Is Your Contract Packaging Applications Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for contract packaging applications

In an increasingly competitive global marketplace, businesses face the pressing challenge of efficiently sourcing contract packaging applications that meet their unique product requirements. As companies strive to optimize their operations while maintaining compliance with industry standards, understanding the intricacies of contract packaging becomes essential. This guide delves into the diverse applications of contract packaging, covering critical sectors such as food and beverage, pharmaceuticals, consumer goods, and more. It provides an extensive overview of the types of services available, the latest market trends, and key considerations for vetting suppliers.

International B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, will find this resource invaluable for making informed purchasing decisions. By addressing factors such as cost efficiency, regulatory compliance, and scalability, this guide equips businesses with actionable insights to navigate the complexities of contract packaging. Whether you are looking to enhance product presentation, streamline logistics, or ensure quality control, the knowledge contained within these pages will empower your organization to forge successful partnerships with contract packaging providers. Embrace the opportunity to elevate your packaging strategy and gain a competitive edge in the global market.

Understanding contract packaging applications Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Food and Beverage Contract Packaging | Compliance with food safety regulations, high throughput | Snacks, beverages, frozen meals, sauces | Pros: Access to specialized facilities; Cons: Risk of dependency on co-packer. |

| Pharmaceutical Packaging | GMP-certified cleanrooms, serialization, tamper-evidence | Prescription drugs, OTC medications, medical devices | Pros: High compliance standards; Cons: Higher costs due to stringent regulations. |

| Consumer Goods Packaging | Versatile packaging formats, regulatory compliance | Cosmetics, personal care products, household cleaners | Pros: Flexibility in design; Cons: Potential quality variability. |

| Industrial and Chemical Packaging | Handling of hazardous materials, safety sealing | Lubricants, adhesives, paints, solvents | Pros: Expertise in hazardous materials; Cons: Limited to specific industries. |

| E-commerce and Retail Packaging | Custom kitting, rapid turnaround for seasonal products | Subscription boxes, promotional packaging, gift sets | Pros: Quick response to market trends; Cons: May require higher logistics coordination. |

What are the key characteristics of Food and Beverage Contract Packaging?

Food and beverage contract packaging is characterized by its strict adherence to health and safety regulations, such as FDA and HACCP standards. This type of packaging often involves processes like bottling, pouch filling, and vacuum sealing. It is particularly suitable for businesses looking to scale production without significant capital investment in packaging facilities. When considering a food co-packer, buyers should evaluate the provider’s compliance history, facility certifications, and production capabilities to ensure quality and safety.

How does Pharmaceutical Packaging ensure compliance?

Pharmaceutical packaging is distinguished by its focus on compliance and safety, often requiring GMP-certified environments and tamper-evident seals. This type of packaging is essential for prescription and over-the-counter medications, as well as medical devices. Buyers in the pharmaceutical sector must prioritize co-packers who can demonstrate stringent quality control measures, serialization capabilities, and a thorough understanding of regulatory requirements. This ensures product integrity and consumer safety, albeit at a potentially higher cost.

What makes Consumer Goods Packaging versatile?

Consumer goods packaging is known for its versatility in accommodating a wide range of products, including cosmetics and personal care items. This type of packaging can involve various formats, such as tubes, jars, and sachets, and must comply with labeling regulations. B2B buyers should consider the co-packer’s ability to handle diverse product lines and their experience with regulatory compliance. While this flexibility can be beneficial, it may also lead to variability in quality, making supplier reliability critical.

Why is Industrial and Chemical Packaging specialized?

Industrial and chemical packaging is specialized for handling hazardous materials and ensuring compliance with safety regulations such as OSHA and EPA. This type of packaging is suitable for products like lubricants and solvents, where safety is paramount. Buyers in this sector should look for co-packers with expertise in managing hazardous materials and the necessary certifications. While this specialization can provide peace of mind regarding safety, it may limit options to specific industries or product types.

How does E-commerce and Retail Packaging adapt to market demands?

E-commerce and retail packaging is characterized by its ability to respond quickly to changing market demands, particularly for seasonal or promotional products. This type of packaging often involves custom kitting and assembly for subscription boxes or gift sets. Buyers should prioritize co-packers that offer rapid turnaround times and flexible solutions to accommodate fluctuating demand. However, managing logistics and coordination can be more complex, requiring careful planning and communication with the co-packer.

Key Industrial Applications of contract packaging applications

| Industry/Sector | Specific Application of Contract Packaging Applications | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Co-packing of ready-to-eat meals and snacks | Access to food-safe facilities and compliance with regulations | Certification and compliance with local food safety standards |

| Pharmaceuticals | Blister packaging for tablets and capsules | Ensures product safety, traceability, and regulatory compliance | GMP certification and tamper-evident packaging capabilities |

| Consumer Goods and Personal Care | Filling and labeling of cosmetics and personal care products | Scalable production and regulatory adherence | Equipment compatibility for diverse packaging formats |

| Industrial Chemicals | Packaging of hazardous materials like solvents | Compliance with safety regulations and efficient handling | Knowledge of hazardous material regulations and safety protocols |

| Electronics and Technology | Assembly and packaging of consumer electronics | Protection of sensitive components and enhanced retail appeal | ESD-safe environments and custom packaging solutions |

How is Contract Packaging Used in the Food and Beverage Industry?

In the food and beverage sector, contract packaging is crucial for companies looking to efficiently package products like ready-to-eat meals and snacks. Co-packers provide specialized facilities that comply with stringent food safety regulations, allowing brands to focus on product development rather than packaging logistics. This approach not only ensures compliance with local standards but also mitigates the risks associated with in-house packaging, such as contamination or inefficiency. International buyers must consider the co-packer’s certifications and their ability to meet specific food safety standards relevant to their market.

What Are the Applications of Contract Packaging in Pharmaceuticals?

Pharmaceutical companies frequently utilize contract packaging for blister packaging of tablets and capsules. This process is vital for ensuring product integrity and traceability, particularly in highly regulated environments. Co-packers must adhere to Good Manufacturing Practices (GMP) to ensure that packaging meets the necessary safety and compliance requirements. For international buyers, sourcing a co-packer with experience in regulatory compliance is essential to avoid costly delays and ensure that products are market-ready.

How Do Consumer Goods Companies Benefit from Contract Packaging?

In the consumer goods and personal care sector, contract packaging allows brands to efficiently fill and label products such as cosmetics and personal care items. Co-packers offer the flexibility to scale production according to demand while ensuring compliance with labeling regulations. This is particularly advantageous for startups that may not have the capital to invest in their own packaging lines. For international buyers, it’s crucial to assess the co-packer’s capability to handle diverse packaging formats and maintain quality across production runs.

