A B2B Buyer’s Guide to Big Concrete Molds: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for big concrete molds

Navigating the global market for big concrete molds presents unique challenges for international B2B buyers, particularly when it comes to sourcing reliable and high-quality products. With the increasing demand for durable and versatile molds in construction and decorative applications, understanding the nuances of the market is crucial. This comprehensive guide will delve into the various types of big concrete molds available, their specific applications across industries, and key factors to consider when vetting suppliers.

Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam, will find actionable insights tailored to their unique purchasing needs. We will address critical aspects such as pricing strategies, shipping logistics, and the importance of supplier reliability in ensuring timely project execution.

By equipping you with the knowledge to make informed purchasing decisions, this guide empowers you to select the right big concrete molds that not only meet your specifications but also enhance your operational efficiency. Whether you are looking for molds for construction projects, decorative elements, or innovative DIY solutions, understanding the global landscape will position you to negotiate effectively and achieve the best value for your investment.

Understanding big concrete molds Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicone Molds | Flexible, reusable, easy to demold | Decorative items, planters | Pros: Versatile, detailed designs; Cons: Higher upfront cost. |

| Plastic Molds | Durable, lightweight, often less expensive | Large-scale construction, pavers | Pros: Cost-effective, reusable; Cons: Less detail than silicone. |

| Steel Molds | Heavy-duty, long-lasting, ideal for high-volume production | Industrial precast components | Pros: Highly durable, suitable for large projects; Cons: Heavy, requires more handling. |

| Wooden Molds | Traditional, customizable, often for artistic designs | Artistic features, bespoke projects | Pros: Customizable, aesthetic appeal; Cons: Less durable, limited reuse. |

| Fiberglass Molds | Lightweight, strong, and resistant to wear | Complex shapes, architectural elements | Pros: High precision, smooth finish; Cons: Higher cost, requires careful handling. |

What Are the Key Characteristics of Silicone Molds?

Silicone molds are notable for their flexibility and ease of use, making them ideal for creating intricate designs such as decorative items and planters. Their non-stick surface allows for easy demolding, which is crucial for B2B buyers focused on efficiency in production. The initial investment may be higher than other materials, but their reusability and versatility often justify the cost, particularly for businesses that require detailed craftsmanship in their concrete products.

Illustrative image related to big concrete molds

How Do Plastic Molds Benefit Large-Scale Production?

Plastic molds are favored for their lightweight nature and cost-effectiveness, making them suitable for large-scale construction projects, including pavers and precast components. They are reusable and can withstand multiple casting cycles, reducing overall costs for B2B buyers. However, while they are durable, they may not capture details as precisely as silicone molds, which is a consideration for buyers prioritizing aesthetics.

Why Are Steel Molds Ideal for Heavy-Duty Applications?

Steel molds are designed for heavy-duty applications, offering longevity and the ability to handle high-volume production. They are perfect for industrial precast components, where durability is critical. While their weight can be a drawback in terms of handling and transport, their robustness ensures that they can withstand repeated use in demanding environments, making them a reliable choice for serious construction projects.

What Advantages Do Wooden Molds Offer for Custom Projects?

Wooden molds provide a traditional approach to mold-making, allowing for customization and artistic expression. They are particularly popular for bespoke projects where unique designs are required. However, their durability is limited compared to other materials, and they may not be suitable for high-volume production. Buyers should weigh the aesthetic appeal and customization options against the potential for wear and tear over time.

How Do Fiberglass Molds Enhance Precision in Concrete Casting?

Fiberglass molds are lightweight yet strong, making them suitable for creating complex shapes and architectural elements. They are known for their high precision and smooth finish, which can significantly enhance the quality of the final product. While the initial cost may be higher than other mold types, the long-term benefits of durability and detail make them an attractive option for businesses focused on high-quality concrete products. Buyers must consider handling requirements due to their sensitive nature, ensuring that proper care is taken during use.

Key Industrial Applications of big concrete molds

| Industry/Sector | Specific Application of big concrete molds | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Precast concrete elements for buildings and bridges | Reduces labor costs and construction time; enhances quality | Durability, precision, and compliance with local regulations |

| Landscaping & Garden | Decorative garden features and hardscaping elements | Enhances aesthetic appeal; increases property value | Custom designs, material quality, and ease of installation |

| Infrastructure | Utility structures like manholes and drainage systems | Improves infrastructure longevity and functionality | Load-bearing capacity, drainage efficiency, and durability |

| Transportation | Concrete barriers and sound walls for roads | Enhances safety and noise reduction in urban areas | Compliance with safety standards and environmental impact |

| Art & Sculpture | Large-scale sculptures and artistic installations | Unique branding opportunities; enhances cultural value | Customization options and artistic design capabilities |

How Are Big Concrete Molds Used in Construction Projects?

In the construction industry, big concrete molds are crucial for producing precast concrete elements like beams, columns, and panels. These molds allow for the mass production of uniform components, significantly reducing labor costs and construction timelines. For international buyers, especially in regions like Africa and South America, sourcing durable molds that comply with local building codes is essential. Buyers should consider the mold’s ability to withstand various weather conditions and its reusability, ensuring a cost-effective solution over time.

