Def Drum Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for def drum

In today’s rapidly evolving global marketplace, sourcing Diesel Exhaust Fluid (DEF) in 55-gallon drums presents a significant challenge for international B2B buyers. With stringent emission regulations and the increasing reliance on Selective Catalytic Reduction (SCR) systems across various industries, understanding how to effectively procure DEF is crucial for compliance and operational efficiency. This comprehensive guide delves into the intricacies of the DEF market, covering the types of DEF available, their applications in various sectors, supplier vetting processes, and cost considerations.

By equipping buyers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Vietnam—with actionable insights, this guide aims to empower informed purchasing decisions. Whether you are managing a fleet of heavy-duty vehicles or ensuring compliance in manufacturing processes, our resource will help you navigate the complexities of sourcing high-quality DEF. We address common pitfalls, highlight reputable suppliers, and provide strategies for maintaining product integrity, ultimately enabling you to streamline your procurement process and enhance your operational performance.

As the demand for environmentally friendly solutions continues to grow, ensuring the right DEF supply is not just a regulatory requirement but a strategic advantage in your business operations.

Understanding def drum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 55-Gallon Drum | Standard size, API certified, made of high-purity urea solution | Transportation, logistics, fleet services | Pros: Widely available, suitable for various vehicles. Cons: Limited volume for larger operations. |

| 275-Gallon Tote | Larger capacity, designed for bulk storage | Large fleets, industrial applications | Pros: Reduces frequency of refills. Cons: Higher upfront cost, requires more space. |

| 330-Gallon Tote | Maximum capacity, often used for centralized dispensing systems | Heavy-duty commercial vehicles, fleets | Pros: Cost-effective for high usage, fewer handling issues. Cons: May require specialized handling equipment. |

| 2.5-Gallon Case | Smaller packaging, ideal for retail or low-volume users | Retail, small businesses | Pros: Easy to handle, suitable for small operations. Cons: Higher cost per gallon compared to larger drums. |

| Closed System Containers | Designed to maintain DEF purity, minimizes contamination risks | Fleet management, industrial use | Pros: Protects fluid integrity, prolongs catalyst life. Cons: More complex setup and potentially higher initial investment. |

What are the characteristics of the 55-Gallon Drum for DEF?

The 55-gallon drum is a popular choice for many businesses due to its manageable size and API certification. Composed of a high-purity urea solution, this drum is ideal for transportation and logistics applications. It is particularly suitable for fleets operating medium to heavy-duty diesel engines. Buyers appreciate its availability and compatibility with various vehicles, though its limited volume may necessitate more frequent refills for larger operations.

How does the 275-Gallon Tote serve B2B needs?

The 275-gallon tote offers a larger storage capacity, making it ideal for businesses with substantial DEF usage, such as large fleets and industrial applications. This type of container reduces the frequency of refills, which can enhance operational efficiency. While the upfront cost is higher, the long-term savings in labor and logistics can justify the investment. However, businesses must ensure they have adequate storage space for these larger units.

Why choose a 330-Gallon Tote for DEF storage?

For companies with very high DEF consumption, the 330-gallon tote is often the best option. This container is designed for centralized dispensing systems, making it suitable for heavy-duty commercial vehicles and extensive fleet operations. The significant capacity reduces the need for frequent handling and restocking, leading to operational efficiencies. However, the initial investment may be substantial, and specialized equipment may be required for handling.

Illustrative image related to def drum

What are the advantages of using a 2.5-Gallon Case?

The 2.5-gallon case is perfect for retail operations or businesses with low DEF requirements. Its smaller size allows for easy handling and transport, making it an attractive option for small businesses. While it is convenient, buyers should consider that the cost per gallon is typically higher compared to larger containers, which may not be ideal for those with higher volume needs.

How do Closed System Containers enhance DEF management?

Closed system containers are designed to maintain the purity of diesel exhaust fluid, significantly reducing the risk of contamination. They are particularly beneficial for fleet management and industrial applications, where maintaining DEF integrity is crucial for optimal SCR system performance. Although these systems may involve a higher initial investment and complexity, the long-term benefits of protecting vehicle investments and reducing maintenance costs can be substantial for B2B buyers.