Why Is Contract Packaging Important for Industrial Chemicals?

Contract packaging plays a significant role in the industrial chemicals sector, particularly for hazardous materials such as solvents and adhesives. Co-packers ensure compliance with safety regulations, including OSHA and EPA standards, which is critical for protecting both employees and consumers. They also provide specialized equipment for safe handling and labeling of these materials. Buyers in this sector must prioritize sourcing partners with a deep understanding of hazardous material regulations and a proven track record in safety compliance.

What Are the Key Considerations for Electronics and Technology Packaging?

In the electronics and technology industry, contract packaging is essential for the assembly and packaging of sensitive products like USB drives and batteries. Co-packers provide ESD-safe environments that protect against static damage, ensuring product safety during packaging. Additionally, custom packaging solutions can enhance retail appeal and branding. For international buyers, it’s important to evaluate a co-packer’s experience with electronics, including their ability to provide tailored packaging solutions that meet specific market demands.

3 Common User Pain Points for ‘contract packaging applications’ & Their Solutions

Scenario 1: Navigating Compliance Challenges in Contract Packaging

The Problem:

In the highly regulated sectors of food and pharmaceuticals, B2B buyers often struggle to meet stringent compliance requirements. For example, a mid-sized health supplement company may find itself overwhelmed by the need to adhere to FDA regulations, including GMP (Good Manufacturing Practices) and labeling laws. This challenge can lead to costly delays and potential fines if compliance issues arise, ultimately impacting market entry and brand reputation.

The Solution:

To effectively navigate these compliance challenges, it’s crucial to partner with a contract packaging provider that specializes in your industry. Look for companies with a proven track record of compliance and certifications relevant to your sector. Conduct thorough due diligence by requesting documentation of their compliance history and certifications. Moreover, engage in a collaborative dialogue with your chosen provider to ensure they understand your specific requirements and can offer tailored solutions. For instance, if you need to package a new line of dietary supplements, ensure your partner can provide GMP-certified facilities and expertise in regulatory labeling to avoid potential pitfalls. Additionally, consider leveraging technology solutions such as compliance management software to streamline documentation and track adherence to regulations throughout the packaging process.

Scenario 2: Managing Fluctuating Demand and Production Scale

The Problem:

B2B buyers in industries like consumer goods often face unpredictable demand fluctuations, making it difficult to maintain an efficient packaging operation. For example, a seasonal snack brand may experience a surge in demand during holidays but struggle with excess inventory during off-peak months. This volatility can lead to wasted resources, increased costs, and challenges in maintaining product quality.

The Solution:

To manage fluctuating demand effectively, consider implementing a flexible contract packaging arrangement. Choose a partner that offers scalable solutions, allowing you to increase or decrease production volume as needed without incurring hefty costs. For instance, you could negotiate a contract that allows for on-demand production during peak seasons while enabling reduced capacity during slower periods. Additionally, explore the possibility of utilizing just-in-time (JIT) inventory strategies. This approach minimizes excess inventory by synchronizing packaging production with actual sales forecasts. Collaborate closely with your packaging partner to share sales data and market insights, allowing them to adapt their resources and capabilities to better align with your needs.

Scenario 3: Ensuring Consistency in Quality and Brand Integrity

The Problem:

For B2B buyers, maintaining product quality and brand integrity is paramount. A cosmetics brand may face challenges when outsourcing its packaging, risking inconsistency in product presentation and customer perception. If the contract packaging provider fails to adhere to the specified quality standards, it can lead to a poor customer experience and damage brand reputation.

The Solution:

To ensure consistency in quality and brand integrity, establish clear quality metrics and expectations with your contract packaging partner from the outset. Create a comprehensive quality assurance plan that outlines specific standards for packaging materials, processes, and final product inspections. Regularly schedule quality audits and encourage open communication channels to address any issues proactively. Additionally, consider implementing a trial run or pilot project before full-scale production. This allows you to evaluate the packaging process and make necessary adjustments to meet your quality standards. Investing in advanced packaging technologies, such as automated inspection systems, can also enhance quality control by identifying defects or inconsistencies in real-time, ensuring your products consistently reflect your brand’s values and quality commitments.

Strategic Material Selection Guide for contract packaging applications

What Are the Key Properties of Common Materials Used in Contract Packaging Applications?

When selecting materials for contract packaging applications, understanding their properties is crucial. Here, we analyze four common materials: polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and paperboard. Each material has unique characteristics that influence its suitability for various products.

Polyethylene (PE)

Polyethylene is one of the most widely used plastics in packaging due to its versatility and cost-effectiveness. It offers excellent moisture resistance and is suitable for a range of temperatures, making it ideal for food and beverage applications. PE can withstand low temperatures without becoming brittle, which is beneficial for frozen products.

Pros: PE is lightweight, durable, and has good chemical resistance. It is also recyclable, which appeals to environmentally conscious brands.

Cons: However, it has limited barrier properties against gases and aromas, which may not be suitable for products requiring extended shelf life.

Impact on Application: PE is commonly used for flexible packaging, such as pouches and bags, particularly in the food industry.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local food safety regulations. Standards such as ASTM D882 for tensile properties are essential for quality assurance.

Polypropylene (PP)

Polypropylene is another popular choice, known for its high clarity and strength. It has a higher melting point than PE, making it more suitable for products that require heat sealing. PP is also resistant to many chemicals, which is advantageous for packaging pharmaceuticals and personal care products.

Pros: Its rigidity and toughness provide excellent protection for products, while its transparency enhances shelf appeal.

Cons: The main limitation of PP is its higher cost compared to PE, which may not be feasible for all budget ranges.

Impact on Application: PP is often used for containers, bottles, and rigid packaging solutions, especially in the cosmetics and personal care sectors.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of compliance with regulations such as REACH and the European Plastics Regulation. Familiarity with DIN standards for testing the mechanical properties of PP can also be beneficial.

Polyvinyl Chloride (PVC)

PVC is known for its durability and versatility, making it suitable for a wide range of applications. It offers excellent barrier properties against moisture, gases, and UV light, which is particularly beneficial for sensitive products.

Pros: PVC is highly customizable, allowing for various formulations that can enhance its properties, such as flexibility or rigidity.

Cons: However, environmental concerns regarding the production and disposal of PVC can be a drawback, as it is not as easily recyclable as other plastics.

Impact on Application: Commonly used in blister packaging for pharmaceuticals and electronics, PVC ensures product protection and visibility.