What Role Do Big Concrete Molds Play in Landscaping and Garden Design?

Big concrete molds are increasingly used in landscaping for creating decorative features, such as planters, benches, and decorative walls. These molds enable the production of custom designs that enhance the aesthetic appeal of outdoor spaces, thereby increasing property value. For buyers in the Middle East and Europe, considerations include the mold’s design versatility and the quality of materials used, which should withstand harsh environmental conditions. Additionally, ease of installation and maintenance is a significant factor for landscaping businesses looking to optimize their operations.

How Are Big Concrete Molds Essential for Infrastructure Development?

In infrastructure, big concrete molds are employed to create essential utility structures such as manholes, drainage systems, and retaining walls. These molds help ensure that the structures are built to last, improving the overall longevity and functionality of urban infrastructure. Buyers from developing regions must prioritize sourcing molds that meet local load-bearing and drainage requirements. Understanding local regulations and environmental impact assessments is also vital to ensure compliance and successful project execution.

What Benefits Do Big Concrete Molds Provide in Transportation Projects?

In the transportation sector, big concrete molds are used to produce barriers, sound walls, and other safety features along highways. These molds contribute to enhanced safety and noise reduction, particularly in urban areas where traffic is heavy. For international buyers, it is crucial to source molds that meet safety standards and consider the environmental impact of concrete production. Additionally, the ability to customize designs for specific locations can provide a competitive edge in securing contracts.

How Can Big Concrete Molds Be Utilized in Art and Sculpture?

Artists and designers are increasingly turning to big concrete molds for creating large-scale sculptures and artistic installations. These molds allow for unique branding opportunities and can enhance the cultural value of public spaces. Buyers should look for suppliers that offer customization options to meet specific artistic visions. Moreover, understanding the durability and weather resistance of the molds is important, especially for outdoor installations in diverse climates across Africa and Europe.

Illustrative image related to big concrete molds

3 Common User Pain Points for ‘big concrete molds’ & Their Solutions

Scenario 1: Sourcing High-Quality Big Concrete Molds for Consistency in Production

The Problem: B2B buyers often face the challenge of sourcing big concrete molds that deliver consistent quality and durability. In regions with fluctuating material standards, such as parts of Africa or South America, buyers may encounter molds that warp or degrade quickly, leading to inconsistent product quality and increased costs. This inconsistency can significantly impact production timelines and project budgets, especially when molds are needed for large-scale construction or decorative applications.

The Solution: To overcome this issue, buyers should prioritize suppliers that offer high-quality materials and robust manufacturing processes. Look for suppliers that provide detailed specifications and certifications for their molds, such as ISO standards or material certifications. Consider investing in silicone molds for concrete, as they are known for their flexibility and durability, allowing for easier demolding and longer life spans. Additionally, always request samples before making large orders to assess the quality firsthand. Establishing long-term relationships with reputable manufacturers can also lead to better pricing and reliability in supply.

Scenario 2: Managing Logistics and Shipping Challenges with Large Molds

The Problem: International buyers frequently encounter logistical challenges when ordering large concrete molds. Shipping costs can be prohibitively high, and the risk of damage during transit is a significant concern. Buyers from regions like the Middle East or Europe may also face delays due to customs and import regulations, which can disrupt project timelines and lead to financial losses.

The Solution: To mitigate these logistical challenges, buyers should choose suppliers that offer comprehensive shipping solutions, including insurance and tracking services. It is beneficial to work with vendors that have experience in international shipping and can provide clear timelines and costs upfront. Additionally, consider sourcing molds that can be disassembled or stacked to reduce shipping volume and costs. Collaborating with local distributors or logistics companies familiar with regional customs can further streamline the process and minimize delays.

Scenario 3: Ensuring Proper Use and Maintenance of Big Concrete Molds

The Problem: Even the best molds can fail if they are not properly used or maintained. Buyers may struggle with understanding the best practices for curing, cleaning, and storing big concrete molds, leading to premature wear and subpar results in their concrete products. This is especially important for businesses in sectors such as construction and landscaping, where the quality of concrete products directly impacts their reputation and profitability.

The Solution: To ensure longevity and optimal performance of big concrete molds, buyers should invest in training for their staff on proper usage and maintenance protocols. This includes understanding the correct mixing ratios for concrete, appropriate curing times, and the best cleaning agents to use after demolding. Suppliers should provide detailed user manuals and maintenance guides with every mold purchase. Additionally, consider implementing a regular maintenance schedule that includes inspecting molds for cracks or wear and tear, which can prevent larger issues down the line. Engaging with suppliers who offer ongoing support and resources can also enhance the buyer’s operational efficiency and product quality.

Strategic Material Selection Guide for big concrete molds

What Are the Most Common Materials for Big Concrete Molds?

When selecting materials for big concrete molds, understanding the properties, advantages, and limitations of each option is crucial for international B2B buyers. The choice of material can significantly impact the mold’s performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the production of big concrete molds.

How Does Polypropylene Perform in Concrete Mold Applications?

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and lightweight properties. It can withstand moderate temperatures, making it suitable for various concrete applications.

