A B2B Buyer’s Guide to Alkin Compressor: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for alkin compressor

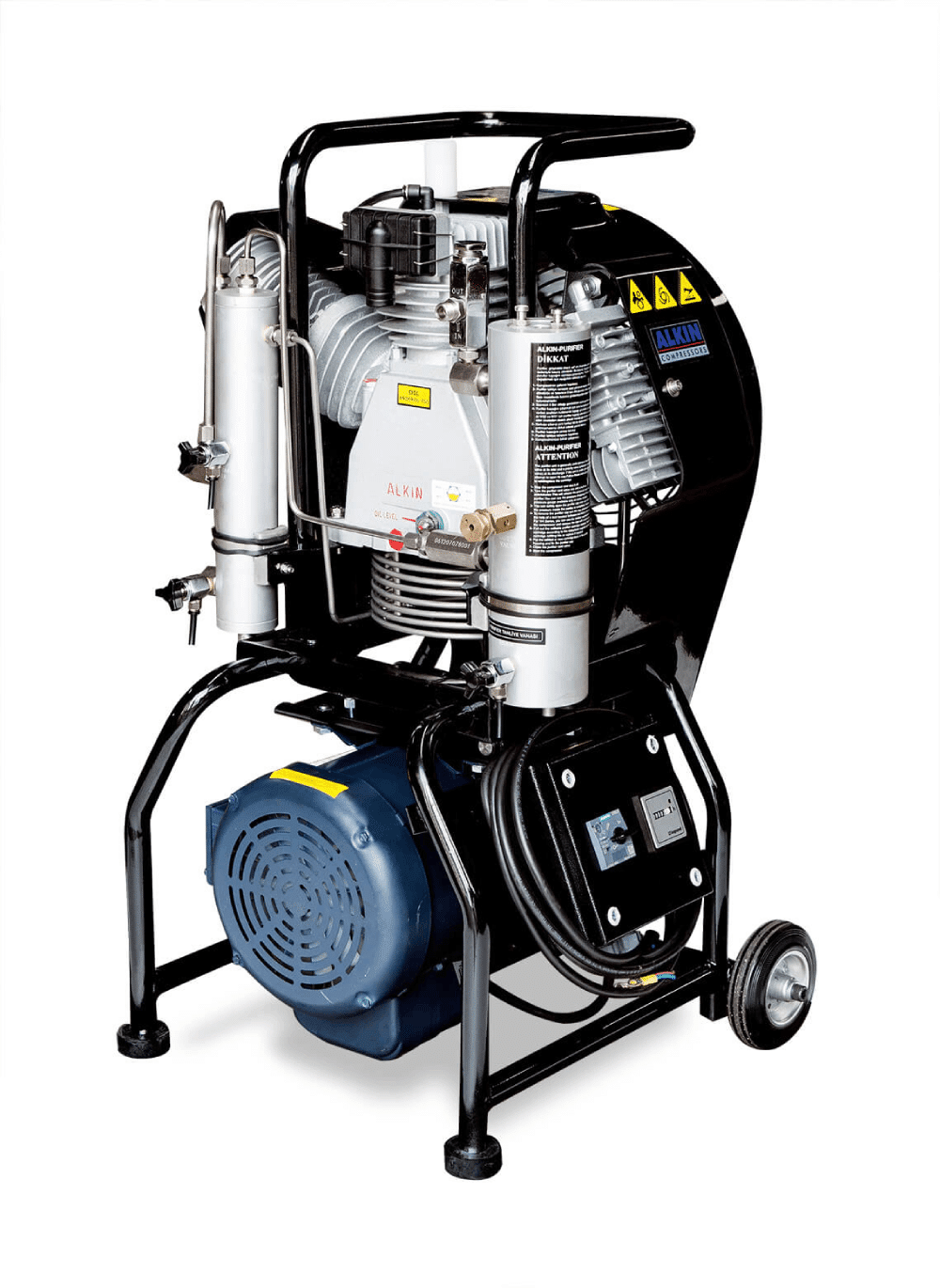

Navigating the global market for Alkin compressors presents a unique set of challenges for B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe. With the increasing demand for high-pressure air compressors across various industries—including diving, firefighting, and manufacturing—sourcing the right equipment can be daunting. This guide aims to simplify that process by providing an in-depth exploration of Alkin compressors, highlighting their diverse applications, and offering insights into supplier vetting, pricing structures, and maintenance considerations.

Alkin Compressors, with over 30 years of experience, stands out as a reputable manufacturer known for its innovative designs and commitment to quality. This comprehensive resource will help international buyers understand the nuances of Alkin’s product offerings, including scuba, paintball, and industrial compressors, and how they can effectively meet specific operational needs. By addressing key factors such as product reliability, service availability, and cost-effectiveness, this guide empowers B2B buyers to make informed purchasing decisions that align with their strategic goals.

Whether you are seeking to enhance operational efficiency, ensure safety compliance, or improve the sustainability of your air compression solutions, this guide serves as your essential toolkit for navigating the Alkin compressor market effectively.

Understanding alkin compressor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High Pressure Compressors | Designed for pressures up to 6000 PSI; low RPM operation | Scuba diving, fire departments, military | Pros: High efficiency, durable; Cons: Higher upfront cost. |

| Medium Pressure Compressors | Operates up to 80 bar; suitable for various industrial uses | Pet bottle filling, shipyards, gas filling | Pros: Versatile applications; Cons: Limited to medium pressure. |

| Low Pressure Compressors | Reliable for sensitive applications; minimal maintenance | General industrial use, pneumatic tools | Pros: Cost-effective, low maintenance; Cons: Limited pressure range. |

| Water Cooled Compressors | Ideal for extreme ambient conditions; compact design | Marine applications, industrial environments | Pros: Efficient in harsh conditions; Cons: More complex installation. |

| Nitrogen and Air Booster Compressors | High efficiency for specific applications; compresses air to high pressures | Metal industry, gas injection, laser cutting | Pros: Specialized performance; Cons: May require additional equipment for operation. |

What are the Key Characteristics of High Pressure Compressors?

High pressure compressors are engineered to deliver air at pressures reaching up to 6000 PSI. These units typically operate at low RPM, which enhances durability and reduces wear on components, making them ideal for high-demand environments such as scuba diving, fire services, and military applications. When considering a high pressure compressor, buyers should evaluate the energy efficiency, maintenance requirements, and the total cost of ownership, as the initial investment is generally higher compared to other types.

How Do Medium Pressure Compressors Serve Industrial Applications?

Medium pressure compressors operate efficiently at pressures up to 80 bar, catering to diverse industrial needs. They are well-suited for applications like pet bottle filling, shipyards, and gas filling facilities. Their versatility makes them an attractive option for businesses looking to optimize their operations. Buyers should assess the compressor’s capacity, efficiency ratings, and compatibility with existing systems to ensure it meets their specific operational requirements.

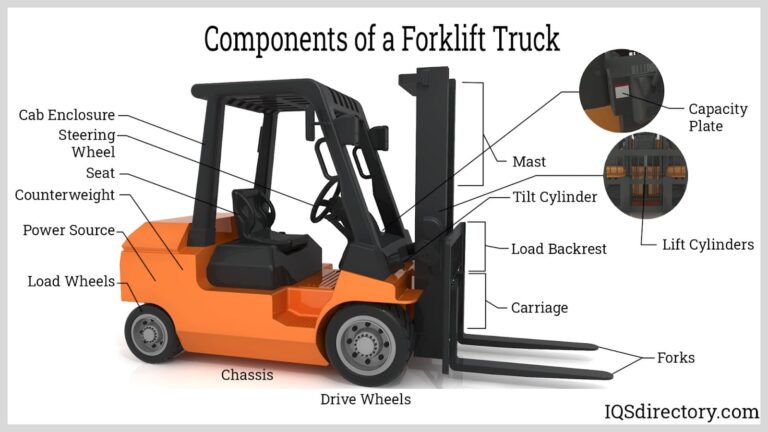

Illustrative image related to alkin compressor

Why Choose Low Pressure Compressors for Sensitive Applications?

