A B2B Buyer’s Guide to 3 Pin Plug: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for 3 pin plug

In today’s interconnected world, sourcing reliable 3-pin plugs can pose significant challenges for international B2B buyers. From ensuring compliance with local safety standards to navigating varying voltage requirements, the complexity of the global market requires a comprehensive approach. This guide is designed to empower businesses in Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—by providing insights into the diverse types of 3-pin plugs, their applications across different sectors, and strategies for effective supplier vetting.

Within these pages, you will discover an in-depth analysis of the various 3-pin plug configurations available, including their suitability for different electrical devices and environments. We delve into the critical aspects of cost considerations, helping you balance quality with budget constraints. Additionally, we outline best practices for evaluating potential suppliers, ensuring that your partnerships are built on reliability and compliance with global standards.

By the end of this guide, you will be equipped with the knowledge to make informed purchasing decisions that not only meet your operational needs but also align with regulatory requirements. Whether you are looking to source for industrial applications or consumer electronics, this resource is your roadmap to navigating the intricate landscape of 3-pin plug procurement.

Understanding 3 pin plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type G (UK Plug) | Rectangular pins, fuse protection | Appliances, IT equipment, medical devices | Pros: High safety standards; Cons: Bulkier design may limit compatibility. |

| Type I (Australian Plug) | Flat angled pins, often includes a switch | Industrial machinery, consumer electronics | Pros: Versatile use; Cons: Limited availability outside Australia. |

| Type N (Brazilian Plug) | Round pins, compact size, safety features | Home appliances, power tools | Pros: Compact and lightweight; Cons: Compatibility issues in other regions. |

| Type B (NEMA 5-15) | Flat parallel pins with a grounding pin | North American appliances, office equipment | Pros: Widely used and easily available; Cons: Less robust than other types. |

| Type C (Europlug) | Two round pins, no grounding | Lightweight devices, travel adapters | Pros: Universally compatible; Cons: Not suitable for high-power appliances. |

What Are the Key Characteristics of Type G (UK Plug)?

Type G plugs are characterized by their rectangular pins and built-in fuse protection, making them one of the safest plug types available. They are commonly used in appliances, IT equipment, and medical devices across the UK and other regions. For B2B buyers, the safety features and robust design are significant advantages. However, the bulkier size may limit compatibility with certain sockets, which can be a consideration for international procurement.

Why Choose Type I (Australian Plug) for Industrial Applications?

The Type I plug features flat, angled pins and often includes an integrated switch for added convenience. It is widely used in industrial machinery and consumer electronics, making it a versatile option for B2B applications. Buyers appreciate its reliability, although its limited availability outside Australia can pose challenges for global sourcing. Understanding local standards is crucial for ensuring compatibility in international markets.

What Makes Type N (Brazilian Plug) Suitable for Home Appliances?

Type N plugs are distinguished by their round pins and compact design, which often includes safety features like grounding. They are primarily used in home appliances and power tools in Brazil. B2B buyers may find their compact size advantageous for space-constrained applications. However, compatibility issues may arise when attempting to use them in other regions, making it essential to consider the target market’s plug standards.

How Does Type B (NEMA 5-15) Stand Out in the North American Market?

The Type B plug, with its flat parallel pins and grounding pin, is commonly used in North American appliances and office equipment. Its widespread use and availability make it an attractive option for B2B buyers. While it is generally reliable, some may find it less robust compared to other plug types. Understanding local electrical standards is vital for ensuring compliance and safety in product design.

Why Is Type C (Europlug) Popular for Lightweight Devices?

Type C plugs, known for their two round pins and lack of grounding, are favored for lightweight devices and travel adapters. Their universal compatibility across many European and Asian countries makes them a go-to choice for B2B buyers looking to serve diverse markets. However, they are not suitable for high-power appliances, which limits their application scope. Buyers should consider the specific power requirements of their devices when opting for this plug type.

Key Industrial Applications of 3 pin plug

| Industry/Sector | Specific Application of 3 Pin Plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power tools and machinery | Ensures reliable power supply for operational efficiency | Compliance with local electrical safety standards, durability under heavy use, and temperature tolerance. |

| Healthcare | Medical equipment | Guarantees safety and reliability in patient care | Must meet stringent medical device regulations and certifications, including biocompatibility and EMI shielding. |

| Information Technology | Desktops and server equipment | Supports high-performance computing needs | Compatibility with global electrical standards, customization options for cable lengths and designs. |

| Consumer Electronics | Home appliances (e.g., refrigerators) | Enhances energy efficiency and safety | Energy efficiency ratings, compliance with international safety standards, and ease of installation. |

| Construction | Temporary power supply for construction sites | Provides safe and efficient power distribution | Weather resistance, rugged design for outdoor use, and ability to withstand physical stress. |

How Are 3 Pin Plugs Used in Manufacturing?

In the manufacturing sector, 3 pin plugs are essential for connecting power tools and heavy machinery to power sources. These plugs ensure a reliable power supply, which is crucial for maintaining operational efficiency and minimizing downtime. Buyers in this sector need to consider compliance with local electrical safety standards, as well as the durability of the plugs to withstand heavy use and extreme temperatures. Additionally, sourcing plugs with robust insulation can help prevent electrical hazards in a demanding industrial environment.

What Role Do 3 Pin Plugs Play in Healthcare Applications?

3 pin plugs are vital in healthcare settings for connecting various medical equipment, such as diagnostic machines and patient monitoring systems. The reliability and safety of these plugs directly impact patient care, making it essential for healthcare providers to source plugs that meet stringent medical device regulations. Buyers should prioritize products with certifications for biocompatibility and electromagnetic interference (EMI) shielding to ensure safe operation within sensitive medical environments.

