A B2B Buyer’s Guide to Alumina Ceramic Coating: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for alumina ceramic coating

Navigating the global market for alumina ceramic coating presents unique challenges for B2B buyers seeking reliable and durable solutions. As industries increasingly demand coatings that offer superior wear resistance, thermal insulation, and corrosion protection, sourcing the right alumina ceramic coatings becomes critical. This guide delves into the diverse types of alumina coatings available, their specific applications across various sectors, and essential criteria for supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Brazil, will benefit from a comprehensive analysis of market trends, pricing strategies, and technological advancements. By understanding the nuances of alumina ceramic coatings, companies can make informed purchasing decisions that align with their operational needs and budget constraints.

This guide aims to empower B2B buyers by providing actionable insights into the selection process, ensuring they can navigate supplier options effectively while maximizing the performance and longevity of their coated products. With a focus on practical applications and supplier evaluation, we equip decision-makers with the tools necessary to thrive in a competitive marketplace. Whether your focus is on enhancing product durability or reducing maintenance costs, this resource will serve as a vital reference in your procurement journey.

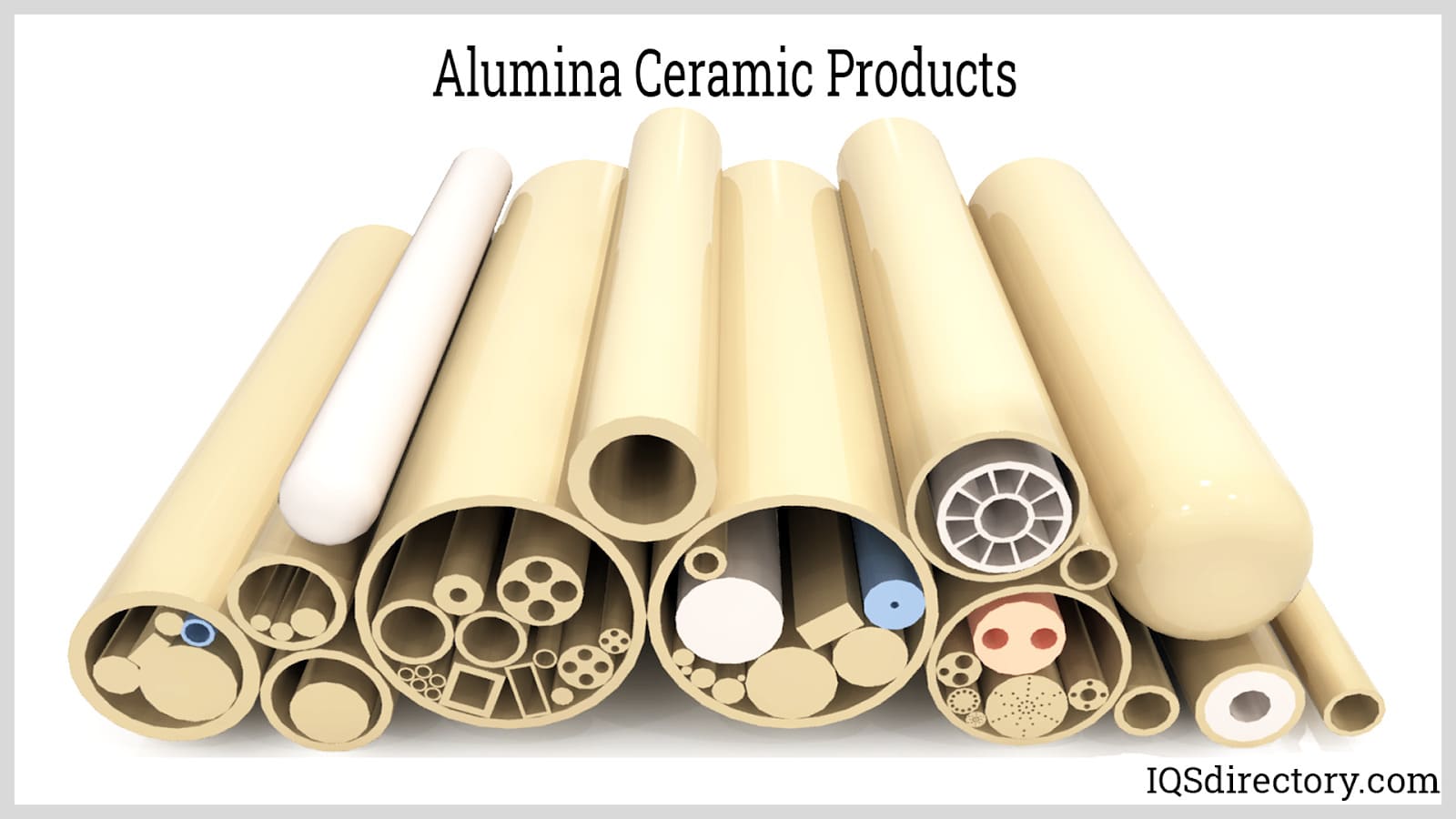

Understanding alumina ceramic coating Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alumina Coating | Inexpensive, good wear and corrosion resistance | Automotive, electrical components, textiles | Pros: Cost-effective, versatile. Cons: Limited high-temperature stability. |

| Alumina-Titania Coating | Combines alumina with titanium dioxide for enhanced toughness | Chemical processing, textile machinery, aerospace | Pros: Excellent wear resistance, good dielectric properties. Cons: Slightly higher cost. |

| Chrome Oxide Coating | Strong wear and corrosion resistance, ideal for harsh environments | Heavy industry, mining, and oil & gas sectors | Pros: High durability, excellent performance. Cons: Higher application complexity. |

| Zirconia Coating | Superior thermal barrier properties, ideal for high-temperature applications | Aerospace, automotive engines, and power generation | Pros: Extends service life, excellent thermal management. Cons: More expensive than other coatings. |

| Alumina Coat | Liquid formulation used for surface hardening | Insulation materials, furnace linings | Pros: Easy application, improves refractory properties. Cons: Limited to specific applications. |

What Are the Key Characteristics of Alumina Coating?

