A B2B Buyer’s Guide to Alumina Sheet Price: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for alumina sheet price

In today’s competitive landscape, sourcing high-quality alumina sheets at competitive prices can be a daunting challenge for international B2B buyers. With the growing demand across various industries—from automotive to electronics—understanding the nuances of alumina sheet pricing is crucial for making informed purchasing decisions. This comprehensive guide delves into the key factors influencing alumina sheet prices, including material purity, manufacturing processes, and regional market trends.

Our exploration covers a wide array of alumina sheet types, their diverse applications, and essential tips for vetting suppliers effectively. Whether you are based in Africa, South America, the Middle East, or Europe—countries like Saudi Arabia and Vietnam included—this guide aims to equip you with the insights needed to navigate the global market confidently. By understanding cost structures, potential suppliers, and application-specific requirements, you will be better positioned to negotiate favorable terms and ensure the quality of your materials.

With a focus on actionable insights and strategic sourcing, this guide empowers B2B buyers to streamline their procurement processes and optimize their operational efficiencies. Prepare to enhance your knowledge and make well-informed decisions that drive your business forward in the dynamic world of alumina products.

Understanding alumina sheet price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Purity Alumina Sheets | >99% purity, excellent thermal stability, high hardness | Metallurgy, automotive, chemical processing | Pros: High performance, durability. Cons: Higher cost, limited sizes. |

| Laser-Cut Alumina Substrates | Precision laser machining, customizable dimensions | Electronics, medical devices, aerospace | Pros: High precision, tailored designs. Cons: Longer lead times for custom orders. |

| Standard Alumina Plates | Various thicknesses and sizes, moderate purity (96-99%) | General industrial applications, insulation, wear parts | Pros: Versatile, cost-effective. Cons: Lower performance compared to high purity options. |

| Alumina Tubes and Rods | Specific shapes for tailored applications | Structural components, thermal barriers, insulators | Pros: Customizable shapes, good mechanical properties. Cons: May require additional machining. |

| Specialty Alumina Products | Unique formulations for specific applications | Electronics (substrates), biomedical applications | Pros: Tailored for specific uses, innovative solutions. Cons: Potentially higher costs and longer development times. |

What Are High Purity Alumina Sheets and Their Key Characteristics?

High purity alumina sheets contain over 99% aluminum oxide, offering exceptional thermal stability and hardness. These sheets are ideal for industries requiring materials that can withstand high temperatures and corrosive environments, such as metallurgy and automotive sectors. When purchasing, buyers should consider factors like thickness, size, and the specific purity level required for their application, as these can significantly impact performance and pricing.

How Do Laser-Cut Alumina Substrates Stand Out?

Laser-cut alumina substrates are characterized by their precision machining capabilities, allowing for highly customized dimensions and shapes. This makes them particularly suitable for electronics and medical devices, where exact specifications are critical. Buyers should evaluate their design requirements and lead times, as custom orders may take longer to fulfill. The ability to create tailored solutions can justify the higher costs associated with these products.

What Are the Benefits of Standard Alumina Plates?

Standard alumina plates are widely used across various industries due to their moderate purity levels (typically between 96% and 99%) and availability in multiple sizes and thicknesses. They are an economical choice for general industrial applications, insulation, and wear parts. Buyers should assess the balance between cost and performance, as lower purity may lead to reduced durability in extreme environments compared to high-purity alternatives.

Why Consider Alumina Tubes and Rods for B2B Applications?

Alumina tubes and rods offer specific shapes that cater to various industrial needs, such as structural components and thermal barriers. These products can be customized, but buyers must consider additional machining requirements that may arise from their specific applications. Understanding the mechanical properties and thermal resistance of these components is crucial for ensuring they meet the necessary performance criteria.

What Are Specialty Alumina Products and Their Applications?

Specialty alumina products are designed with unique formulations tailored for specific applications, such as electronic substrates or biomedical uses. These products can provide innovative solutions but often come at a higher cost and longer development time. Buyers should weigh the benefits of specialized performance against potential budget constraints and timelines, ensuring that the chosen product aligns with their operational requirements.

Key Industrial Applications of alumina sheet price

| Industry/Sector | Specific Application of alumina sheet price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metallurgy | High-temperature furnace linings | Enhanced durability and thermal stability | Purity levels, thermal conductivity, and dimensions |

| Automotive | Brake pads and wear-resistant components | Improved performance and safety | Friction properties, hardness, and customization options |

| Electronics | Insulating substrates for electronic circuits | Reliable electrical insulation and heat resistance | Thickness, precision machining capabilities, and lead times |

| Chemical Processing | Reaction vessels and containment systems | Corrosion resistance and chemical stability | Chemical compatibility, size requirements, and certifications |

| Aerospace | Engine components and thermal barriers | Lightweight and high-strength materials | Weight specifications, thermal properties, and compliance with industry standards |

In the metallurgy sector, alumina sheets are utilized as linings in high-temperature furnaces, providing exceptional thermal stability and resistance to wear. This application is critical for maintaining operational efficiency and extending equipment lifespan. International buyers, particularly from regions with high industrial activity, must consider the purity levels of alumina, as impurities can significantly affect performance under extreme conditions.