How Are 3 Pin Plugs Utilized in Information Technology?

In the IT sector, 3 pin plugs are commonly used to connect desktops, servers, and other electronic devices to power sources. These plugs support high-performance computing needs, ensuring that equipment operates effectively without interruptions. For international buyers, compatibility with global electrical standards is crucial. Additionally, customization options for cable lengths and designs can help businesses tailor solutions to their specific infrastructure needs.

What Are the Benefits of 3 Pin Plugs in Consumer Electronics?

In the consumer electronics market, 3 pin plugs are widely used in household appliances like refrigerators and washing machines. These plugs enhance energy efficiency, contributing to lower electricity costs while ensuring safety during operation. Buyers should look for plugs that carry energy efficiency ratings and comply with international safety standards. Ease of installation is also a critical factor, as it can significantly affect the overall user experience and operational reliability.

How Do 3 Pin Plugs Support Construction Projects?

On construction sites, 3 pin plugs are used for temporary power supply setups to run tools and equipment. They provide a safe and efficient method for distributing power in challenging environments. When sourcing these plugs, it is important to consider their weather resistance and rugged design, which enable them to withstand physical stress and outdoor conditions. Ensuring that the plugs meet safety regulations is also vital to prevent electrical hazards in dynamic construction settings.

3 Common User Pain Points for ‘3 pin plug’ & Their Solutions

Scenario 1: Sourcing Quality and Compliant 3 Pin Plugs for Export

The Problem:

B2B buyers, especially those operating in international markets like Africa and South America, often struggle with sourcing 3 pin plugs that meet both local and international safety standards. This is particularly challenging when they need to ensure that the plugs are compliant with the regulations of multiple countries. Non-compliance can result in costly delays, product recalls, or even legal repercussions. Furthermore, the buyers face difficulties in verifying the quality and authenticity of products from various manufacturers, leading to concerns about reliability and safety.

The Solution:

To effectively source quality 3 pin plugs, B2B buyers should prioritize working with reputable manufacturers who provide clear documentation of compliance with international safety standards, such as IEC or local standards specific to their markets. Buyers should request samples and certifications before making bulk purchases. Additionally, leveraging the services of third-party inspection agencies can help verify product quality and compliance. Creating long-term relationships with a select few trusted suppliers can also streamline the sourcing process, ensuring consistent quality and compliance across shipments. Utilizing platforms that specialize in B2B connections can provide buyers with reviews and ratings of manufacturers, aiding in informed decision-making.

Scenario 2: Managing Inventory and Supply Chain Challenges

The Problem:

Another common pain point for B2B buyers dealing with 3 pin plugs is inventory management and supply chain disruptions. Fluctuations in demand can lead to overstocking or stockouts, both of which can be detrimental to business operations. Additionally, global supply chain issues, such as shipping delays or increased freight costs, can impact the timely availability of 3 pin plugs, affecting production schedules and customer satisfaction.

The Solution:

To mitigate inventory and supply chain challenges, B2B buyers should implement a robust inventory management system that incorporates demand forecasting tools. Utilizing data analytics can help predict market trends and adjust orders accordingly. Establishing partnerships with multiple suppliers can provide alternatives in case of disruptions, ensuring a steady supply of 3 pin plugs. Buyers should also consider just-in-time (JIT) inventory practices to reduce holding costs while maintaining flexibility in their supply chain. Regular communication with suppliers can facilitate better planning and responsiveness to market changes, ultimately leading to more efficient inventory management.

Scenario 3: Ensuring Compatibility with Diverse Electrical Standards

The Problem:

B2B buyers often encounter compatibility issues when integrating 3 pin plugs into various electrical systems, particularly when their products are intended for global markets. Different countries have distinct electrical standards and plug types, which can result in additional costs for adapters or redesigns if not addressed early in the product development process. This challenge can delay product launches and create barriers to market entry.

The Solution:

To ensure compatibility with diverse electrical standards, B2B buyers should conduct thorough market research to understand the specific requirements of each target market. Selecting 3 pin plugs that are versatile—such as those with interchangeable heads or multi-standard compliance—can help address this issue. Collaborating with design engineers during the product development phase to incorporate universal plug designs can also reduce the need for future modifications. Additionally, buyers should maintain close relationships with local distributors and electrical engineers who can provide insights into regional standards, facilitating smoother market entry and customer satisfaction.

Strategic Material Selection Guide for 3 pin plug

What Are the Key Materials Used in 3 Pin Plugs?

When selecting materials for 3 pin plugs, it is essential to consider their properties, advantages, disadvantages, and suitability for various applications. This guide analyzes four common materials used in the manufacturing of 3 pin plugs: thermoplastic, thermoset rubber, PVC, and metal. Each material has distinct characteristics that influence performance, durability, and compliance with international standards.

How Does Thermoplastic Perform in 3 Pin Plug Applications?

Thermoplastic materials, such as nylon and polycarbonate, are widely used in 3 pin plugs due to their excellent electrical insulation properties and resistance to impact. These materials can typically withstand temperatures ranging from -40°C to 120°C, making them suitable for various environments.

Pros: Thermoplastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for versatile design options. They also offer good chemical resistance, which is crucial for applications exposed to various substances.

Cons: While thermoplastics are durable, they may not perform well under extreme temperatures or prolonged exposure to UV light, leading to degradation over time.

Impact on Application: Thermoplastics are compatible with a wide range of electrical devices, making them ideal for consumer electronics and household appliances.

Considerations for International Buyers: Compliance with standards such as IEC 60884-1 is essential, especially in regions like Europe and the Middle East, where safety regulations are stringent.

What Advantages Do Thermoset Rubber Materials Offer?

