A B2B Buyer’s Guide to Awm E11 8077: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for awm e11 8077

In today’s interconnected global marketplace, sourcing reliable components such as AWM E11 8077 ribbon cables presents unique challenges for B2B buyers. The quest for high-quality, compliant products often collides with concerns about supplier reliability, cost fluctuations, and shipping logistics, particularly for businesses operating in diverse regions like Africa, South America, the Middle East, and Europe. This guide aims to equip international buyers with comprehensive insights into the AWM E11 8077, covering its various types, applications, and specifications.

Throughout this guide, we will explore the essential elements of sourcing AWM E11 8077 ribbon cables, including best practices for supplier vetting, understanding compliance standards, and evaluating pricing structures. We will also highlight the potential applications of these cables in industries ranging from electronics to automotive, ensuring you can make informed purchasing decisions that meet both your quality and budgetary requirements.

By providing actionable strategies and expert advice, this guide empowers B2B buyers to navigate the complexities of the global market confidently. Whether you’re a buyer in Nigeria looking for cost-effective solutions or a procurement officer in Germany seeking high-performance components, understanding the intricacies of AWM E11 8077 will be instrumental in enhancing your supply chain efficiency and driving business success.

Understanding awm e11 8077 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AWM E11 8077 2896 | 80C temperature rating, VW-1 flame rating, 20-pin configuration | Computer hardware, consumer electronics | Pros: High reliability; Cons: Limited to specific applications. |

| AWM E11 8077 300V | 300V voltage rating, flexible design, multi-conductor options | Industrial machinery, automation systems | Pros: Suitable for high-voltage applications; Cons: May require specialized connectors. |

| AWM E11 8077 80C VW-1 | 80C temperature rating, excellent insulation properties | Telecommunications, data transmission | Pros: Great for data integrity; Cons: Not as durable under extreme conditions. |

| AWM E11 8077 UL 20276 | UL certification, low smoke emission, halogen-free materials | Aerospace, automotive applications | Pros: Meets stringent safety standards; Cons: Higher cost due to certification. |

| AWM E11 8077 150C | 150C temperature rating, high-density wiring | High-performance computing, robotics | Pros: Ideal for high-heat environments; Cons: May not be compatible with all devices. |