Pros: Polypropylene molds are durable and reusable, which reduces long-term costs. They are also easy to clean and maintain, ensuring a longer lifespan.

Cons: However, they may not perform well under extreme temperatures or heavy loads, which can limit their application in high-stress environments. Additionally, the initial manufacturing cost can be higher compared to other materials.

Impact on Application: Polypropylene is compatible with a wide range of concrete mixtures, making it versatile for decorative and structural applications.

Illustrative image related to big concrete molds

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the polypropylene used complies with international standards such as ASTM or ISO. Local regulations may also dictate specific requirements for construction materials.

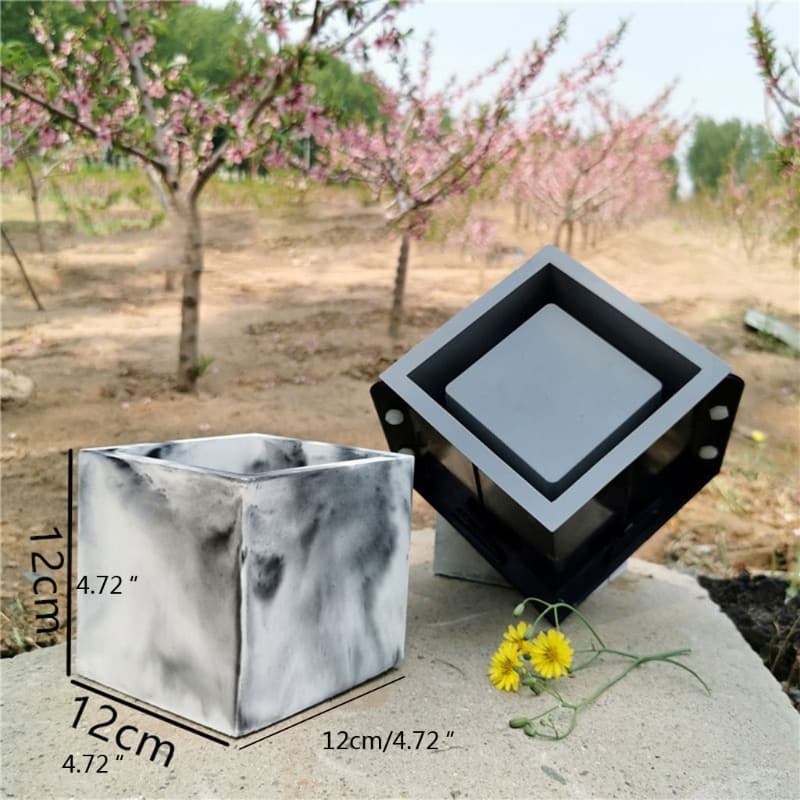

What Are the Advantages of Using Silicone for Concrete Molds?

Silicone molds are increasingly popular due to their flexibility and ease of use. They can withstand high temperatures and provide excellent detail in the final product.

Pros: The key advantage of silicone is its non-stick surface, which allows for easy demolding. This feature is particularly beneficial for intricate designs, ensuring high-quality finishes. Silicone molds are also highly durable and can be reused multiple times.

Cons: On the downside, silicone molds can be more expensive to produce than other materials, which may deter some buyers. They may also require special handling to avoid damage.

Illustrative image related to big concrete molds

Impact on Application: Silicone is ideal for producing detailed decorative elements and complex shapes, making it suitable for artistic projects and high-end construction.

Considerations for International Buyers: Buyers should verify that silicone molds meet relevant safety and quality standards, especially in regions like Europe, where regulations can be stringent.

Why Choose Steel for Big Concrete Molds?

Steel molds are known for their strength and durability, making them a preferred choice for large-scale concrete production.

Pros: Steel molds can withstand high pressures and temperatures, providing excellent structural integrity. They are also highly reusable, making them a cost-effective solution for large production runs.

Cons: The main drawback is that steel molds can be heavy and cumbersome to handle. They also require significant upfront investment and maintenance to prevent rust and corrosion.

Impact on Application: Steel molds are particularly suitable for heavy-duty applications, such as precast concrete elements used in construction.

Considerations for International Buyers: Buyers in regions like the Middle East should consider the local climate’s impact on steel, ensuring that appropriate coatings or treatments are applied to prevent corrosion.

How Do Plastic Molds Compare in the Concrete Mold Market?

Plastic molds, often made from high-density polyethylene (HDPE) or ABS, are widely used due to their affordability and versatility.

Pros: Plastic molds are lightweight and easy to handle, making them ideal for small to medium-sized projects. They are also resistant to chemicals and moisture, which enhances their durability.

Cons: However, plastic molds may not hold up under high pressure or extreme temperatures, limiting their use in more demanding applications. They can also wear out faster than metal or silicone options.

Impact on Application: Plastic molds are suitable for less demanding applications, such as garden decor or small architectural elements.

Considerations for International Buyers: Buyers should ensure that plastic molds comply with local and international standards, particularly in regions where environmental regulations are strict.

