A B2B Buyer’s Guide to 3 Phase Transformers: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for 3 phase transformers

Navigating the complexities of sourcing three-phase transformers can present a significant challenge for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The demand for reliable and efficient power distribution systems has never been higher, and understanding the various types of transformers, their applications, and the nuances of supplier vetting is crucial for making informed purchasing decisions. This guide serves as an essential resource, exploring the different configurations—such as Delta and Star connections—as well as their specific applications in industrial and commercial settings.

Within these pages, you will find a comprehensive examination of three-phase transformers, including insights into cost considerations, performance metrics, and maintenance requirements. The guide also addresses key supplier selection criteria, enabling you to identify trusted manufacturers and distributors who can meet your specific needs. By empowering you with knowledge, this guide aims to streamline the procurement process, minimize risks, and enhance operational efficiency. Whether you are in Saudi Arabia, Brazil, or any other region, our insights will help you navigate the global market confidently and effectively, ensuring that your organization benefits from the advantages that high-quality three-phase transformers can provide.

Understanding 3 phase transformers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Delta-Delta (Dd) | All three phases are interconnected in a closed loop. | Industrial motor drives, heavy machinery | Pros: High reliability, can operate with one transformer down. Cons: Requires full line voltage for each transformer. |

| Star-Star (Yy) | Each transformer has a neutral point; lower winding turns needed. | Power distribution, residential areas | Pros: Provides neutral point, better for low voltage applications. Cons: If one transformer fails, the whole system may be compromised. |

| Star-Delta (Yd) | Combines star connection on the primary and delta on the secondary. | Initial startup of motors, high starting current applications | Pros: Reduces starting current; offers flexibility. Cons: More complex design and potential for phase imbalance. |

| Delta-Star (Dy) | Delta connection on the primary and star on the secondary. | Transformer stations, industrial plants | Pros: Suitable for high voltage applications; provides neutral. Cons: Increased complexity in design and installation. |

| Zig-Zag (Zz) | Interconnected star configuration, often used for grounding. | Special applications, grounding systems | Pros: Effective for neutral grounding; reduces harmonics. Cons: Not commonly used; may require specialized knowledge for installation. |

What Are the Characteristics of Delta-Delta Transformers and Their B2B Suitability?

Delta-Delta transformers interconnect all three phases in a closed loop, making them highly reliable for industrial applications. They are particularly advantageous in scenarios where one transformer can be taken offline without disrupting power supply, allowing continued operation at approximately two-thirds capacity. However, they require transformers to be designed for the full line voltage, leading to higher initial costs. B2B buyers should consider their operational reliability and maintenance costs when evaluating Delta-Delta transformers for heavy machinery or motor drives.

How Do Star-Star Transformers Function and What Are Their Applications?

Star-Star transformers feature a neutral point, making them suitable for power distribution and residential applications. With fewer turns in the winding, they are often more economical and easier to insulate than Delta configurations. However, a key drawback is that if one transformer fails, the entire system may become inoperative. B2B buyers in sectors like construction or urban development should weigh the advantages of a neutral point against the potential risks of system failure in their purchasing decisions.

What Are the Advantages of Star-Delta Transformers for B2B Buyers?

Star-Delta transformers combine a star connection on the primary side with a delta connection on the secondary, making them ideal for applications requiring high starting currents, such as motor startups. This configuration helps reduce the initial current draw, mitigating potential damage to electrical equipment. However, they can be more complex and may lead to phase imbalances if not properly managed. Buyers should assess their specific operational needs and the complexity of integration when considering Star-Delta transformers.

What Makes Delta-Star Transformers Suitable for High Voltage Applications?

Delta-Star transformers connect the primary windings in a delta configuration and the secondary in a star configuration, making them suitable for high voltage applications. They provide a neutral point, which is beneficial for grounding and system stability. However, the design can be complex, requiring careful installation and maintenance. B2B buyers in industries such as energy production or large-scale manufacturing should prioritize Delta-Star transformers for their capacity to handle high voltages while ensuring system reliability.

Why Consider Zig-Zag Transformers for Specialized Applications?

Zig-Zag transformers feature an interconnected star configuration primarily used for grounding purposes. They are effective in reducing harmonics and providing neutral grounding, which is essential in certain specialized applications. However, they are less commonly used and may require specialized knowledge for installation and maintenance. B2B buyers should consider Zig-Zag transformers for their unique grounding needs and harmonic mitigation strategies, particularly in industrial settings where power quality is critical.

