A B2B Buyer’s Guide to Board Latch: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for board latch

In today’s competitive landscape, sourcing reliable board latches can be a daunting task for international B2B buyers. Whether you are in Nigeria seeking durable solutions for educational tools or in Germany looking for high-quality components for industrial applications, understanding the intricacies of the board latch market is crucial. This guide offers a comprehensive exploration of board latches, detailing various types, their specific applications, and essential factors to consider when vetting suppliers.

By delving into aspects such as material quality, design versatility, and compliance with international standards, this resource empowers buyers to make informed purchasing decisions. We will also discuss pricing structures and the logistics of sourcing from different regions, ensuring that you not only find the right product but also at the right price.

For B2B buyers in Africa, South America, the Middle East, and Europe, navigating the global market requires a nuanced understanding of local needs and international supply dynamics. This guide aims to bridge that gap, providing actionable insights and practical strategies to enhance your procurement process. As you embark on your journey to find the ideal board latch, let this guide serve as your authoritative resource, equipping you with the knowledge to succeed in the global marketplace.

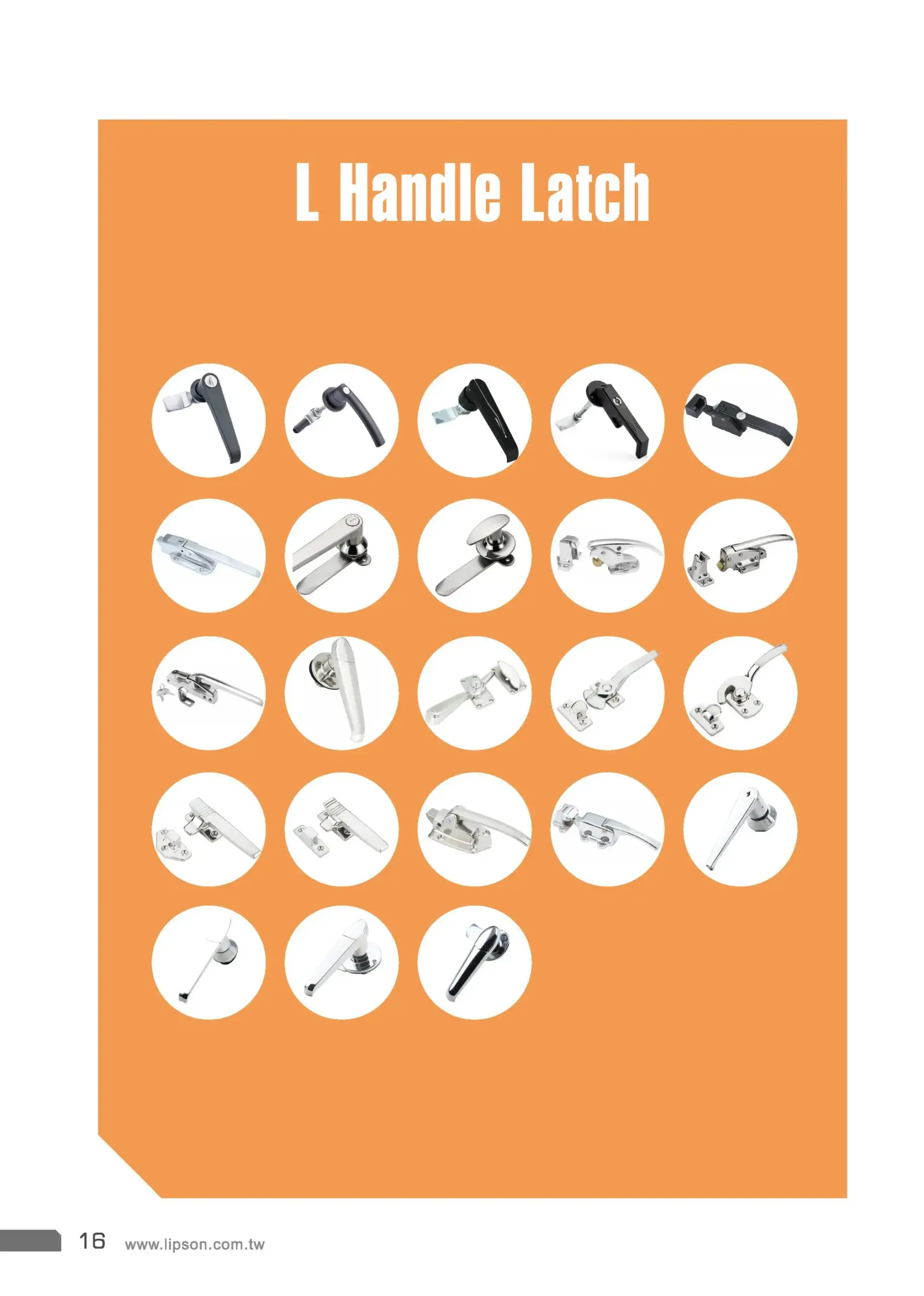

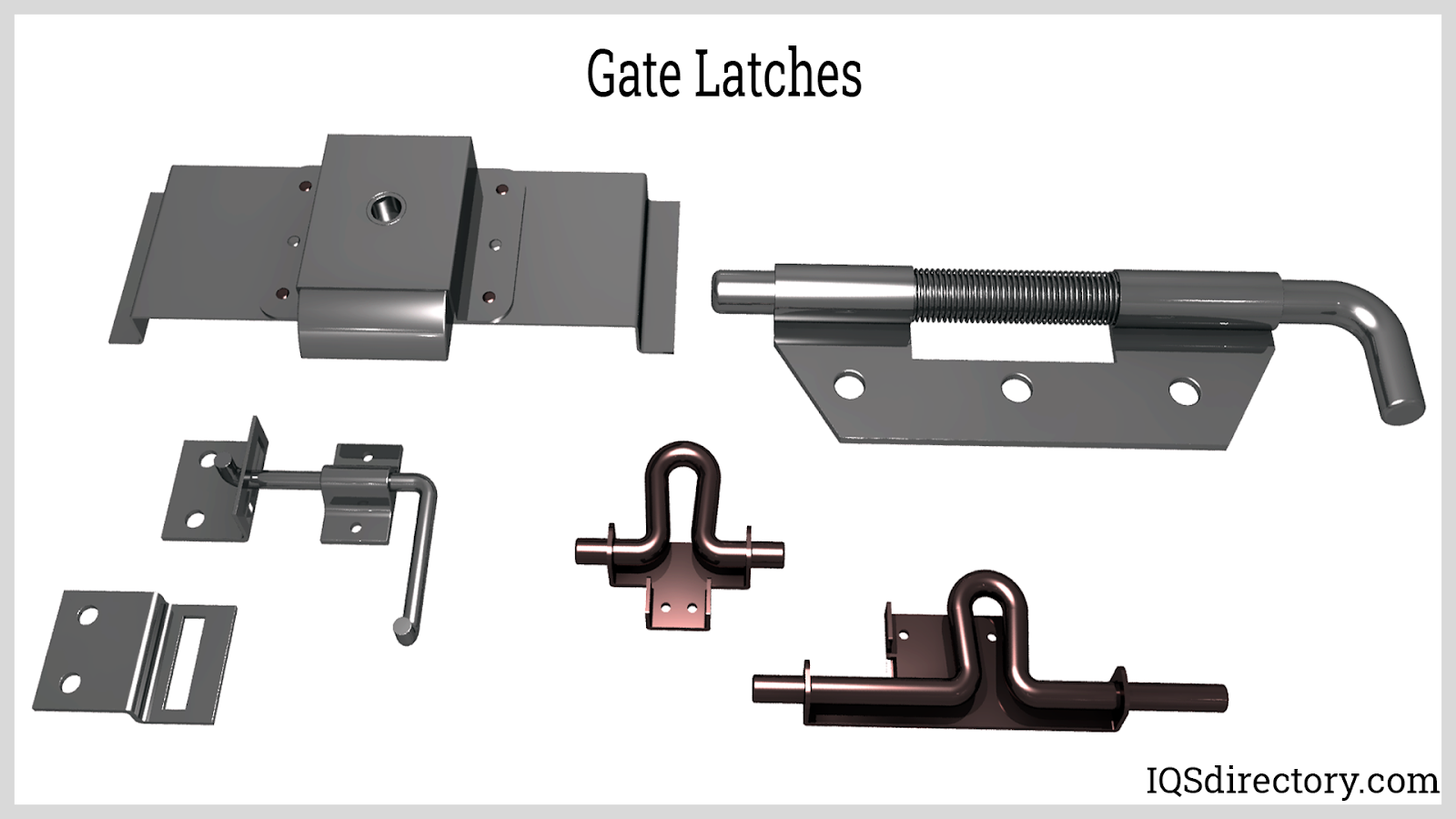

Understanding board latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Board Latch | Simple design, typically made from metal or plastic | Furniture, cabinetry, and general hardware | Pros: Cost-effective, easy to install. Cons: Limited security features. |

| M.2 Board Latch | Designed for securing M.2 SSDs, compact and specialized | Electronics and computing industries | Pros: High stability, tailored for tech applications. Cons: Requires specific installation knowledge. |

| Deadbolt Board Latch | Enhanced security with a locking mechanism | Commercial doors, secure storage solutions | Pros: Superior security, durable. Cons: More expensive, complex installation. |

| Sliding Door Latch | Mechanism allows for sliding doors, often with a locking feature | Residential and commercial sliding doors | Pros: Space-saving design, user-friendly. Cons: May require regular maintenance. |

| Activity Board Latch | Engaging design for skill development in children | Educational settings, therapy centers | Pros: Promotes learning, durable construction. Cons: Limited to specific use cases. |

What are the Characteristics of Standard Board Latches?

Standard board latches are the most basic type of latch, often made from metal or plastic. They feature a straightforward design that allows for easy installation and use in various applications, such as furniture and cabinetry. B2B buyers should consider their cost-effectiveness and ease of installation, which makes them suitable for bulk orders in manufacturing or retail settings. However, their limited security features may not meet the needs of industries requiring higher security levels.

