A B2B Buyer’s Guide to 500 Gallon Drum: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for 500 gallon drum

In today’s dynamic global marketplace, sourcing the right 500-gallon drum can pose significant challenges for B2B buyers. Whether you’re storing water, chemicals, or other vital liquids, understanding the diverse options available is crucial for ensuring compliance, safety, and efficiency. This guide delves into the various types of 500-gallon drums, including vertical tanks, cone-bottom designs, and portable models, while also addressing their specific applications across industries such as agriculture, emergency services, and manufacturing.

International buyers from regions like Africa, South America, the Middle East, and Europe—specifically Brazil and Saudi Arabia—will find this guide particularly beneficial. It provides actionable insights into supplier vetting processes, cost considerations, and shipping logistics, empowering businesses to make informed purchasing decisions. By highlighting key factors such as material quality, storage capacity, and regulatory compliance, this comprehensive resource equips buyers with the knowledge necessary to navigate the complexities of the global market.

Ultimately, whether you are looking to enhance your operational efficiency or ensure safety in your storage practices, this guide serves as your essential roadmap for sourcing the ideal 500-gallon drum tailored to your specific needs. With the right information at your fingertips, you can confidently engage with suppliers and secure the best solutions for your business.

Understanding 500 gallon drum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical Water Storage Tank | Tall, cylindrical design; often food-grade; various heights available | Water supply, agriculture, industrial use | Pros: Space-efficient; Cons: Limited access for cleaning. |

| Cone Bottom Tank | Sloped bottom for complete drainage; robust construction | Chemical storage, food processing, wastewater | Pros: Easy cleaning; Cons: Higher cost. |

| Folding Frame Tank | Portable, collapsible design; open top; lightweight materials | Emergency water supply, firefighting, aquaculture | Pros: Highly portable; Cons: Less durable. |

| Emergency Water Tank | Designed for quick deployment; often has a protective cover | Disaster relief, construction sites | Pros: Rapid setup; Cons: May require frequent maintenance. |

| Utility Tank | Versatile use; can be horizontal or vertical; rugged materials | Transporting various liquids, including fuels | Pros: Multi-functional; Cons: Size may be cumbersome. |

What Are the Characteristics of Vertical Water Storage Tanks?

Vertical water storage tanks are designed with a tall, cylindrical structure that optimizes space and provides a significant volume of storage. These tanks are often constructed from food-grade materials, making them suitable for potable water applications. They are ideal for businesses in agriculture, construction, and industrial sectors that require reliable water supply solutions. When purchasing, consider height and diameter specifications to ensure compatibility with existing infrastructure.

How Do Cone Bottom Tanks Facilitate Efficient Storage?

Cone bottom tanks feature a sloped bottom that allows for complete drainage, making them particularly useful in scenarios requiring frequent cleaning, such as food processing and chemical storage. Their robust construction ensures durability, which is vital in industrial settings. Buyers should evaluate the tank’s material and size to ensure it meets their specific storage needs and complies with safety regulations.

Illustrative image related to 500 gallon drum

Why Choose Folding Frame Tanks for Portability?

Folding frame tanks stand out due to their portability and ease of setup. Designed for quick deployment, they are often used in emergency situations, such as firefighting and disaster relief. Their lightweight materials enable easy transport, making them a preferred choice for businesses needing flexible water storage solutions. However, buyers should be aware that while convenient, these tanks may not offer the same durability as more permanent options.

What Are the Benefits of Emergency Water Tanks?

Emergency water tanks are specifically engineered for rapid deployment, often featuring protective covers to safeguard water quality. These tanks are crucial in disaster relief scenarios, providing immediate access to water in affected areas. When selecting an emergency tank, consider factors such as capacity, transportability, and the tank’s ability to withstand harsh conditions, ensuring it meets your operational requirements.

How Do Utility Tanks Support Versatile Liquid Transport?

Utility tanks are designed for a range of applications, including the transportation of various liquids like fuels, chemicals, and water. They can be configured in both horizontal and vertical formats, allowing businesses to choose the best fit for their logistical needs. When purchasing utility tanks, it’s essential to assess the materials used for construction and ensure they are suitable for the specific liquids being stored or transported, as this impacts safety and compliance.

Key Industrial Applications of 500 gallon drum

| Industry/Sector | Specific Application of 500 gallon drum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Fertilizer and pesticide storage | Ensures safe and compliant storage of chemicals, reducing risk of contamination. | Look for food-grade materials, UV resistance, and compatibility with stored substances. |

| Water Management | Emergency water supply and rainwater harvesting | Provides reliable access to potable water in emergencies, essential for rural areas. | Ensure tanks meet NSF standards for drinking water and have proper sealing mechanisms. |

| Oil and Gas | Bulk liquid storage for fuel and chemicals | Facilitates safe transportation and storage of hazardous materials, minimizing spill risks. | Consider compliance with international safety standards and chemical resistance of materials. |

| Construction | Temporary water supply for construction sites | Supports dust control and equipment operation, enhancing site productivity. | Evaluate portability, ease of setup, and durability against construction site conditions. |

| Environmental Services | Spill containment and decontamination efforts | Aids in environmental protection by effectively managing hazardous spills. | Look for tanks with robust containment features and easy mobility for rapid deployment. |

How is the 500 Gallon Drum Used in Agriculture and What Challenges Does It Solve?