Illustrative image related to big concrete molds

Summary Table of Material Selection for Big Concrete Molds

| Material | Typical Use Case for big concrete molds | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Decorative and structural applications | Durable and reusable | Limited performance under stress | Medium |

| Silicone | Intricate designs and artistic projects | Easy demolding and high detail | Higher production costs | High |

| Steel | Heavy-duty precast elements | Excellent strength and durability | Heavy and requires maintenance | High |

| Plastic | Small to medium projects | Lightweight and cost-effective | Limited pressure and temperature resistance | Low |

This guide provides actionable insights for B2B buyers to make informed decisions when selecting materials for big concrete molds, ensuring they choose options that align with their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for big concrete molds

What Are the Key Stages in the Manufacturing Process of Big Concrete Molds?

The manufacturing process of big concrete molds involves several critical stages that ensure the molds meet industry standards and customer specifications. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting high-quality raw materials, which may include steel, plastic, or silicone, depending on the desired mold characteristics. For instance, steel molds offer durability and longevity, while silicone molds provide flexibility and ease of use. Manufacturers must ensure that the materials are sourced from reliable suppliers to maintain quality.

-

Forming: This stage is crucial as it involves shaping the molds. Techniques such as injection molding, vacuum forming, and handcrafting are common. Injection molding is particularly efficient for producing high volumes of consistent molds, whereas handcrafting is often used for custom designs. Advanced technology, like CNC machining, can also be employed to achieve precise dimensions and intricate designs.

-

Assembly: After forming, the components of the molds are assembled. This process may involve welding, fastening, or sealing, depending on the mold’s design. Proper assembly techniques are vital to ensure that the molds are robust and capable of withstanding the pressures of concrete casting.

-

Finishing: The final stage involves surface treatment and quality checks. Finishing processes may include sandblasting, painting, or applying a release agent to ensure easy demolding. This stage is also where aesthetic features are added, especially for decorative molds.

How is Quality Assurance Integrated into the Manufacturing of Big Concrete Molds?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that the molds produced meet the required specifications and standards. International standards such as ISO 9001 provide a framework for quality management systems, which many manufacturers adopt.

-

Relevant International Standards: For B2B buyers, understanding the certifications that a supplier holds is crucial. ISO 9001 focuses on consistent quality and customer satisfaction, while CE marking indicates compliance with European health, safety, and environmental protection standards. Additionally, industry-specific certifications like API (American Petroleum Institute) are essential for molds used in specific applications.

-

Quality Control Checkpoints: Various checkpoints throughout the manufacturing process help maintain quality:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the production process helps identify and rectify defects early.

– Final Quality Control (FQC): A thorough examination of the finished molds ensures they meet all design specifications and quality requirements. -

Common Testing Methods for Concrete Molds: Various tests are employed to assess the quality of concrete molds, including:

– Dimensional Accuracy Testing: Ensures that the molds meet the specified dimensions.

– Durability Testing: Evaluates the mold’s ability to withstand repeated use and exposure to concrete.

– Surface Finish Testing: Checks for any imperfections that could affect the final product’s appearance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensure they receive high-quality products.

Illustrative image related to big concrete molds

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s quality management processes firsthand. This includes reviewing their manufacturing practices, quality control measures, and adherence to industry standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into a supplier’s performance. These reports should include data on defect rates, compliance with standards, and results from any testing performed.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections often cover material quality, manufacturing practices, and compliance with relevant standards.

What Are the Nuances of Quality Certification for International B2B Buyers?

When dealing with international suppliers, B2B buyers should be aware of the nuances associated with quality certifications. Different regions may have varying standards, and understanding these can prevent potential issues.

-

Regional Variations in Standards: For instance, while ISO 9001 is recognized globally, other certifications may vary in acceptance across regions. Buyers should familiarize themselves with the specific standards applicable in their target markets to ensure compliance.

-

Documentation Requirements: International shipments often require specific documentation to prove compliance with quality standards. Buyers should ensure that suppliers provide all necessary certificates and reports, facilitating smoother customs processes.

-

Cultural Considerations: Understanding cultural differences in business practices can also play a role in supplier relationships. Open communication about quality expectations and standards can help bridge gaps and foster better partnerships.

Conclusion: Ensuring Quality in Big Concrete Molds Manufacturing

For B2B buyers, a comprehensive understanding of the manufacturing processes and quality assurance practices associated with big concrete molds is essential. By focusing on supplier certifications, engaging in thorough quality control checks, and maintaining open communication, buyers can secure high-quality products that meet their specific needs. This diligence not only enhances the buyer-supplier relationship but also ensures successful project outcomes across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘big concrete molds’

To successfully procure big concrete molds, international B2B buyers must navigate a series of critical steps. This checklist serves as a practical guide to streamline the sourcing process, ensuring that buyers make informed decisions while minimizing risks associated with procurement.

Step 1: Define Your Technical Specifications

Before engaging suppliers, it is essential to clearly outline your technical requirements. This includes determining the size, shape, and material of the molds you need, as well as any specific features such as durability or design. Having well-defined specifications ensures that suppliers understand your needs, which helps avoid miscommunication and reduces the likelihood of receiving unsuitable products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in big concrete molds. Focus on companies with a proven track record in your target markets, such as Africa, South America, the Middle East, and Europe. Utilize online platforms, industry directories, and trade shows to gather information about suppliers and their offerings.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers hold relevant certifications and comply with international quality standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management systems. Compliance with local regulations is also crucial, especially in regions with stringent construction standards, to ensure that your molds are safe and reliable.