How Do M.2 Board Latches Stand Out?

M.2 board latches are specifically engineered to secure M.2 solid-state drives (SSDs) within electronic devices. These latches are compact and designed for high stability, making them ideal for the electronics and computing sectors. When purchasing M.2 latches, B2B buyers should focus on compatibility with existing hardware and the installation process, as these latches often require specialized knowledge. While they offer tailored solutions, their niche application can limit their market appeal.

Why Choose Deadbolt Board Latches for Security?

Deadbolt board latches provide enhanced security through a locking mechanism that is more robust than standard options. They are commonly used in commercial doors and secure storage solutions, making them a preferred choice for industries prioritizing safety. Buyers should consider the durability and security features when selecting deadbolt latches. Although they tend to be more expensive and may require complex installation, the peace of mind they offer can justify the investment.

What Are the Advantages of Sliding Door Latches?

Sliding door latches are designed for use with sliding doors, featuring mechanisms that allow for smooth operation while providing a locking feature. These latches are prevalent in both residential and commercial settings where space-saving solutions are needed. B2B buyers should evaluate the ease of use and maintenance requirements associated with sliding door latches. While they are user-friendly and efficient, regular maintenance is essential to ensure optimal performance.

How Do Activity Board Latches Benefit Educational Settings?

Activity board latches are specifically designed for educational and therapeutic environments, offering engaging activities that promote skill development in children. These latches are durable and often constructed from solid materials, making them suitable for high-traffic areas like schools and therapy centers. B2B buyers should consider their educational value and suitability for various age groups when purchasing. While they serve a specific purpose, their limited applications may not appeal to all sectors.

Key Industrial Applications of board latch

| Industry/Sector | Specific Application of board latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Classroom Activity Boards | Enhances fine motor skills in children, promoting learning | Durability, safety certifications, and ease of maintenance |

| Healthcare | Rehabilitation Tools | Supports therapy sessions, aiding in patient recovery | Compliance with health standards and material safety |

| Manufacturing | Electronic Component Enclosures | Protects sensitive equipment while ensuring accessibility | Compatibility with existing systems and material quality |

| Retail | Display Cases and Security Fixtures | Increases product security and enhances customer experience | Aesthetic design, lock quality, and installation ease |

| Home Appliances | Appliance Assembly and Security | Ensures safe operation and user accessibility of appliances | Reliability, weather resistance, and compatibility |

How Are Board Latches Used in Educational Settings?