Illustrative image related to alumina sheet price

Within the automotive industry, alumina sheets are used in the production of brake pads and other wear-resistant components. The high hardness of alumina improves the longevity and performance of these parts, thereby enhancing vehicle safety. B2B buyers should focus on sourcing materials that offer specific friction properties and can be customized to meet unique design requirements.

In electronics, alumina sheets serve as insulating substrates for various electronic circuits. Their excellent electrical insulation and thermal resistance make them ideal for high-performance applications. Buyers in this sector need to prioritize precision machining capabilities, as the dimensions of the alumina sheets must meet exact specifications to ensure optimal functionality in electronic devices.

The chemical processing industry benefits from alumina sheets used in reaction vessels and containment systems, where chemical stability and corrosion resistance are paramount. This application is particularly relevant for international buyers in regions with stringent chemical regulations. It is essential to verify the chemical compatibility of the alumina with specific substances and to ensure that the product meets necessary certifications.

Illustrative image related to alumina sheet price

Finally, in the aerospace sector, alumina sheets are employed in engine components and thermal barriers due to their lightweight and high-strength characteristics. This application is crucial for enhancing fuel efficiency and performance. Buyers must ensure that the alumina meets rigorous industry standards and specifications, particularly regarding thermal properties and weight limitations, to maintain compliance and safety in aerospace applications.

3 Common User Pain Points for ‘alumina sheet price’ & Their Solutions

Scenario 1: Navigating Fluctuating Alumina Sheet Prices

The Problem: B2B buyers in industries such as automotive, metallurgy, and chemical manufacturing often face unpredictable fluctuations in alumina sheet prices. These price variations can significantly affect project budgets and lead to financial strain, especially when large volumes are involved. For instance, a company may have budgeted a specific amount for alumina sheets, only to find that prices have surged unexpectedly. This situation can lead to either project delays or the need for emergency budget adjustments, which can strain relationships with stakeholders.

The Solution: To mitigate the impact of fluctuating prices, buyers should establish long-term relationships with multiple suppliers. This approach not only allows for better negotiation power but also opens up avenues for bulk purchasing agreements that can lock in prices over a specified period. Additionally, implementing a hedging strategy, such as committing to a set volume of alumina sheets at a fixed price for a future date, can protect against sudden price spikes. Buyers should also continuously monitor market trends and supply chain factors that influence pricing, enabling them to make informed purchasing decisions.

Scenario 2: Difficulty in Comparing Alumina Sheet Quality and Pricing

The Problem: B2B buyers often struggle with the challenge of comparing the quality and pricing of alumina sheets from different suppliers. Variations in purity, thickness, and other specifications can lead to confusion and difficulty in assessing value. For example, one supplier might offer a lower price for a lower purity alumina sheet, while another offers a higher-priced, high-purity option that may be more suitable for the buyer’s application. This complexity can result in poor purchasing decisions that impact production quality and operational efficiency.

The Solution: To navigate this issue, buyers should develop a comprehensive specification sheet that outlines the critical requirements for their applications, including purity levels, dimensions, and thermal properties. With this document in hand, they can request detailed quotes from multiple suppliers that explicitly address these specifications. It’s also beneficial to ask for samples to evaluate the physical properties and performance of the alumina sheets before making a large purchase. Engaging in direct conversations with suppliers about their manufacturing processes and quality control measures can provide additional insight into the product’s value.

Illustrative image related to alumina sheet price

Scenario 3: Understanding the Total Cost of Ownership for Alumina Sheets

The Problem: Many B2B buyers focus solely on the initial purchase price of alumina sheets, neglecting to consider the total cost of ownership (TCO). Factors such as shipping costs, potential waste during processing, and the longevity of the material can significantly impact the overall expenditure. For example, a cheaper alumina sheet might lead to higher processing costs due to its brittleness or lower thermal stability, making it less cost-effective in the long run.

The Solution: To gain a better understanding of the total cost of ownership, buyers should conduct a thorough analysis that includes all associated costs beyond the initial purchase. This analysis should factor in shipping fees, processing yields, and the expected lifespan of the alumina sheets in their specific applications. Working closely with suppliers to understand the long-term performance characteristics of their products can also provide insights into durability and maintenance needs. By employing a holistic approach to procurement that considers the full lifecycle costs, buyers can make more informed decisions that enhance overall operational efficiency and profitability.

Strategic Material Selection Guide for alumina sheet price

What Are the Key Properties of Alumina Sheets for B2B Buyers?

Alumina sheets are primarily made from aluminum oxide (Al₂O₃) and are valued for their exceptional properties. The most notable characteristics include high thermal stability, withstanding temperatures up to 1600°C, and excellent mechanical strength. These sheets exhibit remarkable chemical resistance, making them suitable for harsh environments where exposure to corrosive substances is common. Additionally, their low thermal expansion and good electrical insulation properties make them ideal for various industrial applications, including electronics and automotive components.

What Are the Pros and Cons of Different Alumina Sheet Materials?

High Purity Alumina (99% and above)

Pros: High purity alumina sheets offer superior mechanical strength and thermal stability, making them ideal for applications requiring high-performance materials. Their excellent wear resistance and low porosity enhance their durability, making them suitable for demanding environments.

Cons: The manufacturing process for high purity alumina can be complex and costly. This might lead to a higher price point compared to lower purity options, which could be a consideration for budget-sensitive projects.