Key Industrial Applications of def drum

| Industry/Sector | Specific Application of def drum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Fueling heavy-duty trucks and commercial vehicles | Ensures compliance with emissions regulations, reducing fines and maintaining fleet efficiency | Quality certifications (ISO 22241), supply chain reliability, and local regulations |

| Agriculture | Operation of agricultural machinery | Enhances engine performance and reduces harmful emissions, promoting sustainability in farming practices | Bulk purchasing options, storage capabilities, and delivery logistics |

| Construction | Powering diesel-powered construction equipment | Supports regulatory compliance while improving operational efficiency and reducing downtime | Availability of DEF in local markets and compatibility with equipment |

| Mining | Fueling mining vehicles and equipment | Reduces NOx emissions, enhancing environmental compliance and operational sustainability | Sourcing from reputable suppliers to ensure product purity and quality |

| Marine | Used in marine diesel engines with SCR technology | Improves fuel efficiency and reduces emissions, crucial for compliance with maritime regulations | Access to specialized handling equipment and regional distribution networks |

In the Transportation & Logistics sector, DEF drums are essential for fueling heavy-duty trucks and commercial vehicles equipped with Selective Catalytic Reduction (SCR) systems. By using DEF, companies can significantly reduce nitrogen oxide (NOx) emissions, ensuring compliance with stringent environmental regulations. This not only avoids potential fines but also enhances fleet efficiency. B2B buyers should prioritize sourcing DEF that meets ISO 22241 standards to ensure quality and reliability in supply chains, especially in regions with varying regulations.

Illustrative image related to def drum

In Agriculture, DEF is utilized in diesel-powered machinery to promote cleaner operations. As the agricultural sector increasingly focuses on sustainability, using DEF helps reduce emissions, contributing to a greener farming practice. Buyers should consider bulk purchasing to ensure consistent supply, while also evaluating storage capabilities that meet local safety standards to prevent contamination.

The Construction industry relies on DEF for powering diesel construction equipment. The use of DEF not only helps in meeting environmental compliance but also improves the overall efficiency of machinery, minimizing costly downtime. When sourcing DEF, construction companies should assess the availability of products in local markets and ensure compatibility with their existing equipment to streamline operations.

In the Mining sector, DEF is critical for fueling vehicles and equipment, helping to reduce harmful emissions and meet environmental standards. The use of DEF supports sustainable mining practices, which is increasingly important for regulatory compliance and corporate responsibility. Buyers should focus on sourcing DEF from reputable suppliers to ensure product purity, which is vital for maintaining the performance of SCR systems.

Finally, in the Marine industry, DEF is used in marine diesel engines equipped with SCR technology. This application is vital for improving fuel efficiency and adhering to maritime emissions regulations. B2B buyers in this sector should ensure access to specialized handling equipment and establish relationships with regional distributors to facilitate timely and compliant deliveries of DEF.

3 Common User Pain Points for ‘def drum’ & Their Solutions

Scenario 1: Navigating Supply Chain Challenges with DEF Drums

The Problem: Many B2B buyers face significant challenges in sourcing Diesel Exhaust Fluid (DEF) drums due to supply chain disruptions. This is particularly critical for companies operating in industries that rely on heavy-duty diesel engines, such as transportation and logistics. Delays in receiving DEF can lead to compliance issues with emissions regulations and result in costly downtime for fleets that require SCR (Selective Catalytic Reduction) systems. Buyers may find themselves scrambling to find alternative suppliers or facing inflated prices due to scarcity, which adds to their operational stress.

The Solution: To mitigate supply chain issues, buyers should establish relationships with multiple suppliers to diversify their sourcing channels. This proactive approach allows for flexibility and better pricing options. Additionally, investing in forecasting tools can help predict DEF needs based on usage patterns, thus enabling timely orders. Implementing a just-in-time inventory system ensures that DEF drums are available when needed without overstocking. Furthermore, buyers should consider suppliers who offer robust logistics support and real-time tracking for shipments, ensuring greater transparency and reliability in the supply chain.

Scenario 2: Ensuring Quality and Compliance of DEF Drums

The Problem: Another common pain point is ensuring the quality and compliance of DEF drums. Not all DEF products are created equal; subpar fluid can lead to catalyst poisoning, reduced engine efficiency, and potential voiding of warranties. B2B buyers, especially in regions with less stringent regulations, might inadvertently purchase contaminated or low-quality DEF, resulting in costly repairs and operational inefficiencies. This scenario is particularly concerning for international buyers who may have limited visibility into the sourcing practices of suppliers.

The Solution: To ensure high-quality DEF, buyers should prioritize sourcing from manufacturers that adhere to industry standards such as ISO 22241. Requesting certification documents and safety data sheets from suppliers can help verify the quality of the DEF being purchased. Additionally, implementing a rigorous testing protocol upon receipt of DEF drums can identify any potential contamination or quality issues before they affect operations. Consider investing in closed system dispensing solutions to maintain the integrity of DEF throughout the supply chain. These systems minimize exposure to contaminants and ensure that the fluid remains within compliance.

