A B2B Buyer’s Guide to Auger Screw Manufacturers: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for auger screw manufacturers

In an increasingly interconnected world, sourcing reliable auger screw manufacturers can pose a significant challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Whether you are in Nigeria seeking efficient material handling solutions or in Brazil looking to enhance production capabilities, understanding the nuances of auger screw technology is crucial. This guide aims to navigate the complexities of the global market for auger screw manufacturers, addressing key considerations such as types of augers, their diverse applications, and effective supplier vetting processes.

We delve into the specifications of different auger types, including vertical, free-flow, and non-free-flow augers, highlighting their unique functionalities tailored to various materials—from powders to viscous liquids. Additionally, we explore the cost factors involved in procurement, providing insights into pricing structures that can impact your bottom line. By presenting a comprehensive overview of the market landscape, our guide empowers B2B buyers to make informed purchasing decisions, ensuring that you choose the right manufacturer for your specific needs. With this knowledge, you can confidently enhance your operational efficiency and drive your business forward in today’s competitive environment.

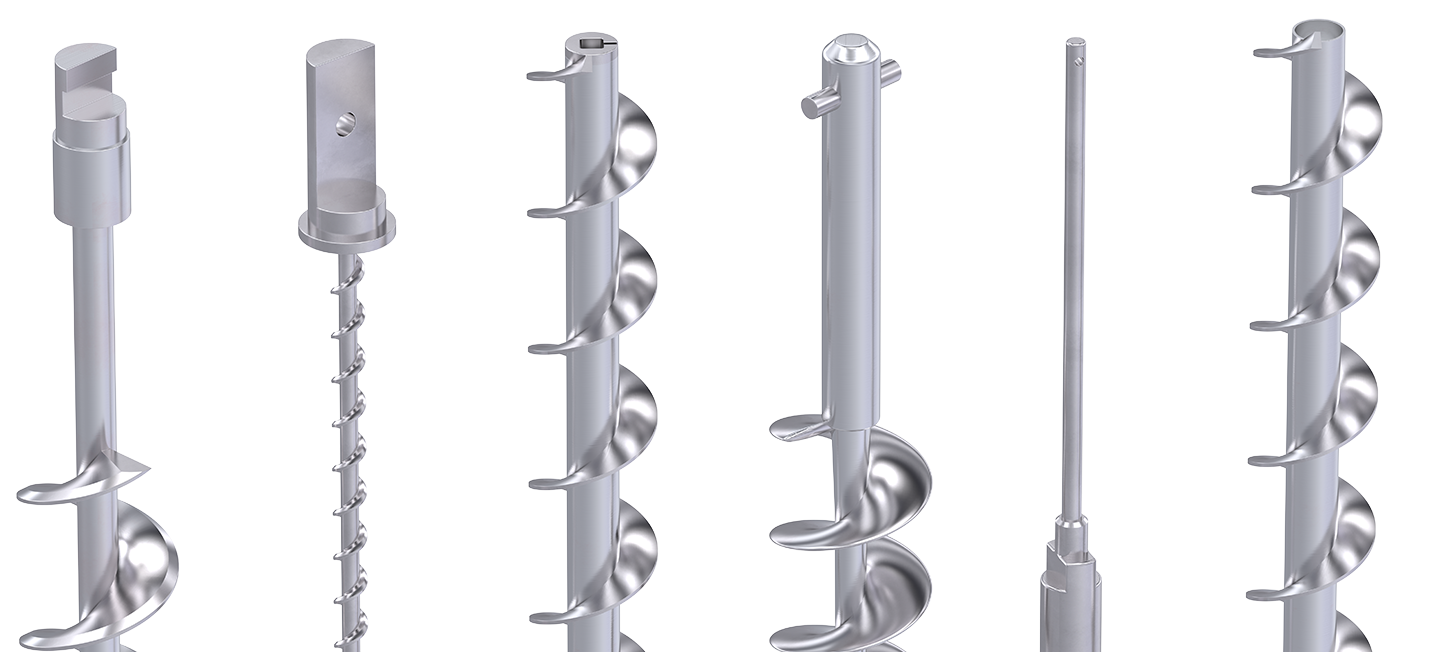

Understanding auger screw manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Free-Flow Augers | Designed for free-flowing materials; often used with slow-speed agitators and spinner plates. | Filling machines for powders like sugar, salt, and breadcrumbs. | Pros: Efficient metering, accurate dispensing. Cons: Limited to free-flowing materials. |

| Non-Free-Flow Augers | Engineered for dense, non-free-flowing materials; features over-flight design to compact products. | Handling bakery mixes, carbon powders, and talcum powder. | Pros: Effective for challenging materials, prevents drips. Cons: More complex design may require specialized maintenance. |

| Liquid Tooling Augers | Adapted for viscous liquids and pastes; incorporates pump rotors and stators instead of traditional auger shafts. | Dispensing creams, oils, and gels in cosmetic and food industries. | Pros: Versatile for various liquids, customizable. Cons: Requires careful calibration for optimal performance. |

| Vertical Augers | Utilizes a vertical orientation for material transport; often includes custom designs for specific applications. | Elevating materials in confined spaces, such as in warehouses or factories. | Pros: Space-efficient, ideal for height-restricted areas. Cons: Installation complexity may increase costs. |

| Screw Conveyors | Comprises a rotating helical screw element to move bulk materials; can be shafted or shaftless. | Bulk material handling in agriculture, mining, and food processing. | Pros: Versatile applications, customizable configurations. Cons: Potential for wear and tear depending on material handled. |

What Are Free-Flow Augers and Their Applications in B2B Settings?

Free-flow augers are specifically designed to handle materials that flow easily, such as granulated sugar, salt, and breadcrumbs. They typically operate with a slow-speed agitator and a spinner plate that ensures accurate dispensing into containers. B2B buyers should consider the nature of their materials when opting for free-flow augers, as they are not suitable for denser substances. Their efficiency in metering and dispensing makes them a preferred choice for many filling machine applications, allowing for streamlined operations.

How Do Non-Free-Flow Augers Differ from Free-Flow Variants?

