A B2B Buyer’s Guide to 7-In-1 Folding Workbench: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for 7-in-1 folding workbench

In an increasingly competitive global market, B2B buyers face the challenge of sourcing versatile and reliable tools that meet diverse operational needs. The 7-in-1 folding workbench stands out as a multifunctional solution, combining the utility of a workbench, sawhorse, scaffold, and more into a single, portable design. This guide offers an in-depth exploration of the 7-in-1 folding workbench, covering various types available, their applications across industries, supplier vetting processes, pricing strategies, and crucial factors to consider when making a purchase.

For international buyers, particularly those in emerging markets like Africa, South America, the Middle East, and Europe, understanding the intricacies of this product category is essential. This guide empowers decision-makers by providing actionable insights into sourcing high-quality workbenches that can enhance productivity and adaptability in various work environments. Whether you are a contractor in Nigeria looking for reliable equipment, or a manufacturer in Vietnam seeking efficient workspace solutions, this comprehensive resource equips you with the knowledge needed to make informed purchasing decisions. By addressing key considerations and supplier evaluation criteria, we aim to streamline your procurement process, ensuring you invest in a workbench that meets your specific business requirements.

Understanding 7-in-1 folding workbench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Workbench | Lightweight, foldable design, adjustable height | Construction, DIY projects | Pros: Easy to transport; Cons: May lack stability under heavy loads. |

| Multi-functional Workbench | Combines workbench, sawhorse, and scaffold capabilities | Workshops, maintenance, event setups | Pros: Versatile; Cons: Complexity may require training for optimal use. |

| Heavy-Duty Workbench | Robust construction with high weight capacity | Industrial environments, heavy lifting | Pros: Durable; Cons: Heavier and less portable. |

| Electric Workbench | Integrated power outlets, often with additional features | Manufacturing, assembly lines | Pros: Convenient power access; Cons: Higher initial cost. |

| Compact Workbench | Space-saving design, often with built-in storage solutions | Small workshops, home use | Pros: Saves space; Cons: Limited workspace area. |

What Are the Characteristics of a Portable Workbench?

A portable workbench is designed for ease of transport and storage, making it ideal for contractors and DIY enthusiasts who need flexibility in their workspace. Typically lightweight and featuring adjustable heights, these workbenches can support various tasks, from woodworking to assembly. When considering a purchase, B2B buyers should assess weight capacity and stability, particularly if used for heavy-duty applications.

How Does a Multi-functional Workbench Benefit Businesses?

Multi-functional workbenches are versatile tools that can serve multiple roles, such as a workbench, sawhorse, or scaffold. This adaptability makes them particularly valuable in settings like workshops or during event setups, where space and equipment variety are crucial. B2B buyers should evaluate ease of conversion between functions and durability, as complexity in design may necessitate user training.

Why Choose a Heavy-Duty Workbench?

Heavy-duty workbenches are built to withstand significant weight and impact, making them suitable for industrial environments where heavy lifting and robust tasks are routine. Their sturdy construction ensures longevity and reliability under tough conditions. Buyers in sectors such as manufacturing should prioritize weight capacity and material quality when selecting a heavy-duty workbench, as these factors directly influence performance.

What Advantages Does an Electric Workbench Offer?

Electric workbenches come equipped with integrated power outlets, streamlining the workflow in manufacturing and assembly lines. These workbenches enhance efficiency by providing immediate access to power tools without the need for additional extension cords. While they offer significant convenience, B2B buyers should weigh the initial investment against long-term operational benefits, as these workbenches often come at a higher price point.

How Does a Compact Workbench Fit into Limited Spaces?

Compact workbenches are designed for environments where space is at a premium, featuring foldable designs and built-in storage solutions. They are particularly useful in small workshops or home settings, providing a functional workspace without occupying excessive floor area. Buyers should consider the trade-off between workspace size and functionality, ensuring that the compact design still meets their operational needs.

Key Industrial Applications of 7-in-1 folding workbench

| Industry/Sector | Specific Application of 7-in-1 folding workbench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Portable workstations for on-site assembly and repairs | Enhanced mobility and versatility for various tasks | Durability, load capacity, and ease of transport |

| Automotive Repair | Workbench for vehicle maintenance and repairs | Provides a stable and adjustable platform for repairs | Stability, weight capacity, and multi-functionality |

| Manufacturing | Temporary assembly stations for production lines | Flexibility in setup and reconfiguration to optimize workflow | Material quality, height adjustability, and portability |

| Event Management | Setup for temporary workstations during events | Quick assembly and disassembly for efficient operations | Lightweight design, ease of storage, and transportability |

| DIY Projects and Home Improvement | Versatile workspace for various home improvement tasks | Cost-effective solution for multiple applications | Multi-functionality, user-friendly assembly, and storage options |

How is the 7-in-1 Folding Workbench Used in the Construction Sector?

In the construction industry, the 7-in-1 folding workbench serves as a portable workstation that can be easily transported to various job sites. It provides a stable surface for assembly, cutting, and repairs, addressing the need for flexibility in dynamic environments. Buyers in this sector should prioritize durability and load capacity to ensure the workbench can handle heavy materials and tools while being lightweight enough for mobility.

What Role Does the 7-in-1 Folding Workbench Play in Automotive Repair?