Alumina coatings are known for their affordability and effective wear and corrosion resistance. They can be applied to a wide range of materials, making them suitable for industries such as automotive and textiles. When considering alumina coatings, buyers should focus on their cost-effectiveness and versatility. However, it is essential to note that they may not perform as well under extreme temperatures compared to other ceramic coatings.

How Does Alumina-Titania Coating Enhance Performance?

Alumina-titania coatings blend aluminum oxide with titanium dioxide, enhancing toughness and wear resistance. This combination is particularly beneficial in chemical processing and textile machinery, where durability is critical. Buyers should evaluate the added dielectric properties and wear resistance against the slightly higher costs. This coating is ideal for applications requiring smooth finishes and high friction resistance.

Why Choose Chrome Oxide Coating for Heavy Industries?

Chrome oxide coatings offer robust wear and corrosion resistance, making them ideal for demanding environments such as heavy industry and mining. These coatings are known for their high durability, which can significantly extend the life of equipment. However, the complexity of the application process may deter some buyers. Understanding the specific needs of your operations will help in determining if this coating is the right fit.

What Advantages Does Zirconia Coating Provide?

Zirconia coatings are recognized for their superior thermal barrier properties, making them suitable for high-temperature applications in aerospace and automotive engines. These coatings can significantly improve the service life of components exposed to extreme conditions. While they are more expensive than other options, the long-term benefits in performance and durability can justify the investment for B2B buyers.

How Can Alumina Coat Improve Surface Hardness?

Alumina coat is a liquid formulation designed for surface hardening of low-density alumina and alumina-silica materials. It enhances the refractoriness of surfaces, making it suitable for insulation materials and furnace linings. The ease of application and ability to improve refractory properties make this coating an attractive option for specific applications. However, its use is limited to certain materials, which buyers should consider when evaluating their options.

Key Industrial Applications of alumina ceramic coating

| Industry/Sector | Specific Application of alumina ceramic coating | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Coating for engine components and thrust chambers | Enhances durability and thermal resistance, extending component life | High purity alumina for reliability; compliance with aviation standards |

| Oil & Gas | Coating for drilling equipment and pipeline protection | Reduces wear and corrosion, minimizing operational downtime | Resistance to harsh environments; availability of bulk quantities |

| Automotive | Coating for brake components and engine parts | Improves wear resistance and thermal management, enhancing safety | Compatibility with various substrates; cost-effectiveness |

| Textile Manufacturing | Coating for heating plates and yarn guides | Provides wear resistance and smooth operation, increasing efficiency | Customizable thickness and finish; adherence to industry regulations |

| Chemical Processing | Coating for pumps and valves | Protects against chemical erosion, ensuring reliability and safety | Chemical compatibility; sourcing from certified suppliers |

How is alumina ceramic coating utilized in the aerospace industry?

In the aerospace sector, alumina ceramic coatings are applied to engine components and thrust chambers to enhance their durability and thermal resistance. These coatings protect against extreme temperatures and wear, significantly extending the lifespan of critical components. For international buyers, especially from regions like Europe and the Middle East, sourcing high-purity alumina is vital to meet stringent aviation standards and ensure reliable performance under challenging conditions.

What are the benefits of alumina ceramic coating in the oil & gas industry?

In the oil and gas industry, alumina ceramic coatings are extensively used on drilling equipment and pipelines to mitigate wear and corrosion caused by harsh environmental conditions. By enhancing the durability of these components, businesses can minimize operational downtime and reduce maintenance costs. Buyers from South America and Africa should consider the coating’s resistance to extreme conditions and the availability of bulk quantities to meet large-scale operational demands.

How does alumina ceramic coating enhance automotive applications?

Alumina ceramic coatings are applied to brake components and engine parts within the automotive industry to improve wear resistance and thermal management. This results in enhanced vehicle safety and performance, critical factors for automotive manufacturers. Buyers in Germany and Brazil should focus on the compatibility of coatings with various substrates and their cost-effectiveness, ensuring that they meet both performance and budgetary constraints.

In what ways does alumina ceramic coating benefit textile manufacturing?

In textile manufacturing, alumina ceramic coatings are utilized on heating plates and yarn guides to provide excellent wear resistance and facilitate smooth operation. This leads to increased efficiency in production processes. For B2B buyers, particularly in Europe and South America, it is essential to consider customizable thickness options and adherence to industry regulations to ensure optimal performance in their specific applications.

How is alumina ceramic coating crucial in chemical processing?

Alumina ceramic coatings are crucial in the chemical processing industry for protecting pumps and valves from chemical erosion. These coatings ensure reliability and safety in operations, which is paramount for businesses in this sector. International buyers must prioritize chemical compatibility and the sourcing of coatings from certified suppliers to meet regulatory requirements and ensure long-term performance in challenging environments.

