A B2B Buyer’s Guide to Adjustable Tube Connector Clamp Square 1 3/8: Price, Quality,…

Introduction: Navigating the Global Market for adjustable tube connector clamp square 1 3/8

In today’s fast-paced global market, sourcing the right adjustable tube connector clamp square 1 3/8 can pose significant challenges for B2B buyers. With varying specifications, materials, and applications, making an informed purchasing decision is crucial to ensure compatibility and durability in diverse environments. This guide aims to illuminate the complexities of sourcing these essential components, providing a comprehensive overview that covers different types of clamps, their various applications, and the critical factors to consider when evaluating suppliers.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—will find invaluable insights tailored to their unique market needs. We delve into the nuances of material selection, cost implications, and supplier vetting processes, empowering buyers to navigate the complexities of international procurement with confidence. By understanding the market landscape and leveraging best practices, organizations can optimize their supply chains and ensure they are equipped with reliable, high-quality products.

This guide serves as a strategic resource, helping B2B buyers make informed decisions that align with their operational goals while mitigating risks associated with sourcing adjustable tube connector clamps. Whether you are looking to enhance production efficiency or improve structural integrity, the insights provided here will enable you to make choices that contribute to your long-term success.

Understanding adjustable tube connector clamp square 1 3/8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Two-Way Connector Clamp | Allows connection of two square tubes at a right angle | Industrial frameworks, shelving units | Pros: Easy to install, versatile. Cons: Limited to two-way connections. |

| Flanged Connector Clamp | Features mounting holes for secure attachment | Machinery assembly, structural supports | Pros: Enhanced stability, customizable. Cons: Requires precise alignment. |

| Base Plate Connector Clamp | Comes with a base plate for added support | Heavy-duty applications, equipment mounting | Pros: Excellent load distribution. Cons: Bulkier design may limit flexibility. |

| Swivel Connector Clamp | Offers rotational movement for dynamic applications | Adjustable frameworks, display setups | Pros: High adaptability, easy adjustments. Cons: May have a higher wear rate. |

| Multi-Part Assembly Clamp | Designed for complex structures with unequal bore sizes | Custom machinery, specialized frameworks | Pros: Flexibility in design, accommodates various sizes. Cons: More complex installation. |

What Are the Key Characteristics of Two-Way Connector Clamps?

Two-way connector clamps are essential for creating right-angle connections between two square tubes, typically measuring 1 3/8 inches. Their straightforward design allows for quick assembly, making them ideal for constructing industrial frameworks and shelving units. When purchasing, consider the load capacity and material (aluminum or stainless steel) to ensure it meets specific application requirements.

How Do Flanged Connector Clamps Enhance Stability?

Flanged connector clamps come equipped with mounting holes, which provide additional stability when securing the connection. These clamps are widely used in machinery assembly and structural supports, where precise alignment is crucial. Buyers should assess the compatibility of the flange size with existing structures and consider the installation space to avoid complications.

Why Choose Base Plate Connector Clamps for Heavy-Duty Applications?

Base plate connector clamps are designed to distribute loads evenly, making them suitable for heavy-duty applications like equipment mounting. The base plate adds extra support, ensuring stability under significant weight. Buyers should evaluate the dimensions of the base plate and its compatibility with the intended application to maximize efficiency.

What Advantages Do Swivel Connector Clamps Offer?

Swivel connector clamps provide the flexibility of rotational movement, making them excellent for adjustable frameworks and display setups. Their design allows for quick modifications and adjustments, which is beneficial in dynamic environments. However, buyers should be aware that this increased adaptability may lead to a higher wear rate over time, necessitating regular maintenance.

How Can Multi-Part Assembly Clamps Accommodate Complex Structures?

Multi-part assembly clamps are specifically engineered to handle complex structures, particularly when dealing with unequal bore sizes. They are ideal for custom machinery and specialized frameworks, allowing for flexibility in design. Buyers should consider the complexity of installation and ensure they have the necessary tools and expertise to assemble these clamps effectively.

Key Industrial Applications of adjustable tube connector clamp square 1 3/8

| Industry/Sector | Specific Application of adjustable tube connector clamp square 1 3/8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Structural frameworks for assembly lines | Provides quick assembly and flexibility for layout changes | Ensure compatibility with existing systems and materials used |

| Construction | Temporary scaffolding and support structures | Enhances safety and stability during construction projects | Verify load-bearing capacity and environmental resistance |

| Automotive | Custom vehicle racks and display stands | Optimizes space utilization and enhances product visibility | Check for durability under varying weather conditions |

| Retail | Display fixtures for merchandising | Improves product presentation and accessibility | Consider modularity and ease of assembly/disassembly |

| Agriculture | Adjustable equipment supports for irrigation systems | Increases efficiency in farming operations | Assess corrosion resistance and compatibility with agricultural chemicals |

How is the Adjustable Tube Connector Clamp Square 1 3/8 Used in Manufacturing?