Considerations for International Buyers: Compliance with international standards like ISO 11607 for packaging of terminally sterilized medical devices is crucial for buyers in the healthcare sector.

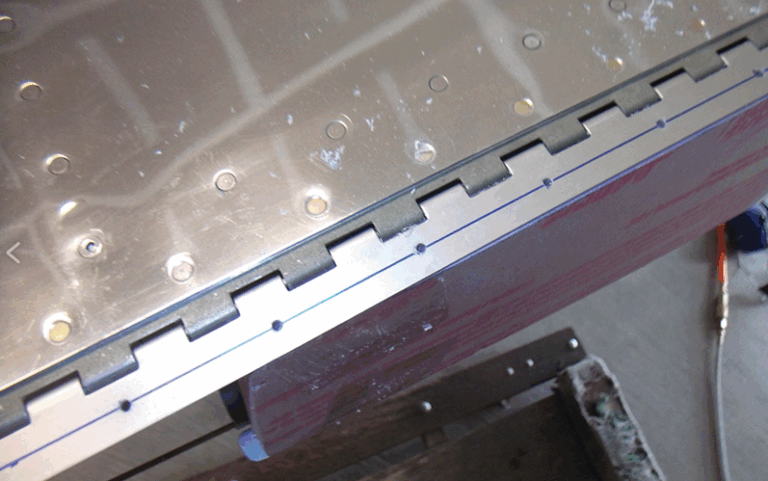

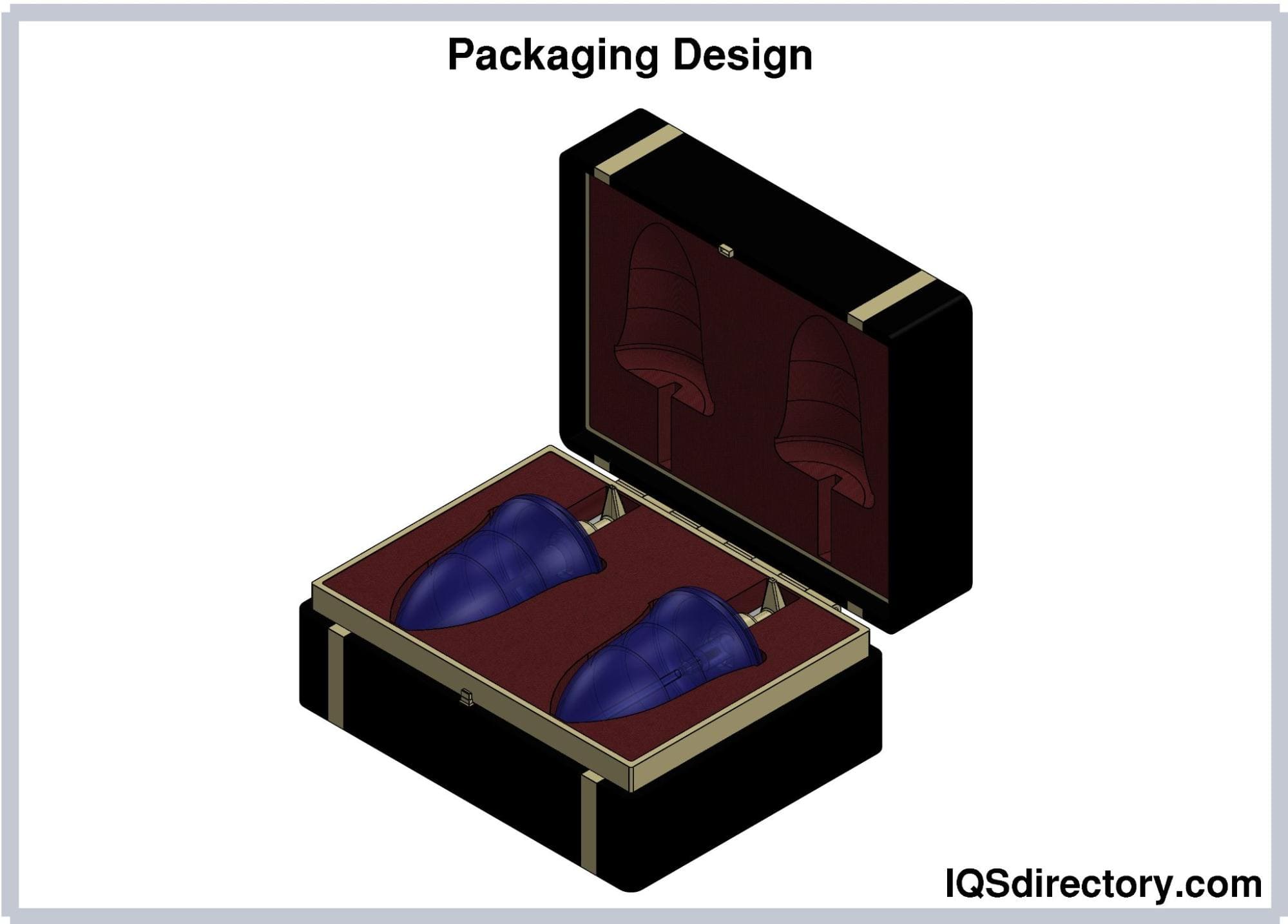

Illustrative image related to contract packaging applications

Paperboard

Paperboard is a sustainable option that offers excellent printability and branding opportunities. It is lightweight yet strong, making it suitable for a variety of products, including food, cosmetics, and consumer goods.

Pros: Its recyclability and biodegradability make it an attractive option for eco-conscious brands.

Cons: Paperboard is less moisture-resistant than plastics, which may limit its use for certain applications without additional coatings.

Impact on Application: It is often used for boxes, cartons, and displays, providing a strong branding presence on retail shelves.

Considerations for International Buyers: Buyers from regions like South America and Africa should consider local recycling capabilities and compliance with standards such as ISO 14001 for environmental management.

Summary Table of Material Selection for Contract Packaging

| Material | Typical Use Case for contract packaging applications | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Flexible packaging (pouches, bags) | Excellent moisture resistance | Limited barrier properties against gases | Low |

| Polypropylene (PP) | Rigid packaging (containers, bottles) | High clarity and strength | Higher cost compared to PE | Med |

| Polyvinyl Chloride (PVC) | Blister packaging (pharmaceuticals, electronics) | Excellent barrier properties | Environmental concerns regarding recyclability | Med |

| Paperboard | Boxes, cartons, and displays | Sustainable and strong branding opportunities | Less moisture-resistant without coatings | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in contract packaging applications. Understanding these factors can help businesses make informed decisions that align with their product requirements and market regulations.