Illustrative image related to alumina ceramic coating

3 Common User Pain Points for ‘alumina ceramic coating’ & Their Solutions

Scenario 1: Quality Assurance in High-Stakes Applications

The Problem: In industries such as aerospace and automotive, where safety and performance are critical, B2B buyers often face the challenge of ensuring that alumina ceramic coatings meet stringent quality and reliability standards. The fear of subpar coatings leading to premature failures can result in costly downtimes and even jeopardize safety. This concern is heightened when sourcing coatings from international suppliers, where quality consistency may vary significantly.

The Solution: To mitigate these risks, buyers should implement a thorough vetting process for suppliers. This includes requesting certifications, such as ISO 9001, and reviewing case studies or testimonials from previous clients within their industry. Establishing a strong line of communication with potential suppliers can also facilitate transparency regarding production methods and quality control measures. Moreover, conducting small-scale pilot tests of the coatings in relevant applications before full-scale implementation can help verify their performance under actual operating conditions. This proactive approach ensures that the coatings used are not only compliant with industry standards but also tailored to meet specific operational needs.

Scenario 2: Balancing Cost and Performance

The Problem: Many B2B buyers are often caught in a dilemma between opting for high-performance alumina ceramic coatings and managing tight budgets. While the latest advanced coatings offer superior durability and resistance properties, their higher costs can be prohibitive, especially for small to medium-sized enterprises operating with limited financial flexibility. This situation can lead to decisions that compromise either performance or budget, both of which can have long-term implications.

The Solution: Buyers should conduct a detailed cost-benefit analysis that considers the lifecycle costs of coatings rather than just the upfront price. Factors such as maintenance requirements, expected service life, and potential downtime should be factored into the decision-making process. Additionally, exploring composite coatings, such as alumina-titania blends, can provide a balanced solution that meets performance requirements while remaining cost-effective. Engaging in negotiations with suppliers for bulk purchasing discounts or exploring alternative suppliers that offer competitive pricing for similar quality can also help bridge the gap between performance and budget.

Illustrative image related to alumina ceramic coating

Scenario 3: Application Challenges and Technical Support

The Problem: Applying alumina ceramic coatings effectively requires specialized knowledge and equipment. B2B buyers often encounter difficulties in ensuring that the application processes—such as thermal spraying—are executed correctly to achieve optimal adhesion and performance. Inadequate application can lead to issues like poor coating adhesion, uneven surfaces, or insufficient thickness, which can ultimately affect the coating’s performance and durability.

The Solution: To address these application challenges, buyers should prioritize working with suppliers who offer comprehensive technical support and guidance throughout the application process. This includes providing training for in-house teams on the best practices for applying alumina ceramic coatings. Moreover, sourcing coatings that come with detailed application instructions and support from the manufacturer can be beneficial. Buyers can also consider partnering with experienced coating applicators who specialize in thermal spray techniques to ensure that the coatings are applied correctly and meet the required specifications. Regular inspections during and after the application process can help catch potential issues early, leading to better performance and longer-lasting results.

Strategic Material Selection Guide for alumina ceramic coating

What Are the Key Properties of Alumina Ceramic Coatings?

Alumina ceramic coatings, primarily composed of aluminum oxide (Al₂O₃), are recognized for their excellent hardness and durability. They can withstand high temperatures, typically up to 1650°C (3002°F), making them suitable for applications in extreme environments. Their corrosion resistance is notable, particularly in alkaline solutions, which is critical for industries such as chemical processing and textiles. Additionally, alumina coatings exhibit low porosity, enhancing their protective capabilities against wear and chemical attacks.

What Are the Pros and Cons of Using Alumina Ceramic Coatings?

When considering alumina ceramic coatings, there are several advantages and disadvantages to weigh.

Pros:

– Durability: Alumina coatings are highly resistant to wear, scratching, and abrasion, which extends the lifespan of components.

– Cost-Effectiveness: Compared to other ceramic coatings, alumina is relatively inexpensive, making it an attractive option for budget-conscious projects.

– Versatility: These coatings can be applied to a wide range of substrates, providing thermal and electrical insulation.

Cons:

– Manufacturing Complexity: The application process can be intricate, requiring specialized equipment such as thermal spray systems, which may increase initial setup costs.

– Limited High-Temperature Performance: While alumina is effective up to a certain temperature, other materials like zirconia may be more suitable for extreme thermal applications.

Illustrative image related to alumina ceramic coating

How Do Alumina Ceramic Coatings Impact Specific Applications?

Alumina ceramic coatings are utilized across various industries, including automotive, aerospace, and chemical processing. Their compatibility with different media is a significant factor. For instance, in chemical processing, they effectively resist corrosion from dilute alkalies, while in the textile industry, they provide the necessary wear resistance for components like rollers and guides. However, it’s essential to consider the specific environmental conditions, such as temperature fluctuations and exposure to chemicals, to ensure optimal performance.

What Should International B2B Buyers Consider When Selecting Alumina Ceramic Coatings?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, several factors must be taken into account when selecting alumina ceramic coatings. Compliance with international standards (e.g., ASTM, DIN, JIS) is crucial for ensuring product quality and reliability. Furthermore, understanding local market preferences and regulations can significantly influence purchasing decisions. For example, buyers in Germany may prioritize high-performance coatings that meet stringent environmental regulations, while those in Brazil might focus on cost-effectiveness and availability.