Automotive repair shops utilize the 7-in-1 folding workbench for vehicle maintenance tasks, offering an adjustable platform that can be configured for different vehicles and repairs. This versatility allows mechanics to work comfortably at various heights, reducing strain and increasing efficiency. Key considerations for automotive buyers include stability and weight capacity to support tools and equipment during maintenance activities.

How Can the 7-in-1 Folding Workbench Enhance Manufacturing Processes?

In manufacturing, the 7-in-1 folding workbench can be employed as a temporary assembly station, allowing for quick adjustments in production lines. Its flexibility enables businesses to reconfigure workspaces based on changing production needs, optimizing workflow and productivity. Manufacturers should focus on sourcing workbenches made from high-quality materials that can withstand heavy use while being easy to transport and set up.

What Advantages Does the 7-in-1 Folding Workbench Offer for Event Management?

Event management companies benefit from the 7-in-1 folding workbench by using it to create temporary workstations for setup and coordination during events. The ability to quickly assemble and disassemble the workbench saves time and enhances operational efficiency. When sourcing, businesses should consider the lightweight design and ease of storage to facilitate transportation to various event locations.

How Does the 7-in-1 Folding Workbench Support DIY Projects and Home Improvement?

For DIY enthusiasts and home improvement projects, the 7-in-1 folding workbench offers a cost-effective and versatile workspace that can adapt to various tasks, from woodworking to painting. Its multi-functionality allows users to switch between different modes, such as a sawhorse or scaffold, making it a valuable tool for diverse applications. Buyers should look for user-friendly assembly features and convenient storage options to maximize their investment in this workbench.

3 Common User Pain Points for ‘7-in-1 folding workbench’ & Their Solutions

Scenario 1: Limited Space in Work Environments

The Problem: Many B2B buyers operate in environments where space is at a premium, such as small workshops, crowded job sites, or urban construction areas. The challenge is finding a versatile workbench that can accommodate various tasks without taking up unnecessary floor space. Users often struggle with bulky equipment that cannot be easily stored or transported, leading to inefficiencies and frustration during operations.

The Solution: The 7-in-1 folding workbench is designed specifically for compact spaces, offering multiple functions while maintaining a manageable footprint. To maximize its utility, businesses should look for models that easily convert between functions—such as a workbench, scaffold, and dolly—without requiring extensive setup. When sourcing, consider workbenches with a robust folding mechanism and lightweight materials for easy transport. Additionally, training staff on how to quickly fold and unfold the workbench can improve workflow efficiency and help maintain a clutter-free workspace. Regular maintenance checks should also be implemented to ensure the folding mechanisms remain in good working condition.

Scenario 2: Versatility for Diverse Tasks

The Problem: B2B buyers often face the dilemma of needing equipment that can handle a variety of tasks, from cutting and painting to assembly and loading. Investing in multiple specialized workbenches is often cost-prohibitive and leads to storage challenges. Buyers may find themselves limited by the functionality of their existing equipment, which can hinder productivity and increase project costs.

The Solution: The 7-in-1 folding workbench provides a solution to this issue by combining multiple functionalities into one unit. When selecting a workbench, buyers should prioritize models that offer adjustable height settings and robust load capacities, enabling them to adapt to different tasks seamlessly. Additionally, consider features such as built-in clamps or power outlets for added convenience during various applications. To further enhance versatility, businesses can create a standardized training program for employees that covers the various configurations of the workbench, ensuring that all team members can effectively utilize the equipment for different needs.

Scenario 3: Durability Under Heavy Use

The Problem: In industrial or construction settings, equipment is often subjected to heavy loads and rigorous usage, leading to concerns about durability and longevity. B2B buyers may worry about investing in a workbench that cannot withstand the demands of daily operations, leading to increased replacement costs and project downtime.

The Solution: To address durability concerns, buyers should seek 7-in-1 folding workbenches constructed from high-quality materials such as heavy-duty steel frames and reinforced joints. It is essential to evaluate the weight capacity of the workbench and ensure it aligns with the expected workload. Buyers should also inquire about warranties and manufacturer support, which can provide peace of mind regarding product longevity. Implementing a routine inspection and maintenance schedule can help identify any wear and tear before it becomes a significant issue, allowing businesses to extend the lifespan of their workbenches. Additionally, providing employees with guidelines on proper usage and loading limits can mitigate damage caused by misuse.

Strategic Material Selection Guide for 7-in-1 folding workbench

What are the Key Materials Used in 7-in-1 Folding Workbenches?

When selecting materials for a 7-in-1 folding workbench, various factors influence performance, durability, and cost. Here, we analyze four common materials: aluminum, steel, plastic, and wood composites, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Perform in Folding Workbench Applications?

Aluminum is a lightweight yet robust material, making it a popular choice for portable workbenches. It boasts excellent corrosion resistance, which is crucial for outdoor use or in humid environments. Aluminum can typically withstand temperatures up to 300°C, making it suitable for various applications.

Pros: The primary advantages of aluminum include its lightweight nature, which enhances portability, and its resistance to rust and corrosion, ensuring longevity. Additionally, it is relatively easy to manufacture and can be formed into complex shapes.

Cons: However, aluminum can be more expensive than other materials and may not support as much weight as steel. Its susceptibility to dents and scratches can also be a concern for heavy-duty applications.