Illustrative image related to contract packaging applications

In-depth Look: Manufacturing Processes and Quality Assurance for contract packaging applications

What Are the Main Stages of Manufacturing Processes in Contract Packaging?

Contract packaging encompasses a series of manufacturing processes tailored to meet the unique needs of diverse industries. Understanding these processes is essential for B2B buyers aiming to partner with the right contract packaging firms. The main stages of manufacturing in contract packaging typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Contract Packaging?

The first step in the manufacturing process involves material preparation, where raw materials are sourced and prepped for packaging. This includes selecting appropriate packaging materials that comply with industry standards, such as food safety regulations for the food and beverage sector or tamper-proof requirements for pharmaceuticals. The materials must undergo quality checks to ensure they meet the specifications set by the client, which may involve testing for durability, safety, and compliance with relevant regulations.

What Techniques Are Used in the Forming Stage of Contract Packaging?

Once the materials are prepared, the next stage is forming. This involves converting raw materials into the desired packaging formats. Techniques such as thermoforming for blister packs, injection molding for containers, and die-cutting for cartons are commonly employed. Each technique is selected based on the product type and the required specifications. For example, food packaging may require vacuum sealing to extend shelf life, while pharmaceutical packaging often necessitates blister packaging to ensure product integrity.

How Does the Assembly Process Work in Contract Packaging?

Following the forming stage, the assembly process brings together various components of the packaging. This may include filling products into containers, sealing pouches, and labeling. Advanced automation is increasingly utilized to enhance efficiency and reduce human error, especially in high-volume production runs. For instance, a co-packer may use high-speed filling machines to fill thousands of bottles per hour, ensuring consistent volume and quality.

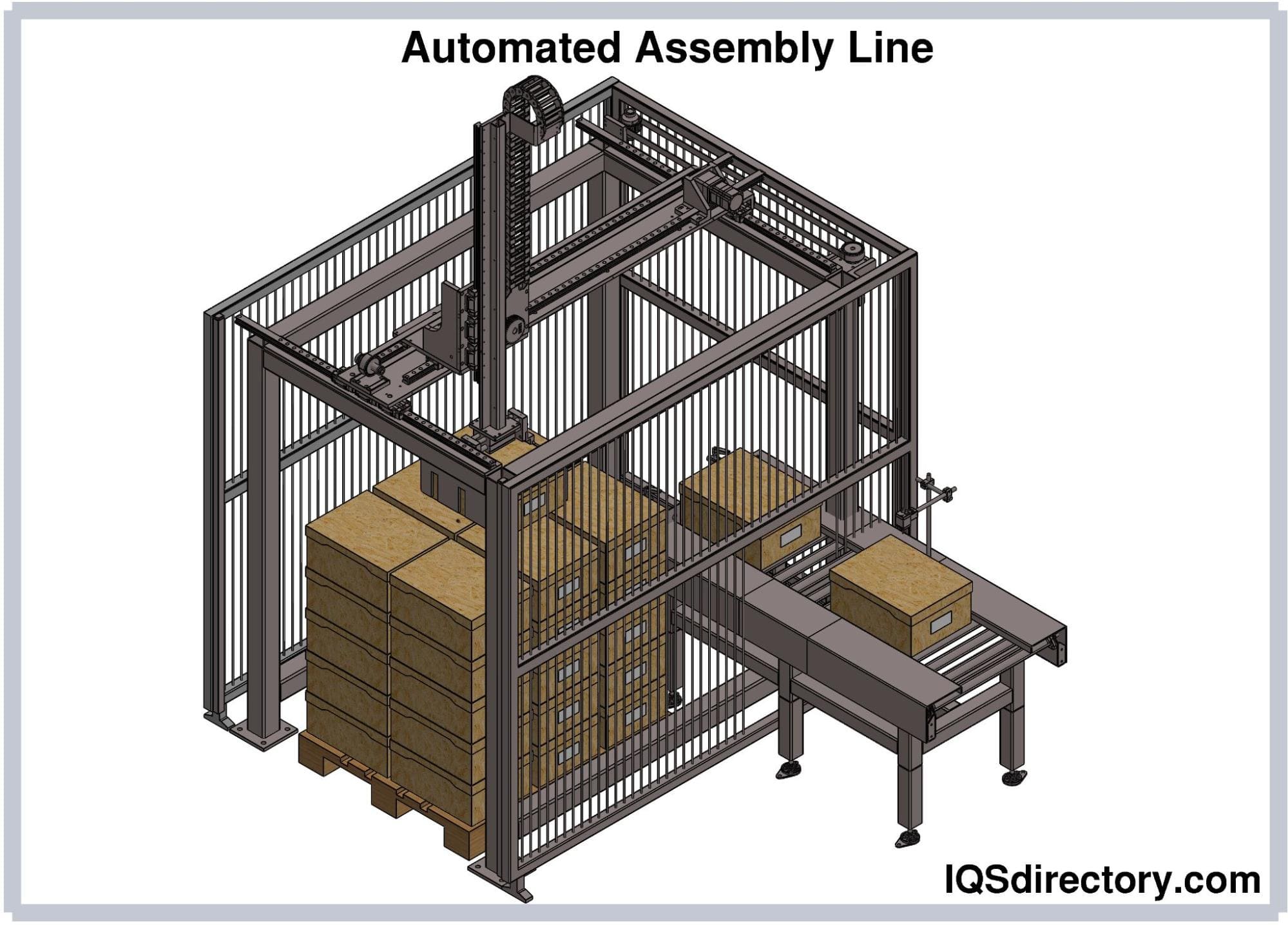

Illustrative image related to contract packaging applications

What Quality Control Measures Are Essential for Contract Packaging?

Quality assurance is paramount in contract packaging, as it directly impacts product safety and compliance. Buyers should be aware of the international and industry-specific standards that govern quality control processes. Adhering to these standards not only ensures product integrity but also builds trust with consumers.

Which International Standards Should B2B Buyers Consider?

Internationally recognized standards, such as ISO 9001, provide a framework for quality management systems. Compliance with these standards indicates that a contract packaging company has established processes for ensuring consistent quality across all operations. Additionally, industry-specific certifications, such as CE marking for medical devices or API certification for pharmaceuticals, demonstrate adherence to stringent regulatory requirements.

What Are the Key Quality Control Checkpoints in Contract Packaging?