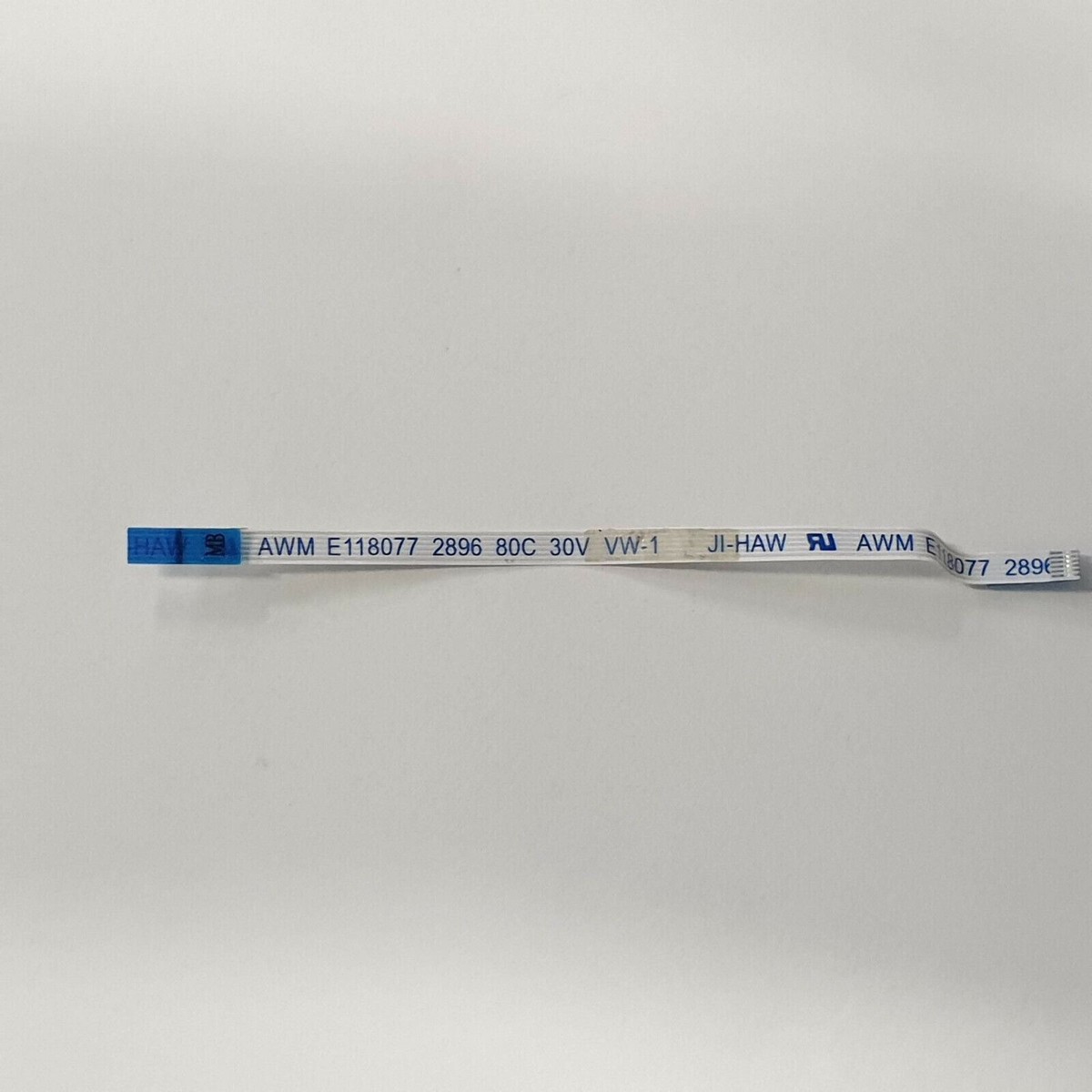

What Are the Key Characteristics of AWM E11 8077 2896?

The AWM E11 8077 2896 variant is characterized by its 80C temperature rating and VW-1 flame rating, making it suitable for consumer electronics and computer hardware applications. Its 20-pin configuration allows for easy integration into various systems. When purchasing, buyers should consider compatibility with existing systems and the specific requirements of their applications, as this type is primarily designed for low-voltage environments.

How Does AWM E11 8077 300V Stand Out in Industrial Applications?

With a voltage rating of 300V, the AWM E11 8077 300V variant is designed for industrial machinery and automation systems. Its flexible design and multi-conductor options make it versatile for various setups. Buyers should evaluate the environmental conditions and ensure that the cable can withstand the operational demands of their machinery, as well as confirm that it meets all necessary safety regulations.

Why Choose AWM E11 8077 80C VW-1 for Telecommunications?

The AWM E11 8077 80C VW-1 type is distinguished by its excellent insulation properties and 80C temperature rating, making it ideal for telecommunications and data transmission applications. This type provides high reliability in maintaining data integrity. Buyers should ensure that the cable meets their specific data transmission needs and consider the potential limitations in durability under extreme conditions.

What Advantages Does AWM E11 8077 UL 20276 Offer in Safety?

The AWM E11 8077 UL 20276 variant is notable for its UL certification, low smoke emissions, and halogen-free materials, making it suitable for aerospace and automotive applications. It meets stringent safety standards, which is a significant advantage for industries that prioritize safety. However, buyers should be prepared for a potentially higher cost due to the certification and ensure that their applications require such standards.

When is AWM E11 8077 150C the Right Choice for High-Performance Computing?

The AWM E11 8077 150C type features a high-temperature rating of 150C, making it suitable for high-performance computing and robotics applications. This variant is designed to operate effectively in high-heat environments, which is crucial for advanced technological setups. Buyers should assess the compatibility with their devices and consider the operational heat levels to ensure optimal performance and longevity of the cable.

Key Industrial Applications of awm e11 8077

| Industry/Sector | Specific Application of awm e11 8077 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Internal wiring for consumer electronics | Enhances product reliability and performance | Ensure compliance with international safety standards |

| Automotive | Wiring harnesses for vehicle electronics | Improves safety and functionality of automotive systems | Assess temperature and environmental resistance |

| Industrial Automation | Signal transmission in automation systems | Increases efficiency and reduces downtime | Verify compatibility with existing systems |

| Telecommunications | Data transmission in communication devices | Supports high-speed data transfer | Evaluate length and gauge requirements |

| Medical Devices | Connections in diagnostic and therapeutic equipment | Ensures precision and safety in medical applications | Confirm biocompatibility and regulatory compliance |

How is AWM E11 8077 Used in Electronics Manufacturing?

In the electronics manufacturing sector, AWM E11 8077 is widely utilized for internal wiring in consumer electronics, such as televisions, computers, and audio systems. This type of cable is designed to provide efficient signal transmission and power distribution, ensuring that devices operate reliably under various conditions. For international B2B buyers, particularly in regions like Africa and South America, sourcing AWM E11 8077 requires attention to compliance with international safety standards to ensure product quality and marketability.

What Role Does AWM E11 8077 Play in the Automotive Industry?

Within the automotive industry, AWM E11 8077 is integral to the creation of wiring harnesses that connect various electronic components in vehicles. This application is crucial for enhancing the safety and functionality of automotive systems, such as airbag deployment and infotainment systems. Buyers from Europe, such as Germany, must consider the cable’s temperature and environmental resistance, as these factors significantly impact the performance and longevity of automotive electronics.

How is AWM E11 8077 Applied in Industrial Automation?

AWM E11 8077 serves as a vital component in industrial automation systems, facilitating signal transmission between sensors, controllers, and actuators. This application is essential for increasing efficiency and reducing downtime in manufacturing processes. For businesses in the Middle East looking to enhance their automation capabilities, it is important to verify that the sourced cables are compatible with existing systems to ensure seamless integration.

How Does AWM E11 8077 Support Telecommunications?

In the telecommunications sector, AWM E11 8077 is used for data transmission in various communication devices, including routers and switches. Its ability to support high-speed data transfer is crucial for maintaining the performance of communication networks. B2B buyers in regions like Africa should evaluate the specific length and gauge requirements of AWM E11 8077 to ensure optimal performance in their telecommunications infrastructure.

What is the Importance of AWM E11 8077 in Medical Devices?