Impact on Application: Aluminum’s low weight and high strength make it ideal for mobile workbenches used in construction or automotive repairs.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider the availability of aluminum and its cost implications. Compliance with standards such as ASTM for material quality is essential.

What Advantages Does Steel Offer for Workbench Durability?

Steel is renowned for its strength and durability, often used in heavy-duty applications. It can withstand high temperatures (up to 600°C) and is resistant to deformation under pressure, making it suitable for demanding tasks.

Pros: Steel’s primary advantage is its high load-bearing capacity, which is critical for a multi-functional workbench. It also has a lower cost compared to aluminum, making it a cost-effective option for businesses.

Cons: On the downside, steel is heavier, which can hinder portability. It is also prone to rust if not properly coated or maintained, especially in humid environments.

Impact on Application: Steel workbenches are ideal for industrial settings where heavy materials are handled, such as in manufacturing or metalworking.

Considerations for International Buyers: Buyers should ensure that the steel used meets international standards such as DIN or JIS, particularly in regions with stringent regulations.

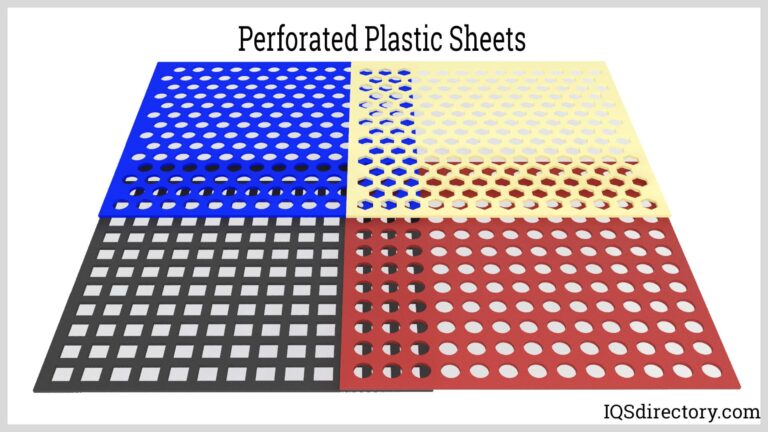

How Does Plastic Compare as a Material for Folding Workbenches?

Plastic, particularly high-density polyethylene (HDPE) or polypropylene, is increasingly used in portable workbenches due to its lightweight and resistance to chemicals and moisture.

Pros: The main advantages of plastic include its resistance to corrosion and ease of cleaning. It is also lightweight, enhancing portability, and can be produced at a lower cost.

Cons: However, plastic may not support heavy loads as effectively as metal materials, limiting its use in more demanding applications. It can also be less durable over time, especially under UV exposure.

Impact on Application: Plastic workbenches are suitable for light-duty tasks, such as painting or crafting, where portability is more critical than load-bearing capacity.

Considerations for International Buyers: Buyers should verify that the plastic materials comply with safety and environmental regulations, especially in regions like the Middle East where standards may vary.

What Role Do Wood Composites Play in Folding Workbench Design?

Wood composites, such as plywood or MDF, are often used for workbench surfaces due to their aesthetic appeal and versatility. They can support moderate loads and provide a stable work surface.

Pros: Wood composites are generally less expensive than metals and can be easily machined to create custom designs. They also provide a natural look that many users prefer.

Cons: However, wood composites are susceptible to moisture damage and may warp or swell over time. They also have a lower load capacity compared to metal options.

Impact on Application: Wood composites are ideal for applications where aesthetics matter, such as in workshops or home garages.

Considerations for International Buyers: Buyers should ensure that wood composites are sourced from sustainable suppliers and comply with local regulations regarding formaldehyde emissions and other environmental standards.

Summary of Material Selection for 7-in-1 Folding Workbenches

| Material | Typical Use Case for 7-in-1 Folding Workbench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable workbench for construction and repairs | Lightweight and corrosion-resistant | Higher cost and lower load capacity | Medium |

| Steel | Heavy-duty industrial applications | High load-bearing capacity | Heavier and prone to rust | Low |

| Plastic | Light-duty tasks (painting, crafting) | Easy to clean and lightweight | Limited load capacity and durability | Low |

| Wood Composites | Aesthetic applications in workshops | Cost-effective and customizable | Susceptible to moisture damage | Medium |

This strategic material selection guide provides B2B buyers with a comprehensive overview of the materials used in 7-in-1 folding workbenches, enabling informed purchasing decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 7-in-1 folding workbench

What are the Main Stages of Manufacturing a 7-in-1 Folding Workbench?

The manufacturing process for a 7-in-1 folding workbench involves several critical stages that ensure the final product meets quality standards and customer expectations. Understanding these stages is vital for B2B buyers looking to source reliable workbenches.

Material Preparation: What Materials Are Used?

The first stage involves sourcing and preparing high-quality materials. Common materials for a folding workbench include:

- Aluminum and Steel: These materials provide strength and durability, essential for supporting heavy loads.

- Plastic Components: Used for handles, wheels, and certain joints to reduce weight and enhance portability.

- Wood or Composite Surfaces: Often used for the work surface to offer a stable and versatile platform.

