A B2B Buyer’s Guide to Blueprint Tubes: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for blueprint tubes

Navigating the complexities of sourcing blueprint tubes can be a daunting challenge for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. As businesses expand their operations globally, the need for reliable and high-quality storage solutions for important documents, architectural plans, and artwork becomes paramount. Blueprint tubes not only protect these valuable items but also facilitate their safe transportation, making them indispensable in various industries, including architecture, engineering, and design.

This comprehensive guide delves into the multifaceted world of blueprint tubes, covering essential topics such as different types available in the market, their various applications, and critical factors for supplier vetting. Additionally, it addresses cost considerations and best practices for procurement, ensuring that buyers can navigate the global landscape with confidence. By arming B2B buyers with the knowledge needed to make informed purchasing decisions, this guide empowers them to identify the best solutions tailored to their unique operational needs.

Whether you are in Saudi Arabia looking to streamline your architectural firm’s supplies, or in Vietnam sourcing quality materials for educational purposes, understanding the nuances of blueprint tubes will enhance your procurement strategy and ultimately drive business success.

Understanding blueprint tubes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Telescoping Drafting Tubes | Adjustable lengths, durable construction, shoulder strap | Architecture, Engineering, Art, Education | Pros: Versatile for various document sizes, portable. Cons: Potential for wear at adjustable joints. |

| Square Mailing Tubes | Rigid square design, often made from cardboard or plastic | Shipping blueprints, art, and documents | Pros: Space-efficient for storage, sturdy protection. Cons: Limited to specific document dimensions. |

| Large Diameter Tubes | Wider diameter options, often over 5 inches | Large-format printing, oversized documents | Pros: Accommodates larger documents, robust protection. Cons: Bulkier and may be less portable. |

| Heavy-Duty Tubes | Reinforced materials, extra durability | Industrial applications, long-term storage | Pros: Extreme durability, ideal for heavy items. Cons: Higher cost, heavier weight. |

| Eco-Friendly Tubes | Made from recycled materials, biodegradable options | Sustainable businesses, environmentally conscious firms | Pros: Reduces carbon footprint, appeals to eco-minded buyers. Cons: May have a higher price point. |

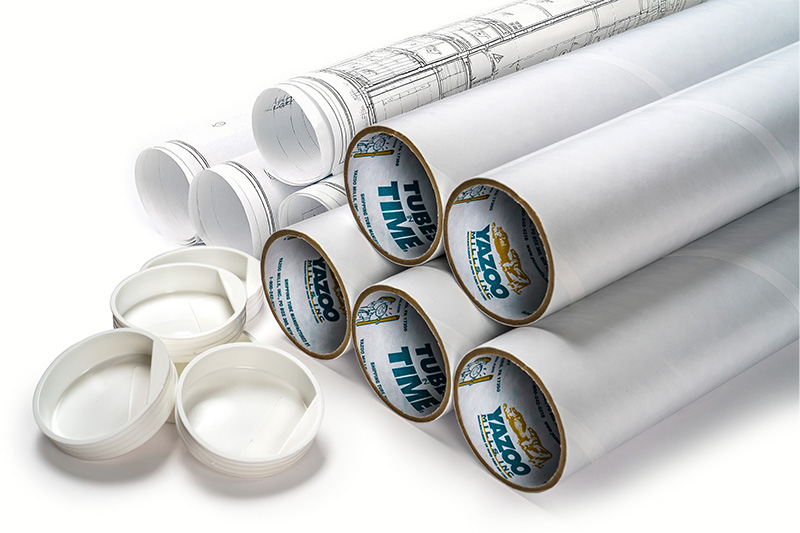

What Are Telescoping Drafting Tubes and Their Benefits for B2B Buyers?

Telescoping drafting tubes are highly versatile storage solutions that can be adjusted in length, making them ideal for transporting various sizes of blueprints, artwork, or documents. Typically constructed from durable plastic, these tubes often come with shoulder straps for easy carrying. B2B buyers, particularly in industries like architecture and engineering, value their portability and adaptability, allowing for the secure transport of important documents without damage.

How Do Square Mailing Tubes Serve Businesses?

Square mailing tubes are designed for shipping and storing documents in a more space-efficient manner than traditional cylindrical tubes. Their rigid structure provides excellent protection against crushing and bending, making them suitable for mailing blueprints and large-format prints. Businesses focused on shipping efficiency and document integrity will find these tubes advantageous, though their dimensions may limit the types of documents they can accommodate.

Illustrative image related to blueprint tubes

What Makes Large Diameter Tubes Ideal for Oversized Documents?

Large diameter tubes are specifically designed for oversized documents, providing ample space to prevent crumpling or folding. These tubes, often exceeding 5 inches in diameter, are perfect for industries that require the transport of large-scale prints, such as construction or large architectural designs. While they offer robust protection, buyers should consider their bulkiness, which may affect portability and storage options.

Why Choose Heavy-Duty Tubes for Industrial Applications?

Heavy-duty tubes are constructed from reinforced materials, providing exceptional durability for storing or transporting items that require extra protection. They are particularly beneficial for industrial applications where documents may be subject to rough handling or extreme conditions. Although these tubes come with a higher price tag and added weight, their long-term reliability often justifies the investment for businesses requiring robust storage solutions.