Low pressure compressors are designed for reliability and performance in sensitive applications, providing a cost-effective solution for general industrial use and pneumatic tools. With minimal maintenance requirements, these compressors are ideal for businesses seeking longevity and reduced downtime. Buyers should consider the compressor’s pressure range and efficiency to ensure it aligns with their operational needs while keeping costs manageable.

What Advantages Do Water Cooled Compressors Offer in Harsh Environments?

Water cooled compressors are specifically designed to function in extreme ambient conditions where air cooling may not suffice. Their compact design is advantageous for marine applications and other demanding industrial environments. While they excel in challenging conditions, buyers should be aware of the complexity involved in installation and maintenance. Evaluating the operational environment and specific cooling needs is crucial for making an informed purchase decision.

How Do Nitrogen and Air Booster Compressors Enhance Performance?

Nitrogen and air booster compressors are tailored for high-efficiency applications, compressing air to elevated pressures suitable for the metal industry, gas injection, and laser cutting. These specialized units are designed to enhance operational efficiency, but potential buyers should consider the need for additional equipment and the specific requirements of their applications. Understanding the operational context and performance capabilities can lead to better investment decisions.

Key Industrial Applications of alkin compressor

| Industry/Sector | Specific Application of Alkin Compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Diving & Marine | Breathing air systems for scuba diving | Ensures safety and reliability for divers in critical situations | Compliance with international safety standards; service support availability |

| Fire & Safety | Air compressors for SCBA (Self-Contained Breathing Apparatus) | Provides essential breathing air for firefighters during rescue operations | Robustness in extreme conditions; maintenance and repair services |

| Manufacturing | Compressed air for pet bottle blowing | Enhances production efficiency and product quality | Energy efficiency; compatibility with existing systems |

| Defense & Military | High-pressure air systems for military applications | Supports critical operations in defense scenarios | Durability under harsh conditions; rapid deployment capabilities |

| Automotive | Tire inflation and engine starting systems | Improves operational efficiency and reduces downtime | Portability; ease of use in various environments |

How is Alkin Compressor Used in Diving & Marine Applications?

In the diving and marine sector, Alkin compressors provide high-quality breathing air systems essential for scuba diving. These compressors ensure that divers have access to safe, clean air, which is critical for underwater exploration and safety. The compressors are designed to meet stringent international safety standards, making them suitable for use in various diving schools and marine operations. International buyers should consider the availability of local service support and compliance with safety regulations when sourcing these compressors.

What Role Do Alkin Compressors Play in Fire & Safety Operations?

Alkin compressors are integral to fire and safety operations, specifically in supplying air for Self-Contained Breathing Apparatus (SCBA). These compressors ensure that firefighters have reliable access to breathable air during rescue missions, thereby enhancing their safety and performance. Given the extreme conditions firefighters often face, sourcing compressors that are robust and maintain consistent performance is crucial. Additionally, potential buyers should prioritize vendors that offer comprehensive maintenance and support services.

How Do Alkin Compressors Enhance Manufacturing Efficiency?

In manufacturing, particularly in pet bottle blowing, Alkin compressors are utilized to provide compressed air that drives the production process. These compressors help enhance production efficiency and improve the quality of the final products. For businesses looking to optimize their operations, selecting energy-efficient compressors that can seamlessly integrate with existing production systems is vital. International buyers should also evaluate the long-term operational costs and maintenance requirements associated with these compressors.

Why Are Alkin Compressors Essential for Defense & Military Applications?

In defense and military applications, Alkin compressors serve critical roles, including providing high-pressure air systems necessary for various operations. These compressors are designed to operate effectively in challenging environments, supporting essential tasks such as equipment maintenance and logistics. When sourcing for military applications, buyers must consider the durability and rapid deployment capabilities of the compressors, ensuring they can withstand the rigors of military use.

How Do Alkin Compressors Improve Automotive Operations?

Alkin compressors are widely used in the automotive sector for tire inflation and engine starting systems. These compressors enhance operational efficiency by ensuring that vehicles are ready for use quickly and reliably, minimizing downtime. Buyers in this sector should look for compressors that offer portability and ease of use, as these factors can significantly impact their operational workflow. Additionally, the ability to perform well in diverse environments is a key consideration for international buyers.

3 Common User Pain Points for ‘alkin compressor’ & Their Solutions

Scenario 1: Difficulties in Sourcing Replacement Parts for Alkin Compressors

The Problem: One common challenge that B2B buyers face is the unavailability of replacement parts for Alkin compressors, especially when operating in remote locations or regions with limited supply chains. This can lead to extended downtimes, resulting in lost revenue and operational inefficiencies. Buyers often find themselves struggling to source specific components quickly, which can be frustrating and impact their ability to meet customer demands.

The Solution: To mitigate this issue, it is crucial for buyers to establish a proactive relationship with Alkin Compressors and their authorized distributors. By registering products and maintaining open communication, buyers can receive updates on part availability and lead times. Additionally, implementing a robust inventory management system that includes critical spare parts can ensure that essential components are always on hand. Buyers should also consider taking advantage of Alkin’s same-day shipping services for urgent replacements, which can drastically reduce downtime.

Scenario 2: Inadequate Knowledge of Compressor Specifications for Unique Applications

The Problem: Another pain point arises when buyers are unsure about which Alkin compressor model suits their specific application needs, such as scuba diving, industrial use, or paintball. This lack of knowledge can lead to purchasing the wrong equipment, resulting in inefficiencies and dissatisfaction. For example, a diving school might invest in a compressor that does not meet the required pressure specifications, putting their operations at risk.

The Solution: To avoid such pitfalls, buyers should conduct thorough research on the specifications and capabilities of various Alkin compressor models. Engaging with Alkin’s technical support team or consulting the comprehensive product guides available on their website can provide valuable insights. Buyers should clearly define their operational requirements, including the volume of air needed, pressure levels, and frequency of use. Furthermore, participating in industry forums or attending trade shows can help buyers gain firsthand knowledge from other users and experts, facilitating informed purchasing decisions.

Scenario 3: Challenges with Compressor Maintenance and Longevity

The Problem: Maintenance of high-pressure air compressors is a critical concern for businesses, especially when dealing with high usage rates in demanding environments. Buyers often face challenges in understanding the maintenance requirements of Alkin compressors, which can lead to premature wear and tear or unexpected failures. This lack of maintenance awareness can not only shorten the lifespan of the equipment but also affect the safety and reliability of operations.

The Solution: To ensure optimal performance and longevity of Alkin compressors, buyers should implement a proactive maintenance schedule. This includes regular inspections, oil changes, and filter replacements as outlined in the user manual. Alkin offers training and support services that can help teams understand the best maintenance practices tailored to their specific models. Additionally, buyers can leverage Alkin’s 24/7 customer support line to address any maintenance queries or concerns promptly. By fostering a culture of preventive maintenance, companies can significantly reduce the risk of unexpected failures and ensure that their compressors operate efficiently for years to come.

Strategic Material Selection Guide for alkin compressor

What Are the Key Materials Used in Alkin Compressors?

When selecting materials for Alkin compressors, it’s essential to consider their properties, performance, and compatibility with various applications. Here, we analyze four common materials used in the manufacturing of Alkin compressors: aluminum, stainless steel, carbon steel, and composite materials. Each material has unique advantages and disadvantages that can significantly impact performance and suitability for specific applications.

How Does Aluminum Benefit Compressor Design?

Aluminum is widely used in compressor components due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 200°C and can withstand moderate pressures, making it suitable for various applications, including scuba and paintball compressors.