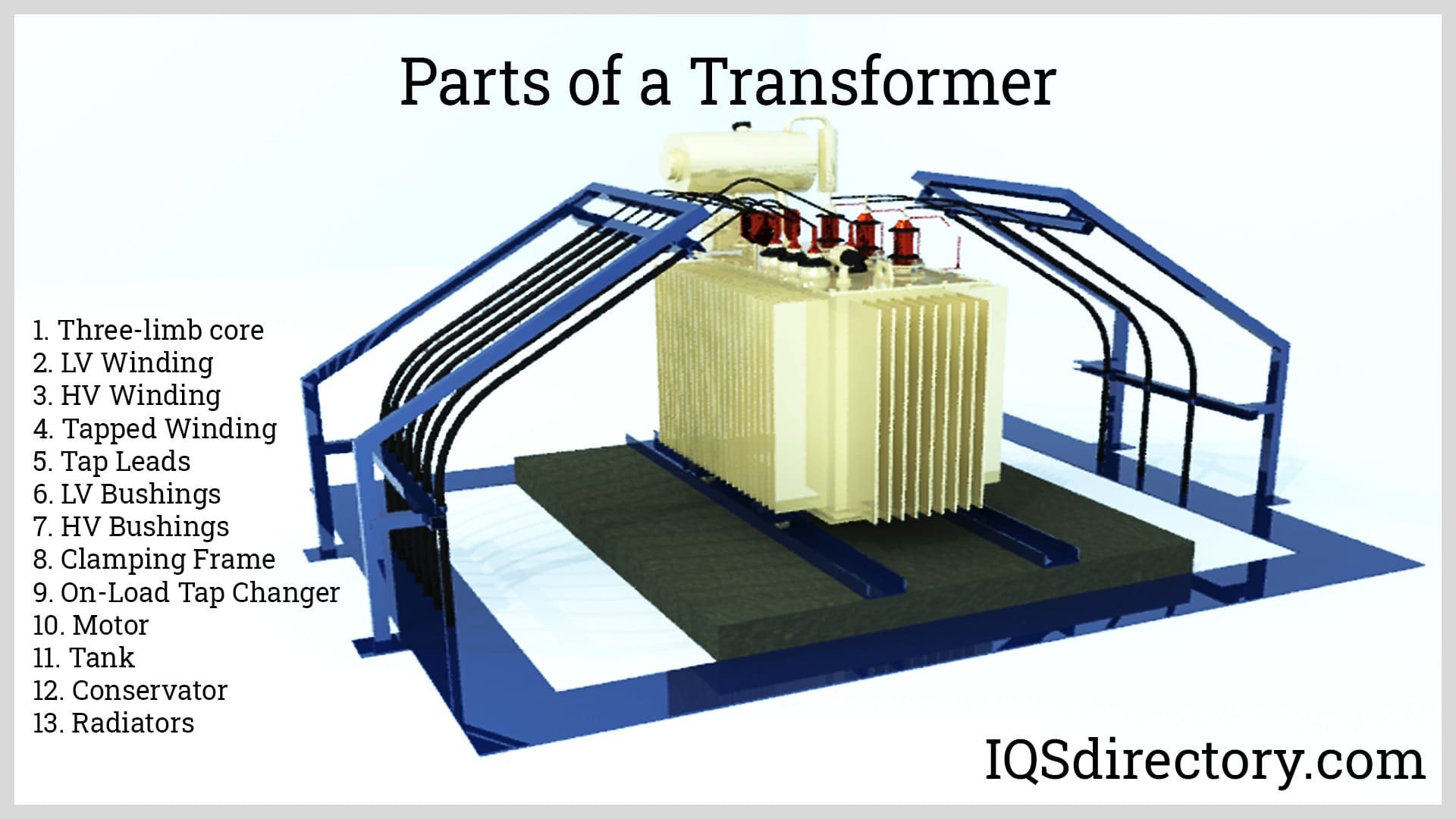

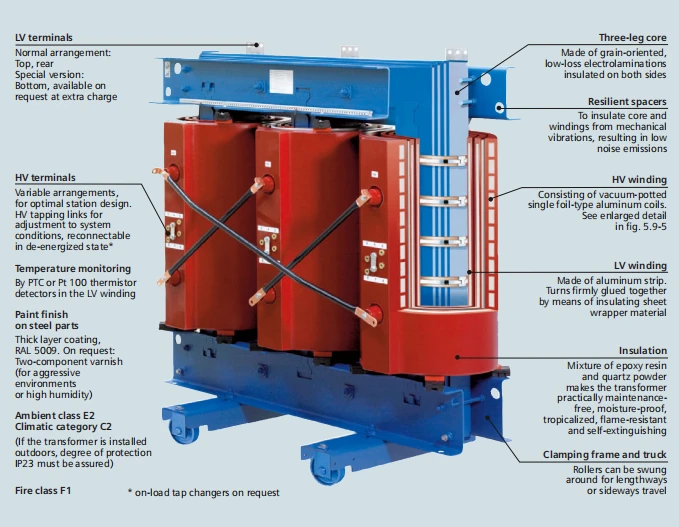

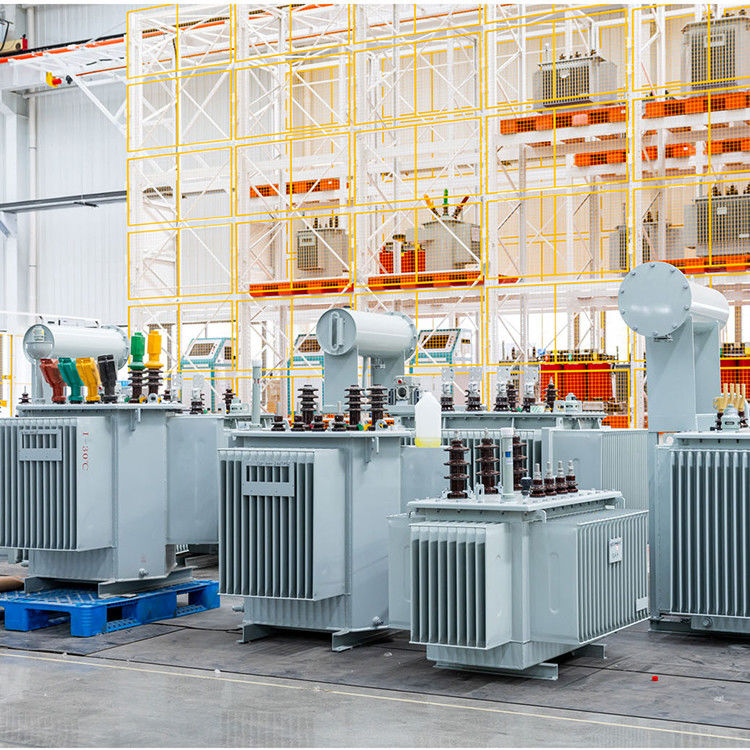

Illustrative image related to 3 phase transformers

Key Industrial Applications of 3 phase transformers

| Industry/Sector | Specific Application of 3 phase transformers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power supply for heavy machinery and equipment | Enhanced operational efficiency and reduced downtime | Reliability, voltage ratings, and compatibility with existing systems |

| Oil and Gas | Voltage regulation in offshore platforms and refineries | Improved safety and operational stability | High durability, environmental resistance, and maintenance support |

| Mining | Power distribution for large-scale mining operations | Effective energy management and cost savings | Customization options, local support, and compliance with industry standards |

| Renewable Energy | Integration with wind and solar energy systems | Increased energy efficiency and sustainability | Scalability, adaptability to fluctuating loads, and certification for renewable integration |

| Construction | Temporary power supply for construction sites | Flexibility in power management and reduced project delays | Portability, ease of installation, and safety certifications |

How Are 3 Phase Transformers Used in Manufacturing?

In the manufacturing sector, 3 phase transformers are essential for providing reliable power to heavy machinery and equipment. They ensure that large motors and industrial machines operate efficiently, reducing the risk of downtime caused by power fluctuations. Buyers should consider reliability and voltage ratings when sourcing transformers, as these factors directly influence operational efficiency and productivity. Additionally, compatibility with existing systems is crucial to ensure seamless integration.

What Role Do 3 Phase Transformers Play in Oil and Gas?

In the oil and gas industry, 3 phase transformers are utilized for voltage regulation in offshore platforms and refineries. They help stabilize power supply, enhancing safety and operational stability in environments where equipment is often exposed to harsh conditions. Buyers in this sector need to prioritize high durability and environmental resistance when sourcing transformers. Maintenance support is also vital to ensure continuous operation in critical applications.

How Are 3 Phase Transformers Beneficial in Mining?

Mining operations rely heavily on 3 phase transformers for efficient power distribution across large sites. These transformers facilitate effective energy management, enabling cost savings through optimized power usage. Buyers should look for customization options that cater to the specific demands of their operations, as well as local support to ensure quick response times during emergencies. Compliance with industry standards is another key consideration to avoid regulatory issues.

Why Are 3 Phase Transformers Important for Renewable Energy?

In the renewable energy sector, 3 phase transformers are crucial for integrating wind and solar energy systems into the grid. They enhance energy efficiency and contribute to sustainability goals by ensuring that power generated from renewable sources is effectively utilized. Buyers should focus on scalability and adaptability to fluctuating loads when sourcing transformers for renewable applications. Certification for renewable integration is also important to meet regulatory requirements.

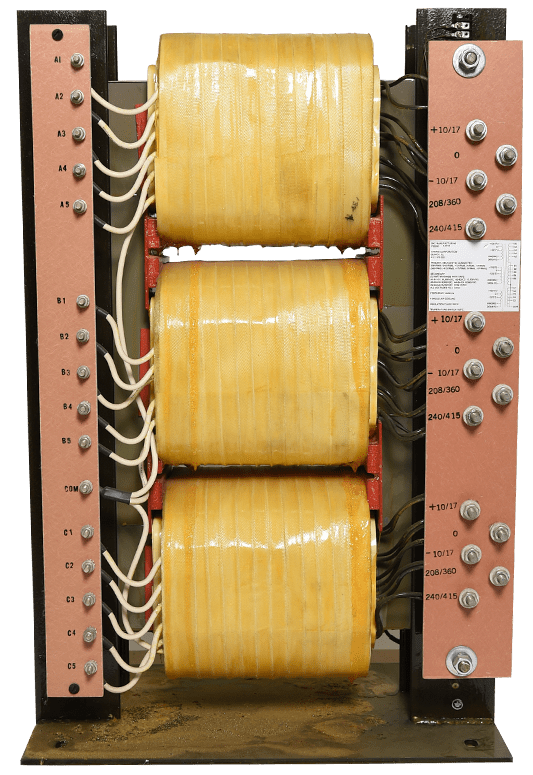

Illustrative image related to 3 phase transformers

How Do 3 Phase Transformers Support Construction Projects?

3 phase transformers are commonly used as temporary power supplies on construction sites, providing flexibility in power management. They allow for the efficient operation of tools and equipment, helping to reduce project delays. When sourcing these transformers, buyers should consider portability and ease of installation to facilitate quick deployment. Safety certifications are also essential to ensure compliance with regulations and protect workers on-site.