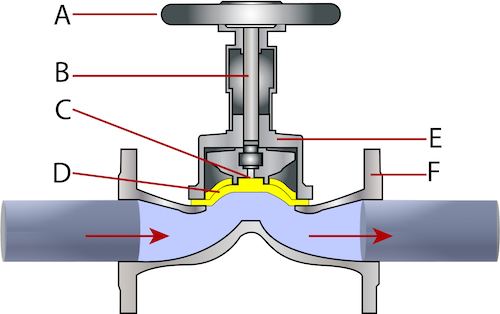

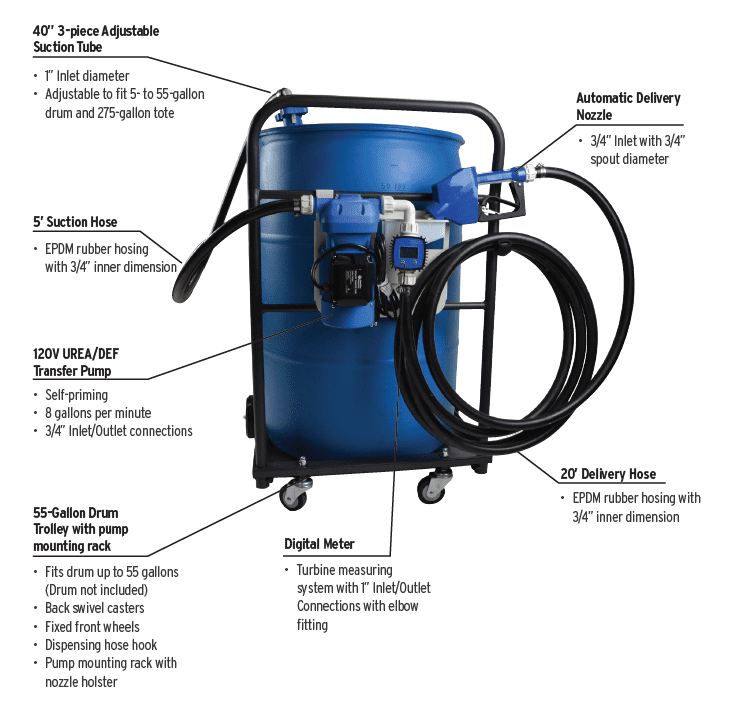

Illustrative image related to def drum

Scenario 3: Handling DEF Drums Safely and Efficiently

The Problem: Proper handling and storage of DEF drums can present challenges, particularly in ensuring safety and maintaining fluid purity. Mishandling can lead to spills, contamination, or accidents that not only pose risks to workers but can also result in product loss. This is a significant concern for B2B buyers managing large fleets or operations with multiple touchpoints for DEF usage. Inadequate training and improper equipment can exacerbate these issues, leading to increased operational costs.

The Solution: To address safety and efficiency in handling DEF, companies should invest in comprehensive training programs for employees on the proper procedures for storing and dispensing DEF. Utilizing specialized DEF transfer products, such as pumps and meters designed for fluid purity, can further streamline operations while minimizing the risk of spills. Establishing dedicated storage areas with clear labeling and containment systems can prevent cross-contamination and ensure compliance with safety regulations. Regular audits of handling practices can help identify areas for improvement and reinforce a culture of safety within the organization.

Strategic Material Selection Guide for def drum

What Are the Key Materials Used for DEF Drums and Their Properties?

When selecting materials for Diesel Exhaust Fluid (DEF) drums, it is crucial to consider properties that directly affect the performance, safety, and compliance of the product. The most common materials used for DEF drums include high-density polyethylene (HDPE), stainless steel, carbon steel, and aluminum. Each material has unique characteristics that can influence operational efficiency and regulatory compliance in various international markets.

Illustrative image related to def drum

How Does High-Density Polyethylene (HDPE) Perform in DEF Applications?

HDPE is a popular choice for DEF drums due to its excellent chemical resistance and lightweight nature. It can withstand temperatures ranging from -40°F to 120°F (-40°C to 49°C), making it suitable for various climates. HDPE is also resistant to UV radiation, which is essential for outdoor storage.

Pros:

– Durability: HDPE is resistant to corrosion and impact, ensuring longevity.

– Cost-Effective: Generally lower in cost compared to metal options.

– Manufacturing Simplicity: Easier to mold and shape, reducing production complexity.

Cons:

– Temperature Limitations: Not suitable for extreme temperatures beyond its rated limits.

– Potential for Contamination: If not produced under strict conditions, it may harbor impurities.