Thermoset rubber, such as silicone or EPDM (ethylene propylene diene monomer), is another popular choice for 3 pin plugs. These materials are known for their high elasticity and excellent thermal stability, withstanding temperatures between -60°C and 200°C.

Pros: Thermoset rubber provides superior durability and resistance to wear, making it ideal for heavy-duty applications. It also offers excellent insulation properties and is highly resistant to moisture and chemicals.

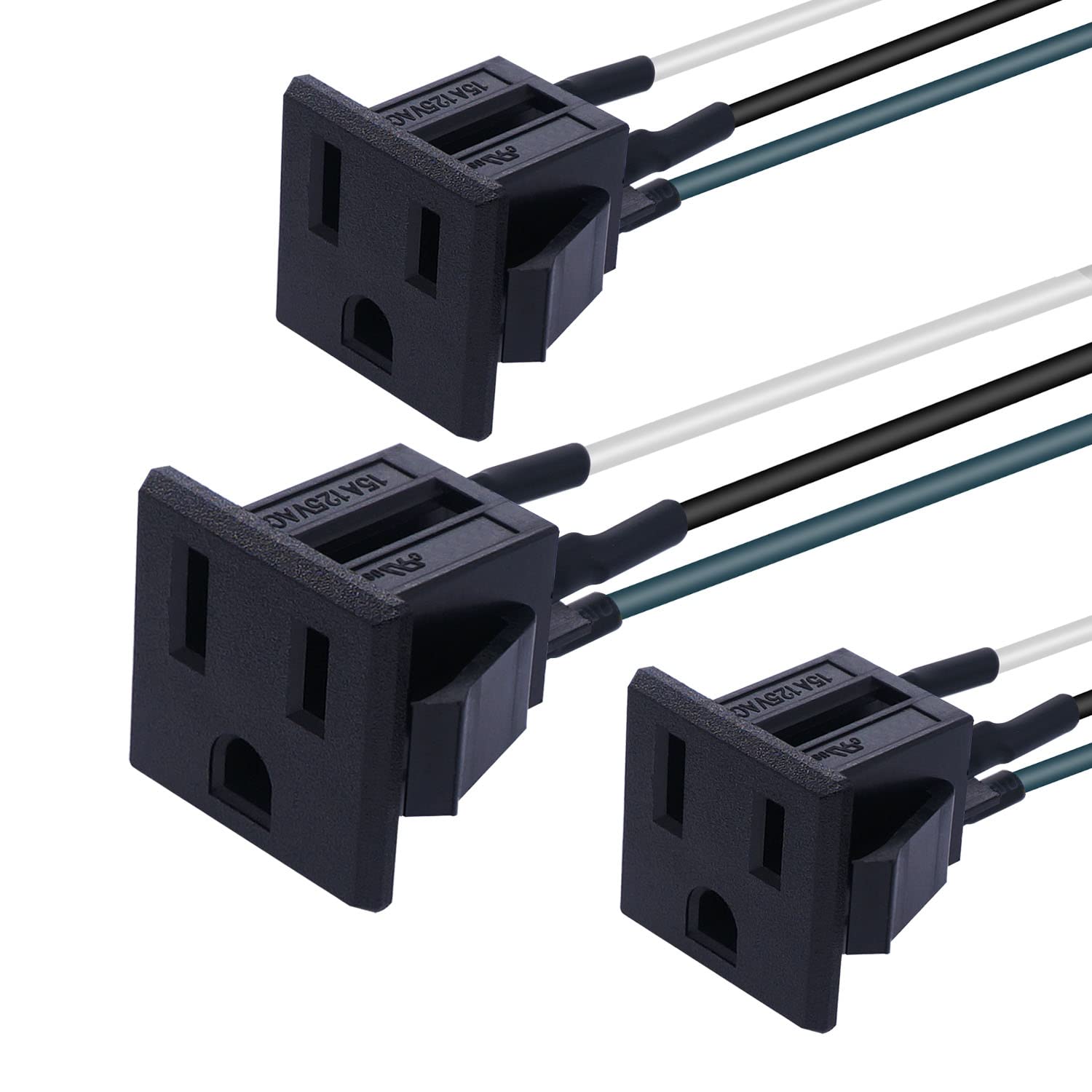

Illustrative image related to 3 pin plug

Cons: The manufacturing process for thermoset rubber can be more complex and expensive compared to thermoplastics. Additionally, it may not be suitable for applications requiring frequent disassembly.

Impact on Application: These materials are particularly useful in industrial settings where plugs may be subjected to harsh conditions, such as extreme temperatures or exposure to chemicals.

Considerations for International Buyers: Buyers should ensure compliance with local safety standards, such as ASTM D2000 or EN 45545, especially in regions like Africa and South America, where regulations may vary.

Why is PVC a Common Choice for 3 Pin Plugs?

Polyvinyl chloride (PVC) is commonly used in the production of 3 pin plugs due to its low cost and versatility. PVC can withstand temperatures from -10°C to 70°C and offers decent electrical insulation.

Pros: PVC is widely available and cost-effective, making it an attractive option for manufacturers. It is also resistant to corrosion and has a good balance of flexibility and rigidity.

Cons: However, PVC is less durable than other materials and can become brittle over time, especially when exposed to UV light. Its combustion can release harmful toxins, raising environmental concerns.

Impact on Application: PVC is suitable for low to medium-duty applications, such as household appliances and light industrial use.

Considerations for International Buyers: Compliance with environmental regulations, such as RoHS (Restriction of Hazardous Substances), is crucial, particularly in Europe and Germany, where sustainability is prioritized.

What Role Do Metals Play in 3 Pin Plug Construction?

Metal components, typically copper or brass, are essential for the conductive pins of 3 pin plugs. These materials offer excellent electrical conductivity and mechanical strength.