In the manufacturing sector, the adjustable tube connector clamp square 1 3/8 is essential for creating structural frameworks for assembly lines. These clamps enable manufacturers to quickly assemble and modify layouts, accommodating changes in production processes. The flexibility offered by these clamps can significantly reduce downtime during reconfiguration, allowing businesses to adapt to market demands swiftly. For international buyers, sourcing clamps that meet specific material standards for durability and compatibility with existing machinery is crucial.

What Role Does the Adjustable Tube Connector Clamp Play in Construction?

In construction, the adjustable tube connector clamp square 1 3/8 is widely used in temporary scaffolding and support structures. These clamps provide crucial safety and stability during various construction phases, allowing workers to focus on their tasks without worrying about structural integrity. Buyers must ensure that the clamps meet local building codes and standards, particularly regarding load-bearing capacities and weather resistance, to ensure compliance and safety on-site.

How is the Adjustable Tube Connector Clamp Beneficial in Automotive Applications?

The automotive industry employs adjustable tube connector clamps to create custom vehicle racks and display stands. These clamps allow for efficient use of space while providing a sturdy platform for showcasing products. This adaptability is vital for automotive businesses looking to enhance their product visibility and streamline their operations. Buyers should consider the clamps’ ability to withstand diverse environmental conditions, as automotive applications often expose them to varying temperatures and moisture levels.

Illustrative image related to adjustable tube connector clamp square 1 3/8

In What Ways Does the Adjustable Tube Connector Clamp Enhance Retail Display Fixtures?

In retail, adjustable tube connector clamps are instrumental in constructing display fixtures that effectively showcase merchandise. These clamps facilitate easy adjustments and reconfigurations, ensuring that the display can adapt to changing inventory or promotional needs. This flexibility enhances the shopping experience and improves product accessibility for customers. Retailers should prioritize sourcing clamps that offer aesthetic appeal and structural integrity, ensuring that they align with brand image and customer expectations.

How Does the Adjustable Tube Connector Clamp Support Agricultural Efficiency?

In agriculture, the adjustable tube connector clamp square 1 3/8 is utilized for adjustable equipment supports in irrigation systems. These clamps allow farmers to modify the height and angle of irrigation equipment, optimizing water distribution and enhancing crop yield. For buyers in the agricultural sector, it is essential to consider the clamps’ resistance to corrosion and compatibility with various agricultural chemicals to ensure longevity and reliability in field conditions.

3 Common User Pain Points for ‘adjustable tube connector clamp square 1 3/8’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Clamps

The Problem: B2B buyers often face challenges when sourcing adjustable tube connector clamps that are compatible with their specific applications. This issue is particularly pronounced in regions with limited access to diverse suppliers, such as parts of Africa and South America. Buyers may find that the clamps they receive are not suited for their intended use, leading to project delays and increased costs. Additionally, mismatched specifications can result in improper fits, compromising the structural integrity of the assembly.

The Solution: To overcome sourcing challenges, buyers should conduct thorough research to identify reputable suppliers who specialize in adjustable tube connector clamps, particularly those that offer a comprehensive range of products in the desired dimensions, including 1 3/8-inch square options. Engaging with local distributors who have established relationships with manufacturers can also streamline the sourcing process. When specifying clamps, ensure to communicate the exact requirements, including load capacities, material types (like aluminum or stainless steel), and any specific features needed for your application. Consider requesting samples or detailed specifications to verify compatibility before placing bulk orders.

Scenario 2: Installation Issues Leading to Structural Weakness

The Problem: Many B2B buyers encounter difficulties during the installation of adjustable tube connector clamps. Improper installation can lead to structural weaknesses, especially in applications that require high stability, such as shelving units or support frames. These issues are often exacerbated by a lack of clear guidelines or training on best practices for using the clamps, resulting in frustration and potential safety hazards.

Illustrative image related to adjustable tube connector clamp square 1 3/8

The Solution: To address installation issues, companies should invest in comprehensive training programs for their staff on the correct installation procedures for adjustable tube connector clamps. This training should cover the importance of using the right tools, following manufacturer guidelines, and understanding the torque specifications for securing the clamps. Additionally, creating easy-to-follow installation guides or videos can serve as valuable resources during the installation process. For complex assemblies, consider consulting with engineers or manufacturers who can provide tailored advice and design assistance to ensure that the clamps are installed correctly and safely.

Scenario 3: Inadequate Load-Bearing Capacity

The Problem: Another common pain point for B2B buyers is the inadequate load-bearing capacity of adjustable tube connector clamps, which can lead to failures in critical applications. Buyers may not fully understand the load ratings of the clamps they purchase, leading to underperformance when subjected to stress. This issue is particularly relevant in industries like construction or manufacturing, where safety and reliability are paramount.

The Solution: To prevent issues related to load-bearing capacity, it is essential for buyers to engage in thorough product evaluation prior to purchase. This includes understanding the specifications related to load limits and ensuring that the selected clamps are rated appropriately for their intended application. Buyers should consult with suppliers to obtain detailed load rating information and request recommendations based on their specific use cases. Additionally, conducting stress tests or simulations can help in validating the performance of the clamps under real-world conditions before full-scale implementation. By prioritizing these evaluations, companies can ensure that they invest in products that meet their operational demands, thereby enhancing safety and efficiency.