Non-free-flow augers are tailored for handling dense, non-free-flowing materials like bakery mixes and carbon powders. These augers feature a unique over-flight design that compacts the product as it moves through the auger, ensuring consistent dispensing without drips. B2B buyers should assess the specific characteristics of the materials they intend to process, as the complex design of non-free-flow augers may require specialized maintenance. Their effectiveness in managing challenging materials makes them invaluable in various industrial applications.

What Are Liquid Tooling Augers and Their Key Advantages?

Liquid tooling augers are engineered to dispense viscous liquids and pastes, replacing traditional auger shafts with pump rotors and stators. This design allows them to handle products like creams, oils, and gels, making them essential in cosmetic and food industries. B2B buyers should focus on the viscosity and characteristics of their liquids when selecting liquid tooling augers, as proper calibration is crucial for optimal performance. Their versatility and customization options provide significant advantages in diverse manufacturing settings.

When Should Businesses Consider Vertical Augers?

Vertical augers are designed to transport materials in a vertical orientation, making them ideal for operations with limited floor space. They can be customized to meet specific operational needs and are particularly useful in warehouses and factories. B2B buyers should evaluate their spatial constraints and material types when considering vertical augers, as their installation can be more complex than horizontal systems. Their space-saving design can lead to increased efficiency in material handling.

Illustrative image related to auger screw manufacturers

How Do Screw Conveyors Fit into the Auger Market?

Screw conveyors utilize a rotating helical screw to transport bulk materials and can be configured as either shafted or shaftless. They are widely used across various industries, including agriculture, mining, and food processing, due to their versatility. B2B buyers should consider the specific material characteristics and operational requirements when selecting screw conveyors, as these factors can influence wear and tear on the equipment. Their adaptability and efficiency make them a staple in bulk material handling solutions.

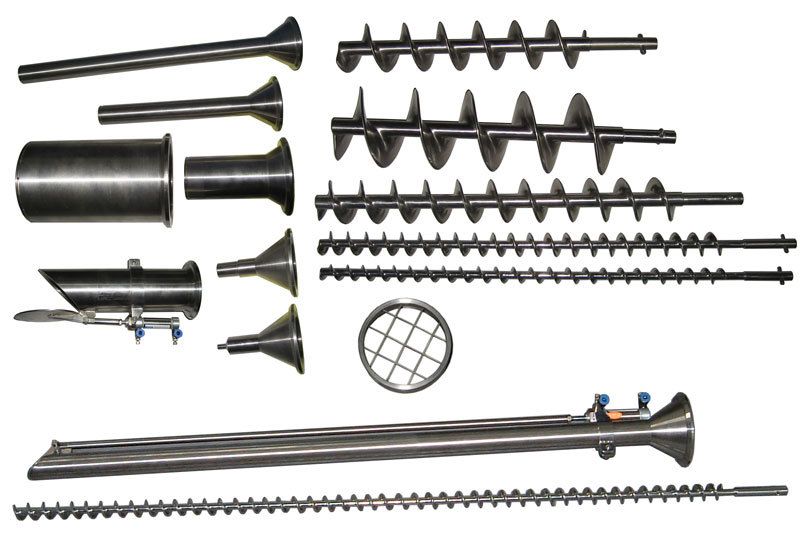

Key Industrial Applications of auger screw manufacturers

| Industry/Sector | Specific Application of auger screw manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Handling and dispensing bulk ingredients like flour and sugar | Ensures precise metering and reduces waste | Material compatibility, compliance with food safety standards |

| Agriculture | Grain handling and storage systems | Enhances efficiency in grain transport and storage | Durability against abrasives, customization for specific grain types |

| Chemical Manufacturing | Mixing and transporting powdered chemicals | Improves consistency and reduces contamination | Resistance to corrosive materials, ability to handle various viscosities |

| Waste Management | Transporting and processing waste materials | Increases operational efficiency and safety | Adaptability to different waste types, ease of maintenance |

| Construction | Conveying cement and other construction materials | Streamlines material handling on-site | Heavy-duty design, compatibility with various material sizes |

How are Auger Screw Manufacturers Used in Food Processing?

In the food processing industry, auger screw manufacturers provide essential equipment for handling and dispensing bulk ingredients, such as flour, sugar, and spices. These augers are designed to ensure precise metering, which minimizes waste and enhances product consistency. For international buyers, particularly in regions like Africa and South America, sourcing augers that comply with local food safety standards is crucial. Buyers must also consider the material compatibility of the augers to ensure they can handle various food products without contamination.

What Role Do Auger Screws Play in Agriculture?

In agriculture, auger screw manufacturers produce systems that facilitate the efficient handling and storage of grains. These augers transport bulk grains from storage to processing facilities, enhancing operational efficiency. For businesses in regions like Nigeria and Brazil, selecting augers that can withstand abrasive materials and harsh environmental conditions is vital. Additionally, customization options for specific grain types can significantly improve handling effectiveness, making it essential for buyers to communicate their needs clearly.

Illustrative image related to auger screw manufacturers

How are Auger Screws Utilized in Chemical Manufacturing?

Auger screw manufacturers are integral to the chemical manufacturing sector, where they are used for mixing and transporting powdered chemicals. These augers ensure that materials are handled safely and consistently, reducing the risk of contamination during the production process. Buyers in the Middle East and Europe should prioritize sourcing augers that are resistant to corrosive materials and capable of handling varying viscosities. Understanding the specific chemical properties of the materials being processed will help in selecting the right auger design.

What Benefits Do Auger Screws Offer in Waste Management?

In waste management, auger screw manufacturers supply equipment that efficiently transports and processes various waste materials. The use of augers in this sector increases operational efficiency and safety by minimizing manual handling of hazardous materials. For international buyers, especially in developing regions, it is important to source augers that are adaptable to different waste types and easy to maintain. Additionally, durability and reliability are key considerations to ensure continuous operation in challenging environments.

How are Auger Screws Applied in the Construction Industry?