Pros: Metals provide reliable electrical connections and are resistant to corrosion when properly plated. They can handle high current loads, making them suitable for heavy-duty applications.

Cons: The primary drawback of metals is their susceptibility to oxidation, which can affect conductivity over time. Additionally, they can be more expensive compared to plastic materials.

Impact on Application: Metal pins are essential in applications requiring high power, such as industrial machinery and high-performance electrical devices.

Considerations for International Buyers: Buyers should ensure that metal components meet international standards, such as IEC 60947, particularly in regions with strict electrical safety requirements.

Summary Table of Material Selection for 3 Pin Plugs

| Material | Typical Use Case for 3 Pin Plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Consumer electronics, household appliances | Lightweight, cost-effective | May degrade under extreme conditions | Low |

| Thermoset Rubber | Industrial applications | Superior durability and thermal stability | Complex manufacturing process | High |

| PVC | Household appliances, light industrial use | Cost-effective and widely available | Less durable, environmental concerns | Low |

| Metal | Heavy-duty applications | Excellent conductivity and strength | Susceptible to oxidation | Medium |

This strategic material selection guide provides valuable insights for B2B buyers, enabling them to make informed decisions based on performance, compliance, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 pin plug

What Are the Main Stages in the Manufacturing Process of 3 Pin Plugs?

The manufacturing process of 3 pin plugs involves several critical stages, each essential for ensuring quality and compliance with international standards.

-

Material Preparation: The first step in the manufacturing process involves selecting high-quality raw materials. Typically, 3 pin plugs are made from thermoplastic or rubber materials that provide durability and electrical insulation. Manufacturers often source virgin copper for the electrical conductors, ensuring optimal conductivity and safety. Prior to usage, these materials undergo rigorous quality checks to confirm they meet specified industry standards.

-

Forming: In this stage, the prepared materials are molded into the desired shapes. For thermoplastic plugs, injection molding is commonly used, where heated plastic is injected into molds to form the plug housing and pins. This method allows for high precision and repeatability, ensuring uniformity across batches. For rubber plugs, compression molding may be utilized, which involves pressing heated rubber into a mold to achieve the necessary shape.

-

Assembly: After the individual components are formed, they are assembled. This includes inserting the pins into the plug body and connecting the wires to the electrical contacts. Automated assembly lines are often employed to enhance efficiency, but manual assembly may also be necessary for complex designs. During assembly, manufacturers ensure that all components fit correctly and securely to prevent electrical failures.

-

Finishing: The final stage involves applying surface treatments and inspections. This may include adding protective coatings, branding, or labels. Finishing processes also involve trimming excess materials, polishing surfaces, and conducting visual inspections to ensure aesthetic quality.

What Quality Control Measures Are Used in Manufacturing 3 Pin Plugs?

Quality control (QC) is a crucial aspect of the manufacturing process for 3 pin plugs, ensuring that products meet safety and performance standards.

Illustrative image related to 3 pin plug

-

International Standards and Certifications: Manufacturers of 3 pin plugs must comply with various international standards, such as ISO 9001 for quality management systems. Additionally, specific safety certifications like CE marking in Europe, UL certification in the United States, and IEC standards globally are essential. These certifications not only enhance product credibility but also ensure compliance with regional regulations.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This is the initial checkpoint where raw materials are inspected upon arrival. Tests are conducted to confirm that materials meet predefined specifications before they are used in production.

– In-Process Quality Control (IPQC): During the manufacturing process, various inspections are performed to monitor the assembly and molding processes. This includes checking for dimensional accuracy and verifying that assembly procedures are followed correctly.

– Final Quality Control (FQC): Once the plugs are fully assembled, they undergo final inspections. This stage includes electrical testing, visual inspections for defects, and functional testing to ensure the plugs perform as expected under load. -

Common Testing Methods: Manufacturers employ several testing methods to ensure quality. These may include:

– Electrical Testing: To check for continuity, insulation resistance, and load capacity.

– Mechanical Testing: To assess durability under stress and strain, simulating real-world conditions.

– Environmental Testing: Evaluating the plug’s performance under extreme temperatures and humidity levels.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability.

-

Supplier Audits: Conducting supplier audits is one of the most effective ways to assess a manufacturer’s QC capabilities. These audits can be performed on-site or remotely and should focus on the supplier’s adherence to quality standards, documentation practices, and production processes.

-

Quality Reports: Requesting quality reports from suppliers can provide insights into their QC performance. These reports typically include information about testing results, certifications, and any non-conformance incidents. A transparent supplier will readily provide these documents.

-

Third-party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct random inspections of production batches, ensuring compliance with agreed-upon specifications and standards.

-

Certifications and Compliance: Buyers should verify that suppliers possess the necessary certifications and are compliant with international standards. This may involve checking the validity of certifications and understanding the scope of compliance, especially concerning safety and environmental regulations.

What Are the Nuances of Quality Control for International Buyers?

International buyers must navigate several nuances in quality control when sourcing 3 pin plugs from different regions.

-

Regulatory Compliance: Different countries have varying regulations regarding electrical safety and product standards. Buyers must ensure that the products they import comply with local regulations in their respective markets. This may involve additional testing or certification processes.

-

Cultural Differences: Quality perceptions can vary significantly between regions. Understanding local manufacturing practices and cultural attitudes toward quality can help buyers set realistic expectations and foster better supplier relationships.

-

Logistical Challenges: International shipping can introduce risks that may affect product quality. Buyers should discuss with suppliers how they handle logistics and what measures are in place to protect products during transport. This includes packaging standards and handling procedures.