What Are the Advantages of Eco-Friendly Tubes for Sustainable Businesses?

Eco-friendly tubes are increasingly popular among businesses that prioritize sustainability. Made from recycled materials or designed to be biodegradable, these tubes help reduce environmental impact. B2B buyers in sectors focused on green practices will appreciate the alignment with their values, although they may face a higher upfront cost compared to conventional options. Investing in eco-friendly tubes can enhance a company’s reputation and appeal to environmentally conscious clients.

Key Industrial Applications of blueprint tubes

| Industry/Sector | Specific Application of blueprint tubes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Architecture & Engineering | Transporting architectural plans and blueprints | Ensures protection and preservation of critical documents | Durability, size options, and ease of transport |

| Construction | Storing and organizing construction project plans | Streamlines project management and reduces document damage | Weather-resistant materials, cost-effectiveness, and availability |

| Education | Carrying educational posters and project presentations | Enhances presentation quality and protects materials | Customization options, size variety, and affordability |

| Art & Design | Transporting artwork and design drafts | Provides secure transport and prevents damage | Lightweight materials, expandability, and aesthetic appeal |

| Shipping & Logistics | Mailing blueprints and large documents | Reduces shipping costs while ensuring document integrity | Compliance with international shipping standards and durability |

How Are Blueprint Tubes Used in the Architecture and Engineering Sectors?

In the architecture and engineering sectors, blueprint tubes serve as essential carriers for transporting architectural plans, engineering schematics, and project documentation. These tubes protect sensitive documents from environmental factors such as moisture and physical damage during transit. Buyers in this sector should prioritize durability and size options to accommodate various document dimensions, ensuring secure transport without compromising the integrity of critical designs.

What Role Do Blueprint Tubes Play in the Construction Industry?

In construction, blueprint tubes are vital for storing and organizing project plans, allowing teams to access essential documents easily. They help streamline project management by reducing document damage and loss, which can lead to costly delays. For international buyers, sourcing tubes that are weather-resistant and cost-effective is crucial, especially in regions prone to harsh conditions, ensuring the longevity of stored documents.

How Are Blueprint Tubes Utilized in Educational Settings?

Educational institutions frequently use blueprint tubes for carrying educational posters, project presentations, and student artwork. These tubes enhance the quality of presentations by protecting the materials from creasing and damage. Buyers in the education sector should consider customization options for branding and specific size requirements to accommodate various educational materials, ensuring that the tubes meet their unique needs.

Why Are Blueprint Tubes Important for the Art and Design Industries?

In the art and design industries, blueprint tubes are used to transport artwork and design drafts securely. They provide a reliable means of preventing damage during transit, which is critical for artists and designers who need to maintain the integrity of their work. Buyers should look for lightweight materials that also offer expandability, making it easier to transport larger pieces without compromising security or aesthetic appeal.

How Do Blueprint Tubes Benefit Shipping and Logistics Operations?

In shipping and logistics, blueprint tubes are often employed for mailing blueprints and large documents. They reduce shipping costs while ensuring that documents arrive intact, maintaining their professional appearance. For international buyers, it’s important to source tubes that comply with shipping standards in their region, focusing on durability to withstand the rigors of transportation and handling.

Illustrative image related to blueprint tubes

3 Common User Pain Points for ‘blueprint tubes’ & Their Solutions

Scenario 1: Ensuring Durability During Transportation

The Problem: B2B buyers often face the challenge of ensuring that blueprints and important documents remain intact during transport. In regions with varying climates, such as Africa or the Middle East, heat and humidity can warp or damage paper, leading to costly reprints and delays. Additionally, if the tubes are not sturdy enough, they may crush or collapse under pressure, risking the integrity of the contents inside.

The Solution: To address this issue, buyers should focus on sourcing high-quality, durable blueprint tubes specifically designed for travel. Opt for telescoping tubes that offer adjustable sizes and robust materials like heavy-duty plastic or reinforced cardboard. When placing an order, ensure that the manufacturer provides details about the tube’s resistance to environmental factors like moisture and temperature. Additionally, consider investing in tubes that come with built-in cushioning or padding to provide extra protection for the documents during transit. This proactive approach not only safeguards the documents but also reduces the risk of delays due to damaged materials.

Scenario 2: Managing Different Document Sizes

The Problem: In many industries, such as architecture or engineering, professionals often deal with a variety of document sizes, from standard A0 blueprints to custom designs. Buyers may find themselves frustrated when their storage solutions do not accommodate these varying dimensions, leading to disorganization and increased time spent searching for specific documents.

The Solution: A practical solution is to select blueprint tubes that are adjustable or come in a range of sizes. Telescoping tubes are particularly useful as they can expand or contract to fit different document lengths. When purchasing, look for suppliers that offer a variety of diameters as well, ensuring that the tube can handle multiple sheets without crumpling. Additionally, consider implementing a color-coded labeling system for different sizes or types of documents stored in the tubes. This organizational strategy will streamline access and improve efficiency, allowing teams to focus on their projects instead of searching for documents.