In educational environments, board latches are commonly integrated into activity boards designed for young children. These boards feature various latches and locks that children can manipulate, fostering the development of fine motor skills and hand-eye coordination. For B2B buyers in the education sector, sourcing durable, non-toxic materials is essential, especially for international markets in Africa and South America, where safety standards may vary. Ensuring that the product meets local regulations can enhance trust and facilitate smoother procurement processes.

What Role Do Board Latches Play in Healthcare?

In healthcare, board latches are utilized in rehabilitation tools and therapy aids. They provide patients with engaging activities that promote hand strength and dexterity during recovery. For international buyers, particularly in the Middle East and Europe, it’s vital to consider the compliance of these latches with health and safety regulations. Additionally, sourcing from manufacturers that offer customizable options can address specific therapeutic needs, ensuring that products are effective and safe for diverse patient populations.

How Are Board Latches Essential in Manufacturing?

In manufacturing, board latches are often used in the assembly of electronic component enclosures. These latches secure sensitive equipment, preventing unauthorized access while allowing for easy maintenance. B2B buyers in this sector must prioritize sourcing latches that are compatible with existing systems and robust enough to withstand industrial environments. Consideration of material quality and durability is crucial, especially for businesses operating in regions with varying climate conditions, such as Africa and South America.

Why Are Board Latches Important for Retail Display?

Retail environments leverage board latches in display cases and security fixtures to protect products while enhancing the customer experience. These latches allow for easy access for staff while deterring theft. For international buyers in Europe and the Middle East, aesthetic design alongside functional security features is a critical consideration. Ensuring the latches are visually appealing and easy to install can significantly impact overall customer satisfaction and sales performance.

What Is the Significance of Board Latches in Home Appliances?

In the home appliance industry, board latches are integral to ensuring the secure assembly and operation of various devices. They help maintain user safety by preventing accidental openings while allowing for accessibility during maintenance. Buyers in this sector should focus on sourcing reliable latches that offer weather resistance and compatibility with different appliance models. Understanding local market preferences and regulatory requirements is essential for successful procurement, particularly in diverse regions like Africa and Europe.

3 Common User Pain Points for ‘board latch’ & Their Solutions

Scenario 1: Sourcing Quality Board Latches for Diverse Applications

The Problem: B2B buyers often struggle to find board latches that meet specific quality standards for various applications, such as educational tools, industrial machinery, or consumer products. The challenge is compounded when sourcing from international suppliers, where inconsistent quality and compliance with local regulations can lead to significant project delays and increased costs. Additionally, buyers may face difficulties in understanding the specifications required for their specific use cases, resulting in purchasing unsuitable or subpar products.

The Solution: To overcome this challenge, it’s essential to establish a clear set of specifications for the board latches you require, including material, durability, and compliance with local regulations. Start by researching reputable suppliers with a proven track record in your industry. Utilize platforms that allow for supplier reviews and ratings to gauge reliability. When requesting quotes, ensure you ask for product samples or prototypes to assess quality firsthand. Engage in open communication with suppliers regarding your specific needs and any certifications required in your region. This proactive approach will help you source high-quality board latches that align with your project requirements, minimizing the risk of delays and enhancing overall product performance.

Scenario 2: Ensuring Compatibility with Existing Systems

The Problem: Many buyers encounter compatibility issues when integrating new board latches into existing systems or products. This can be particularly frustrating when the latches are intended for use in multi-component assemblies or where precise fit and function are critical. Incompatibility can lead to increased costs due to redesign, re-engineering, and additional testing phases, ultimately affecting project timelines and budgets.

The Solution: To ensure compatibility, conduct a thorough assessment of the existing systems where the board latches will be used. Create a detailed list of the dimensions, materials, and operational requirements of the current setup. When evaluating potential board latches, prioritize those that offer adjustable features or come with customizable options. Collaborate closely with your engineering team and suppliers during the selection process, discussing any potential integration challenges upfront. Furthermore, consider suppliers who provide technical support or consultation services to assist in the compatibility evaluation. This collaborative approach will facilitate a smoother integration process and help avoid costly modifications down the line.

Scenario 3: Managing Inventory and Supply Chain Risks

The Problem: B2B buyers often face inventory management challenges related to board latches, especially when dealing with fluctuating demand or unpredictable supply chain disruptions. This unpredictability can lead to overstocking, which ties up capital, or understocking, which can delay production and fulfillment schedules. Additionally, international shipping can introduce further complications, such as delays or increased costs due to tariffs and customs issues.

The Solution: Implement a robust inventory management system that utilizes demand forecasting tools to analyze trends and predict future needs accurately. Establish strong relationships with multiple suppliers to diversify your sourcing options and mitigate supply chain risks. Consider adopting a just-in-time (JIT) inventory strategy, which minimizes excess stock and reduces storage costs while ensuring that you have the necessary components on hand when demand spikes. Additionally, keep abreast of global trade developments that could impact shipping costs and timelines, and maintain an emergency buffer stock of critical components. This proactive strategy will enhance your ability to respond to market changes while maintaining a healthy cash flow.

Strategic Material Selection Guide for board latch

What Materials Are Commonly Used for Board Latches?

When selecting materials for board latches, it is essential to consider various factors such as durability, cost, and specific application requirements. Below, we analyze four common materials used in the manufacturing of board latches, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform as a Material for Board Latches?

Key Properties: Steel is renowned for its strength and durability, with a high tensile strength rating. It can withstand significant mechanical stress and has good resistance to wear and tear. However, its susceptibility to corrosion necessitates protective coatings or treatments.

Pros & Cons: The primary advantage of steel is its robustness, making it suitable for heavy-duty applications. It is relatively cost-effective compared to other metals. However, the need for corrosion protection can increase manufacturing complexity and costs. Additionally, in humid or coastal environments, untreated steel may degrade quickly.

Impact on Application: Steel latches are compatible with a wide range of media, including liquids and gases, but may not be suitable for environments with high humidity unless properly treated.