AWM E11 8077 is crucial in the medical device industry, where it connects various components in diagnostic and therapeutic equipment. This application demands high precision and safety, as it directly impacts patient care. Buyers in Europe and South America must confirm the cable’s biocompatibility and adherence to regulatory compliance to ensure that the medical devices meet stringent safety standards.

3 Common User Pain Points for ‘awm e11 8077’ & Their Solutions

Scenario 1: Compatibility Confusion in Sourcing AWM E11 8077 Components

The Problem:

One of the most significant challenges faced by B2B buyers when dealing with AWM E11 8077 components is ensuring compatibility with existing systems. Buyers, particularly in regions like Africa and South America, may not have access to comprehensive technical specifications or may struggle with varying standards across suppliers. This lack of clarity can lead to costly errors—ordering cables that do not fit the required specifications, resulting in delays in production and increased costs due to returns or replacements.

The Solution:

To mitigate compatibility issues, buyers should take a systematic approach to sourcing AWM E11 8077 products. First, always request detailed technical specifications from suppliers, including dimensions, electrical ratings, and compliance with local standards. Create a checklist of requirements based on your existing systems to cross-reference with potential suppliers. Additionally, consider establishing relationships with reputable suppliers who can provide technical support and guidance on compatibility. This could involve leveraging online platforms or trade shows to connect with manufacturers that specialize in AWM E11 8077 products. By prioritizing detailed communication and maintaining a checklist, buyers can significantly reduce the risk of compatibility issues and ensure smooth operations.

Scenario 2: Quality Assurance Challenges with AWM E11 8077 Products

The Problem:

Quality assurance is a pressing concern for B2B buyers of AWM E11 8077 cables, particularly in regions where counterfeit products are prevalent. The consequences of using substandard components can include equipment failures, safety hazards, and reputational damage. Buyers often find it challenging to assess the quality of products when purchasing from international suppliers, leading to anxiety about whether they are getting what they paid for.

The Solution:

To ensure quality assurance, buyers should adopt a multi-faceted approach. Start by selecting suppliers that are certified and have a proven track record in providing high-quality AWM E11 8077 components. Request samples before placing bulk orders to evaluate the product firsthand. Additionally, implement stringent quality control measures upon receiving shipments—this could involve visual inspections, testing for compliance with relevant standards, and keeping records of quality checks. Establishing a feedback loop with suppliers regarding quality issues can also foster better relationships and encourage them to maintain high standards. By taking proactive measures in quality assurance, buyers can protect their investments and maintain the integrity of their operations.

Scenario 3: Difficulty in Understanding Technical Specifications of AWM E11 8077

The Problem:

Many B2B buyers, especially those new to sourcing electronic components like AWM E11 8077, often face difficulties in understanding complex technical specifications. This can lead to misinterpretation of product requirements and subsequent procurement of unsuitable items. The challenge is heightened in regions where educational resources on technical specifications may be limited, making it harder for buyers to make informed decisions.

The Solution:

To overcome this challenge, buyers should invest time in educating themselves about the technical aspects of AWM E11 8077 components. This can be achieved through online courses, webinars, or workshops focused on electrical components and their specifications. Many manufacturers provide resources, including guides and tutorials, which can help demystify technical jargon. Furthermore, forming a partnership with a knowledgeable distributor or consultant can provide invaluable insights and support during the purchasing process. Engaging in forums or industry groups can also facilitate knowledge sharing among peers. By enhancing their understanding of technical specifications, buyers can make more informed decisions and optimize their procurement strategies for AWM E11 8077 products.

Strategic Material Selection Guide for awm e11 8077

What Are the Key Materials Used in AWM E11 8077 and Their Properties?

When selecting materials for AWM E11 8077 applications, it is essential to consider the specific properties that impact performance, durability, and compliance with international standards. Here, we analyze four common materials used in AWM E11 8077 cables, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. PVC (Polyvinyl Chloride)

Key Properties:

PVC is widely recognized for its excellent electrical insulation properties and resistance to moisture. It can operate effectively in temperatures ranging from -20°C to 70°C, making it suitable for various environments.

Pros & Cons:

PVC is cost-effective and easy to manufacture, leading to lower production costs. However, it has limitations in terms of temperature resistance and can degrade under prolonged exposure to UV light.

Impact on Application:

PVC is compatible with a variety of media, including water and oils, but may not be suitable for high-temperature applications or exposure to harsh chemicals.

Considerations for International Buyers:

PVC materials must comply with regulations such as RoHS in Europe and other international standards. Buyers in regions like Africa and South America should ensure that suppliers meet local compliance requirements.

2. TPE (Thermoplastic Elastomer)

Key Properties:

TPE offers flexibility, durability, and resistance to extreme temperatures, ranging from -40°C to 125°C. Its excellent mechanical properties make it ideal for applications requiring frequent bending.

Pros & Cons:

The key advantage of TPE is its resilience and ability to withstand repeated stress without losing shape. However, it typically comes at a higher cost than PVC and may require more complex manufacturing processes.

Impact on Application:

TPE is highly compatible with various media, including chemicals and oils, making it suitable for diverse applications. Its flexibility is particularly beneficial in environments where cables are subject to movement.