Scenario 3: Reducing Environmental Impact

The Problem: As sustainability becomes a priority for many businesses, B2B buyers are increasingly concerned about the environmental impact of their packaging and storage solutions. Traditional blueprint tubes often utilize non-recyclable materials, leading to waste and negative brand perception among environmentally conscious clients and stakeholders.

The Solution: Buyers should actively seek out suppliers that provide eco-friendly blueprint tubes made from recyclable or biodegradable materials. When evaluating options, inquire about the sustainability practices of the manufacturers, such as their sourcing and production processes. Additionally, consider using reusable tubes that can serve multiple purposes, thereby minimizing waste. Promote a company-wide initiative to recycle or properly dispose of old tubes, encouraging a culture of sustainability. By making informed choices about materials and practices, businesses can enhance their reputation and align with the growing demand for environmentally responsible operations.

Strategic Material Selection Guide for blueprint tubes

When selecting materials for blueprint tubes, B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of blueprint tubes: plastic, cardboard, metal, and composite materials. Each material has unique properties, advantages, and limitations that can impact the overall effectiveness of the product in diverse international markets.

What Are the Key Properties of Plastic Blueprint Tubes?

Plastic blueprint tubes, often made from PVC or polyethylene, are lightweight and flexible. They typically exhibit excellent resistance to moisture and chemicals, making them suitable for environments where exposure to elements is a concern. The temperature range for plastic tubes generally allows them to perform well in varying climates, which is particularly beneficial for international buyers from regions like Africa and the Middle East, where temperatures can fluctuate significantly.

Pros and Cons:

The primary advantage of plastic tubes is their affordability and durability. They are less prone to corrosion compared to metal options, making them ideal for long-term storage. However, they may not withstand extreme temperatures as effectively as metal tubes. Additionally, the manufacturing process can be complex, potentially increasing costs in regions with limited access to advanced production technologies.

How Do Cardboard Blueprint Tubes Compare?

Cardboard blueprint tubes are an economical choice for temporary storage and transport. They are biodegradable and recyclable, appealing to environmentally conscious buyers. The structural integrity of cardboard tubes is generally adequate for lightweight documents but may be compromised under heavy loads or in humid conditions.

Pros and Cons:

The key advantage of cardboard tubes is their low cost and ease of production. They are readily available and can be customized easily for branding purposes. However, they lack durability compared to plastic and metal options, making them less suitable for long-term storage or transport in harsh conditions. International buyers should consider local climate conditions, as cardboard may not perform well in humid or wet environments.

What Are the Benefits of Metal Blueprint Tubes?

Metal blueprint tubes, typically made from aluminum or steel, offer superior durability and protection against physical damage. They are resistant to moisture and corrosion, making them suitable for long-term storage of valuable documents. Metal tubes can also withstand higher temperatures and pressures compared to their plastic and cardboard counterparts.

Pros and Cons:

The main advantage of metal tubes is their strength and longevity, making them ideal for high-value applications. However, they tend to be more expensive and heavier, which can increase shipping costs. Additionally, the manufacturing process for metal tubes can be more complex, requiring specialized equipment that may not be readily available in all regions.

What Role Do Composite Materials Play in Blueprint Tube Production?

Composite materials, which can include a combination of plastics and metals, offer a balance between durability and weight. These materials can be engineered to provide specific properties, such as enhanced strength or flexibility, making them versatile for various applications.

Pros and Cons:

The key advantage of composite tubes is their adaptability; they can be designed to meet specific performance requirements. However, they can be more expensive due to the advanced manufacturing processes involved. International buyers should be aware of the availability of composite materials in their region and any compliance standards that may apply.

Summary Table of Material Selection for Blueprint Tubes

| Material | Typical Use Case for blueprint tubes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Long-term storage and transport | Lightweight and moisture-resistant | Limited temperature resistance | Low |

| Cardboard | Temporary storage and shipping | Economical and environmentally friendly | Not suitable for heavy loads or humid conditions | Low |

| Metal | High-value document protection | Superior durability and corrosion resistance | Higher cost and weight | High |

| Composite | Custom applications requiring flexibility | Adaptable properties for specific needs | More expensive and complex manufacturing | Med |

In conclusion, understanding the properties, advantages, and limitations of each material is crucial for international B2B buyers when selecting blueprint tubes. By considering factors such as local climate, storage needs, and compliance with regional standards, buyers can make informed decisions that align with their operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for blueprint tubes

