prepared to discuss lead times and pricing, as custom orders may have longer production schedules and additional costs.

Top 3 Bolt Anatomy Manufacturers & Suppliers List

1. HR Fastener – Bolts and Components

Domain: hrfastener.com

Registered: 2024 (1 years)

Introduction: Bolt Head: The topmost part gripped by tools for tightening or loosening. Common types include Hex Head, Socket Cap, and Slotted Head. Shank: The smooth, cylindrical section between the head and threaded portion, used for alignment. Threads: The helical grooves that allow the bolt to screw into a nut or tapped hole, creating a mechanical grip. Tip: Pointed or flat, guiding the bolt into place. Nec…

2. Tuhu Fasteners – Bolt Anatomy

Domain: tuhufasteners.com

Registered: 2024 (1 years)

Introduction: Bolt Anatomy: Key Parts and Their Functions – Bolt Head: Topmost part for gripping and turning, available in shapes like hexagonal, square, or round. – Shank: Unthreaded, smooth portion providing structural support and alignment during installation. – Threads: Spiral ridges essential for fastening, affecting holding power and resistance to loosening. – Pitch: Distance between threads, crucial for …

3. MetricBolt – Precision Threading Solutions

Domain: metricbolt.com

Registered: 1999 (26 years)

Introduction: 1. Threads:

– Profile: Triangular, square, trapezoidal shapes for specific applications.

– Pitch: Distance between threads; finer pitch offers more grip.

– Handedness: Right-hand (common) and left-hand (rare) threads.

2. Heads:

– Hexagonal: Six-sided for easy gripping.

– Button/Dome: Rounded top for a smoother finish.

– Countersunk: Sits flush with the surface for a seamless l…

Strategic Sourcing Conclusion and Outlook for bolt anatomy

How Can Understanding Bolt Anatomy Enhance Your Sourcing Strategy?

In today’s competitive landscape, a comprehensive understanding of bolt anatomy is essential for strategic sourcing decisions. By recognizing the significance of each component—from the drive and head to the threads and finishes—buyers can ensure they select the right fasteners for their specific applications. This knowledge not only enhances product reliability but also minimizes the risk of costly failures due to improper fastening.

Strategic sourcing enables businesses to optimize their supply chains by identifying the most suitable materials and finishes based on environmental conditions and performance requirements. For international buyers in regions such as Africa, South America, the Middle East, and Europe, this means leveraging local suppliers who understand regional challenges while also maintaining high-quality standards.

As industries increasingly prioritize sustainability and performance, the demand for specialized fasteners will continue to rise. Buyers are encouraged to engage with manufacturers and suppliers who can provide tailored solutions that address both current and future needs. By investing in strategic sourcing practices today, businesses can secure a competitive advantage and drive long-term growth in their respective markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to bolt anatomy

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.