In the agriculture sector, 500-gallon drums are predominantly utilized for the storage of fertilizers and pesticides. These drums ensure that chemicals are stored safely and in compliance with regulatory standards, which is crucial for preventing contamination of crops and groundwater. For international buyers, especially in developing regions, it’s essential to source drums made from food-grade materials that are resistant to UV rays and compatible with various chemical properties. This helps mitigate risks associated with chemical degradation and environmental impact.

What Role Does the 500 Gallon Drum Play in Water Management?

Water management relies heavily on 500-gallon drums for emergency water supply and rainwater harvesting systems. These drums can be crucial in rural areas where access to clean water is limited, especially during crises or natural disasters. Buyers should ensure that the tanks comply with NSF standards for potable water and are equipped with effective sealing mechanisms to prevent contamination. This guarantees that the stored water remains safe for consumption, addressing public health concerns.

How Does the Oil and Gas Industry Benefit from 500 Gallon Drums?

In the oil and gas industry, 500-gallon drums are essential for the bulk storage of fuels and chemicals. Their robust construction allows for the safe transportation and storage of hazardous materials, significantly reducing the risk of spills and environmental hazards. For B2B buyers, sourcing drums that meet international safety standards is vital. Additionally, the chemical resistance of the drum materials must be evaluated to ensure compatibility with the stored liquids, thereby promoting operational safety and environmental compliance.

In What Ways are 500 Gallon Drums Used on Construction Sites?

Construction sites frequently employ 500-gallon drums for temporary water supply, which is essential for dust control and the operation of machinery. The ability to have a portable and easily deployable water source enhances site productivity and ensures compliance with safety regulations. Buyers should consider the durability and ease of setup of these drums, particularly in rugged construction environments where conditions can be challenging. The right drum can significantly contribute to the efficiency and safety of construction operations.

How are 500 Gallon Drums Utilized in Environmental Services?

In environmental services, 500-gallon drums are vital for spill containment and decontamination efforts. They help manage hazardous spills effectively, thereby protecting the environment and public health. For international buyers, sourcing tanks with robust containment features is crucial, as is ensuring that they are mobile enough for rapid deployment in emergency situations. This adaptability can significantly enhance the effectiveness of environmental cleanup operations, making them an indispensable asset for companies in this sector.

3 Common User Pain Points for ‘500 gallon drum’ & Their Solutions

Scenario 1: Navigating Compliance Challenges with Chemical Storage

The Problem: B2B buyers often face stringent regulatory requirements when storing hazardous materials in 500-gallon drums. In regions like Africa and the Middle East, compliance with local environmental and safety regulations can be complex. Buyers may find themselves overwhelmed by the specific requirements for material safety data sheets (MSDS), labeling, and containment protocols. Failure to comply can lead to significant fines, operational shutdowns, or even legal repercussions.

The Solution: To navigate these compliance challenges, it is essential to partner with suppliers who understand the local regulations and can provide drums that meet safety standards. When sourcing 500-gallon drums, ensure they are certified for the specific materials you intend to store—look for drums made from chemical-resistant materials such as polyethylene or steel, which are often required for hazardous substances. Additionally, consider investing in double-walled drums or secondary containment solutions to enhance safety and compliance. Regular training sessions for staff on handling, labeling, and emergency procedures can also mitigate risks and ensure adherence to regulations.

Scenario 2: Managing Supply Chain Disruptions

The Problem: International B2B buyers frequently encounter supply chain disruptions that affect the availability of 500-gallon drums. Factors such as geopolitical tensions, shipping delays, and fluctuating demand can create uncertainties in procurement, leading to potential project delays and increased costs. This unpredictability can hinder operational efficiency, especially for industries relying on consistent supply for manufacturing or storage purposes.

The Solution: To effectively manage these supply chain disruptions, establish relationships with multiple suppliers across different regions. This diversification allows for backup options in case one supplier faces delays. Furthermore, consider utilizing predictive analytics tools to forecast demand and optimize inventory levels, ensuring you have sufficient stock on hand. Engaging in long-term contracts with key suppliers can also provide stability in pricing and availability. Finally, maintaining open lines of communication with suppliers can help you stay informed about any potential disruptions and adapt your strategies accordingly.

Illustrative image related to 500 gallon drum

Scenario 3: Ensuring Safe Transportation of Fluids

The Problem: Transporting fluids in 500-gallon drums poses significant safety risks, particularly for hazardous materials. B2B buyers must ensure that the drums are not only durable but also securely sealed to prevent leaks during transit. Inadequate transportation methods can lead to spills, environmental damage, and costly liabilities, which can severely impact a company’s reputation and finances.

