A B2B Buyer’s Guide to 2Jz Engine For Sale: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for 2jz engine for sale

In the ever-evolving automotive landscape, sourcing a 2JZ engine for sale can pose significant challenges for international B2B buyers. The demand for high-performance engines, particularly the legendary 2JZ series, has surged across various markets, making it imperative for buyers to navigate a complex web of suppliers, regulations, and pricing structures. This guide aims to demystify the global market for 2JZ engines, equipping buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—with the knowledge necessary to make informed purchasing decisions.

Within this comprehensive resource, we delve into the diverse types of 2JZ engines available, their applications in various automotive projects, and essential tips for vetting suppliers to ensure quality and reliability. Furthermore, we explore pricing trends and factors that influence costs, enabling buyers to budget effectively while maximizing value. By providing actionable insights and a clear understanding of the market dynamics, this guide empowers B2B buyers to confidently engage with suppliers, streamline their procurement processes, and ultimately enhance their competitive edge in the automotive industry. Whether you’re an established dealer or a new entrant in the market, this guide is your essential companion in navigating the global marketplace for 2JZ engines.

Understanding 2jz engine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2JZ-GTE VVTI | Twin-turbocharged, inline-6 engine; high power output (~276 HP) | High-performance racing, custom builds | Pros: Proven reliability, extensive aftermarket support. Cons: Higher initial cost, potential for over-engineering. |

| 2JZ-GE | Naturally aspirated variant; robust design with good torque | Daily drivers, project cars | Pros: Lower cost, good for moderate performance. Cons: Less power compared to turbo variants. |

| 2JZ-GTE (Non-VVTI) | Older twin-turbo model; simpler design, easier to modify | Vintage restorations, motorsport | Pros: Classic appeal, easier to tune. Cons: Limited availability, may require more maintenance. |

| 2JZ Turnkey Engine Package | Fully assembled and dyno-tuned; plug-and-play installation | Racing teams, performance shops | Pros: Ready to use, reduces installation time. Cons: Higher price point, limited customization options. |

| Built 2JZ Engines | Custom-built engines tailored for specific performance needs | Competitive racing, specialized builds | Pros: High performance potential, tailored specifications. Cons: Longer lead times, potential for higher costs based on customization. |

What Are the Key Characteristics of the 2JZ-GTE VVTI Engine?

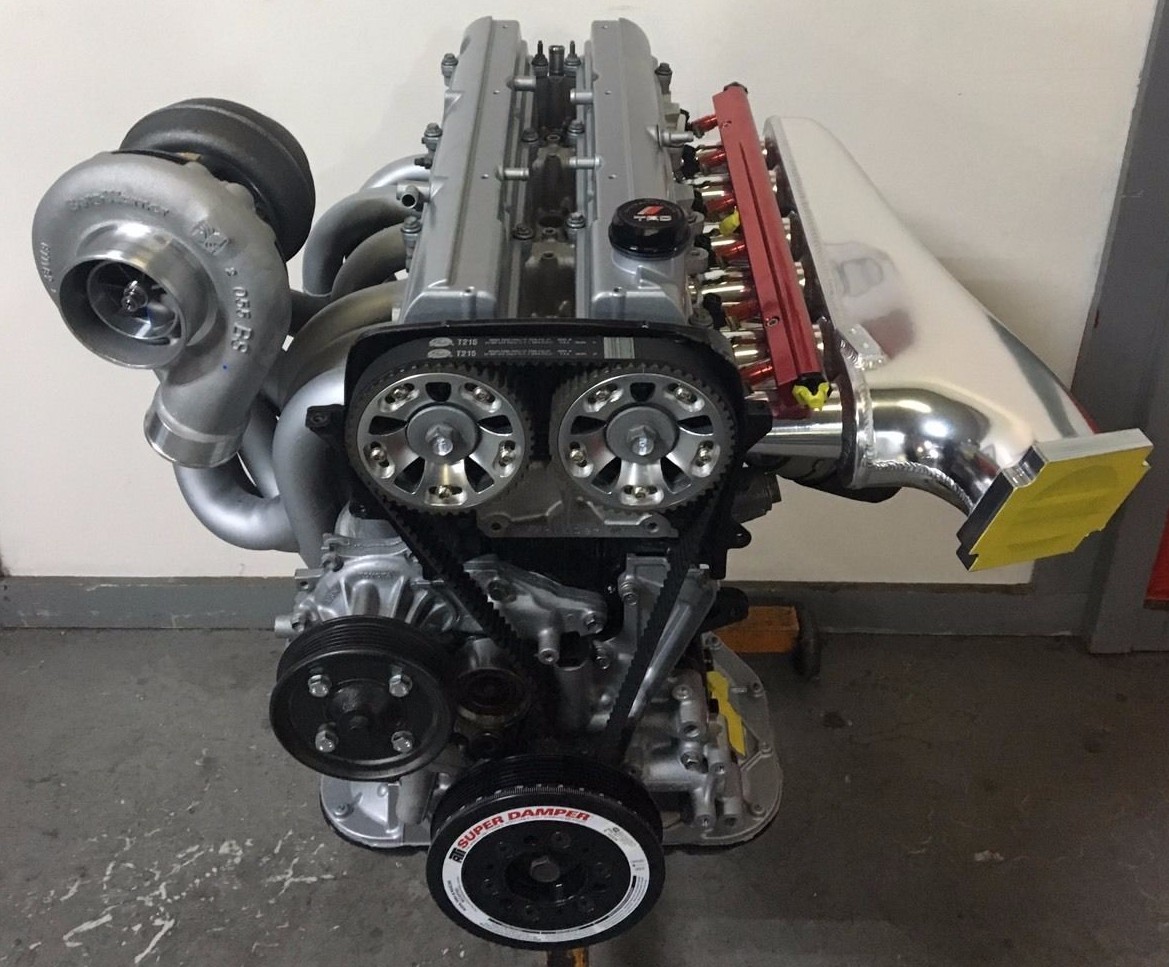

The 2JZ-GTE VVTI is renowned for its powerful twin-turbocharged inline-6 configuration, delivering approximately 276 HP. This engine is particularly suited for high-performance applications, making it a popular choice among racing teams and custom automotive builders. When considering a purchase, B2B buyers should evaluate the engine’s compatibility with their existing setups and the availability of performance parts for upgrades. The extensive aftermarket support enhances its appeal, but potential buyers should be aware of the higher initial investment required.