Pros: Aluminum is durable, easy to machine, and offers excellent thermal conductivity, which helps in dissipating heat during operation. Its lightweight nature reduces shipping costs and makes installation easier.

Cons: While aluminum is resistant to corrosion, it can be susceptible to wear under high-stress conditions, which may require more frequent maintenance. Additionally, its cost can be higher than that of carbon steel.

Impact on Application: Aluminum is ideal for applications involving compressed air and gases, especially where weight is a concern, such as in portable compressors.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B221 for aluminum extrusions and consider the specific corrosion resistance requirements based on local environmental conditions.

What Advantages Does Stainless Steel Offer?

Stainless steel is another popular choice for compressor components, particularly in high-pressure applications. It boasts a high-temperature rating (up to 600°C) and excellent corrosion resistance, making it suitable for harsh environments.

Pros: Stainless steel is incredibly durable and resistant to oxidation and corrosion. Its strength allows it to handle high pressures, making it ideal for applications like fire safety and industrial use.

Cons: The primary drawback of stainless steel is its higher cost compared to aluminum and carbon steel. Additionally, its heavier weight can increase transportation and installation costs.

Impact on Application: Stainless steel is particularly effective in applications where exposure to moisture or corrosive substances is a concern, such as in marine or chemical industries.

Considerations for International Buyers: Compliance with standards like ASTM A240 for stainless steel is crucial. Buyers in regions with stringent quality regulations, such as Europe, should prioritize certified materials.

How Does Carbon Steel Compare in Terms of Cost and Durability?

Carbon steel is commonly used in compressor frames and structural components due to its strength and cost-effectiveness. It typically has a temperature rating of up to 400°C and can handle substantial pressure.

Pros: Carbon steel is relatively inexpensive and offers good tensile strength, making it suitable for various applications. It is also easier to weld and fabricate compared to other materials.

Cons: The main disadvantage is its susceptibility to corrosion, requiring protective coatings or treatments. Additionally, it is heavier than aluminum, which can impact portability.

Impact on Application: Carbon steel is well-suited for stationary compressors in industrial settings where weight is less of a concern and cost efficiency is prioritized.

Illustrative image related to alkin compressor

Considerations for International Buyers: Buyers should consider coatings that comply with local regulations, especially in humid or corrosive environments, to enhance the longevity of carbon steel components.

What Role Do Composite Materials Play in Compressor Design?

Composite materials are increasingly being used in compressor design due to their unique properties. They can withstand high pressures and temperatures while being lightweight and resistant to corrosion.

Pros: Composites can be engineered for specific applications, offering tailored solutions. Their lightweight nature can significantly reduce shipping and installation costs.

Cons: The primary limitation is the higher manufacturing complexity and cost associated with composite materials. Additionally, they may not be suitable for all applications, particularly where structural integrity is critical.

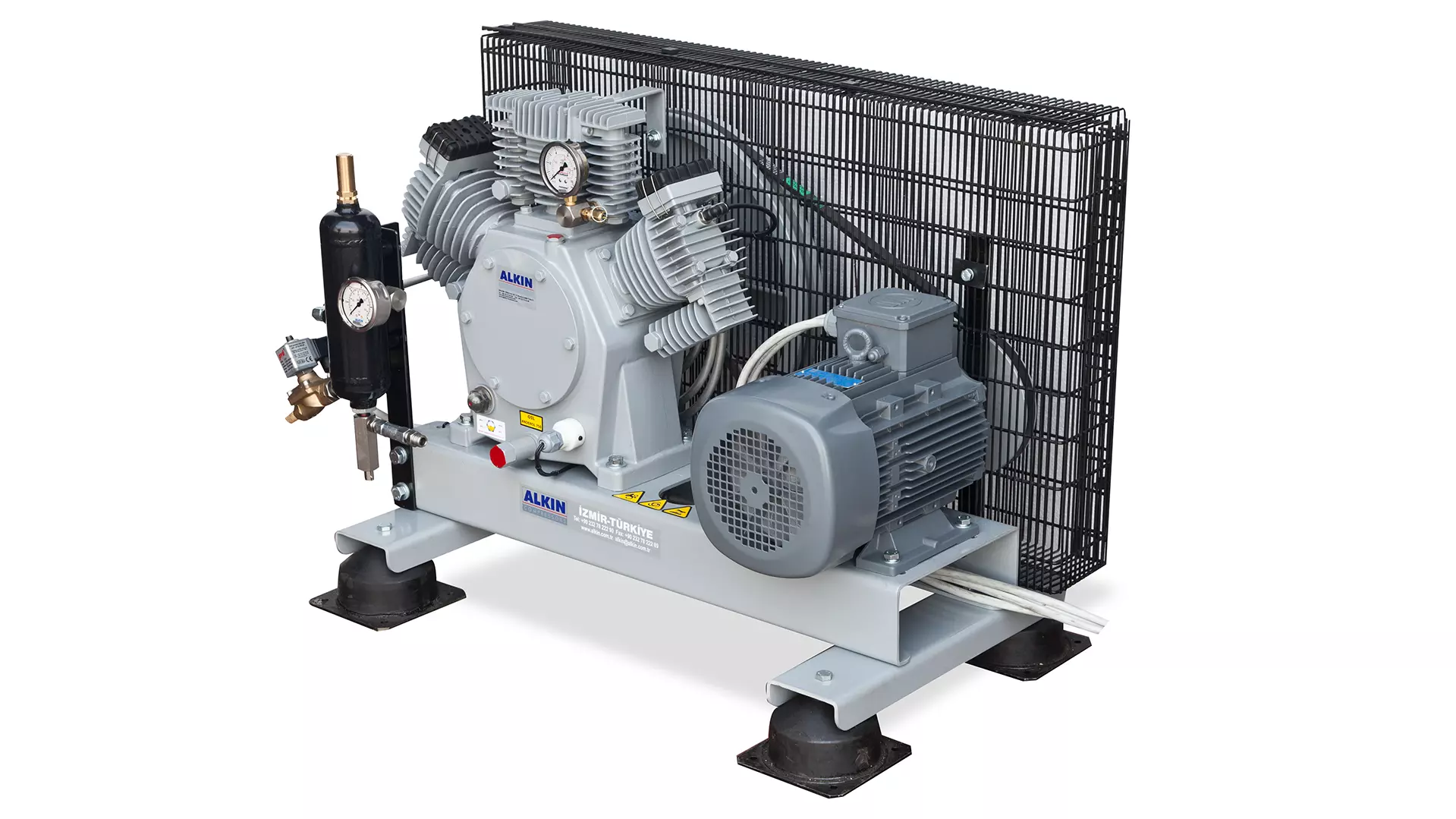

Illustrative image related to alkin compressor

Impact on Application: Composites are ideal for specialized applications, such as aerospace or high-performance diving equipment, where weight and performance are paramount.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant standards, such as ASTM D3039 for tensile properties, and consider the specific performance requirements for their applications.

Summary Table of Material Selection for Alkin Compressors

| Material | Typical Use Case for alkin compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Scuba and paintball compressors | Lightweight and excellent corrosion resistance | Susceptible to wear under high stress | Medium |

| Stainless Steel | High-pressure industrial applications | High durability and corrosion resistance | Higher cost and weight | High |

| Carbon Steel | Stationary industrial compressors | Cost-effective and strong | Corrosion susceptibility | Low |

| Composite | Specialized high-performance applications | Tailored solutions and lightweight | Higher manufacturing complexity | High |

This strategic material selection guide provides valuable insights for international B2B buyers looking to invest in Alkin compressors, ensuring they choose the most suitable materials for their specific needs and applications.

Illustrative image related to alkin compressor

In-depth Look: Manufacturing Processes and Quality Assurance for alkin compressor

What Are the Key Stages in the Manufacturing Process of Alkin Compressors?