In the construction industry, auger screw manufacturers provide solutions for conveying materials such as cement, sand, and gravel. These augers streamline material handling on job sites, improving workflow and reducing labor costs. Buyers should look for heavy-duty augers designed to withstand the rigors of construction environments and capable of handling various material sizes. Compatibility with existing equipment and ease of installation are also critical factors for international B2B buyers seeking reliable solutions in this sector.

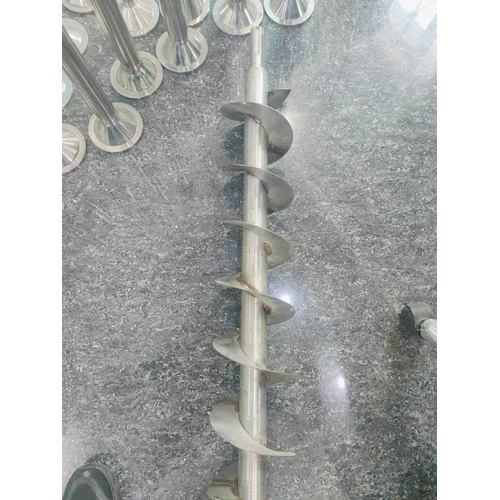

3 Common User Pain Points for ‘auger screw manufacturers’ & Their Solutions

Scenario 1: Inconsistent Quality of Auger Screws

The Problem: One of the most pressing issues B2B buyers face when sourcing auger screws is the inconsistency in quality. This can manifest as variations in material strength, dimensional tolerances, and overall craftsmanship. Such inconsistencies not only lead to operational inefficiencies but can also result in increased downtime, higher maintenance costs, and ultimately, reduced productivity. For businesses relying on precise material handling—especially in industries like food processing or pharmaceuticals—these variations can have serious repercussions, including compromised product integrity and compliance issues.

Illustrative image related to auger screw manufacturers

The Solution: To mitigate quality inconsistency, buyers should prioritize sourcing auger screws from manufacturers that offer comprehensive quality assurance processes. Look for manufacturers that provide detailed information about their fabrication methods, materials used, and testing protocols. Engaging in pre-purchase discussions can help clarify the manufacturer’s quality control measures, such as certifications (e.g., ISO standards) and the use of advanced manufacturing technologies like CNC machining. Additionally, consider requesting samples or conducting site visits to assess the manufacturing environment and craftsmanship firsthand. Establishing a long-term partnership with a reliable manufacturer that understands your specific needs will further enhance quality consistency.

Scenario 2: Lack of Customization Options

The Problem: Many B2B buyers encounter challenges when their specific material handling needs require customized auger screws, yet manufacturers offer limited options. This lack of customization can hinder operational efficiency, as standard solutions may not effectively handle unique materials or specific environmental conditions. For example, a company dealing with abrasive materials may find that standard auger designs wear down quickly, leading to frequent replacements and increased costs.

The Solution: When seeking auger screw manufacturers, it is crucial to identify those that specialize in custom solutions. Engage in discussions about your unique requirements, including material properties, expected throughput, and environmental conditions. Manufacturers with a dedicated engineering team can collaborate with you to design augers tailored to your specifications. Additionally, inquire about the materials used in the auger construction, as options like stainless steel or specialized coatings can enhance durability against wear and corrosion. Be proactive in requesting prototypes or pilot runs to evaluate the performance of the custom augers before full-scale production.

Scenario 3: Extended Lead Times and Delivery Issues

The Problem: Timely delivery of auger screws is vital for maintaining production schedules. However, many buyers experience frustrating delays due to extended lead times from manufacturers, which can be exacerbated by supply chain disruptions. Such delays can lead to production halts, increased operational costs, and potential loss of revenue, particularly in industries with tight timelines.

The Solution: To address lead time challenges, buyers should conduct thorough research on the supply chain capabilities of potential manufacturers. Look for manufacturers that offer transparent lead time estimates and have a proven track record of on-time delivery. Building relationships with manufacturers that maintain adequate inventory levels or have in-house fabrication capabilities can also mitigate delays. Consider implementing a just-in-time (JIT) inventory system, which aligns the ordering of auger screws with production schedules, thereby reducing the risk of stockouts. Furthermore, maintaining open communication with manufacturers regarding any potential delays can help you adjust your production plans proactively and minimize disruptions.

Illustrative image related to auger screw manufacturers

Strategic Material Selection Guide for auger screw manufacturers

What Are the Key Materials for Auger Screw Manufacturing?

When selecting materials for auger screws, manufacturers must consider various factors such as the specific application, environmental conditions, and regulatory compliance. Here, we analyze four commonly used materials: carbon steel, stainless steel, Hardox steel, and plastic composites. Each material presents unique properties, advantages, and limitations that can significantly impact performance and suitability for different applications.

How Does Carbon Steel Perform in Auger Screw Applications?

Key Properties: Carbon steel is known for its strength and durability, making it a popular choice for auger screws. It can withstand moderate temperatures and pressures but lacks inherent corrosion resistance.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and ease of manufacturing. However, its susceptibility to rust and corrosion in humid or wet environments can lead to shorter lifespans and increased maintenance costs.

Impact on Application: Carbon steel is suitable for handling dry bulk materials like grains and powders. However, it is not recommended for corrosive substances or environments, as it can degrade quickly.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of local climate conditions that may affect carbon steel’s performance. Compliance with ASTM standards for structural steel may also be necessary.

What Are the Benefits of Using Stainless Steel for Auger Screws?

Key Properties: Stainless steel, particularly types 304 and 316, offers excellent corrosion resistance and can handle higher temperatures and pressures compared to carbon steel.

Pros & Cons: The main advantage of stainless steel is its longevity and resistance to various chemicals, making it ideal for food processing and pharmaceutical applications. However, it comes with a higher price tag and can be more complex to manufacture.

Impact on Application: Stainless steel augers are particularly effective for handling corrosive materials or liquids, such as chemicals, food products, and pharmaceuticals. Their durability ensures consistent performance over time.

Considerations for International Buyers: Compliance with food safety standards, such as those set by the FDA or EU regulations, is crucial for buyers in Europe and the Middle East. Buyers should also consider the availability of stainless steel grades in their local markets.

Why Choose Hardox Steel for Heavy-Duty Applications?