Materials undergo rigorous testing to ensure they meet industry standards for strength and safety. Suppliers often provide certifications for the materials used, allowing buyers to assess their quality.

Forming: How Are Components Shaped?

The forming process involves transforming raw materials into usable parts. Key techniques include:

- CNC Machining: This computer-controlled process allows for precise cutting, shaping, and drilling of metal components.

- Injection Molding: Commonly used for plastic parts, this technique creates complex shapes that are lightweight yet sturdy.

- Sheet Metal Forming: Used to create the frame and support structures, ensuring they can handle the designated weight capacity.

Each component’s manufacturing method should align with the workbench’s intended use, balancing strength and weight.

Assembly: How Are Workbenches Put Together?

Assembly is a crucial stage where all the manufactured components are brought together. Typical practices include:

- Automated Assembly Lines: These lines streamline the process, improving efficiency and consistency.

- Manual Assembly for Complex Parts: Skilled workers assemble intricate components that require a higher level of precision.

Quality checks are implemented throughout the assembly process to ensure that each workbench meets design specifications. For B2B buyers, understanding the assembly process can help in evaluating a supplier’s capability to deliver consistent quality.

Finishing: What Final Touches Are Applied?

The finishing stage enhances the workbench’s aesthetic appeal and durability. Common techniques include:

- Powder Coating: This method provides a durable, weather-resistant finish, which is particularly important for outdoor use.

- Surface Treatments: Processes such as anodizing can improve corrosion resistance for metal parts.

- Quality Control Inspections: Final inspections are conducted to check for surface defects, alignment issues, and overall functionality.

B2B buyers should inquire about the finishing techniques used by suppliers, as these can significantly impact the product’s longevity and performance.

What Quality Assurance Standards Are Relevant for 7-in-1 Folding Workbenches?

Quality assurance is paramount in manufacturing, especially for products intended for heavy-duty use. Understanding relevant standards can help B2B buyers assess suppliers.

Which International Standards Apply?

- ISO 9001: This widely recognized standard outlines the requirements for a quality management system (QMS). Manufacturers certified under ISO 9001 demonstrate a commitment to continuous improvement and customer satisfaction.

- CE Marking: Required in the European Economic Area, CE marking indicates compliance with safety, health, and environmental protection standards. This is crucial for workbenches used in various industries.

- API Standards: For workbenches used in the oil and gas sector, compliance with American Petroleum Institute standards ensures they can withstand specific operational conditions.

B2B buyers should request documentation proving compliance with these standards, as they reflect a manufacturer’s commitment to quality.

What Quality Control Checkpoints Are Essential?

Quality control (QC) checkpoints ensure that products meet established quality standards. For a 7-in-1 folding workbench, critical QC stages include:

- Incoming Quality Control (IQC): This initial inspection checks raw materials for defects before they enter the production process.

- In-Process Quality Control (IPQC): Conducted at various stages of manufacturing, IPQC ensures that each component meets specifications during production.

- Final Quality Control (FQC): A comprehensive check of the finished product, FQC assesses functionality, safety, and aesthetic quality before shipping.

These checkpoints help minimize defects and ensure that only high-quality products reach the market.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods play a crucial role in quality assurance. Common tests for a 7-in-1 folding workbench include:

- Load Testing: Ensures the workbench can support the specified weight capacity without deforming or failing.

- Durability Testing: Simulates real-world use over time to assess wear and tear.

- Stability Testing: Evaluates how the workbench performs under various conditions, ensuring it remains safe and functional.

Understanding these testing methods allows B2B buyers to gauge the reliability of the products they are considering.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should adopt a proactive approach to verify a supplier’s quality control measures:

- Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality assurance practices.

- Request Quality Control Reports: Suppliers should be able to provide documentation on their QC processes, including results from IQC, IPQC, and FQC stages.

- Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s compliance with international standards.

For buyers in regions such as Africa, South America, and the Middle East, verifying supplier QC is crucial due to varying standards and practices across different markets.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges regarding quality control:

- Cultural Differences: Understanding the local practices and standards in countries like Vietnam or Nigeria is vital for effective communication with suppliers.

- Regulatory Compliance: Different regions may have specific regulations that affect product quality, requiring buyers to be aware of local standards.

- Logistical Challenges: Ensuring that quality assurance practices are maintained throughout the supply chain can be difficult, especially when shipping products internationally.

By being aware of these nuances, B2B buyers can better navigate the complexities of sourcing quality products from global suppliers.

Conclusion

The manufacturing processes and quality assurance measures for 7-in-1 folding workbenches are critical for ensuring product reliability and customer satisfaction. By understanding these processes, B2B buyers can make informed decisions and establish strong partnerships with suppliers that prioritize quality and compliance with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘7-in-1 folding workbench’

In the competitive landscape of B2B procurement, sourcing a versatile product like the 7-in-1 folding workbench requires careful consideration and strategic planning. This guide outlines a practical checklist that will help international buyers effectively navigate the procurement process, ensuring they select a product that meets their operational needs while maximizing value.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline the specific technical requirements for the 7-in-1 folding workbench. Consider the various functionalities you need—such as its weight capacity, adjustability, and modes of use (e.g., workbench, scaffold, or dolly).