The manufacturing process of Alkin compressors is meticulously designed to ensure efficiency, quality, and durability, catering to a diverse range of industries, including scuba diving, automotive, and defense. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The foundation of any high-quality compressor begins with the selection of premium materials. Alkin utilizes high-grade metals and alloys that are resistant to corrosion and wear, ensuring longevity and reliability. Materials undergo rigorous inspections upon arrival to confirm they meet specified standards.

-

Forming: Advanced techniques, such as precision machining and casting, are employed to shape components. CNC (Computer Numerical Control) machining ensures high accuracy and repeatability, vital for parts that require exact specifications. This stage is critical as any deviations can affect the compressor’s performance.

-

Assembly: The assembly process is where all components come together. Alkin’s assembly lines are designed for efficiency and flexibility, allowing for both standard and custom compressor configurations. Skilled technicians assemble the units while adhering to strict guidelines that prioritize safety and operational efficiency.

-

Finishing: After assembly, compressors undergo finishing processes, including surface treatment and painting. These not only enhance aesthetic appeal but also provide additional protection against environmental factors. The final inspection is conducted to ensure that each unit meets Alkin’s stringent quality standards before being dispatched.

How Does Alkin Compressor Ensure Quality Control?

Quality control (QC) is integral to Alkin’s manufacturing philosophy, ensuring that each compressor meets international and industry-specific standards. Alkin follows a systematic QC approach that includes several checkpoints throughout the manufacturing process.

-

International Standards Compliance: Alkin compressors are manufactured in accordance with ISO 9001 standards, ensuring a quality management system that consistently meets customer expectations. Additionally, products often comply with CE and API standards, which are crucial for various applications, especially in Europe and the Middle East.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint verifies that incoming materials meet predefined specifications. Any non-conformance is addressed before production begins.

– In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC checks are conducted to monitor processes and ensure components are being produced correctly. This includes measuring tolerances and inspecting welds.

– Final Quality Control (FQC): Once assembly is complete, each compressor undergoes FQC, which includes functional testing to verify performance under operational conditions. This stage is vital for ensuring that the compressors operate reliably and safely. -

Testing Methods: Alkin employs a variety of testing methods, including:

– Hydrostatic Testing: To ensure pressure vessels can withstand operational pressures without leaks.

– Performance Testing: Assessing airflow, pressure, and efficiency under controlled conditions.

– Durability Testing: Simulating long-term use to identify potential failures before products reach the market.

What Verification Methods Can B2B Buyers Use to Assess Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability and compliance with local regulations.

-

Audits: Conducting on-site audits can provide buyers with firsthand insights into the supplier’s manufacturing processes and QC measures. This includes reviewing documentation, inspecting facilities, and interviewing quality assurance personnel.

-

Quality Reports: Requesting detailed quality reports can help buyers understand a supplier’s QC history and performance metrics. This includes data on defect rates, return rates, and customer feedback.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s operations. These inspections can verify compliance with international standards and assess the quality of finished products.

-

Certifications: Buyers should verify the authenticity of certifications like ISO 9001, CE, and API. Checking with the certifying bodies can ensure that the supplier maintains its compliance status.

What Unique Quality Control Considerations Should International Buyers Be Aware Of?

International buyers must navigate various nuances when dealing with suppliers from different regions, particularly in terms of regulatory compliance and quality assurance.

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and environmental impact. Understanding local requirements is crucial, especially when importing equipment like compressors that may be subject to stringent regulations.

-

Language and Cultural Barriers: Miscommunication can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and possibly employing bilingual staff can mitigate these risks.

-

Supply Chain Integrity: Buyers should consider the entire supply chain when assessing quality control. This includes the sourcing of materials, transportation logistics, and potential delays that could impact quality.

-

Post-Sale Support and Warranty: Alkin offers a two-year warranty on all units, a critical aspect for buyers concerned about long-term reliability. Understanding the terms of support, including parts availability and service response times, can significantly affect operational efficiency.

Conclusion

Alkin’s commitment to quality and rigorous manufacturing processes positions it as a reliable partner for international B2B buyers. By understanding the manufacturing and quality assurance practices, buyers can make informed decisions that align with their operational needs and standards, ensuring the longevity and performance of their compressor systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alkin compressor’

Introduction

Navigating the procurement process for high-pressure air compressors, such as those offered by Alkin, requires careful consideration and strategic planning. This guide provides a step-by-step checklist to help B2B buyers make informed decisions, ensuring that they select the right compressor to meet their operational needs while maximizing value and efficiency.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the compressor meets your operational requirements. Consider factors such as pressure ratings, airflow capacity, and the specific applications for which the compressor will be used. This will help you narrow down the models that fit your needs and avoid purchasing equipment that may be over- or under-capacity.

- Key Specifications to Consider:

- Maximum operating pressure (e.g., 3000 PSI or higher).

- Flow rate requirements for your specific applications (e.g., scuba diving, fire safety).

- Power source compatibility (electric, diesel, etc.).

Step 2: Research Supplier Background and Reputation

Before making a purchasing decision, it’s essential to investigate the supplier’s history and reputation in the market. Alkin has over 30 years of experience, but assessing their standing among peers and clients can provide further insights. Look for reviews, testimonials, and case studies that reflect their reliability and product quality.

- What to Look For:

- Certifications and compliance with international standards.

- Client testimonials from businesses in your industry.

- Participation in industry events or trade shows.

Step 3: Evaluate Product Range and Customization Options

Examine the variety of products offered by Alkin, ensuring they have the right models for your specific needs. Additionally, inquire about customization options, as some applications may require tailored solutions. Understanding the breadth of their offerings can help you find the best fit for your operational requirements.

Illustrative image related to alkin compressor

- Considerations:

- Availability of different types of compressors (high, medium, low pressure).

- Options for custom features or adaptations to suit unique applications.

- Add-ons and accessories that enhance functionality.

Step 4: Assess Warranty and After-Sales Support

Review the warranty terms provided by Alkin, as this can significantly impact the total cost of ownership. A robust warranty and responsive after-sales support can save you time and money in the long run, particularly if maintenance or repairs are needed.

- Key Points to Confirm:

- Duration and coverage of the warranty (e.g., two years on parts).

- Availability of customer support (24/7 support is ideal).

- Access to parts and service (same-day shipping options).

Step 5: Request Quotes and Compare Pricing

Once you have identified potential models and suppliers, request detailed quotes from multiple vendors. Comparing pricing is essential, but it’s also important to consider the value offered, including warranty, support, and additional features.

- Comparison Tips:

- Ensure quotes include all costs (shipping, installation, etc.).

- Evaluate the cost-effectiveness based on your long-term usage.

- Consider any financing options available.

Step 6: Check for Compliance with International Standards

Ensure that the compressors meet necessary international standards, particularly if your operations are in regions with stringent regulations. Alkin’s compressors are designed to comply with such standards, which can mitigate risks associated with non-compliance.

- What to Verify:

- Certification from recognized bodies (e.g., ISO, NFPA).

- Documentation that proves adherence to safety and environmental regulations.

Step 7: Finalize Your Purchase and Arrange Logistics

After thorough evaluation and comparison, finalize your decision and arrange for the purchase. Coordinate logistics for delivery, installation, and training for your team on how to operate and maintain the equipment properly.