-

Long-term Relationships: Building long-term relationships with reliable suppliers can lead to improved quality control and consistency over time. Establishing communication channels and feedback mechanisms is essential for continuous improvement.

In conclusion, understanding the manufacturing processes and quality assurance protocols for 3 pin plugs is vital for B2B buyers looking to ensure product reliability and compliance. By prioritizing quality control, engaging in thorough supplier verification, and remaining aware of international nuances, buyers can make informed decisions that support their operational needs.

Illustrative image related to 3 pin plug

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 pin plug’

Introduction

Navigating the procurement of 3-pin plugs requires a structured approach to ensure you meet your technical, safety, and regulatory needs. This guide offers a practical checklist designed for B2B buyers, focusing on essential steps to source 3-pin plugs effectively while aligning with international standards, especially for markets in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the 3-pin plugs you intend to procure. Consider factors such as voltage rating, current capacity, and pin configuration. Clearly defined specifications help in narrowing down suppliers who can meet your precise needs and ensure compatibility with your equipment.

- Voltage and current ratings must align with your application’s requirements.

- Pin configuration should match the devices for which the plugs will be used.

Step 2: ✅ Verify Compliance with Safety Standards

Ensure that the plugs meet international safety standards relevant to your market, such as IEC, UL, or local certifications. Compliance is critical not only for legal reasons but also to guarantee the safety and reliability of the products you are sourcing.

- Request documentation proving compliance with applicable safety standards.

- Consider certifications that are recognized in your target market.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product catalogs, and case studies showcasing their experience with similar products. Engaging with references from existing customers can provide insights into the supplier’s reliability and quality.

- Look for suppliers with a strong track record in the electrical components industry.

- Consider their manufacturing capabilities and quality control processes.

Step 4: ✅ Assess Product Quality and Materials

Investigate the materials used in the manufacturing of the 3-pin plugs. High-quality materials contribute to durability and performance, which is essential for long-term use in various environments.

Illustrative image related to 3 pin plug

- Check for plugs made from robust thermoplastic or rubber materials.

- Ensure that the plugs are designed for the intended application, whether for indoor, outdoor, or heavy-duty use.

Step 5: Understand Pricing and Payment Terms

Request quotes from multiple suppliers to compare pricing structures. Beyond the base price, consider total cost implications, including shipping, tariffs, and payment terms. Understanding these elements upfront can prevent unexpected costs later in the procurement process.

- Look for bulk pricing options if you plan to purchase large quantities.

- Clarify payment terms, including deposit requirements and credit options.

Step 6: ✅ Plan for Logistics and Delivery

Coordinate logistics by discussing shipping options, delivery timelines, and potential customs issues with your chosen supplier. Efficient logistics planning is crucial, especially when dealing with international suppliers, to ensure timely delivery of your products.

- Confirm the shipping methods available and estimated delivery times.

- Assess the supplier’s ability to handle customs clearance in your region.

Step 7: ✅ Establish a Quality Assurance Process

Once you finalize your supplier, set up a quality assurance process to ensure that the products received meet your specifications and standards. This step is vital for maintaining product quality and addressing any discrepancies quickly.

Illustrative image related to 3 pin plug

- Define inspection criteria and testing methods for the received plugs.

- Maintain communication with the supplier for ongoing quality feedback.

By following this checklist, B2B buyers can ensure a streamlined and effective sourcing process for 3-pin plugs, ultimately leading to successful procurement and operational efficiency.

Comprehensive Cost and Pricing Analysis for 3 pin plug Sourcing

What Are the Key Cost Components in Sourcing 3 Pin Plugs?

When sourcing 3 pin plugs, understanding the cost structure is crucial for B2B buyers. The primary cost components typically include:

-

Materials: The choice of materials significantly affects pricing. Common materials include thermoplastics and rubber, with variations in quality influencing the overall cost. High-quality materials may offer better durability and performance but come at a premium.

-

Labor: Labor costs can vary widely based on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can also lead to variations in product quality.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing practices can help reduce overhead, positively impacting the final price.

-

Tooling: Custom tooling for specific designs can add to upfront costs. However, investing in the right tooling can lead to cost savings in mass production.

-

Quality Control (QC): Stringent QC processes ensure product reliability and safety, especially for electrical components. While this may increase initial costs, it often results in lower warranty claims and returns.

-

Logistics: Shipping costs, including freight and handling, play a significant role in total sourcing costs. Consideration of Incoterms is essential to understand who bears these costs.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. This margin can vary based on the supplier’s market positioning and the competitiveness of the product.

How Do Price Influencers Affect the Sourcing of 3 Pin Plugs?

Several factors can influence the pricing of 3 pin plugs, particularly in international B2B transactions:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often yield lower unit prices. Understanding the supplier’s MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Custom designs or specific electrical certifications can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., CE, UL) can lead to increased costs. Buyers should assess whether the added expense aligns with their quality requirements.

-

Supplier Factors: Supplier reputation, reliability, and their manufacturing capabilities can impact pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: The choice of Incoterms affects cost allocation between buyer and seller. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost analysis.

What Are the Best Tips for Negotiating 3 Pin Plug Prices?

B2B buyers can adopt several strategies to ensure cost-efficiency when sourcing 3 pin plugs:

-

Negotiate for Better Terms: Leverage bulk purchasing power to negotiate better prices or favorable payment terms. Building long-term relationships with suppliers can also lead to discounts over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the long-term costs associated with maintenance, warranty, and potential replacements. This holistic view can lead to better decision-making.

-

Be Aware of Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and trade agreements can impact overall costs. Buyers from regions like Africa, South America, and the Middle East should be particularly attentive to these factors.

-

Research Market Rates: Understanding the average market price for 3 pin plugs can equip buyers with the necessary information to negotiate effectively. Utilize online resources and industry reports for insights.