Impact on Application: High purity alumina is particularly well-suited for high-temperature applications, such as in furnaces or reactors in the metallurgy and chemical industries. It is also compatible with various media, including corrosive chemicals.

Standard Alumina (Alumina 96%)

Pros: Standard alumina sheets provide a balanced combination of performance and cost, making them a popular choice for many industrial applications. They exhibit good thermal and chemical resistance, while also being more affordable than high-purity options.

Cons: While still durable, standard alumina may not perform as well in extreme conditions compared to high purity variants. This could limit their use in specialized applications requiring the highest levels of performance.

Impact on Application: Standard alumina is often used in applications such as wear-resistant coatings and insulators, where moderate performance is acceptable. It is generally compatible with a wide range of industrial media.

Laser-Cut Alumina Substrates

Pros: Laser-cut alumina substrates allow for precise customization, making them ideal for specific applications. The high precision achieved through laser cutting results in minimal waste and can accommodate complex designs.

Cons: The cost of laser-cut alumina can be higher due to the advanced manufacturing process. Additionally, lead times may be longer for custom orders, which can impact project timelines.

Impact on Application: These substrates are particularly useful in electronics and medical applications where precision is critical. Their compatibility with various electronic components makes them a preferred choice for manufacturers in these sectors.

What Should International B2B Buyers Consider When Selecting Alumina Sheets?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider compliance with local and international standards such as ASTM, DIN, and JIS. Understanding these standards is crucial for ensuring product quality and compatibility with regional regulations. Additionally, buyers should assess the availability of materials and suppliers in their region to minimize shipping costs and lead times. Preferences for specific grades of alumina may vary by industry and application, so it is essential to align material selection with the specific needs of the intended use.

Summary Table of Alumina Sheet Materials

| Material | Typical Use Case for alumina sheet price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High Purity Alumina (99%+) | High-temperature reactors | Superior mechanical strength and stability | Higher manufacturing cost | High |

| Standard Alumina (96%) | Wear-resistant coatings | Good balance of performance and cost | Limited performance in extreme conditions | Medium |

| Laser-Cut Alumina Substrates | Electronics and medical applications | High precision and customization | Higher cost and longer lead times | High |

This guide provides a comprehensive overview of the strategic material selection for alumina sheets, helping B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for alumina sheet price

Alumina sheets, known for their exceptional hardness and thermal stability, undergo a meticulous manufacturing process to ensure their suitability for various industrial applications. This guide delves into the stages of manufacturing, quality assurance practices, and how B2B buyers can effectively evaluate suppliers, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Stages in the Manufacturing Process of Alumina Sheets?

The production of alumina sheets involves several critical stages, each essential for achieving the desired quality and specifications.

1. Material Preparation: Sourcing and Processing Raw Materials

The first step in manufacturing alumina sheets is sourcing high-purity aluminum oxide (Al2O3) as the primary raw material. Suppliers often use various methods to purify alumina, including calcination, which enhances its properties. The material must meet specific purity standards, typically above 99%, to ensure optimal performance in end applications.

After sourcing, the alumina is processed into a fine powder, which may involve milling and sieving to achieve the required particle size. This fine powder is crucial for creating a uniform and consistent sheet.

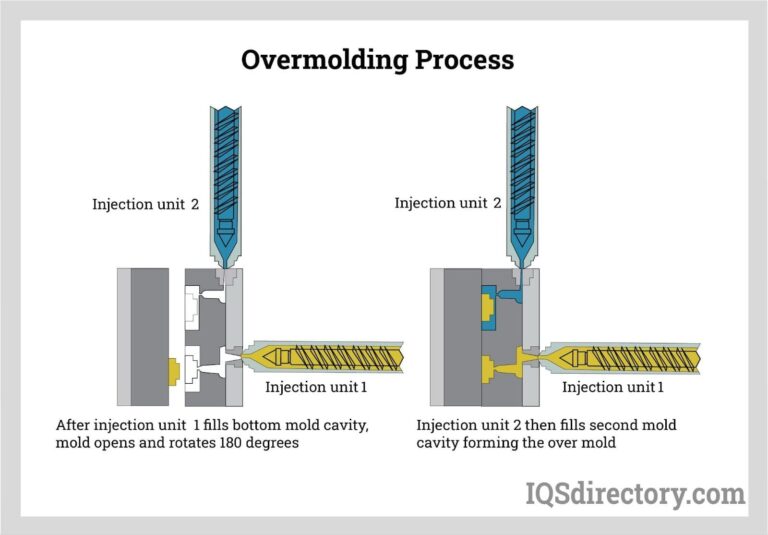

2. Forming: Techniques for Shaping Alumina

The forming stage can be accomplished through different techniques, with the most common being uniaxial pressing and slip casting.

-

Uniaxial Pressing: This method involves compacting the alumina powder into a mold under high pressure, which helps in achieving a dense and uniform sheet.

-

Slip Casting: In this technique, a slurry of alumina powder and water is poured into porous molds. Once the water is absorbed, a solid layer forms, which is then dried and demolded.

Each method has its advantages, depending on the desired thickness and dimensions of the final product.

Illustrative image related to alumina sheet price

3. Assembly: Preparing for Firing

Once shaped, the alumina sheets are assembled and prepped for the firing process. This stage may include drying the sheets to remove moisture, ensuring they are adequately prepared for sintering.