Step 4: Request Samples and Product Specifications

Before finalizing your order, request samples of the molds you are interested in. This allows you to assess the quality, craftsmanship, and suitability of the molds for your projects. Additionally, ask for detailed product specifications, including material composition and manufacturing processes, to ensure they align with your technical requirements.

Step 5: Assess Pricing and Payment Terms

Analyze the pricing structures of your shortlisted suppliers. Look for transparency in pricing, including any additional costs such as shipping or customs duties. Negotiate payment terms that suit your cash flow needs, and consider options such as letters of credit or escrow services to mitigate financial risks.

Illustrative image related to big concrete molds

Step 6: Inquire About Lead Times and Delivery Options

Understanding lead times is crucial for project planning. Inquire about the typical production timelines and delivery methods offered by suppliers. Ensure that they can meet your deadlines, especially if your projects are time-sensitive. Discuss logistics options, including shipping methods and potential customs clearance processes, particularly if sourcing from international suppliers.

Step 7: Establish a Communication Plan

Effective communication with your supplier is vital throughout the procurement process. Establish a clear communication plan that outlines how often you will check in on progress and updates. This not only builds a strong relationship but also ensures that any issues or changes can be addressed promptly, minimizing disruptions to your project timelines.

By following these steps, B2B buyers can streamline the sourcing of big concrete molds, ensuring they select the right suppliers and products to meet their construction needs.

Illustrative image related to big concrete molds

Comprehensive Cost and Pricing Analysis for big concrete molds Sourcing

When sourcing big concrete molds, understanding the cost structure and pricing dynamics is critical for international B2B buyers. This analysis breaks down the key components of costs, influential pricing factors, and strategic buyer tips to optimize procurement.

What Are the Key Cost Components in Big Concrete Molds Manufacturing?

-

Materials: The cost of raw materials significantly impacts the overall pricing of concrete molds. Common materials include high-quality plastics or silicone, which can vary in price based on quality and supplier. For instance, silicone molds tend to be more expensive due to their durability and reusability compared to traditional plastic molds.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this can also affect the quality of craftsmanship. Skilled labor is essential for ensuring that molds meet precise specifications and durability standards.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help reduce these overhead costs, which is reflected in the final price of the molds.

-

Tooling: The initial investment in tooling for custom molds can be substantial. Tooling costs can be amortized over large production runs, making it essential for buyers to consider minimum order quantities (MOQs) to spread this cost effectively.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the molds meet industry standards and buyer specifications. While this may add to the initial cost, it ultimately reduces returns and enhances customer satisfaction.

-

Logistics: Transportation costs, including shipping and handling, can significantly affect the total cost of ownership. Factors such as distance, shipping method, and customs duties must be considered, especially for international buyers.

-

Margin: Suppliers typically add a markup to cover their costs and profit margins. Understanding the standard margins in the industry can aid in negotiations.

How Do Price Influencers Affect Big Concrete Mold Costs?

Several factors influence the pricing of concrete molds, including:

-

Volume/MOQ: Bulk orders often lead to discounts. Buyers should assess their needs and negotiate MOQs to optimize costs.

-

Specifications and Customization: Customized molds can incur higher costs due to additional design and tooling requirements. Clear specifications help suppliers provide accurate quotes.

-

Materials and Quality Certifications: Higher quality materials or molds with specific certifications (such as ISO or CE) typically command higher prices. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: Supplier reputation, location, and manufacturing practices can impact pricing. Engaging with reputable suppliers who prioritize quality can mitigate risks.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects logistics and cost responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers manage their total costs effectively.

What Are Strategic Buyer Tips for Cost-Efficient Sourcing?

-

Negotiation: Always negotiate pricing, especially for larger orders. Suppliers may be willing to lower their margins to secure significant business.

-

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also shipping, handling, and potential rework costs. A lower-priced mold might not be the best option if it leads to higher long-term costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international shipping costs, which can affect pricing. Establish relationships with local suppliers when possible to reduce shipping complexities.

-

Research and Benchmarking: Conduct market research to understand average prices and terms in different regions. This knowledge can strengthen your negotiation position.

-

Build Long-term Relationships: Establishing a reliable partnership with suppliers can lead to better pricing, priority service, and improved product quality over time.

Conclusion

Understanding the intricate cost structure and pricing dynamics of big concrete molds is essential for international B2B buyers. By considering various cost components, price influencers, and strategic sourcing tips, buyers can make informed decisions that enhance their procurement efficiency and overall project success.