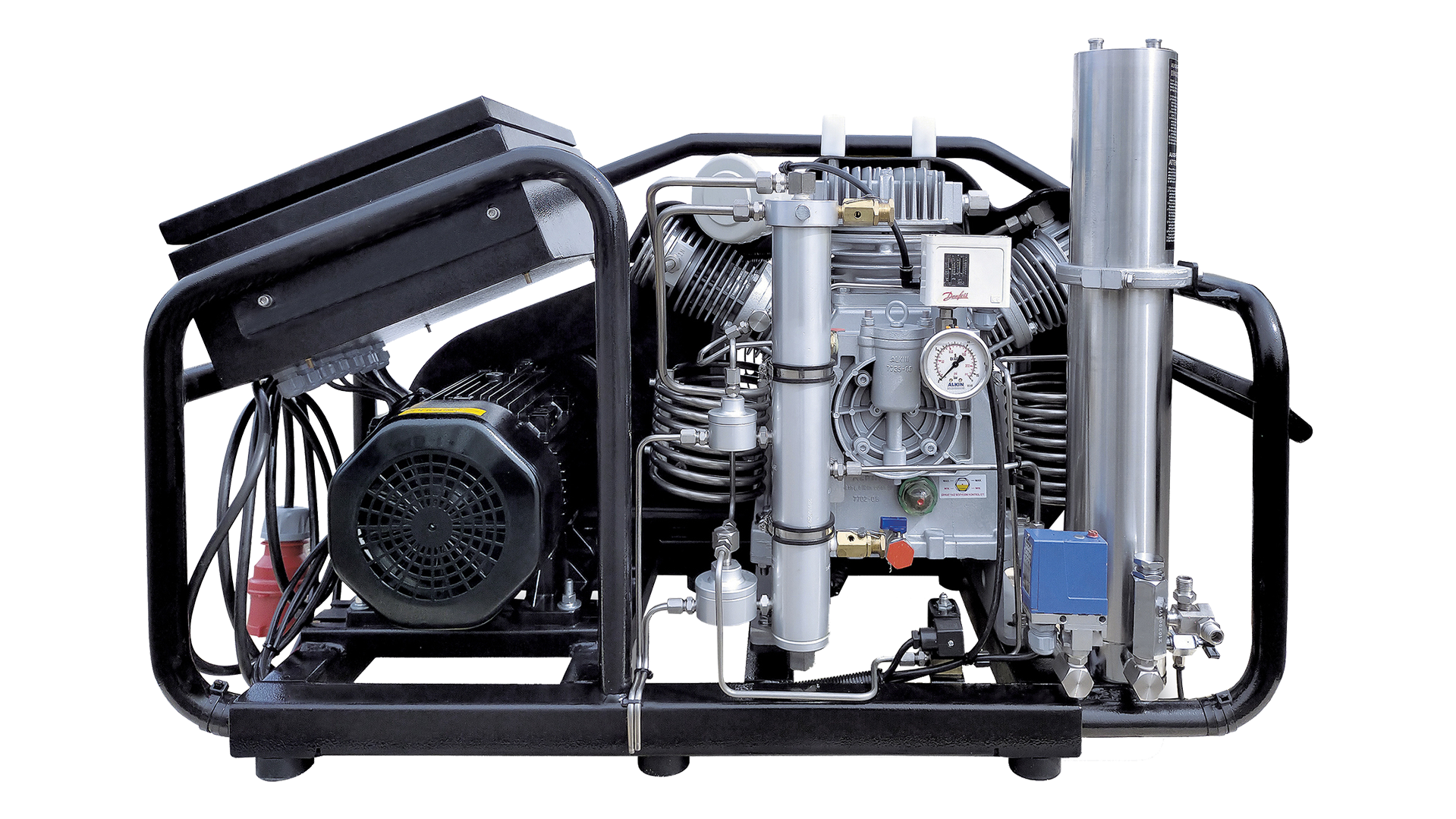

Illustrative image related to alkin compressor

- Logistical Considerations:

- Delivery timelines and costs.

- Installation requirements and support.

- Training sessions to ensure proper use and maintenance of the compressor.

Following this checklist will help ensure that you make a well-informed decision when sourcing Alkin compressors, ultimately enhancing your operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for alkin compressor Sourcing

What Are the Key Cost Components in Alkin Compressor Sourcing?

When sourcing Alkin compressors, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: Alkin compressors are manufactured using high-quality materials that ensure durability and performance. The choice of materials directly impacts the cost, as premium materials may increase the price but also enhance the longevity and efficiency of the compressors.

-

Labor: Labor costs in Turkey, where Alkin compressors are produced, play a significant role in the overall pricing. Skilled labor is essential for the assembly and quality assurance processes, which may result in higher costs compared to countries with lower wage standards.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Alkin’s commitment to maintaining state-of-the-art manufacturing facilities contributes to overhead costs but also ensures high-quality output.

-

Tooling: Customization or specific tooling requirements can add to the cost. Alkin offers various models and specifications, and tooling for customized solutions can significantly influence the final price.

-

Quality Control (QC): Rigorous QC processes are essential to meet international standards. Investing in quality assurance can lead to higher upfront costs but ultimately reduces long-term expenses related to repairs and replacements.

-

Logistics: The cost of shipping compressors, especially for international buyers, can vary based on destination, shipping methods, and customs duties. Understanding Incoterms is vital to accurately assess logistics costs.

-

Margin: Alkin’s pricing strategy includes a profit margin that reflects the brand’s market position and the value of its products. Buyers should consider the added value of service and support when evaluating the margin.

How Do Price Influencers Impact Alkin Compressor Sourcing?

Several factors can influence the pricing of Alkin compressors, making it essential for buyers to consider:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Alkin may offer better pricing for larger orders, so understanding the minimum order quantity (MOQ) can help in negotiating favorable terms.

-

Specifications and Customization: Custom features or specifications can increase the price. Buyers should clearly define their needs to avoid unexpected costs.

-

Materials and Quality Certifications: The level of certification (e.g., ISO standards) can affect pricing. Products that comply with stringent quality standards typically command higher prices but offer greater reliability.

-

Supplier Factors: The reputation and experience of the supplier can impact cost. Alkin’s established presence in the market may justify a higher price point due to reliability and support.

-

Incoterms: Understanding the chosen Incoterms can clarify who bears the shipping costs and risks, affecting the total landed cost of the compressors.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Alkin Compressors?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, adopting strategic approaches can enhance cost-efficiency:

-

Negotiate Terms: Engaging in negotiations about pricing, payment terms, and delivery schedules can yield significant savings. Establishing a good rapport with the supplier may lead to better deals.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term operational costs, including maintenance, energy consumption, and potential downtime. Alkin compressors, known for their low RPM and durability, can be more cost-effective over time.

-

Stay Informed About Market Trends: Understanding market dynamics, such as supply chain disruptions or changes in material costs, can provide leverage during negotiations and help anticipate price fluctuations.

-

Leverage Local Partnerships: Establishing partnerships with local distributors or service providers can reduce logistics costs and improve service support, ultimately enhancing the overall sourcing experience.

Disclaimer on Indicative Prices

Prices for Alkin compressors can vary widely based on the aforementioned factors. It is advisable for buyers to request detailed quotations tailored to their specific requirements and to keep abreast of any changes in market conditions that may affect pricing.

Illustrative image related to alkin compressor

Alternatives Analysis: Comparing alkin compressor With Other Solutions

Introduction to Alternative Solutions for High-Pressure Air Compressors

When evaluating high-pressure air compressors, it’s crucial for businesses to consider various options that may meet their operational needs. The Alkin Compressor, renowned for its efficiency and reliability, competes with several alternatives in the marketplace. Understanding the differences in performance, cost, ease of implementation, maintenance, and best use cases can help B2B buyers make informed decisions tailored to their specific requirements.

| Comparison Aspect | Alkin Compressor | Alternative 1: Bauer Compressors | Alternative 2: Ingersoll Rand Compressors |

|---|---|---|---|

| Performance | High efficiency with low RPM operation | High performance, suitable for heavy-duty applications | Reliable, versatile with multiple configurations |

| Cost | Competitive pricing with long-term value | Higher initial investment but durable | Mid-range cost with good ROI |

| Ease of Implementation | Simple setup, suitable for various sectors | Requires professional installation | User-friendly with extensive resources |

| Maintenance | Low maintenance, high durability | Moderate maintenance requirements | Regular maintenance needed for optimal performance |

| Best Use Case | Scuba diving, fire safety, industrial applications | Military, scuba, and commercial diving | General industrial applications and automotive |

Detailed Breakdown of Alternatives

Bauer Compressors

Bauer Compressors are often recognized for their robust performance, particularly in demanding environments. They excel in heavy-duty applications, such as military and commercial diving operations. However, their upfront costs are significantly higher than those of Alkin Compressors. While they provide excellent durability, the need for professional installation can complicate the initial setup. Maintenance is moderate; users must adhere to scheduled upkeep to ensure optimal operation.