Considerations for International Buyers:

TPE materials should meet ASTM standards, particularly for temperature and chemical resistance. Buyers in Europe, such as Germany, may prioritize TPE for applications requiring high performance in challenging environments.

3. XLPE (Cross-Linked Polyethylene)

Key Properties:

XLPE is known for its superior thermal and chemical resistance, with operating temperatures up to 90°C. Its cross-linking structure enhances its mechanical strength and durability.

Pros & Cons:

The primary advantage of XLPE is its long-term reliability and resistance to environmental stress. However, it is more expensive than both PVC and TPE and may require specialized processing techniques.

Impact on Application:

XLPE is suitable for high-voltage applications and environments where exposure to harsh chemicals is expected. It is also used in applications requiring high-temperature resistance.

Considerations for International Buyers:

Buyers should ensure that XLPE products comply with relevant international standards, such as IEC and UL, to guarantee safety and reliability. This is particularly crucial for buyers in the Middle East, where extreme temperatures can impact performance.

4. PUR (Polyurethane)

Key Properties:

PUR offers excellent abrasion resistance and flexibility, with a temperature range of -40°C to 80°C. Its high tensile strength makes it suitable for demanding applications.

Pros & Cons:

The advantage of PUR is its durability and performance in harsh environments. However, it is generally more expensive and may have limited chemical resistance compared to other materials.

Impact on Application:

PUR is ideal for applications where cables are exposed to mechanical stress or abrasion, such as in industrial settings. Its flexibility also allows for easy installation in tight spaces.

Considerations for International Buyers:

Compliance with international standards such as DIN and JIS is essential for PUR materials. Buyers from regions like Africa and South America should verify that suppliers provide certifications that meet local regulations.

Summary Table

| Material | Typical Use Case for awm e11 8077 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General electrical insulation | Cost-effective and easy to manufacture | Limited temperature resistance | Low |

| TPE | Flexible applications requiring durability | Excellent mechanical properties | Higher cost and complex manufacturing | Medium |

| XLPE | High-voltage and harsh chemical environments | Superior thermal and chemical resistance | More expensive and specialized processing | High |

| PUR | Industrial applications with mechanical stress | High abrasion resistance and flexibility | Limited chemical resistance | High |

This strategic material selection guide provides insights into the properties and considerations of various materials used in AWM E11 8077 applications. Understanding these aspects is crucial for B2B buyers looking to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for awm e11 8077

What Are the Key Stages in the Manufacturing Process of AWM E11 8077?

The manufacturing process of AWM E11 8077 cables involves several critical stages that ensure the final product meets the required standards for quality and functionality.

Material Preparation

The first step in the manufacturing process is the preparation of raw materials. AWM E11 8077 cables typically use high-quality copper conductors that are insulated with various materials such as PVC or Teflon. These materials are selected based on their electrical properties, durability, and resistance to environmental factors. Suppliers often perform a thorough analysis of the raw materials to ensure they meet industry specifications before moving to the next stage.

Forming

Once the materials are prepared, the next step is forming. This involves the shaping of the conductors and insulation to the required dimensions. Techniques such as extrusion are commonly employed for insulating the wires. Extrusion allows for precise control over the thickness and uniformity of the insulation, which is crucial for the cable’s performance. Additionally, this stage may include the twisting of pairs of wires to reduce electromagnetic interference, enhancing signal integrity.

Assembly

The assembly stage is where the individual components come together. This includes the integration of the insulated conductors into a ribbon cable format. Automated machinery is often used to ensure precision and efficiency in this process. The assembly must be conducted in a controlled environment to prevent contamination and ensure adherence to specifications.

Finishing

The finishing stage involves several processes, including cutting the cable to length, applying markings or labels, and performing any additional treatments such as surface coating. This stage is vital for ensuring that the final product is not only functional but also visually appealing and easy to handle. Quality checks are often performed at this stage to catch any defects before the product is packaged.

How Is Quality Assurance Implemented in AWM E11 8077 Manufacturing?

Quality assurance is a critical component of the manufacturing process, particularly for products like AWM E11 8077 that are used in sensitive applications.

What International Standards Are Relevant for AWM E11 8077?

Manufacturers of AWM E11 8077 cables must adhere to various international standards to ensure product quality and safety. The ISO 9001 standard, which focuses on quality management systems, is commonly implemented to enhance operational efficiency and customer satisfaction. Additionally, compliance with specific industry standards such as CE (Conformité Européenne) for electrical safety and performance is crucial, especially for buyers in Europe.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality Control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure that the final product meets the necessary specifications. The main checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): During the manufacturing stages, samples are regularly tested to monitor the quality of the assembly and adherence to specifications.

-

Final Quality Control (FQC): Once the product is finished, a comprehensive inspection is conducted, including electrical testing, visual inspections, and functional tests to ensure the cable performs as intended.

What Common Testing Methods Are Used for AWM E11 8077?

Manufacturers employ several testing methods to verify the quality and performance of AWM E11 8077 cables. Common testing techniques include:

-

Electrical Testing: This includes tests for continuity, insulation resistance, and voltage breakdown to ensure the cable can handle the required electrical load.

-

Environmental Testing: Cables may be subjected to temperature cycling, humidity exposure, and chemical resistance tests to evaluate their durability in various environments.