Key Properties: Hardox steel is a wear-resistant material designed for heavy-duty applications. It offers high toughness and can withstand extreme conditions, including abrasive materials.

Pros & Cons: The key advantage of Hardox steel is its exceptional durability, making it ideal for applications involving abrasive substances. However, it is more expensive than standard steel options and may require specialized manufacturing processes.

Impact on Application: Hardox steel is particularly suitable for industries such as mining and construction, where augers are exposed to harsh materials like gravel and sand. Its wear resistance significantly reduces maintenance needs.

Considerations for International Buyers: Buyers in regions with heavy industrial activity, such as Brazil and the Middle East, may find Hardox steel particularly beneficial. Compliance with local standards for heavy machinery and equipment is essential.

When Should Plastic Composites Be Considered for Auger Screws?

Key Properties: Plastic composites offer lightweight, corrosion-resistant options for auger screws. They can handle moderate temperatures and pressures but may not be suitable for heavy loads.

Pros & Cons: The primary advantage of plastic composites is their resistance to corrosion and chemical reactions, making them ideal for specific applications. However, they may lack the strength and durability of metal options.

Impact on Application: Plastic augers are often used in food processing and chemical industries where corrosion is a concern. They are suitable for handling granular materials but may not perform well under heavy loads.

Considerations for International Buyers: Buyers should ensure that the selected plastic composites meet relevant industry standards for safety and performance, especially in food-related applications.

Illustrative image related to auger screw manufacturers

Summary of Material Selection for Auger Screws

| Material | Typical Use Case for auger screw manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Handling dry bulk materials like grains and powders | Cost-effective and easy to manufacture | Susceptible to rust and corrosion | Low |

| Stainless Steel | Food processing and pharmaceutical applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Hardox Steel | Heavy-duty applications in mining and construction | Exceptional durability and wear resistance | Expensive and requires specialized manufacturing | High |

| Plastic Composites | Food processing and chemical industries | Corrosion-resistant and lightweight | Limited strength for heavy loads | Medium |

This guide provides a strategic overview for B2B buyers to make informed decisions regarding material selection for auger screws, considering both performance characteristics and regional compliance requirements.

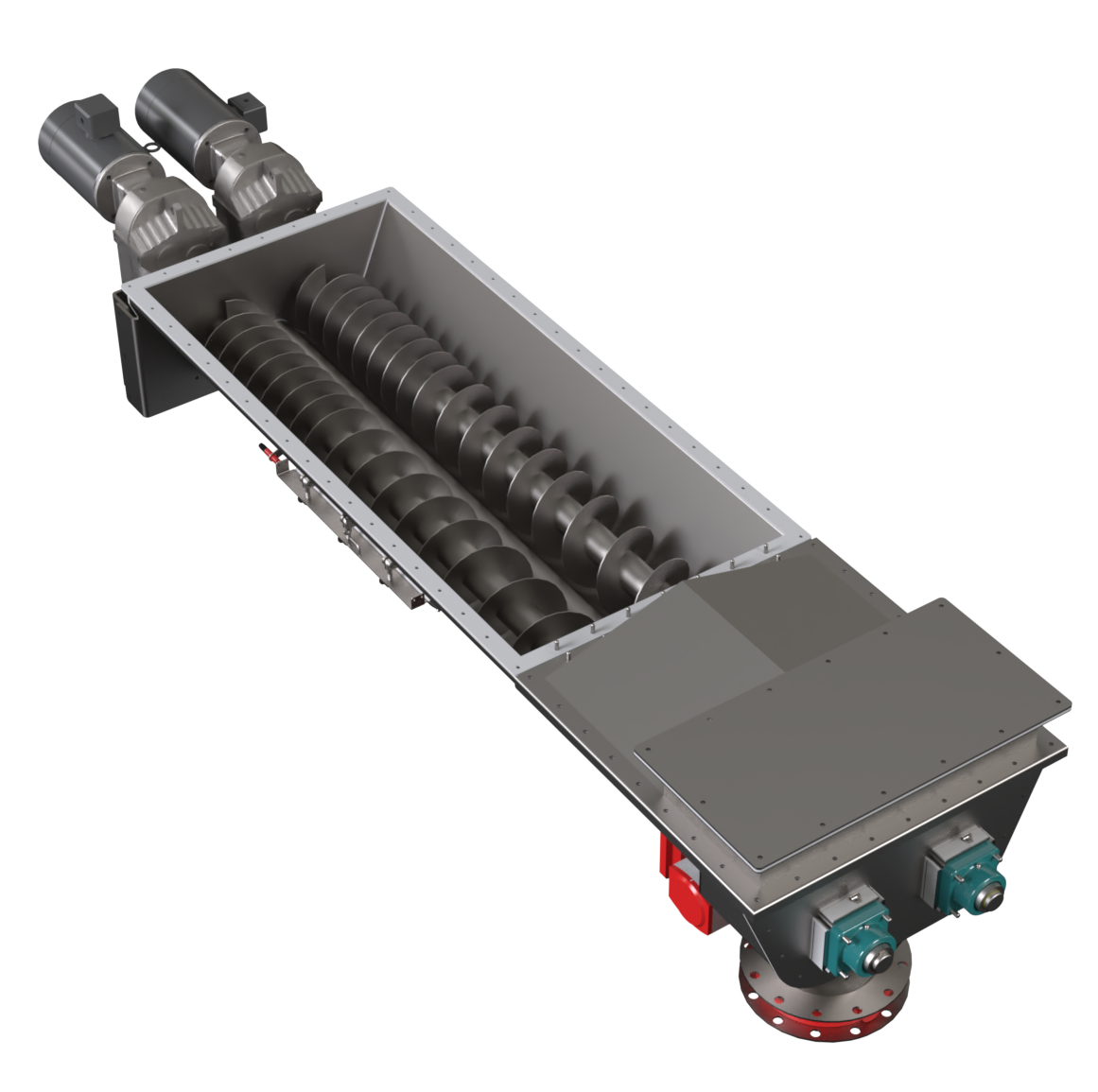

In-depth Look: Manufacturing Processes and Quality Assurance for auger screw manufacturers

Manufacturing high-quality auger screws involves a series of critical processes and quality assurance measures to ensure that the final products meet international standards and customer specifications. This section outlines the typical manufacturing processes and quality control protocols that auger screw manufacturers should adhere to, providing actionable insights for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe.