Summary Table of Alumina Ceramic Coatings

| Material | Typical Use Case for alumina ceramic coating | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina (Al₂O₃) | Automotive components, chemical processing | Excellent wear and corrosion resistance | Limited high-temperature performance | Low |

| Alumina-Titania (Al₂O₃/TiO₂) | Textile machinery, aerospace parts | Enhanced toughness and wear resistance | More complex application process | Medium |

| Chrome Oxide (Cr₂O₃) | Heavy-duty industrial applications | Superior wear and corrosion resistance | Higher cost compared to alumina coatings | High |

| Zirconia (ZrO₂) | High-temperature applications | Exceptional thermal barrier properties | Higher cost and manufacturing complexity | High |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding alumina ceramic coatings, ensuring they select the most suitable materials for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for alumina ceramic coating

What Are the Key Stages in the Manufacturing Process of Alumina Ceramic Coating?

The manufacturing of alumina ceramic coatings involves several critical stages to ensure optimal performance and quality. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

Material Preparation: How Is Alumina Sourced and Processed?

The first step in the manufacturing process is the sourcing and preparation of raw materials. High-purity aluminum oxide (Al₂O₃) is typically used for alumina ceramic coatings. Suppliers must ensure that the raw materials meet specific purity standards to guarantee the desired properties of the final product. This often involves stringent quality checks and certifications to verify the composition of the alumina.

Once sourced, the alumina is processed into a fine powder through milling and sieving. This powder serves as the base material for the coating. Depending on the application, additives such as titanium dioxide may be included to enhance specific properties, such as wear resistance and thermal stability.

What Techniques Are Used for Forming Alumina Ceramic Coatings?

The forming stage employs various advanced techniques to apply the alumina coating onto the substrate. Thermal spray methods are among the most common, including:

- High Velocity Oxy-Fuel (HVOF): This method utilizes high-velocity combustion gases to propel the alumina particles onto the substrate, resulting in a dense, strong bond.

- Plasma Spray Coating: In this technique, an electric arc generates a plasma that melts the alumina powder, which is then sprayed onto the surface, creating a uniform coating.

- Flame Spray: A more traditional method, flame spraying involves melting the alumina powder with an oxy-fuel flame and spraying it onto the substrate.

Each of these techniques offers unique advantages and can be selected based on the specific requirements of the application, such as thermal resistance or surface finish.

How Is Finishing Achieved in Alumina Ceramic Coating Manufacturing?

Finishing is a critical stage that enhances the coating’s surface characteristics. After application, the coated parts may undergo various finishing processes, including grinding, polishing, or shot peening. These processes help achieve the required surface roughness and dimensional tolerances. The finishing stage also contributes to the coating’s overall durability and performance.

What Quality Assurance Measures Are in Place for Alumina Ceramic Coatings?

Quality assurance (QA) is paramount in the manufacturing of alumina ceramic coatings, particularly given the high-performance requirements in various industries such as aerospace, automotive, and chemical processing.

Which International Standards Should B2B Buyers Look For?

B2B buyers should prioritize suppliers that comply with international standards such as ISO 9001:2015, which focuses on quality management systems. Compliance with these standards indicates a commitment to maintaining quality throughout the manufacturing process. Additionally, industry-specific certifications like CE marking or API standards may also be relevant depending on the application.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This stage verifies the quality of raw materials before they enter production. Ensuring that the alumina powder meets specified standards is crucial for the final product’s performance.

- In-Process Quality Control (IPQC): During the coating application, IPQC checks the process parameters, such as temperature and spray distance, to ensure consistent coating quality.

- Final Quality Control (FQC): After the coating is applied and finished, FQC involves thorough inspections and testing to verify that the coatings meet predefined specifications. Common tests include wear resistance, adhesion strength, and thickness measurements.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain rigorous quality standards, B2B buyers should consider conducting audits or requesting comprehensive quality reports. Third-party inspections can provide an unbiased evaluation of the supplier’s quality control processes. Buyers should also inquire about the supplier’s track record of compliance with international standards and any industry-specific certifications.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Differences in regulations, standards, and expectations may exist between regions. For instance, European buyers may have stricter requirements concerning environmental and safety regulations compared to other regions.

B2B buyers should ensure that suppliers are familiar with the local regulations in their target markets. This includes compliance with import/export regulations, safety standards, and environmental considerations, which can affect the overall quality assurance process.

Conclusion: Ensuring Quality and Performance in Alumina Ceramic Coatings

Understanding the manufacturing processes and quality assurance measures for alumina ceramic coatings is vital for B2B buyers looking to source high-quality products. By focusing on the key stages of manufacturing and the relevant quality control checkpoints, buyers can make informed decisions and establish long-term partnerships with reliable suppliers. Always prioritize suppliers with robust quality assurance practices and a solid understanding of international standards to ensure the success of your applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alumina ceramic coating’

Introduction

This practical sourcing guide aims to assist B2B buyers in procuring alumina ceramic coatings. These coatings are essential in various industries due to their durability, wear resistance, and thermal insulating properties. By following this checklist, buyers can ensure they select the right coating solution that meets their technical and economic requirements.

Illustrative image related to alumina ceramic coating

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your alumina ceramic coating. Consider factors such as the desired thickness, application method, and performance characteristics like wear resistance and thermal stability. This step is critical to ensure that the coating aligns with your operational needs and industry standards.