Strategic Material Selection Guide for adjustable tube connector clamp square 1 3/8

When selecting materials for adjustable tube connector clamps, particularly for square 1 3/8″ applications, it is essential to consider various factors that influence performance, durability, and cost-effectiveness. Here, we analyze four common materials: aluminum, stainless steel, plastic (polyamide), and cast iron, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Aluminum for Adjustable Tube Connector Clamps?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating of up to 150°C (302°F) and can withstand moderate pressures. Its properties make aluminum a popular choice for applications where weight reduction is crucial, such as in portable structures or equipment.

Pros: Aluminum clamps are easy to manufacture, allowing for cost-effective production. They are also highly resistant to oxidation, which is beneficial in humid environments.

Cons: While durable, aluminum can be less robust than steel, especially under high-stress conditions. It may also be more susceptible to deformation under extreme loads.

Impact on Application: Aluminum is suitable for general-purpose applications, including indoor and outdoor settings. However, it may not be ideal for environments with high mechanical stress or exposure to certain chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America may prefer aluminum for its lightweight nature, which reduces shipping costs.

How Does Stainless Steel Compare for Adjustable Tube Connector Clamps?

Stainless steel is renowned for its strength and exceptional corrosion resistance, making it suitable for harsh environments. It can typically handle temperatures up to 870°C (1600°F) and high pressures, depending on the grade.

Pros: Its durability and resistance to rust make stainless steel ideal for outdoor applications and industries like food processing, where hygiene is critical.

Cons: The higher cost of stainless steel compared to aluminum and plastic can be a barrier for budget-sensitive projects. Additionally, it may require specialized tools for manufacturing.

Illustrative image related to adjustable tube connector clamp square 1 3/8

Impact on Application: Stainless steel clamps are perfect for applications exposed to moisture, chemicals, or extreme temperatures, ensuring long-term performance.

Considerations for International Buyers: Buyers in the Middle East and Europe often prefer stainless steel for its longevity and compliance with international standards.

What Are the Benefits of Using Plastic (Polyamide) for Adjustable Tube Connector Clamps?

Plastic, particularly polyamide, is a versatile material known for its lightweight and good chemical resistance. It is suitable for temperatures up to 120°C (248°F) and can handle moderate pressures.

Pros: Plastic clamps are cost-effective and easy to mold, allowing for complex shapes and designs. They are also non-corrosive, making them suitable for various environments.

Cons: Plastic may not be as durable as metal options, particularly under high-stress or high-temperature conditions. It can also degrade over time when exposed to UV light.

Impact on Application: Ideal for indoor applications and environments where chemical exposure is a concern, plastic clamps can be used in automotive and electronics industries.

Considerations for International Buyers: Buyers in regions with stringent environmental regulations may prefer plastic due to its lightweight nature and compliance with recycling standards.

Illustrative image related to adjustable tube connector clamp square 1 3/8

How Does Cast Iron Perform for Adjustable Tube Connector Clamps?

Cast iron is known for its exceptional strength and rigidity. It can withstand high temperatures (up to 1200°C or 2192°F) and substantial pressure, making it suitable for heavy-duty applications.

Pros: The robustness of cast iron makes it ideal for structural applications where high load-bearing capacity is required.

Cons: Cast iron is heavier and more brittle than other materials, making it less suitable for portable applications. Its manufacturing process can also be more complex and costly.

Impact on Application: Best suited for industrial applications where strength is paramount, cast iron clamps can be found in construction and heavy machinery.

Considerations for International Buyers: Buyers in regions with significant industrial activity may favor cast iron for its strength, but they must consider the increased shipping costs due to its weight.

Summary Table of Material Selection for Adjustable Tube Connector Clamps

| Material | Typical Use Case for adjustable tube connector clamp square 1 3/8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General-purpose applications, portable structures | Lightweight and corrosion-resistant | Less robust under high stress | Medium |

| Stainless Steel | Outdoor applications, food processing, harsh environments | Exceptional durability and rust resistance | Higher cost and manufacturing complexity | High |

| Plastic (Polyamide) | Indoor applications, automotive, electronics | Cost-effective and easy to mold | Less durable under stress and UV exposure | Low |

| Cast Iron | Heavy-duty industrial applications | High strength and load-bearing capacity | Heavy and brittle, complex manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions regarding adjustable tube connector clamps, ensuring compatibility with their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for adjustable tube connector clamp square 1 3/8

What Are the Key Manufacturing Processes for Adjustable Tube Connector Clamps?

The production of adjustable tube connector clamps, particularly those designed for square tubes measuring 1 3/8 inches, involves several critical stages that ensure both functionality and reliability.

1. Material Preparation: What Materials Are Commonly Used?

The manufacturing process typically begins with the selection of materials. Adjustable tube connector clamps are often made from aluminum, stainless steel, or high-strength plastic (like polyamide). These materials are chosen for their excellent strength-to-weight ratios and corrosion resistance, making them suitable for various industrial applications.