The Solution: To ensure safe transportation, select 500-gallon drums specifically designed for transport, such as those with secure closures and robust construction. Employ specialized carriers who are experienced in handling hazardous materials and comply with relevant transport regulations. It’s also critical to conduct regular inspections of the drums before loading to ensure they are free from damage and leaks. Additionally, providing comprehensive training for staff involved in the loading and unloading process can further enhance safety. Implementing a tracking system for shipments can help monitor conditions during transport and provide real-time alerts if any issues arise.

Strategic Material Selection Guide for 500 gallon drum

What Are the Key Properties of Common Materials Used for 500 Gallon Drums?

When selecting materials for 500-gallon drums, it is essential to consider the specific properties that impact performance, durability, and application suitability. Below, we analyze four common materials used in the manufacturing of 500-gallon drums: polyethylene, steel, fiberglass, and aluminum.

How Does Polyethylene Perform in 500 Gallon Drums?

Polyethylene is a widely used thermoplastic known for its excellent chemical resistance and lightweight nature. It typically has a temperature rating of up to 120°F (49°C) and is resistant to corrosion from various chemicals, making it suitable for storing water and many industrial liquids.

Pros: Polyethylene drums are generally more affordable than their metal counterparts and are easier to handle due to their lightweight nature. They are also less prone to rust and corrosion, which enhances their longevity in various environments.

Cons: However, polyethylene can be less durable under extreme temperature fluctuations and may not withstand high-pressure applications. Additionally, UV exposure can degrade the material over time, which is a consideration for outdoor storage.

Impact on Application: Polyethylene is ideal for storing potable water and non-hazardous chemicals but may not be suitable for aggressive solvents or high-temperature applications.

What Advantages Does Steel Offer for 500 Gallon Drums?

Steel drums are renowned for their strength and durability, withstanding high pressures and extreme temperatures. They typically have a temperature rating of up to 400°F (204°C) and excellent resistance to punctures and impacts.

Pros: The primary advantage of steel drums is their robustness, making them suitable for hazardous materials and high-pressure applications. They are also recyclable, which can appeal to environmentally conscious buyers.

Cons: On the downside, steel is prone to corrosion if not properly coated or maintained, particularly in humid environments. The cost of steel drums is generally higher than that of plastic drums, and they are heavier, which can increase shipping costs.

Impact on Application: Steel drums are suitable for storing flammable liquids, chemicals, and other hazardous materials, but they require careful handling and maintenance to prevent rust.

How Does Fiberglass Compare for 500 Gallon Drums?

Fiberglass drums are made from reinforced plastic and are known for their excellent chemical resistance and lightweight properties. They can handle a wide range of temperatures, typically from -40°F to 150°F (-40°C to 65°C).

Pros: The chemical resistance of fiberglass makes it ideal for storing aggressive chemicals, and its lightweight nature facilitates easier transport. Additionally, fiberglass does not corrode, making it suitable for long-term storage.

Cons: However, fiberglass can be more expensive than both polyethylene and steel. It is also less impact-resistant, which may lead to cracking under heavy stress.

Impact on Application: Fiberglass drums are excellent for storing corrosive chemicals and can be used in various industrial applications, but their higher cost may limit their use in budget-sensitive projects.

What Role Does Aluminum Play in 500 Gallon Drums?

Aluminum drums offer a lightweight alternative to steel while maintaining good strength and corrosion resistance. They typically have a temperature rating similar to steel, making them versatile for various applications.

Pros: The lightweight nature of aluminum reduces shipping costs, and its corrosion resistance makes it suitable for outdoor use. Aluminum drums are also recyclable, which adds to their appeal.

Cons: However, aluminum is softer than steel and may be more susceptible to dents and damage. Additionally, they can be more expensive than polyethylene and may not be suitable for all chemical applications.

Impact on Application: Aluminum drums are suitable for a range of liquids, including food-grade applications, but care must be taken with certain chemicals that can react with aluminum.

Summary Table of Material Selection for 500 Gallon Drums

| Material | Typical Use Case for 500 gallon drum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Potable water, non-hazardous liquids | Lightweight, corrosion-resistant | Limited temperature range | Low |

| Steel | Hazardous materials, flammable liquids | High durability and strength | Prone to corrosion, heavier | High |

| Fiberglass | Corrosive chemicals | Excellent chemical resistance | Higher cost, less impact-resistant | Med |

| Aluminum | Food-grade liquids, general storage | Lightweight, corrosion-resistant | Susceptible to dents, costlier | Med |

This guide provides a comprehensive overview of the key materials used for 500-gallon drums, helping international B2B buyers make informed decisions based on their specific needs and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 500 gallon drum

What Are the Main Stages of Manufacturing a 500 Gallon Drum?