What Are the Main Stages in the Manufacturing Process for Auger Screws?

The manufacturing process for auger screws generally consists of four main stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the durability, efficiency, and reliability of the final product.

How Is Material Prepared for Auger Screw Production?

Material preparation is the first step in the manufacturing process, where raw materials are selected based on the specific requirements of the auger screw. Common materials include carbon steel, stainless steel (304 and 316), and specialized alloys for high-abrasion applications.

During this stage, manufacturers perform material inspections to verify compliance with specifications, including chemical composition and mechanical properties. Effective sourcing from reputable suppliers is crucial, as the quality of the raw materials directly affects the performance of the augers.

Illustrative image related to auger screw manufacturers

What Techniques Are Used for Forming Auger Screws?

The forming process involves shaping the raw materials into the desired auger screw configurations. Techniques may include:

- Cold Forming: This method is often used for creating helical flights and offers superior strength and precision.

- Welding: For custom augers, welding techniques are employed to join different components, ensuring structural integrity.

- Machining: Precision machining is used to create exact dimensions and tolerances, especially for components that require a perfect fit with other machinery parts.

Automated CNC machinery often plays a role in enhancing efficiency and consistency during the forming phase.

How Are Auger Screws Assembled?

Assembly is a critical step where individual components, such as the screw shaft, flights, and any necessary fittings, are brought together. Manufacturers often utilize jigs and fixtures to ensure alignment and accuracy during assembly.

Quality checks are typically performed at this stage to ensure that all components fit together correctly. Some manufacturers also implement modular designs, allowing for easier assembly and maintenance.

Illustrative image related to auger screw manufacturers

What Finishing Processes Are Applied to Auger Screws?

Finishing processes enhance the appearance and functionality of the auger screws. These may include:

- Surface Treatment: Processes such as sandblasting, polishing, or coating with protective layers (e.g., chromium carbide for abrasion resistance) are common.

- Heat Treatment: This technique is used to improve the mechanical properties of the steel, enhancing its strength and wear resistance.

- Final Inspection: Before packaging, a thorough inspection is conducted to identify any defects or inconsistencies.

What Quality Control Standards Should Auger Screw Manufacturers Follow?

Quality control (QC) is essential to ensure that the manufactured auger screws meet both customer expectations and regulatory requirements.

Which International Standards Are Relevant for Auger Screw Manufacturers?

Many auger screw manufacturers adhere to international standards like ISO 9001, which provides a framework for quality management systems. Compliance with industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications is also crucial.

These certifications not only validate the quality of the manufacturing processes but also enhance the credibility of the supplier in international markets.

What Are the Key Quality Control Checkpoints in Auger Screw Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

Illustrative image related to auger screw manufacturers

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular checks to monitor critical dimensions and tolerances.

- Final Quality Control (FQC): The final inspection assesses the complete product for any defects and verifies that it meets all specified requirements.

What Common Testing Methods Are Used to Ensure Quality?

Common testing methods for auger screws include:

- Dimensional Inspection: Utilizing calipers and gauges to confirm that all dimensions meet the specified tolerances.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle inspection help detect internal flaws without damaging the product.

- Functional Testing: This involves running the auger screws in actual working conditions to evaluate their performance and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers.

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s QC processes. Buyers should:

- Request Documentation: Suppliers should provide quality manuals, inspection reports, and certificates of compliance with relevant standards.

- Perform Site Visits: Visiting the manufacturing facility allows buyers to observe QC processes in action and verify the equipment and techniques being used.

- Engage Third-Party Inspectors: Utilizing independent third-party inspectors can provide an unbiased assessment of the supplier’s quality practices.

Are There Specific QC Considerations for International Buyers?

International buyers, particularly from regions such as Africa and South America, should be aware of additional QC nuances. Factors such as local regulations, import/export standards, and potential language barriers can complicate the procurement process. Establishing clear communication channels and understanding the specific quality requirements for each market can help mitigate these challenges.

Conclusion

Understanding the manufacturing processes and quality assurance protocols of auger screw manufacturers is crucial for B2B buyers seeking reliable suppliers. By familiarizing themselves with these processes and implementing thorough verification practices, buyers can ensure they select partners who meet their quality standards and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘auger screw manufacturers’

To assist B2B buyers in sourcing auger screw manufacturers effectively, this guide outlines a structured checklist. Each step is designed to streamline the procurement process, ensuring that buyers select the right manufacturer that meets their specific needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the auger screws you need. This includes the materials, dimensions, and specific functionalities such as whether the augers will handle free-flowing or viscous materials. Having detailed specifications helps in communicating your needs effectively to potential suppliers and ensures that they can meet your operational requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify manufacturers with a strong reputation in the industry. Look for companies that specialize in auger screws and have experience in your specific market sector. Utilize online platforms, industry forums, and trade shows to gather information and create a shortlist of potential suppliers.

Step 3: Evaluate Supplier Certifications

Verify that the manufacturers have relevant industry certifications and comply with international standards. Certifications such as ISO 9001 can indicate a commitment to quality management systems. Ensure that suppliers have certifications that are recognized in your region, particularly if you are sourcing from international manufacturers.

Step 4: Assess Manufacturing Capabilities

Inquire about the manufacturing processes and technologies employed by the suppliers. Look for capabilities in producing customized augers if your specifications require unique designs. Consider their capacity for producing large orders and the lead times they can offer, as this will impact your project timelines.

Step 5: Request Samples and Product Testing

Ask for samples of the auger screws to evaluate their quality and performance. Testing the samples in your operational environment can provide insights into their durability and efficiency. This step is crucial to ensure that the products meet your expectations before committing to a bulk order.