Alternatives Analysis: Comparing big concrete molds With Other Solutions

When evaluating the use of big concrete molds for construction and decorative purposes, it’s essential to consider alternative solutions that can offer similar functionality. Different methods and technologies have emerged, providing various benefits and drawbacks. This analysis will compare big concrete molds against two viable alternatives: prefabricated concrete products and 3D printing for concrete applications.

| Comparison Aspect | Big Concrete Molds | Prefabricated Concrete Products | 3D Printing for Concrete |

|---|---|---|---|

| Performance | High durability and custom designs | Consistent quality and precision | Highly customizable, complex shapes |

| Cost | Moderate upfront investment | Higher due to production costs | Variable, often lower for small runs |

| Ease of Implementation | Requires skilled labor for setup | Quick installation on-site | Requires specialized equipment and training |

| Maintenance | Minimal maintenance needed | Low maintenance, long-lasting | Ongoing maintenance for printers |

| Best Use Case | Large-scale projects, custom designs | Mass production of standard elements | Unique, intricate designs, rapid prototyping |

What Are the Advantages and Disadvantages of Prefabricated Concrete Products?

Prefabricated concrete products offer numerous advantages, including consistent quality and reduced on-site labor time. These products are manufactured in controlled environments, ensuring high precision and durability. However, they typically come at a higher cost due to the manufacturing process. Additionally, their designs may be less customizable compared to molds, limiting creativity in unique projects. Prefabricated elements are best suited for large-scale construction projects where uniformity is crucial.

How Does 3D Printing for Concrete Compare?

3D printing technology for concrete is revolutionizing the construction industry with its ability to create complex shapes and structures that traditional methods cannot achieve. The customization potential is vast, allowing for rapid prototyping and adjustments. However, the initial investment in 3D printing equipment can be significant, and there is a steep learning curve for operators. This technology is ideal for innovative designs and smaller projects where unique architectural features are desired.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right solution between big concrete molds, prefabricated products, and 3D printing depends on various factors, including project requirements, budget, and desired outcomes. For large-scale projects needing durability and customization, big concrete molds are often the best choice. Conversely, if consistency and speed are paramount, prefabricated concrete products may be preferable. Finally, for projects requiring innovative designs, 3D printing presents exciting possibilities. By carefully assessing these alternatives, B2B buyers can make informed decisions that align with their project goals and operational capabilities.

Essential Technical Properties and Trade Terminology for big concrete molds

What Are the Key Technical Properties of Big Concrete Molds?

When selecting big concrete molds, understanding their essential technical properties is crucial for ensuring that they meet your project requirements. Here are several critical specifications to consider:

-

Material Grade

The material used in the construction of concrete molds significantly impacts their durability and performance. Common materials include high-density polyethylene (HDPE), silicone, and ABS plastic. Each material offers varying levels of flexibility, longevity, and resistance to wear. For instance, silicone molds are ideal for intricate designs due to their flexibility, while HDPE molds are preferred for larger, more robust applications. Selecting the right material ensures that molds can withstand repeated use and adverse conditions, thereby reducing long-term costs. -

Tolerance

Tolerance refers to the allowable variation in mold dimensions, which is critical for achieving the desired precision in concrete casting. A tight tolerance ensures that the finished concrete product matches specifications closely, reducing the risk of costly rework or material wastage. Understanding tolerance levels helps buyers assess whether the molds will fit their operational capabilities and quality standards. -

Reusability

The ability to reuse molds multiple times is a significant cost-saving factor in large-scale production. Molds made from durable materials can be used for hundreds of cycles without significant degradation. When evaluating molds, inquire about their expected lifespan and how many casts they can handle before needing replacement. This consideration is essential for project budgeting and long-term sustainability. -

Weight Capacity

Each mold has a specific weight capacity that indicates the maximum weight of the concrete it can support during the casting process. Understanding this capacity is vital to prevent structural failure and ensure safe handling during both production and transportation. Choosing molds with the appropriate weight capacity for your specific concrete mix and project scale is crucial for operational efficiency. -

Surface Finish

The surface finish of the mold affects the texture and appearance of the final concrete product. Molds can be smooth, textured, or even decorative, depending on the desired aesthetic. Selecting the right surface finish can enhance the visual appeal of concrete products, making them more marketable, especially in competitive industries such as construction and landscaping.

What Are Common Trade Terms Used in the Big Concrete Mold Industry?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of concrete molds, an OEM may supply molds that are branded and sold by another company. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better pricing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for buyers looking to manage inventory costs and optimize cash flow. Knowing the MOQ helps businesses plan their purchases effectively, ensuring they do not over-invest in inventory that may not sell quickly. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing, terms, and conditions for specific products or services. For buyers of big concrete molds, an RFQ can facilitate competitive bidding, ensuring they receive the best possible price and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international transactions, helping prevent misunderstandings and disputes. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is vital for project planning, especially in construction, where delays can have significant financial implications. Buyers should always inquire about lead times when negotiating terms to align production schedules effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing big concrete molds, ultimately enhancing operational efficiency and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the big concrete molds Sector

What Are the Key Market Drivers and Trends in the Big Concrete Molds Sector?

The global market for big concrete molds is influenced by several key drivers, including urbanization, infrastructure development, and the growing demand for precast concrete products. Countries in Africa, South America, the Middle East, and Europe are experiencing a surge in construction projects, necessitating efficient and durable mold solutions. As cities expand and new infrastructure projects emerge, the need for reliable concrete molds that can produce high-quality products quickly and cost-effectively becomes paramount.