The manufacturing of a 500-gallon drum typically involves several stages that ensure the final product meets the necessary specifications for durability and functionality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in the manufacturing process is selecting the appropriate materials, which can range from high-density polyethylene (HDPE) for plastic drums to steel for metal drums. The materials must be sourced from reputable suppliers to ensure compliance with international standards. Once selected, the materials undergo cleaning and treatment processes to remove impurities and enhance bonding capabilities during forming.

-

Forming: This stage involves the shaping of the drum. For plastic drums, techniques such as rotational molding or blow molding are commonly used. In rotational molding, the plastic is heated and rotated within a mold, allowing it to coat the interior evenly. For metal drums, processes like rolling and welding are utilized, where flat sheets of metal are rolled into a cylindrical shape and then welded at the seams. Both methods require precision to ensure that the drums have uniform thickness and structural integrity.

-

Assembly: After forming, components such as lids, valves, and fittings are added to the drum. This stage may involve welding, bolting, or using adhesives, depending on the material. For drums that require additional features, such as handles or stacking capabilities, these components are integrated during assembly to enhance usability and transportability.

-

Finishing: The final stage includes surface treatments, which may involve painting, coating, or applying UV protection to enhance durability and resistance to environmental factors. Quality checks are performed at this stage to ensure that the finish meets aesthetic and functional requirements.

How Is Quality Assurance Managed in 500 Gallon Drum Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of 500-gallon drums, particularly for B2B buyers who require assurance of product reliability. The QA process typically aligns with international standards, such as ISO 9001, and may include industry-specific certifications like CE and API, depending on the application of the drum.

-

Quality Control Checkpoints: QA is structured around several key checkpoints:

– Incoming Quality Control (IQC): At this initial stage, raw materials are inspected for compliance with specified standards. This includes checking for material integrity and ensuring that suppliers provide necessary documentation.

– In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is conducted to identify any deviations from quality standards. Techniques such as statistical process control (SPC) may be employed to track variations in production.

– Final Quality Control (FQC): Before shipment, each drum undergoes a final inspection to ensure it meets all specifications and standards. This includes testing for leaks, structural integrity, and compliance with safety regulations. -

Common Testing Methods: Various testing methods are employed to ensure quality:

– Hydrostatic Testing: This method assesses the drum’s ability to withstand internal pressure and checks for leaks.

– Drop Testing: Used primarily for plastic drums, this test simulates impacts during transport to ensure durability.

– Chemical Resistance Testing: For drums intended for hazardous materials, testing is conducted to ensure that the drum can safely contain chemicals without degradation.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is essential. Here are some actionable strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place. Audits should focus on the entire production process, from raw material sourcing to final testing.

-

Requesting Quality Reports: Buyers should request documentation that outlines the supplier’s quality assurance processes, including certifications and testing results. This documentation should detail compliance with international standards and any industry-specific certifications.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an impartial assessment of the supplier’s quality control processes. These inspectors can conduct random checks on production batches and confirm adherence to specified quality standards.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must be aware of specific nuances related to quality control and certification when sourcing 500-gallon drums. Regulations may vary significantly by region, affecting how products are certified and what standards must be met.

-

Understanding Regional Standards: Buyers should familiarize themselves with the specific regulations applicable in their countries. For example, in Europe, CE marking indicates compliance with health, safety, and environmental protection standards, while in the U.S., adherence to the American National Standards Institute (ANSI) may be required.

-

Customs and Import Regulations: Different countries have varying import regulations that may necessitate additional certifications or documentation. Understanding these requirements is crucial to avoid delays and ensure compliance upon arrival.

-

Cultural and Language Considerations: When dealing with suppliers from different regions, language barriers and cultural differences can impact communication regarding quality expectations. Engaging local representatives or consultants can help bridge these gaps and ensure that quality standards are clearly understood and met.

In conclusion, the manufacturing processes and quality assurance practices for 500-gallon drums are critical factors for B2B buyers to consider. By understanding the stages of production, quality checkpoints, and verification methods, buyers can make informed decisions and establish reliable partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘500 gallon drum’

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for 500-gallon drums. Whether you’re based in Africa, South America, the Middle East, or Europe, following this checklist will help you make informed decisions and secure the right products for your needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications of the 500-gallon drum you require. Consider factors such as material (plastic vs. metal), intended use (potable water, chemicals, or bulk storage), and design features (cone bottom, vertical, or portable). A precise specification will help you communicate your needs effectively to potential suppliers.

Step 2: Research Regulatory Compliance

Ensure that the drums you intend to purchase comply with local and international regulations. This is particularly important for drums that will store food-grade materials or hazardous substances. Verify certifications such as NSF or FDA approvals and check whether the materials used in the drums are safe and suitable for your intended application.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering quality products and timely service. Online reviews and industry reputation can provide valuable insights into their reliability.

Step 4: Request Samples for Testing

When narrowing down your options, request samples of the 500-gallon drums for testing. Evaluating the product firsthand allows you to assess quality, durability, and whether it meets your specifications. Additionally, check for any noticeable defects and gauge the overall design efficiency, which can impact your operational processes.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and evaluated their products, engage in negotiations. Discuss pricing, payment terms, delivery schedules, and warranty conditions. Ensure that you understand the total cost of ownership, which includes shipping and potential customs duties, especially if you are importing from abroad.