- Weight Capacity: Ensure it can support your typical loads, with many models offering capacities between 330 lbs to 1000 lbs.

- Adjustability: Look for features like adjustable height settings to accommodate different tasks and user preferences.

Step 2: Research and Identify Reliable Suppliers

Finding reputable suppliers is crucial in ensuring product quality and reliability. Start by researching manufacturers and distributors that specialize in workbench solutions.

- Supplier Reputation: Check online reviews and testimonials, particularly from businesses in similar industries or regions.

- Experience: Opt for suppliers with a proven track record in providing durable and multifunctional workbenches.

Step 3: Evaluate Product Features and Usability

Not all 7-in-1 folding workbenches are created equal. Assess the features that enhance usability and functionality, as these can significantly impact your operations.

- Multi-functionality: Ensure the workbench can transition seamlessly between different modes (e.g., from a workbench to a scaffold).

- Portability: Look for models with features such as foldable designs and wheels for easy transport.

Step 4: Verify Compliance with International Standards

Given the global nature of your procurement, it’s vital to ensure that the workbench complies with relevant safety and quality standards.

- Certifications: Request documentation proving compliance with international safety standards such as ISO or CE marking.

- Material Safety: Ensure that the materials used are safe and suitable for the intended applications, particularly if used in environments with strict regulations.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples to evaluate the product firsthand. This step is critical in assessing quality and functionality.

- Testing: Conduct tests to ensure the workbench meets your operational demands, focusing on stability and load capacity.

- Feedback: Involve team members who will use the workbench to gather insights on its practicality and ease of use.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, engage in negotiations to secure favorable terms. This includes pricing, delivery schedules, and payment terms.

- Volume Discounts: Inquire about discounts for bulk purchases, which can significantly reduce overall costs.

- Warranty and Support: Ensure that the supplier offers warranties and after-sales support, which are crucial for addressing any issues post-purchase.

Step 7: Finalize Your Purchase Order

After all evaluations and negotiations, finalize your order by placing a detailed purchase order. Ensure that it includes all agreed-upon specifications, terms, and delivery timelines.

- Documentation: Keep a record of all correspondence and agreements for future reference.

- Follow-Up: Stay in contact with the supplier to confirm shipping and delivery, ensuring a smooth procurement process.

By following this checklist, B2B buyers can effectively source a 7-in-1 folding workbench that meets their operational needs, ensuring efficiency and productivity in their projects.

Comprehensive Cost and Pricing Analysis for 7-in-1 folding workbench Sourcing

What Are the Key Cost Components of a 7-in-1 Folding Workbench?

When sourcing a 7-in-1 folding workbench, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials directly influences the workbench’s durability and functionality. Common materials include high-grade steel for the frame and plywood or composite materials for the work surface. Higher quality materials may increase upfront costs but can lead to lower maintenance expenses over time.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and the complexity of the manufacturing process. Automated manufacturing may reduce labor costs, but it may also limit customization options.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production facilities. Efficient manufacturing processes can help keep these costs in check.

-

Tooling: Initial setup costs for molds and specialized equipment can be significant. For customized workbenches, tooling costs may be higher, impacting the overall price.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability and safety. While this adds to costs, it can prevent expensive recalls and enhance brand reputation.

-

Logistics: Shipping costs, including freight and customs duties, can vary significantly based on the destination. International buyers should account for these costs in their total sourcing budget.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on competition, brand positioning, and perceived value in the market.

How Do Price Influencers Affect the Cost of 7-in-1 Folding Workbenches?

Several factors can influence the pricing of 7-in-1 folding workbenches:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk discounts, reducing the per-unit cost. However, buyers must balance inventory holding costs with potential savings.

-

Specifications and Customization: Custom features can significantly impact pricing. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: Workbenches made from premium materials or those that meet specific quality certifications (like ISO) may command higher prices but offer better long-term value.

-

Supplier Factors: Supplier reputation, reliability, and history in the industry can affect pricing. Established suppliers may offer warranties and better service, justifying a higher price point.

-

Incoterms: Understanding delivery terms is critical. Different Incoterms (like FOB, CIF) can affect the total landed cost, impacting the overall pricing strategy.

What Negotiation and Cost-Efficiency Tips Should Buyers Consider?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management are essential:

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and favorable terms. Regular communication can also help in understanding market trends and adjustments in pricing.

-

Assess Total Cost of Ownership (TCO): Consider all costs associated with the product, including maintenance, potential repairs, and operational costs. A lower purchase price may not always equate to better value if the product requires frequent replacements or repairs.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and import duties that can impact pricing. Understanding local market conditions can also provide leverage during negotiations.

-

Request Detailed Quotes: Ask suppliers for itemized pricing that breaks down all costs. This transparency can reveal areas for potential savings and help in comparing offers from different suppliers.

Disclaimer on Indicative Prices

Prices for 7-in-1 folding workbenches can vary widely based on the aforementioned factors. It is crucial for buyers to conduct thorough market research and obtain multiple quotes to ensure they are getting the best deal for their specific needs.