-

Evaluate Supplier Alternatives: Don’t hesitate to explore multiple suppliers. Comparing quotes and capabilities can reveal opportunities for cost savings and better service.

Disclaimer on Indicative Prices

Pricing for 3 pin plugs can vary based on numerous factors including market conditions, supplier negotiations, and material costs. The prices referenced (e.g., $3.00 to $7.50 for various plug types) serve as a guideline and may not reflect actual current market rates. Always conduct thorough market research and engage with suppliers directly for the most accurate pricing information tailored to specific needs.

Alternatives Analysis: Comparing 3 pin plug With Other Solutions

When evaluating power connection solutions, it’s crucial to consider the various alternatives available to the traditional 3 pin plug. Each alternative presents unique features, advantages, and limitations, making it essential for B2B buyers to understand these differences to make informed purchasing decisions.

| Comparison Aspect | 3 Pin Plug | Alternative 1: 2 Pin Plug | Alternative 2: Industrial Socket |

|---|---|---|---|

| Performance | Provides grounding, enhancing safety; supports high power loads. | Lacks grounding, suitable for low-power devices; may pose safety risks. | Designed for heavy-duty applications; can handle high current and voltage. |

| Cost | Generally affordable, with prices ranging from $3 to $7.50 per unit. | Typically lower cost, averaging around $2 to $5. | Higher initial investment, often $20 or more per unit, due to robust construction. |

| Ease of Implementation | Simple installation, compatible with standard outlets. | Easy to use and install; however, may require adapters for grounding. | More complex installation; often requires professional assistance. |

| Maintenance | Minimal maintenance required, durable and long-lasting. | Generally low maintenance, but prone to wear if overused. | Requires periodic inspection and maintenance due to heavy-duty use. |

| Best Use Case | Ideal for household and office appliances that require grounding. | Best for lightweight devices, such as lamps and chargers. | Suitable for industrial equipment, machinery, and high-power applications. |

What Are the Advantages and Disadvantages of Using a 2 Pin Plug as an Alternative?

The 2 pin plug is a popular alternative primarily used for low-power devices. Its main advantage is cost-effectiveness, making it an attractive option for buyers looking to minimize expenses. However, the absence of a grounding pin raises safety concerns, particularly when used with high-power appliances. While it is easy to install and widely compatible, reliance on adapters for grounding can complicate its use in certain environments.

Why Consider Industrial Sockets Over 3 Pin Plugs?

Industrial sockets are designed for heavy-duty applications, accommodating high current and voltage loads. They are robust and reliable, making them ideal for industrial settings where equipment operates under demanding conditions. However, their installation can be more complex and costly, often requiring professional expertise. While they provide excellent performance for heavy machinery, they may not be suitable for general consumer applications due to their higher cost and specific use case.

Conclusion: How Should B2B Buyers Choose the Right Power Connection Solution?

When selecting the appropriate power connection solution, B2B buyers must evaluate their specific needs, including the type of devices to be powered, safety requirements, and budget constraints. The 3 pin plug is a versatile and safe option for most household and office applications. In contrast, the 2 pin plug can be a cost-effective choice for low-power devices, while industrial sockets are essential for high-demand environments. By carefully assessing these alternatives, buyers can make informed decisions that align with their operational requirements and safety standards.

Essential Technical Properties and Trade Terminology for 3 pin plug

What Are the Key Technical Properties of a 3 Pin Plug?

Understanding the essential technical specifications of a 3 pin plug is crucial for B2B buyers to ensure compliance, safety, and performance in various applications. Here are several critical specifications to consider:

-

Material Grade

The materials used in the construction of a 3 pin plug significantly affect its durability and safety. Common materials include thermoplastics and rubber. Thermoplastics are lightweight and resistant to heat, while rubber offers superior flexibility and resistance to environmental factors. Selecting the right material is essential for ensuring the plug can withstand its intended use, especially in harsh conditions. -

Current Rating

This specification indicates the maximum current that the plug can safely carry, typically measured in Amperes (A). For example, a 15A rating is common for heavy-duty plugs used in industrial settings. Understanding the current rating is vital for matching plugs to their applications, preventing overheating, and ensuring compliance with local electrical standards. -

Pin Configuration

The arrangement and shape of the pins are crucial for compatibility with sockets and for ensuring proper grounding. The standard configuration involves three pins: live, neutral, and earth (ground). Different regions may have specific pin shapes and sizes, making it essential for international buyers to verify compatibility with local electrical systems. -

Fusing Mechanism

Some 3 pin plugs include a built-in fuse that provides an additional layer of safety by interrupting the electrical circuit in case of overload. This feature is particularly important in environments where electrical safety is paramount, such as healthcare or industrial applications. Understanding the fusing mechanism can aid in selecting plugs that offer enhanced protection against electrical faults. -

Temperature Tolerance

This specification refers to the range of temperatures that a plug can safely operate under without degrading. A higher temperature tolerance allows for use in more demanding environments. For B2B buyers, this property is critical for ensuring that the plug will function reliably in various climatic conditions. -

Insulation Type

Insulation materials can range from PVC to halogen-free options. Halogen-free materials are increasingly preferred for their environmental benefits and reduced toxicity in case of fire. Understanding the insulation type helps buyers choose plugs that align with sustainability goals and safety regulations.

What Are Common Trade Terms Associated with 3 Pin Plugs?