Emerging technologies are reshaping the sourcing landscape. The integration of digital platforms allows B2B buyers to access a wider range of suppliers and product options, facilitating competitive pricing and better supply chain management. Additionally, advancements in mold manufacturing processes, such as 3D printing and automated production, are enabling suppliers to create more complex designs while maintaining consistency and reducing lead times. Buyers are increasingly seeking suppliers who can offer customizable solutions tailored to specific project requirements.

How Do Sustainability and Ethical Sourcing Impact the Big Concrete Molds Market?

Environmental considerations are becoming a significant factor in the sourcing of big concrete molds. The construction industry is under pressure to adopt sustainable practices, and this extends to the materials used in mold production. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through the use of recycled materials, eco-friendly production methods, and certifications such as ISO 14001 for environmental management.

Illustrative image related to big concrete molds

Ethical sourcing is equally important, as buyers seek to ensure that their suppliers adhere to fair labor practices and responsible sourcing standards. This focus on ethical supply chains not only enhances brand reputation but also aligns with the growing consumer demand for sustainable and socially responsible products. As a result, suppliers who can provide transparent supply chain information and demonstrate compliance with international labor standards will likely gain a competitive advantage in the market.

What Is the Historical Context of Big Concrete Molds in the B2B Landscape?

The evolution of big concrete molds can be traced back to the early days of concrete construction, where basic wooden forms were used to shape concrete structures. Over time, advancements in materials and technology have transformed the industry. The introduction of metal and plastic molds in the mid-20th century significantly improved the durability and versatility of mold solutions.

In recent decades, the rise of precast concrete technology has further revolutionized the sector, allowing for more efficient construction processes and the ability to meet complex architectural demands. As the market continues to evolve, the emphasis on customization, sustainability, and technological integration will likely shape the future of big concrete molds, presenting new opportunities and challenges for B2B buyers across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of big concrete molds

-

1. How do I ensure the quality of big concrete molds when sourcing internationally?

To ensure the quality of big concrete molds, start by vetting suppliers through third-party certifications, such as ISO or CE, which indicate adherence to international standards. Request samples to evaluate the mold’s durability, finish, and precision before making a larger order. Additionally, consider conducting factory audits or utilizing inspection services to assess production practices. Finally, check references or reviews from previous clients to gain insights into the supplier’s reliability and product performance. -

2. What is the best material for big concrete molds?

The best material for big concrete molds largely depends on the intended use. For durability and longevity, high-quality plastic ABS molds are recommended, as they resist wear and can be reused multiple times. Silicone molds offer flexibility and ease of demolding, making them ideal for intricate designs. If cost-effectiveness is a priority, consider polypropylene molds, which are lightweight and suitable for less complex shapes. Always assess your project needs to determine the most suitable material. -

3. What are the common minimum order quantities (MOQs) for big concrete molds?

Minimum order quantities (MOQs) for big concrete molds can vary significantly based on the supplier and mold type. Generally, MOQs range from 10 to 100 units. Suppliers often set MOQs to cover production costs and ensure efficiency. For custom molds, MOQs may be higher due to the added complexity of design and manufacturing. Always clarify MOQs during negotiations, and consider discussing bulk order discounts to maximize your investment. -

4. What payment terms are typically offered for international orders of concrete molds?

Payment terms for international orders of concrete molds can vary but often include options like a 30% deposit with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or escrow services to secure transactions. It’s essential to discuss payment methods that suit both parties, considering factors such as transaction fees and currency exchange rates. Establishing clear payment terms can help prevent misunderstandings and ensure a smooth purchasing process. -

5. How can I customize my big concrete molds to meet specific design requirements?

To customize big concrete molds, begin by communicating your design specifications clearly to the supplier, including dimensions, textures, and any specific features. Many manufacturers offer design services or have the capability to create bespoke molds based on your requirements. It’s advisable to provide sketches or CAD drawings to minimize misunderstandings. Keep in mind that customization may affect lead times and costs, so discuss these aspects upfront to align expectations. -

6. What logistics should I consider when importing big concrete molds?

When importing big concrete molds, consider shipping methods (air vs. sea), which impact cost and delivery time. Evaluate the total landed cost, including freight, duties, and taxes. Ensure that your supplier provides accurate documentation for customs clearance, such as invoices and packing lists. Additionally, consider working with a freight forwarder who can navigate international shipping complexities and provide real-time tracking for your order. -

7. How do I handle potential disputes with suppliers of concrete molds?

To handle potential disputes with suppliers, maintain clear and open communication throughout the transaction. Establish a written contract that outlines all terms, including quality standards, delivery timelines, and payment terms. In case of disputes, refer back to the contract and attempt to resolve issues amicably through discussion. If necessary, involve a third-party mediator or legal counsel familiar with international trade laws to assist in reaching a resolution. -

8. What certifications should I look for in suppliers of big concrete molds?

When sourcing big concrete molds, look for suppliers with relevant certifications, such as ISO 9001 for quality management systems, which indicates a commitment to quality and continuous improvement. Additionally, certifications like CE mark ensure compliance with European safety standards. For environmental considerations, suppliers with ISO 14001 can demonstrate adherence to sustainable practices. These certifications can provide assurance of product quality and supplier reliability.