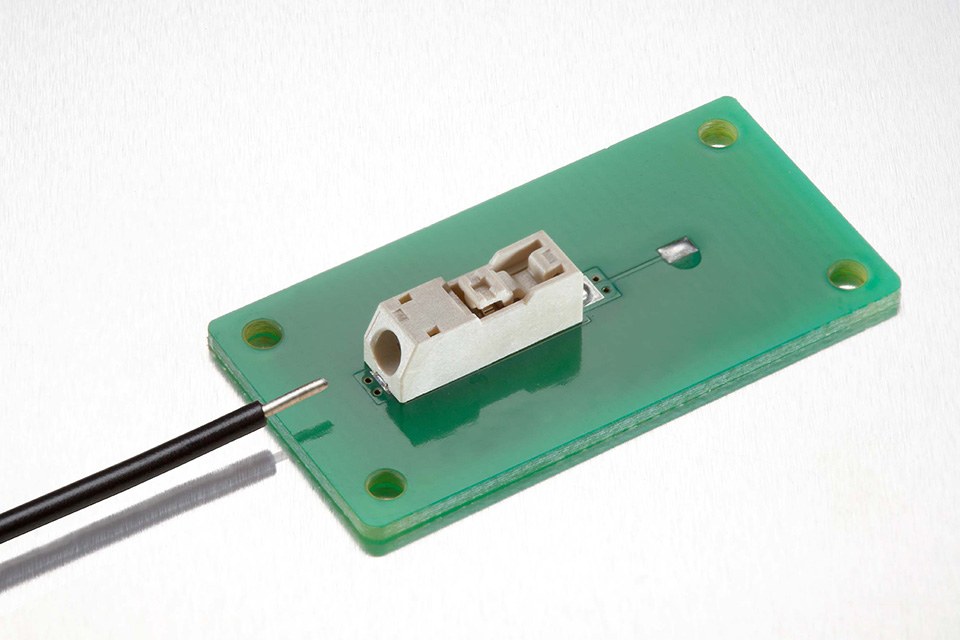

Illustrative image related to board latch

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers in regions like Europe may prefer stainless steel options to meet corrosion resistance requirements, especially in marine environments.

What Role Does Plastic Play in Board Latch Manufacturing?

Key Properties: Plastic latches are lightweight and can be engineered for specific properties, such as UV resistance and impact strength. They typically have lower temperature and pressure ratings compared to metals.

Pros & Cons: The primary advantage of plastic is its versatility and low cost, making it suitable for a variety of applications, including educational toys and light-duty latches. However, plastic may not offer the same durability as metal options and can degrade under extreme temperatures or chemical exposure.

Impact on Application: Plastic latches are ideal for environments where weight is a concern, and they are often used in applications that do not require heavy load-bearing capabilities.

Considerations for International Buyers: Buyers should ensure that the plastic materials comply with safety standards relevant to their region, such as REACH in Europe or ASTM standards in the U.S. Additionally, the choice of plastic may be influenced by local preferences for recyclable materials.

How Does Aluminum Compare as a Material for Board Latches?

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance due to its natural oxide layer. It has good thermal and electrical conductivity, making it versatile for various applications.

Pros & Cons: The key advantage of aluminum is its lightweight nature combined with strength, making it suitable for portable applications. However, it can be more expensive than steel and may not be as strong under heavy loads.

Impact on Application: Aluminum latches are suitable for applications where weight savings are critical, such as in aerospace or automotive industries. They are also compatible with various environmental conditions due to their corrosion resistance.

Considerations for International Buyers: Compliance with international standards such as ISO 9001 for quality management is essential. Buyers in regions like Germany may prioritize aluminum for its lightweight properties in automotive applications.

What Are the Benefits of Using Brass for Board Latches?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and aesthetic appeal. It has good machinability and can withstand moderate mechanical stress.

Pros & Cons: The primary advantage of brass is its durability and resistance to tarnishing, making it suitable for decorative applications. However, brass can be more expensive than other materials and may not be suitable for heavy-duty applications.

Impact on Application: Brass latches are often used in applications where aesthetics are important, such as in furniture or decorative cabinetry. They are compatible with various media but may not withstand extreme conditions.

Illustrative image related to board latch

Considerations for International Buyers: Buyers should consider compliance with standards such as ASTM B36 for brass alloys. In regions like South America, preferences for traditional materials may influence the choice of brass for decorative applications.

Summary Table of Material Selection for Board Latches

| Material | Typical Use Case for board latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High strength and durability | Susceptible to corrosion without treatment | Medium |

| Plastic | Educational toys, light-duty latches | Lightweight and cost-effective | Lower durability and temperature resistance | Low |

| Aluminum | Aerospace and automotive applications | Lightweight with good corrosion resistance | Higher cost than steel | High |

| Brass | Decorative cabinetry and furniture | Attractive finish and corrosion resistance | Not suitable for heavy loads | Medium |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their specific application needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for board latch

What Are the Key Manufacturing Processes for Board Latches?

The manufacturing of board latches involves several critical stages that ensure the final product meets both functional and safety standards. Each stage is designed to enhance the quality, durability, and reliability of the board latch, making it suitable for various applications, from home appliances to industrial machinery.

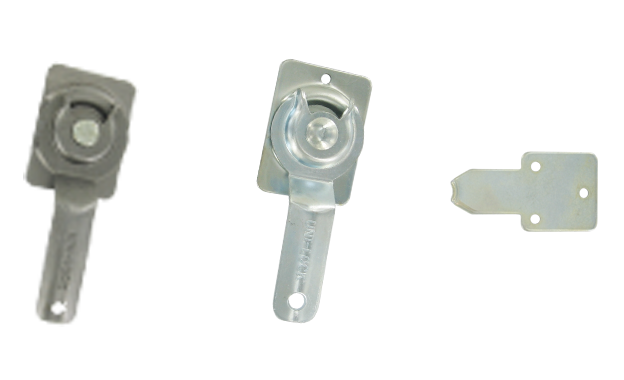

Material Preparation: What Materials Are Used in Board Latch Manufacturing?

The first step in manufacturing board latches is the selection and preparation of materials. Common materials include high-strength steel, brass, and sometimes plastic composites. Each material is chosen based on its specific properties such as strength, corrosion resistance, and weight.