3 Common User Pain Points for ‘3 phase transformers’ & Their Solutions

Scenario 1: Struggling with Voltage Imbalance in 3-Phase Systems

The Problem:

B2B buyers, especially those managing industrial plants or large commercial facilities, often face the challenge of voltage imbalance in their three-phase transformer systems. Voltage imbalance can lead to inefficient operation, overheating of equipment, and increased energy costs. For instance, if one phase carries significantly more load than the others, it can cause equipment failures, reduced lifespan, and even safety hazards. This imbalance is particularly problematic in regions where the power supply may fluctuate due to unreliable infrastructure.

The Solution:

To combat voltage imbalances, it is essential for buyers to invest in properly sized transformers that match their load requirements. Understanding the load distribution across phases is crucial. Conducting a thorough load analysis can help identify which transformers need adjustment or replacement. Additionally, implementing a monitoring system can provide real-time data on voltage levels and load conditions, allowing for proactive management. Buyers should also consider using phase-balancing transformers or introducing capacitors to improve power factor and balance loads across phases. Collaborating with experienced electrical engineers during the installation process will ensure that the transformers are configured correctly, minimizing the risk of future imbalances.

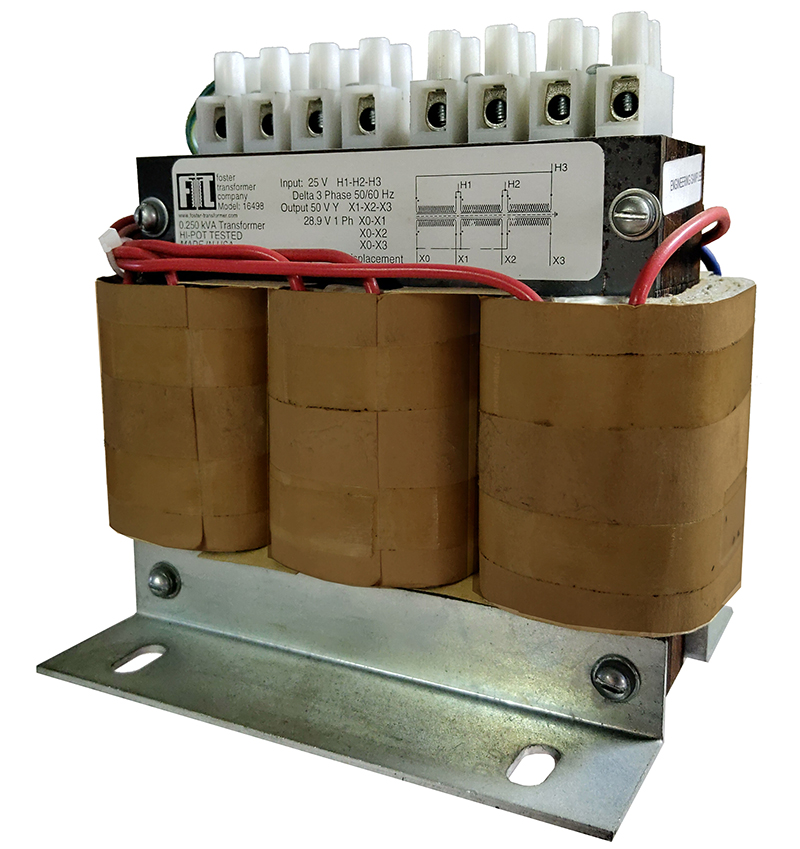

Illustrative image related to 3 phase transformers

Scenario 2: Overcoming High Maintenance Costs and Downtime

The Problem:

High maintenance costs and unexpected downtime are significant concerns for companies relying on three-phase transformers for their operations. For example, if a transformer fails and requires urgent repairs, it can lead to production halts, lost revenue, and increased repair expenses. This is particularly critical in industries like manufacturing and mining, where continuous operation is vital. B2B buyers may feel trapped by the costs associated with frequent maintenance and the lack of reliable service options.

The Solution:

To reduce maintenance costs and minimize downtime, buyers should prioritize the selection of high-quality, robust transformers from reputable manufacturers. Investing in transformers with advanced cooling systems and higher insulation ratings can lead to longer operational life and lower maintenance needs. Establishing a routine inspection and preventive maintenance schedule is also essential. This includes regular thermal imaging, vibration analysis, and cleaning to identify potential issues before they escalate. Additionally, buyers should consider establishing contracts with service providers for regular maintenance checks and emergency repairs, ensuring quick response times in case of failures.

Scenario 3: Navigating Complexity in Transformer Configurations

The Problem:

B2B buyers often encounter confusion when navigating the various configurations of three-phase transformers, such as Delta, Star, or hybrid connections. Misunderstanding the appropriate configuration for specific applications can lead to inefficiencies, safety risks, and increased operational costs. This is particularly true in regions with diverse operational standards and practices, where improper configuration can result in equipment damage or suboptimal performance.

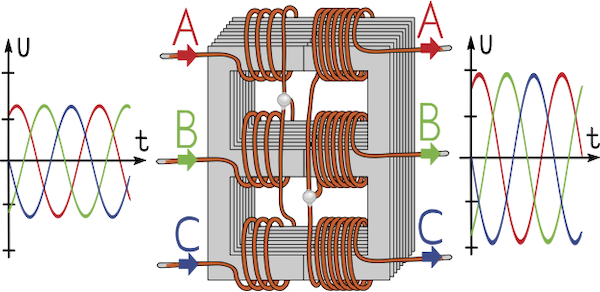

Illustrative image related to 3 phase transformers

The Solution:

To effectively navigate transformer configurations, buyers should engage with knowledgeable suppliers and electrical engineers who can provide insights into the best practices for their specific applications. It is essential to understand the differences between Delta and Star configurations, including their advantages and disadvantages in various scenarios. Buyers should also leverage simulation software to model different configurations and predict their performance under varying loads. Furthermore, investing in training for in-house technical teams can enhance their understanding of transformer operations and configurations, enabling them to make informed decisions that optimize their systems. Documentation of configuration choices and ongoing performance evaluations will also assist in future upgrades or modifications.

Strategic Material Selection Guide for 3 phase transformers

What Are the Key Materials Used in 3 Phase Transformers?

When selecting materials for three-phase transformers, it’s essential to consider their properties, advantages, disadvantages, and how they align with international standards. Below is an analysis of four common materials used in the manufacturing of three-phase transformers.

1. Silicon Steel

Key Properties:

Silicon steel, often used for transformer cores, has excellent magnetic properties, high permeability, and low hysteresis loss. It typically operates efficiently at temperatures up to 150°C and can withstand moderate pressure.

Pros & Cons:

The primary advantage of silicon steel is its ability to reduce energy losses due to its magnetic efficiency. However, it is relatively brittle, making it susceptible to mechanical damage during manufacturing and transportation. Additionally, while it is cost-effective, the manufacturing process can be complex, requiring precise control over the silicon content.

Illustrative image related to 3 phase transformers

Impact on Application:

Silicon steel is highly compatible with electrical applications, providing efficient magnetic flux paths. However, it is not suitable for environments with high humidity or corrosive media without protective coatings.

Considerations for International Buyers:

Buyers in regions like Africa and the Middle East should ensure compliance with local standards such as ASTM A laminations. The preference for silicon steel may vary based on the availability of local suppliers and the cost of importation.

2. Copper

Key Properties:

Copper is renowned for its excellent electrical conductivity, with a conductivity rating of 97% IACS (International Annealed Copper Standard). It can operate effectively at high temperatures, typically up to 200°C, and has good resistance to corrosion.

Pros & Cons:

The key advantage of copper is its superior conductivity, which allows for smaller wire gauges and reduced energy losses. However, it is more expensive than aluminum and can be prone to oxidation if not properly insulated, which can lead to increased maintenance costs.

Impact on Application:

Copper’s high conductivity makes it ideal for high-performance applications, ensuring efficient energy transfer. However, its weight may be a consideration in applications where weight reduction is critical.