How Does the 2JZ-GE Engine Differ from Its Turbocharged Counterparts?

The 2JZ-GE is the naturally aspirated variant of the 2JZ family, known for its robust design and good torque characteristics. This engine is ideal for daily drivers and project cars where moderate performance is sufficient. B2B buyers can benefit from its lower cost compared to turbo variants, making it an attractive option for businesses looking to provide reliable yet less performance-intensive solutions. However, it does not offer the same power levels as its turbocharged counterparts, which may limit its appeal in high-performance markets.

What Are the Advantages of Purchasing a Non-VVTI 2JZ-GTE Engine?

The non-VVTI version of the 2JZ-GTE is favored for its simpler design, making it easier to modify and tune. This engine is often sought after for vintage restorations and motorsport applications where classic appeal and performance are paramount. B2B buyers should consider the availability of these engines, as they may be more challenging to find. While they offer a nostalgic value, prospective buyers should also prepare for potential maintenance needs that come with older engines.

Why Choose a 2JZ Turnkey Engine Package for Your Business?

A turnkey engine package offers a fully assembled and dyno-tuned solution that is ready for immediate installation. This option is particularly beneficial for racing teams and performance shops looking to minimize installation time and ensure reliability. B2B buyers should weigh the convenience against the higher price point and limited customization options. The ease of use and reduced labor costs often justify the investment, especially for businesses focused on delivering quick turnaround times.

What Should Buyers Consider When Opting for Built 2JZ Engines?

Built 2JZ engines are custom-engineered to meet specific performance needs, making them ideal for competitive racing and specialized builds. Buyers in the B2B space should assess the lead times associated with these custom builds, as well as the potential for higher costs based on the desired specifications. While the performance potential is significant, the complexity of the build may require a deeper understanding of the engine’s capabilities and the expected outcomes, which is crucial for businesses aiming to meet specific customer demands.

Key Industrial Applications of 2jz engine for sale

| Industry/Sector | Specific Application of 2JZ Engine for Sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Performance | High-Performance Racing Vehicles | Enhanced speed and power, suitable for competitive racing. | Ensure compatibility with existing vehicle systems and regulations. |

| Motorsports | Custom Race Builds for Events | Tailored performance enhancements for specific racing needs. | Look for turnkey packages for quick installation and tuning. |

| Automotive Restoration | Engine Swaps for Classic Cars | Modern powertrain upgrades while retaining classic aesthetics. | Verify engine condition and compatibility with classic models. |

| Commercial Transport | Performance Upgrades for Delivery Vehicles | Increased efficiency and load capacity for logistics firms. | Assess fuel efficiency and emissions compliance for local regulations. |

| Specialty Vehicle Manufacturing | Custom Builds for Off-Road and Adventure Vehicles | Improved durability and performance in challenging terrains. | Evaluate the need for rugged components and aftermarket support. |

How is the 2JZ Engine Used in Automotive Performance?

The 2JZ engine is a favorite in the automotive performance sector, particularly for high-performance racing vehicles. Its robust design and high horsepower output make it ideal for competitive racing, where speed and reliability are crucial. International buyers from regions like Africa and South America often seek these engines to enhance their racing capabilities. When sourcing, businesses must ensure that the engine meets local regulations and is compatible with their current vehicle systems.

What Role Does the 2JZ Engine Play in Motorsports?

In motorsports, the 2JZ engine is frequently utilized for custom race builds tailored to specific events. This flexibility allows teams to fine-tune their vehicles for optimal performance under various racing conditions. Buyers in Europe, especially in countries like Germany, should consider turnkey packages that come pre-tuned for specific applications, minimizing installation time and maximizing track readiness.

Why is the 2JZ Engine Ideal for Automotive Restoration?

The 2JZ engine serves as an excellent option for classic car restorations, enabling enthusiasts to modernize their vehicles with contemporary powertrains. This engine allows for significant performance upgrades while preserving the classic aesthetic. Buyers need to verify the engine’s condition and compatibility with their classic models, ensuring that the installation process aligns with their restoration goals.

How Does the 2JZ Engine Benefit Commercial Transport?

For commercial transport, performance upgrades using the 2JZ engine can lead to increased efficiency and load capacity for delivery vehicles. Logistics firms in the Middle East and Africa can benefit from the enhanced power and reliability, which translates to improved service delivery. When sourcing these engines, businesses must assess fuel efficiency and ensure compliance with local emissions regulations to avoid operational disruptions.

In What Ways Does the 2JZ Engine Support Specialty Vehicle Manufacturing?

The 2JZ engine is popular in the specialty vehicle manufacturing sector, particularly for off-road and adventure vehicles. Its durability and performance in challenging terrains make it a preferred choice for manufacturers looking to create robust vehicles. Buyers should evaluate the need for rugged components and consider aftermarket support options to enhance the vehicle’s overall performance and longevity in demanding environments.

3 Common User Pain Points for ‘2jz engine for sale’ & Their Solutions

Scenario 1: Difficulty in Verifying Engine Quality and Authenticity

The Problem:

B2B buyers in regions such as Africa and South America often struggle with the authenticity and quality of 2JZ engines available for purchase. The fear of acquiring a subpar or counterfeit product can lead to hesitation and significant financial risk. In many cases, buyers may have had previous experiences with unreliable suppliers, resulting in lost investments and unresolved disputes. The challenge is compounded by the lack of accessible information regarding engine specifications and performance history, leading to uncertainty about whether the engine will meet their specific needs for high-performance applications.