Illustrative image related to board latch

During material preparation, raw materials undergo cutting, shearing, and surface treatment processes. Steel and brass components may be treated with anti-corrosive coatings to enhance durability, especially for applications in humid or outdoor environments. The preparation phase is crucial as it lays the groundwork for the structural integrity of the board latch.

How Are Board Latches Formed?

The forming process is where raw materials are transformed into their desired shapes. This typically involves techniques such as stamping, forging, or machining.

-

Stamping: This method uses dies to shape flat metal sheets into various components of the latch. It is cost-effective for high-volume production.

-

Forging: This technique involves shaping metal using localized compressive forces. Forged components tend to have better mechanical properties due to the refinement of the grain structure.

-

Machining: For precision components, machining processes like CNC milling and turning are employed. This ensures tight tolerances and high-quality finishes.

Each of these techniques is selected based on the specific design requirements and the expected load-bearing capacity of the latch.

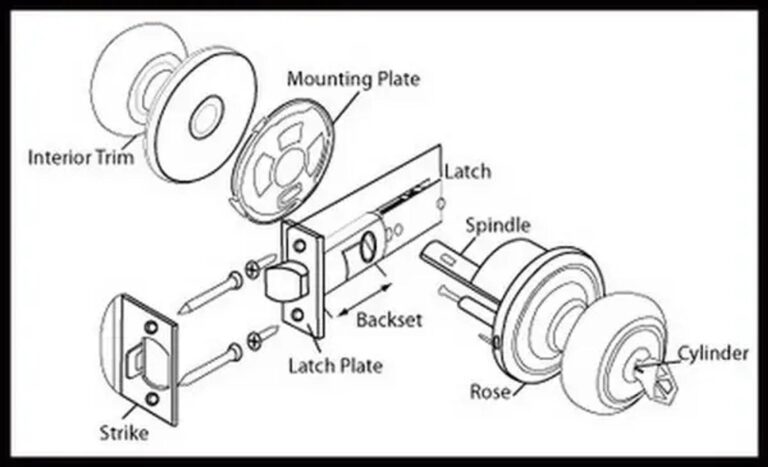

What Does the Assembly Process Involve?

Once the individual components are formed, they move to the assembly stage. This phase involves:

-

Joining Techniques: Components are assembled using various methods, including riveting, welding, or using screws and fasteners. The choice of joining technique can affect the latch’s durability and ease of disassembly.

-

Integration of Features: Many board latches incorporate features like locking mechanisms, springs, or electronic components. Careful attention is paid to ensure these components function correctly within the assembly.

-

Quality Checks: Assemblers perform visual inspections and functional tests to ensure that all components fit correctly and operate as intended before moving on to finishing.

What Finishing Techniques Are Used for Board Latches?

The finishing stage enhances both the aesthetic appeal and functional performance of board latches. Common finishing processes include:

Illustrative image related to board latch

-

Coating: Protective coatings, such as powder coating or electroplating, are applied to prevent rust and enhance appearance.

-

Polishing: Some latches undergo polishing to achieve a smooth surface finish, which can improve their resistance to wear and tear.

-

Final Inspection: A final quality check is conducted to ensure that the latch meets all specifications and standards before packaging and shipping.

How Is Quality Assurance Implemented in Board Latch Manufacturing?

Quality assurance (QA) is critical to the manufacturing process, ensuring that board latches not only meet customer expectations but also comply with international and industry-specific standards.

Which International Standards Are Relevant for Board Latch Quality Assurance?

The manufacturing of board latches often adheres to several international standards:

-

ISO 9001: This standard outlines criteria for a quality management system, ensuring that organizations consistently provide products that meet customer and regulatory requirements.

-

CE Marking: In Europe, products must meet certain safety, health, and environmental protection standards to receive CE marking, indicating compliance.

-

API Standards: For latches used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is essential.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is implemented at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process. This includes checking dimensions, surface finishes, and functional aspects of components.

-

Final Quality Control (FQC): Once assembly is complete, a thorough inspection is conducted. This may include functional testing, load testing, and dimensional checks to confirm that the finished product meets all requirements.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, it’s essential to ensure that suppliers maintain high-quality standards. Here are some strategies to verify QC processes:

-

Supplier Audits: Conducting on-site audits can provide insight into the manufacturing processes, quality control measures, and overall operational efficiency of the supplier.

-

Quality Reports: Requesting detailed QC reports can help buyers understand the supplier’s adherence to standards and their historical performance concerning quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and compliance with international standards.

What Are the Nuances of Quality Certification for International B2B Buyers?

International buyers must navigate various certification requirements that can differ significantly by region:

-

Documentation: Ensure that all certifications are properly documented and available for review. This includes compliance certificates, test reports, and quality management system certifications.

-

Cultural Considerations: Understanding local regulations and standards in the supplier’s country can impact the quality assurance process. Buyers should familiarize themselves with these to ensure compliance.

-

Shipping and Logistics: Quality assurance does not end at manufacturing. Buyers should also consider the logistics involved in shipping, as improper handling can affect the quality of the product upon arrival.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when selecting suppliers for board latches, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘board latch’

In the competitive landscape of international B2B procurement, sourcing the right board latch can significantly impact your product’s functionality and reliability. This guide provides a step-by-step checklist to streamline your sourcing process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your board latch. Consider factors such as size, weight capacity, and material durability. This step is essential as it helps narrow down options that meet your specific application needs, whether for industrial use, electronics, or consumer products.

- Material Considerations: Look for latches made from corrosion-resistant materials if used in outdoor or humid environments.

- Load Requirements: Ensure the latch can withstand the maximum load it will face in practical use.

Step 2: Research the Market Landscape

Conduct thorough market research to understand the various types of board latches available. This includes examining different designs, functionalities, and pricing structures. By gaining a comprehensive view of the market, you can identify products that best fit your specifications and budget.

- Competitive Analysis: Compare products from multiple suppliers to ensure you are aware of the best options available.

- Industry Trends: Stay updated on innovations in latch design that could enhance functionality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request company profiles, product catalogs, and references from past clients, particularly those within your industry or region. This vetting process helps ensure that you partner with a reliable supplier who can meet your quality standards.

- Supplier Reputation: Look for reviews and testimonials from other businesses to gauge reliability.

- Certifications: Verify that suppliers have relevant certifications, which can indicate adherence to industry standards.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the board latches. Testing these samples in real-world conditions is essential to assess their functionality and durability. This step can save you from costly mistakes later in the procurement process.