Familiarity with industry terminology can facilitate smoother transactions and better communication between suppliers and buyers. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality manufacturers and secure reliable products that meet specific requirements. -

MOQ (Minimum Order Quantity)

This term refers to the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory costs and negotiate better deals, especially when sourcing plugs in bulk for projects. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain price quotes for specific products. This process is essential for B2B buyers to compare prices, lead times, and terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms can help buyers negotiate better terms and understand their obligations in cross-border transactions. -

Lead Time

This refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for effective project planning and inventory management, particularly in industries with tight deadlines. -

Certification Standards

Certifications indicate that a product meets specific safety and quality standards. Common certifications for 3 pin plugs include UL (Underwriters Laboratories) and CE (Conformité Européenne). Knowing which certifications are necessary can help buyers ensure compliance with regulations and enhance product reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 3 pin plugs, ensuring that their selections meet both operational and safety standards.

Navigating Market Dynamics and Sourcing Trends in the 3 pin plug Sector

What Are the Key Trends Shaping the Global 3 Pin Plug Market?

The global 3 pin plug market is currently experiencing significant growth driven by several factors, including the rapid expansion of the electronics industry, increased demand for energy-efficient appliances, and the growing need for safe and reliable power solutions. International buyers, especially from regions like Africa, South America, the Middle East, and Europe, are particularly focused on sourcing high-quality products that comply with local safety standards. Emerging trends include the integration of smart technology into electrical components, which allows for enhanced functionality and monitoring. Additionally, the rise of e-commerce platforms has transformed the sourcing landscape, enabling buyers to access a broader range of products and suppliers globally.

Another important trend is the shift towards customized solutions. Manufacturers are increasingly offering tailored plug designs to meet specific market requirements, including variations in voltage and amperage. This customization caters to diverse applications, from consumer electronics to industrial machinery, making it essential for B2B buyers to engage with suppliers who can provide flexible manufacturing capabilities. Furthermore, the emphasis on safety and reliability is driving the adoption of plugs that incorporate advanced materials and technologies, which can withstand harsh environmental conditions and reduce the risk of electrical failures.

How Is Sustainability Influencing the Sourcing of 3 Pin Plugs?

Sustainability is becoming a critical consideration for B2B buyers in the 3 pin plug sector. As environmental regulations tighten and consumer awareness increases, businesses are expected to adopt sustainable practices throughout their supply chains. This includes sourcing materials that minimize environmental impact, such as halogen-free plastics and recycled components. Buyers should prioritize suppliers who demonstrate a commitment to sustainability through certifications like ISO 14001, which indicates effective environmental management systems.

Moreover, ethical sourcing practices are gaining traction, with companies focusing on transparency and accountability in their supply chains. This involves ensuring that materials are sourced responsibly and that workers are treated fairly. For international buyers, aligning with suppliers who adhere to ethical labor practices can enhance brand reputation and foster trust among consumers. As sustainability becomes a differentiator in the marketplace, integrating green certifications and materials into sourcing strategies will not only meet regulatory requirements but also resonate with environmentally conscious customers.

Illustrative image related to 3 pin plug

What Is the Historical Context of 3 Pin Plugs Relevant to Today’s B2B Environment?

The evolution of the 3 pin plug can be traced back to the early 20th century, with the standardization of electrical connections aimed at improving safety and functionality. Initially designed for specific applications, the 3 pin plug has become ubiquitous across various sectors, including residential, commercial, and industrial environments. Historical advancements in electrical safety standards have led to the incorporation of features such as grounded connections, which minimize the risk of electric shock.

As the demand for electrical devices surged during the latter half of the 20th century, manufacturers focused on enhancing the design and materials used in plugs to meet the growing needs of consumers and businesses alike. Today, the focus has shifted towards integrating innovative technologies and sustainable practices in the manufacturing process. Understanding this historical context allows B2B buyers to appreciate the significant advancements that have shaped current product offerings and to make informed decisions about sourcing reliable, safe, and efficient electrical components.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 pin plug

-

How do I choose the right 3 pin plug for my equipment?

When selecting a 3 pin plug, consider the voltage and current ratings of your equipment. Ensure the plug complies with the safety standards applicable in your region, such as IEC standards in Europe or UL standards in the U.S. Evaluate the plug’s material—look for durable options like thermoplastic or heavy rubber for enhanced longevity. Additionally, if your equipment requires grounding, opt for plugs with a grounded design to ensure safety and prevent electrical hazards. -

What are the key safety standards for 3 pin plugs?

Safety standards for 3 pin plugs vary by region but often include certifications such as IEC 60884 for Europe, NEMA standards in the U.S., and SANS standards in South Africa. These certifications ensure that the plugs meet stringent safety, reliability, and performance criteria. Verify that your supplier can provide documentation for compliance with these standards to ensure your products meet local regulations and reduce liability risks. -

What customization options are available for 3 pin plugs?

Many manufacturers offer customization for 3 pin plugs, including variations in size, shape, material, and pin configuration. You can request specific features such as anti-tracking design, built-in fuses, or particular color coding to match your branding. Discuss your requirements with the supplier early in the negotiation process to understand the feasibility and costs associated with custom designs. -

What is the typical minimum order quantity (MOQ) for 3 pin plugs?

The MOQ for 3 pin plugs can vary significantly depending on the manufacturer and the complexity of the product. Generally, standard plugs may have an MOQ of 500 to 1,000 units, while custom designs may require larger orders, often starting at 1,500 to 5,000 units. Always clarify the MOQ with your supplier to ensure it aligns with your purchasing capacity and project timelines. -

What payment terms should I expect when sourcing 3 pin plugs?

Payment terms can differ based on the supplier’s policies and your negotiation strength. Common arrangements include a 30% upfront deposit with the remaining 70% due before shipping. Some suppliers may offer net 30 or net 60 terms for established buyers. It’s essential to discuss and agree on payment terms upfront to avoid any misunderstandings later in the procurement process. -

How can I vet suppliers of 3 pin plugs effectively?