The Solution:

To effectively mitigate these concerns, buyers should prioritize sourcing engines from reputable suppliers known for their transparency and customer service. When evaluating potential suppliers, consider asking for detailed documentation, including engine history reports, dyno test results, and warranty information. Suppliers that offer turnkey solutions often provide additional assurances through thorough testing and certification of their products. Furthermore, establishing direct communication with the supplier can facilitate a better understanding of the engine’s specifications and performance metrics, allowing buyers to make more informed decisions. Engaging with online forums or communities dedicated to 2JZ engines can also yield valuable insights and recommendations for trustworthy suppliers.

Scenario 2: Challenges with Engine Installation and Compatibility

The Problem:

Another common pain point for B2B buyers is the installation and compatibility of the 2JZ engine with existing vehicle systems. Many buyers may not have the technical expertise or resources to ensure that the engine fits seamlessly into their vehicles or projects. Additionally, the complexity of modern vehicles means that integrating a new engine often requires additional components, such as transmission adapters or modified wiring harnesses. This can lead to unexpected costs and delays in project timelines, which are particularly problematic for businesses operating on tight schedules.

The Solution:

To address installation challenges, buyers should look for suppliers that offer comprehensive installation support, including detailed guides or manuals specific to the 2JZ engine. Many reputable suppliers provide turnkey packages that come with all necessary components for a successful installation, minimizing compatibility issues. Additionally, investing in professional installation services, if feasible, can ensure that the engine is integrated correctly and efficiently. For companies with in-house mechanics, training sessions or workshops offered by suppliers can enhance their technical capabilities, ultimately leading to smoother installation processes in future projects.

Scenario 3: Navigating Regulatory Compliance and Emissions Standards

The Problem:

B2B buyers, particularly in Europe and the Middle East, frequently face the challenge of complying with stringent emissions regulations when purchasing and installing high-performance engines like the 2JZ. Non-compliance can result in legal penalties, increased costs, and reputational damage. Buyers may be unsure about which engine versions meet local emissions standards, complicating their purchasing decisions and potentially leading to costly modifications post-purchase.

The Solution:

To navigate these regulatory hurdles, it is crucial for buyers to conduct thorough research on local emissions laws and regulations relevant to high-performance engines. Engaging with legal experts or consultants who specialize in automotive compliance can provide clarity on what is permissible in their region. When sourcing a 2JZ engine, buyers should inquire about emissions certifications and compliance reports from suppliers. Opting for engines that are specifically designed for markets with stringent emissions requirements can significantly reduce the risk of non-compliance. Additionally, suppliers that offer modifications or alternative options to meet local standards should be prioritized, ensuring that the engine can be used legally and effectively in the intended applications.

Strategic Material Selection Guide for 2jz engine for sale

What Are the Key Materials Used in the 2JZ Engine?

When considering the 2JZ engine for sale, understanding the materials used in its construction is vital for B2B buyers looking for performance, durability, and compliance with international standards. The 2JZ engine, particularly the 2JZ-GTE variant, is renowned for its robust design and high performance. Below, we analyze four common materials used in the 2JZ engine, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Aluminum in the 2JZ Engine?

Aluminum is a primary material used in the engine block and cylinder heads of the 2JZ engine.

-

Key Properties: Aluminum offers excellent thermal conductivity, making it effective for dissipating heat. It has a relatively low density, which contributes to a lighter engine weight. The material is also resistant to corrosion, especially when anodized or treated.

-

Pros & Cons: The advantages of aluminum include its lightweight nature, which enhances vehicle performance, and its good machinability. However, aluminum can be less durable than other materials under extreme stress or high temperatures, potentially leading to warping or cracking.

-

Impact on Application: Aluminum’s thermal properties make it suitable for high-performance applications, as it can withstand significant temperature fluctuations. However, it may require careful management of operating temperatures to prevent failure.

-

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the availability of aluminum machining services and the need for corrosion protection in humid environments. Compliance with local standards such as ASTM or JIS is crucial for ensuring material quality.

How Does Cast Iron Contribute to Engine Durability?

Cast iron is often used in the engine block of the 2JZ, particularly in high-performance variants.

-

Key Properties: Cast iron has high tensile strength and excellent wear resistance, making it suitable for high-stress applications. It can withstand high temperatures and pressures, which is critical for turbocharged engines.

-

Pros & Cons: The primary advantage of cast iron is its durability and longevity under high-stress conditions. However, it is significantly heavier than aluminum, which can affect overall vehicle performance. Additionally, cast iron can be more challenging to machine, increasing manufacturing complexity.

-

Impact on Application: The strength of cast iron makes it ideal for applications requiring high durability, such as racing or heavy-duty use. Its weight may be a disadvantage in performance-focused applications where weight reduction is critical.

-

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the availability of cast iron components and the need for proper handling to prevent rust. Compliance with standards like DIN is essential for ensuring material quality.

What Role Does Steel Play in 2JZ Engine Components?

Steel is commonly used for various components in the 2JZ engine, including crankshafts, connecting rods, and fasteners.

-

Key Properties: Steel is known for its high tensile strength and toughness, making it suitable for components that experience significant mechanical stress. It also offers good resistance to wear and fatigue.

-

Pros & Cons: The key advantage of steel is its strength and reliability under load. However, the material is heavier than aluminum, which can impact performance. Additionally, steel components may require additional treatments to prevent corrosion.

-

Impact on Application: Steel’s strength makes it ideal for high-performance applications where durability is paramount. However, its weight may be a consideration for buyers focused on optimizing vehicle performance.

-

Considerations for International Buyers: Buyers from regions like Nigeria and Germany should consider the availability of high-quality steel components and ensure compliance with local standards such as JIS or ASTM for quality assurance.