Step 6: Check Customer References and Reviews

Seek testimonials and references from previous clients, especially those who have similar needs. Engaging with existing customers can provide valuable insights into the supplier’s reliability, product performance, and after-sales support. Look for reviews on independent platforms to get an unbiased view of the manufacturer’s reputation.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, enter into negotiations regarding pricing, payment terms, and delivery schedules. Ensure that all agreements are clearly documented, covering aspects like warranty and after-sales service. A transparent negotiation process helps establish a strong partnership and mitigates potential disputes in the future.

Illustrative image related to auger screw manufacturers

By following this checklist, B2B buyers can make informed decisions when sourcing auger screw manufacturers, ensuring that they select a partner capable of meeting their specific operational needs.

Comprehensive Cost and Pricing Analysis for auger screw manufacturers Sourcing

What are the Key Cost Components for Auger Screw Manufacturers?

Understanding the cost structure of auger screw manufacturing is essential for international B2B buyers looking to source competitively priced products. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials include carbon steel, stainless steel (304 and 316), and specialized coatings for durability. Higher-grade materials increase costs but also enhance performance and longevity.

-

Labor: Labor costs can vary widely based on geographical location and the complexity of manufacturing processes. Skilled labor is required for precision fabrication and assembly, which can add to overall costs, especially in regions with higher wage standards.

-

Manufacturing Overhead: This encompasses expenses related to utilities, facility maintenance, and administrative costs. Manufacturers often factor these overheads into pricing, influencing the final quote provided to buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom augers. The investment in specialized machinery or molds is typically amortized over the production volume, affecting unit pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but also adds to manufacturing costs. Buyers should inquire about the QC processes in place, as higher standards may justify premium pricing.

-

Logistics: Shipping costs, tariffs, and import duties play a crucial role in the final pricing. Buyers from different regions should account for these factors, as they can significantly increase the total cost.

-

Margin: Manufacturers typically add a profit margin to cover their operational costs and ensure sustainability. This margin can vary based on market competition and the manufacturer’s reputation.

How Do Price Influencers Affect Auger Screw Costs?

Several factors influence the pricing of auger screws, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract bulk discounts. Understanding the MOQ can help buyers negotiate better pricing terms.

-

Specifications and Customization: Custom augers tailored to specific applications will typically incur additional costs. Buyers should weigh the benefits of customization against the price increase.

-

Quality and Certifications: Products with industry certifications or those made from high-quality materials often come at a premium. Buyers should assess whether the additional cost aligns with their quality requirements.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established manufacturers may charge higher rates due to their proven track record.

-

Incoterms: The terms of sale can significantly influence the total cost. Understanding Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers anticipate additional shipping and handling charges.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to more favorable pricing:

-

Research and Compare: Conduct thorough market research to understand average pricing and identify competitive suppliers. This information can be leveraged in negotiations.

-

Focus on Total Cost of Ownership (TCO): Rather than just the initial purchase price, consider long-term costs such as maintenance, durability, and efficiency. This approach can justify a higher upfront investment if it leads to lower overall costs.

-

Build Relationships with Suppliers: Establishing long-term partnerships with manufacturers can lead to better pricing and priority service. Suppliers are often more willing to negotiate with loyal customers.

-

Be Clear on Specifications: Clearly communicate your needs and specifications to avoid misunderstandings that could lead to additional costs. This clarity can also help in receiving accurate quotes quickly.

-

Leverage Local Insights: Utilize local representatives or agents who understand the market dynamics and can assist in negotiations and logistics, especially in unfamiliar territories.

Disclaimer on Pricing

Prices for auger screws can vary widely based on the factors outlined above. The information provided here serves as a guideline and may not reflect current market conditions. Always request detailed quotes from multiple suppliers to ensure competitive pricing tailored to your specific requirements.

Alternatives Analysis: Comparing auger screw manufacturers With Other Solutions

Introduction: Understanding Alternative Solutions to Auger Screw Manufacturing

In the realm of material handling and processing, auger screws are a popular choice for transporting bulk solids due to their efficiency and reliability. However, B2B buyers should consider alternative solutions that might better meet their specific operational needs. This section compares auger screw manufacturers with other viable technologies, helping businesses make informed decisions that align with their operational goals.

Illustrative image related to auger screw manufacturers

Comparison Table

| Comparison Aspect | Auger Screw Manufacturers | Pneumatic Conveying Systems | Belt Conveyors |

|---|---|---|---|

| Performance | High efficiency for bulk solids | Excellent for powders & granules | Versatile for various materials |

| Cost | Moderate to high initial cost | High initial investment | Generally lower cost |

| Ease of Implementation | Requires specific installation | Complex setup and design | Easy to install and operate |

| Maintenance | Moderate maintenance needs | High maintenance requirements | Low maintenance |

| Best Use Case | Heavy-duty bulk material handling | Fine powders, fragile materials | General material transport |

Detailed Breakdown of Alternatives

Pneumatic Conveying Systems

Pneumatic conveying systems utilize air pressure to transport materials through pipes. This method is particularly effective for fine powders and fragile materials, minimizing product degradation. While pneumatic systems offer excellent performance in terms of speed and efficiency, they come with high initial costs and complex installation requirements. Additionally, maintenance can be intensive due to the need for regular checks on air pressure and system integrity. Businesses dealing with sensitive materials might find pneumatic systems advantageous despite the higher upfront investment.

Belt Conveyors

Belt conveyors are a widely used alternative for transporting a variety of materials, including bulk solids, packaged goods, and even fragile items. They are generally easier to install and operate compared to auger systems, making them a cost-effective choice for businesses looking for a straightforward material handling solution. However, belt conveyors may lack the efficiency of auger screws in handling certain bulk materials, particularly those that are sticky or prone to clogging. Their versatility and lower maintenance requirements make them suitable for industries with diverse material handling needs.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between auger screw manufacturers and alternative solutions such as pneumatic conveying systems or belt conveyors, B2B buyers should evaluate their specific operational requirements, budget constraints, and the types of materials they handle. Each option presents unique advantages and challenges, and the best choice will depend on factors like the nature of the materials, the scale of operations, and maintenance capabilities. By conducting a thorough analysis of these alternatives, businesses can make informed decisions that enhance their material handling efficiency and align with their long-term operational goals.