Considerations for International Buyers:

In Europe and South America, compliance with standards such as EN 1977 for copper quality is crucial. Buyers should also consider the availability of copper and its price volatility in their regions.

Illustrative image related to 3 phase transformers

3. Aluminum

Key Properties:

Aluminum is lightweight and has a conductivity rating of approximately 61% IACS. It can operate at temperatures up to 150°C and has good resistance to corrosion, especially when anodized.

Pros & Cons:

Aluminum’s lightweight nature makes it easier to handle and install, reducing transportation costs. However, its lower conductivity compared to copper means that larger wire sizes are required, which can increase material costs. Additionally, aluminum is more prone to fatigue and may require more frequent maintenance.

Impact on Application:

Aluminum is often used in applications where weight is a critical factor, such as in portable transformers. However, its lower conductivity may limit its use in high-efficiency applications.

Considerations for International Buyers:

Buyers in regions like Brazil and Saudi Arabia should be aware of local standards such as NBR (Brazilian Standards) and SASO (Saudi Standards) for aluminum components. The choice of aluminum may also depend on local availability and cost.

4. Insulating Materials (e.g., Paper, Resin)

Key Properties:

Insulating materials like paper and resin are crucial for transformer operation, providing electrical insulation and thermal stability. They can withstand temperatures up to 120°C and have excellent dielectric properties.

Pros & Cons:

The main advantage of insulating materials is their ability to prevent electrical shorts and ensure safe operation. However, they can degrade over time, particularly in high-temperature environments, necessitating regular maintenance and replacement.

Impact on Application:

Insulating materials are essential for ensuring the longevity and reliability of transformers. However, their performance can be affected by environmental conditions, such as humidity and temperature fluctuations.

Considerations for International Buyers:

International buyers must ensure that insulating materials meet local standards like IEC 60085 for thermal insulation. The choice of insulating materials may also be influenced by regional climate conditions.

Summary Table

| Material | Typical Use Case for 3 phase transformers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Transformer cores | Reduces energy losses | Brittle, complex manufacturing | Medium |

| Copper | Windings and connections | Superior electrical conductivity | High cost, prone to oxidation | High |

| Aluminum | Lightweight transformers | Easy to handle and install | Lower conductivity, fatigue-prone | Low |

| Insulating Materials | Electrical insulation | Prevents shorts, ensures safety | Degrades over time, requires maintenance | Medium |

This strategic material selection guide provides insights into the various materials used in three-phase transformers, helping B2B buyers make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 phase transformers

What Are the Key Stages in the Manufacturing Process of 3 Phase Transformers?

The manufacturing of 3 phase transformers is a complex process that involves several critical stages, each of which contributes to the overall quality and performance of the final product. Understanding these stages is essential for B2B buyers looking to ensure they are sourcing high-quality transformers.

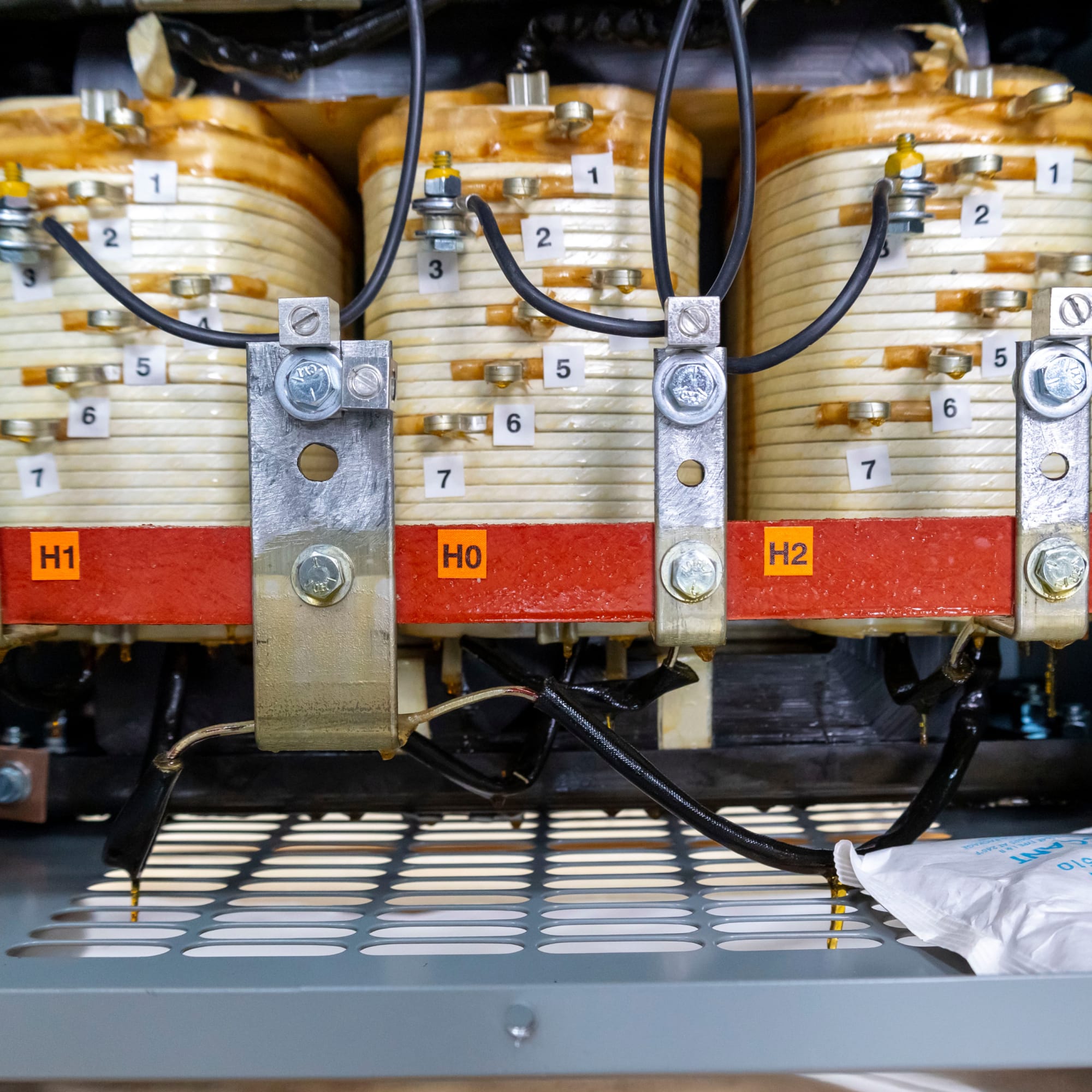

Material Preparation: How Are Raw Materials Selected and Processed?

The manufacturing process begins with the careful selection and preparation of raw materials. Key components include silicon steel for the core, copper or aluminum for the windings, and insulating materials. Manufacturers often prioritize high-grade silicon steel to minimize losses due to hysteresis and eddy currents.

Once the materials are selected, they undergo preparation, which includes cutting the steel sheets into specific sizes for the core and producing copper or aluminum wire of the required gauge. This preparation is crucial as it impacts the efficiency and durability of the transformer.