In some cases, the sheets may be combined with other materials or coatings to enhance their properties, such as adding a protective layer for specific applications.

4. Finishing: Achieving Precision and Quality

The finishing process is where alumina sheets are machined to precise dimensions and surface finishes. Techniques such as grinding, lapping, and laser cutting are commonly employed to achieve the desired specifications.

Final treatments may also include polishing, which enhances the surface quality, making the sheets suitable for applications in the electronics and medical industries.

What Quality Assurance Standards Are Relevant for Alumina Sheet Manufacturing?

Quality assurance is critical in ensuring that alumina sheets meet international standards and customer expectations. Various quality certifications and practices are in place to uphold product integrity.

International Standards: ISO Certifications

ISO 9001 is a widely recognized quality management standard that outlines requirements for a quality management system (QMS). Manufacturers of alumina sheets should adhere to ISO 9001 to demonstrate their commitment to quality and customer satisfaction.

Additionally, other certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can further enhance a manufacturer’s credibility.

Illustrative image related to alumina sheet price

Industry-Specific Certifications: CE and API

Depending on the application, industry-specific certifications may also be relevant. For instance, CE marking is essential for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

For applications in the oil and gas sector, the American Petroleum Institute (API) certification may be necessary to ensure that products meet stringent performance and safety criteria.

What Are the Quality Control Checkpoints in Alumina Sheet Production?

Quality control (QC) checkpoints are crucial in maintaining product quality throughout the manufacturing process.

Incoming Quality Control (IQC)

At the IQC stage, raw materials are inspected for purity and consistency before being used in production. This step is vital to prevent defects in the final product.

In-Process Quality Control (IPQC)

During production, regular monitoring of the forming, pressing, and firing processes is conducted. Parameters such as temperature, pressure, and humidity are closely regulated to ensure consistency.

Final Quality Control (FQC)

After production, alumina sheets undergo thorough inspection and testing to verify that they meet specified dimensions, mechanical properties, and surface quality. Common testing methods include:

- Dimensional Inspection: Measuring the thickness and dimensions of sheets using calipers and micrometers.

- Mechanical Testing: Assessing properties such as hardness, tensile strength, and thermal stability through standardized tests.

- Surface Quality Assessment: Checking for defects like cracks or uneven surfaces using visual inspection and advanced imaging techniques.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers should take proactive steps to verify the quality assurance practices of alumina sheet suppliers, especially when sourcing from international markets.

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can include reviewing their QMS documentation and assessing compliance with international standards.

Requesting Quality Reports and Certifications

Buyers should request certificates of conformity and quality reports for each batch of alumina sheets. These documents should detail the results of quality tests and compliance with relevant standards.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality practices. These services can conduct on-site inspections and testing, ensuring that products meet the specified requirements before shipping.

What Nuances Should International Buyers Consider Regarding QC and Certification?

For international buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding local regulations and certifications is essential.

Some countries may have specific requirements regarding product compliance and certification, which can differ significantly from international standards. Buyers should familiarize themselves with these nuances to avoid potential regulatory issues and ensure smooth importation of alumina sheets.

Illustrative image related to alumina sheet price

In conclusion, understanding the manufacturing processes and quality assurance practices for alumina sheets is crucial for B2B buyers. By being informed and proactive, buyers can ensure they partner with reliable suppliers that meet their quality expectations and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alumina sheet price’

Introduction

Navigating the procurement of alumina sheets can be complex, especially for B2B buyers operating in diverse international markets. This checklist provides a systematic approach to sourcing alumina sheets, ensuring you secure competitive pricing while meeting your technical and quality requirements.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to establish your specific technical requirements. Consider factors such as purity levels, dimensions, thickness, and any industry-specific standards that must be met. Clear specifications will not only streamline your search but also help suppliers provide accurate quotes.

- Purity Level: Ensure you know whether you need high-purity (99%+) alumina for critical applications.

- Dimensions: Specify the exact size and thickness needed for your application, as this can significantly affect the price.

Step 2: Research and Identify Reliable Suppliers

Once you have your specifications, it’s time to identify potential suppliers. Look for companies with a proven track record in the alumina sheet market, especially those that serve your region.

- Supplier Reputation: Review online testimonials, ratings, and case studies to gauge reliability.

- Industry Experience: Suppliers with experience in your specific industry will better understand your needs and challenges.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and quality control processes. This step is crucial for ensuring that the alumina sheets meet the necessary industry standards.

- Quality Standards: Check for ISO certifications or other relevant industry-specific certifications.

- Material Traceability: Ensure that suppliers can provide documentation for the sourcing and quality of their materials.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations. This should include not only the price per unit but also shipping costs, lead times, and any additional fees.

- Comparative Analysis: Ensure that you are comparing like for like in terms of quality and specifications.

- Volume Discounts: Inquire about discounts for bulk purchases or long-term contracts to optimize your budget.

Step 5: Assess Shipping and Logistics

The logistical aspect of sourcing alumina sheets can significantly impact overall costs. Evaluate shipping options, lead times, and potential customs duties based on your location.

Illustrative image related to alumina sheet price

- Shipping Costs: Ask suppliers about shipping methods and associated costs to avoid unexpected expenses.