- Performance Testing: Evaluate how the latch operates under stress or in varying environmental conditions.

- User Feedback: If applicable, gather input from end-users to ensure the latch meets their expectations.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your chosen supplier to negotiate favorable terms and pricing. This includes establishing payment terms, delivery schedules, and warranty conditions. A well-negotiated contract can lead to long-term cost savings and better supply chain stability.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Delivery Assurance: Ensure that the supplier can meet your timelines without compromising quality.

Step 6: Finalize the Order and Monitor Delivery

After agreeing on terms, finalize your order while ensuring all specifications and terms are documented. Once the order is placed, monitor the delivery process closely to ensure compliance with agreed timelines and quality standards.

- Tracking: Use tracking tools to keep tabs on shipment progress.

- Quality Checks: Prepare to conduct quality checks upon receipt to confirm that the products meet your specifications.

By following this checklist, you will enhance your sourcing process for board latches, ensuring that you select a product that meets your technical requirements and aligns with your business goals.

Comprehensive Cost and Pricing Analysis for board latch Sourcing

What Are the Key Cost Components in Board Latch Manufacturing?

When analyzing the cost structure of board latches, several key components must be considered. The primary cost drivers include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include various metals (e.g., brass, stainless steel) and plastics. Higher-quality materials often come with increased costs but can enhance durability and performance.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor for precision work may demand higher wages, especially in regions with a strong manufacturing presence.

-

Manufacturing Overhead: This includes costs associated with factory utilities, equipment maintenance, and facility management. Efficient operations can help minimize overhead, contributing to lower overall costs.

-

Tooling: Custom tooling is often necessary for specialized latch designs. Initial tooling investments can be high but are amortized over larger production runs.

-

Quality Control: Ensuring product quality through rigorous QC processes incurs additional costs but is essential for maintaining compliance with industry standards and certifications.

-

Logistics: Transportation and warehousing costs also play a crucial role, particularly for international shipments. Factors such as shipping method and distance can vary costs significantly.

-

Margin: Finally, the manufacturer’s profit margin will depend on the overall cost structure and market demand, influencing the final pricing strategy.

How Do Pricing Influencers Affect Board Latch Sourcing?

Several factors influence the pricing of board latches, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lower the per-unit cost due to economies of scale. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Customized latches that meet specific design requirements often cost more due to the additional engineering and production processes involved.

-

Material Quality and Certifications: Latches that require specific certifications (e.g., safety, environmental) may incur higher costs. Buyers should assess whether these certifications are necessary for their target markets.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can significantly impact pricing. Established suppliers may charge more but offer better quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) affect shipping responsibilities and costs. Understanding these terms can help buyers manage logistics expenses effectively.

What Are Effective Negotiation Strategies for Board Latch Procurement?

When sourcing board latches, B2B buyers should consider several negotiation strategies to optimize costs:

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and benefit from bulk pricing. This can lead to significant savings over time.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, replacements, and logistics. A higher upfront cost may lead to lower TCO if the product is more durable.

-

Request Multiple Quotes: Engaging with several suppliers can provide a clearer picture of market pricing and leverage in negotiations.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing, improved service, and priority treatment during supply shortages.

-

Be Aware of Regional Pricing Nuances: Prices can vary significantly across regions, influenced by local market conditions, economic factors, and currency fluctuations. Buyers in Africa, South America, the Middle East, and Europe should be aware of these variances when negotiating.

What Should International Buyers Keep in Mind Regarding Indicative Pricing?

It is crucial for international buyers to understand that indicative pricing can fluctuate based on market demand, material availability, and geopolitical factors. Always request a detailed breakdown of costs from suppliers to avoid unexpected charges. Moreover, consider the potential impact of tariffs and taxes on the final landed cost of products. By being informed and proactive, buyers can make strategic decisions that optimize their sourcing of board latches.

Alternatives Analysis: Comparing board latch With Other Solutions

When evaluating the efficacy of a board latch, it is essential to consider various alternative solutions that can fulfill similar functions. Each alternative presents unique advantages and disadvantages, making it crucial for international B2B buyers to assess their specific needs before making a decision. This analysis will compare board latches with two viable alternatives: magnetic locks and electronic locking systems.

Illustrative image related to board latch

| Comparison Aspect | Board Latch | Magnetic Lock | Electronic Locking System |

|---|---|---|---|

| Performance | Reliable and sturdy for basic locking needs. | Excellent for quick access; may not be as secure. | High security with customizable access control. |

| Cost | Generally low-cost; affordable for bulk purchases. | Moderate cost; slightly higher than board latches. | Higher initial investment; ongoing costs for maintenance. |

| Ease of Implementation | Simple installation; requires basic tools. | Easy to install; may need alignment adjustments. | Requires professional installation and setup. |

| Maintenance | Low maintenance; durable materials. | Minimal maintenance; occasional battery checks. | Higher maintenance; battery replacements and software updates needed. |

| Best Use Case | Ideal for basic security in schools, homes, and low-security environments. | Suitable for commercial spaces needing quick access. | Best for high-security areas requiring controlled access. |

What are the advantages and disadvantages of using magnetic locks as an alternative to board latches?

Magnetic locks are a popular alternative due to their ability to provide quick access without the need for mechanical keys. They are often used in commercial settings where frequent entry and exit are required. The primary advantage of magnetic locks is their ease of use; they can be opened with a swipe card or fob, making them efficient for high-traffic areas. However, they may not offer the same level of security as a board latch, especially if not properly installed, and they can be more susceptible to power outages unless equipped with backup systems.

How does an electronic locking system compare to a board latch?

Electronic locking systems provide advanced security features such as remote access and audit trails, making them suitable for high-security applications. Their primary advantage is the ability to customize access levels for different users, which is invaluable in businesses that require strict entry control. However, these systems typically come with a higher initial cost and may require professional installation. Additionally, ongoing maintenance and potential software updates can add to the total cost of ownership, making them less appealing for businesses with tighter budgets.

How should B2B buyers select the right locking solution for their needs?

