A B2B Buyer’s Guide to Automatic Spray Painting: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for automatic spray painting

In today’s competitive manufacturing landscape, sourcing the right automatic spray painting solutions can be a daunting task for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying reliable suppliers but also in ensuring that the equipment meets specific production needs while maintaining cost efficiency. This guide aims to illuminate the complexities of the global market for automatic spray painting, equipping buyers with the insights necessary to make informed purchasing decisions.

Within this comprehensive resource, we delve into various types of automatic spray painting systems, their applications across industries, and the critical factors to consider when vetting suppliers. From robotic paint systems to traditional spray guns, we explore the latest technological advancements that enhance quality and efficiency, helping manufacturers reduce waste and improve their bottom line. Additionally, we provide actionable insights into cost considerations, including potential return on investment and operational savings.

By navigating this guide, international buyers will gain a deeper understanding of the automatic spray painting landscape, empowering them to select solutions that not only meet their operational requirements but also align with their strategic goals. With an emphasis on practical advice and detailed analysis, this resource is designed to facilitate successful procurement strategies in a rapidly evolving global market.

Understanding automatic spray painting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Robotic Spray Painting Systems | High precision, programmable robots with multiple axes | Automotive, Aerospace, Electronics | Pros: High efficiency, reduced labor costs; Cons: High initial investment. |

| Electrostatic Spray Guns | Uses charged particles for improved paint adhesion | Metal finishing, Furniture, Automotive parts | Pros: Excellent transfer efficiency; Cons: Requires specific training for optimal use. |

| Airless Spray Systems | Delivers paint at high pressure without air | Industrial coatings, Large surface applications | Pros: Faster application, reduced overspray; Cons: Limited to specific paint types. |

| Automated Paint Mixing Systems | Integrates with paint lines for precise mixing | Custom manufacturing, Specialty coatings | Pros: Reduces waste, consistent quality; Cons: Complexity may require specialized training. |

| Custom Spray Painting Machines | Tailored solutions for unique production needs | Diverse industries including furniture and hardware | Pros: Meets specific production requirements; Cons: Longer lead times for customization. |

What are the Characteristics of Robotic Spray Painting Systems?

Robotic spray painting systems are characterized by their high precision and programmability, often utilizing multiple axes to navigate complex surfaces. These systems are particularly suitable for industries like automotive and aerospace, where consistent quality and speed are paramount. When considering a purchase, B2B buyers should evaluate the initial investment against potential labor savings and efficiency improvements.

How Do Electrostatic Spray Guns Enhance Application?

Electrostatic spray guns are distinguished by their ability to charge paint particles, which enhances adhesion to surfaces and minimizes overspray. This technology is commonly employed in metal finishing and furniture production. Buyers should consider the training required for optimal operation and the potential for increased material savings through improved transfer efficiency.

What Are the Benefits of Airless Spray Systems?

Airless spray systems operate by delivering paint at high pressure without the use of air, making them ideal for large surface applications in industrial coatings. They provide faster application rates and significantly reduce overspray, which can lead to cost savings. However, buyers should be aware that these systems may have limitations regarding the types of paint that can be used.

Why Invest in Automated Paint Mixing Systems?

Automated paint mixing systems are designed to integrate seamlessly into existing paint lines, offering precise mixing of various components. These systems are beneficial for custom manufacturing and specialty coatings where consistency is critical. While they can reduce waste and improve overall quality, the complexity of these systems may necessitate specialized training for staff.

What Advantages Do Custom Spray Painting Machines Offer?

Custom spray painting machines are tailored to meet specific production needs, making them versatile across various industries, including furniture and hardware. The key advantage lies in their ability to handle unique manufacturing challenges, though potential buyers should consider the longer lead times associated with custom designs.

Key Industrial Applications of automatic spray painting

| Industry/Sector | Specific Application of automatic spray painting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Painting car bodies and components | Enhances finish quality, reduces labor costs, and minimizes waste | Compatibility with existing robotic systems and color change efficiency |

| Electronics | Coating circuit boards and electronic housings | Protects components from corrosion, improves aesthetics | Precision in application and compliance with industry standards |

| Furniture | Finishing wooden and metal furniture | Provides a durable, high-quality finish while reducing labor costs | Flexibility for different materials and ease of maintenance |

| Aerospace | Painting aircraft components and fuselage | Ensures high-quality finishes and reduces operator error | Compliance with safety regulations and ability to handle large components |

| Construction Equipment | Coating heavy machinery and equipment | Increases durability and resistance to environmental factors | Robustness of equipment and ability to handle various paint types |

How is Automatic Spray Painting Used in Automotive Manufacturing?

In the automotive industry, automatic spray painting is essential for applying high-quality finishes to car bodies and components. This technology addresses common challenges such as inconsistent paint application and excessive waste. By automating the painting process, manufacturers can achieve a uniform coat while reducing labor costs and minimizing material waste by up to 30%. Buyers should consider compatibility with existing robotic systems and the efficiency of color change mechanisms to optimize production.

What are the Benefits of Automatic Spray Painting in Electronics?

In the electronics sector, automatic spray painting is utilized for coating circuit boards and electronic housings, providing essential protection against corrosion while enhancing aesthetic appeal. This application is particularly critical for maintaining product integrity and compliance with industry standards. For international buyers, precision in application and adherence to safety regulations are paramount when sourcing equipment that guarantees high-quality finishes and reliable performance.