Top 8 Big Concrete Molds Manufacturers & Suppliers List

1. Trove Warehouse – Concrete Mold-Large

Domain: trovewarehouse.com

Registered: 2010 (15 years)

Introduction: {“name”: “Concrete Mold-Large”, “price”: “$212”, “description”: “The rectangle-shaped Bleached Concrete Mold is a vintage wood casing that was once used in the construction of buildings in India. Each mold has its own decorative style and is lightly sand blasted and bleach finished to create an inspired decorative display.”, “dimensions”: “W:” , “D:” , “H:” , “materials”: “Vintage Wood”, “colors”:…

2. LCMOLDS – Roman Column Concrete Molds

Domain: lcmolds.com

Registered: 2017 (8 years)

Introduction: Concrete Molds available at LCMOLDS.COM include various types such as Roman Column Concrete Molds, Square Concrete Pillar Molds, Concrete Planter Molds, and Garden Concrete Bird Bath Molds.

1. **Roman Column Concrete Molds**:

– Price: €409.95 – €930.01

– Variants: Dia15x200CM, Dia20x345CM, Dia25x300CM, Dia30x255CM, Dia30x305CM, Dia30x345CM, Dia35x370CM, Dia40x370CM, Dia50x365CM

– Col…

3. Man About Tools – Plastic Concrete Molds

Domain: manabouttools.com

Registered: 2017 (8 years)

Introduction: Plastic Concrete Molds for casting concrete raised bed blocks. Available in Original and Thin designs. Original molds cast 2-1/2″ thick panels, available in lengths of 24″, 36″, and 48″. Thin molds cast 1-1/2″ thick panels, also available in 24″ and 36″ lengths. Options include single molds, 2-PACKs, 4-PACKs, and combo packs. Pricing: Original 24″ single – $91.00, 36″ single – $119.00, 48″ single …

4. Duncan – Luna Bean 1305 Keepsake

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Large Concrete Molds for sale on eBay include various materials such as ceramic, plastic, latex, concrete, plaster, rubber, and aluminum. Popular brands featured are Duncan, Unbranded, Holland, Alberta, Atlantic, Kimple, Gare, and Gostatue. Some specific products listed are the Luna Bean 1305 Keepsake Hands Casting Kit, Gostatue heart pawprint stepping stone mold, latex Halloween pumpkin mold, Gos…

5. VIVAT COMPANY – Architectural Concrete Molds

Domain: mouldsart.com

Registered: 2023 (2 years)

Introduction: VIVAT COMPANY offers high-quality architectural concrete molds produced by experienced craftsmen with over 15 years in the industry. The molds are made from high-quality polyester resins approved by Lloyd’s Register. The product catalog includes traditional planters, modern planters, sculptures, parking elements, benches, L-blocks, fountains, garden furniture, and bins. Custom molds can be created…

6. Manufacturers – Polyurethane and Mold Rubber Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Manufacturers: Smooth On, BJB Enterprises, Polytek; Retailers: Reynolds Advanced Materials, Brick in the Yard, EnvironMolds; Product types mentioned: polyurethane for concrete, brush-on mold rubber, latex for concrete casting, silicone molds, urethane mold rubber.

7. Etsy – Concrete Molds

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Concrete Molds, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Moldcreations – Dragonfly Leaf Border Stepping Stone Mold

Domain: moldcreations.com

Registered: 2004 (21 years)

Introduction: Shop Plaster, Soap, Concrete Molds for sale – Moldcreations offers a huge selection of easy to use reusable molds for sale. Products include:

– Dragonfly Leaf Border Stepping Stone Concrete Mold (1267) – Price: $35.95

– Huge 16in Footprints Bare Feet Stepping Stone Concrete Molds (1260) – Price: $69.95

– Sunflower Flower Concrete Stepping Stone Mold (1144) – Price: $35.95

– Hummingbird w/ Flowers …

Strategic Sourcing Conclusion and Outlook for big concrete molds

In the ever-evolving landscape of construction and design, strategic sourcing of big concrete molds emerges as a critical component for businesses aiming to enhance operational efficiency and product quality. By leveraging diverse mold options, such as silicone and plastic, companies can not only cater to unique project requirements but also capitalize on cost-effective solutions that drive profitability. The importance of building strong supplier relationships cannot be overstated, as this ensures access to innovative designs and reliable supply chains.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize sourcing from manufacturers that offer robust support, competitive pricing, and adaptability to local market needs. As you consider your next procurement strategy, evaluate suppliers who provide clear communication, efficient logistics, and a commitment to sustainability in their products.

Looking ahead, the demand for customized concrete solutions is set to rise, making it imperative for businesses to stay ahead of market trends and technological advancements. Engaging with proactive suppliers and embracing innovative mold designs will position your company favorably for future projects. Take the next step in your strategic sourcing journey and explore the vast opportunities within the global concrete mold market today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to big concrete molds

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.