Once the material is selected, it undergoes cutting and shaping. Sheets or bars of the chosen material are cut into specific dimensions, ready to be formed into the desired shape. This step is crucial as it sets the foundation for the entire manufacturing process.

2. How Are Adjustable Tube Connector Clamps Formed?

The forming stage involves several techniques, including:

- Bending: Using CNC bending machines, materials are bent into the desired angles to create the clamp’s body.

- Welding: For stainless steel clamps, high-frequency resistance welding is often employed to ensure strong joints. This method provides a clean and efficient way to join pieces without compromising structural integrity.

- Machining: Precision machining techniques, such as milling and drilling, are applied to achieve tight tolerances required for proper fit and functionality.

These processes ensure that the clamps can securely hold the tubing in place while allowing for adjustability.

3. Assembly: What Are the Assembly Techniques Used?

After forming, the components are assembled. This stage may involve:

- Fastening: Screws, bolts, or rivets are used to connect the different parts of the clamp. The choice of fastening method can influence the clamp’s final strength and durability.

- Adjustable Mechanisms: Some clamps include adjustable levers or locking mechanisms, which are integrated during assembly to enhance usability.

Attention to detail during assembly is crucial, as any misalignment can affect the clamp’s overall performance.

4. What Finishing Processes Are Applied?

Finishing processes enhance the appearance and functionality of the clamps. Common techniques include:

- Surface Treatment: Processes like anodizing for aluminum or passivation for stainless steel improve corrosion resistance and aesthetic appeal.

- Painting or Coating: Applying a powder coat or paint can provide additional protection against environmental factors and wear.

These finishing touches not only enhance the product’s longevity but also contribute to its marketability.

How is Quality Assurance Implemented in Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final product meets international standards and customer expectations.

1. What International Standards Are Relevant?

Manufacturers of adjustable tube connector clamps often adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards is essential for ensuring consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) certifications for use in oil and gas applications may also be relevant.

2. What Are the Key QC Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to catch defects early. These checkpoints typically include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested to confirm adherence to specifications.

- Final Quality Control (FQC): The finished products undergo rigorous testing to ensure they meet all quality criteria before shipment.

3. What Common Testing Methods Are Used?

Testing methods employed to ensure quality can vary but typically include:

- Dimensional Inspection: Using calipers and gauges to verify that the clamps meet specified dimensions.

- Load Testing: Applying weight to the clamps to assess their strength and durability.

- Corrosion Resistance Testing: Exposing samples to corrosive environments to evaluate their performance over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial.

1. What Are the Best Practices for Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control practices. Buyers should look for:

- Documented Quality Management Systems: Ensure that the supplier has a robust system in place that complies with relevant international standards.

- Records of Previous Audits: Review findings from past audits to gauge the supplier’s track record regarding quality control.

2. How Can Buyers Request Quality Reports?

Buyers should not hesitate to request quality control reports, including:

- Inspection Reports: Detailed documents that outline the results of various QC checks.

- Certificates of Compliance: Proof that the products meet specific international and industry standards.

3. What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide additional assurance of product quality. These independent organizations can conduct audits and testing, offering unbiased evaluations of a supplier’s quality control processes.

What Are the Unique QC Considerations for International Buyers?

International buyers must also navigate various nuances in quality control, such as differing standards and regulations across regions. Understanding these differences can help buyers make informed decisions:

- Regional Standards Compliance: Familiarize yourself with local regulations in your target market, such as CE marking in Europe or ANSI standards in the U.S.

- Logistics and Supply Chain Factors: Consider how shipping delays and customs regulations may affect product quality upon arrival.

By thoroughly evaluating manufacturing processes and quality assurance practices, B2B buyers can ensure they partner with reliable suppliers of adjustable tube connector clamps, thus safeguarding their investments and ensuring product performance in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘adjustable tube connector clamp square 1 3/8’

The following guide serves as a comprehensive checklist for B2B buyers looking to procure adjustable tube connector clamps with a square section of 1 3/8 inches. This resource outlines essential steps to ensure a successful sourcing process, focusing on critical factors that influence quality, compatibility, and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the exact requirements for the adjustable tube connector clamps, including material (e.g., aluminum, stainless steel, or plastic), load capacity, and environmental conditions (corrosion resistance, temperature tolerance). This clarity will help you communicate effectively with suppliers and avoid misunderstandings.

Step 2: Research the Market Landscape

Conduct thorough market research to understand the availability and pricing of adjustable tube connector clamps. Identify leading manufacturers and suppliers in regions relevant to your business needs, such as Africa, South America, the Middle East, and Europe. Pay attention to market trends, as they can influence both pricing and supply chain dynamics.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, perform a comprehensive evaluation. Request company profiles, case studies, and references from existing clients, particularly those in similar industries or regions. Look for suppliers with a proven track record of reliability and quality, and consider their ability to provide after-sales support.

- Supplier Certification: Ensure the supplier adheres to international quality standards, such as ISO certifications, which indicate a commitment to quality management.

- Product Samples: If possible, request samples of the adjustable tube connector clamps to assess their quality and compatibility with your existing systems.