Essential Technical Properties and Trade Terminology for auger screw manufacturers

What Are the Key Technical Properties of Auger Screws and Why Are They Important?

When selecting auger screws, understanding their technical properties is crucial for ensuring optimal performance in material handling applications. Here are some essential specifications that B2B buyers should consider:

1. Material Grade

The material used to manufacture auger screws can significantly impact durability and performance. Common materials include carbon steel, stainless steel (304 and 316 grades), and specialized alloys. For instance, stainless steel is preferred for corrosive environments, while carbon steel is often used for standard applications. Choosing the right material grade ensures that the auger can withstand the specific conditions of its operational environment, minimizing maintenance and replacement costs.

2. Tolerance Levels

Tolerance refers to the permissible limit or limits of variation in a physical dimension. For auger screws, maintaining precise tolerances ensures proper fit and function, which is crucial for efficient material flow. Tighter tolerances may be required for applications involving fine powders or sensitive materials. Understanding tolerance requirements can help buyers avoid operational issues such as material clogging or inconsistent dispensing.

3. Flight Thickness

The thickness of the auger flight affects its strength and the type of materials it can handle. Thicker flights are generally used for heavy-duty applications, while thinner flights may be adequate for lighter materials. Selecting the appropriate flight thickness ensures the auger can effectively manage the intended bulk material without excessive wear or failure.

4. Pitch and Helix Angle

The pitch (the distance between the centers of two adjacent flights) and the helix angle (the angle of the flight) determine the auger’s material handling capacity and efficiency. A larger pitch allows for faster material movement, while a steeper helix angle can improve the auger’s ability to convey materials vertically. Understanding these parameters helps buyers select augers that align with their specific operational needs.

5. Load Capacity

Load capacity indicates the maximum weight or volume of material an auger can handle without compromising performance. This specification is vital for ensuring that the auger can meet the demands of the application without risk of failure. Buyers should assess the load requirements based on their operational scenarios to avoid under or over-specifying equipment.

What Are Common Trade Terms Used in Auger Screw Manufacturing?

Understanding industry terminology is essential for effective communication and negotiation between buyers and manufacturers. Here are some common terms you may encounter:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of auger screws, buyers may engage with OEMs to procure components that are compatible with their existing systems or for custom applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it impacts inventory levels and cost-effectiveness. Knowing the MOQ helps businesses plan their procurement strategies and manage budgets effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing information for specific products or services. It is an essential step in the procurement process, allowing buyers to compare costs and terms from different manufacturers before making a decision.

Illustrative image related to auger screw manufacturers

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers navigate international purchases and manage logistics effectively.

5. Custom Fabrication

Custom fabrication refers to the process of creating unique components tailored to specific requirements. This term is significant for buyers looking for specialized auger screws that meet unique operational needs or conform to specific industry standards.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing auger screws, ensuring they select the right products for their material handling applications.

Navigating Market Dynamics and Sourcing Trends in the auger screw manufacturers Sector

What Are the Key Trends Driving the Auger Screw Manufacturers Market?

The auger screw manufacturing sector is experiencing dynamic shifts influenced by various global drivers. One major trend is the increasing demand for automation and efficiency in material handling processes across industries such as food and beverage, pharmaceuticals, and agriculture. The adoption of Industry 4.0 technologies, including IoT and advanced robotics, allows manufacturers to optimize production lines, reduce downtime, and improve operational efficiency. This trend is particularly relevant for international buyers in emerging markets like Nigeria and Brazil, where rapid industrialization is driving the need for modern, efficient equipment.

Moreover, there is a rising emphasis on customization and flexibility. B2B buyers are increasingly seeking tailored solutions that meet specific operational needs, such as handling varying material types and sizes. This trend fosters collaboration between manufacturers and buyers, as manufacturers leverage advanced engineering capabilities to design bespoke auger systems that enhance productivity.

Illustrative image related to auger screw manufacturers

Additionally, sustainability is becoming a cornerstone of sourcing strategies. Buyers are looking for manufacturers that prioritize eco-friendly materials and processes, which aligns with the growing global focus on reducing carbon footprints. The demand for high-quality, durable augers made from recyclable materials is on the rise, particularly in regions like Europe, where strict environmental regulations influence purchasing decisions.

How Are Sustainability and Ethical Sourcing Shaping Auger Screw Manufacturing?

As the focus on sustainability intensifies, ethical sourcing is becoming a critical consideration for B2B buyers in the auger screw manufacturing sector. Companies are increasingly aware of the environmental impact of their supply chains, leading them to seek suppliers who prioritize sustainable practices. This includes sourcing raw materials from certified suppliers who adhere to environmental regulations and ethical labor practices.

The use of ‘green’ materials is also gaining traction. Manufacturers are exploring options such as recycled metals and eco-friendly coatings that minimize environmental impact without compromising product quality. Certifications like ISO 14001 (Environmental Management) and Fair Trade can serve as indicators for buyers looking to partner with manufacturers committed to sustainability.

Furthermore, many companies are implementing life cycle assessments (LCAs) to evaluate the environmental impact of their products from production to disposal. This practice not only helps manufacturers reduce waste but also provides transparency for buyers concerned about the sustainability of their supply chains. In regions like South America and the Middle East, where environmental awareness is growing, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable and ethical sourcing practices.

What Is the Historical Context of Auger Screw Manufacturing?

The auger screw has a rich history that dates back to ancient civilizations, where it was primarily used for irrigation and lifting water. Over the centuries, the design and application of augers evolved significantly, leading to the development of more sophisticated machinery tailored for various industrial applications.

In the 19th century, the industrial revolution spurred advancements in material handling technologies, including the auger screw. Manufacturers began using augers in agriculture for grain handling and in mining for transporting materials. The 20th century saw further innovations, with the introduction of electric motors and automation, transforming augers into essential components of modern manufacturing processes.