Quality control in contract packaging typically involves several key checkpoints, including:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials and packaging components before production begins. It ensures that all materials meet specified quality standards.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor production processes. This includes checking machine calibration, verifying fill levels, and ensuring labeling accuracy.

-

Final Quality Control (FQC): After production, the final product undergoes comprehensive testing to confirm compliance with quality standards. This may involve sampling and testing for physical, chemical, and microbiological properties.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should actively seek to verify the quality control measures implemented by potential contract packaging partners. Here are several strategies to ensure robust quality assurance:

What Role Do Audits and Reports Play in Quality Verification?

Conducting supplier audits is an effective way to assess a contract packager’s quality management practices. Buyers can request to review internal quality assurance reports, which should detail the results of quality checks, compliance with standards, and any corrective actions taken. Audits can be conducted by the buyer’s quality assurance team or through third-party inspection firms, providing an unbiased evaluation of the supplier’s operations.

Illustrative image related to contract packaging applications

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services adds another layer of assurance. These independent organizations can perform routine checks and audits, ensuring that the contract packaging company adheres to industry standards and regulations. By receiving third-party validation, buyers can have greater confidence in the quality of their packaged products.

What Nuances Should International B2B Buyers Be Aware of in Quality Control?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, understanding regional regulatory requirements is crucial. Different countries may have varying standards for packaging materials and processes. Therefore, buyers should ensure that their contract packaging partner is compliant with both local and international regulations.

How Can Buyers Address Regulatory Compliance in Different Markets?

When entering new markets, buyers should conduct thorough research on the regulatory landscape. This includes understanding the requirements for packaging materials, labeling, and safety standards. Collaborating with contract packaging companies that have experience in these markets can facilitate compliance, as they are often well-versed in local regulations and can help navigate the complexities of international trade.

Conclusion: Ensuring Quality and Compliance in Contract Packaging

Navigating the complexities of manufacturing processes and quality assurance in contract packaging requires diligence from B2B buyers. By understanding the stages of production, verifying quality control measures, and ensuring compliance with international standards, businesses can forge successful partnerships with contract packagers. This approach not only enhances product safety and market readiness but also optimizes operational efficiency in an increasingly competitive global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘contract packaging applications’

Introduction

Navigating the world of contract packaging applications can be complex, especially for international B2B buyers. This step-by-step checklist is designed to help you systematically evaluate and procure contract packaging services that align with your business needs. By following these actionable steps, you can ensure you partner with the right co-packing provider to enhance efficiency, compliance, and product appeal.

Step 1: Define Your Packaging Requirements

Start by clearly outlining your specific packaging needs, including product type, volume, and any regulatory compliance requirements. This foundational step helps you communicate effectively with potential suppliers and ensures that their capabilities align with your expectations.

- Product Characteristics: Consider the dimensions, weight, and fragility of your products.

- Regulatory Standards: Identify any industry-specific regulations that must be adhered to, such as FDA or GMP standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify contract packaging companies that specialize in your industry. Explore their experience, service offerings, and market reputation to ensure they can meet your requirements.

- Industry Focus: Look for suppliers with a proven track record in your specific sector, whether it’s food, pharmaceuticals, or consumer goods.

- Client Testimonials: Read reviews and case studies to gauge customer satisfaction and service reliability.

Step 3: Evaluate Supplier Certifications

Before making a selection, verify that potential suppliers hold the necessary certifications and compliance credentials. This step is crucial for ensuring product safety and regulatory adherence.

- Certifications to Look For: Common certifications include ISO, GMP, and HACCP.

- Audit Reports: Request recent audit reports to assess their compliance with industry standards.

Step 4: Request Samples and Prototypes

Ask shortlisted suppliers for product samples or prototypes to evaluate their packaging quality and design. This hands-on assessment allows you to see firsthand how your products will be presented to consumers.

- Quality Assessment: Examine the durability, aesthetics, and functionality of the samples.

- Feedback Loop: Involve your marketing and product teams in the evaluation process to gather diverse insights.

Step 5: Discuss Pricing and Terms

Engage in discussions about pricing structures, minimum order quantities, and payment terms. Understanding the financial implications is essential for budget management and long-term partnership viability.

- Transparent Pricing: Ensure all costs, including setup fees and ongoing charges, are clearly outlined.

- Contract Flexibility: Look for flexibility in terms of order adjustments and potential volume discounts.

Step 6: Review Lead Times and Production Capacity

Assess the lead times and production capabilities of your selected suppliers. This information is vital for planning your supply chain and ensuring timely product launches.

- Production Scalability: Confirm that the supplier can handle fluctuating order volumes, especially during peak seasons.

- Communication Protocols: Establish clear timelines for updates on production status and delivery schedules.

Step 7: Finalize the Contract and Terms

Once you have evaluated all aspects, finalize the contract with your chosen supplier. Ensure that all agreed-upon terms are documented, including service level agreements (SLAs) and quality assurance processes.

- Legal Review: Consider having legal counsel review the contract to protect your interests.

- Performance Metrics: Define key performance indicators (KPIs) to measure the success of the partnership.

By following this checklist, you can make informed decisions that will ultimately enhance your product packaging strategy and support your business goals.

Illustrative image related to contract packaging applications

Comprehensive Cost and Pricing Analysis for contract packaging applications Sourcing

What Are the Key Cost Components in Contract Packaging Applications?

Understanding the cost structure of contract packaging is crucial for B2B buyers to make informed sourcing decisions. The primary cost components include:

-

Materials: This often represents the largest portion of the overall cost. The choice of packaging materials—whether plastic, glass, or biodegradable options—significantly impacts pricing. Additionally, sourcing sustainable materials may incur higher costs but can enhance brand value.

-

Labor: Labor costs vary based on the complexity of the packaging process and the region. Skilled labor may command higher wages, affecting the overall budget. Efficient labor practices can also lead to cost savings.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, equipment depreciation, and administrative costs. A well-managed overhead can lead to more competitive pricing.

-

Tooling: Custom tooling for specialized packaging can be a substantial initial investment. However, this cost is often amortized over large production runs, making it more economical per unit.

-

Quality Control (QC): Ensuring compliance with industry standards necessitates a robust QC process. While it may add to costs, it is vital for maintaining product integrity and avoiding costly recalls.

-

Logistics: Transportation and warehousing costs must be considered, especially for international shipping. The choice of Incoterms can affect who bears these costs, influencing overall pricing.

-

Margin: Contract packagers typically add a profit margin to their costs. This margin can fluctuate based on market demand, competition, and the complexity of the services provided.

How Do Volume and Customization Influence Pricing?