Ingersoll Rand Compressors

Ingersoll Rand offers a versatile range of compressors that can adapt to various industrial applications, including automotive and manufacturing. They are known for their reliability and user-friendly design, making them accessible for businesses without extensive technical expertise. However, they typically require more frequent maintenance compared to Alkin Compressors, which could lead to higher long-term costs. Their mid-range pricing makes them a viable option for companies seeking a balance between performance and budget.

Conclusion: Choosing the Right High-Pressure Air Compressor for Your Business

Selecting the appropriate high-pressure air compressor involves assessing your specific operational needs, budget constraints, and the level of maintenance you are prepared to commit to. While the Alkin Compressor offers a competitive edge with its low RPM design, low maintenance requirements, and affordability, alternatives like Bauer and Ingersoll Rand present their own unique benefits for specialized applications. By carefully evaluating the comparative aspects outlined above, B2B buyers can make well-informed decisions that align with their operational goals and enhance productivity in their respective industries.

Illustrative image related to alkin compressor

Essential Technical Properties and Trade Terminology for alkin compressor

What Are the Key Technical Properties of Alkin Compressors?

Understanding the essential technical properties of Alkin compressors is vital for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications that define the quality and reliability of these high-pressure air compressors:

-

Pressure Rating

The pressure rating, typically measured in PSI (pounds per square inch), indicates the maximum pressure the compressor can generate. Alkin compressors offer models that reach up to 6000 PSI, making them suitable for demanding applications such as scuba diving and industrial use. For buyers, selecting the right pressure rating ensures that the compressor can meet specific operational needs without risking equipment failure. -

Flow Rate

Flow rate, expressed in liters per minute (L/min), measures how much compressed air the unit can deliver over time. Alkin compressors are designed to deliver high flow rates, which is essential for applications requiring continuous air supply, such as paintball and airgun filling stations. A higher flow rate can lead to increased productivity, making it a crucial factor for businesses focused on efficiency. -

Cooling Method

Compressors can be cooled via air or water, with Alkin offering water-cooled options for extreme environments. The cooling method affects the compressor’s performance and longevity. Water-cooled compressors are ideal for high-demand operations where air cooling may be insufficient, ensuring that the unit runs efficiently and has a longer service life. -

RPM (Revolutions Per Minute)

Alkin compressors operate at lower RPMs compared to many competitors. This feature results in reduced wear and tear on components, leading to extended maintenance intervals and longer overall equipment life. For B2B buyers, lower RPM units can translate into lower operational costs and less downtime, enhancing the overall return on investment. -

Warranty and Support

Alkin offers a two-year warranty on all units and parts, underscoring the manufacturer’s confidence in product quality. Comprehensive customer support, including 24/7 assistance, is crucial for businesses that rely on their compressors for critical operations. This level of service can significantly reduce the risks associated with equipment failure.

What Are Common Trade Terms Related to Alkin Compressors?

Familiarity with industry jargon can significantly enhance communication and negotiation processes for B2B buyers. Here are some common terms relevant to the procurement of Alkin compressors:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. In the context of Alkin compressors, buyers might deal with OEM parts for replacements or upgrades. Understanding this term helps in sourcing the right components that maintain compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Alkin compressors, knowing the MOQ can help businesses plan their inventory and budget accordingly. It can also affect pricing negotiations, as higher orders often lead to better rates. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. B2B buyers should issue RFQs when seeking competitive pricing for Alkin compressors or related accessories, enabling them to make informed purchasing decisions based on cost and specifications. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. For Alkin compressors shipped globally, understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for negotiating contracts and clarifying shipping responsibilities. -

Lead Time

Lead time is the period between placing an order and receiving the product. Knowing the lead time for Alkin compressors is crucial for businesses planning their operations, especially when tight deadlines are involved. Effective communication regarding lead times can help in managing customer expectations and supply chain logistics.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of procuring Alkin compressors more effectively, ultimately leading to better investment decisions and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the alkin compressor Sector

What are the Key Market Trends Impacting Alkin Compressors?

The global market for high-pressure air compressors is witnessing significant transformation, driven by increasing industrialization and the need for efficient energy solutions. Key trends include a rising demand for advanced compressors that cater to specific applications such as scuba diving, fire safety, and automotive industries. In regions like Africa and South America, expanding infrastructure projects are propelling the need for reliable air compressors, particularly in construction and mining. Meanwhile, Europe, with its stringent regulations on emissions and energy efficiency, is leaning towards low RPM compressors that minimize wear and enhance durability, aligning with the increasing focus on operational cost savings.

Illustrative image related to alkin compressor

Emerging technologies, such as IoT integration in compressor systems, are gaining traction, allowing for real-time monitoring and predictive maintenance. This trend is particularly appealing to B2B buyers in sectors where uptime is critical. Additionally, the rise of e-commerce platforms is reshaping the sourcing landscape, enabling buyers from the Middle East and Europe to access a broader range of compressor solutions quickly. As buyers increasingly seek suppliers with robust service and support frameworks, companies like Alkin Compressor that offer 24/7 customer support and same-day parts availability are well-positioned to capture market share.

How is Sustainability Influencing Sourcing Decisions in the Alkin Compressor Market?

Sustainability has become a central theme in B2B sourcing decisions, particularly for high-pressure air compressors. With increasing awareness of environmental impacts, buyers are prioritizing suppliers that adhere to ethical sourcing practices and offer environmentally friendly products. Alkin Compressors, for instance, emphasizes energy efficiency and low carbon footprints, which resonate well with businesses aiming to minimize their environmental impact.

The importance of ethical supply chains cannot be overstated. Companies are now more inclined to partner with manufacturers who demonstrate a commitment to sustainable practices, such as using recyclable materials and reducing waste in production processes. Certifications like ISO 14001 for environmental management systems can provide buyers with assurances regarding a supplier’s sustainability credentials. Furthermore, the demand for green certifications is shaping procurement strategies, compelling manufacturers to innovate and adopt greener technologies in their compressor designs. Buyers in regions like Europe are particularly vigilant about these certifications, as compliance with stringent regulations is essential for market access.

What is the Historical Context of Alkin Compressors in the B2B Landscape?

Alkin Compressors has established a formidable presence in the high-pressure air compressor sector since its inception in 1990. With over three decades of experience, the company has evolved from producing low-pressure compressors to becoming Turkey’s first and only high-pressure breathing air compressor manufacturer. This evolution is marked by significant milestones, including the introduction of high-pressure models that cater to diverse applications ranging from scuba diving to military uses.

The company’s commitment to innovation is evident in its establishment of an R&D center in 2018, which underscores its dedication to advancing compressor technology. Alkin’s focus on quality and customer service has facilitated its expansion into over 120 countries, making it a trusted name in both domestic and international markets. As B2B buyers continue to seek reliable and efficient solutions, Alkin’s history of innovation and commitment to quality positions it as a leader in the high-pressure air compressor sector.

Frequently Asked Questions (FAQs) for B2B Buyers of alkin compressor

1. How do I choose the right Alkin compressor for my industry needs?

Selecting the appropriate Alkin compressor involves understanding your specific operational requirements. Consider factors such as the pressure and volume of air needed, the nature of your applications (e.g., scuba diving, industrial use, or fire safety), and the environmental conditions where the compressor will operate. Alkin offers a range of compressors tailored for various industries, so consulting with an Alkin representative can provide insights into the best model for your needs, ensuring optimal performance and efficiency.