Alternatives Analysis: Comparing 7-in-1 folding workbench With Other Solutions

Exploring Alternatives to the 7-in-1 Folding Workbench

When considering a 7-in-1 folding workbench, it’s essential to evaluate various alternatives that can serve similar functions. Understanding the pros and cons of different solutions can help B2B buyers make informed decisions based on their specific operational needs and budget constraints. Below is a comparison of the 7-in-1 folding workbench against two viable alternatives: a traditional workbench and a modular scaffolding system.

| Comparison Aspect | 7-In-1 Folding Workbench | Traditional Workbench | Modular Scaffolding System |

|---|---|---|---|

| Performance | Versatile with multiple configurations; supports up to 1000 lbs. | Stable for heavy-duty tasks; fixed size limits versatility. | Excellent height adaptability; can support large loads. |

| Cost | Moderate cost ($189.99 to $249.99) | Typically higher initial investment (upwards of $300). | Variable costs based on size and configuration; can be expensive. |

| Ease of Implementation | Quick setup; ready to use out of the box. | Requires assembly and installation; less portable. | Requires setup and often multiple components; more complex. |

| Maintenance | Minimal maintenance; easy to clean and store. | Requires regular maintenance; can suffer from wear and tear. | Maintenance can be extensive, depending on the materials used. |

| Best Use Case | Ideal for mobile work environments and small spaces. | Best for dedicated workspaces where stability is key. | Suitable for construction sites needing height flexibility. |

Detailed Breakdown of Alternatives

Traditional Workbench

Traditional workbenches are built for stability and durability, making them ideal for heavy-duty tasks. They often feature a solid surface and can support significant weight, but their fixed size limits versatility. While they may require a higher initial investment, they offer a long-term solution for businesses with dedicated workshops. However, their lack of portability can be a disadvantage for companies needing flexibility in their workspace.

Modular Scaffolding System

A modular scaffolding system provides excellent adaptability and height flexibility, making it suitable for various construction tasks. These systems can be configured to fit different project needs, offering a significant advantage in terms of height adjustments. However, they typically require more complex assembly and maintenance compared to the 7-in-1 folding workbench. The cost can also vary significantly based on the components chosen, which may not be ideal for all budgets.

Conclusion: How to Choose the Right Solution for Your Business

When selecting the appropriate work solution, B2B buyers should carefully assess their specific operational requirements, budget, and the versatility of each option. The 7-in-1 folding workbench stands out for its portability and multifunctionality, making it a practical choice for businesses operating in diverse environments. In contrast, traditional workbenches and modular scaffolding systems may be better suited for more specialized applications where stability or height flexibility is paramount. Ultimately, understanding the specific needs of your projects will guide you toward the most suitable solution.

Essential Technical Properties and Trade Terminology for 7-in-1 folding workbench

What are the Key Technical Properties of a 7-in-1 Folding Workbench?

Understanding the technical properties of a 7-in-1 folding workbench is crucial for B2B buyers looking to invest in versatile and durable equipment. Here are some essential specifications to consider:

-

Load Capacity

The load capacity of a workbench indicates the maximum weight it can safely support. Common capacities range from 330 lbs to 1000 lbs, depending on the design and materials used. For B2B buyers, selecting a workbench with an appropriate load capacity ensures safety and efficiency in various applications, from woodworking to automotive repairs. -

Material Composition

The materials used in construction significantly affect durability and stability. Most 7-in-1 workbenches are made from a combination of aluminum for lightweight portability and steel for strength. Understanding material composition helps buyers assess longevity and performance under different working conditions. -

Height Adjustment Range

Height adjustability is a vital feature that allows users to customize the workbench to suit various tasks. Typical height ranges are between 20.47 inches to 30.7 inches. This adaptability is particularly important for B2B buyers who cater to diverse projects and user preferences. -

Foldability and Portability

The ability to fold the workbench flat for storage and transport is a key selling point. A well-designed folding mechanism can reduce storage space requirements, making it ideal for businesses with limited workshop space. This feature is especially appealing to mobile service providers and contractors. -

Stability Design

A stable workbench is essential for safety and precision. Features such as a triangular design or anti-slip rubber feet enhance stability. Buyers should prioritize these features to ensure that the workbench remains secure during heavy-duty tasks. -

Additional Features

Many 7-in-1 workbenches come equipped with extra functionalities, such as integrated power outlets or clamps. These features add value by increasing the versatility of the workbench, making it suitable for a wider range of projects.

What are Common Trade Terms Relevant to 7-in-1 Folding Workbenches?

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are some essential trade terms for B2B buyers:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality sources for workbench components and negotiate better pricing. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps B2B buyers plan their inventory and budget effectively, especially when sourcing workbenches in bulk. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This process is critical for buyers to compare costs and features across different suppliers before making purchasing decisions. -

Incoterms (International Commercial Terms)

These are predefined commercial terms that define the responsibilities of buyers and sellers in international transactions, including shipping and insurance. Familiarity with Incoterms can help buyers mitigate risks and understand the logistics involved in importing workbenches from various regions. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to manage project timelines and ensure that they have the necessary equipment when needed. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the product’s condition and performance over a specified period. Knowing the warranty terms can provide buyers with peace of mind regarding the longevity and reliability of the workbench.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and product offerings.

Navigating Market Dynamics and Sourcing Trends in the 7-in-1 folding workbench Sector

What Are the Key Market Drivers for 7-in-1 Folding Workbenches?