Pricing in contract packaging is heavily influenced by volume and customization. Higher order volumes (Minimum Order Quantities or MOQs) often lead to economies of scale, reducing the per-unit cost. Conversely, smaller orders may incur higher rates due to setup and changeover costs.

Customization also plays a significant role. Unique designs, specific materials, or specialized processes can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses. It’s advisable to discuss potential trade-offs between customization and cost to achieve an optimal solution.

Illustrative image related to contract packaging applications

What Buyer Tips Can Enhance Cost Efficiency in Contract Packaging?

To navigate the complexities of contract packaging pricing, consider the following strategies:

-

Negotiate Terms: Engage in discussions with potential suppliers about pricing structures, especially when committing to long-term contracts. Building a strong relationship can lead to better terms and pricing flexibility.

-

Assess Total Cost of Ownership (TCO): Beyond initial pricing, evaluate the long-term costs associated with logistics, quality assurance, and potential rework. A lower upfront cost may not always equate to the best value.

-

Understand Pricing Nuances for International Transactions: For buyers in Africa, South America, the Middle East, and Europe, be aware of additional costs such as tariffs, customs duties, and shipping fees. Familiarize yourself with Incoterms to clarify responsibilities for costs and risks during shipping.

-

Request Detailed Quotes: Ensure that quotes from suppliers break down the cost components clearly. This transparency allows for better comparison and understanding of where adjustments can be made.

What Should International Buyers Consider When Sourcing Contract Packaging?

International buyers should be particularly vigilant about local regulations, which can vary significantly. Compliance with standards in both the sourcing country and the destination market is essential. Additionally, cultural factors may influence negotiations and supplier relationships.

Buyers should also consider the impact of currency fluctuations on pricing, especially when dealing with suppliers in different regions. Building a buffer into your budget can help mitigate these risks.

Disclaimer on Indicative Prices

Prices for contract packaging services can vary widely based on numerous factors. The information provided here is for illustrative purposes only and should not be considered definitive. Always consult with multiple suppliers and obtain detailed quotes to understand the current market conditions and pricing structures.

Alternatives Analysis: Comparing contract packaging applications With Other Solutions

Exploring Alternatives to Contract Packaging Applications: What Are Your Options?

In the landscape of packaging solutions, contract packaging applications serve as a vital resource for companies looking to streamline their packaging processes. However, there are alternative methods that businesses can consider based on their specific needs, resources, and operational goals. Below, we will compare contract packaging against two viable alternatives: in-house packaging and automated packaging machinery.

Comparison Table

| Comparison Aspect | Contract Packaging Applications | In-House Packaging | Automated Packaging Machinery |

|---|---|---|---|

| Performance | High-quality, specialized services | Variable, dependent on workforce | Consistent, high-speed production |

| Cost | Lower initial investment, variable | High initial setup and labor costs | High upfront costs, lower per-unit cost over time |

| Ease of Implementation | Quick setup and onboarding | Time-consuming, requires training | Requires technical expertise and setup |

| Maintenance | Minimal, handled by the provider | Ongoing, requires skilled labor | Regular maintenance and repairs needed |

| Best Use Case | Seasonal products, startups, and compliance-focused sectors | Established brands with stable demand | High-volume production with consistent demand |

What Are the Pros and Cons of In-House Packaging?

In-house packaging allows companies to control their packaging processes fully. This method can be beneficial for businesses with stable demand and sufficient resources. The primary advantage is that it offers complete oversight and potential cost savings in the long run, especially if the operation scales. However, the drawbacks include significant initial capital investment in equipment and labor, as well as ongoing maintenance costs. Additionally, it may lack the flexibility to adapt to seasonal demand fluctuations, potentially leading to inefficiencies.

Illustrative image related to contract packaging applications

How Does Automated Packaging Machinery Compare?

Automated packaging machinery provides a high-speed, consistent solution for companies with large production volumes. This method excels in settings where efficiency and uniformity are paramount, such as in mass production lines for consumer goods. The main advantage of automated systems is the significant reduction in labor costs and the ability to maintain high output levels. However, the initial investment can be substantial, and it requires technical expertise to operate and maintain the machinery. For businesses with fluctuating demand or those just starting, this option may not be the most practical due to the high setup costs and complexity.

Conclusion: How to Choose the Right Packaging Solution for Your Business Needs

When selecting a packaging solution, B2B buyers must assess their operational goals, budget, and product demand. Contract packaging applications offer a flexible, cost-effective solution ideal for companies looking to scale quickly or those with seasonal products. In-house packaging may be suitable for established brands with stable demand, while automated machinery is best for high-volume production settings where consistency is crucial. Ultimately, the decision should align with the company’s strategic objectives, operational capabilities, and the specific market dynamics they face.

Essential Technical Properties and Trade Terminology for contract packaging applications

What Are the Key Technical Properties in Contract Packaging?

When engaging with contract packaging, understanding the critical technical properties can help ensure that the chosen solutions meet both regulatory and operational needs. Here are some essential specifications:

Material Grade

Material grade refers to the quality and type of materials used in packaging, such as plastics, paperboard, or metals. The selection of the right material grade is crucial as it affects product protection, shelf life, and compliance with industry regulations. For instance, food-grade materials must meet specific safety standards to prevent contamination. B2B buyers should prioritize suppliers that offer certified materials appropriate for their industry to ensure both quality and compliance.

Illustrative image related to contract packaging applications

Tolerance

Tolerance defines the allowable variations in dimensions and weights of the packaging components. This specification is vital in ensuring that products fit correctly within their packaging, which can influence sealing effectiveness and protection during transport. For example, a pharmaceutical company must adhere to strict tolerances to maintain the integrity of its products. Understanding tolerance levels helps buyers avoid costly errors and reduce waste.

Barrier Properties

Barrier properties indicate how well packaging protects products from external factors such as moisture, oxygen, and light. This is particularly important in the food and beverage industry, where the packaging must preserve freshness and prevent spoilage. Buyers should evaluate the barrier properties of materials to select the most suitable options that align with their product longevity and quality standards.

Compliance Standards

Compliance standards encompass regulations that packaging must meet, such as FDA, ISO, or GMP certifications. Adherence to these standards is critical for minimizing risks associated with legal liabilities and product recalls. B2B buyers should verify that their contract packaging partners are compliant with relevant standards to ensure their products can be marketed without hindrance.

Scalability

Scalability refers to a packaging solution’s ability to adjust production volumes to meet varying demand levels. This is particularly significant for businesses anticipating seasonal fluctuations or rapid growth. Engaging a contract packaging partner with scalable solutions enables companies to efficiently manage costs and avoid over-investing in resources that may not be needed year-round.