When choosing the right solution, B2B buyers should consider the specific requirements of their environment, including security needs, ease of use, and budget constraints. For basic locking needs in educational or residential settings, board latches provide an affordable and reliable option. In contrast, businesses seeking quick access solutions may find magnetic locks more suitable, while those requiring stringent security measures should invest in electronic locking systems. Ultimately, the choice will depend on balancing cost, security, and functionality to meet the unique demands of each application.

Essential Technical Properties and Trade Terminology for board latch

When sourcing board latches for your business, understanding the technical properties and industry terminology is crucial for making informed purchasing decisions. Below are key specifications and trade terms that every B2B buyer should be familiar with.

What Are the Essential Technical Properties of Board Latches?

1. Material Grade

Board latches are commonly made from materials such as stainless steel, brass, or high-grade plastic. The material grade significantly affects the latch’s durability, resistance to corrosion, and overall lifespan. For B2B buyers, selecting the right material is essential to ensure that the latch can withstand the intended environment, whether it’s for outdoor use or in a high-humidity area.

Illustrative image related to board latch

2. Load Rating

The load rating indicates the maximum weight the latch can securely hold. This is particularly important in applications like cabinetry or industrial equipment, where inadequate load-bearing could lead to failure. Buyers should always verify the load rating to align it with their specific use case, thus preventing operational failures.

3. Tolerance

Tolerance refers to the permissible limits of variation in the dimensions of the latch. This specification is critical in ensuring that the latch fits precisely within its designated space. High tolerance levels lead to better performance and reliability, making it essential for B2B buyers to consider during procurement.

4. Finish Type

Board latches can come in various finishes such as matte, polished, or coated. The finish not only impacts aesthetics but also affects corrosion resistance and friction levels. Selecting the right finish is crucial for ensuring that the latch performs well under specific conditions, such as exposure to moisture or chemicals.

5. Installation Type

Different board latches may require different installation methods, such as screw-in, snap-in, or adhesive types. Understanding the installation requirements is vital for operational efficiency and ease of use. Buyers should assess whether the installation type aligns with their existing infrastructure to avoid complications.

6. Safety Features

Many board latches come equipped with safety features such as child-proof locks or tamper-resistant designs. For B2B buyers, particularly those in education or childcare sectors, selecting latches with enhanced safety features can mitigate risks and enhance user security.

What Are the Common Trade Terms Used in the Board Latch Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding this term is important for buyers looking to procure board latches that are compatible with existing systems and machinery.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers to understand, as it impacts inventory management and cash flow. Knowing the MOQ can help businesses plan their purchases more effectively.

3. RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on specific products or services. For businesses looking to procure board latches, issuing an RFQ can streamline the procurement process, enabling them to compare prices and specifications from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery timelines, which are essential for effective supply chain management.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving it. This is a crucial factor for businesses to consider when planning their inventory and production schedules. Knowing the lead time allows buyers to manage expectations and maintain operational efficiency.

6. Certification Standards

Certification standards, such as ISO or ASTM, ensure that products meet specific quality and safety criteria. For B2B buyers, sourcing board latches that comply with these standards can enhance product reliability and customer satisfaction.

Illustrative image related to board latch

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing board latches, ultimately leading to more efficient operations and better product outcomes.

Navigating Market Dynamics and Sourcing Trends in the board latch Sector

What Are the Key Trends Driving the Global Board Latch Market?

The board latch market is influenced by several global drivers, notably the increasing demand for secure and user-friendly mechanisms in various industries, including construction, automotive, and consumer goods. Technological advancements have led to the development of innovative latch designs that enhance functionality and durability. For instance, the rise of smart home technologies has prompted manufacturers to integrate electronic latches, which are gaining popularity among international B2B buyers.

Emerging sourcing trends highlight a shift towards just-in-time manufacturing, allowing companies to reduce inventory costs and respond quickly to market changes. This is particularly relevant for buyers in Africa, South America, the Middle East, and Europe, where supply chain agility is paramount. Additionally, the growing importance of e-commerce has spurred the demand for efficient logistics solutions, enabling buyers to access a broader range of products, including specialized board latches, with ease.

Market dynamics also reveal a competitive landscape characterized by a mix of established players and new entrants. B2B buyers must navigate these dynamics by assessing factors such as product quality, supplier reliability, and pricing strategies. Understanding regional variations in demand, particularly in emerging markets, is crucial for making informed sourcing decisions.

How Are Sustainability and Ethical Sourcing Shaping the Board Latch Sector?

The emphasis on sustainability is reshaping the board latch sector, with buyers increasingly prioritizing products that have a minimal environmental impact. Manufacturers are responding by adopting eco-friendly materials and processes. For instance, using sustainably sourced wood or recyclable metals not only meets buyer expectations but also appeals to a growing consumer base that values environmental responsibility.

Ethical sourcing is another critical aspect for B2B buyers. Ensuring that suppliers adhere to fair labor practices and responsible environmental policies is essential for maintaining brand integrity and compliance with international regulations. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) provide assurance that products are sourced responsibly.

Moreover, incorporating ‘green’ materials into product designs can enhance marketability. Buyers who prioritize sustainable sourcing can differentiate themselves in competitive markets, particularly in regions such as Europe, where regulatory frameworks are increasingly stringent regarding sustainability practices. Emphasizing these values can also foster stronger relationships with consumers, who are more inclined to support brands that align with their ethical standards.

What Is the Evolution of Board Latch Technology and Its Significance for B2B Buyers?

The evolution of board latch technology has been marked by significant advancements in design and functionality. Initially, board latches were primarily mechanical devices, relying on basic locking mechanisms. Over the years, innovations have introduced more complex systems that combine mechanical reliability with electronic components, enhancing security and ease of use.

The introduction of smart latches, which can be controlled remotely via mobile applications, exemplifies this shift. These technologies not only cater to the growing demand for automation but also align with the preferences of modern consumers and businesses alike. For B2B buyers, understanding this evolution is crucial, as it informs purchasing decisions that impact product offerings and market competitiveness.

Additionally, the historical context of board latches underscores the importance of quality and reliability. As the demand for safety and security in various applications grows, buyers must ensure that their sourcing strategies align with the latest technological advancements, ultimately leading to better product performance and customer satisfaction.

Frequently Asked Questions (FAQs) for B2B Buyers of board latch

-

How do I determine the right type of board latch for my application?