Step 4: Verify Compliance and Certifications

Ensure that the products meet relevant industry standards and regulations. Compliance with safety and environmental regulations is crucial, especially if you are operating in highly regulated markets. Suppliers should provide documentation proving that their products conform to required standards.

Step 5: Negotiate Terms and Conditions

Engage in discussions regarding pricing, payment terms, and delivery schedules. Be clear about your expectations for lead times and any penalties for delays. Understanding the total cost of ownership, including shipping and potential customs duties, will help you make informed financial decisions.

Step 6: Plan for Logistics and Supply Chain Management

Consider the logistics involved in transporting the adjustable tube connector clamps to your location. Factor in shipping methods, potential customs issues, and local distribution capabilities. Establish a plan for inventory management to ensure you can meet demand without excess stock.

Step 7: Establish a Long-term Relationship

Once you have successfully sourced your adjustable tube connector clamps, focus on building a strong relationship with your supplier. Regular communication can lead to better service, more favorable terms, and insights into upcoming product innovations. Consider periodic reviews to ensure that the supplier continues to meet your evolving needs.

By following this practical sourcing checklist, you can streamline the procurement process for adjustable tube connector clamps, ensuring that you secure high-quality products that meet your specifications while fostering reliable supplier partnerships.

Comprehensive Cost and Pricing Analysis for adjustable tube connector clamp square 1 3/8 Sourcing

The cost structure and pricing analysis for adjustable tube connector clamps, specifically the 1 3/8 size, involve several interrelated components that can significantly affect the overall expenditure for B2B buyers. Understanding these cost components and price influencers can lead to more informed purchasing decisions, especially for international buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Adjustable Tube Connector Clamps?

-

Materials: The primary materials used for manufacturing adjustable tube connector clamps include aluminum, stainless steel, and various plastics like polyamide. Aluminum is lightweight and cost-effective, while stainless steel offers superior strength and corrosion resistance, which can drive up costs. The choice of material directly impacts the pricing of the clamps.

-

Labor: Labor costs can vary significantly based on the region and the complexity of the manufacturing process. In countries with higher wage rates, such as those in Europe, labor costs will be higher compared to regions in Africa or South America. Automation in manufacturing can reduce labor costs but may require a higher initial investment.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and indirect labor. Efficient manufacturing processes can help minimize overhead, but higher quality standards may require additional investments in quality assurance.

-

Tooling: The tooling costs for producing adjustable tube connector clamps can be substantial, particularly for custom designs or specialized fittings. Tooling costs are often amortized over production runs, making larger orders more cost-effective.

-

Quality Control (QC): Implementing rigorous QC measures ensures that products meet specified standards, which can increase production costs. Certifications and compliance with international standards (e.g., ISO) can also add to the cost but are essential for quality assurance.

-

Logistics: Shipping and handling costs are critical, particularly for international orders. Factors like shipping method, distance, and customs duties can significantly affect the total cost. Buyers should consider Incoterms that define responsibilities for shipping, insurance, and tariffs.

-

Margin: Supplier margins can vary widely based on market competition, brand reputation, and product quality. Understanding a supplier’s pricing strategy can aid in negotiation.

How Do Price Influencers Impact the Cost of Adjustable Tube Connector Clamps?

Several factors can influence the pricing of adjustable tube connector clamps:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs). Higher volumes can lead to bulk discounts, making it more economical for buyers to purchase in larger quantities.

-

Specifications/Customization: Custom clamps or those with specific features (e.g., enhanced load capacity or specific finishes) will typically cost more than standard models. Buyers should evaluate whether customization is necessary for their application.

-

Quality/Certifications: Products that meet higher quality standards or have specific certifications may command a premium price. Buyers should assess the trade-off between cost and the assurance of quality.

-

Supplier Factors: The supplier’s reputation, reliability, and service quality can affect pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding the implications of Incoterms (e.g., FOB, CIF) is essential as they dictate the responsibilities of buyers and sellers, influencing total costs.

What Are Some Tips for International Buyers to Optimize Costs?

-

Negotiate Effectively: Buyers should be prepared to negotiate terms and prices. Having a clear understanding of market rates and competitor pricing can empower buyers during discussions.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A lower upfront cost may result in higher long-term expenses if quality is compromised.

-

Be Aware of Pricing Nuances: Currency fluctuations and import tariffs can significantly affect costs for international buyers. Pricing should be evaluated in the context of local economic conditions.

-

Leverage Local Suppliers: Whenever possible, sourcing from local suppliers can mitigate shipping costs and simplify logistics, especially for urgent requirements.

-

Plan for Future Orders: If you anticipate ongoing needs, consider establishing a long-term relationship with suppliers for better pricing and reliability.

Disclaimer

Prices for adjustable tube connector clamps can vary widely based on the aforementioned factors. The information provided is indicative and may not reflect real-time market conditions. Always conduct thorough market research and consult with suppliers for the most accurate pricing.