Illustrative image related to 3 phase transformers

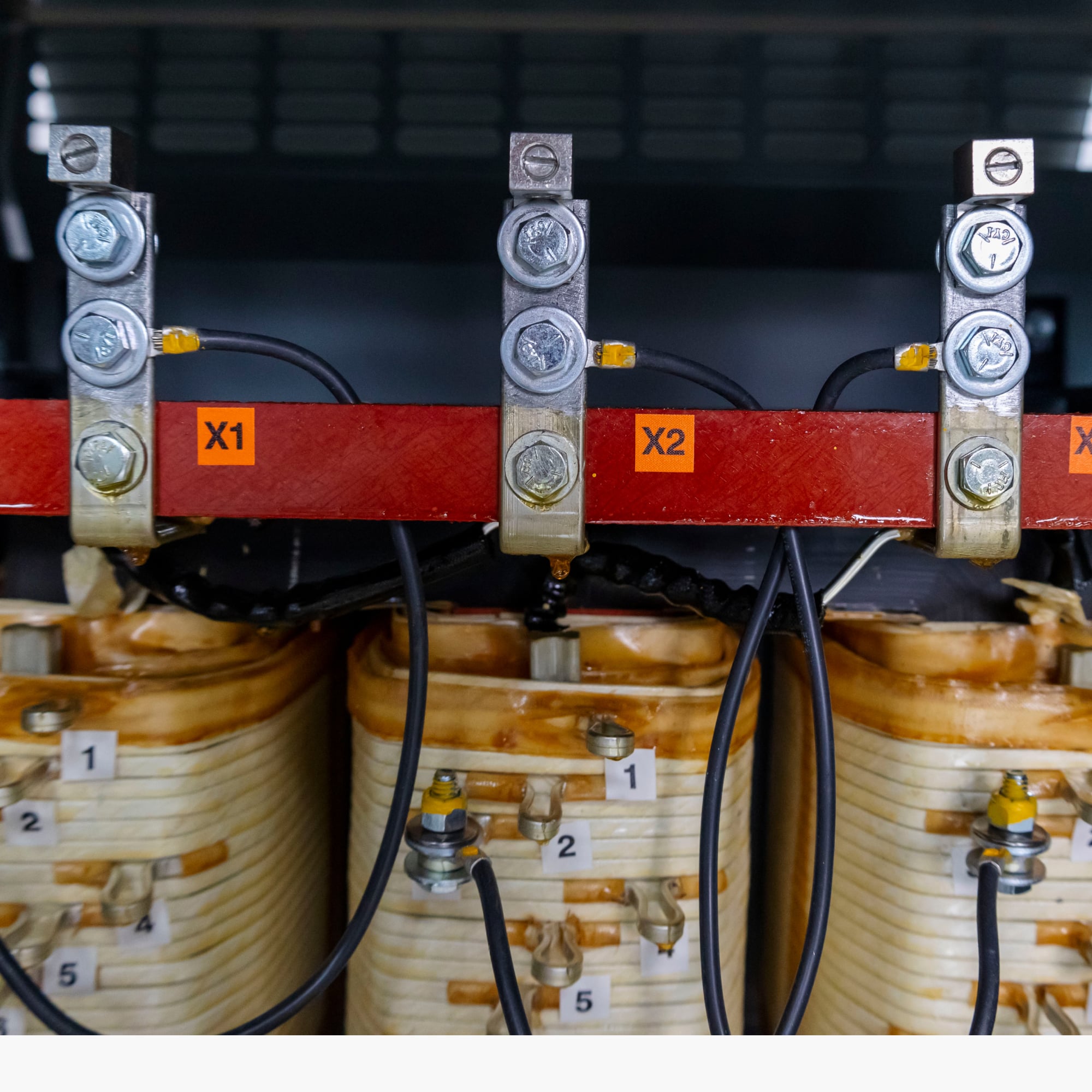

What Techniques Are Used in the Forming Stage?

The next stage is forming, where the core and windings are shaped. The core is constructed by stacking the silicon steel sheets in a specific configuration, typically using a “C” or “E” shape to optimize magnetic flux. This stage may involve techniques such as laser cutting or punching to ensure precise dimensions.

For the windings, manufacturers utilize winding machines to ensure uniformity and consistency in the number of turns. The winding process is critical, as the number of turns directly affects the voltage transformation ratio. High-quality insulation is applied between windings to prevent short circuits and improve electrical performance.

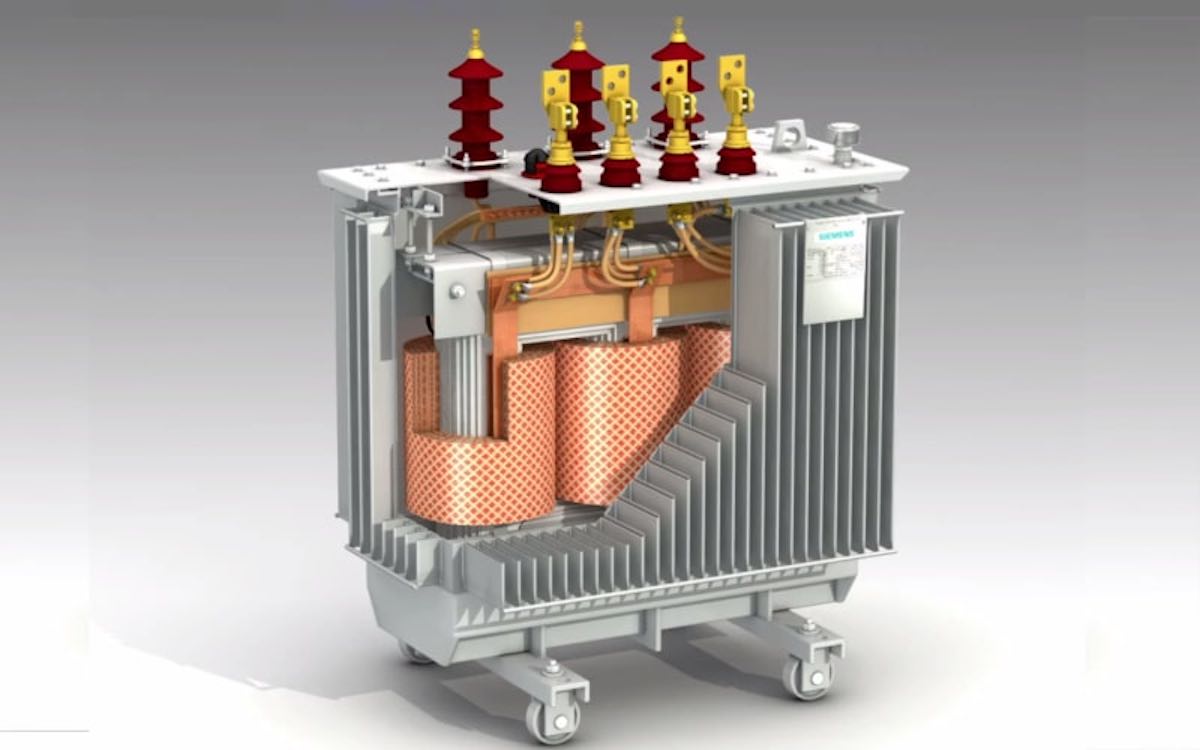

How Is the Assembly Process Conducted?

Following the forming stage, assembly begins. This involves combining the core and windings into a single unit. During assembly, manufacturers must ensure proper alignment and secure connections to minimize losses and enhance reliability.

Additionally, transformers are often encapsulated with resin or oil to provide further insulation and cooling. This stage is vital for ensuring that the transformer operates efficiently under various load conditions.

Illustrative image related to 3 phase transformers

What Quality Assurance Measures Are Implemented During Manufacturing?

Quality assurance is a critical component of the manufacturing process for 3 phase transformers. It ensures that the products meet international standards and customer expectations.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with international quality standards such as ISO 9001, which outlines requirements for a quality management system. This certification ensures that manufacturers adhere to consistent quality processes throughout production.

In addition to ISO standards, industry-specific certifications such as CE marking (for compliance with EU safety standards) and API standards (for products used in the oil and gas sector) may also be relevant. Compliance with these standards is a strong indicator of a manufacturer’s commitment to quality.

What Are the Key Quality Control Checkpoints in Transformer Manufacturing?

Quality control checkpoints are established throughout the manufacturing process to ensure that each component meets specified standards. These checkpoints typically include:

Illustrative image related to 3 phase transformers

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Quality checks are conducted at various stages of the manufacturing process, such as during core assembly and winding.