How Does Automatic Spray Painting Enhance Furniture Production?

Automatic spray painting plays a significant role in the furniture industry by providing high-quality finishes for wooden and metal products. This method not only improves the durability of the finish but also significantly reduces labor costs associated with manual painting. Buyers should seek equipment that offers flexibility for various materials, as well as ease of maintenance to ensure continuous operation and minimal downtime in production.

Why is Automatic Spray Painting Important in Aerospace?

In aerospace manufacturing, automatic spray painting is critical for applying finishes to aircraft components and fuselages. This process ensures high-quality finishes while minimizing operator-related errors, which are vital for safety and aesthetics. International buyers must prioritize equipment that complies with stringent safety regulations and can handle the unique challenges of painting large components, such as ensuring even coverage and durability under extreme conditions.

What are the Key Applications of Automatic Spray Painting in Construction Equipment?

Automatic spray painting is widely used in the construction equipment sector for coating heavy machinery and equipment. This application not only enhances the durability of the machinery but also provides resistance to environmental factors such as moisture and UV exposure. When sourcing painting solutions, buyers should consider the robustness of the equipment and its ability to handle a variety of paint types to ensure long-lasting protection and aesthetic appeal.

3 Common User Pain Points for ‘automatic spray painting’ & Their Solutions

Scenario 1: High Material Waste and Environmental Concerns

The Problem: Many manufacturers encounter significant material waste when using traditional painting methods. This inefficiency not only leads to increased costs but also raises environmental concerns, especially in regions with strict regulations on VOC emissions. B2B buyers often struggle to balance quality with sustainability, leading to frustration over wasted resources and potential penalties.

The Solution: To address these challenges, investing in an advanced automatic spray painting system that boasts high transfer efficiency is essential. Systems equipped with electrostatic spray guns, like the Pro Xp Auto Electrostatic Spray Guns, can enhance paint adhesion and reduce overspray, cutting material waste by up to 30%. Moreover, integrating a positive displacement mixing system, such as the ProMix PD, can further minimize flushing waste by up to 80%. By selecting equipment that not only meets production needs but also aligns with environmental standards, manufacturers can achieve significant cost savings while enhancing their sustainability profile. Regular training for operators on the efficient use of these systems is also crucial to ensure optimal performance and adherence to best practices.

Scenario 2: Labor Shortages and Skills Gap in Painting Operations

The Problem: Many companies face acute labor shortages, particularly in skilled positions like paint application. As experienced operators retire or leave, newer employees often lack the expertise necessary to achieve consistent quality, leading to increased scrap rates and rework. This situation is particularly pronounced in regions where skilled labor is scarce, leaving businesses at risk of production delays and increased costs.

The Solution: Implementing an automatic spray painting solution can significantly alleviate these issues by reducing dependence on skilled labor. Robotic systems, such as the 6 Axis Painting Robot, can be programmed to handle complex shapes and provide consistent, high-quality finishes. This technology not only operates around the clock but also requires minimal supervision, allowing companies to reallocate human resources to other critical areas. Furthermore, investing in user-friendly interfaces and comprehensive training programs can enhance operator confidence and ensure smooth operations. Engaging with suppliers that offer lifetime technical support and training will empower businesses to maximize their investment and maintain high production standards without relying heavily on skilled labor.

Scenario 3: Frequent Downtime and Maintenance Challenges

The Problem: Downtime due to equipment failure or maintenance can severely disrupt production schedules and inflate operational costs. B2B buyers often find that traditional painting machines require frequent repairs and can be difficult to service, leading to frustration and financial losses. This is particularly critical in industries with tight deadlines, where delays can result in lost contracts or dissatisfied customers.

The Solution: To mitigate these challenges, selecting automatic spray painting machines designed for reliability and ease of maintenance is crucial. Machines equipped with self-lubricating moving guides and robust servo motors, like those from Robotic Paint Group, are built for longevity and minimal maintenance needs. Additionally, sourcing equipment from suppliers that offer comprehensive service agreements and a readily available inventory of spare parts can ensure swift repairs and reduced downtime. Implementing a proactive maintenance schedule, guided by the manufacturer’s recommendations, can also help preempt issues before they escalate. By prioritizing reliable technology and service support, companies can maintain smooth operations and meet production demands consistently.

Strategic Material Selection Guide for automatic spray painting

What Are the Key Materials for Automatic Spray Painting?

When selecting materials for automatic spray painting, it is essential to consider their properties, advantages, disadvantages, and specific implications for international B2B buyers. Here, we analyze four common materials used in this context: waterborne coatings, solvent-based coatings, powder coatings, and UV-curable coatings.

How Do Waterborne Coatings Perform in Automatic Spray Painting?

Waterborne coatings are increasingly popular due to their lower volatile organic compound (VOC) emissions and ease of cleanup. These coatings typically have good adhesion, flexibility, and resistance to yellowing, making them suitable for various substrates.

Pros: Waterborne coatings are environmentally friendly, leading to compliance with stringent regulations, especially in Europe. They offer excellent color retention and are less toxic, which is crucial for worker safety.

Cons: However, they may have a shorter shelf life and can require longer drying times compared to solvent-based options. Their performance can also be affected by humidity and temperature, which may be a concern in regions with variable climates.

Impact on Application: Waterborne coatings are compatible with a wide range of media and are ideal for indoor applications where low odor is desired.