-

Mechanical Testing: Tests such as tensile strength and flexural testing are performed to assess the physical robustness of the cable.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to ensure quality in their supply chain can take several proactive steps to verify supplier quality control practices:

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and adherence to quality standards. Buyers should focus on both documentation and physical inspections.

-

Request Quality Reports: Suppliers should be willing to provide quality assurance reports that detail their testing methods, results, and certifications. This transparency is crucial for building trust.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can help verify that the manufacturing processes and quality control measures are being followed correctly.

What Are the QC Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of QC certifications is essential. Different regions may have specific requirements or standards that must be met. For example:

-

Africa: Buyers should be aware of local regulations and standards that may differ significantly from European or North American standards.

-

South America: Compliance with local certifications can vary widely, making it crucial for buyers to confirm that suppliers meet the necessary legal and quality requirements.

-

Middle East and Europe: Here, certifications such as CE or RoHS (Restriction of Hazardous Substances) are often mandatory, and buyers should ensure that suppliers possess these certifications to avoid compliance issues.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing AWM E11 8077 cables, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘awm e11 8077’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure AWM E11 8077 components. Given the complexities of international sourcing, particularly in regions like Africa, South America, the Middle East, and Europe, it’s essential to follow a structured approach. This checklist will help ensure that you secure high-quality products from reliable suppliers while minimizing risks.

1. Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for AWM E11 8077. This includes understanding the dimensions, material properties, and any compliance standards relevant to your industry. A well-defined specification sheet will facilitate better communication with suppliers and help ensure that the products meet your operational needs.

2. Conduct Market Research

Engage in thorough market research to identify potential suppliers. Utilize online platforms, trade shows, and industry publications to gather information. Focus on suppliers with a proven track record in providing AWM E11 8077 products, and be sure to check reviews and ratings from previous customers. This step is crucial for establishing a shortlist of qualified candidates.

3. Evaluate Potential Suppliers

Before committing to a supplier, vet them thoroughly to ensure reliability. Request company profiles, product samples, and references from buyers in similar industries or regions. Look for certifications that validate their compliance with industry standards, such as ISO or CE certifications, which can indicate quality and reliability.

4. Request and Compare Quotes

Once you have a list of potential suppliers, request quotes for the AWM E11 8077 components. Ensure that each quote includes detailed pricing, shipping terms, and lead times. Comparing these factors will help you identify the best value for your investment while also considering factors like payment terms and after-sales support.

5. Verify Supplier Certifications

It’s critical to verify the certifications of your chosen supplier to ensure they meet international standards. This may include quality management certifications, environmental standards, or specific industry-related certifications. A supplier that adheres to these standards is more likely to provide reliable products and services.

6. Negotiate Terms and Conditions

Once you’ve identified a preferred supplier, engage in negotiations to finalize the terms and conditions of the purchase. Discuss pricing, payment terms, delivery schedules, and warranty provisions. Clear agreements on these aspects can prevent misunderstandings and ensure smooth transactions.

7. Establish a Communication Plan

Finally, set up a communication plan to maintain ongoing dialogue with your supplier. Regular updates on order status, potential delays, or changes in specifications will help you manage expectations and foster a strong partnership. Effective communication is essential for long-term collaboration and ensures that any issues can be addressed promptly.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for AWM E11 8077, ensuring they partner with reliable suppliers while securing high-quality products tailored to their needs.

Comprehensive Cost and Pricing Analysis for awm e11 8077 Sourcing

In the competitive landscape of sourcing AWM E11 8077 cables, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe. This section outlines the key cost components, price influencers, and valuable buyer tips to optimize sourcing strategies.

What Are the Key Cost Components for AWM E11 8077 Cables?

-

Materials: The primary cost driver in AWM E11 8077 sourcing is the raw materials used in manufacturing the cables, including copper for conductors and various plastics for insulation. Fluctuations in commodity prices can significantly impact overall costs, so buyers should stay informed about market trends.

-

Labor: Labor costs vary by region and supplier, affecting the overall pricing of the AWM E11 8077 cables. Countries with higher labor costs may produce cables at a premium price, while regions with lower labor expenses can offer more competitive rates.

-

Manufacturing Overhead: This includes expenses related to utilities, maintenance, and administrative costs associated with production facilities. Suppliers with well-optimized operations may pass on savings to buyers.

-

Tooling: The initial investment in specialized equipment and molds for cable production can influence pricing, particularly for customized orders. Buyers requiring unique specifications should factor in these costs when negotiating prices.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability and compliance with industry standards. Suppliers with stringent QC measures may charge higher prices, reflecting their commitment to quality.

-

Logistics: Shipping costs, including packaging, freight, and customs duties, can significantly affect the total cost of ownership. Buyers should assess logistics efficiency and explore various shipping options to mitigate costs.

-

Margin: Supplier profit margins vary based on market positioning and competition. Understanding a supplier’s pricing strategy can provide insights into potential negotiation levers.

What Influences Pricing for AWM E11 8077 Cables?

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly influence pricing. Higher order volumes typically lead to lower per-unit costs, making it beneficial for buyers to consolidate orders where possible.