Step 6: Confirm Shipping and Logistics Arrangements

Efficient logistics are critical for timely delivery. Confirm the shipping methods and lead times with your supplier. Discuss options for tracking shipments and handling potential delays, especially if you are operating in regions where logistics can be challenging. Understanding these details can help you plan better and avoid operational disruptions.

Step 7: Establish a Communication Plan

Maintain clear communication with your supplier throughout the procurement process. Set up regular check-ins to monitor the progress of your order and address any concerns that may arise. A proactive communication strategy can foster a strong relationship with your supplier, ensuring smoother transactions in the future.

By following this step-by-step checklist, B2B buyers can confidently navigate the sourcing process for 500-gallon drums, ensuring that they select the right products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for 500 gallon drum Sourcing

What Are the Key Cost Components in Sourcing 500 Gallon Drums?

When sourcing 500-gallon drums, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

Materials: The type of material significantly affects pricing. Plastic drums, for example, are generally less expensive than metal options. The cost of materials can fluctuate based on market demand, availability, and geographical sourcing, particularly for international buyers.

Illustrative image related to 500 gallon drum

Labor and Manufacturing Overhead: Labor costs vary by region and can be influenced by local wage standards and labor laws. Manufacturing overhead includes costs associated with running production facilities, such as utilities, maintenance, and operational inefficiencies. These costs are typically higher in regions with stricter regulations or higher living costs.

Tooling and Quality Control (QC): Tooling refers to the setup costs for production, which can be significant for customized or specialized drum designs. Quality control is vital, especially for drums intended for food or hazardous materials. Certifications like NSF or ISO can add to the overall cost but are crucial for ensuring safety and compliance.

Logistics and Margin: Logistics costs encompass shipping, handling, and tariffs, which can be especially complex for international transactions. Supplier margins will vary based on competition and the perceived value of the product, impacting the final price.

Illustrative image related to 500 gallon drum

How Do Price Influencers Impact the Cost of 500 Gallon Drums?

Several price influencers can significantly affect the final cost of 500-gallon drums:

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for larger orders, making it beneficial for companies with substantial storage needs.

Specifications and Customization: Custom designs or specific features (e.g., cone bottom, collapsible frames) typically come at a premium. Clearly defining your requirements can help suppliers provide accurate quotes and avoid unexpected costs.

Materials and Quality Certifications: The choice of materials directly impacts price. Drums made from food-grade or chemically resistant materials will be costlier. Moreover, certifications can add to the price but are essential for compliance in specific industries.

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers may offer higher prices due to their quality assurance practices, while newer entrants might provide lower prices to gain market share.

Incoterms: Understanding shipping terms (Incoterms) is crucial for international buyers. These terms define responsibilities for shipping costs, insurance, and risk, which can significantly affect the total landed cost.

Illustrative image related to 500 gallon drum

What Buyer Tips Can Enhance Cost-Efficiency in 500 Gallon Drum Sourcing?

For international buyers, particularly in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negotiation: Always negotiate pricing with suppliers. Be prepared to discuss volume discounts, payment terms, and lead times to find mutually beneficial arrangements.

Total Cost of Ownership (TCO): Evaluate the total cost of ownership, not just the purchase price. This includes maintenance, logistics, and disposal costs. A lower initial price may result in higher long-term costs if the product is not durable or compliant with regulations.

Understanding Pricing Nuances: Familiarize yourself with local market conditions and fluctuations that may affect pricing. Currency exchange rates, tariffs, and regional supply chain challenges can impact costs, especially for international transactions.

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Loyal customers may receive preferential pricing or priority in production schedules.

Conclusion

The cost and pricing analysis for 500-gallon drums involve a complex interplay of materials, labor, overhead, logistics, and supplier margins. By understanding these components and their influencers, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always approach sourcing strategically to optimize both cost and quality.

Alternatives Analysis: Comparing 500 gallon drum With Other Solutions

When considering the best solution for liquid storage and transport, the 500-gallon drum is a popular choice, particularly in industrial and agricultural settings. However, various alternatives exist that may better suit specific needs depending on factors such as cost, performance, and intended use. This analysis will compare the 500-gallon drum against two viable alternatives: the 500-gallon folding frame tank and the 500-gallon cone bottom tank.

| Comparison Aspect | 500 Gallon Drum | 500 Gallon Folding Frame Tank | 500 Gallon Cone Bottom Tank |

|---|---|---|---|

| Performance | High durability; suitable for various liquids | Portable; good for emergency use | Efficient for liquid drainage and mixing |

| Cost | Moderate cost; generally affordable | Higher initial investment, but reusable | Mid-range cost; varies with material quality |

| Ease of Implementation | Easy to transport and store; standard fittings | Requires setup; folds for storage | Heavier; may need equipment for placement |

| Maintenance | Low maintenance; minimal care needed | Requires occasional inspection; replaceable liners | Moderate maintenance; clean regularly to prevent residue |

| Best Use Case | General-purpose storage; safe for many liquids | Firefighting, disaster relief, and temporary storage | Chemical storage, wastewater treatment, and agricultural applications |

What Are the Advantages and Disadvantages of a 500 Gallon Folding Frame Tank?