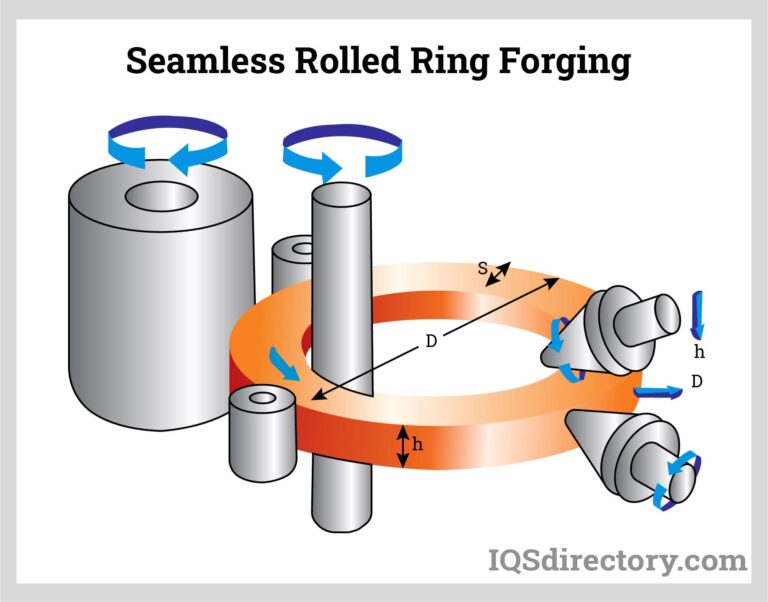

What Are the Main Stages in the Manufacturing Process of Blueprint Tubes?

The manufacturing process of blueprint tubes is a systematic approach that involves several key stages, ensuring that the final product meets the necessary quality and durability standards. This process typically encompasses material preparation, forming, assembly, and finishing.

-

Material Preparation: The first stage involves selecting high-quality raw materials, which are often made from durable plastics or cardboard. The material is sourced based on specifications that dictate the required strength, flexibility, and resistance to environmental factors. Suppliers often conduct pre-production quality checks on these materials to ensure they meet the required standards.

-

Forming: In this phase, the prepared materials are shaped into the desired dimensions for the tubes. Techniques such as extrusion or molding are commonly employed for plastic tubes, while cardboard tubes may be produced through cutting and rolling processes. Advanced technologies, like CNC (Computer Numerical Control) machining, can be utilized for precision cutting, ensuring consistency in size and shape.

-

Assembly: After forming, the tubes may require additional components, such as end caps or closures. This stage involves assembling these parts, which may be done manually or through automated systems, depending on the scale of production. Care is taken to ensure that all components fit securely to prevent any damage to the contents during transport.

-

Finishing: The final stage includes applying surface treatments or coatings to enhance the durability and aesthetics of the tubes. This may involve printing logos, adding labels, or applying protective coatings to make the tubes water-resistant or UV-resistant. Quality checks are also conducted at this stage to ensure that the finishing meets the specifications.

How Is Quality Assurance Implemented in Blueprint Tube Manufacturing?

Quality assurance is critical in the manufacturing of blueprint tubes, as it ensures that the products are safe, reliable, and meet industry standards. Several international and industry-specific standards guide this process.

-

International Standards: Compliance with ISO 9001 is fundamental for manufacturers. This standard focuses on quality management systems and requires companies to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. It emphasizes continual improvement and the implementation of effective processes.

-

Industry-Specific Certifications: Depending on the market, additional certifications may be relevant. For instance, CE marking is essential for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards. For markets in sectors like oil and gas, certifications like API (American Petroleum Institute) may be necessary, ensuring that products meet specific technical standards.

-

Quality Control Checkpoints: Effective quality control (QC) processes are established at various stages of production:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Suppliers are often required to provide certificates of compliance or test reports.

– In-Process Quality Control (IPQC): During production, random samples are taken to ensure that the manufacturing process is functioning correctly. This may include dimensional checks and material integrity tests.

– Final Quality Control (FQC): At the end of the production line, finished products undergo rigorous testing to ensure they meet specifications. This may include drop tests, load tests, and visual inspections for defects.

What Testing Methods Are Commonly Used in Quality Assurance for Blueprint Tubes?

Several testing methods are employed to verify the integrity and performance of blueprint tubes, ensuring they can withstand the rigors of transportation and storage.

-

Dimensional Inspection: This involves measuring the physical dimensions of the tubes to ensure they conform to specified tolerances. Calipers and micrometers are often used for precise measurements.

-

Impact Resistance Testing: This test evaluates how well the tubes can withstand impacts without damage. Tubes may be subjected to drop tests from specified heights to assess their durability.

-

Environmental Testing: Tubes may be exposed to various environmental conditions, such as humidity and temperature extremes, to evaluate their performance in real-world scenarios.

-

Load Testing: This method assesses the strength of the tubes by applying weight to determine how much pressure they can handle without deforming or breaking.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers maintain high-quality standards. Here are several strategies for verifying supplier QC practices:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance measures. During an audit, buyers can review documentation, observe production processes, and evaluate compliance with standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC processes in place. These reports should outline testing methods, results, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These inspections can be conducted at various stages of production, from raw material sourcing to finished product evaluation.

-

Certification Verification: Buyers should verify that suppliers possess relevant certifications, such as ISO 9001, CE, or API. This can typically be done through the certifying bodies or by requesting copies of certificates.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring product quality. Understanding the nuances of quality control and certification can help mitigate risks:

-

Regulatory Differences: Different countries have varying regulatory requirements. Buyers should familiarize themselves with local regulations that may affect product compliance, particularly when importing goods.

-

Cultural and Communication Barriers: Language differences and cultural nuances can impact the clarity of quality expectations. Establishing clear communication channels and documentation standards is crucial for successful partnerships.