- Delivery Times: Understand the estimated lead times to ensure they align with your project timelines.

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations to finalize terms and conditions. This includes payment terms, warranties, and return policies.

- Payment Terms: Establish favorable payment conditions that align with your cash flow requirements.

- Warranties: Ensure that warranties cover any defects or quality issues that may arise post-delivery.

Step 7: Conduct a Final Review

Before placing your order, conduct a final review of all agreements and supplier commitments. This step helps to mitigate risks associated with procurement.

- Contract Clarity: Ensure that all terms are clearly outlined in the contract to avoid misunderstandings.

- Supplier Commitment: Confirm the supplier’s commitment to your specifications and delivery schedules.

By following this checklist, B2B buyers can approach the procurement of alumina sheets with confidence, ensuring they secure the best price while meeting their technical and quality requirements.

Comprehensive Cost and Pricing Analysis for alumina sheet price Sourcing

What Are the Key Cost Components in Alumina Sheet Pricing?

The pricing structure of alumina sheets is influenced by various cost components that are essential for B2B buyers to understand. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of high-purity alumina (Al₂O₃) is a significant factor, with prices varying based on purity levels and source. Higher purity alumina, which is often required for specialized applications, typically commands a premium.

-

Labor: Skilled labor is needed for the production and machining of alumina sheets. Labor costs can vary significantly based on geographical location, with regions offering lower labor costs generally reflecting in the final price.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The initial investment in tooling for custom shapes or sizes can be substantial. Buyers should consider this when requesting customized products, as it may affect the overall cost if the design requires unique tooling.

-

Quality Control (QC): Ensuring that products meet industry standards and customer specifications incurs additional costs. Certifications and testing are essential, especially for buyers in regulated industries, adding to the overall price.

-

Logistics: Shipping and handling costs are crucial, particularly for international buyers. Factors such as distance, shipping method, and Incoterms can significantly influence logistics expenses.

-

Margin: Suppliers will add a profit margin to cover their operational costs and risks. Understanding the typical margins in the market can help buyers gauge the fairness of quoted prices.

How Do Volume and Specifications Impact Alumina Sheet Pricing?

Volume and specifications play a critical role in determining the cost of alumina sheets.

-

Volume/MOQ: Higher order volumes typically lead to reduced per-unit costs due to economies of scale. Suppliers often have minimum order quantities (MOQ), and negotiating a larger order can yield better pricing and terms.

-

Specifications and Customization: Custom specifications, such as thickness, size, and machining requirements, can increase costs. Standard sizes generally have a lower price point, while custom dimensions may necessitate additional tooling and setup time.

What Influences Pricing for Quality and Certification?

Quality and certification requirements can significantly affect alumina sheet pricing.

-

Materials and Quality: The choice of materials and the required quality standards will influence costs. Higher quality and certified products often come at a premium due to the rigorous testing and validation processes involved.

-

Supplier Factors: The reputation and reliability of suppliers can also impact pricing. Established suppliers with a track record of quality may charge more due to their assurance of consistency and service.

What Are Some Negotiation Tips for B2B Buyers?

B2B buyers should adopt strategic approaches when negotiating alumina sheet prices:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with maintenance, durability, and performance of the alumina sheets. This holistic view can justify a higher upfront cost if it leads to lower overall expenses.

-

Leverage Volume for Discounts: Buyers should negotiate based on volume and potential for future orders. Committing to larger orders can often secure better pricing.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers provides leverage in negotiations. It also allows buyers to compare specifications and service levels.

How Do Pricing Nuances Affect International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique pricing nuances:

-

Logistics and Incoterms: Understanding Incoterms is crucial for calculating the total landed cost of products. Different terms can shift responsibilities for shipping, duties, and insurance, impacting the final price.

-

Currency Fluctuations: Exchange rates can affect pricing, especially for international transactions. Buyers should consider hedging strategies to mitigate risks associated with currency volatility.

-

Regulatory Compliance: Import duties, tariffs, and compliance with local regulations can add hidden costs to procurement. Buyers should ensure they are aware of all potential costs involved in importing alumina sheets.

In summary, the pricing of alumina sheets is multifaceted, influenced by various cost components and market dynamics. Understanding these elements enables B2B buyers to make informed decisions and negotiate effectively.

Alternatives Analysis: Comparing alumina sheet price With Other Solutions

Introduction to Alternative Solutions in the Ceramic Industry

In the quest for high-performance materials, B2B buyers often explore various solutions that can meet their operational requirements. Alumina sheets, known for their excellent thermal and electrical insulation properties, are widely used in industries such as automotive, metallurgy, and electronics. However, alternatives may offer comparable performance, cost-effectiveness, or unique advantages tailored to specific applications. This analysis will compare the pricing and performance of alumina sheets against two viable alternatives: silicon carbide (SiC) substrates and aluminum nitride (AlN) ceramics.