-

Specifications and Customization: Custom specifications, such as length, gauge, and insulation type, can increase production costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: Cables that meet higher quality standards or industry certifications may command a premium price. Buyers should weigh the benefits of quality against cost to make informed decisions.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may offer better support and assurance, justifying a higher price.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can influence the final cost. Terms that place more responsibility on the buyer may reduce upfront costs but increase total expenses due to logistics and customs.

What Are Some Buyer Tips for Cost-Efficient Sourcing of AWM E11 8077?

-

Negotiation Strategies: Engaging in open discussions with suppliers about pricing and terms can uncover opportunities for discounts or better payment terms. Building long-term relationships can also lead to more favorable pricing.

-

Assess Total Cost of Ownership: Buyers should consider not just the purchase price but also the long-term implications of sourcing decisions, including durability, maintenance, and potential downtime costs.

-

Understand Pricing Nuances for International Buyers: Different regions may have unique pricing structures influenced by local market conditions, tariffs, and currency fluctuations. Buyers in Africa, South America, the Middle East, and Europe should be aware of these factors when comparing suppliers.

-

Stay Informed About Market Trends: Regularly monitoring trends in material costs, labor rates, and technological advancements can help buyers make proactive sourcing decisions and negotiate effectively.

Conclusion

Sourcing AWM E11 8077 cables requires a strategic approach to understand the cost components and pricing influences. By leveraging negotiation techniques, assessing the total cost of ownership, and staying informed about market dynamics, international B2B buyers can optimize their sourcing strategies and achieve better value in their purchases. Always remember that the prices mentioned in this analysis are indicative and may vary based on specific supplier conditions and market fluctuations.

Alternatives Analysis: Comparing awm e11 8077 With Other Solutions

Understanding Alternatives for AWM E11 8077

In the fast-evolving landscape of technology and product solutions, it’s crucial for B2B buyers to explore various alternatives to ensure they make informed purchasing decisions. The AWM E11 8077, known for its specific applications in electronics and wiring, can be compared against other solutions that fulfill similar roles. This analysis will provide insights into its performance, cost, ease of implementation, maintenance, and ideal use cases, helping buyers find the best fit for their needs.

Comparison Table

| Comparison Aspect | AWM E11 8077 | Alternative 1: JI-HAW E118077 | Alternative 2: Standard Ribbon Cable |

|---|---|---|---|

| Performance | High flexibility and durability, suitable for various electronic applications | Comparable flexibility, designed for specific low-voltage applications | Basic performance, adequate for general wiring needs |

| Cost | Moderate pricing, varies by supplier | Generally lower cost per unit | Cost-effective, bulk purchasing available |

| Ease of Implementation | Straightforward installation; requires minimal tools | Easy to integrate with existing systems | Simple to use, familiar to most technicians |

| Maintenance | Low maintenance, robust against wear | Low maintenance, but specific to its use case | Requires more frequent checks for wear and tear |

| Best Use Case | Ideal for complex wiring in electronics | Best for low-voltage applications in consumer electronics | Suitable for general-purpose wiring in less demanding environments |

Detailed Breakdown of Alternatives

Alternative 1: JI-HAW E118077

The JI-HAW E118077 ribbon cable serves as a solid alternative to the AWM E11 8077. With its comparable flexibility and robustness, it is particularly effective for low-voltage applications, making it suitable for consumer electronics. However, while it offers similar performance, it may not be as versatile as the AWM E11 8077 for more complex electronic needs. Buyers should consider whether their applications require the specialized features of the AWM E11 8077 or if the JI-HAW E118077 meets their requirements at a lower cost.

Alternative 2: Standard Ribbon Cable

Standard ribbon cables are an economical choice for many general wiring needs. They are widely available and easy to implement, making them a go-to option for technicians. However, they may lack the specific durability and flexibility that the AWM E11 8077 provides. While they can be suitable for basic applications, companies requiring high performance and reliability in their wiring should weigh the benefits of investing in the AWM E11 8077 against the cost savings of standard ribbon cables.

Conclusion: Making the Right Choice for Your Business

Choosing the right wiring solution depends on a variety of factors, including performance requirements, budget constraints, and the specific application needs of your business. For B2B buyers, it’s essential to evaluate how each option aligns with their operational goals. The AWM E11 8077 excels in performance and durability for complex applications, while alternatives like JI-HAW E118077 and standard ribbon cables offer cost-effective solutions for less demanding scenarios. Ultimately, understanding the unique requirements of your projects will guide you to the most suitable choice.

Essential Technical Properties and Trade Terminology for awm e11 8077

What Are the Essential Technical Properties of AWM E11 8077?