-

Logistics and Supply Chain Considerations: International shipping can expose products to additional risks. Buyers should ensure that suppliers have robust packaging and handling processes to protect products during transit.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing blueprint tubes, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blueprint tubes’

When sourcing blueprint tubes, especially for international B2B transactions, a structured approach is essential. This guide outlines critical steps to ensure that you procure the right products efficiently and effectively.

Illustrative image related to blueprint tubes

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly define the specifications of the blueprint tubes you need. Consider dimensions, material type, and durability. For instance, determine whether you require telescoping tubes that can expand for larger items or standard fixed-size options. This clarity will help you communicate effectively with suppliers and streamline the selection process.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to identify those that meet your specifications. Look for companies with a strong reputation in the industry, especially those that have experience serving businesses in your target regions, such as Africa, South America, or the Middle East. Utilize platforms like LinkedIn or industry-specific forums to gather insights and reviews from previous customers.

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers. This step is crucial for ensuring product quality and safety standards, especially when dealing with international shipments. Check if suppliers have ISO certifications or other relevant quality assurance certifications that demonstrate their commitment to excellence.

Step 4: Request Product Samples

Before making a bulk purchase, always request samples of the blueprint tubes. This allows you to assess the quality, functionality, and design of the products firsthand. Pay attention to aspects such as durability, ease of use, and packaging, as these factors can significantly impact your overall satisfaction and the protection of your documents during transport.

Illustrative image related to blueprint tubes

Step 5: Discuss Pricing and Payment Terms

Engage in detailed discussions regarding pricing structures and payment terms with your selected suppliers. Ensure you understand the total cost, including shipping, taxes, and any potential customs fees. Negotiate payment terms that align with your cash flow needs, and consider using secure payment methods to protect your investment.

Step 6: Check for Shipping and Delivery Options

Inquire about the shipping methods and delivery times offered by your suppliers. Given the international scope of your business, understanding these logistics is vital. Confirm whether the supplier can accommodate specific delivery timelines and how they handle customs clearance, as this can greatly affect your project schedules.

Step 7: Establish a Long-Term Relationship

Once you have successfully sourced your blueprint tubes, consider establishing a long-term relationship with your supplier. This can lead to better pricing, priority service, and a more streamlined procurement process in the future. Regular communication and feedback will help both parties align on quality expectations and foster a mutually beneficial partnership.

By following this checklist, you can navigate the complexities of sourcing blueprint tubes effectively, ensuring that your procurement process is efficient, reliable, and tailored to your specific business needs.

Comprehensive Cost and Pricing Analysis for blueprint tubes Sourcing

What Are the Key Cost Components in Blueprint Tubes Sourcing?

When sourcing blueprint tubes, understanding the cost structure is crucial for effective budget management. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of materials used can significantly affect costs. Common materials include durable plastics, cardboard, and metal. Higher quality materials typically lead to increased durability and protection for the contents, which may justify a higher price point.

-

Labor: Labor costs can vary based on the region and the complexity of the manufacturing process. For instance, countries with lower wage standards may offer cheaper labor, thus reducing overall costs.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Custom tooling for specific designs may require significant upfront investment, which can be amortized over large production runs.

-

Quality Control (QC): Investing in quality assurance processes is essential to ensure product integrity, especially for international shipping where damage could occur. Enhanced QC measures can increase costs but also reduce returns and customer dissatisfaction.

-

Logistics: Transportation and handling costs should not be overlooked. The shipping method, distance, and packaging can all impact the final price.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This can vary greatly depending on market competition and demand.

How Do Price Influencers Impact Blueprint Tubes Pricing?

Several factors can influence the pricing of blueprint tubes, making it essential for buyers to understand these variables.

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Negotiating favorable MOQ terms can yield significant savings.

-

Specifications and Customization: Customization options such as sizes, colors, and branding can increase costs. Ensure that the specifications are well-defined to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials may come with certifications (e.g., eco-friendly, fire-retardant) that can affect pricing. Buyers should weigh the benefits of these certifications against the additional costs.

-

Supplier Factors: The supplier’s reputation, experience, and service level can influence pricing. Established suppliers may charge more for their reliability and service quality.

-

Incoterms: Understanding Incoterms is vital for international transactions as they define responsibilities between buyers and sellers regarding shipping costs, risk, and insurance. Choosing the right terms can help manage overall costs effectively.

What Tips Can Help Buyers Negotiate Better Pricing for Blueprint Tubes?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider several strategies when negotiating prices for blueprint tubes.

-

Conduct Thorough Market Research: Understanding market rates and competitor pricing can provide leverage during negotiations. Familiarize yourself with standard pricing for similar products.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs such as shipping, storage, and potential damages. A slightly higher upfront cost could lead to savings in other areas.

-

Negotiate Terms: Be prepared to negotiate payment terms, delivery schedules, and discounts for larger orders. Flexibility can yield better pricing.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing over time. Suppliers may offer discounts for repeat orders or loyalty.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and taxes that can affect the final cost. Keeping these factors in mind during negotiations can prevent unexpected expenses.