- Final Quality Control (FQC): Before shipment, the finished transformer undergoes rigorous testing, including electrical and thermal tests, to confirm it meets performance criteria.

What Testing Methods Are Commonly Used for 3 Phase Transformers?

Testing methods play a crucial role in verifying the performance and safety of 3 phase transformers. Common testing methods include:

- Insulation Resistance Testing: Measures the integrity of insulation materials.

- Power Factor Testing: Assesses the dielectric strength of the insulation system.

- Winding Resistance Testing: Ensures proper winding configurations and identifies any potential issues.

- Short-Circuit Testing: Evaluates the transformer’s ability to withstand short-circuit conditions.

By employing these methods, manufacturers can identify defects and ensure that the transformers operate reliably under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some strategies to ensure quality:

Illustrative image related to 3 phase transformers

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing and quality control practices. This includes assessing their compliance with international standards and their internal quality processes.

- Request Quality Reports: Suppliers should provide documentation of quality control measures, including test results and certifications. This transparency is crucial for building trust.

- Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of a supplier’s quality control practices and the quality of the products being manufactured.

What Nuances Should International B2B Buyers Consider Regarding QC and Certifications?

Navigating quality control and certification nuances is particularly important for international B2B buyers. Different regions may have specific compliance requirements, and understanding these can prevent costly errors.

For instance, buyers from the Middle East may need to consider local regulations regarding electrical equipment, while European buyers might focus on CE marking and RoHS compliance. Buyers should also be aware of potential language barriers or differing standards in documentation, which could affect the clarity of quality assurances provided by suppliers.

In summary, understanding the manufacturing processes and quality assurance measures for 3 phase transformers is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and stringent quality control processes, buyers can ensure they are sourcing reliable and efficient transformers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 phase transformers’

Introduction

This practical sourcing guide is designed for B2B buyers looking to procure three-phase transformers. Whether you are in Africa, South America, the Middle East, or Europe, following this checklist will ensure you make informed decisions, meet technical requirements, and select reliable suppliers.

Illustrative image related to 3 phase transformers

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the three-phase transformer you need. This includes voltage ratings, power capacity (kVA), configuration type (Delta, Star, or Zig-Zag), and insulation class. Having precise specifications helps to avoid compatibility issues and ensures that the transformer can handle your operational needs effectively.

- Voltage Ratings: Determine the line-to-line and line-to-neutral voltage requirements.

- Power Capacity: Assess your load requirements to choose an appropriately rated transformer.

Step 2: Research Different Transformer Types

Understanding the various types of three-phase transformers is crucial for making an informed decision. Familiarize yourself with the differences between Delta-Delta, Star-Star, Star-Delta, and Delta-Star configurations, as each has unique benefits and applications.

- Delta Configuration: Ideal for high-load applications; provides redundancy.

- Star Configuration: Offers a neutral point and is more economical for power distribution.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; a robust supplier network can lead to better service and product quality.

- Certifications: Ensure suppliers have relevant industry certifications (ISO, CE, etc.).

- Experience: Look for suppliers with a proven track record in delivering similar transformers.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations. A comprehensive quote should include pricing, delivery timelines, warranty terms, and after-sales support. This information is vital for making a comparative analysis.

Illustrative image related to 3 phase transformers

- Pricing Structure: Look for transparency in pricing and possible additional costs.

- Delivery Timeline: Ensure the supplier can meet your project deadlines.

Step 5: Assess After-Sales Support and Warranty

Quality after-sales support is a critical factor in your decision-making process. Check the warranty period offered and the support services available for installation, maintenance, and troubleshooting.

- Warranty Terms: A longer warranty often indicates confidence in product quality.

- Support Services: Ensure the supplier offers technical support and training.

Step 6: Conduct a Site Visit (if possible)

If feasible, conduct a site visit to the supplier’s manufacturing facility. This allows you to assess their production capabilities, quality control processes, and overall operational standards firsthand.

- Production Capacity: Verify that the supplier can scale production to meet your needs.

- Quality Assurance: Observe the quality control measures in place during manufacturing.

Step 7: Finalize the Contract

Once you have evaluated all factors, finalize the contract with your chosen supplier. Ensure that all terms discussed, including delivery, payment, and service agreements, are clearly outlined.

- Legal Review: Have your legal team review the contract to avoid potential pitfalls.

- Clear Terms: Specify payment schedules and penalties for delays or non-compliance.

By following this checklist, B2B buyers can confidently navigate the procurement process for three-phase transformers, ensuring they choose the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for 3 phase transformers Sourcing

What Are the Key Cost Components in Sourcing 3 Phase Transformers?

When sourcing three-phase transformers, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The core materials, such as copper and silicon steel, contribute significantly to the cost. Higher quality materials enhance performance and longevity but also increase prices. Buyers should assess the balance between material quality and cost-effectiveness.

-

Labor: Labor costs vary widely depending on the manufacturing location. Regions with lower labor costs may offer cheaper transformers, but this can come at the expense of quality and expertise.

-

Manufacturing Overhead: This includes the costs associated with running the factory, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can lower these overheads.

-

Tooling: Initial tooling costs for specialized transformer designs can be substantial. However, these costs are often amortized over larger production runs, making volume purchases more economical.

-

Quality Control: Rigorous QC procedures ensure reliability and compliance with international standards. While this adds to the cost, it is essential for minimizing failures and ensuring customer satisfaction.

-

Logistics: Shipping and handling costs can vary based on distance, mode of transport, and packaging. Buyers should consider Incoterms to understand who bears these costs and risks during transit.

-

Margin: Supplier margins also affect pricing. Higher margins may reflect superior service, warranty options, or additional certifications that can be beneficial in certain markets.

How Do Price Influencers Impact the Cost of 3 Phase Transformers?

Several factors influence pricing beyond the basic cost structure, particularly for international buyers.

Illustrative image related to 3 phase transformers

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to price reductions per unit. Understanding MOQ requirements can help buyers negotiate better deals and optimize their inventory costs.

-

Specifications and Customization: Custom designs or specific technical specifications can significantly impact pricing. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Transformers with higher quality materials or additional certifications (like ISO or IEC standards) may command higher prices. Buyers should evaluate whether these certifications are necessary for their application.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence costs. Established suppliers may offer better warranties and support, justifying a higher price point.

-

Incoterms: Understanding shipping terms is vital for budgeting. Different Incoterms (like FOB, CIF, or DDP) can affect the total landed cost and risk exposure during transportation.

What Buyer Tips Can Help Optimize Costs in 3 Phase Transformer Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can optimize sourcing costs.

-

Negotiation: Engage in open discussions with suppliers to negotiate terms, discounts for bulk orders, or extended payment terms. Building a long-term relationship can lead to better pricing and service.

-

Focus on Cost-Efficiency: Assess the total cost of ownership rather than just the purchase price. Consider installation, maintenance, and energy efficiency when evaluating transformer options.

-

Understand Pricing Nuances for International Buyers: Currency fluctuations, tariffs, and trade agreements can impact costs. Buyers should stay informed about these factors to make better purchasing decisions.

-

Request Indicative Prices: Prices for three-phase transformers can vary widely based on the factors discussed. Always request indicative pricing from multiple suppliers and consider obtaining detailed quotes that break down costs for transparency.

In conclusion, a thorough understanding of the cost components and pricing influencers, along with strategic negotiation and awareness of international nuances, can empower B2B buyers to make informed decisions in sourcing three-phase transformers.

Alternatives Analysis: Comparing 3 phase transformers With Other Solutions

Introduction to Alternative Solutions for Power Distribution

In the realm of power distribution, three-phase transformers are a widely accepted solution due to their efficiency and reliability. However, several alternative technologies and methods exist that can meet similar needs, especially in diverse industrial contexts. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their specific operational requirements.