When considering AWM E11 8077, understanding its critical specifications is paramount for B2B buyers. Here are the key technical properties that play a vital role in procurement decisions:

-

Material Composition

AWM E11 8077 typically comprises a combination of PVC (Polyvinyl Chloride) and copper conductors. This material selection ensures flexibility, durability, and excellent electrical conductivity. For businesses, choosing the right material is crucial as it impacts performance, lifespan, and overall reliability of the cable in various applications. -

Temperature Rating

This specification indicates the maximum and minimum temperatures that AWM E11 8077 can withstand, often rated between -40°C to 105°C. Understanding the temperature rating is essential for applications in extreme environments, as exceeding these limits can lead to insulation failure and potential hazards. -

Voltage Rating

AWM E11 8077 cables are generally rated for low voltage applications, commonly up to 300V. This property is vital for ensuring the cable can safely handle the electrical load without risk of overheating or failure. Buyers must match the voltage rating with their specific application requirements to ensure safety and compliance. -

Conductor Size and Stranding

The gauge of the conductor, often specified in AWG (American Wire Gauge), affects the cable’s current-carrying capacity. AWM E11 8077 typically features stranded conductors, which offer greater flexibility and resistance to breakage. Understanding the conductor size helps buyers select a cable that meets their current requirements while maintaining safety standards. -

Flame Resistance

Many AWM E11 8077 cables are designed with flame-retardant properties (VW-1 rating), which prevent the spread of fire. This specification is crucial for industries where fire safety is paramount, as it reduces risks and complies with regulatory standards. -

Shielding Type

Depending on the application, AWM E11 8077 may come with different types of shielding (e.g., foil or braid). Shielding is essential for reducing electromagnetic interference (EMI), ensuring signal integrity in sensitive electronic applications. Buyers should assess their specific needs for shielding to ensure optimal performance.

What Are Common Trade Terms Related to AWM E11 8077?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers seeking customized solutions or replacement parts, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, especially for companies looking to maintain optimal stock levels without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is essential for buyers to gather competitive offers and ensure they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses navigate shipping, insurance, and delivery responsibilities, reducing potential disputes and misunderstandings. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for supply chain management, as it affects project timelines and inventory levels. -

Certification Standards

These are compliance marks that indicate a product meets specific safety and quality standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne). Buyers should prioritize certified products to ensure compliance with industry regulations and enhance their product’s credibility.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing AWM E11 8077, ultimately leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the awm e11 8077 Sector

What Are the Key Market Trends Impacting the AWM E11 8077 Sector?

The AWM E11 8077 sector is currently experiencing significant growth driven by advancements in technology and increasing demand for high-performance cables in diverse applications. Global drivers include the rapid expansion of the electronics industry, particularly in regions such as Africa, South America, the Middle East, and Europe. The rise of smart devices and the Internet of Things (IoT) has led to an increased need for reliable and efficient wiring solutions, making AWM E11 8077 cables particularly sought after.

Emerging trends show a shift towards automation and digitalization in manufacturing processes. B2B buyers are increasingly leveraging e-commerce platforms to source components, allowing for streamlined procurement processes and broader access to international suppliers. This trend is particularly pronounced in regions like Germany, where a robust industrial base demands high-quality components, and in Nigeria, where local manufacturers are beginning to adopt more advanced technologies.

Additionally, there is a growing focus on customization and flexibility in product offerings, as businesses seek to differentiate themselves in competitive markets. As a result, suppliers who can provide tailored solutions alongside standard products are likely to gain a competitive edge.

How Important Is Sustainability and Ethical Sourcing in the AWM E11 8077 Sector?

Sustainability has become a critical focus for B2B buyers in the AWM E11 8077 sector. Environmental impact considerations are influencing sourcing decisions, with companies increasingly seeking suppliers who adhere to sustainable practices. This includes the use of eco-friendly materials and adherence to stringent environmental regulations.

The importance of ethical supply chains cannot be overstated. Buyers are now looking for partners who demonstrate transparency and responsibility in their sourcing practices, ensuring that materials are sourced without harming the environment or exploiting workers. Certifications such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) are becoming prerequisites for suppliers wishing to engage with conscientious buyers.

Furthermore, the demand for “green” materials is on the rise. Companies that can offer AWM E11 8077 cables made from recyclable or biodegradable materials are likely to attract more business from environmentally conscious clients, particularly in Europe and North America.

What Is the Historical Context of the AWM E11 8077 Sector?

The AWM E11 8077 cable standard was developed to meet the growing needs of the electronics industry for reliable and efficient wire harnessing solutions. Its evolution reflects broader trends in technology and manufacturing, particularly the shift towards miniaturization and increased functionality in electronic devices.

Initially designed for general-purpose applications, the AWM E11 8077 standard has adapted over the years to accommodate more stringent performance requirements, particularly in high-temperature and high-voltage scenarios. This adaptability has made it a staple in various industries, including telecommunications, automotive, and consumer electronics, establishing a robust market presence.

As the demand for advanced electronic systems continues to grow, the relevance of AWM E11 8077 will likely expand, reinforcing its significance in the global supply chain.

Frequently Asked Questions (FAQs) for B2B Buyers of awm e11 8077

-

How can I ensure the quality of AWM E11 8077 cables before purchasing?

To ensure the quality of AWM E11 8077 cables, request samples from potential suppliers to evaluate their performance and compliance with international standards. Verify certifications such as UL and IEC to ensure safety and reliability. Additionally, consider conducting third-party testing for quality assurance. Establish clear quality expectations in your contract and maintain open communication with suppliers throughout the manufacturing process to address any concerns promptly. -

What are the typical minimum order quantities (MOQs) for AWM E11 8077 cables?

Minimum order quantities for AWM E11 8077 cables can vary significantly among suppliers, typically ranging from 100 to 1,000 units. It’s essential to discuss MOQs with your supplier upfront and evaluate whether they align with your purchasing needs. Some manufacturers may offer flexibility based on your business relationship or order frequency, so negotiating these terms can lead to more favorable conditions. -

What payment terms should I expect when sourcing AWM E11 8077 cables?