How Does Composite Material Enhance Engine Performance?

Composite materials, particularly in gaskets and seals, are increasingly used in the 2JZ engine.

-

Key Properties: Composites offer excellent resistance to heat and chemicals, making them suitable for high-performance applications. They are lightweight and can be engineered to provide specific performance characteristics.

-

Pros & Cons: The main advantage of composites is their ability to withstand harsh conditions while being lightweight. However, they can be more expensive than traditional materials and may require specialized manufacturing processes.

-

Impact on Application: Composites are particularly beneficial in applications where weight savings and thermal resistance are critical. However, their cost may be a limiting factor for some buyers.

-

Considerations for International Buyers: Buyers should ensure that composite materials meet local regulations and standards, particularly in regions with stringent automotive compliance requirements.

Summary Table of Material Selection for 2JZ Engine

| Material | Typical Use Case for 2JZ Engine for Sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine block, cylinder heads | Lightweight and corrosion-resistant | Less durable under extreme stress | Medium |

| Cast Iron | Engine block | High durability and strength | Heavier, complex machining | Medium |

| Steel | Crankshafts, connecting rods, fasteners | High tensile strength | Heavier, corrosion treatment needed | Medium |

| Composite | Gaskets, seals | Lightweight, heat resistant | Higher cost, specialized manufacturing | High |

This strategic material selection guide serves as a valuable resource for B2B buyers, enabling informed decisions regarding the purchase and application of 2JZ engines in various markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 2jz engine for sale

What Are the Main Stages in the Manufacturing Process of a 2JZ Engine?

The manufacturing of a 2JZ engine, renowned for its durability and performance, involves several critical stages, each requiring precision and expertise. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: Ensuring Quality from the Start

The first step in the manufacturing process is material preparation, where high-quality raw materials are sourced, typically including aluminum for engine blocks and steel for components like crankshafts and camshafts. Suppliers must adhere to strict specifications to ensure the materials can withstand the high stress and temperatures associated with performance engines. This stage often involves rigorous testing of materials, including chemical composition and tensile strength tests, to confirm that they meet industry standards.

Forming: Crafting Engine Components

Once materials are prepared, the forming stage begins. This can involve various techniques, such as casting, forging, and machining.

-

Casting: Engine blocks are often produced through sand casting, where molten metal is poured into molds. This technique allows for complex shapes and excellent dimensional accuracy.

-

Forging: Components that require enhanced strength, like crankshafts, are typically forged. This process involves shaping the metal under high pressure, resulting in a denser and more resilient material.

-

Machining: After forming, components undergo machining processes to achieve precise dimensions and surface finishes. Techniques such as CNC (Computer Numerical Control) machining are commonly employed for their accuracy and efficiency.

Assembly: Bringing It All Together

The assembly phase is where individual components are brought together to create the complete engine. This stage is critical for ensuring that all parts fit correctly and function as intended. Each engine is assembled in a clean environment to prevent contamination, and technicians often use specialized tools and fixtures to maintain consistency.

During assembly, various components such as pistons, crankshafts, camshafts, and turbochargers are installed. Attention to detail is paramount, as even minor errors can lead to significant performance issues.

Finishing: Ensuring Optimal Performance

After assembly, the finishing stage involves several processes aimed at optimizing engine performance. This may include surface treatments, such as anodizing or painting, to enhance durability and resistance to environmental factors. Additionally, engines often undergo balancing procedures to ensure smooth operation at high RPMs.

What Quality Assurance Measures Are Used in 2JZ Engine Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each engine meets specific performance and safety standards. Manufacturers typically adhere to international standards such as ISO 9001, which outlines quality management principles.

What Are the Key Quality Control Checkpoints?

In the context of engine manufacturing, several checkpoints are critical for maintaining quality:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, IPQC involves ongoing inspections and testing at various stages to identify and rectify defects early. This may include dimensional checks, visual inspections, and functional tests.

-

Final Quality Control (FQC): Once assembly is complete, FQC ensures that the entire engine meets performance specifications. This often includes dynamometer testing to verify power output and efficiency.

What International Standards and Certifications Are Relevant for 2JZ Engines?

In addition to ISO 9001, there are several industry-specific standards and certifications that manufacturers may adhere to:

-

CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API Certification: For lubricants used in the engine, API (American Petroleum Institute) certification ensures the oil meets specific performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

Conducting Supplier Audits

B2B buyers should conduct thorough audits of potential suppliers. This can include on-site visits to assess manufacturing processes, cleanliness, and adherence to quality standards. During audits, buyers can review documentation related to quality assurance, including inspection reports and compliance certifications.

Requesting Quality Control Reports

Buyers should request detailed quality control reports that outline the procedures and results of various tests conducted throughout the manufacturing process. This documentation should provide insight into the supplier’s commitment to quality and transparency.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can perform independent evaluations of materials, processes, and finished products, offering buyers peace of mind regarding their purchases.

What Are the Specific Quality Control Nuances for International Buyers?

International buyers must navigate various challenges when sourcing 2JZ engines. This includes understanding the specific regulations and standards in their home countries. For instance, buyers in Europe must be aware of EU regulations regarding emissions and safety standards, while those in Africa and South America may face different compliance requirements.

Moreover, language barriers and cultural differences can impact communication with suppliers. Establishing clear channels of communication and expectations upfront can help mitigate these challenges.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance

The manufacturing processes and quality assurance measures in the production of 2JZ engines are crucial for ensuring that these high-performance engines meet the demands of B2B buyers. By understanding the intricacies of these processes and actively verifying supplier quality controls, international buyers can make informed purchasing decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2jz engine for sale’

To successfully procure a 2JZ engine, particularly for businesses in regions like Africa, South America, the Middle East, and Europe, it is essential to follow a structured approach. This guide provides a step-by-step checklist to help international B2B buyers navigate the sourcing process efficiently.