2. What are the advantages of Alkin compressors over competitors?

Alkin compressors stand out due to their low RPM design, which promotes longevity and reduces maintenance needs. With over 45 years of experience, Alkin ensures high-quality materials and advanced technology in manufacturing. Their compressors come with a two-year warranty, same-day parts availability, and 24/7 customer support. Additionally, Alkin’s practical designs cater to self-servicing clients, making them a reliable choice for businesses requiring consistent performance.

3. What is the minimum order quantity (MOQ) for purchasing Alkin compressors?

The minimum order quantity for Alkin compressors can vary based on the specific model and your location. Generally, for bulk purchases, engaging directly with an Alkin sales representative or authorized distributor will provide clarity on MOQ and pricing structures. For international buyers, discussing your needs can also lead to customized solutions that fit your operational scale.

4. What payment terms are available for international buyers of Alkin compressors?

Alkin offers flexible payment terms for international buyers, including options such as bank transfers, letters of credit, and payment upon delivery. The specific terms may depend on the order size, shipping method, and your location. It’s advisable to discuss payment preferences during the negotiation phase to ensure alignment with your financial processes.

5. How does Alkin ensure quality assurance for its compressors?

Alkin implements rigorous quality assurance processes throughout its manufacturing. Each compressor undergoes thorough testing to ensure compliance with international standards. The company’s R&D team continually innovates to enhance performance and reliability. Additionally, their commitment to quality extends to after-sales service, ensuring customers receive support for any operational issues.

6. What logistics options are available for shipping Alkin compressors internationally?

Alkin provides various logistics solutions for international shipping, including air freight and sea freight options, depending on urgency and cost considerations. They have partnerships with reputable logistics companies to ensure timely delivery while maintaining the integrity of the compressors. It’s crucial to discuss your delivery timelines and preferred shipping methods when placing an order.

Illustrative image related to alkin compressor

7. Can I customize Alkin compressors for specific applications?

Yes, Alkin offers customization options for their compressors to meet specific application needs. Businesses can request modifications in design, capacity, and additional features tailored to their operational requirements. Engaging with Alkin’s technical team during the initial consultation can help identify the best customization options for your unique applications.

8. What industries benefit most from using Alkin compressors?

Alkin compressors serve a wide array of industries, including scuba diving, fire safety, automotive, aerospace, and industrial manufacturing. Their products are designed to meet the diverse needs of sectors requiring high-pressure air solutions, from filling stations to specialized applications like nitrogen boosting and laser cutting. Understanding your industry’s specific demands will help in selecting the most suitable compressor model.

Top 3 Alkin Compressor Manufacturers & Suppliers List

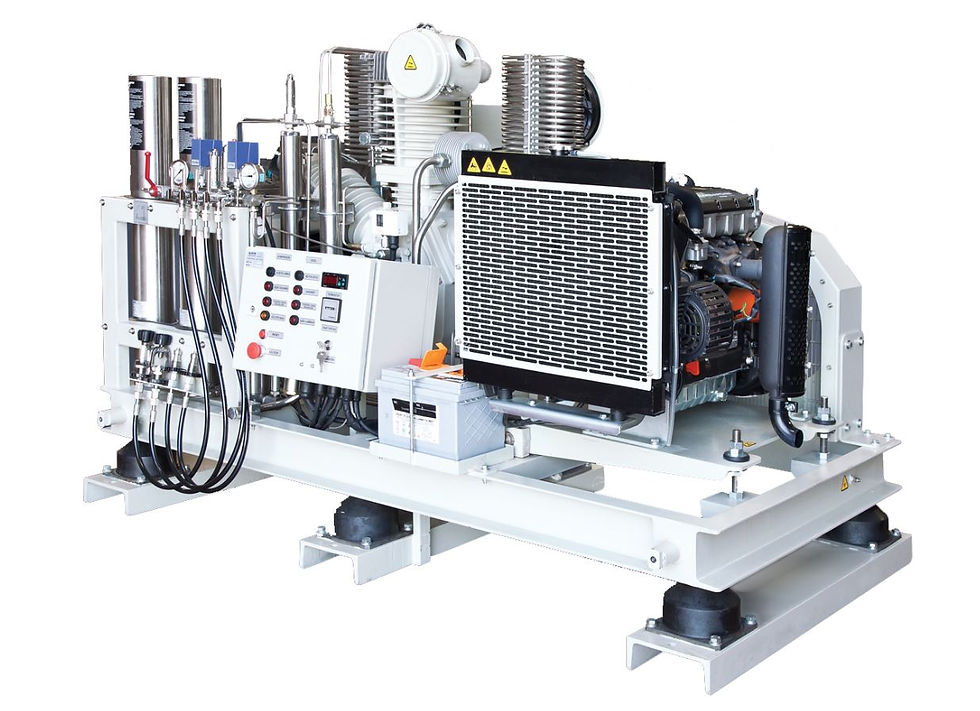

1. Alkın Compressors – Air and Gas Solutions

Domain: alkin-compressors.com

Registered: 2005 (20 years)

Introduction: Alkın Compressors offers a range of air and gas compressors including: 1. High Pressure Compressors – Designed for industries such as diving schools, fire departments, and military applications, compliant with international standards. 2. Medium Pressure Compressors – Suitable for applications like pet bottle filling, shipyards, and gas filling facilities, providing compressed air up to 80 bar. 3. …