In conclusion, a comprehensive understanding of the cost structure, pricing influencers, and effective negotiation strategies can empower international B2B buyers to make informed sourcing decisions for blueprint tubes. It’s essential to approach sourcing with a well-rounded perspective to optimize costs and ensure product quality.

Alternatives Analysis: Comparing blueprint tubes With Other Solutions

Exploring Alternatives to Blueprint Tubes for Document Storage and Transport

In the realm of document storage and transport, blueprint tubes serve as a popular choice due to their durability and ease of use. However, there are alternative solutions that may better suit specific needs or preferences. This analysis aims to compare blueprint tubes with other viable options, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to blueprint tubes

| Comparison Aspect | Blueprint Tubes | Square Mailing Tubes | Drafting Tubes |

|---|---|---|---|

| Performance | Excellent protection; water-resistant | Good for flat documents; limited height | Versatile; expandable for varying sizes |

| Cost | Moderate ($20 – $70) | Low to moderate ($10 – $30) | Moderate to high ($20 – $100) |

| Ease of Implementation | Simple to use; ready for transport | Requires careful packing; less robust | Easy to use; adjustable lengths |

| Maintenance | Low; typically durable | Low; generally recyclable | Low; requires minimal cleaning |

| Best Use Case | Ideal for architects and artists | Best for mailing flat documents | Suitable for transporting oversized documents |

What are the Benefits and Drawbacks of Square Mailing Tubes?

Square mailing tubes are designed primarily for flat documents, such as blueprints, photographs, or artwork. Their square shape allows for efficient stacking and storage. On the positive side, they are generally lower in cost compared to blueprint tubes and provide decent protection for documents. However, their limited height can be a disadvantage when dealing with taller items, and they may not provide the same level of durability against water and environmental damage as blueprint tubes.

How Do Drafting Tubes Compare as an Alternative?

Drafting tubes, similar to blueprint tubes, offer a robust solution for transporting large documents. They often feature a telescoping design, allowing users to adjust the length according to their needs. This adaptability is a significant advantage, particularly for businesses that handle various document sizes. While drafting tubes can be more expensive than blueprint tubes, their versatility and durability make them a worthwhile investment for industries such as architecture and engineering. Nevertheless, they may not be as easily stackable or space-efficient as square mailing tubes.

What Should B2B Buyers Consider When Choosing the Right Solution?

When determining the most suitable storage and transport solution, B2B buyers should evaluate their specific requirements, including the types of documents they handle, the frequency of transport, and budget constraints. Blueprint tubes are ideal for those needing robust protection for oversized documents, while square mailing tubes may be better suited for flat items. Drafting tubes offer versatility but come with a higher price tag. Ultimately, the choice will depend on balancing performance with cost-effectiveness and ease of use tailored to the buyer’s operational needs.

Illustrative image related to blueprint tubes

Essential Technical Properties and Trade Terminology for blueprint tubes

What Are the Essential Technical Properties of Blueprint Tubes?

When sourcing blueprint tubes, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications that buyers should consider:

-

Material Grade: Blueprint tubes are commonly made from materials such as plastic, cardboard, or metal. Plastic tubes are lightweight and water-resistant, making them ideal for outdoor use. Cardboard tubes are generally more economical and suitable for indoor storage. Metal tubes offer durability and protection against physical damage, which is essential for long-term storage. Selecting the right material depends on the intended use and environmental conditions.

-

Diameter and Length Specifications: Blueprint tubes are available in various diameters and lengths, typically ranging from 2 to 10 inches in diameter and 25 to 62 inches in length. The diameter affects the tube’s capacity to hold rolled documents, while the length determines the maximum size of the documents it can accommodate. Understanding these dimensions is vital for ensuring that the tubes meet specific project requirements.

-

Telescoping Design: Many blueprint tubes feature a telescoping design, allowing them to be adjustable in length. This feature enhances versatility, enabling users to carry different sizes of documents without the need for multiple tubes. For B2B buyers, this can reduce inventory costs and improve logistical efficiency.

-

Wall Thickness: The wall thickness of a blueprint tube directly impacts its durability and ability to protect contents. Thicker walls provide better protection against bending or crushing during transport. Buyers should evaluate wall thickness based on the expected handling conditions to ensure adequate protection.

-

Closure Mechanism: Various closure options are available, including screw caps, snap closures, and end plugs. The chosen closure mechanism affects the ease of use and security of the contents. A secure closure is essential for protecting valuable documents during transport, making it a critical specification for B2B buyers.

Which Trade Terms Are Commonly Used in the Blueprint Tube Industry?

Understanding industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms relevant to blueprint tubes:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces components or products that are used in another company’s final product. In the context of blueprint tubes, an OEM might supply specific tube designs or materials to businesses that require customized solutions.

-

MOQ (Minimum Order Quantity): MOQ specifies the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, especially small businesses, as it affects budgeting and inventory planning. Understanding MOQ helps in negotiating orders that align with demand and financial constraints.

-

RFQ (Request for Quotation): An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. In the blueprint tube market, submitting an RFQ can help buyers compare prices, specifications, and terms from multiple suppliers, leading to better purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify who is responsible for shipping costs, insurance, and risks associated with transporting blueprint tubes across borders.