Comparison Table

| Comparison Aspect | Alumina Sheet Price | Silicon Carbide (SiC) | Aluminum Nitride (AlN) |

|---|---|---|---|

| Performance | High hardness, good chemical stability, high thermal resistance | Superior thermal conductivity, high hardness, excellent wear resistance | High thermal conductivity, excellent electrical insulation, low thermal expansion |

| Cost | $15.95 – $50 per sheet depending on size and purity | $25 – $100 per substrate depending on specifications | $30 – $120 per substrate depending on size and properties |

| Ease of Implementation | Easy to source, available in various sizes | Requires specialized processing; not as widely available | Requires precise manufacturing processes; limited suppliers |

| Maintenance | Low maintenance, high durability | Low maintenance; however, brittle under extreme conditions | Low maintenance, highly durable |

| Best Use Case | General applications in furnaces and chemical industries | High-temperature environments, power electronics | High-frequency electronics, heat sinks, and LED applications |

Detailed Breakdown of Alternatives

Silicon Carbide (SiC)

Silicon carbide substrates are renowned for their exceptional thermal conductivity and hardness, making them ideal for high-temperature applications such as power electronics and semiconductor devices. While SiC offers superior performance, the cost can be significantly higher than alumina sheets, ranging from $25 to $100 depending on size and specifications. Additionally, SiC may require specialized manufacturing processes, which can complicate sourcing and implementation. However, its low maintenance and durability make it a worthy investment for applications demanding high performance.

Aluminum Nitride (AlN)

Aluminum nitride ceramics are another alternative that provides excellent thermal conductivity and electrical insulation properties. They are particularly beneficial in high-frequency electronics and applications requiring efficient heat dissipation, such as LED technology. The pricing for AlN substrates typically ranges from $30 to $120, influenced by size and specific properties. While AlN substrates require precise manufacturing and may not be as readily available as alumina, their unique advantages make them suitable for specialized applications. The durability and low maintenance needs further enhance their appeal.

Conclusion: How to Choose the Right Solution

When selecting the appropriate material, B2B buyers must consider the specific requirements of their applications, including performance, cost, and ease of implementation. Alumina sheets may be ideal for general applications due to their affordability and availability, while silicon carbide and aluminum nitride offer superior performance for specialized needs. By carefully analyzing these factors, buyers can make informed decisions that align with their operational goals and budget constraints, ensuring optimal material selection for their projects.

Essential Technical Properties and Trade Terminology for alumina sheet price

What Are the Key Technical Properties of Alumina Sheets Relevant to Pricing?

When considering alumina sheets for procurement, understanding their technical specifications is crucial for ensuring product suitability and quality. Here are some key properties that impact pricing and decision-making:

-

Material Grade (Purity)

Alumina sheets are available in various purity levels, typically measured as a percentage of Al₂O₃ content. For instance, high-purity alumina (99% or greater) is often more expensive due to its superior mechanical and thermal properties. This grade is essential in applications requiring high reliability, such as electronics and advanced manufacturing, where performance is critical. -

Dimensional Tolerance

Tolerance refers to the allowable variation in dimensions, such as thickness, length, and width. In B2B transactions, tighter tolerances can lead to higher costs due to the increased precision required in manufacturing. For industries like aerospace or medical devices, precise dimensions ensure compatibility and functionality, making this a vital consideration in pricing. -

Temperature Resistance

The maximum operating temperature of alumina sheets can significantly influence their price. Materials that can withstand higher temperatures (up to 1600 °C) are typically more expensive. This property is particularly important for applications in furnaces and high-heat environments, where material integrity is paramount. -

Surface Finish

The surface finish of alumina sheets can impact their performance and price. Options range from standard finishes to specialized ones that enhance wear resistance or reduce friction. A finer surface finish may incur additional costs but can be beneficial in applications requiring precise interactions, such as in semiconductor manufacturing. -

Electrical Insulation

Alumina is known for its excellent electrical insulation properties. This characteristic makes it a preferred choice for electronic and electrical applications. Buyers should consider the insulation rating as it can affect both the performance and price, especially in industries where electrical safety is critical.

What Trade Terminology Should B2B Buyers Know When Discussing Alumina Sheet Pricing?

Familiarity with industry-specific terminology can enhance communication and negotiation processes in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding this term is crucial when sourcing alumina sheets, as it can indicate the level of quality assurance and compatibility with existing products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to manage inventory effectively and assess whether the investment aligns with their project needs. -

RFQ (Request for Quote)

An RFQ is a standard business process where a buyer requests pricing and terms from suppliers. This process is essential for comparing costs and ensuring that buyers receive competitive pricing on alumina sheets. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including who pays for shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand total costs and logistical responsibilities when importing alumina sheets from international suppliers. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. In industries where time-to-market is critical, understanding lead times for alumina sheets can affect production schedules and overall project timelines. -

Customization

This term refers to the ability to alter product specifications to meet specific customer needs. Customization can influence pricing, as tailored solutions often involve more complex manufacturing processes and additional costs. Understanding customization options allows buyers to make informed decisions that align with their project requirements.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions regarding alumina sheet procurement, ensuring they select the right materials for their applications while navigating pricing effectively.

Navigating Market Dynamics and Sourcing Trends in the alumina sheet price Sector

What Are the Current Market Dynamics and Key Trends Affecting Alumina Sheet Prices?

The alumina sheet market is experiencing a notable transformation driven by several global factors. Increased demand for high-purity alumina, particularly in the electronics, automotive, and aerospace sectors, is propelling market growth. Countries in Africa, South America, the Middle East, and Europe are witnessing a surge in industrial activities, prompting a rise in alumina sheet applications. In addition, the ongoing shift towards automation and advanced manufacturing technologies is influencing sourcing trends. Buyers are increasingly seeking suppliers that offer customization options, such as laser-cut and precision-machined alumina sheets, catering to specific industry requirements.