The 500-gallon folding frame tank is designed for portability and ease of storage. Its open-top design allows for quick access, making it ideal for emergency situations such as firefighting or disaster relief efforts. The tank can be easily transported when folded and is suitable for various applications, including potable water storage and decontamination. However, the initial cost may be higher compared to traditional drums, and it requires a bit more setup time. Maintenance involves regular inspections and potential liner replacements, which could add to long-term costs.

Illustrative image related to 500 gallon drum

How Does a 500 Gallon Cone Bottom Tank Compare?

The 500-gallon cone bottom tank offers superior performance for applications requiring efficient liquid drainage and mixing. Its conical shape allows for complete emptying, making it an excellent choice for chemical storage and wastewater treatment. While the tank is relatively easy to maintain, it can be heavier and may require specialized equipment for installation and relocation. The cost is typically in the mid-range, but the investment can be justified by its efficiency in specific industrial applications.

Conclusion: Which Solution is Right for Your Needs?

Choosing the right liquid storage solution depends on your specific requirements. If portability and emergency use are your primary concerns, the folding frame tank may be the best choice despite its higher initial cost. For applications where complete drainage is critical, the cone bottom tank is optimal, especially in chemical and agricultural contexts. Conversely, the 500-gallon drum remains a versatile and economical option for general-purpose storage. B2B buyers should assess their operational needs, budget constraints, and the specific liquids being stored to determine the most suitable solution for their business.

Essential Technical Properties and Trade Terminology for 500 gallon drum

What Are the Key Technical Properties of a 500 Gallon Drum?

Understanding the essential technical properties of a 500-gallon drum is crucial for B2B buyers, especially when selecting the right drum for specific applications. Here are some critical specifications to consider:

1. Material Grade

The material used in manufacturing the drum significantly impacts its durability and suitability for various applications. Common materials include high-density polyethylene (HDPE) and steel. HDPE is lightweight, corrosion-resistant, and suitable for storing liquids, while steel drums offer strength and are ideal for hazardous materials. Selecting the appropriate material grade ensures compliance with safety standards and long-term performance.

2. Capacity and Dimensions

The nominal capacity of 500 gallons is essential for determining how much liquid can be stored. However, dimensions such as height, diameter, and shape (vertical, horizontal, or cone-bottom) also affect space utilization and transportation logistics. Understanding these dimensions helps buyers optimize storage and transport efficiencies, especially in constrained environments.

Illustrative image related to 500 gallon drum

3. Weight and Portability

The weight of the drum, typically ranging from 110 to 2,500 pounds depending on the material and design, is a vital consideration for transport and handling. Lighter models facilitate easier movement and installation, while heavier drums may be more stable but require specialized equipment for transport. Buyers should assess their logistical capabilities when choosing a drum based on weight.

4. Chemical Resistance

Different applications require drums to hold specific types of substances. Chemical resistance ratings indicate whether a drum can safely contain corrosive or reactive materials. It is critical for buyers to verify that the drum is compatible with the chemicals it will store to prevent leaks, spills, and potential environmental hazards.

5. Temperature Tolerance

Temperature tolerance defines the range of temperatures within which the drum can safely operate. For instance, some plastics may become brittle in cold temperatures, while metals can corrode if exposed to moisture at high temperatures. This specification is particularly important in regions with extreme climates or for applications involving temperature-sensitive materials.

What Are Common Trade Terms Used in the 500 Gallon Drum Industry?

Familiarity with industry jargon is essential for effective communication and decision-making. Here are some common trade terms relevant to 500-gallon drums:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the drum industry, an OEM may create drums that meet specific standards for another company’s brand. Understanding OEM relationships can help buyers ensure they are sourcing high-quality, compliant products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is vital for buyers as it affects purchasing decisions, inventory management, and budgeting. Suppliers often set MOQs to ensure profitability and minimize logistical costs.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. This term is crucial for B2B buyers, as it allows them to compare prices, negotiate terms, and secure the best deal for their needs.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for buyers importing 500-gallon drums from different countries. Familiarity with these terms helps avoid misunderstandings and ensures compliance with trade regulations.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is critical for effective supply chain management, particularly for businesses that rely on timely availability of drums for production or storage needs.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the 500 gallon drum Sector

What Are the Key Market Dynamics and Trends Influencing the 500 Gallon Drum Sector?