Considerations for International Buyers: Compliance with local regulations regarding VOC emissions is critical. Buyers in regions like Europe may prefer waterborne options due to stricter environmental laws.

What Are the Advantages of Solvent-Based Coatings?

Solvent-based coatings are known for their durability and excellent resistance to chemicals and abrasion. They are often used in automotive and industrial applications due to their robust performance under harsh conditions.

Pros: These coatings typically cure faster and provide a high-gloss finish, making them suitable for applications requiring aesthetic appeal.

Cons: The main drawback is the higher VOC content, which can lead to regulatory challenges, especially in environmentally conscious markets. They also require more extensive safety measures during application.

Impact on Application: Solvent-based coatings are highly compatible with various substrates, including metals and plastics, making them versatile for different industries.

Considerations for International Buyers: Buyers should be aware of compliance with local VOC regulations and may need to invest in additional safety equipment for workers.

Why Choose Powder Coatings for Automatic Spray Painting?

Powder coatings are a dry finishing process that provides a thick, durable finish. They are particularly effective for metal surfaces and are known for their excellent resistance to chipping, scratching, and fading.

Pros: One of the key advantages is the absence of solvents, resulting in zero VOC emissions. This makes powder coatings an environmentally friendly option that can enhance a company’s sustainability profile.

Cons: However, the application process requires specific equipment and conditions, such as electrostatic spray guns and curing ovens, which can increase initial investment costs.

Impact on Application: Powder coatings are ideal for high-volume production runs, providing a uniform finish and excellent durability.

Considerations for International Buyers: Buyers should consider the availability of suitable application equipment and the need for specialized training for staff. Compliance with international standards for powder coatings may also be necessary.

What Are the Benefits of UV-Curable Coatings?

UV-curable coatings are rapidly gaining traction due to their fast curing times and high-performance characteristics. These coatings cure when exposed to UV light, making them ideal for high-speed production environments.

Pros: They offer excellent chemical resistance and durability, making them suitable for various applications, including electronics and automotive components.

Cons: The initial setup cost can be high due to the need for UV curing equipment. Additionally, not all substrates are compatible with UV-curable coatings.

Impact on Application: UV-curable coatings provide a high-gloss finish and can be applied in thin layers, reducing material usage.

Considerations for International Buyers: Understanding the compatibility of UV coatings with local substrates and ensuring compliance with safety standards is essential, particularly in regions with stringent regulations.

Summary of Material Selection for Automatic Spray Painting

| Material | Typical Use Case for automatic spray painting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Waterborne Coatings | Indoor furniture, automotive interiors | Environmentally friendly, low VOC | Longer drying times, humidity sensitivity | Medium |

| Solvent-Based Coatings | Automotive parts, industrial machinery | Fast curing, high gloss finish | Higher VOC content, safety concerns | Medium |

| Powder Coatings | Metal furniture, appliances | Zero VOC emissions, durable finish | Requires specialized equipment | High |

| UV-Curable Coatings | Electronics, automotive components | Fast curing, excellent durability | High initial setup cost | High |

This guide provides a comprehensive overview of the strategic material selection process for automatic spray painting, enabling B2B buyers to make informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic spray painting

What Are the Key Stages in the Manufacturing Process of Automatic Spray Painting?

The manufacturing process for automatic spray painting encompasses several critical stages that ensure the quality and efficiency of the final product. Understanding these stages can help B2B buyers identify reliable suppliers and the capabilities of their systems.

Material Preparation: How Is It Done?

Material preparation is the first step in the automatic spray painting process. It involves cleaning and pre-treating the surfaces to be painted. This stage is crucial as any contaminants can affect paint adhesion and finish quality. Techniques such as sandblasting, chemical cleaning, or using ultrasonic cleaners are common. Additionally, surface profiling may be performed to enhance adhesion, particularly for metals and plastics.

Forming: What Techniques Are Used?

The forming stage involves shaping the materials into their final configurations. For metal components, this could include stamping, welding, or machining. For plastics, injection molding may be employed. The choice of forming technique influences the durability and design of the painted surface. B2B buyers should assess whether suppliers can accommodate specific forming requirements, as this impacts the overall quality of the finished product.

Assembly: How Is It Integrated?

Following forming, the assembly stage integrates various components. This can include attaching parts that require painting together before they undergo the spray painting process. Automated systems often utilize robotic arms for precise assembly, ensuring that components fit perfectly. Buyers should inquire about the assembly capabilities of their suppliers, particularly if their products require intricate designs or multiple components.