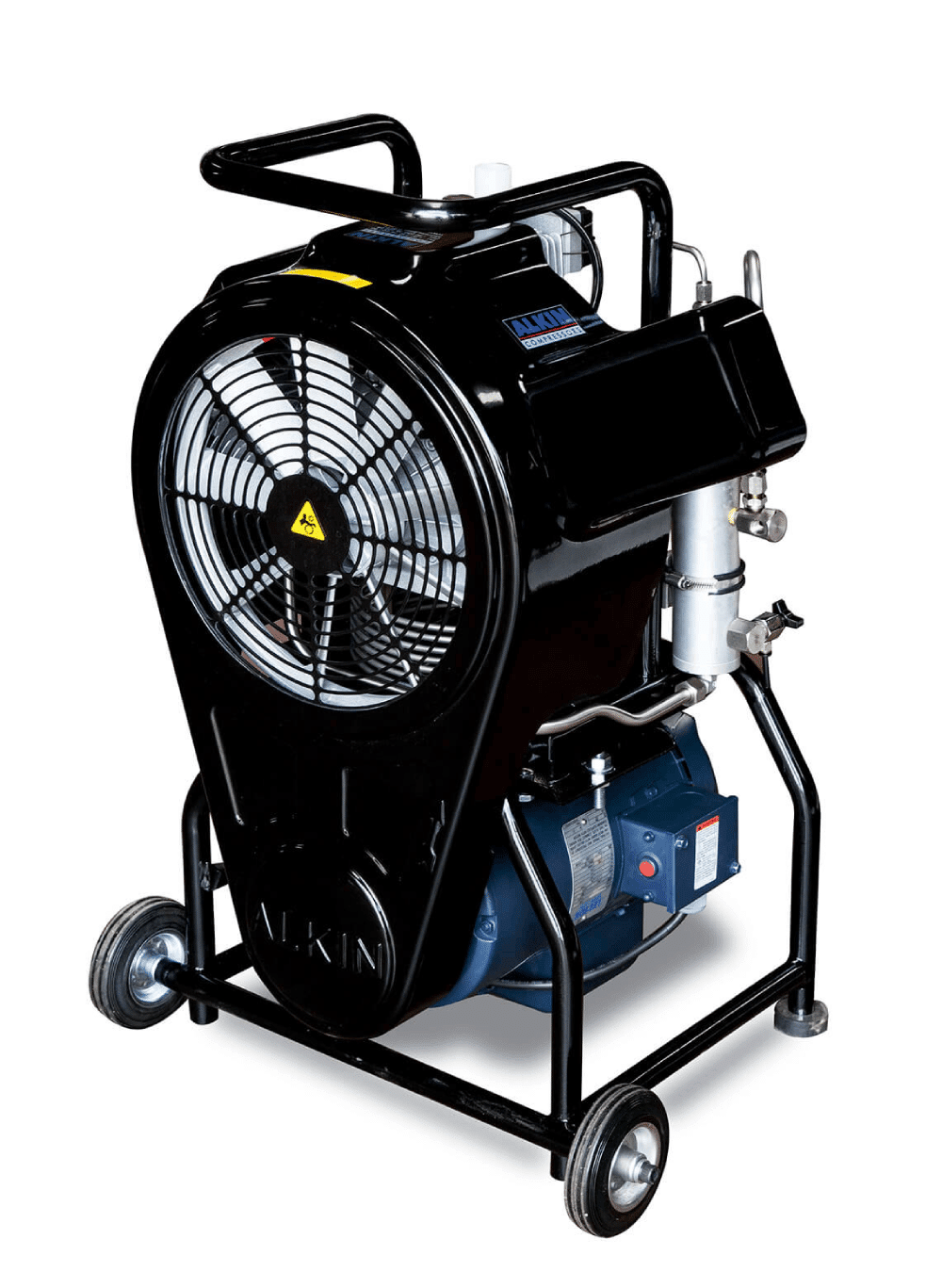

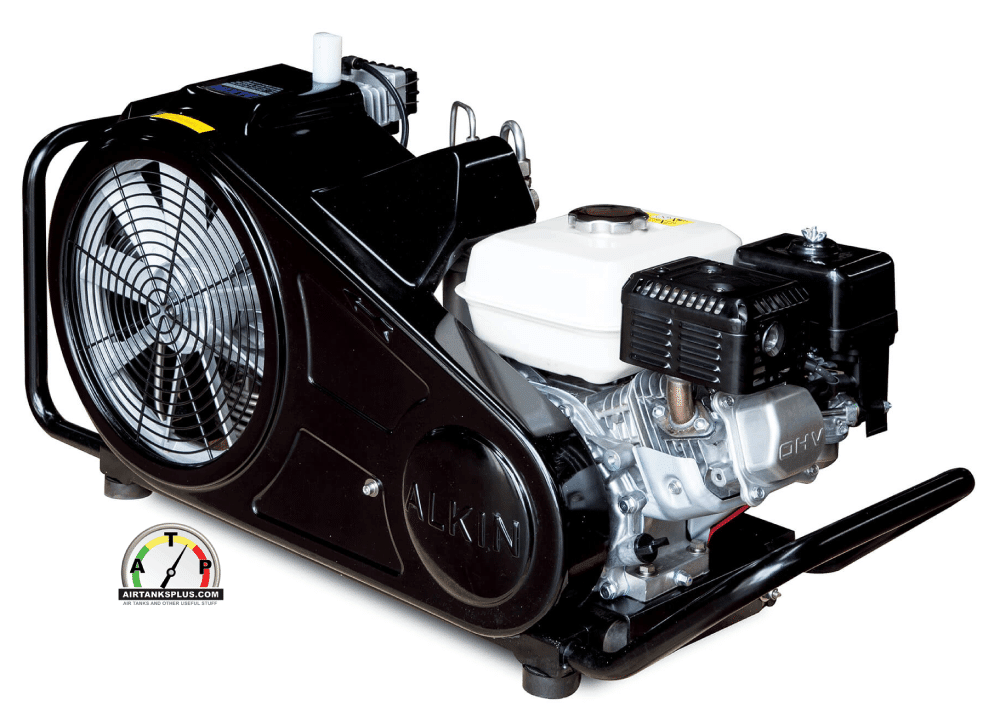

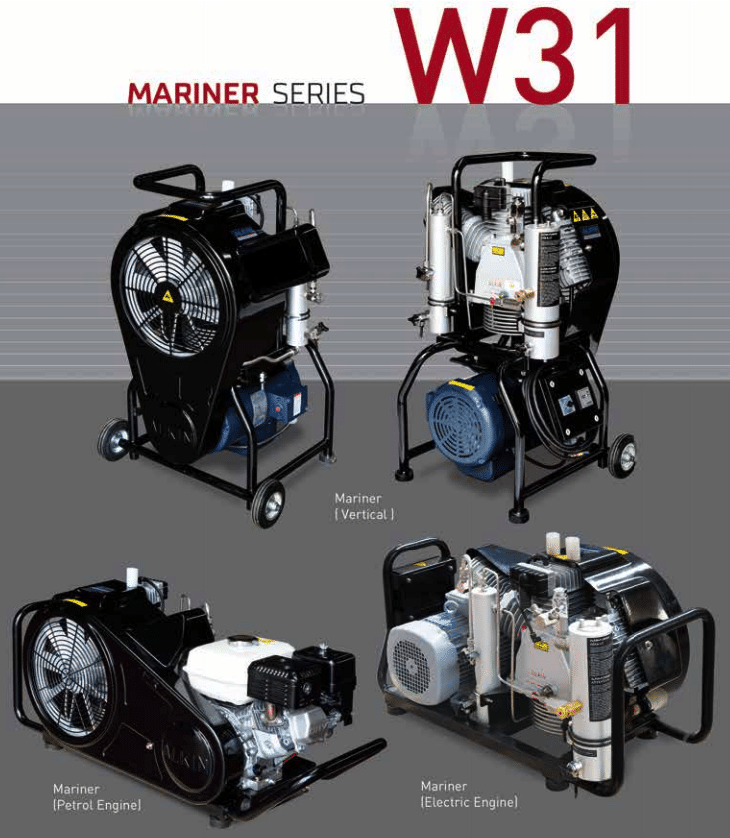

2. Alkin – W31 Compressors

Domain: airtanksplus.com

Registered: 2013 (12 years)

Introduction: Alkin W31 Compressors can compress air up to 5000 psi with an output of 3.7 or 4.9 Cfm. They can be equipped with either an electric motor or a Honda gas engine for portability. The fill whip hose can be configured for various tank types, including DIN300 with scuba yoke, CGA 347 (scba), or female foster fitting for paintball tanks. Price range for Alkin W31 Compressors is between $4,150.00 and $6…

3. Alkin – High Pressure Air Compressors

Domain: pyramydair.com

Registered: 1998 (27 years)

Introduction: Alkin Compressors are high pressure air compressors and fill stations manufactured in Turkey, known for their low RPM operation which allows them to run cool and continuously without downtime. They are designed for both individual and professional use, requiring little maintenance that can be easily administered by the end user. Key products include: 1. Alkin W31 Intake Filter – Rectangular, Price…

Strategic Sourcing Conclusion and Outlook for alkin compressor

In the dynamic landscape of high-pressure air compressors, Alkin Compressors stands out as a trusted partner for B2B buyers across various sectors, including diving, fire safety, and industrial applications. With over 30 years of experience, Alkin offers cutting-edge technology, robust design, and exceptional service, ensuring reliability and efficiency. Their commitment to quality is evident in the use of high-grade materials and innovative manufacturing processes, leading to lower maintenance needs and longer product lifespans.

Illustrative image related to alkin compressor

For international buyers, particularly from Africa, South America, the Middle East, and Europe, strategic sourcing of Alkin Compressors provides a competitive edge. The combination of affordable pricing, rapid parts availability, and 24/7 customer support makes Alkin an attractive choice for businesses looking to enhance operational efficiency while minimizing downtime.

As industries evolve and the demand for high-performance equipment grows, partnering with Alkin Compressors not only fulfills immediate needs but also positions companies for future success. We encourage B2B buyers to explore the extensive product range offered by Alkin and leverage their expertise to optimize their operations. Investing in Alkin means investing in quality, sustainability, and innovation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to alkin compressor