Step 1: Define Your Technical Specifications

Understanding your needs is critical. Before initiating the search for a 2JZ engine, clearly outline the specific technical requirements. This includes the desired engine type (e.g., 2JZ-GTE or 2JZ-GE), power output, and any additional components such as a transmission or ECU.

- Consider performance goals: Are you looking for an engine suitable for racing or everyday use?

- Identify compatibility: Ensure the engine matches the specifications of the vehicle it will be installed in.

Step 2: Research Reputable Suppliers

Identify trustworthy suppliers to ensure quality. Conduct thorough research to find suppliers who specialize in 2JZ engines. Look for companies with a solid track record and positive reviews from previous customers.

- Utilize online platforms: Explore forums, social media, and B2B marketplaces for recommendations.

- Check ratings and reviews: Look for testimonials specifically mentioning the quality of the engines and customer service.

Step 3: Evaluate Potential Suppliers

Thorough vetting is essential. Before committing to a supplier, evaluate their credibility by requesting company profiles, case studies, and references from similar businesses.

- Ask for certifications: Verify if the supplier has relevant industry certifications that ensure quality and compliance with international standards.

- Request past performance examples: Look for evidence of successful engine installations or sales in your region.

Step 4: Compare Pricing and Warranty Options

Pricing transparency is key to budgeting effectively. Obtain quotes from multiple suppliers and compare not only the prices but also the warranty options offered.

- Understand what’s included: Ensure the price covers all necessary components and shipping costs.

- Review warranty terms: A robust warranty can indicate supplier confidence in their product’s reliability.

Step 5: Assess Shipping and Delivery Terms

Logistics can impact your project timeline. Confirm the shipping options available for your region and understand the delivery timelines.

- Inquire about shipping methods: Air freight may be faster but more expensive, while sea freight is typically more economical but slower.

- Check customs requirements: Be aware of any import regulations specific to your country that may affect delivery.

Step 6: Confirm After-Sales Support

Post-purchase support can save you time and money. Ensure the supplier provides adequate after-sales support, including technical assistance and spare parts availability.

- Ask about support channels: Determine if support is offered through phone, email, or in-person consultations.

- Verify parts availability: Confirm the supplier’s ability to provide replacement parts should they be needed in the future.

Step 7: Finalize the Purchase Agreement

Document everything to protect your investment. Once you have chosen a supplier, carefully review and finalize the purchase agreement.

- Include all agreed terms: Ensure the contract includes price, specifications, delivery terms, and warranty conditions.

- Read the fine print: Pay attention to any clauses that could affect your rights as a buyer, such as return policies or liability limits.

By adhering to this checklist, international B2B buyers can streamline the sourcing process for 2JZ engines, ensuring they make informed decisions that align with their operational needs and expectations.

Comprehensive Cost and Pricing Analysis for 2jz engine for sale Sourcing

What Are the Key Cost Components in Sourcing a 2JZ Engine for Sale?

When sourcing a 2JZ engine, understanding the cost structure is crucial for making informed purchasing decisions. The main cost components include:

-

Materials: The cost of raw materials varies based on the engine specifications. High-performance engines often require advanced materials that can increase costs significantly. Consider the quality of components such as pistons, crankshafts, and turbochargers, as these directly impact performance and durability.

-

Labor: Skilled labor is essential in engine assembly and tuning. Labor costs can vary widely depending on the geographical location of the supplier. For instance, manufacturers in regions with higher labor costs, such as Europe, may charge more than those in Africa or South America.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Overhead can differ based on the production scale and the technological sophistication of the manufacturing process.

-

Tooling: Specialized tools and machinery are often needed to manufacture performance engines. The initial investment in tooling can be substantial, and this cost may be amortized over larger production volumes.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure that the engines meet performance standards. The cost of QC can vary based on the complexity of the engine and the certifications required for international sales.

-

Logistics: Shipping costs, including freight charges and insurance, can fluctuate based on the origin and destination. International shipping may involve additional complexities, such as customs duties and taxes.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can be influenced by the supplier’s reputation, the uniqueness of the engine, and market demand.

How Do Price Influencers Affect the Cost of 2JZ Engines?

Several factors influence the pricing of 2JZ engines, which buyers should consider:

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it beneficial for businesses planning to resell or use multiple engines.

-

Specifications and Customization: Custom features or modifications can significantly increase the price. Buyers should clearly define their specifications to avoid unexpected costs during the manufacturing process.

-

Materials and Quality Certifications: Engines made from high-grade materials or those that meet specific quality certifications (like ISO standards) typically command higher prices. Buyers should assess the long-term benefits of investing in quality.

-

Supplier Factors: The supplier’s experience, reputation, and market position can impact pricing. Established suppliers with a track record of reliability may charge a premium, but they often provide better support and warranty options.

-

Incoterms: Understanding the terms of sale, including who is responsible for shipping and insurance, can affect overall costs. Buyers should clarify these terms to avoid hidden fees.

What Negotiation Strategies Can Help Buyers Obtain Better Prices on 2JZ Engines?

To maximize cost-efficiency when sourcing 2JZ engines, consider the following buyer tips:

-

Negotiate Volume Discounts: If your business requires multiple engines, leverage this to negotiate better pricing. Suppliers are often willing to offer significant discounts for larger orders.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, warranty, and potential resale value. A slightly higher upfront cost may be justified by lower long-term expenses.

-

Research Market Prices: Conduct thorough market research to understand the average prices for 2JZ engines. Having a benchmark will empower you during negotiations and help identify reasonable offers.

-

Be Aware of Pricing Nuances for International Buyers: International buyers should consider factors such as currency fluctuations, import duties, and local regulations. These can affect the final cost and should be factored into budget planning.

Conclusion

Sourcing a 2JZ engine involves careful consideration of various cost components and price influencers. By understanding these elements and employing strategic negotiation techniques, international buyers can secure favorable deals while ensuring high-quality performance. Always remember that indicative prices can fluctuate based on market conditions and specific requirements, so remain flexible and informed throughout the purchasing process.