Today, auger screw manufacturers are at the forefront of technological advancements, continually adapting to meet the changing demands of industries worldwide. This historical evolution not only highlights the versatility of augers but also underscores their critical role in enhancing operational efficiency across various sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of auger screw manufacturers

-

1. How do I solve issues with auger screw performance?

To resolve performance issues with auger screws, first assess the material being handled. Factors such as viscosity, particle size, and flow characteristics can significantly impact performance. Ensure that the auger design is suitable for the specific material—whether it is free-flowing or non-free-flowing. Regular maintenance checks for wear and tear, along with proper alignment and speed settings, can also prevent issues. Consulting with the manufacturer for tailored solutions can provide insights into optimizing your setup. -

2. What is the best auger screw design for handling different materials?

The best auger screw design depends on the characteristics of the material being conveyed. For free-flowing materials like grains or powders, a straight auger design is typically most effective. Conversely, for cohesive or non-free-flowing materials, a self-feeding auger with an over-flight design is recommended. Custom designs may be necessary for specific applications, and working with manufacturers who offer engineering support can help ensure you select the right configuration for your needs. -

3. What are the key factors to consider when selecting an auger screw manufacturer?

When choosing an auger screw manufacturer, consider their experience, reputation, and specialization in your industry. Evaluate their manufacturing capabilities, including the range of materials used and the customization options available. Quality assurance processes are crucial; ensure they have certifications and standards in place. Additionally, assess their customer support and after-sales service, as these can significantly impact your operational efficiency and satisfaction. -

4. How can I ensure the quality of auger screws from international suppliers?

To ensure quality from international suppliers, request detailed product specifications and certifications. Conduct supplier audits or factory visits, if possible, to assess their manufacturing processes and quality control measures. Utilize third-party inspection services to validate the quality before shipment. It’s also wise to start with smaller trial orders to evaluate performance and build trust before committing to larger quantities. -

5. What is the minimum order quantity (MOQ) for auger screws?

Minimum order quantities (MOQ) for auger screws can vary significantly among manufacturers. Some may offer flexible MOQs for standard designs, while custom augers often require higher MOQs due to the specific materials and engineering involved. It’s advisable to discuss your needs directly with manufacturers to negotiate terms that suit your purchasing strategy, especially if you are looking to source in bulk. -

6. What payment terms should I expect when sourcing auger screws internationally?

Payment terms for international orders can differ widely based on the supplier and the nature of the transaction. Common practices include advance payments, letters of credit, or net payment terms upon delivery. Be sure to clarify the payment structure upfront to avoid misunderstandings. Consider using secure payment methods that protect both parties, and ensure that you are aware of any additional costs, such as shipping or tariffs. -

7. How does logistics impact the procurement of auger screws?

Logistics play a crucial role in the procurement of auger screws, particularly when dealing with international suppliers. Factors such as shipping times, customs clearance, and transportation costs can affect your overall supply chain efficiency. Collaborate with suppliers to understand their shipping processes and timelines, and consider local regulations that may impact delivery. Efficient logistics management can reduce lead times and ensure timely availability of equipment. -

8. What customization options are typically available for auger screws?

Customization options for auger screws can include variations in size, material composition, and design features tailored to specific applications. Manufacturers may offer choices such as different flight designs, coatings for abrasion resistance, and modifications for unique material handling needs. Engaging in discussions with manufacturers about your specific requirements can lead to tailored solutions that enhance performance and efficiency in your operations.

Top 4 Auger Screw Manufacturers Manufacturers & Suppliers List

1. Auger Fabrication – Augers and Material Handling Solutions

Domain: augerfab.com

Registered: 1999 (26 years)

Introduction: Auger Fabrication specializes in supplying new and replacement augers for filling machines, manufacturing a variety of parts for material handling equipment including:

– Vertical Augers

– Horizontal Augers

– Free-Flow Augers

– Non-Free-Flow Augers

– Liquid Tooling

– Auger Funnels (Collector Funnels, Straight Funnels, Lip Funnels)

– Auger Shafts

– Vertical Form Fill & Seal Tooling

– Auger …

2. Seft Group – Stainless Steel Auger Conveyors

Domain: seftgroup.com

Registered: 2016 (9 years)

Introduction: Screw – Auger conveyors made of stainless steel, customized manufacturing. Models include TSA and TCA, which can have or not have a shaft, designed for transferring solid or semi-solid materials. Available in various versions with accessories suitable for intended purposes. Constructed from 304L / 316L stainless steel or high-strength carbon steel, with different pitch types and thicknesses. ISO 9…

3. IQS Directory – Auger Conveyor Manufacturers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: IQS Directory is a comprehensive industrial directory listing leading auger conveyor manufacturers and suppliers in Indiana. The directory includes detailed product descriptions, company profiles, and contact information. Auger conveyor products can be designed, engineered, and manufactured to meet specific application needs. Key features include variable speeds for material flow adjustment, vario…

4. JM Fastener – Auger Screws

Domain: jm-fastener.com

Registered: 2021 (4 years)

Introduction: Auger screws are crucial in various industries, including agriculture, manufacturing, mining, construction, environmental engineering, pharmaceuticals, chemicals, and food processing. Key manufacturers include: 1. Flight Manufacturing Corp.: Known for custom auger screws tailored to specific requirements, enhancing operational efficiency. 2. Continental Augers: Offers a diverse range of auger scre…

Strategic Sourcing Conclusion and Outlook for auger screw manufacturers

As the auger screw manufacturing sector evolves, international B2B buyers must prioritize strategic sourcing to enhance operational efficiency and product quality. Key insights reveal that selecting manufacturers who specialize in customized solutions, such as those offering tailored auger designs and materials, can significantly impact the effectiveness of material handling processes. Buyers should also consider manufacturers with robust engineering capabilities and a reputation for rapid lead times, as these factors contribute to minimizing downtime and maximizing productivity.

Moreover, understanding the specific applications of different auger types—ranging from free-flow to non-free-flow designs—enables buyers to make informed decisions that align with their operational needs. As market dynamics shift, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strong relationships with reputable manufacturers will be critical.

Looking ahead, the demand for innovative and efficient auger solutions will continue to grow. Buyers are encouraged to engage proactively with manufacturers, exploring partnerships that not only meet immediate requirements but also anticipate future challenges. By doing so, they can secure a competitive edge in their respective markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.