-

Lead Time: This term refers to the amount of time it takes from placing an order to the delivery of the product. For businesses relying on blueprint tubes for project deadlines, understanding lead time is essential for effective project planning and resource allocation.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing blueprint tubes, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the blueprint tubes Sector

What Are the Key Market Dynamics and Trends Influencing the Blueprint Tubes Sector?

The blueprint tubes market is experiencing significant growth driven by the increasing demand for high-quality storage solutions across various sectors, including architecture, engineering, and design. Global urbanization and infrastructure development projects in regions such as Africa, South America, and the Middle East are propelling the need for reliable packaging and transportation of blueprints and large documents. Moreover, advancements in manufacturing technologies, including the use of durable yet lightweight materials, are enhancing the product offerings available in the market.

Emerging trends show a shift towards customization and versatility in blueprint tubes, with options like telescoping designs that cater to different document sizes and storage needs. B2B buyers are increasingly looking for products that combine functionality with aesthetics, as they often serve dual purposes in professional environments. Additionally, the integration of e-commerce platforms for B2B transactions is streamlining the sourcing process, allowing buyers from diverse regions like Saudi Arabia and Vietnam to access a broader range of suppliers and products.

Illustrative image related to blueprint tubes

How Is Sustainability and Ethical Sourcing Shaping the Blueprint Tubes Market?

The importance of sustainability and ethical sourcing is becoming paramount in the blueprint tubes sector. Buyers are increasingly aware of the environmental impact of their purchasing decisions, prompting a demand for products made from recycled and eco-friendly materials. Manufacturers are responding by incorporating sustainable practices into their production processes, ensuring that their products not only meet quality standards but also align with environmental goals.

Certifications such as FSC (Forest Stewardship Council) and ISO 14001 are gaining traction, as they signify commitment to sustainable practices. B2B buyers are encouraged to seek suppliers who prioritize these certifications, as they reflect a responsible approach to sourcing. Moreover, adopting sustainable practices can enhance a company’s brand image and appeal to environmentally conscious consumers, providing a competitive advantage in the market.

What Is the Historical Context of Blueprint Tubes and Their Evolution?

Blueprint tubes have evolved significantly since their inception, originally designed for the transportation of architectural blueprints and plans. Traditionally made from paper or cardboard, early versions lacked durability and often resulted in damaged documents. Over the years, advancements in materials and design have led to the development of more robust solutions, such as plastic and composite materials that offer better protection against environmental elements.

The introduction of telescoping designs marked a turning point, allowing users to adjust the tube’s size according to the documents being stored or transported. This adaptability has made blueprint tubes an essential tool for professionals in various fields, including architecture, engineering, and art. As the market continues to grow, ongoing innovations are expected to further enhance the functionality and sustainability of blueprint tubes, catering to the evolving needs of B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of blueprint tubes

-

How do I choose the right blueprint tube for my needs?

Selecting the appropriate blueprint tube involves considering several factors. First, evaluate the size of the documents you need to transport. Telescoping tubes offer versatility in length, making them ideal for varying document sizes. Additionally, assess the tube’s diameter to ensure it accommodates your materials without bending or creasing. Material durability is also crucial; opt for tubes made from robust materials that can withstand travel and storage conditions. Lastly, consider any additional features, such as shoulder straps for ease of transport, particularly if the tubes will be used frequently. -

What are the benefits of using telescoping blueprint tubes?

Telescoping blueprint tubes are designed for flexibility and convenience. They can adjust in length to accommodate documents of different sizes, which minimizes the need for multiple tubes. This feature not only saves space but also reduces shipping costs. Additionally, these tubes are typically made from durable materials that provide protection against environmental factors, ensuring that your blueprints remain intact during transit. Their lightweight design also makes them easy to carry, which is essential for professionals on the go. -

What should I consider when sourcing blueprint tubes from international suppliers?

When sourcing blueprint tubes internationally, it is essential to evaluate the supplier’s reputation and reliability. Look for suppliers with positive reviews and a proven track record in exporting products. Understanding the supplier’s manufacturing capabilities and compliance with international standards is crucial. Additionally, assess their ability to customize products to meet your specific needs, such as size or branding. Lastly, consider the supplier’s logistics capabilities, including shipping times and costs, to ensure timely delivery of your orders. -

What are the typical minimum order quantities (MOQs) for blueprint tubes?

Minimum order quantities (MOQs) for blueprint tubes can vary significantly based on the supplier and the type of tube. Generally, MOQs can range from as low as 50 units to several hundred for custom orders. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing the market or have specific budget constraints. Some suppliers may offer lower MOQs for standard products, while custom designs might require a higher commitment. Understanding these dynamics can help you plan your inventory more effectively. -

How can I ensure the quality of blueprint tubes before purchasing?

To ensure the quality of blueprint tubes, request samples from suppliers before placing a bulk order. Inspect the materials used, the tube’s construction, and any additional features such as closures and straps. Additionally, inquire about the supplier’s quality assurance processes, including any certifications they hold. Reviews and testimonials from previous clients can provide insight into the product’s performance. Establishing a clear understanding of your quality expectations with the supplier can help prevent future issues. -

What payment terms should I expect when buying blueprint tubes internationally?