Illustrative image related to contract packaging applications

What Are Common Trade Terms in the Contract Packaging Industry?

Familiarity with industry jargon can facilitate smoother communication between buyers and packaging providers. Here are several key terms:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are used in another company’s end product. In contract packaging, an OEM may provide packaging machinery or components, allowing businesses to focus on their core competencies while leveraging specialized expertise.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for B2B buyers to ensure that they can meet their needs without overcommitting resources or incurring unnecessary costs. Negotiating MOQs can help businesses align their purchasing strategies with production schedules.

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. It is a critical step in the procurement process, allowing buyers to compare options and make informed decisions. A well-prepared RFQ can lead to better pricing and terms, which is beneficial for overall project budgets.

Illustrative image related to contract packaging applications

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that delineate the responsibilities of buyers and sellers in shipping arrangements. Understanding these terms helps businesses clarify who bears the risk and costs at each stage of the shipping process, which is crucial for international transactions.

Kitting

Kitting refers to the process of assembling individual items into ready-to-ship sets. This is often utilized in e-commerce and retail to streamline order fulfillment. Buyers should consider kitting capabilities when evaluating contract packaging partners to enhance efficiency and reduce lead times.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding contract packaging solutions, ultimately leading to improved operational efficiency and market competitiveness.

Illustrative image related to contract packaging applications

Navigating Market Dynamics and Sourcing Trends in the contract packaging applications Sector

What Are the Key Trends Shaping the Contract Packaging Applications Market?

The global contract packaging market is experiencing robust growth, driven by several key factors. As of 2023, the market reached approximately $70 billion, with food and pharmaceuticals dominating the landscape. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking cost-effective solutions to meet rising consumer demands without the burden of significant capital investment. One notable trend is the rise of e-commerce, which has propelled the need for flexible packaging solutions that cater to direct-to-consumer (D2C) models. This shift has led to an uptick in demand for co-packing services that streamline logistics and enhance product presentation.

Emerging technologies, such as automation and advanced data analytics, are transforming the sourcing landscape. Automated packaging lines increase efficiency and reduce labor costs, while data analytics provide insights into consumer preferences, enabling contract packagers to offer customized solutions. Additionally, sustainability is becoming a driving force, with companies prioritizing eco-friendly materials and practices in their packaging processes. As B2B buyers look to differentiate their products in crowded markets, aligning with contract packaging partners that emphasize innovation and sustainability will be critical.

How Does Sustainability Influence Sourcing Decisions in Contract Packaging?

Sustainability is no longer a mere trend but a vital component of strategic sourcing in the contract packaging sector. The environmental impact of packaging is under scrutiny, compelling businesses to seek solutions that minimize waste and carbon footprints. Buyers are increasingly prioritizing suppliers that implement ethical sourcing practices, which include using renewable materials and ensuring fair labor practices throughout the supply chain.

Certifications such as FSC (Forest Stewardship Council) and ISO 14001 signal a commitment to sustainable practices, making them essential considerations for B2B buyers. The use of biodegradable and recyclable materials is gaining traction, particularly in markets that are sensitive to environmental issues. For instance, companies are opting for plant-based plastics or recycled paper products to enhance their brand image and meet consumer expectations for sustainability. By choosing contract packaging partners who prioritize environmental stewardship, businesses can not only reduce their ecological impact but also appeal to a growing segment of eco-conscious consumers.

What Is the Evolution of Contract Packaging and Its Relevance to Today’s B2B Landscape?

The evolution of contract packaging can be traced back several decades, initially emerging as a response to the complexities of consumer goods distribution. As companies began to recognize the advantages of outsourcing their packaging processes, the industry saw significant advancements in technology and service offerings. The introduction of automated machinery and enhanced quality control measures allowed contract packagers to meet the diverse needs of various sectors, from food and beverage to pharmaceuticals.

Illustrative image related to contract packaging applications

Today, this evolution is characterized by a heightened focus on flexibility, compliance, and speed to market. With the global landscape continually shifting due to factors such as economic fluctuations and regulatory changes, contract packaging has become an indispensable component of the supply chain. For international B2B buyers, understanding this evolution is crucial for making informed sourcing decisions that align with their business objectives and market demands. Embracing innovative contract packaging solutions not only streamlines operations but also positions companies for sustainable growth in a competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of contract packaging applications

-

How do I select the right contract packaging partner for my business?

To choose the ideal contract packaging partner, start by assessing their industry expertise and the specific services they offer. Look for a company with experience in your sector, such as food, pharmaceuticals, or consumer goods, and ensure they comply with relevant regulations. Evaluate their production capabilities, technology, and flexibility in meeting your demands. Request case studies or references to gauge their reliability and quality standards. Additionally, consider their geographical location and logistics capabilities to ensure efficient distribution, especially for international operations. -

What are the typical minimum order quantities (MOQs) for contract packaging services?

Minimum order quantities (MOQs) can vary widely among contract packaging companies, often depending on the type of product, packaging complexity, and production capabilities. Generally, MOQs may range from a few hundred to several thousand units. It’s essential to discuss your specific needs with potential partners to understand their MOQ requirements. Some companies may offer flexibility for startups or smaller brands, while others may have strict thresholds that reflect their production efficiencies. Always clarify these details early in negotiations. -

What customization options should I consider when sourcing contract packaging?

Customization options in contract packaging are crucial for branding and product differentiation. Consider aspects such as packaging design, materials, sizes, and labeling requirements. Many co-packers offer tailored solutions, including unique shapes, finishes, and eco-friendly materials. Ensure the partner can accommodate your specific branding guidelines and regulatory compliance, especially if you operate in multiple countries. Engaging in early discussions about customization can also help streamline the design process and align expectations. -

How can I ensure quality assurance (QA) in contract packaging?

Ensuring quality assurance (QA) involves selecting a contract packaging partner with robust QA processes in place. Look for companies that adhere to Good Manufacturing Practices (GMP) and have certifications relevant to your industry, such as ISO or HACCP. Ask about their QA protocols, including inspection methods, testing procedures, and traceability systems. Regular audits and third-party inspections can further enhance confidence in their quality standards. Establishing clear communication regarding QA expectations from the outset is vital for a successful partnership. -

What payment terms should I expect when working with contract packaging suppliers?

Payment terms can vary significantly among contract packaging suppliers, typically influenced by factors such as order size, project scope, and the supplier’s policies. Common arrangements include upfront deposits, milestone payments, or net terms (e.g., net 30 or net 60 days). It’s essential to clarify these terms during initial discussions and to negotiate terms that align with your cash flow needs. Understanding the payment structure can help prevent misunderstandings and ensure a smoother working relationship throughout the project. -

How does international trade impact my contract packaging decisions?