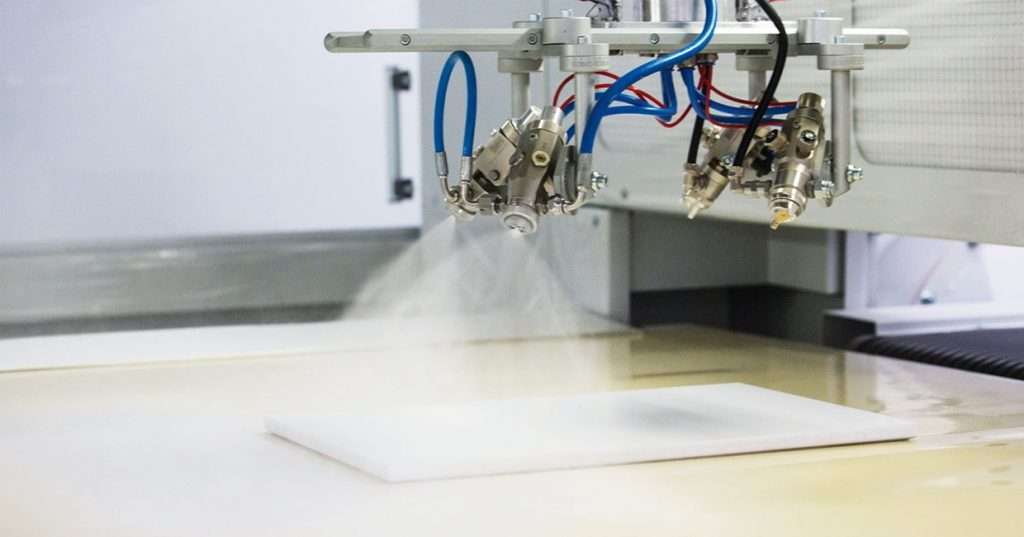

Finishing: What Are the Key Techniques and Technologies?

Finishing is where the automatic spray painting process shines. This stage typically involves the application of paint through advanced technologies such as robotic spray guns, electrostatic systems, or rotary atomizers. Robotic systems offer high precision and consistency, significantly reducing paint waste and improving transfer efficiency. The choice of technology can also influence the final finish quality, as some systems are better suited for specific materials or types of coatings. B2B buyers should evaluate the finishing technologies employed by potential suppliers to ensure they meet their quality standards.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is a critical aspect of the automatic spray painting process. Implementing robust QA measures can significantly enhance product reliability and customer satisfaction.

What International Standards Should Be Considered?

For international B2B buyers, compliance with recognized quality standards is vital. ISO 9001 is a widely accepted standard that outlines quality management systems, ensuring consistent product quality and service delivery. Additionally, industry-specific standards such as CE marking for safety and performance or API standards for oil and gas applications may apply. Buyers should verify that suppliers are certified to these standards as part of their due diligence.

What Are the Key QC Checkpoints in the Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials and components before production begins. It ensures that only materials that meet specified standards are used in the manufacturing process.

-

In-Process Quality Control (IPQC): This checkpoint monitors the ongoing manufacturing process. It includes regular inspections and tests to identify any issues that may arise during production, such as paint consistency or equipment calibration.

-

Final Quality Control (FQC): At this stage, the finished products undergo comprehensive testing and inspection to ensure they meet the required specifications and standards before shipping. This may include checking for uniformity in paint application, adhesion tests, and visual inspections for defects.

What Common Testing Methods Are Used in Quality Control?

Several testing methods are employed during the QC process to validate the quality of the painted surfaces:

-

Adhesion Testing: This method evaluates how well the paint adheres to the substrate. Techniques such as the cross-hatch test or peel tests are commonly used.

-

Thickness Measurement: Measuring the thickness of the paint layer ensures that it meets specified requirements. This can be done using non-destructive methods like magnetic or ultrasonic thickness gauges.

-

Gloss and Color Consistency: These tests assess the aesthetic quality of the finish. Gloss meters and color spectrophotometers are typically used to ensure uniformity across batches.

How Can B2B Buyers Verify Supplier Quality Control?

To establish confidence in a supplier’s quality control measures, B2B buyers should consider the following approaches:

What Role Do Audits and Reports Play?

Conducting regular audits of suppliers can provide insights into their quality management practices. Buyers should request audit reports that detail the supplier’s compliance with ISO standards and their internal QC processes. This transparency can help identify potential risks and areas for improvement.

Why Is Third-Party Inspection Important?

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s manufacturing processes and quality assurance measures. These inspections can be particularly beneficial for international transactions, ensuring that products meet local regulations and standards.

What Are the Specific QC Considerations for International B2B Buyers?

For international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Each region may have specific requirements regarding safety, environmental impact, and product quality. Buyers should ensure that suppliers are not only compliant with international standards but also aware of and aligned with local regulations.

Additionally, language barriers and differing business practices can complicate communication. Establishing clear lines of communication and ensuring that suppliers can provide documentation in the buyer’s preferred language will facilitate smoother transactions.

Conclusion: How to Choose the Right Supplier for Automatic Spray Painting?

In summary, B2B buyers looking for automatic spray painting solutions should thoroughly understand the manufacturing processes and quality assurance measures in place. By focusing on key stages such as material preparation, forming, assembly, and finishing, as well as robust QC protocols and international compliance, buyers can make informed decisions when selecting suppliers. Engaging in proactive communication, conducting audits, and considering third-party inspections will further enhance confidence in supplier capabilities, ensuring high-quality outcomes for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic spray painting’

Introduction

This practical sourcing guide is designed to assist B2B buyers in selecting and procuring automatic spray painting solutions. With the increasing demand for efficiency and quality in manufacturing, understanding the essential steps in the sourcing process is vital for achieving optimal results.

1. Identify Your Painting Requirements

Before diving into the procurement process, clarify your specific painting needs. Consider the types of materials you will be painting, the volume of production, and the desired finish quality. Understanding these requirements will help you narrow down your options and select a system that aligns with your operational goals.

2. Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring compatibility with your existing production line. This includes details on the types of spray guns, mixing systems, and robotic arms you require. Pay attention to factors such as the range of colors, the viscosity of materials, and the necessary automation features to optimize performance.

3. Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request company profiles, product catalogs, and case studies that demonstrate their capabilities. Look for references from other businesses in your industry or region to gauge their reliability and service quality. This step is essential to ensure you partner with a reputable supplier that meets your expectations.

4. Assess Automation Features and Technologies

Investigate the automation technologies offered by suppliers. Look for systems that integrate seamlessly with robotic arms and provide advanced features such as intelligent paint mixing and precise fluid control. Understanding the technology will help you choose a system that enhances efficiency and reduces waste, ultimately driving down costs.

5. Request Samples and Demonstrations

Before finalizing your purchase, request sample painting services or live demonstrations of the equipment. This will provide you with firsthand experience of the machine’s capabilities and performance. Evaluate the quality of the finish, speed of operation, and ease of use to ensure it meets your operational standards.

6. Review After-Sales Support and Training

Consider the level of after-sales support and training offered by the supplier. Look for companies that provide comprehensive training for your staff, as well as ongoing technical support. A strong support system can significantly reduce downtime and enhance the overall efficiency of your painting operations.

7. Negotiate Terms and Pricing

Finally, engage in negotiations regarding pricing, delivery timelines, and warranty terms. Ensure that you understand all costs involved, including installation, maintenance, and any additional parts or accessories. Clear communication during this phase can help establish a mutually beneficial partnership and prevent misunderstandings down the line.

By following this checklist, B2B buyers can make informed decisions when sourcing automatic spray painting solutions, ultimately leading to improved operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for automatic spray painting Sourcing

What Are the Key Cost Components in Automatic Spray Painting?

When evaluating the costs associated with automatic spray painting, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of paint and coating materials significantly impacts the overall cost. High-quality, specialized paints may cost more but can enhance durability and finish quality, ultimately reducing the need for frequent reapplications.

-

Labor: While automation reduces the labor cost per unit, initial setup and maintenance require skilled technicians. Understanding the balance between automated processes and required human oversight is crucial for cost assessment.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, facility maintenance, and equipment depreciation. Efficient operations can minimize these overheads, contributing to lower overall pricing.

-

Tooling: Customization of spray painting systems often necessitates specific tooling. The cost for this can vary widely based on the complexity and precision required for the job.

-

Quality Control: Implementing stringent QC measures ensures that the final product meets industry standards. This can incur additional costs, but it also mitigates the risk of rework and waste.

-

Logistics: Shipping costs, especially for international buyers, can significantly affect pricing. Understanding local import tariffs and logistics can aid in budgeting accurately.

-

Margin: Suppliers typically add a margin to cover their risks and operational costs. This can vary based on market competition and perceived value of the technology.

How Do Price Influencers Affect Automatic Spray Painting Costs?

Several factors influence the pricing of automatic spray painting systems, particularly for international buyers:

-

Volume/MOQ: Purchasing in bulk often leads to discounts. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

-

Specifications and Customization: Custom-designed systems tailored to specific needs can increase costs. Buyers should balance customization against standard options to optimize pricing.

-

Materials Used: The type of materials specified for the painting process can significantly impact pricing. Waterborne paints, for example, may be more expensive but offer better environmental compliance.

-

Quality and Certifications: Suppliers offering certified products may charge a premium. However, these certifications can be crucial for compliance in certain markets, making them a worthwhile investment.

-

Supplier Factors: The supplier’s reputation, experience, and after-sales support can also influence pricing. Established suppliers may charge higher prices but provide better service and reliability.

-

Incoterms: Understanding the shipping terms (Incoterms) is vital for international purchases. They dictate responsibility for shipping costs, insurance, and risk, which can affect the total cost.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Automatic Spray Painting?

To maximize cost-efficiency, buyers should consider the following strategies:

-

Negotiation: Always approach suppliers with a clear understanding of your requirements and budget. Effective negotiation can lead to better pricing or additional services without added costs.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess maintenance, operational efficiency, and potential savings from waste reduction and quality improvements.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local taxes, and import tariffs, as these can significantly alter the effective price.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and priority service. Consider establishing partnerships rather than one-off transactions.

-

Research and Benchmarking: Conduct thorough market research to understand pricing norms and competitor offerings. This can empower buyers during negotiations and help identify the best value propositions.

Conclusion

In summary, the cost structure and pricing of automatic spray painting systems involve multiple components and influencers. By understanding these elements and employing strategic purchasing practices, international buyers can optimize their sourcing decisions and achieve significant cost savings. Always remember that indicative prices can vary based on specific requirements and market conditions, so thorough due diligence is essential.

Alternatives Analysis: Comparing automatic spray painting With Other Solutions

Understanding Alternatives to Automatic Spray Painting

In the realm of industrial painting, automatic spray painting stands out for its efficiency and precision. However, it’s essential for B2B buyers to explore alternative solutions to determine the best fit for their specific operational needs. This section compares automatic spray painting with two notable alternatives: manual spray painting and powder coating. Each method has its unique advantages and disadvantages, making it crucial for manufacturers to evaluate them against their requirements.