Comparison Table

| Comparison Aspect | 3 Phase Transformers | Static Frequency Converters | Rotary Phase Converters |

|---|---|---|---|

| Performance | High efficiency for large loads | Moderate efficiency, limited by design | Good efficiency, but varies with load |

| Cost | Higher initial investment | Moderate initial costs, lower operating costs | Moderate to high initial costs, ongoing maintenance |

| Ease of Implementation | Requires careful installation | Easier to integrate with existing systems | Requires significant space and installation effort |

| Maintenance | Moderate; periodic checks needed | Low; typically requires minimal upkeep | Higher; regular maintenance necessary |

| Best Use Case | Large-scale industrial applications | Renewable energy systems, variable loads | Small to medium enterprises needing phase conversion |

Detailed Breakdown of Alternatives

Static Frequency Converters

Static frequency converters are solid-state devices that convert power from one frequency to another. They are particularly effective in renewable energy applications, such as wind and solar power systems, where variable loads are common. The primary advantage of these converters is their ability to integrate seamlessly into existing power systems without extensive modifications. However, they have moderate efficiency and may not perform as well under high-load conditions compared to three-phase transformers.

Illustrative image related to 3 phase transformers

Rotary Phase Converters

Rotary phase converters are another alternative, designed to convert single-phase power into three-phase power. They utilize a rotating machine to create the additional phases required for three-phase systems. This solution is beneficial for small to medium-sized enterprises that need to run three-phase equipment but only have access to single-phase power. While rotary converters can be effective, they tend to require more maintenance and space than static solutions, making them less suitable for larger operations.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a power distribution solution, B2B buyers should assess their specific operational needs, including load requirements, budget constraints, and maintenance capabilities. Three-phase transformers offer robust performance for larger industrial applications, while static frequency converters provide flexibility in renewable energy contexts. Rotary phase converters serve as a practical choice for smaller enterprises with limited power options. By carefully evaluating these alternatives, buyers can ensure they choose the most effective and efficient solution for their unique requirements.

Essential Technical Properties and Trade Terminology for 3 phase transformers

What Are the Critical Specifications of 3-Phase Transformers?

When sourcing 3-phase transformers, international B2B buyers should pay attention to several key specifications that can significantly impact performance, efficiency, and cost-effectiveness. Below are essential technical properties to consider:

Illustrative image related to 3 phase transformers

-

Material Grade

– Definition: This refers to the quality of materials used in the construction of the transformer, particularly the core and windings. Common materials include silicon steel for the core and copper or aluminum for windings.

– B2B Importance: Higher-grade materials enhance energy efficiency and reduce losses, leading to lower operational costs over time. In regions with fluctuating energy prices, investing in higher-grade materials can yield significant savings. -

Voltage Rating

– Definition: This is the maximum voltage the transformer can handle safely. It is crucial to match the transformer’s voltage rating with the electrical system’s voltage requirements.

– B2B Importance: Understanding voltage ratings ensures compatibility with existing infrastructure and prevents potential damage or downtime. In markets with varying voltage standards, such as those in Africa and South America, this is particularly critical. -

KVA Rating

– Definition: The kilovolt-ampere (KVA) rating indicates the transformer’s capacity to handle electrical loads. It is a measure of apparent power.

– B2B Importance: Selecting a transformer with the appropriate KVA rating is vital to avoid overloading or underutilization, which can lead to inefficiencies and increased costs. B2B buyers must accurately assess their load requirements to make informed decisions. -

Efficiency Rating

– Definition: This rating indicates the transformer’s ability to convert input power to output power with minimal losses, typically expressed as a percentage.

– B2B Importance: Higher efficiency ratings lead to lower energy costs and contribute to sustainability goals, a growing concern for companies globally. Buyers should prioritize transformers with efficiency ratings aligned with their operational goals. -

Temperature Rise

– Definition: This refers to the increase in temperature of the transformer components during operation, typically measured in degrees Celsius.

– B2B Importance: A lower temperature rise indicates better thermal management and longevity of the transformer. This is crucial in hot climates found in many African and Middle Eastern countries, where excessive heat can lead to failures. -

Insulation Class

– Definition: The insulation class defines the temperature rating of the insulating materials used in the transformer. Common classes include A, B, F, and H, with H being the highest temperature capability.

– B2B Importance: Selecting the appropriate insulation class is essential for ensuring reliability and compliance with local standards. For international buyers, understanding insulation classes can help in navigating regulatory requirements.

What Are Common Trade Terms Relevant to 3-Phase Transformers?

In the B2B environment, familiarity with industry-specific terminology is crucial for effective communication and negotiation. Here are some common trade terms associated with 3-phase transformers:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Identifying reputable OEMs can assure buyers of quality and reliability, which is critical when purchasing large-scale electrical equipment. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers plan their procurement strategies and avoid excess inventory costs, particularly in diverse markets like South America and Africa. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit bids from suppliers for specific products or services.

– Importance: An RFQ is essential for comparing pricing and terms from multiple suppliers, allowing for informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international commercial transactions.

– Importance: Familiarity with Incoterms helps buyers understand their responsibilities and risks during the shipping and delivery process, which is vital for international transactions, especially in regions with complex logistics. -

Lead Time

– Definition: The amount of time that passes from the initiation of a process until its completion, specifically in manufacturing and delivery.

– Importance: Knowing the lead time is crucial for planning projects and ensuring that electrical installations are completed on schedule, especially in fast-paced markets. -

Warranty Period

– Definition: The period during which a manufacturer guarantees the performance and reliability of the product.

– Importance: A longer warranty period can indicate confidence in product quality and provide buyers with peace of mind regarding their investment.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing 3-phase transformers, ensuring compatibility, reliability, and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the 3 phase transformers Sector

What Are the Key Market Drivers for 3-Phase Transformers in Global Trade?

The market for 3-phase transformers is primarily driven by the increasing demand for reliable and efficient power transmission systems. As global economies industrialize, particularly in regions like Africa and South America, there is a heightened need for robust electrical infrastructure. The growing renewable energy sector, particularly solar and wind power, also necessitates advanced transformer technologies for efficient energy distribution. Additionally, the shift towards smart grids in Europe and the Middle East is propelling innovations in transformer designs to enhance energy efficiency and integration with digital technologies.

Emerging technologies such as IoT (Internet of Things) are influencing sourcing trends, where smart transformers equipped with real-time monitoring capabilities are becoming more sought after. These innovations facilitate predictive maintenance, reducing downtime and operational costs. Furthermore, as international buyers become increasingly focused on total cost of ownership rather than just initial purchase price, there is a trend towards investing in higher-quality, durable transformers that offer long-term savings.

How Are Sustainability and Ethical Sourcing Transforming the 3-Phase Transformer Market?

Sustainability is becoming a critical factor in the procurement process for 3-phase transformers. Buyers are increasingly aware of the environmental impact of electrical equipment manufacturing, including the carbon footprint associated with production and disposal. Consequently, there is a growing demand for transformers that utilize eco-friendly materials and processes. Manufacturers are responding by adopting green certifications, such as ISO 14001, which demonstrates their commitment to environmental management.

Ethical sourcing is equally important, particularly in regions like Africa and South America where supply chain transparency can be a challenge. Buyers are seeking suppliers who prioritize ethical labor practices and responsible sourcing of raw materials. This trend not only helps mitigate risks associated with supply chain disruptions but also enhances brand reputation in increasingly environmentally-conscious markets.

The use of recyclable materials and energy-efficient designs in 3-phase transformers is becoming a standard expectation rather than a competitive advantage, urging manufacturers to innovate continuously. As a result, buyers can align their procurement strategies with broader corporate social responsibility goals, contributing to a more sustainable future.

What Is the Historical Context Behind the Development of 3-Phase Transformers?

The evolution of 3-phase transformers dates back to the late 19th century when Nikola Tesla and George Westinghouse advocated for alternating current (AC) systems. The introduction of 3-phase systems revolutionized power distribution, allowing for efficient transmission over long distances. This technology quickly became the standard for electrical engineering, significantly enhancing the capacity and reliability of electrical grids.