International trade can significantly affect your contract packaging decisions, especially regarding regulatory compliance, shipping logistics, and customs requirements. Different countries have varying standards for packaging materials and labeling, which can impact your product’s marketability. Additionally, consider the implications of tariffs and trade agreements, as they can influence overall costs and supply chain efficiency. Working with a contract packaging partner experienced in international operations can help navigate these complexities and ensure compliance with local regulations. -

What logistics considerations should I keep in mind when sourcing contract packaging?

When sourcing contract packaging, logistics play a critical role in ensuring timely delivery and cost efficiency. Evaluate the supplier’s proximity to your manufacturing or distribution centers to minimize shipping times and costs. Consider their capabilities in handling storage, inventory management, and order fulfillment, especially for seasonal or fluctuating demand. Additionally, inquire about their experience with international shipping if you plan to distribute products across borders. Clear logistics planning can streamline your supply chain and enhance overall efficiency. -

How can I assess the reliability of a contract packaging supplier?

Assessing the reliability of a contract packaging supplier involves multiple factors, including their industry reputation, financial stability, and operational history. Request references or testimonials from previous clients to gauge their satisfaction levels. Additionally, evaluate their facility certifications and compliance with industry standards. Conducting site visits can provide insights into their operational capabilities and quality control measures. Regular communication and transparency during the negotiation process can also indicate a supplier’s reliability and commitment to building a long-term partnership.

Top 8 Contract Packaging Applications Manufacturers & Suppliers List

1. Nautical Direct – Contract Packaging Solutions

Domain: nautical-direct.com

Registered: 2019 (6 years)

Introduction: Contract packaging, also known as co-packing, is a strategic business arrangement where a company outsources its packaging and related services to a third-party provider. This includes tasks such as designing, assembling, labeling, and preparing products for distribution or retail. Types of contract packaging services include: Primary Packaging (e.g., bottles, blister packs), Secondary Packaging (…

2. Jonco Industries – Contract Packaging Solutions

Domain: joncoind.com

Registered: 1998 (27 years)

Introduction: Jonco Industries offers a wide range of contract packaging services, including:

– Packaging design: In-house design team reviews product specifications to create optimal packaging.

– Inventory control: Management of product receiving, auditing, and tracking.

– Plastic production and thermoforming: On-site manufacturing of clamshells, trays, and blisters.

– Assembly and fulfillment: Accurate sequen…

3. IQS Directory – Contract Packaging Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Contract packaging, also known as co-packing or co-packaging, involves outsourcing the product packaging process to specialized companies. These firms manage packaging tasks, storage, and distribution for various industries, including pharmaceuticals, retail, and industrial equipment. Key services offered by contract packaging companies include sterilization, blister packaging, cardboard package d…

4. Graphic Packaging – Contract Manufacturing & Packaging Solutions

Domain: graphicpkg.com

Registered: 1997 (28 years)

Introduction: Contract Manufacturing and Contract Packaging solutions include a wide range of packaging products such as:

1. **Packaging Types:**

– CleanClose™ Detergent Packaging

– Heavyweight Folding Cartons

– IntegraFlute™ Bag-in-Box Packaging

– LithoFlute and Litho-Laminated Heavyweight Cartons

– Z-Flute™ Strategically Laminated Folding Cartons

– Fresh Produce Packaging

– Gift Boxes

…

5. Ryder – Co-Packaging Solutions

Domain: ryder.com

Introduction: Co-packaging services specializing in customized solutions for emerging and established brands. Services include research & development, display engineering, product manufacturing, technology, and scalability. Key offerings:

– Product Manufacturing: Sourcing raw materials, product development with in-house food scientists, and packaging.

– General Assembly: Customized contract assembly solutions…

6. GenPackaging – Contract Packaging Services

Domain: genpackaging.com

Registered: 2000 (25 years)

Introduction: Contract Packaging Services offered by GenPackaging include: Packaging Assembly, Unitizing, Shrink wrapping, Pouching, Kitting and Bagging, Pallet Repackaging/Reconfiguring, Unitizing & Merchandising, Labeling, Bar code labeling, RFID labeling, Fulfillment, Warehousing, Logistics, and Hazardous Material Handling certified (Haz-Mat). They provide a cost-effective packaging system with zero capital …

7. Praxis Packaging – Contract Packaging Solutions

Domain: praxispackaging.com

Registered: 2000 (25 years)

Introduction: Praxis Packaging specializes in contract packaging for retail, OTC, and RX products. Key offerings include: Primary Packaging – Solid Dose Bottling (flexible options for dosages, bottle sizes, and cap types), Solid Dose Blistering (latest technologies for flexible options), Single-Use Flexible Packaging (customizable foil and plastic options), Rigid Tube Filling (capable of filling plastic laminat…

8. Managed Packaging Systems – Contract Packaging Solutions

Domain: managedpackaging.com

Registered: 2001 (24 years)

Introduction: Managed Packaging Systems (MPS) offers a wide range of solutions for the Contract Packaging Industry, including multi-packs, automatic labeling, brochure inserts, box erecting, taping, automatic pouching, vertical form fill seal, and auto-bagging. They provide flexible machinery and materials for both low volume sporadic projects and high volume long term contracts. Key equipment includes automati…

Strategic Sourcing Conclusion and Outlook for contract packaging applications

As the contract packaging landscape evolves, international B2B buyers are presented with significant opportunities to enhance their operational efficiency and market reach. Strategic sourcing in contract packaging not only streamlines logistics but also allows companies to tap into specialized expertise and advanced technologies without the burden of substantial capital investments. The diverse applications across industries—from food and beverage to pharmaceuticals and consumer goods—underscore the critical role of co-packing in meeting regulatory compliance and consumer demand.

For businesses in Africa, South America, the Middle East, and Europe, leveraging contract packaging services can facilitate rapid scaling and adaptability in an increasingly competitive marketplace. By partnering with established contract packagers, companies can ensure product integrity, optimize supply chain management, and enhance brand presentation while focusing on their core competencies.

Looking ahead, the contract packaging sector is poised for continued growth, driven by trends such as e-commerce expansion and the rising demand for sustainable packaging solutions. International buyers are encouraged to explore strategic partnerships with reputable contract packaging firms to stay ahead of market trends and consumer preferences. Embrace the future of packaging—unlock the potential of contract packaging to propel your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.