- Performance Criteria: Identify the necessary durability, hardness, and corrosion resistance levels.

- Application Method: Determine if you will use thermal spray techniques or other application methods.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in alumina ceramic coatings. Look for companies with a proven track record in your industry and those who understand your specific requirements. This step is vital to ensure you partner with reliable suppliers who can deliver quality products.

- Supplier Reputation: Check for certifications, industry affiliations, and customer reviews.

- Experience: Evaluate their experience with similar applications and industries.

Step 3: Evaluate Supplier Capabilities

Once you’ve identified potential suppliers, assess their manufacturing and technical capabilities. Understanding their production processes will help you gauge the quality and consistency of their coatings.

- Technology and Equipment: Ensure they utilize advanced application methods such as plasma spray or HVOF for optimal adhesion and durability.

- Quality Control: Inquire about their quality assurance processes to confirm that they meet required standards.

Step 4: Request Samples and Test

Before making a bulk purchase, request samples of the alumina ceramic coating. Testing these samples will help you evaluate their performance in real-world applications, ensuring they meet your specifications.

- Performance Testing: Assess the samples for wear resistance, adhesion, and thermal properties.

- Application Trials: Conduct trials in your operational environment to verify compatibility.

Step 5: Review Pricing and Economic Considerations

Analyze the pricing structures of the coatings offered by different suppliers. While cost is a significant factor, it should be balanced against quality and performance.

- Total Cost of Ownership: Consider long-term savings associated with durability and reduced maintenance.

- Bulk Discounts: Inquire about pricing for larger orders to maximize your budget.

Step 6: Verify Supplier Certifications

Ensure that the supplier holds relevant certifications that indicate compliance with industry standards. This step is essential to mitigate risks associated with product quality and reliability.

- ISO Certifications: Look for suppliers with ISO 9001:2015 certifications, which indicate a commitment to quality management.

- Industry-Specific Certifications: Depending on your industry, other certifications may also be relevant.

Step 7: Establish Clear Communication Channels

Finally, set up effective communication channels with your chosen supplier. Clear communication is vital for addressing any issues that may arise during the procurement process or application of the coatings.

- Regular Updates: Establish a schedule for updates on production, shipping, and quality assurance.

- Point of Contact: Designate specific contacts on both sides for efficient resolution of inquiries or concerns.

By following this checklist, B2B buyers can navigate the complexities of sourcing alumina ceramic coatings effectively, ensuring they make informed decisions that enhance their operational efficiency and product longevity.

Comprehensive Cost and Pricing Analysis for alumina ceramic coating Sourcing

What Are the Key Cost Components in Alumina Ceramic Coating Sourcing?

When sourcing alumina ceramic coatings, several cost components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The cost of raw materials, such as aluminum oxide and any additional components (like titanium dioxide for alumina-titania composites), significantly influences the overall pricing. The purity and quality of these materials can vary, impacting costs directly.

-

Labor: Labor costs encompass both direct and indirect labor involved in the coating application process. Skilled labor is often required for precise application techniques like thermal spraying, which can drive up costs.

-

Manufacturing Overhead: Overhead costs include utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help minimize these costs, but they still form a significant part of the total cost structure.

-

Tooling: The initial investment in specialized tools and machinery for applying ceramic coatings can be substantial. This cost can be amortized over time based on production volume, affecting the per-unit cost.

-

Quality Control: Ensuring the coatings meet specific performance and certification standards involves rigorous QC processes. This includes testing for durability, wear resistance, and adherence to industry specifications, which can add to the overall cost.

-

Logistics: Shipping and handling costs vary based on the location of the supplier and the buyer. International shipments may incur additional fees related to customs and tariffs, which should be factored into the total cost.

-

Supplier Margin: Each supplier will have a different markup based on their operational efficiencies, market positioning, and value-added services. Understanding these margins can aid in negotiation.

What Factors Influence the Pricing of Alumina Ceramic Coatings?

Several factors influence the pricing of alumina ceramic coatings that international buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically attract discounts. Buyers should assess their needs and negotiate MOQs to optimize costs.

-

Specifications and Customization: Custom requirements, such as specific performance characteristics or unique application methods, can increase costs. Standard products may offer better pricing.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO standards) can raise costs but may be necessary for specific applications, particularly in regulated industries.

-

Supplier Factors: The supplier’s reputation, location, and reliability can impact costs. Established suppliers may charge a premium for their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs.

What Buyer Tips Can Help in Negotiating Alumina Ceramic Coating Prices?

-

Negotiate Effectively: Leverage volume commitments and long-term partnerships to negotiate better pricing. Suppliers are often willing to offer discounts for guaranteed repeat business.

-

Consider Total Cost of Ownership (TCO): When evaluating offers, consider not just the initial price but the TCO, including maintenance, longevity, and performance. A higher upfront cost might be justified by lower lifecycle costs.

-

Research Market Trends: Stay informed about market conditions and trends affecting raw material prices. Fluctuations in global supply chains can impact pricing, and being aware of these can aid in negotiations.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing strategies based on local demand, competition, and logistics. For buyers in Africa, South America, the Middle East, and Europe, understanding these regional dynamics can lead to more informed purchasing decisions.

-

Request Samples: Before committing to large orders, request samples to evaluate the product quality. This ensures that the specifications meet your requirements and can prevent costly mistakes.