Comparison Table

| Comparison Aspect | Automatic Spray Painting | Manual Spray Painting | Powder Coating |

|---|---|---|---|

| Performance | High transfer efficiency, consistent finish quality | Variable quality, affected by operator skill | Excellent durability and finish quality |

| Cost | Higher initial investment, lower long-term costs due to reduced waste | Low upfront costs but higher labor costs | Moderate initial investment, cost-effective for high volumes |

| Ease of Implementation | Requires integration with existing systems, training needed | Simple setup, minimal training | Requires specialized equipment and training |

| Maintenance | Regular maintenance needed for automated systems | Minimal maintenance, dependent on equipment | Regular maintenance of equipment required |

| Best Use Case | High-volume, consistent production environments | Low-volume, custom jobs where flexibility is needed | Durable finishes for metal products, outdoor applications |

Detailed Breakdown of Alternatives

Manual Spray Painting: Pros and Cons

Manual spray painting involves human operators applying paint using handheld spray guns. Its primary advantage lies in its flexibility, allowing for custom designs and variable production rates. This method is particularly suited for small-scale operations or bespoke projects where the attention to detail is paramount. However, its performance can be inconsistent, as it heavily relies on the skill and experience of the operator. Additionally, manual painting can lead to higher labor costs and material waste, making it less efficient for large production runs.

Powder Coating: Pros and Cons

Powder coating is a process that involves applying a dry powder that is then cured under heat to form a durable finish. This method offers excellent durability and resistance to chipping, scratching, and fading, making it ideal for metal products exposed to harsh conditions. While the initial investment in powder coating equipment can be significant, it becomes cost-effective over time, especially for high-volume applications. However, the setup is more complex compared to manual and automatic spray painting, requiring specialized equipment and training. Furthermore, powder coating cannot be easily adjusted for color changes, which may lead to longer downtimes in production.

Conclusion: Choosing the Right Painting Solution for Your Business

When selecting the appropriate painting solution, B2B buyers must consider various factors, including production volume, product type, and budget constraints. Automatic spray painting is ideal for businesses prioritizing efficiency and consistency in high-volume production. In contrast, manual spray painting might be more suitable for smaller, custom jobs where flexibility is essential. Powder coating serves well for products that demand exceptional durability. By assessing these alternatives against their operational needs, buyers can make informed decisions that enhance their production processes and overall business outcomes.

Essential Technical Properties and Trade Terminology for automatic spray painting

What Are the Essential Technical Properties of Automatic Spray Painting Systems?

When considering automatic spray painting systems, several technical properties are critical for ensuring optimal performance and efficiency. Understanding these specifications can significantly impact operational costs and quality output.

1. Transfer Efficiency

Transfer efficiency refers to the percentage of paint that adheres to the surface being coated compared to the amount of paint used. Higher transfer efficiency indicates less paint waste, which is crucial for cost control and environmental compliance. For B2B buyers, this property directly affects the bottom line by reducing material costs and minimizing VOC emissions.

2. Mixing Accuracy

Mixing accuracy is vital for systems that utilize plural component materials, such as two-component paints. It ensures that the components are blended in the correct ratios, which is essential for achieving the desired finish and performance characteristics. Inaccurate mixing can lead to defects, increased rework, and material waste, impacting both quality and profitability.

3. Automation Compatibility

Automation compatibility refers to the ability of spray painting equipment to integrate with robotic systems and other automation technologies. This property is essential for manufacturers looking to streamline their production processes. A compatible system can enhance workflow efficiency, reduce labor costs, and improve safety by minimizing the need for manual handling.

4. Durability and Maintenance Requirements

The durability of spray painting equipment affects its lifespan and the frequency of maintenance required. Equipment designed with high-quality materials and components often results in lower downtime and repair costs. B2B buyers should consider total cost of ownership, which includes initial investment, maintenance, and potential downtime.

5. Application Versatility

Application versatility refers to the range of materials and finishes that a spray painting system can handle. Systems that accommodate various substrates and coatings allow manufacturers to adapt to changing market demands without needing to invest in new equipment. This flexibility is crucial for businesses aiming to expand their product offerings and maintain competitiveness.

What Are Common Trade Terms in Automatic Spray Painting?

Understanding industry jargon is essential for navigating the procurement process effectively. Here are some key trade terms related to automatic spray painting:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of spray painting systems, buyers may work with OEMs to ensure that they receive quality components that meet specific operational needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers, as it affects inventory management and purchasing decisions. Understanding MOQ can help businesses avoid overstock situations or missed opportunities for bulk pricing.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products or services. In the spray painting industry, an RFQ can help buyers gather competitive pricing and terms from multiple suppliers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. These terms clarify aspects such as shipping costs, risk transfer, and delivery points. For B2B buyers in regions like Africa, South America, or the Middle East, understanding Incoterms can prevent misunderstandings and disputes in cross-border transactions.

5. VOC (Volatile Organic Compounds)

VOCs are organic chemicals that can evaporate into the air and contribute to air pollution. In the context of automatic spray painting, selecting low-VOC paints is essential for compliance with environmental regulations and for promoting workplace safety. B2B buyers should prioritize suppliers that offer eco-friendly options to meet regulatory requirements and enhance their corporate responsibility profile.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding automatic spray painting systems, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the automatic spray painting Sector

What Are the Key Market Trends Driving the Automatic Spray Painting Sector?

The automatic spray painting sector is experiencing significant growth driven by the increasing demand for efficiency, quality, and safety in manufacturing processes. As industries around the globe, particularly in Africa, South America, the Middle East, and Europe, continue to embrace automation, the need for advanced spray painting technologies is becoming paramount. One of the most notable trends is the integration of robotic systems into paint lines, which can reduce material waste by up to 30% and enhance transfer efficiency. This shift not only lowers operational costs but also minimizes environmental impact by reducing volatile organic compounds (VOCs) and waste disposal needs.