The global market for 7-in-1 folding workbenches is driven by several factors, including the increasing demand for versatile and space-saving solutions in both residential and commercial settings. As urbanization continues to rise, particularly in regions like Africa, South America, and parts of Europe, consumers and businesses are looking for multifunctional furniture that can accommodate limited spaces. Additionally, the shift towards DIY projects and home improvement is propelling the sales of portable workbenches, as professionals and hobbyists alike seek tools that offer flexibility and durability.

Emerging technologies are also influencing sourcing trends. The integration of smart features, such as built-in power outlets and adjustable heights, is becoming more common. This trend is particularly appealing to international B2B buyers who prioritize innovation in their product offerings. Suppliers that leverage advanced manufacturing techniques, such as lightweight materials without compromising strength, are gaining competitive advantages in the market.

Furthermore, the increasing emphasis on e-commerce platforms is reshaping how B2B buyers source these products. With the rise of online marketplaces, international buyers can access a broader range of suppliers, fostering healthy competition and driving down costs. This dynamic allows businesses in regions like Vietnam and Nigeria to source high-quality workbenches at competitive prices, catering to their specific market needs.

How Important Are Sustainability and Ethical Sourcing in the 7-in-1 Folding Workbench Market?

Sustainability and ethical sourcing are becoming increasingly significant for B2B buyers in the 7-in-1 folding workbench sector. As consumers grow more environmentally conscious, businesses are compelled to adopt sustainable practices throughout their supply chains. This includes using eco-friendly materials and ensuring responsible sourcing that minimizes environmental impact.

The demand for products with ‘green’ certifications is on the rise. Buyers are actively seeking workbenches made from recycled or sustainably sourced materials, as well as those that are manufactured using energy-efficient processes. These attributes not only appeal to environmentally conscious consumers but also align with regulatory standards that many countries are implementing to combat climate change.

Moreover, ethical supply chains are essential for building brand reputation. B2B buyers prefer suppliers that can demonstrate transparency and accountability in their sourcing practices. This includes ensuring fair labor practices and safe working conditions for employees in the manufacturing process. By prioritizing sustainability and ethical sourcing, businesses can differentiate themselves in a competitive market, attracting more discerning customers and fostering long-term loyalty.

How Has the 7-in-1 Folding Workbench Evolved Over Time?

The evolution of the 7-in-1 folding workbench reflects broader trends in manufacturing and consumer preferences. Initially, workbenches were designed for specific tasks, limiting their utility and appeal. However, as the DIY culture gained traction, manufacturers began to innovate, creating multifunctional designs that could serve various purposes—from sawhorses to scaffolding.

The introduction of lightweight materials, such as aluminum and high-grade plastics, has further enhanced the portability and ease of use of these workbenches. Modern designs now prioritize user convenience, featuring adjustable heights and foldable components that cater to diverse work environments. This adaptability has made the 7-in-1 folding workbench a staple in both professional and home settings, effectively bridging the gap between traditional tools and contemporary needs.

As the market continues to evolve, the focus on smart technology integration and sustainable practices suggests that the next phase of development will prioritize not only functionality but also environmental responsibility, ensuring that the 7-in-1 folding workbench remains relevant and desirable for future generations.

Frequently Asked Questions (FAQs) for B2B Buyers of 7-in-1 folding workbench

-

How do I choose the right 7-in-1 folding workbench for my business needs?

Selecting the right 7-in-1 folding workbench involves assessing your specific requirements, such as load capacity, versatility, and portability. Consider the weight limits for different functions; for example, some models support up to 1000 lbs in workbench mode but may vary in other configurations. Evaluate additional features like adjustable height and ease of storage, which can enhance usability across various job sites. Finally, look for a reputable supplier that offers warranties and customer support to address any potential issues. -

What are the benefits of sourcing a 7-in-1 folding workbench from international suppliers?

Sourcing from international suppliers can offer competitive pricing, a wider selection of models, and the ability to customize products to fit your needs. Suppliers in regions such as Asia or Europe may have advanced manufacturing techniques, providing superior quality. Additionally, you may find unique features that cater specifically to the demands of your market, enhancing your offerings. However, consider potential challenges such as shipping times and import regulations. -

What is the typical minimum order quantity (MOQ) for 7-in-1 folding workbenches?

The MOQ for 7-in-1 folding workbenches can vary significantly depending on the supplier and the specific model. Generally, MOQs can range from 50 to 500 units. It’s essential to discuss your needs with potential suppliers to negotiate favorable terms. Some manufacturers may offer lower MOQs for first-time buyers or customized orders, which can be an excellent opportunity for smaller businesses to enter the market without a large upfront investment. -

What payment terms should I expect when purchasing 7-in-1 folding workbenches internationally?

Payment terms for international purchases can vary widely but often include options like letters of credit, advance payments, or payment upon delivery. Many suppliers may require a deposit (typically 30-50%) to initiate production, with the remainder due before shipment or upon delivery. It’s crucial to clarify payment terms upfront and ensure they align with your cash flow capabilities. Utilizing secure payment platforms can also mitigate risks associated with international transactions. -

How can I ensure the quality of the 7-in-1 folding workbench I am sourcing?