Disclaimer on Pricing

Prices for alumina ceramic coatings are subject to change based on market conditions, material availability, and supplier pricing strategies. Always consult multiple suppliers and request updated quotes to ensure competitiveness.

Alternatives Analysis: Comparing alumina ceramic coating With Other Solutions

Understanding Alternatives in Coating Technologies

When evaluating coating solutions for industrial applications, it is essential to consider alternatives to alumina ceramic coatings. Each option has unique properties, advantages, and drawbacks that can significantly impact performance, cost, and suitability for specific applications. This comparison aims to provide B2B buyers with actionable insights on how to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Alumina Ceramic Coating | Zirconia Coating | Chrome Oxide Coating |

|---|---|---|---|

| Performance | Good wear and corrosion resistance; thermal insulation | Superior thermal barrier; excellent wear resistance | High wear resistance; corrosion resistant |

| Cost | Generally low-cost | Moderate to high-cost | Moderate cost |

| Ease of Implementation | Versatile application methods; requires skilled labor | Complex application process; specialized equipment needed | Straightforward application; widely available |

| Maintenance | Low maintenance; durable | Moderate maintenance; can be brittle | Low maintenance; durable |

| Best Use Case | Electrical insulation and general wear protection | High-temperature applications; aerospace | Heavy machinery and high-wear environments |

Detailed Breakdown of Alternatives

Zirconia Coating

Zirconia coatings are renowned for their exceptional thermal barrier properties, making them ideal for high-temperature applications such as aerospace and automotive industries. They offer excellent wear resistance, significantly extending the service life of components. However, the cost of zirconia coatings is typically higher than that of alumina coatings, and the application process can be complex, requiring specialized equipment and skilled technicians. This makes it less accessible for companies with budget constraints or limited technical resources.

Chrome Oxide Coating

Chrome oxide coatings provide a strong defense against wear and corrosion, making them suitable for heavy machinery and applications where durability is paramount. They are relatively easy to apply and do not require as specialized a process as zirconia coatings. However, while they are effective, chrome oxide coatings may not offer the same level of thermal insulation as alumina or zirconia coatings, which could limit their application in certain industries. Additionally, the environmental regulations surrounding chrome usage can pose challenges for compliance.

Conclusion: Choosing the Right Coating Solution

Selecting the appropriate coating solution involves careful consideration of various factors, including performance requirements, budget constraints, and application processes. Alumina ceramic coatings are often the go-to choice for their cost-effectiveness and durability, particularly in electrical insulation and general wear protection applications. However, for high-temperature or specialized environments, exploring alternatives such as zirconia or chrome oxide coatings may yield better long-term results. B2B buyers should assess their specific needs against the properties of each coating type to ensure they make a decision that aligns with both operational efficiency and financial viability.

Essential Technical Properties and Trade Terminology for alumina ceramic coating

What Are the Key Technical Properties of Alumina Ceramic Coating?

Alumina ceramic coatings are characterized by several essential technical properties that make them suitable for a range of industrial applications. Understanding these properties is crucial for B2B buyers looking to enhance the durability and performance of their products.

Illustrative image related to alumina ceramic coating

-

Material Grade

Material grade refers to the purity and quality of the alumina used in the coating. Higher grades (e.g., 99% purity) typically offer superior mechanical strength, wear resistance, and thermal stability. For buyers, selecting the appropriate material grade is essential to ensure the coating meets specific application requirements and performance standards. -

Hardness

The hardness of alumina coatings is a critical factor that affects their wear resistance. Measured on the Mohs scale, alumina can reach hardness levels of 9, making it one of the hardest materials available. This property is particularly important for applications in industries such as automotive and aerospace, where components are subject to high levels of abrasion. -

Thermal Stability

Alumina coatings can withstand extreme temperatures, often exceeding 1000°F (538°C). This thermal stability is vital for applications involving high heat, such as in engines and industrial furnaces. Buyers should consider this property to ensure that the coating will maintain its integrity under operational conditions. -

Corrosion Resistance

Alumina coatings exhibit excellent resistance to corrosive environments, thanks to the formation of a passive oxide layer. This property is crucial for industries where components are exposed to harsh chemicals or moisture, such as oil and gas or chemical processing. Selecting a coating with high corrosion resistance can significantly extend the lifespan of equipment. -

Low Porosity

The porosity of a coating affects its durability and performance. Low porosity in alumina coatings means reduced likelihood of moisture penetration and chemical attack, resulting in enhanced longevity and reliability. For B2B buyers, this characteristic is essential when considering maintenance costs and operational efficiency. -

Dielectric Properties

Alumina coatings also possess good dielectric properties, making them suitable for electrical insulation applications. This is particularly relevant for industries that rely on electrical components, as it helps prevent short circuits and improves overall safety.

What Are Common Trade Terms Used in Alumina Ceramic Coating?

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to alumina ceramic coatings:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is critical for buyers who need coatings that meet the original design criteria of specific components. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For buyers, knowing the MOQ helps in planning inventory and budget, especially when dealing with specialized coatings that may have higher production costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For buyers, preparing a detailed RFQ can lead to better pricing and terms, ensuring that they receive competitive offers for alumina ceramic coatings. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for buyers to avoid misunderstandings regarding shipping, insurance, and delivery responsibilities. -

Thermal Spray

Thermal spray is a coating process where materials are heated and propelled onto a substrate to form a coating. This term is particularly relevant for buyers looking for specific application techniques for alumina coatings. -

Surface Finish

Surface finish refers to the texture and smoothness of a coated surface. This property is vital for applications where aesthetics and frictional characteristics are important, such as in automotive and consumer products.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, leading to enhanced product performance and reduced operational costs.