Emerging technologies, including additive manufacturing and digital supply chain management, are reshaping the procurement landscape. International buyers are leveraging these technologies to streamline sourcing processes, enabling quicker turnaround times and reduced costs. Moreover, the integration of data analytics is allowing companies to forecast demand more accurately and optimize inventory levels. This shift is particularly relevant for B2B buyers in regions like Saudi Arabia and Vietnam, where rapid industrialization necessitates agile supply chain strategies.

How Is Sustainability and Ethical Sourcing Shaping the Alumina Sheet Price Market?

Sustainability and ethical sourcing are becoming pivotal in the alumina sheet market, driven by increasing environmental regulations and consumer demand for responsible sourcing practices. The production of alumina, while essential for various applications, can have significant environmental impacts, including energy consumption and waste generation. Therefore, B2B buyers are prioritizing suppliers that adhere to sustainable practices, such as reducing carbon footprints and implementing waste management strategies.

Certification programs focusing on environmentally friendly materials and practices are gaining traction. Buyers are encouraged to seek out suppliers with certifications that highlight their commitment to sustainability, such as ISO 14001 for environmental management systems or LEED certification for green building materials. These certifications not only enhance the credibility of suppliers but also provide buyers with assurance regarding the environmental impact of their purchases. As global markets move towards stricter environmental standards, incorporating sustainability into sourcing strategies will be vital for companies seeking to maintain competitive advantage.

What Is the Historical Context Behind the Alumina Sheet Price Market?

The history of alumina sheet production can be traced back to the industrial revolution, where aluminum oxide was first recognized for its unique properties. Initially utilized in metallurgy, the material’s applications expanded significantly in the late 20th century with advancements in ceramic technology. The introduction of high-purity alumina made it possible to cater to specialized sectors, including electronics and medical devices.

As global demand for lightweight and durable materials increased, alumina sheets became integral in various industries, leading to a competitive market landscape. Over the years, the focus has shifted from merely sourcing materials to ensuring quality, sustainability, and compliance with international standards. This evolution reflects the changing priorities of B2B buyers, who now seek not only cost-effective solutions but also ethical and environmentally responsible sourcing options.

In conclusion, navigating the alumina sheet price sector requires an understanding of market dynamics, a commitment to sustainability, and an appreciation of the historical context that shapes current trends. By aligning sourcing strategies with these insights, international B2B buyers can make informed decisions that drive long-term success.

Frequently Asked Questions (FAQs) for B2B Buyers of alumina sheet price

-

How can I determine the current price of alumina sheets?

To ascertain the current price of alumina sheets, it is advisable to request quotes from multiple suppliers. Prices can vary based on factors such as purity, dimensions, and order volume. Utilizing online quote request forms on supplier websites can expedite this process. Additionally, consider market trends and fluctuations in raw material costs, as these can significantly impact pricing. Regular communication with suppliers will also help you stay updated on any price changes or promotional offers. -

What factors influence the pricing of alumina sheets?

The pricing of alumina sheets is influenced by several factors, including the purity level (e.g., 99% vs. 96% alumina), thickness, dimensions, and the complexity of any required customization. Additionally, geographical location and shipping costs can affect the final price, especially for international buyers. The manufacturing process, such as whether the sheets are laser-cut or machined, also plays a role in determining costs. Engaging directly with suppliers can provide insights into pricing structures and potential discounts for bulk orders. -

What are the minimum order quantities (MOQs) for alumina sheets?

Minimum order quantities for alumina sheets can vary widely among suppliers. Generally, MOQs may range from a few pieces for standard sizes to larger quantities for customized orders. It is crucial to clarify MOQs when requesting quotes, as some suppliers may offer flexibility based on specific project requirements or long-term partnerships. Understanding these terms can help you better plan your procurement strategy and budget. -

How can I ensure the quality of alumina sheets before purchasing?

To ensure the quality of alumina sheets, request detailed product specifications and certifications from suppliers. Engaging in a dialogue about their quality assurance processes, such as testing for purity and durability, can also provide peace of mind. If possible, ask for samples to evaluate the product before placing a larger order. Additionally, consider suppliers with established reputations and positive reviews in the industry, as this often correlates with product reliability and service quality. -

What customization options are available for alumina sheets?

Many suppliers offer customization options for alumina sheets, including variations in size, thickness, and shapes tailored to specific applications. You may also request special treatments or coatings to enhance properties such as electrical insulation or corrosion resistance. When inquiring about customization, provide detailed specifications to help suppliers understand your requirements. Additionally, inquire about lead times for custom orders, as these can differ from standard products. -

What payment terms should I expect when ordering alumina sheets?

Payment terms for alumina sheets can vary depending on the supplier and the size of the order. Common options include upfront payments, partial payments with the balance due upon delivery, or net payment terms (e.g., net 30 or net 60 days). International buyers should also consider factors such as currency exchange rates and transaction fees. Always clarify payment terms before finalizing orders to avoid misunderstandings and ensure smooth transactions. -

How do shipping and logistics work for international orders of alumina sheets?