Emerging technologies, such as smart paint kitchens and advanced mixing systems, are further transforming the landscape. These innovations allow manufacturers to achieve precise color matching and optimal mixing ratios, thereby reducing rework and improving overall quality. Additionally, the rise of Industry 4.0 and IoT connectivity is facilitating real-time monitoring and data-driven decision-making, enabling businesses to streamline operations and enhance productivity.

International buyers should also pay attention to regional market dynamics. For instance, markets in Saudi Arabia and Brazil are increasingly investing in automation to meet local production demands and compliance with international quality standards. As these regions modernize their manufacturing capabilities, sourcing partnerships with reliable suppliers of automated painting systems will be crucial for maintaining competitive advantage.

How Can Sustainability and Ethical Sourcing Influence B2B Purchasing Decisions in Automatic Spray Painting?

Sustainability is becoming a critical consideration for B2B buyers in the automatic spray painting sector. The environmental impact of traditional painting methods, which often involve harmful chemicals and excessive waste, has prompted manufacturers to seek greener alternatives. This shift towards sustainability is not just a trend; it reflects a growing awareness of corporate responsibility and the necessity of ethical supply chains.

Companies are increasingly looking for suppliers that offer eco-friendly materials and ‘green’ certifications, such as low-VOC paints and recyclable packaging. These certifications not only ensure compliance with environmental regulations but also enhance brand reputation among environmentally conscious consumers. Moreover, implementing sustainable practices can lead to long-term cost savings through reduced waste and energy consumption.

Buyers should evaluate potential suppliers based on their commitment to sustainability and ethical practices, such as fair labor conditions and transparent sourcing. This focus on responsible procurement not only supports environmental goals but also aligns with the values of modern consumers, thereby fostering loyalty and trust.

What Is the Evolution of Automatic Spray Painting and Its Relevance to Today’s B2B Landscape?

The evolution of automatic spray painting technology has been marked by significant advancements since its inception. Initially, spray painting was a manual, labor-intensive process that posed challenges in consistency and quality. However, the introduction of automated systems revolutionized the industry, enabling manufacturers to achieve higher precision and efficiency.

Over the years, the integration of robotics has further enhanced the capabilities of automatic spray painting. Modern systems now feature sophisticated control mechanisms, allowing for complex patterns and finishes that were previously unattainable. As a result, industries such as automotive, aerospace, and electronics have benefited from these innovations, leading to improved product quality and faster production cycles.

In today’s B2B landscape, understanding the historical context of automatic spray painting is essential for making informed purchasing decisions. Buyers can leverage this knowledge to assess the technological maturity of suppliers, ensuring that they invest in solutions that not only meet current demands but are also future-proofed against the rapid pace of technological change.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic spray painting

-

How do I solve issues with inconsistent paint quality during automatic spray painting?

Inconsistent paint quality can stem from several factors, including improper mixing ratios, equipment malfunction, or incorrect spray settings. To resolve these issues, ensure that your mixing systems are calibrated accurately and that you are using the correct proportioners for the materials involved. Regular maintenance and inspection of your spray guns and robots are crucial to ensure optimal performance. Additionally, training operators on the proper settings and procedures can greatly enhance the quality of the finished product. -

What is the best automatic spray painting equipment for high-volume production?

For high-volume production, consider investing in advanced robotic painting systems that offer high transfer efficiency and quick color change capabilities. Systems like the ProBell Rotary Applicators and Pro Xp Auto Electrostatic Spray Guns are designed for optimal performance in high-demand environments. Evaluate your specific production needs, including the types of materials and finishes required, to determine the most suitable equipment. Consult with suppliers to identify solutions that integrate seamlessly into your existing production line. -

How can I customize an automatic spray painting solution for my specific needs?

Many suppliers offer customization options for automatic spray painting systems to align with your production requirements. This can include adjustments in machine size, choice of components, and integration with existing systems. When approaching a supplier, provide detailed specifications of your needs, such as the type of products being painted, the desired finish, and production capacity. Collaborating with an experienced engineering team can help ensure that your customized solution meets performance and efficiency standards. -

What are the minimum order quantities (MOQs) for automatic spray painting systems?

Minimum order quantities can vary widely among suppliers, depending on the complexity of the equipment and the level of customization required. It’s essential to discuss MOQs upfront during your supplier negotiations. Many manufacturers may have flexible terms for bulk orders or long-term contracts, allowing you to scale your purchase according to your production needs. Clarify these terms to avoid unexpected costs and ensure a smooth procurement process. -

What payment terms should I expect when purchasing automatic spray painting equipment?

Payment terms for automatic spray painting equipment can differ between suppliers and may include options such as upfront payments, installment plans, or letters of credit. Always review the terms in detail before finalizing any agreements. It’s advisable to negotiate payment terms that align with your cash flow and procurement strategy. Additionally, consider the reputation of the supplier and their financial stability to mitigate risks associated with large investments. -

How do I ensure quality assurance (QA) in my automatic spray painting process?

Implementing a robust QA process is crucial for maintaining the quality of your finished products. This can include regular inspections of the spray equipment, monitoring of paint viscosity and consistency, and conducting tests on the final paint finish. Collaborating with your supplier for training on quality control measures can enhance your team’s ability to detect issues early. Additionally, consider integrating automated monitoring systems that provide real-time feedback on paint application quality. -

What logistics considerations should I keep in mind when sourcing automatic spray painting equipment internationally?