Payment terms for international purchases of blueprint tubes can vary widely among suppliers. Common options include upfront payment, partial payment with the balance due upon delivery, or payment through letters of credit. It’s advisable to clarify these terms before placing an order to avoid misunderstandings. Additionally, consider the currency exchange rates and transaction fees that may apply. Building a good relationship with your supplier can also facilitate more favorable payment terms, especially for repeat orders. -

What logistics considerations should I be aware of when importing blueprint tubes?

When importing blueprint tubes, logistics plays a critical role in ensuring timely delivery. Understand the shipping options available, including air and sea freight, and choose one that balances cost and speed according to your needs. Be aware of customs regulations in your country, including any tariffs or duties that may apply. Partnering with a reliable freight forwarder can streamline the import process and help navigate any complexities. Additionally, ensure that the packaging is robust enough to protect the tubes during transit. -

Can I customize blueprint tubes to fit my branding needs?

Yes, many suppliers offer customization options for blueprint tubes, allowing you to incorporate your branding elements. This may include printing your logo or choosing specific colors that align with your brand identity. Custom sizes and features can also be requested, depending on the supplier’s capabilities. It’s essential to discuss your requirements upfront and verify any additional costs associated with customization. Having branded packaging can enhance your professional image and improve brand recognition among clients.

Top 6 Blueprint Tubes Manufacturers & Suppliers List

1. Yazoo Mills – Blueprint Storage & Mailing Tubes

Domain: yazoomills.com

Registered: 1998 (27 years)

Introduction: Blueprint Storage & Mailing Tubes by Yazoo Mills are designed for architects to store and ship large documents like blueprints. Made from 100% recycled paperboard, these tubes offer superior crush resistance. Available in over 75 sizes, they include options such as Heavy Duty-Kraft tubes, Heavy-Duty White tubes, and Light-Duty Handout tubes. Customization options for colors and branding are availa…

2. Blueprint Tube – Durable PVC Solution

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Blueprint tube for storing blueprints/large-scale drawings, capable of holding 24×36 prints rolled up into a 4″ diameter. Recommendations include using PVC pipe as a durable, waterproof, and cost-effective solution.

3. Uline – Square Tubes for Documents

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Square Tubes recommended for storing or mailing documents, maps, and blueprints. Ships and stores flat to save warehouse space. Unique square shape for easy insertion and removal. Made from tough 200 lb. test corrugated material. Features locking tabs, eliminating the need for tape. Sold in bundle quantities with various model numbers, dimensions, weights, and prices. Available sizes include: 2x2x…

4. Engineer Supply – Drawing Tubes

Domain: engineersupply.com

Registered: 1999 (26 years)

Introduction: Drawing tubes are designed for storing large documents such as drawings, maps, artwork, posters, and blueprints. They protect contents from exterior elements, folds, and tears while being portable. Suitable for students and professionals, drawing tubes can fit into lockers, cars, or other small spaces.

5. USA Art Supply – Telescoping Adjustable Storage Tube

Domain: usartsupply.com

Registered: 2008 (17 years)

Introduction: [{‘item_number’: ‘USA DT-936’, ‘description’: ‘Telescoping Adjustable 25″ to 42″ – Durable 3-1/4″ Diameter Storage Tube – Art Poster Carrier Holder & Blueprint Storage Drafting Tube Travel & Protection’, ‘price’: ‘$23.99’}, {‘item_number’: ‘USA DT-968’, ‘description’: ‘Telescoping Adjustable 30-1/4″ to 52″ – Durable 4″ Diameter Storage Tube – Art Poster Carrier Holder & Blueprint Storage Drafting …

6. Tranzporter – Premium Poster Tubes

Domain: tranzporter.com

Registered: 1999 (26 years)

Introduction: Tranzporter poster tubes are made of 1000 denier Cordura nylon, available in 7 sizes (6 x 42″ to 8 x 62″). They feature a ¼” walled cardboard insert for stability, a lockable zippered top, exterior zippered pocket, carrying handles, and a detachable shoulder strap. Optional poster tube wheels are available. Price range: $60.00 – $225.00. Monogramming available for $15.00 per line, with specialty l…

Strategic Sourcing Conclusion and Outlook for blueprint tubes

In conclusion, strategic sourcing of blueprint tubes is critical for international B2B buyers looking to enhance their operational efficiency and product delivery. By investing in high-quality, versatile solutions such as telescoping drafting tubes and protective storage options, businesses can ensure the safety of important documents during transit and storage. The diverse offerings available in the market cater to a wide range of needs, from architects and artists to construction firms, making it essential for buyers to align their sourcing strategies with their specific requirements.

Furthermore, engaging with reliable suppliers who understand regional logistics and compliance can streamline procurement processes and reduce costs. As markets in Africa, South America, the Middle East, and Europe continue to evolve, embracing innovative sourcing solutions will empower businesses to remain competitive and responsive to customer demands.

As we look to the future, now is the time for international buyers to reassess their supply chains and invest in robust, scalable solutions for blueprint tubes. Take action today to strengthen your sourcing strategies and position your organization for success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.