Selecting the right board latch involves understanding the specific requirements of your application. Consider factors such as the latch’s intended use (e.g., security, convenience), the materials you will be working with, and the environmental conditions (e.g., exposure to moisture or chemicals). Consult product specifications, including load capacity and durability ratings, and engage with suppliers for recommendations tailored to your needs. It’s also beneficial to review case studies or product testimonials related to similar applications. -

What is the best board latch for securing sensitive equipment?

For securing sensitive equipment, look for board latches that offer robust locking mechanisms, such as deadbolts or keyed locks, which provide higher security. Latches made from corrosion-resistant materials, like stainless steel or brass, are ideal for durability. Additionally, consider latches that offer features like tamper-proof designs or those that can be integrated with electronic locking systems for enhanced security. Engaging with manufacturers to explore options that meet safety standards can also be beneficial. -

What are the typical minimum order quantities (MOQs) for board latches?

Minimum order quantities (MOQs) for board latches can vary significantly depending on the manufacturer and the specific product. Common MOQs range from 100 to 1,000 units, but many suppliers may accommodate smaller orders, especially for custom designs. It’s advisable to inquire directly with suppliers about their MOQs, as well as any discounts available for larger orders, which can significantly affect your overall procurement costs. -

How can I vet suppliers for board latches effectively?

Vetting suppliers involves a combination of research and direct engagement. Start by checking their industry reputation through reviews, ratings, and references from previous clients. Evaluate their certifications and compliance with international quality standards, such as ISO 9001. Request samples to assess product quality firsthand and inquire about their manufacturing processes and lead times. Establishing clear communication regarding your requirements and expectations will also help you gauge their reliability and responsiveness. -

What are the common payment terms for international B2B transactions involving board latches?

Payment terms for international transactions typically vary, but common practices include a deposit upfront (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established relationships. It’s important to discuss and agree upon payment methods that protect both parties, such as letters of credit or escrow services, particularly in high-value transactions, to mitigate risks associated with international trade. -

How do I ensure quality assurance (QA) for board latches?

To ensure quality assurance, establish clear quality standards and specifications before placing an order. Request that suppliers provide documentation of their QA processes, including inspection reports and material certifications. Conduct pre-shipment inspections or audits, especially for large orders, to verify that the products meet your standards. Additionally, consider implementing a return policy or warranty agreement to safeguard against defective products. -

What logistics considerations should I keep in mind when importing board latches?

Logistics considerations include understanding shipping methods, lead times, and customs regulations specific to your region. Choose between air and sea freight based on urgency and cost-efficiency. Factor in duties, taxes, and potential tariffs that may apply to your imports. Collaborating with a freight forwarder can simplify the process by managing documentation and ensuring compliance with international shipping laws, which is crucial for timely delivery. -

Can I customize board latches for specific applications?

Yes, many manufacturers offer customization options for board latches to meet specific requirements. Customizations can include modifications in size, material, color, or locking mechanisms. When approaching suppliers, clearly outline your specifications and intended use to facilitate the design process. Be prepared for additional lead times and costs associated with custom orders, and request prototypes to evaluate before committing to larger production runs.

Top 5 Board Latch Manufacturers & Suppliers List

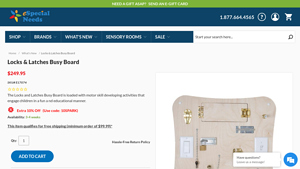

1. Especial Needs – Locks & Latches Busy Board

Domain: especialneeds.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “Locks & Latches Busy Board”, “price”: “$249.95”, “SKU”: “E17074”, “description”: “The Locks and Latches Busy Board is loaded with motor skill developing activities that engage children in a fun and educational manner. Each activity teaches children an everyday skill, helping them develop hand control, muscle strength, dexterity, and memory skills. This is an excellent choice for …

2. GE – WB10X25380 Burner Control Knob

Domain: geapplianceparts.com

Registered: 1999 (26 years)

Introduction: WB10X25380 is a genuine OEM replacement part for GE appliances. It is a burner control knob designed for various models. The part is made of durable materials to ensure longevity and reliable performance. It is essential for controlling the burner settings on your appliance.

3. TagToys – Locks & Latches Activity Board

Domain: tagtoys.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Locks & Latches Activity Board”, “price”: “$129.00”, “description”: “Free standing, large board with a wide variety of common, day-to-day, activities that require fine motor skills and eye-hand coordination.”, “features”: [“Develops hand control, muscle strength and finger dexterity”, “Improves memory skills”, “Entertains children for long periods of time”], “product_dimensions”:…

4. FiveTK – M.2 Board Latch

Domain: fivetk.com

Registered: 2005 (20 years)

Introduction: M.2 Board Latch offers a convenient, tool-free solution for securing M.2 SSDs with a simple push-to-lock/unlock mechanism. Variants include Double M.2 Board Latch and Buckle Lock. Designed for quick installation and disassembly, it maximizes space utilization and is suitable for various server appliances.

5. GE Appliances – BOARD LATCH WB02X21787

Domain: geappliances.com

Registered: 1996 (29 years)

Introduction: BOARD LATCH – Model #: WB02X21787 – Price: $10.82 – Clearance Sale – This model is no longer being manufactured.

Strategic Sourcing Conclusion and Outlook for board latch

In the ever-evolving landscape of board latch sourcing, strategic partnerships are vital for navigating the complexities of international markets. By focusing on high-quality materials and innovative designs, suppliers can cater to diverse applications, from educational tools to advanced electronic devices. The growing demand for durable and secure latching solutions emphasizes the need for manufacturers to invest in robust supply chains and reliable logistics.

Illustrative image related to board latch

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must prioritize sourcing strategies that align with their specific market needs. This involves assessing local regulations, understanding consumer preferences, and evaluating supplier capabilities to ensure compliance and quality. Engaging with suppliers who demonstrate a commitment to sustainability and ethical practices can also enhance brand reputation and customer loyalty.

As we look to the future, the board latch market presents exciting opportunities for innovation and growth. International B2B buyers are encouraged to leverage these insights to forge strategic alliances that not only meet current demands but also anticipate future trends. Embrace the journey of strategic sourcing and position your business for success in an increasingly interconnected world.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to board latch