To ensure quality, request product samples before placing a bulk order. Additionally, investigate the supplier’s certifications and manufacturing processes to confirm adherence to international quality standards. Conducting factory audits or hiring third-party inspection services can provide further assurance. Establishing a clear agreement on quality expectations and return policies in your contract can protect your investment and maintain product integrity. -

What are the logistics considerations when importing 7-in-1 folding workbenches?

Logistics considerations include shipping methods, freight costs, and customs regulations. Depending on your location, you may choose air freight for faster delivery or sea freight for cost-effectiveness. Ensure you are aware of import duties and taxes that may apply to your order. Collaborating with a reliable freight forwarder can simplify the logistics process, ensuring timely and efficient delivery while navigating complex customs procedures. -

Can I customize the features of a 7-in-1 folding workbench?

Yes, many manufacturers offer customization options for 7-in-1 folding workbenches. Customizations can include specific dimensions, weight capacities, additional accessories, or even branding elements. Discuss your requirements with potential suppliers to explore available options and associated costs. Customizing your workbench can help differentiate your product in the market and better meet the needs of your customers. -

What after-sales support should I expect from suppliers of 7-in-1 folding workbenches?

After-sales support can vary by supplier, but you should expect assistance with product warranties, maintenance advice, and troubleshooting. A reputable supplier will provide a clear return policy and support for any defective products. Additionally, consider suppliers that offer training or resources for proper usage to enhance customer satisfaction. Establishing a good relationship with your supplier can also lead to better support for future orders or issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 7-In-1 Folding Workbench Manufacturers & Suppliers List

1. Griot’s Garage – 7-in-1 Multi-Purpose Workbench

Domain: griotsgarage.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “7-in-1 Multi-Purpose Workbench”, “item_number”: “91582”, “UPC”: “”, “price”: “$199.99”, “features”: {“work_area_dimensions”: “42 1/2\” W x 21 3/8\” L”, “outlets”: “2 grounded 120V outlets”, “surge_protector”: “15-amp surge protector”, “USB_ports”: “2 USB ports for mobile device charging”}, “shipping_info”: “Free shipping on orders over $49”, “satisfaction_guarantee”: “100% Satisf…

2. Wood Art Supply – Multifunctional Folding Work Table

Domain: woodartsupply.com

Registered: 2022 (3 years)

Introduction: Multifunctional Folding Work Table, 7 in 1 Work Benches for Garage, Portable Workbench, Sawhorse, Scaffold, Platform, Car Creeper, Hand Truck, with 4 Wheels.

3. LEADALLWAY – 7-in-1 Folding Portable Workbench

Domain: leadallway.com

Registered: 2017 (8 years)

Introduction: {‘product_name’: ‘LEADALLWAY 7-in-1 Folding Portable Workbench’, ‘features’: [‘Workbench mode’, ‘Scaffold mode’, ‘Platform mode’, ‘Sawhorse mode’, ‘Car Creeper mode’, ‘Hand Truck mode’], ‘load_capacity’: {‘scaffold_platform_mode’: ‘550 lbs’, ‘other_modes’: ‘330 lbs’}, ‘dimensions’: ‘21.5″D x 42.7″W x 31.5″H’, ‘color’: ‘Black’, ‘finish_type’: ‘Painted’, ‘base_type’: ‘Casters’, ‘adjustable_height’: …

4. Foter – 7-in-1 Folding Work Table

Domain: foter.com

Registered: 2006 (19 years)

Introduction: 7-in-1 multifunctional folding work table, versatile design, suitable for various tasks, compact and portable, durable construction, easy to set up and store, ideal for home, office, and outdoor use.

5. Sporty’s Tool Shop – 7-in-1 Workbench-Scaffold

Domain: sportystoolshop.com

Registered: 2003 (22 years)

Introduction: Product Name: 7-in-1 Workbench-Scaffold

Price: $199.95 (Sale Price: $159.95)

SKU: 9848

Availability: In stock (Backordered)

Description: A strong, stable work platform that can be used for various tasks including painting, hanging wallpaper, and light repairs. It provides a wider work area to minimize movement.

Dimensions: Work surface measures 43″l x 20 1/2″w

Weight Capacity: Rated to support 330…

6. AliExpress – 7-in-1 Multifunctional Workbench

Domain: aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, AliExpress – 7-in-1 Multifunctional Workbench, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 7-in-1 folding workbench

As the demand for versatile tools in various industries continues to rise, the 7-in-1 folding workbench stands out as a strategic asset for businesses across multiple sectors. This multifunctional solution not only enhances productivity but also optimizes workspace efficiency, making it an ideal choice for international buyers seeking to streamline operations. Key considerations for B2B buyers include evaluating the workbench’s load capacity, portability, and adaptability to different work environments, ensuring it meets diverse project needs.

Strategic sourcing of the 7-in-1 folding workbench offers significant advantages, including cost-effectiveness and access to innovative designs tailored for specific market demands. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers that emphasize quality, durability, and customer support. By aligning with reputable manufacturers, businesses can secure products that contribute to operational excellence and long-term success.

Looking ahead, the market for multifunctional tools is poised for growth, driven by evolving consumer preferences and advancements in technology. Now is the time for international B2B buyers to engage with suppliers and capitalize on the opportunities presented by the 7-in-1 folding workbench. Embrace the future of workspace solutions and make informed sourcing decisions that propel your business forward.