Alternatives Analysis: Comparing adjustable tube connector clamp square 1 3/8 With Other Solutions

Exploring Alternatives for Adjustable Tube Connector Clamps

In the realm of industrial applications, selecting the right connector clamp is crucial for ensuring structural integrity and flexibility. While the adjustable tube connector clamp square 1 3/8 is a popular choice, there are several alternatives that may better suit specific project requirements. This analysis will compare the adjustable tube connector clamp with two alternative solutions: telescoping square tubing and spring clamps designed for square tubing.

Comparison Table

| Comparison Aspect | Adjustable Tube Connector Clamp Square 1 3/8 | Telescoping Square Tubing | Spring Clamp for 1″ Square Tubing |

|---|---|---|---|

| Performance | High load capacity, adjustable tension | Excellent for adjustable lengths | Limited load capacity, quick-release |

| Cost | Moderate to high depending on material | Varies widely, generally cost-effective | Low-cost, budget-friendly option |

| Ease of Implementation | Requires tools for installation | Simple to install, no special tools needed | Very easy to mount, no tools required |

| Maintenance | Low maintenance; durable materials | Low maintenance; corrosion-resistant options available | Minimal maintenance; replace as needed |

| Best Use Case | Structural applications requiring stability | Adjustable structures like shelving and supports | Temporary setups or lightweight applications |

In-Depth Analysis of Alternatives

Telescoping Square Tubing

Telescoping square tubing offers a unique advantage in terms of adjustability. This solution consists of multiple square tubes that fit into one another, allowing for easy length modifications without the need for additional fittings. The primary benefits of telescoping tubing are its versatility and ease of installation, making it ideal for applications like storage racks and extendable arms. However, it may not provide the same load-bearing capacity as the adjustable tube connector clamp, which could be a concern for more demanding structural applications.

Spring Clamp for 1″ Square Tubing

Spring clamps are a cost-effective alternative for lighter applications. They are designed for quick assembly and disassembly, eliminating the need for screws or bolts, which can save time during setup. These clamps are particularly suited for temporary structures or lightweight assemblies, such as displays or fixtures in retail environments. However, their load capacity is limited compared to the adjustable tube connector clamp, making them less suitable for heavy-duty uses.

How to Choose the Right Solution for Your Needs

When deciding between the adjustable tube connector clamp square 1 3/8 and its alternatives, it’s essential to evaluate the specific requirements of your project. Consider factors such as the load capacity needed, the intended duration of use (temporary vs. permanent), and the installation environment. For projects requiring robust and adjustable connections, the adjustable tube connector clamp remains a strong choice. However, if flexibility and cost-effectiveness are paramount, telescoping square tubing or spring clamps may better meet your needs. Ultimately, aligning your selection with project demands will ensure optimal performance and durability.

Essential Technical Properties and Trade Terminology for adjustable tube connector clamp square 1 3/8

What Are the Key Technical Properties of Adjustable Tube Connector Clamps for Square 1 3/8″?

When selecting adjustable tube connector clamps, particularly for square tubing measuring 1 3/8 inches, understanding the essential technical properties is vital for ensuring product compatibility and performance in various applications. Below are several critical specifications:

-

Material Grade

The material used in manufacturing clamps can vary significantly, with options including aluminum, stainless steel, and plastic. Aluminum offers lightweight and corrosion-resistant properties, making it suitable for indoor applications. Stainless steel provides superior strength and durability, ideal for outdoor or high-stress environments. The choice of material affects not only the clamp’s lifespan but also its ability to withstand environmental challenges. -

Load Capacity

Each adjustable tube connector clamp comes with a specified load capacity, which indicates the maximum weight it can support. This specification is crucial for applications involving heavy machinery or structural frameworks. Buyers should ensure that the load capacity meets or exceeds their specific requirements to avoid equipment failure or safety hazards. -

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. For adjustable tube clamps, a tighter tolerance ensures a snug fit, reducing the likelihood of movement or slippage once installed. This is particularly important in applications where precision is paramount, such as in the construction of frameworks or safety supports. -

Finish and Coating

The finish of the clamp, whether anodized, powder-coated, or untreated, plays a significant role in its resistance to corrosion and wear. Anodized coatings can enhance the aesthetic appeal while providing additional protection against environmental factors. Buyers should consider the operational environment when selecting the appropriate finish. -

Adjustability Mechanism

The mechanism that allows for adjustments in the clamp’s grip is critical for versatility. Common mechanisms include screw threads, quick-release levers, or sliding adjustments. Understanding how these mechanisms work will help buyers select a clamp that meets their operational efficiency needs.

What Common Trade Terms Should Buyers Know for Adjustable Tube Connector Clamps?

Understanding industry jargon can significantly streamline the purchasing process and improve communication with suppliers. Here are some common trade terms relevant to adjustable tube connector clamps:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure that they receive high-quality components that meet their specifications. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management, especially for businesses that may not require large volumes of clamps. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers solicit price quotes from suppliers for specific quantities and specifications. Submitting an RFQ allows buyers to compare costs and negotiate better terms, ensuring they obtain the best value. -

Incoterms

Incoterms (International Commercial Terms) are a series of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers avoid misunderstandings in international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for planning and ensuring that project timelines are met, particularly in industries where delays can result in significant costs.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they procure the right adjustable tube connector clamps for their specific applications.