To vet suppliers, start by checking their certifications and compliance with international safety standards. Look for reviews and testimonials from other B2B buyers to gauge reliability and product quality. Request samples to evaluate the plugs’ performance and durability. Additionally, consider their manufacturing capabilities, lead times, and customer service responsiveness to ensure they can meet your specific needs. -

What logistics considerations should I be aware of when importing 3 pin plugs?

When importing 3 pin plugs, consider shipping methods, customs duties, and import regulations for your specific country. Evaluate the supplier’s ability to provide proper documentation, such as certificates of origin and compliance, to facilitate smooth customs clearance. Additionally, factor in lead times for production and shipping to align with your inventory management needs and avoid stock shortages. -

What quality assurance practices should I expect from a reputable supplier?

A reputable supplier should implement rigorous quality assurance (QA) practices, including in-line testing during production, final inspections, and adherence to international quality standards like ISO 9001. Request information on their QA processes and certifications to ensure their products meet your specifications. Additionally, inquire about their return and warranty policies to protect your investment and ensure product reliability.

Top 7 3 Pin Plug Manufacturers & Suppliers List

1. Sundial Wire – 3-Prong Plugs

Domain: sundialwire.com

Registered: 2002 (23 years)

Introduction: 3-Prong Plugs:

– 3 PRONG, HEAVY RUBBER PLUG, Black – $4.00

– 3 PRONG, THERMOPLASTIC PLUG – $3.00

– FEMALE HEAVY-DUTY CONNECTOR for 3-PRONG PLUG, Black – $7.50

– FEMALE GROUNDED CONNECTOR for 3-PRONG PLUG, Black – $7.50

Note: All items are currently sold out.

2. Custom Connector Kits – 3-Pin Electrical Connectors

Domain: customconnectorkits.com

Registered: 2016 (9 years)

Introduction: This company, Custom Connector Kits – 3-Pin Electrical Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Volex – 2-Pin and 3-Pin Plugs

Domain: volex.com

Registered: 1993 (32 years)

Introduction: Volex is a leading manufacturer and supplier of 2-Pin and 3-Pin Plugs. The product portfolio includes a worldwide range of safety approvals for applicable plug types (A, B, C, D, E/F, G, H, I, J, K, L, M & N). Available in straight and angled versions, with options for flat and/or round pins, PVC or halogen-free overmould, standard or housing/anti-tracking types, insulated or non-insulated pins, f…

4. Deutsch – DT 3 Pin Plug Kit Solid Black

Domain: deutschconnectorstore.com

Registered: 2012 (13 years)

Introduction: {‘product_name’: ‘DT 3 Pin Plug Kit Solid Black’, ‘brand’: ‘Deutsch’, ‘item_number’: ‘DT3-N-BK-PLG’, ‘price_per_unit’: ‘$2.943’, ‘availability’: ‘560 Each In Stock’, ‘pricing_breaks’: [{‘quantity’: 1, ‘unit_price’: ‘$2.943’, ‘ext_price’: ‘$2.94’}, {‘quantity’: 10, ‘unit_price’: ‘$2.884’, ‘ext_price’: ‘$28.84’}, {‘quantity’: 25, ‘unit_price’: ‘$2.707’, ‘ext_price’: ‘$67.68’}, {‘quantity’: 50, ‘unit…

5. Reddit – USA to UK Plug Adapters

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: USA plug sockets can be 2 pin or 3 pin. The 3 pin sockets include two normal pins and one additional earth pin. UK appliances typically use an earth pin, so 3 pin adaptors may be more suitable for UK devices. However, not all US wall sockets may accommodate the 3 pin adaptors.

6. HowStuffWorks – Two-Pronged vs. Three-Pronged Plugs

Domain: electronics.howstuffworks.com

Registered: 1998 (27 years)

Introduction: The text discusses the differences between two-pronged and three-pronged plugs. Key details include: 1. Three-prong plugs provide protection against electric shock by grounding the appliance. 2. The left slot in a 120-volt outlet is ‘neutral’, the right is ‘hot’, and the round hole below is ‘ground’. 3. Appliances with metal casings typically use three-prong plugs for safety. 4. Cutting off the gr…

7. Wadsworth City – Three-Prong Plug Safety

Domain: wadsworthcity.com

Registered: 1997 (28 years)

Introduction: The three-prong plug includes a third prong that provides a path to ground for stray or leaking electricity, enhancing safety by protecting equipment and preventing electric shock. It is advised not to remove or bend the third prong to fit a two-slot outlet; instead, use an adapter only if the grounding wire is connected to an electrical ground or install an appropriate three-slot outlet.

Strategic Sourcing Conclusion and Outlook for 3 pin plug

In conclusion, the strategic sourcing of 3-pin plugs is paramount for businesses aiming to ensure reliability and safety in their electrical connections. With a diverse range of products available, from heavy-duty rubber to thermoplastic options, buyers can tailor their purchases to meet specific application needs. Additionally, understanding global safety standards and certifications will aid in mitigating risks associated with product compliance across different markets.

As the demand for 3-pin plugs continues to grow, driven by advancements in technology and increasing consumer electronics usage, international B2B buyers must leverage strategic sourcing to optimize costs and enhance supply chain efficiencies. Partnering with reputable manufacturers, such as Volex and Sundial Wire, can provide access to quality products that align with industry standards.

Looking ahead, businesses should prioritize establishing strong relationships with suppliers to navigate the complexities of global sourcing. By doing so, buyers can not only secure competitive pricing but also ensure a steady supply of innovative and compliant 3-pin plug solutions. Now is the time to assess your sourcing strategies and align them with future market trends, particularly in regions like Africa, South America, the Middle East, and Europe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.