The global market for 500-gallon drums is witnessing robust growth driven by several factors. Increased demand for bulk liquid storage across various industries, such as agriculture, chemicals, and food and beverage, is propelling the sector forward. The rising focus on sustainable practices is also shaping purchasing decisions, pushing buyers toward eco-friendly materials and designs. Furthermore, technological advancements in manufacturing processes, such as automated production and improved material science, are leading to higher quality and more durable products.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Countries such as Brazil and Saudi Arabia have specific import regulations that can impact sourcing strategies. Additionally, emerging trends like the adoption of smart technologies—such as IoT-enabled drums for real-time monitoring—are becoming increasingly relevant, especially for buyers looking to optimize inventory management and enhance operational efficiency.

How Is Sustainability and Ethical Sourcing Impacting the 500 Gallon Drum Sector?

Sustainability is no longer just a buzzword; it has become a critical component of the supply chain in the 500-gallon drum sector. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental stewardship. This includes sourcing materials that are recyclable or made from post-consumer waste, as well as ensuring that the production processes minimize carbon footprints.

Ethical supply chains are essential for maintaining brand reputation, particularly in markets sensitive to environmental concerns. Buyers should look for certifications such as ISO 14001 (Environmental Management) and NSF certification for food-grade materials, which can serve as indicators of a supplier’s commitment to sustainable practices. By choosing suppliers with these credentials, B2B buyers can align their sourcing strategies with their corporate social responsibility goals, thus enhancing their market positioning.

What Is the Historical Context and Evolution of the 500 Gallon Drum?

The 500-gallon drum has evolved significantly since its inception, originally designed for the storage and transportation of liquids in industrial settings. Early versions were primarily made of metal, which provided durability but often lacked the versatility required for various applications. The introduction of plastic and composite materials has revolutionized the sector, allowing for lightweight, corrosion-resistant options that are easier to handle and more cost-effective.

Over the decades, the drum design has also adapted to meet changing regulatory requirements and industry standards, particularly regarding safety and environmental protection. Today, the 500-gallon drum is not only a staple in industrial applications but also plays a crucial role in emergency response scenarios, such as firefighting and disaster relief, illustrating its ongoing relevance in diverse sectors.

In conclusion, the 500-gallon drum sector is characterized by a dynamic interplay of market trends, sustainability imperatives, and historical evolution. For international B2B buyers, understanding these factors is essential for making informed sourcing decisions that align with both operational needs and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of 500 gallon drum

1. How do I choose the right 500-gallon drum for my needs?

Selecting the appropriate 500-gallon drum depends on your specific application. Consider factors such as material (plastic, metal, or composite), design (vertical, cone bottom, or folding frame), and intended use (water storage, chemical containment, or emergency response). Assess whether you need food-grade materials for potable water or specialized linings for chemicals. Additionally, evaluate the tank’s dimensions, weight capacity, and any custom requirements you may have. Consult with suppliers to ensure the drum meets your operational and regulatory standards.

2. What are the key considerations when sourcing 500-gallon drums internationally?

When sourcing 500-gallon drums from international suppliers, focus on quality assurance, compliance with local regulations, and supplier reliability. Research potential vendors by checking their certifications, reviews, and industry reputation. Understand the logistics involved, including shipping costs, import duties, and delivery timelines. It’s vital to establish clear communication regarding product specifications, payment terms, and return policies to avoid misunderstandings.

3. What customization options are available for 500-gallon drums?

Many manufacturers offer customization options for 500-gallon drums, including specific sizes, materials, colors, and fittings. You can request modifications like additional reinforcement for heavy-duty applications or custom labels for branding. Always verify if the supplier can accommodate your requests and inquire about lead times for custom orders. Ensure that any customizations comply with relevant safety and industry standards.

4. What is the minimum order quantity (MOQ) for 500-gallon drums?

Minimum order quantities for 500-gallon drums vary by supplier and may depend on the type of drum and material. Some suppliers may have an MOQ of one unit for standard products, while others might require larger orders for custom designs or specific materials. It’s important to discuss your purchasing needs with potential suppliers to negotiate favorable terms, especially if you are testing a new market or product line.

5. What payment terms should I expect when purchasing 500-gallon drums?

Payment terms can vary widely among suppliers. Common terms include upfront payment, partial payment upon order confirmation, or net payment options (e.g., net 30 or net 60 days). Some suppliers may also offer financing options or discounts for bulk purchases. Always clarify payment terms before finalizing your order to ensure that they align with your budget and cash flow needs.

6. How can I ensure the quality of 500-gallon drums before purchase?

To ensure quality, request samples from potential suppliers to inspect the material and construction. Review certifications such as ISO or NSF to verify compliance with industry standards. Additionally, inquire about the supplier’s quality control processes and warranty policies. Conducting due diligence, including visiting the manufacturing facility if feasible, can provide further assurance of product quality.

7. What are the logistics considerations for importing 500-gallon drums?

Logistics for importing 500-gallon drums include selecting a reliable shipping method, understanding customs regulations, and calculating shipping costs. Determine whether you need full container loads or less than container load (LCL) shipping. Be aware of potential tariffs and taxes that may apply upon importation. Partnering with a freight forwarder experienced in handling industrial goods can streamline the process and reduce potential delays.