Navigating Market Dynamics and Sourcing Trends in the alumina ceramic coating Sector

What Are the Current Market Dynamics and Key Trends in the Alumina Ceramic Coating Sector?

The alumina ceramic coating sector is witnessing significant growth driven by several global factors. The increasing demand for durable, high-performance materials across various industries—including automotive, aerospace, and textiles—has heightened the need for advanced coatings that enhance product lifespan and performance. With a focus on enhancing operational efficiency, manufacturers are increasingly adopting thermal spray techniques, such as High Velocity Oxy-Fuel (HVOF) and plasma spraying, which yield coatings with superior adhesion and mechanical properties.

In addition to traditional applications, the rise of emerging technologies like additive manufacturing is influencing sourcing trends. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for suppliers who can provide customized solutions that cater to specific industry needs. There is also a growing emphasis on digital platforms for sourcing, allowing buyers to access a wider range of suppliers and compare products more effectively. This shift is particularly pronounced in regions like Germany and Brazil, where industries are becoming more interconnected and reliant on high-quality materials.

Furthermore, sustainability is becoming a pivotal factor in purchasing decisions. Buyers are now more inclined to work with suppliers who demonstrate a commitment to environmentally friendly practices and materials, leading to a shift in market dynamics where ethical sourcing becomes a key differentiator.

Illustrative image related to alumina ceramic coating

How Is Sustainability Impacting Sourcing in the Alumina Ceramic Coating Market?

Sustainability is reshaping the alumina ceramic coating sector, influencing both production methods and supply chain management. The environmental impact of manufacturing processes is under scrutiny, prompting companies to seek eco-friendly alternatives. Buyers are increasingly prioritizing suppliers who utilize low-emission techniques and sustainable materials, fostering a market where ‘green’ certifications become essential.

Ethical supply chains are gaining traction as businesses recognize the importance of transparency and social responsibility. B2B buyers are more likely to engage with manufacturers who provide clear information about their sourcing practices, labor conditions, and environmental policies. This shift is particularly relevant in international markets, where consumers and businesses are advocating for sustainability in procurement.

The use of ‘green’ materials in alumina ceramic coatings—such as recycled aluminum oxide or non-toxic additives—is becoming a competitive advantage. Suppliers that can demonstrate compliance with international sustainability standards not only enhance their marketability but also attract a more conscientious customer base. As sustainability becomes ingrained in corporate strategies, buyers can expect to see more innovation in eco-friendly ceramic coatings that align with their values.

Illustrative image related to alumina ceramic coating

What Is the Historical Context of Alumina Ceramic Coatings in B2B Applications?

The evolution of alumina ceramic coatings can be traced back to the mid-20th century when the demand for durable materials began to surge across various industries. Initially, these coatings were primarily used for high-temperature applications, such as in aerospace and power generation, due to their exceptional thermal resistance and hardness.

Over the decades, advancements in coating technologies—particularly thermal spraying—have expanded the applicability of alumina coatings to numerous sectors, including automotive and textiles. The development of composite coatings, such as alumina-titania blends, has further enhanced performance characteristics, enabling coatings to withstand more aggressive environments.

Today, alumina ceramic coatings are recognized for their versatility and durability, providing solutions for wear resistance, electrical insulation, and corrosion protection. This historical context highlights the ongoing innovation within the sector, positioning alumina ceramic coatings as essential components in modern manufacturing processes. As industries continue to evolve, the role of these coatings will likely expand, driven by technological advancements and changing market demands.

Illustrative image related to alumina ceramic coating

Frequently Asked Questions (FAQs) for B2B Buyers of alumina ceramic coating

-

How do I choose the right alumina ceramic coating for my application?

Selecting the appropriate alumina ceramic coating involves evaluating the specific performance properties required for your application. Consider factors such as wear resistance, thermal stability, and corrosion resistance. Additionally, assess the environmental conditions the coating will face, including temperature fluctuations and chemical exposure. Collaborate with suppliers who can provide detailed technical data and samples, allowing you to make an informed decision based on your unique needs and budget constraints. -

What are the primary benefits of using alumina ceramic coatings in industrial applications?

Alumina ceramic coatings offer numerous advantages, including exceptional hardness, wear resistance, and oxidation resistance. They enhance the longevity of components, reducing maintenance costs and downtime. These coatings also provide excellent thermal and electrical insulation, making them ideal for high-temperature applications in industries such as aerospace, automotive, and chemical processing. By extending the service life of parts, they contribute to overall operational efficiency and cost-effectiveness. -

What is the typical lead time for alumina ceramic coating orders?

Lead times for alumina ceramic coatings can vary significantly depending on the supplier, coating type, and order volume. Generally, you can expect a lead time ranging from a few weeks to several months. Factors influencing this timeline include production capacity, customization requirements, and logistics arrangements. It is advisable to communicate your timeline expectations upfront and confirm with suppliers to ensure timely delivery aligned with your project schedules. -

Are there minimum order quantities (MOQs) for alumina ceramic coatings?