Alternatives Analysis: Comparing 2jz engine for sale With Other Solutions

Exploring Alternatives to the 2JZ Engine for Sale

When considering the purchase of a high-performance engine, such as the 2JZ engine, it is crucial to evaluate viable alternatives that may meet your specific operational needs. The 2JZ engine, known for its robust performance and tuning potential, is a popular choice among automotive enthusiasts and professionals. However, alternative engine options may provide similar performance benefits or cost efficiencies. In this analysis, we will compare the 2JZ engine against other performance engines and technologies to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | 2JZ Engine For Sale | Alternative 1: RB26DETT Engine | Alternative 2: LS V8 Engine |

|---|---|---|---|

| Performance | Up to 1,000 HP with tuning | Up to 800 HP with tuning | Up to 1,000 HP with tuning |

| Cost | $3,500 – $10,000 depending on package | $4,000 – $8,000 | $5,000 – $12,000 |

| Ease of Implementation | Turnkey solutions available | Requires custom mounts | Requires custom mounts, but widely supported |

| Maintenance | Moderate; parts availability good | Moderate; parts availability fair | Generally good; widespread parts availability |

| Best Use Case | High-performance builds, drift, and racing | Racing, drift, and street builds | Versatile use in various vehicles, including muscle and sports cars |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of the RB26DETT Engine?

The RB26DETT engine, famed for its use in the Nissan Skyline GT-R, is a well-regarded alternative to the 2JZ engine. It offers exceptional tuning potential, with a power output of up to 800 HP when modified. However, while it provides robust performance, it often requires custom mounts and modifications for installation, which can increase labor costs and complexity. Additionally, parts availability may not be as extensive as that of the 2JZ, making maintenance more challenging in some regions.

How Does the LS V8 Engine Compare?

The LS V8 engine series is a popular choice due to its broad application across various automotive platforms. With the potential to reach power outputs of 1,000 HP, it is a strong contender for performance enthusiasts. The LS engine’s widespread parts availability and support from the aftermarket community make maintenance relatively straightforward. However, installation may require custom mounts, and buyers should be prepared for additional costs related to adapting the engine to their specific vehicle. The LS engine is particularly favored for muscle cars and hot rods, making it a versatile choice for many projects.

Conclusion: How Should B2B Buyers Choose the Right Engine?

When selecting an engine for high-performance applications, B2B buyers must consider their specific needs, including performance goals, budget constraints, and installation capabilities. The 2JZ engine stands out for its tuning capabilities and ease of installation with turnkey solutions. In contrast, the RB26DETT offers an alternative with strong performance but may require additional custom work. The LS V8 engine presents a versatile option with excellent parts availability but comes with its own installation challenges. Ultimately, buyers should assess their operational requirements and long-term goals to determine the best engine solution for their projects.

Essential Technical Properties and Trade Terminology for 2jz engine for sale

What Are the Key Technical Properties of the 2JZ Engine for Sale?

Understanding the technical specifications of the 2JZ engine is crucial for B2B buyers looking to invest in high-performance automotive components. Here are some of the essential properties to consider:

Engine Displacement and Configuration

The 2JZ engine is a 3.0-liter inline-six (straight-six) engine. This configuration is known for its balance and smooth operation. The engine’s displacement of 2,997 cm³ allows for efficient power generation while maintaining a compact design. For buyers, this means they can expect a robust performance, particularly in applications requiring high power output, such as racing or performance tuning.

Power Output and Torque

The 2JZ-GTE variant is equipped with twin turbochargers, delivering a maximum power output of approximately 276 HP in the JDM version and up to 320.5 HP for the North American and European markets. The torque figures range from 318.8 ft-lb to 325.5 ft-lb, depending on the market specification. This high power-to-weight ratio is critical for buyers focusing on performance-driven projects, ensuring that the engine can meet or exceed the demands of high-speed applications.

Fuel System and Injection Type

The engine employs a multi-point fuel injection system, which optimizes fuel delivery for better performance and efficiency. This feature is particularly important for B2B buyers as it enhances the engine’s responsiveness and power output, while also contributing to fuel economy. Understanding the fuel system helps buyers assess compatibility with their existing setups and fuel types.

Materials and Build Quality

The 2JZ engine is constructed with high-grade materials designed for durability and performance under extreme conditions. The use of quality alloys in the engine block and components minimizes wear and tear, extending the engine’s lifespan. Buyers should prioritize engines with verified material quality to ensure reliability in demanding applications.

Weight and Dimensions

Weighing approximately 230 kg (507 lbs), the 2JZ engine’s dimensions allow for versatile installation options in various vehicles. Its weight-to-power ratio is a critical factor for buyers, particularly those considering modifications or swaps in lighter chassis.

What Are the Common Trade Terms Related to 2JZ Engines?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms related to the sale of 2JZ engines:

What Does OEM Mean in the Context of Engine Sales?

OEM stands for Original Equipment Manufacturer. In the context of the 2JZ engine, it refers to parts that are made by the original manufacturer (Toyota) or authorized suppliers. Purchasing OEM parts ensures that the components meet the original specifications and quality standards, which is crucial for maintaining performance and reliability in high-performance applications.

What is MOQ and Why Is It Important?

MOQ stands for Minimum Order Quantity. This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory levels and procurement strategies effectively, especially when sourcing multiple engines or components.

How Does an RFQ Function in Engine Procurement?

RFQ, or Request for Quotation, is a standard business process where buyers solicit price quotes from suppliers for specific products. An RFQ allows buyers to compare prices, terms, and conditions from different suppliers, ensuring they make informed purchasing decisions.

What Are Incoterms and Their Relevance?