Illustrative image related to adjustable tube connector clamp square 1 3/8

Navigating Market Dynamics and Sourcing Trends in the adjustable tube connector clamp square 1 3/8 Sector

What are the Current Market Dynamics and Key Trends for Adjustable Tube Connector Clamps in the 1 3/8 Sector?

The adjustable tube connector clamp market, particularly for the square 1 3/8 size, is experiencing robust growth driven by several global factors. Key drivers include the increasing demand for modular construction solutions and the rise of customizable and adaptable industrial systems. With industries such as manufacturing, construction, and logistics pushing for efficiency and flexibility, adjustable tube connector clamps are becoming essential for creating versatile frameworks and structures. Additionally, advancements in manufacturing technologies, including high-speed roll-forming and precision welding, are enhancing the quality and availability of these components, making them more appealing to international buyers.

Emerging trends also point towards digitalization in sourcing processes. B2B buyers are increasingly utilizing online platforms to streamline procurement, allowing for quicker access to a variety of products and suppliers. This trend is particularly pronounced in regions like Africa and South America, where e-commerce is rapidly evolving. Moreover, the integration of smart technologies, such as IoT-enabled connectors, is beginning to reshape the landscape by offering enhanced tracking and management capabilities. Buyers are encouraged to stay updated on these trends to ensure they are sourcing the most innovative and competitive products available.

How is Sustainability and Ethical Sourcing Shaping the Adjustable Tube Connector Clamp Market?

As global awareness of environmental issues rises, sustainability and ethical sourcing have become paramount in the adjustable tube connector clamp market. The production of clamps using sustainable materials—like recycled aluminum and eco-friendly plastics—reduces the environmental footprint associated with manufacturing. Furthermore, suppliers that adhere to green certifications, such as ISO 14001, demonstrate their commitment to sustainable practices, which can significantly influence purchasing decisions for B2B buyers.

Ethical supply chains are also gaining traction, particularly in regions like Europe and North America, where consumers and businesses alike are demanding transparency. Buyers from Africa, South America, and the Middle East are urged to consider suppliers who prioritize fair labor practices and sustainable resource sourcing. By choosing partners that align with these values, businesses can not only enhance their corporate social responsibility (CSR) profile but also appeal to an increasingly eco-conscious customer base.

What is the Brief Evolution of the Adjustable Tube Connector Clamp Market?

The adjustable tube connector clamp market has evolved significantly over the past few decades, transitioning from basic fastening solutions to sophisticated components integral to modern engineering and design. Initially, these clamps were primarily made from steel and were used in limited applications. However, with the advent of new materials like aluminum and reinforced plastics, the functionality and versatility of these clamps have expanded dramatically.

Today, adjustable tube connector clamps are designed to meet diverse needs, from lightweight structures to heavy-duty applications. Innovations in design, such as split assemblies and multi-part configurations, have further enhanced their adaptability. As industries continue to embrace modular and flexible construction techniques, the demand for these products is expected to grow, reinforcing their importance in the global supply chain.

In summary, international B2B buyers should be mindful of market dynamics, sustainability practices, and the evolving nature of adjustable tube connector clamps to make informed sourcing decisions that align with current trends and future demands.

Frequently Asked Questions (FAQs) for B2B Buyers of adjustable tube connector clamp square 1 3/8

-

How do I select the right adjustable tube connector clamp for my application?

Choosing the right adjustable tube connector clamp involves assessing the specific requirements of your project. Consider factors such as the material (aluminum, stainless steel, or plastic), the load-bearing capacity, and the type of connection needed (e.g., two-way, flanged, or swivel). Additionally, evaluate the environmental conditions, such as exposure to moisture or chemicals, which may affect material selection. If customization is required, engage with suppliers early to ensure they can meet your specifications. -

What are the benefits of using adjustable tube connector clamps?

Adjustable tube connector clamps offer versatility and ease of use in various applications, including structural frames, supports, and modular systems. Their design allows for quick adjustments without the need for specialized tools, making assembly and disassembly efficient. Furthermore, they accommodate different pipe sizes, enhancing compatibility in dynamic environments. This adaptability is particularly beneficial in industries that require frequent modifications or expansions, such as manufacturing and construction. -

What is the minimum order quantity (MOQ) for adjustable tube connector clamps?

Minimum order quantities can vary significantly between suppliers, typically ranging from 50 to 500 units. Factors influencing MOQ include the supplier’s production capabilities, the complexity of the product, and the materials used. When sourcing from international suppliers, it’s essential to clarify MOQ upfront to avoid unexpected costs. Additionally, consider consolidating orders with other components to meet MOQ requirements, which can improve overall shipping efficiency and reduce costs. -

How do I vet suppliers for adjustable tube connector clamps?