Most suppliers impose minimum order quantities (MOQs) for alumina ceramic coatings to ensure production efficiency and cost-effectiveness. MOQs can vary widely based on the coating type, supplier policies, and the complexity of the order. It is crucial to discuss MOQs with potential suppliers early in the sourcing process to understand any limitations and negotiate terms that align with your purchasing strategy, especially for smaller projects or pilot runs. -

How can I assess the quality of alumina ceramic coatings from suppliers?

Quality assessment of alumina ceramic coatings should involve reviewing certifications, technical specifications, and past performance data. Request samples to evaluate adhesion, thickness, and surface finish. Additionally, inquire about the supplier’s quality assurance processes, including testing methodologies and compliance with international standards. Engaging in site visits or audits can also provide insights into the supplier’s manufacturing practices and reliability. -

What payment terms should I expect when sourcing alumina ceramic coatings internationally?

Payment terms for international orders of alumina ceramic coatings can vary by supplier and region. Common practices include upfront payments, letters of credit, or staggered payments based on milestones. It’s essential to clarify these terms before finalizing contracts to avoid misunderstandings. Consider negotiating terms that align with your cash flow needs while ensuring supplier confidence in the transaction, fostering a strong business relationship. -

What are the logistics considerations when importing alumina ceramic coatings?

When importing alumina ceramic coatings, consider logistics factors such as shipping methods, customs regulations, and tariffs that may apply to your region. Choose reliable freight forwarders experienced in handling industrial materials to ensure timely and safe delivery. Understand the documentation required for customs clearance and ensure compliance with local regulations. Additionally, plan for potential delays related to customs processing or global supply chain disruptions. -

Can alumina ceramic coatings be customized for specific applications?

Yes, many suppliers offer customization options for alumina ceramic coatings to meet specific application requirements. Customization may include adjustments to coating thickness, composition, or additional properties such as enhanced corrosion resistance or thermal stability. Collaborate closely with your supplier to communicate your needs and expectations, enabling them to provide tailored solutions that optimize performance for your unique industrial applications.

Top 5 Alumina Ceramic Coating Manufacturers & Suppliers List

1. HTS Coatings – Ceramic Coatings

Domain: htscoatings.com

Registered: 2017 (8 years)

Introduction: Ceramic coatings are available in various types, including Chrome Oxide (Cr 2 O 3), Zirconia (ZrO 2), Alumina (Al 2 O 3), Titania (TiO 2), and Alumina-Titania (Al 2 O 3 /TiO 2) composite coatings. Key properties include good durability, superior hardness, excellent resistance to wear, scratching, and abrasion, good oxidation resistance, superior UV protection, good corrosion resistance, prevention…

2. Industrial Plating – Alumina Titania Coatings

Domain: industrialplating.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Alumina Titania Coatings”, “composition”: “Blend of Aluminum Oxide and Titanium Dioxide”, “properties”: {“wear_resistance”: “Excellent wear and abrasion resistance”, “service_temperature”: “Up to 1000F”, “corrosion_resistance”: “Resists corrosion when in contact with dilute alkalies”, “wetting_resistance”: “Resists wetting by common aqueous solutions”, “dielectric_properties”: “G…

3. ASB Industries – Aluminum Oxide Coatings

Domain: asbindustries.com

Registered: 1997 (28 years)

Introduction: Aluminum Oxide (Al2O3) Coatings are high-performance protective coatings known for their durability and chemical stability. They provide superior wear resistance, electrical insulation, and chemical stability, preventing weathering and environmental corrosion. Key benefits include increased resistance to wear from friction and mechanical abrasion, resistance to acids and alkalis, thermal barrier p…

4. Graphite Store – High Temperature Coatings & Sealants

Domain: graphitestore.com

Registered: 2002 (23 years)

Introduction: This company, Graphite Store – High Temperature Coatings & Sealants, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Morgan Technical Ceramics – Alumina Solutions

Domain: morgantechnicalceramics.com

Registered: 2004 (21 years)

Introduction: Alumina (Al₂O₃) can be produced in a range of purities (90-98% and >98%) with additives to enhance properties. It is processed using various methods including machining and net shape forming. Alumina can be joined to metals or other ceramics through metallising and brazing techniques. Key characteristics include good strength and stiffness, hardness and wear resistance, corrosion resistance, therm…

Strategic Sourcing Conclusion and Outlook for alumina ceramic coating

In navigating the complexities of alumina ceramic coatings, strategic sourcing emerges as a critical component for international B2B buyers. The superior mechanical properties, including enhanced durability, wear resistance, and thermal stability, make alumina ceramic coatings an invaluable asset across various industries, such as automotive, aerospace, and chemical processing. Understanding the diverse applications and selecting the appropriate coating type—be it alumina, alumina-titania, or others—can significantly impact operational efficiency and cost management.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-performance materials will only intensify. Buyers should prioritize suppliers who not only offer competitive pricing but also demonstrate a commitment to quality and innovation. Engaging with manufacturers who utilize advanced application methods, such as thermal spray technologies, ensures optimal adhesion and performance of coatings.

Looking ahead, it is imperative for businesses to stay informed about advancements in ceramic coating technologies and market trends. By leveraging strategic partnerships and sourcing strategies, companies can enhance their product offerings and maintain a competitive edge. Connect with reputable suppliers today to explore how alumina ceramic coatings can elevate your operations and drive sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to alumina ceramic coating

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.