Incoterms, or International Commercial Terms, are pre-defined commercial terms published by the International Chamber of Commerce (ICC) related to international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers involved in international transactions, as it helps clarify shipping responsibilities and costs.

By understanding these technical specifications and trade terms, B2B buyers can make informed decisions when purchasing 2JZ engines, ensuring they select the right components for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the 2jz engine for sale Sector

What Are the Current Market Dynamics and Key Trends in the 2JZ Engine for Sale Sector?

The global market for the 2JZ engine, renowned for its performance and reliability, is experiencing robust growth driven by several factors. The automotive industry is witnessing a resurgence in interest for high-performance engines, particularly among enthusiasts and competitive racers. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where performance modifications are increasingly popular. Key drivers include the rise of motorsports, the growing culture of car tuning, and the increasing accessibility of JDM (Japanese Domestic Market) vehicles.

Emerging technologies are reshaping sourcing strategies within the B2B landscape. Online marketplaces and platforms that specialize in JDM parts are gaining traction, offering international buyers an easier and more transparent purchasing process. Furthermore, advancements in logistics and supply chain management are enabling faster and more cost-effective shipping options. B2B buyers are also increasingly leveraging data analytics to make informed sourcing decisions, ensuring they are purchasing high-quality engines that meet their performance needs.

Additionally, sustainability is becoming a critical consideration in the sourcing of automotive components. Buyers are now more conscious of the environmental impact associated with performance engines, prompting manufacturers to adopt eco-friendly practices. This shift not only aligns with global sustainability goals but also appeals to a growing base of environmentally aware consumers.

How Can Sustainability and Ethical Sourcing Impact the 2JZ Engine Market?

The environmental impact of automotive manufacturing and sourcing is a crucial concern for modern B2B buyers. The production of performance engines like the 2JZ can lead to significant emissions and resource depletion. Therefore, companies in this sector must prioritize sustainability in their operations. This can include utilizing recycled materials, reducing waste during manufacturing, and optimizing energy use throughout the production process.

Ethical sourcing is also gaining prominence, with buyers increasingly seeking suppliers who adhere to responsible labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility are becoming important indicators for B2B buyers when assessing potential suppliers. By choosing partners who prioritize ethical practices, companies can enhance their brand reputation while contributing positively to the communities in which they operate.

Furthermore, the demand for ‘green’ certifications is rising, with buyers looking for engines and components that have been produced with minimal environmental impact. As the automotive industry continues to evolve, integrating sustainability and ethical sourcing into the supply chain will not only be a competitive advantage but also a necessity for long-term viability in the market.

What Is the Historical Context of the 2JZ Engine’s Popularity in B2B Markets?

The 2JZ engine, particularly the 2JZ-GTE variant, has a storied history that significantly influences its current B2B appeal. Originally developed by Toyota in the early 1990s, the 2JZ was designed to power the iconic MKIV Supra, which quickly became a favorite among car enthusiasts and racers. Known for its durability and tunability, the 2JZ gained a reputation as a powerhouse capable of producing impressive horsepower figures, making it a staple in the performance automotive market.

Over the years, the 2JZ has found its way into various applications beyond the Supra, including other Toyota models and custom builds, further solidifying its status as a sought-after engine in the aftermarket scene. The engine’s ability to handle high horsepower modifications without compromising reliability has made it a go-to choice for both casual tuners and professional racers alike.

As interest in motorsports and automotive modifications continues to grow globally, the 2JZ engine remains a pivotal component in the B2B automotive landscape, offering opportunities for suppliers and buyers to connect over a shared passion for performance.

Frequently Asked Questions (FAQs) for B2B Buyers of 2jz engine for sale

-

How do I ensure the quality of a 2JZ engine before purchasing?

To ensure the quality of a 2JZ engine, request detailed specifications and documentation from the supplier. Look for certifications or warranties that guarantee the engine’s performance and reliability. Additionally, consider purchasing from reputable suppliers with positive reviews and a proven track record in the industry. It’s also beneficial to inquire about the engine’s history, including mileage and maintenance records, to assess its condition. -

What are the typical payment terms for purchasing a 2JZ engine internationally?

Payment terms can vary significantly among suppliers. Common options include upfront payment, partial payment before shipment, or payment upon delivery. For international transactions, using secure payment methods like letters of credit or escrow services can protect both parties. Always clarify the payment terms in writing before finalizing the purchase to avoid misunderstandings. -

What is the best way to import a 2JZ engine from the USA to my country?

The best way to import a 2JZ engine from the USA involves selecting a reliable freight forwarder familiar with automotive parts. Ensure compliance with your country’s import regulations, including customs duties and taxes. Prepare all necessary documentation, such as the bill of lading and invoices, to facilitate smooth customs clearance. Additionally, consider insurance for your shipment to protect against potential damages during transit. -

Can I customize a 2JZ engine package to meet specific performance needs?

Yes, many suppliers offer customization options for 2JZ engine packages. You can specify performance upgrades, such as turbocharger enhancements, ECU tuning, and additional components. Discuss your requirements with the supplier to ensure they can accommodate your needs. Customization may also affect the lead time and pricing, so be sure to clarify these details upfront. -

What are the minimum order quantities (MOQ) when sourcing 2JZ engines?

Minimum order quantities for 2JZ engines can vary by supplier. Some may allow single-unit purchases, while others might require bulk orders to offer competitive pricing. It’s advisable to inquire about MOQs before committing to a supplier. If you are a smaller business, negotiating terms or seeking out suppliers who specialize in smaller orders can be beneficial. -

How can I vet potential suppliers for 2JZ engines?

To vet potential suppliers, conduct thorough research, including checking their business credentials, customer reviews, and industry reputation. Request references from past clients and assess their response times and willingness to provide detailed product information. Additionally, consider visiting the supplier’s facilities if possible or arranging a video call to get a better understanding of their operations. -

What logistics considerations should I be aware of when shipping a 2JZ engine?