8. How do I handle potential disputes with suppliers?

Handling disputes with suppliers requires clear communication and a well-defined contract. Establish terms regarding product specifications, delivery timelines, and payment to prevent misunderstandings. If a dispute arises, attempt to resolve it amicably through direct negotiation. If necessary, refer to any contractual agreements regarding dispute resolution methods, such as mediation or arbitration, to find a fair solution. Keeping thorough documentation of all communications can support your case if escalation is needed.

Top 5 500 Gallon Drum Manufacturers & Suppliers List

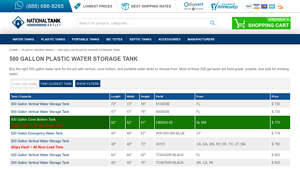

1. NTO Tank – 500 Gallon Plastic Water Storage Tank

Domain: ntotank.com

Registered: 2006 (19 years)

Introduction: 500 Gallon Plastic Water Storage Tank

– Types: Vertical, Cone Bottom, Portable

– Food-grade, potable, safe for drinking water

– Various dimensions and prices:

– 500 Gallon Vertical Water Storage Tank: 72″ L x 72″ W x 38″ H, Price: $730

– 500 Gallon Vertical Water Storage Tank: 47″ L x 47″ W x 78″ H, Price: $730

– 500 Gallon Cone Bottom Tank: 52″ L x 52″ W x 81″ H, Price: $770

– 500 Gallon …

2. McMaster – 500 Gallon Drums

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – 500 Gallon Drums, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

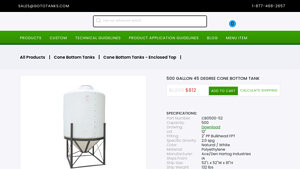

3. Ace – 500 Gallon Cone Bottom Tank

Domain: gototanks.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “500 Gallon 45 Degree Cone Bottom Tank”, “Part Number”: “CB0500-52”, “Capacity”: “500 gallons”, “Lid Size”: “12 inch”, “Fitting”: “2 inch PP Bulkhead FPT”, “Specific Gravity”: “2.0 spg”, “Color”: “Natural / White”, “Material”: “Food Grade Polyethylene”, “Manufacturer”: “Ace/Den Hartog Industries”, “Shipping Information”: {“Ships From”: “IA”, “Ship Size”: “52’L x 52’W x 81’H”, “Shi…

4. Bushman – 500 Gallon Water Storage Tank

Domain: bushmanusa.com

Registered: 2006 (19 years)

Introduction: {“product_name”: “500 Gallon Water Storage Tank”, “type”: “Plastic Water Tank”, “dimensions”: {“diameter”: “48 inches”, “height”: “71 inches”}, “features”: {“vented_lid”: “16 inches”, “inlet_fitting”: “1.5 inch Polypropylene Bulkhead Fitting”, “outlet_fitting”: “2 inch Polypropylene Bulkhead Fitting”, “material”: “High-Density Polyethylene (HDPE)”, “food_safe”: true, “UV_protected”: true, “color_o…

5. Snyder – 500 Gallon HDPE Tank

Domain: shop.snydernet.com

Registered: 1998 (27 years)

Introduction: {“SKU”:”1400100W94303″,”Brand”:”Snyder”,”Capacity”:”500 Gallons”,”Diameter”:”48 in”,”Height”:”53 in”,”Weight”:”154 lb”,”Material”:”High Density Polyethylene (HDPE)”,”Color”:”Natural”,”Bottom Fitting”:”2in BH”,”Lid/Manway”:”18in Manway”,”Specific Gravity”:”1.0 (Water Only)”,”Applications”:[“Above ground storage of potable or non-potable water”,”Rainwater collection storage tank”,”Fire-protection wa…

Strategic Sourcing Conclusion and Outlook for 500 gallon drum

How Can Effective Strategic Sourcing Enhance Your Supply Chain for 500 Gallon Drums?

In conclusion, strategic sourcing of 500-gallon drums is essential for international B2B buyers aiming to optimize their supply chains. Key takeaways include understanding the diverse applications and specifications of these drums, from water storage to containment solutions, which can significantly impact operational efficiency and compliance. By leveraging competitive pricing, ensuring product quality, and considering logistical advantages, businesses can enhance their procurement strategies.

Moreover, international buyers must navigate regional regulations and market demands, particularly in emerging economies across Africa, South America, the Middle East, and Europe. Establishing relationships with reliable suppliers who offer customizable solutions can provide a strategic edge in this competitive landscape.

Looking ahead, as global markets continue to evolve, the demand for versatile and durable 500-gallon drums will rise. Now is the time for B2B buyers to engage proactively in sourcing strategies that not only meet their current needs but also anticipate future challenges. Connect with trusted suppliers to secure your supply chain and ensure that your business is prepared for the growing demands of your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.