When vetting suppliers, prioritize those with a proven track record in the industry. Look for certifications like ISO 9001, which indicates a commitment to quality management. Request samples to evaluate product quality, and review customer testimonials or case studies. It’s also wise to inquire about their production capabilities, lead times, and after-sales support. Engaging in direct communication can provide insight into their reliability and customer service approach. -

What payment terms should I expect when sourcing internationally?

Payment terms for international transactions typically vary based on supplier policies and the buyer’s relationship with them. Common options include advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Be prepared to negotiate terms that align with your cash flow needs while ensuring they are favorable for the supplier. It’s crucial to understand the currency exchange implications and potential transaction fees involved in international payments. -

What quality assurance measures should I consider?

Quality assurance is critical when sourcing adjustable tube connector clamps, especially for international purchases. Ensure your supplier implements rigorous quality control processes, including material inspections, in-process checks, and final product evaluations. Request documentation such as test certificates or compliance reports to verify that products meet relevant industry standards. Establishing a clear return policy can also help mitigate risks associated with defective products. -

How can I handle logistics and shipping for international orders?

Managing logistics for international orders requires careful planning. Work with suppliers who have experience in exporting and can provide necessary documentation, such as invoices and packing lists. Familiarize yourself with incoterms (International Commercial Terms) to clarify responsibilities for shipping costs and risks. Consider partnering with a freight forwarder to streamline the shipping process, ensuring compliance with customs regulations and minimizing delays at ports. -

What customization options are available for adjustable tube connector clamps?

Customization options for adjustable tube connector clamps may include specific sizes, materials, colors, and finishes. Many suppliers can accommodate unique design requirements, such as special mounting configurations or additional features like integrated locking mechanisms. When requesting customization, provide detailed specifications and, if possible, CAD drawings. Engaging early with suppliers can facilitate better design collaboration and ensure your needs are met effectively.

Top 6 Adjustable Tube Connector Clamp Square 1 3/8 Manufacturers & Suppliers List

1. Rose Brand – Pipe and Tube Connectors

Domain: rosebrand.com

Registered: 1995 (30 years)

Introduction: Pipe and Tube Connectors & Clamps from Rose Brand. Call for Sales Support 1-800-223-1624. Part of a larger inventory that includes theatrical fabrics, custom curtains, and production supplies. Related categories include Pipe & Base, Pipe & Base 2.0, Pipe & Base 1.0, and Pipe & Base Accessories.

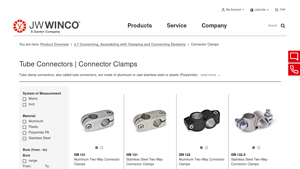

2. JW Winco – Tube Clamp Connectors

Domain: jwwinco.com

Registered: 1997 (28 years)

Introduction: Tube clamp connectors, also called tube connectors, are made of aluminum, cast stainless steel, or plastic (Polyamide). They can be divided into subgroups: two-way connector clamps, flanged connector clamps, base plate connector clamps, swivel connector clamps, and swivel clamp connector joints. They allow for flexible, easy, and quick assembly of round and square pipes and pipe assemblies such as…

3. McMaster – Structural Tube Clamps

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Structural Tube Clamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Econoco – Spring Clamp for 1 Square Tubing

Domain: econoco.com

Registered: 1998 (27 years)

Introduction: Spring Clamp for 1″ Square Tubing with 3/8″ Fitting

5. Elesa Ganter – Tube Clamp Connectors

Domain: elesa-ganter.com

Registered: 1999 (26 years)

Introduction: This company, Elesa Ganter – Tube Clamp Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. 8 Pcs 3 Way T Shape Connector – New

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “8 Pcs 1″ 3 Way T Shape Square Tube Connector Fitting Rail Clamp”, “Condition”: “New”, “Quantity Available”: 2, “Price”: “US $32.73”, “Shipping Cost”: “US $29.81”, “Shipping Location”: “East Falmouth, MA, United States”, “Returns”: “30 days returns, buyer pays for return shipping”, “Included Components”: “8 Pcs Square Tubing Connector”, “Brand”: “Yidu69Q”, “Part Number”: “Gd306-T8…

Strategic Sourcing Conclusion and Outlook for adjustable tube connector clamp square 1 3/8

The strategic sourcing of adjustable tube connector clamps, specifically the square 1 3/8″ models, plays a critical role in enhancing operational efficiency and flexibility across various industries. By leveraging high-quality materials such as aluminum and stainless steel, businesses can ensure durability and reliability in their applications, whether for structural frameworks or machinery support systems. The diverse range of connector types available—ranging from flanged to swivel clamps—allows for tailored solutions that meet specific project requirements, thereby minimizing downtime and maximizing productivity.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize strategic sourcing partnerships that offer not only competitive pricing but also exceptional service and technical support. Engaging with suppliers who understand local market dynamics and can provide rapid delivery options will be crucial for maintaining a competitive edge.

Looking ahead, the demand for adjustable tube connector clamps is expected to grow as industries increasingly value modular designs and quick assembly solutions. Now is the time to explore innovative sourcing strategies and collaborate with trusted suppliers to enhance your operational capabilities and drive sustainable growth in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to adjustable tube connector clamp square 1 3/8

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.