When shipping a 2JZ engine, consider factors such as shipping method, costs, and transit times. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency. Additionally, ensure that the engine is properly packaged to prevent damage during transit. Understanding customs regulations and duties in your country is also crucial to avoid delays. -

What warranties or guarantees should I expect with a 2JZ engine purchase?

Most reputable suppliers offer warranties on their 2JZ engines, typically covering defects in materials or workmanship for a specified period. Warranties may vary by supplier, so it’s essential to read the terms carefully. Additionally, inquire about the process for claiming warranty service, including what documentation is required and how long the turnaround time is for repairs or replacements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 2Jz Engine For Sale Manufacturers & Suppliers List

1. Brangers Racing – Turnkey 2JZ Engine Packages

Domain: brangersracing.com

Registered: 2008 (17 years)

Introduction: 2JZ Engine for Sale – True Dyno Tuned Turnkey 2JZ Engine Packages. Easy installation: hook up 3 wires and go. 1000 HP 2JZ Turn-Key Engine Package and 2500 HP 2JZ BRE Compound Turbo available. Warranties provided on all products (racing parts excluded). Commitment to high-quality parts from reputable brands. Designed for sanctioned off-road/competition non-emissions controlled vehicles only.

2. Toyota – 1989 Supra MA70L 3.0L Engine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 1989 TOYOTA SUPRA MA70L MK3 3.0L 7MGE COMPLETE ENGINE MOTOR 128K MILES, Pre-Owned, Price: $2,989.97 (Was: $3,737.46), Shipping: $300.00, For: Toyota Supra

3. JDM Toyota – 2JZ GTE VVTI Engine

Domain: nwjdmmotors.com

Registered: 2022 (3 years)

Introduction: Product Name: JDM Toyota 2JZ GTE VVTI

Price: $3,350.00

Rating: 4.93 out of 5 based on 122 customer ratings

Mileage: 51,123 miles

Engine Code: 2JZ-GTE

Engine Layout: Inline-6 (Straight-6)

Fuel Type: Gasoline

Displacement: 3.0 L (2,997 cm³)

Fuel System: Multi-point fuel injection

Max Horsepower: JDM: 280 PS (276 HP) at 5,600 rpm; North America/Europe: 325 PS (320.5 HP) at 5,600 rpm

Max Torque: JDM: …

4. JDM Engine Depot – 2JZGTE Engine for Sale

Domain: jdmenginedepotinc.com

Registered: 2017 (8 years)

Introduction: 2JZGTE Engine for Sale – Price: $17,799.00 (originally $17,999.00). Includes Toyota Supra Twin Turbo VVTI Engine, 6SPD Transmission, Loom, and ECU. JDM Engine Depot offers reliable and tested JDM engines, with features such as robust construction, high horsepower potential, and designed for longevity. Located in Belleville, NJ. Contact: (877) 955-9556.

5. GReddy – 2JZ VVTi Complete Crate Engine

Domain: greddy.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “GReddy 2JZ VVTi Complete Crate Engine (Long Block)”, “sale_price”: “$52,000.00”, “regular_price”: “$52,000.00”, “engine_models”: [{“model”: “GReddy 2JZ VVTi Complete Crate Engine (Long Block)”, “price”: “$52,000.00”}, {“model”: “GReddy 2JZ (non-VVTi) Complete Crate Engine (Long Block)”, “price”: “$52,000.00”}], “optional_components”: [{“type”: “Turbo Manifold”, “options”: [“None …

6. Toyota – 2JZ Engine Details

Domain: japan-partner.com

Registered: 2001 (24 years)

Introduction: Toyota 2JZ engine details:

– Models: Aristo V300, Supra, ALTEZZA GITA AS300, CROWN Royal Saloon, CROWN Majesta, BREVIS Ai300, etc.

– Year Range: 1993 to 2003

– Mileage Range: 34,809 km to 215,000 km

– Engine Displacement: 2990cc to 3000cc

– Turbo: Yes/No

– Transmission: Manual (MT) / Automatic (AT)

– Steering: Right

– Prices: Ranging from $2,043 to $43,793

– Stock Numbers: Various (e.g., …

7. SupraForums – 2JZ-GTE Engine Insights

Domain: supraforums.com

Registered: 2000 (25 years)

Introduction: 2JZ-GTE VVTI engine; price range: $2,000 to $10,000; potential for high output (500-1000+ hp); options for building from a GE engine; availability of complete engines for $1.5k-$2k; JDM imports; major issues to look for include engine condition and parts quality; advice on upgrading internals for performance.

8. 2JZ Engine – Options & Recommendations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2JZ engine options include 2JZ-GE (non-turbo) and 2JZ-GTE (turbo). Common vehicles with 2JZ-GE include late 90’s and early 2000’s Lexus models like IS300, GS300, and SC300. The 2JZ-GTE is primarily found in the Toyota Supra turbo and is harder to find and more expensive. Recommendations for purchasing include looking for local importers of half-cuts, searching online marketplaces, or checking loca…

9. Facebook – 2JZ Crate Motor

Strategic Sourcing Conclusion and Outlook for 2jz engine for sale

In conclusion, the market for 2JZ engines presents a unique opportunity for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. Strategic sourcing of these high-performance engines is crucial, as it allows buyers to secure reliable products that meet specific performance needs while optimizing costs. Key takeaways from this guide emphasize the importance of partnering with reputable suppliers who offer turnkey engine packages, ensuring ease of installation and consistent quality.

Investing in a 2JZ engine not only enhances vehicle performance but also provides a competitive edge in the automotive market. As demand for these engines continues to rise, buyers should act proactively, leveraging supplier relationships to access the best products and prices.

Looking ahead, we encourage international buyers to explore partnerships that prioritize quality, customer service, and warranty options. By doing so, businesses can position themselves effectively in a dynamic market. Start your sourcing journey today, and unlock the potential of the legendary 2JZ engine for your projects.