In the decades that followed, advancements in materials science and engineering improved transformer designs, leading to more compact and efficient models. The introduction of digital technology in the late 20th century further transformed the sector, enabling smarter transformers capable of real-time data monitoring. As the global energy landscape continues to evolve with a focus on sustainability and efficiency, the 3-phase transformer market remains poised for innovation, driven by both historical advancements and contemporary demands.

Conclusion

In summary, international B2B buyers in the 3-phase transformer sector must navigate a landscape characterized by rapid technological advancements and increasing emphasis on sustainability and ethical sourcing. By understanding these market dynamics, buyers can make informed decisions that align with their operational goals and contribute to a more sustainable energy future.

Illustrative image related to 3 phase transformers

Frequently Asked Questions (FAQs) for B2B Buyers of 3 phase transformers

-

How do I determine the right configuration for a 3-phase transformer?

Choosing the right configuration—Delta, Star, or Zig-Zag—depends on your specific application and system requirements. Delta configurations are ideal for applications requiring high starting torque and can handle phase imbalances. Conversely, Star connections are beneficial for systems needing a neutral point for grounding and lower line-to-phase voltage. Consider consulting with an electrical engineer to evaluate your load requirements, voltage levels, and existing infrastructure before making a decision. -

What are the key specifications to look for in a 3-phase transformer?

When sourcing a 3-phase transformer, focus on specifications such as voltage rating, kVA capacity, efficiency, cooling method (air or oil), and frequency. It’s also essential to consider the winding material (copper or aluminum), insulation class, and configuration type. These factors will impact the transformer’s performance, reliability, and suitability for your operational needs. -

What should I consider when evaluating potential suppliers for 3-phase transformers?

When vetting suppliers, assess their certifications (like ISO 9001), industry experience, and customer reviews. Verify their manufacturing capabilities, quality assurance processes, and compliance with international standards. Additionally, inquire about their after-sales support and warranty policies. A supplier with a robust track record and transparent communication will be crucial for a successful partnership. -

Are there customization options available for 3-phase transformers?

Yes, many manufacturers offer customization options for 3-phase transformers to meet specific requirements. This may include adjustments to voltage ratings, kVA capacity, physical dimensions, and even specialized features like enhanced insulation or specific cooling methods. Discuss your unique needs with potential suppliers to determine the extent of customization they can provide. -

What is the minimum order quantity (MOQ) for 3-phase transformers?

The MOQ for 3-phase transformers can vary significantly among suppliers and is often influenced by production costs and lead times. Typically, manufacturers may set an MOQ ranging from one unit to several dozen, depending on the transformer type and customization level. It’s advisable to clarify MOQ terms during negotiations to align with your project needs and budget. -

What are the payment terms commonly offered by suppliers for 3-phase transformers?

Payment terms for 3-phase transformers can vary widely, but common options include upfront payments, letters of credit, or staggered payments based on production milestones. Suppliers may also offer discounts for early payments or bulk orders. Always negotiate terms that suit your financial capabilities while ensuring they align with supplier policies. -

How can I ensure quality assurance when purchasing 3-phase transformers?

To ensure quality, request detailed documentation on the manufacturer’s testing and quality assurance processes. Look for compliance with international standards such as IEC or ANSI. It’s beneficial to ask for certificates of compliance and test results from third-party inspections. Establishing clear quality expectations upfront can help mitigate risks associated with product defects. -

What logistics considerations should I keep in mind when importing 3-phase transformers?

When importing transformers, consider factors such as shipping methods, customs regulations, and associated costs. Ensure that your supplier provides adequate packaging to prevent damage during transit. Additionally, familiarize yourself with import duties and taxes in your country. Engaging a logistics partner experienced in handling heavy machinery can streamline the process and ensure timely delivery.

Top 7 3 Phase Transformers Manufacturers & Suppliers List

1. IQS Directory – Three-Phase Transformers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Three-phase transformers are designed for balanced, consistent power delivery in high-demand environments. They consist of six windings: three primary and three secondary, arranged around a laminated steel core to maximize magnetic flux and minimize energy loss. The transformers can be configured in delta (Δ) or star (Y) arrangements, allowing for flexible voltage and current management. They oper…

2. Bel Fuse – 3-Phase Transformers

Domain: belfuse.com

Registered: 1996 (29 years)

Introduction: 3-Phase Transformers are electrical devices that transform power between circuits at the same frequency, typically changing voltage and current values. They are crucial for long-distance power distribution and are constructed by winding three single-phase transformers on a single core, making them smaller, more cost-effective, and lighter than three individual single-phase transformers. They typic…

3. Square D – Low Voltage Distribution Transformers

Domain: se.com

Registered: 1997 (28 years)

Introduction: Low Voltage Distribution Transformers, Three Phase; DOE 2016 Efficiency; EX offering; Designed and manufactured by Square D with 100 years of transformer design experience; Latest technology in core, coil, and enclosure.

4. The Engineering Mindset – Three Phase Transformers

Domain: theengineeringmindset.com

Registered: 2015 (10 years)

Introduction: Three Phase Transformers: Rated for 2kVA, Delta primary and Wye secondary configuration. Converts one AC voltage into multiple voltages (480V, 277V, 240V, 208V, 120V). Types include pad mounted and pole mounted transformers. Designed for commercial buildings with high lighting and equipment needs. Consists of primary and secondary coils around a steel core to enhance efficiency. Can be configured …

5. All About Circuits – Three-Phase Transformers

Domain: allaboutcircuits.com

Registered: 2003 (22 years)

Introduction: Three-phase transformers are designed for power distribution systems, allowing for voltage transformation in various configurations. They consist of three sets of primary and secondary windings connected in either Δ (Delta) or Y (Wye) configurations. Key configurations include: Y-Y, Y-Δ, Δ-Y, Δ-Δ, and V (open-Δ). Y connections enable multiple voltages, while Δ connections provide reliability. The …

6. Power and Beyond – Three-Phase Transformers

Domain: power-and-beyond.com

Registered: 2019 (6 years)

Introduction: Three-phase transformers are essential for efficiently transmitting and distributing large amounts of electrical power, particularly in commercial and industrial areas. They operate using three-phase AC current to transfer electrical energy between circuits, either stepping up or stepping down voltage while maintaining frequency. The market for three-phase distribution transformers was valued at U…

7. UTB Transformers – Single & Three Phase Solutions

Domain: utbtransformers.com

Registered: 2020 (5 years)

Introduction: Single Phase Transformers: Designed for residential and light commercial applications, consist of two windings (primary and secondary), can be pole mounted or pad mounted. Three Phase Transformers: Used in industrial and high-power applications, consist of three sets of windings in delta (Δ) or wye (Y) configuration, can also be pad mounted or pole mounted (though pole mounted versions are less co…

Strategic Sourcing Conclusion and Outlook for 3 phase transformers

In the realm of electrical power distribution, three-phase transformers stand as a critical component, offering efficiency and reliability for industrial applications. Understanding the various configurations—Delta, Star, and their combinations—enables businesses to optimize their energy systems and enhance operational performance.

Strategic sourcing of three-phase transformers not only involves selecting high-quality products but also requires considering factors such as energy efficiency, maintenance needs, and supplier reliability. By collaborating with reputable manufacturers and distributors, international buyers can secure advantageous pricing, ensure timely delivery, and gain access to advanced technology that meets their specific requirements.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for robust power solutions will rise. Companies looking to enhance their electrical infrastructure should prioritize strategic partnerships with suppliers who understand regional nuances and can provide tailored solutions.

Now is the time to leverage the benefits of strategic sourcing for three-phase transformers. Engage with expert suppliers to explore innovative solutions that will propel your business forward, ensuring that your operations are equipped for future challenges and opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to 3 phase transformers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.