Shipping and logistics for international orders typically involve collaboration between the buyer and the supplier to determine the best shipping methods, costs, and timelines. Factors such as the destination, order size, and urgency will influence shipping options. It is important to discuss who will bear shipping costs and whether the supplier can assist with customs clearance. Ensuring proper packaging and labeling is crucial to prevent damage during transit, so confirm these details with your supplier. -

What should I look for when vetting suppliers of alumina sheets?

When vetting suppliers of alumina sheets, consider their industry experience, reputation, and certifications. Look for suppliers who provide transparent information about their manufacturing processes and quality control measures. Customer reviews and case studies can offer insights into their reliability and product performance. Additionally, assess their responsiveness and willingness to accommodate your specific needs, as this can be indicative of their customer service standards and commitment to building long-term partnerships.

Top 8 Alumina Sheet Price Manufacturers & Suppliers List

1. MSE – High Purity 99% Ceramic Alumina Plate

Domain: msesupplies.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “MSE PRO High Purity 99% Ceramic Alumina (Al2O3) Plate”, “SKU”: “JA1301”, “Price”: “$15.95”, “Sizes and Prices”: [{“Dimensions”: “60x40x4 mm”, “Price”: “$15.95”}, {“Dimensions”: “90x45x4 mm”, “Price”: “$27.95”}, {“Dimensions”: “90x65x6 mm”, “Price”: “$34.95”}, {“Dimensions”: “102x76x6 mm”, “Price”: “$43.95”}, {“Dimensions”: “108x53x4 mm”, “Price”: “$42.95”}, {“Dimensions”: “150×80…

2. Graphite Store – Fast Delivery & Easy Returns

Domain: graphitestore.com

Registered: 2002 (23 years)

Introduction: This company, Graphite Store – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. AdValueTech – Alumina Plates

Domain: advaluetech.com

Registered: 2003 (22 years)

Introduction: Alumina plates are high-purity, advanced ceramic materials known for their excellent mechanical properties, thermal stability, and chemical resistance. They are used in various applications including electronics, aerospace, and medical devices. The plates are available in different sizes and thicknesses, customizable to meet specific requirements. Alumina plates are ideal for applications requirin…

4. McMaster – Alumina Oxide Sheets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Alumina Oxide Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Ceramic PCB – Laser-Cut Alumina Substrates

Domain: ceramic-pcb.com

Registered: 2018 (7 years)

Introduction: Laser-cut Alumina (Al2O3) substrates, also known as Aluminum Oxide, are advanced technical ceramic materials used in various industrial, medical, and electronic applications. The substrates are available in precise laser cut and machined formats, with customizable dimensions and thicknesses ranging from 0.25mm to 1.5mm (or equivalent inches). Shapes can be rectangular or square, with options for l…

6. American Elements – Alumina Sheet

Domain: americanelements.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Alumina Sheet”, “CAS Number”: “1344-28-1”, “Linear Formula”: “Al2O3”, “Molecular Weight”: “101.96 g/mol”, “Appearance”: “Solid”, “Melting Point”: “2040 °C (3700 °F)”, “Boiling Point”: “2977 °C (5391 °F)”, “Density”: “3.5 to 4.1 g/cm3”, “Solubility in H2O”: “N/A”, “Exact Mass”: “101.948 g/mol”, “Monoisotopic Mass”: “101.94782 Da”, “Poisson’s Ratio”: “0.22 to 0.24”, “Young’s Modulu…

7. Goodfellow – Alumina Sheet 0.25 mm

Domain: sigmaaldrich.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Alumina sheet”, “thickness”: “0.25 mm”, “size”: “60 × 60 mm”, “purity”: “99%”, “synonym”: “AL603028”, “manufacturer”: “Goodfellow”, “UNSPSC_code”: “11181511”, “NACRES”: “NA.23”}

8. CS Ceramic – Alumina Ceramic Substrate Sheet

Domain: csceramic.com

Registered: 2012 (13 years)

Introduction: Alumina Ceramic Substrate Sheet is an ideal choice for applications requiring high performance, reliability, and durability. It is available in various sizes and thicknesses to suit different applications. Item No.: CS-A-16, Color: White, Purity: Available 99.5%, 99.7%, 99%.

Strategic Sourcing Conclusion and Outlook for alumina sheet price

In navigating the fluctuating landscape of alumina sheet pricing, international B2B buyers should prioritize strategic sourcing to ensure they secure the best value for their investments. Key factors influencing alumina prices include purity levels, dimensional specifications, and sourcing methods. By understanding these elements, businesses can make informed purchasing decisions that align with their operational needs and budget constraints.

The value of strategic sourcing extends beyond mere cost savings; it encompasses building strong supplier relationships that foster reliability and innovation. Engaging with manufacturers that offer customization options can lead to tailored solutions that enhance operational efficiency and product performance. Furthermore, leveraging global supply networks can mitigate risks associated with regional market volatility, especially for buyers in Africa, South America, the Middle East, and Europe.

Looking ahead, as demand for high-purity alumina continues to grow across various industries, proactive engagement with suppliers will be essential. Buyers are encouraged to explore diverse sourcing strategies and maintain open channels of communication with their suppliers. This approach not only secures competitive pricing but also positions businesses to adapt to future market changes effectively. Embrace the opportunity to optimize your sourcing strategy today for a more resilient and profitable tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to alumina sheet price

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.