When sourcing equipment internationally, consider factors such as shipping costs, import duties, and compliance with local regulations. It’s essential to work with suppliers who have experience in international shipping and can provide accurate delivery timelines. Ensure that you understand the total landed cost of the equipment, including transportation and customs fees. Developing a clear communication channel with your supplier will facilitate smoother logistics and help address any potential issues promptly. -

How can I vet suppliers for automatic spray painting equipment?

To effectively vet suppliers, start by researching their reputation in the industry. Look for customer testimonials, case studies, and any relevant certifications that demonstrate their expertise. Request references from previous clients to gauge their satisfaction with the products and services. Additionally, visiting the supplier’s manufacturing facility can provide insights into their production capabilities and quality control processes. Engaging in direct communication about your specific requirements will also help assess their responsiveness and professionalism.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Automatic Spray Painting Manufacturers & Suppliers List

1. Graco – Robotic Paint Systems

Domain: graco.com

Registered: 1994 (31 years)

Introduction: Paint Automation – Robotic Paint Systems, Automated Paint Systems, Paint Kitchen, Paint Circulation and Supply Pumps, Intelligent Paint Kitchen System, Spray Booth, Spray Booth Accessories, Spray Guns & Applicators, Spray Packages.

2. Robotic Paint Group – 5 Axis Spray Painting Machine

Domain: roboticpaint.com

Registered: 2016 (9 years)

Introduction: Robotic Paint Group Ltd specializes in automatic spray painting machines and painting robots. Key products include: 5 Axis Spray Painting Machine, which is popular for a wide range of painting requirements and offers two structures (2 & 4 support trays); 6 Axis Painting Robot, designed for flexibility and capable of spraying complex shapes; and custom design services for tailored machine sizes and…

3. Nordson – Automatic Spray Painting Systems

Domain: nordson.com

Registered: 1993 (32 years)

Introduction: Automatic Spray Painting Systems for Industrial Applications include:

1. Iso-Flo® Systems:

– Iso-Flo® HD Voltage Block System: A patented system providing a safe, cost-effective solution for electrostatically charged waterborne painting systems.

– Iso-Flo® Electrostatic Dolly System: A mobile, versatile system for manual waterborne spray applications that is plug-and-play, requiring just ai…

4. Dubois Equipment – Automated Spray Coating Machines

Domain: duboisequipment.com

Registered: 1998 (27 years)

Introduction: Automated spray coating machines utilize robotic technology to apply coatings (powder, liquid, or solidifying agents) to products. They improve productivity, reduce waste, and ensure higher-quality coatings. Types include: 1. Fan Coaters: Compact units for UV and water-based coatings with adjustable fan tips, dual filters, and can handle substrates up to 12 inches wide at 100-800 FPM. 2. Reciproca…

5. Würth Machinery – Automatic Spray Paint Machines

Domain: wurthmachinery.com

Registered: 2017 (8 years)

Introduction: Automatic Spray Paint Machines & Kraft Paper Rolls | Würth Machinery

6. Fuji – Mini-Mite 5 Spray Paint System

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Fuji Mini-Mite 5 spray paint system; T75G gun; LVLP vs HVLP discussion; recommendation for a 60-gallon compressor; advice on cleaning the gun and adjusting the fluid needle; suggestion of a 5 hp two-stage compressor as a minimum for serious spray gun work.

7. Lronning – Automatic Spray Painting Machine for Gas Cylinders

Domain: lronning.com

Registered: 2008 (17 years)

Introduction: Automatic Spray Painting Machine for gas cylinders – Model M169-108-XXX. Paints up to 6 gas cylinders at once. Features include: cylinder turning device, support arrangement, spray nozzles, travel guide, and high pressure piston paint pump. Capable of painting the shoulder and body in different colors. Individual or simultaneous painting of cylinders. Estimated process time: 2 minutes. Cylinder di…

8. SATA – SATAjet 3000 A

Domain: sata.com

Registered: 1996 (29 years)

Introduction: SATA automatic spray guns are designed for automation in painting and coating processes, primarily used on painting robots. Key features include low downtimes, maintenance efficiency, and high quality. They offer a wide range of nozzles for customization. Notable products include: SATAjet 3000 A (extra fast, material-fed), SATAjet 1000 A (internally controlled high-performance), SATAjet 3000 ROB (…

Strategic Sourcing Conclusion and Outlook for automatic spray painting

In today’s competitive manufacturing landscape, the strategic sourcing of automatic spray painting solutions offers significant advantages. By embracing automation, businesses can achieve remarkable cost savings—up to 30% reduction in material waste and lower labor costs—while enhancing the overall quality of their products. The integration of advanced robotic systems not only increases efficiency but also ensures a safer working environment for employees by minimizing exposure to hazardous conditions.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize partnerships with reputable suppliers that provide customizable, high-quality automated painting solutions. Such collaborations can streamline operations, reduce rework, and enhance production capabilities across various industries, from automotive to consumer electronics.

As the global market continues to evolve, the demand for efficient and sustainable manufacturing practices will only grow. Investing in automatic spray painting technologies is not just a trend; it’s a strategic move towards future-proofing your business. Engage with industry leaders today to explore innovative solutions that meet your specific needs and drive your operations to new heights.