Payment terms for AWM E11 8077 cables often include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers prefer a 30% deposit with the balance due upon shipment. Always clarify payment terms before finalizing your order to avoid misunderstandings. Be mindful of currency fluctuations and consider using secure payment platforms to safeguard your transactions. -

How can I vet suppliers for AWM E11 8077 cables?

Vetting suppliers involves checking their business credentials, reviewing customer testimonials, and assessing their manufacturing capabilities. Request references from past clients and conduct background checks to verify their reliability. Consider visiting the supplier’s facility if possible or using third-party inspection services to evaluate their production processes and quality control measures. A strong supplier relationship is crucial for successful long-term partnerships. -

What should I consider regarding logistics when importing AWM E11 8077 cables?

When importing AWM E11 8077 cables, consider shipping methods, lead times, and customs regulations in your country. Evaluate freight options such as air freight for speed or sea freight for cost-effectiveness. Ensure your supplier provides accurate documentation, including invoices and packing lists, to facilitate smooth customs clearance. Additionally, account for potential tariffs or taxes that may apply upon import. -

Can I customize AWM E11 8077 cables to meet specific requirements?

Yes, many manufacturers offer customization options for AWM E11 8077 cables, including variations in length, color, and connector types. When discussing customization, clearly outline your specifications and any applicable standards. Be aware that customized orders may have different MOQs and lead times, so plan accordingly. Collaborating closely with your supplier during the design phase can help achieve the desired product. -

What are the common applications for AWM E11 8077 cables in various industries?

AWM E11 8077 cables are widely used in electronics, automotive, and telecommunications industries due to their flexibility and reliability. Common applications include internal wiring for computers, signal transmission in medical devices, and power connections in industrial machinery. Understanding the specific application requirements will help you select the right cable variant, ensuring optimal performance in your projects. -

What should I do if there is a problem with the AWM E11 8077 cables I receive?

In the event of issues with your AWM E11 8077 cables, promptly contact the supplier to address the problem. Document the defects with photos and detailed descriptions to support your claim. Most reputable suppliers will have a return policy or warranty that allows for replacements or refunds. Clear communication is vital; ensure you follow up regularly until the issue is resolved to maintain a positive supplier relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Awm E11 8077 Manufacturers & Suppliers List

1. Toshiba – AWM E118077 6 Pin Ribbon Cable

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Genuine AWM E118077 6 Pin 10cm Ribbon Cable 80C 30V for Toshiba Satellite L850. Condition: Open box, removed from an ex demo laptop. Quantity available: 5. Price: Approx. $12.97 AU $19.90 or Best Offer. Item number: 324208334019. Compatible Brand: Toshiba.

2. DHgate – AWM Cord Wire

Domain: dhgate.com

Registered: 2004 (21 years)

Introduction: This company, DHgate – AWM Cord Wire, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. OZON – Free Delivery Deals

Domain: ozon.ru

Registered: 1998 (27 years)

Introduction: This company, OZON – Free Delivery Deals, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

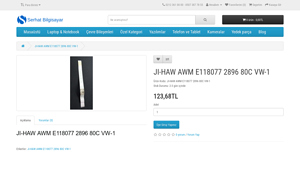

4. JI-HAW – AWM E118077 2896 80C VW-1

Domain: serhatbilgisayar.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “JI-HAW AWM E118077 2896 80C VW-1”, “product_code”: “JI-HAW AWM E118077 2896 80C VW-1”, “stock_status”: “2-3 gün içinde”, “price”: “123,68TL”, “currency”: “TL Türk Lirası”}

5. FLEXCONN – AWM-2896-80C-30V-VW-1 Cable

Domain: radwell.com

Registered: 1995 (30 years)

Introduction: AWM-2896-80C-30V-VW-1 Cable for Computer Network by FLEXCONN

6. Bigl – Шлейф AWM E118077 2896

Domain: bigl.ua

Introduction: Шлейф AWM E118077 2896 80C VW-1, длина 11 см, ширина 0.6 см, цена 190 ₴, готово к отправке.

Strategic Sourcing Conclusion and Outlook for awm e11 8077

The strategic sourcing of AWM E11 8077 components offers significant advantages for international B2B buyers seeking reliability and cost-effectiveness in their supply chains. This cable, known for its durability and compliance with safety standards, is increasingly critical in various applications, from consumer electronics to industrial machinery. By leveraging strategic sourcing practices, buyers can ensure they are obtaining high-quality products while optimizing procurement processes and reducing overall costs.

Furthermore, establishing relationships with reputable suppliers not only facilitates access to the latest technologies but also enhances responsiveness to market demands, particularly in fast-evolving sectors. For businesses in regions such as Africa, South America, the Middle East, and Europe, the ability to source AWM E11 8077 efficiently can drive competitive advantage and bolster operational efficiency.

As the global marketplace continues to evolve, it is essential for B2B buyers to stay proactive in their sourcing strategies. Embrace the opportunities that arise from strategic sourcing and consider diversifying your supply chain to include reliable partners. This approach will not only ensure a steady supply of AWM E11 8077 but also position your business for sustained growth and innovation in the years to come.