For international buyers, especially in regions like Africa and South America, compliance with standards such as ISO 22241 is essential. HDPE drums must also be certified to ensure they do not leach harmful substances into the DEF.

What Advantages Does Stainless Steel Offer for DEF Drums?

Stainless steel drums are known for their robustness and resistance to corrosion, making them ideal for storing DEF in harsh environments. They can handle a wider temperature range and are less likely to degrade over time.

Pros:

– Durability: High resistance to corrosion and physical damage.

– Temperature Resistance: Suitable for extreme conditions, maintaining structural integrity.

– Recyclability: Stainless steel is recyclable, aligning with sustainability goals.

Cons:

– Cost: Generally more expensive than HDPE and other materials.

– Weight: Heavier than plastic alternatives, which may affect transportation costs.

For buyers in Europe and the Middle East, stainless steel drums often meet stringent regulatory requirements, such as those set by ASTM and DIN, ensuring compliance with environmental standards.

Why Consider Carbon Steel for DEF Drums?

Carbon steel is another option, primarily used for its strength and affordability. It is suitable for bulk storage but requires protective coatings to prevent rusting and corrosion.

Pros:

– Strength: High tensile strength makes it suitable for heavy-duty applications.

– Cost-Effective: Generally lower cost compared to stainless steel.

Cons:

– Corrosion Risk: Requires protective coatings to prevent rust, which can add to maintenance costs.

– Temperature Sensitivity: Not as effective in extreme temperatures compared to stainless steel.

Illustrative image related to def drum

International buyers should be aware of the need for coatings that comply with local regulations. In regions like Saudi Arabia, where humidity can be high, proper maintenance is crucial to prevent corrosion.

How Does Aluminum Compare for DEF Drum Applications?

Aluminum is lightweight and resistant to corrosion, making it a viable option for DEF storage. It can withstand a range of temperatures and is often used in portable applications.

Pros:

– Lightweight: Easier to transport, reducing shipping costs.

– Corrosion Resistance: Naturally resistant to rust and corrosion.

Cons:

– Cost: More expensive than HDPE and carbon steel.

– Durability: May not withstand heavy impacts as well as steel options.

For buyers in regions with stringent environmental regulations, aluminum drums can be a good choice, provided they meet the necessary compliance standards.

Illustrative image related to def drum

Summary Table of Material Selection for DEF Drums

| Material | Typical Use Case for DEF Drum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Bulk storage and transportation of DEF | Cost-effective and lightweight | Limited temperature range | Low |

| Stainless Steel | Long-term storage in harsh environments | High durability and temperature resistance | Higher cost and weight | High |

| Carbon Steel | Heavy-duty applications and bulk storage | Strong and cost-effective | Requires protective coatings to prevent rust | Medium |

| Aluminum | Portable DEF storage and transportation | Lightweight and corrosion-resistant | Higher cost and lower impact resistance | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used for DEF drums, aiding in informed decision-making tailored to specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for def drum

What Are the Main Stages of Manufacturing Diesel Exhaust Fluid (DEF) Drums?

The manufacturing process for Diesel Exhaust Fluid (DEF) drums encompasses several critical stages, ensuring that the final product meets stringent quality and safety standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used for DEF Drums?

The primary materials used in the production of DEF drums are high-density polyethylene (HDPE) and other corrosion-resistant materials. HDPE is chosen for its durability, chemical resistance, and lightweight properties, which are essential for safely storing DEF—a solution of urea and deionized water. The preparation stage involves sourcing these materials from certified suppliers who adhere to international standards, ensuring quality and compliance.

How Are DEF Drums Formed?

The forming stage employs advanced techniques such as blow molding or injection molding. Blow molding is particularly common for manufacturing HDPE containers, allowing for the creation of seamless, robust drums. During this stage, the raw material is heated until it becomes pliable, then shaped into the drum form. Precise temperature control and pressure application are vital to ensure uniform thickness and structural integrity.

What Does the Assembly Process Involve for DEF Drums?

Once formed, the drums are assembled with necessary components such as closures and handles. These parts must also be made from compatible materials to prevent chemical reactions with DEF. This assembly process often employs automated systems to enhance efficiency and maintain consistency across production batches.

What Finishing Techniques Are Used in DEF Drum Production?

Finishing processes may include surface treatment, labeling, and quality checks. Surface treatments can enhance the drum’s resistance to environmental factors, while labeling must comply with regulatory requirements, including safety and handling instructions. Each drum is typically tested for leaks and structural integrity before being packaged for distribution.

Which Quality Assurance Standards Are Relevant for DEF Drums?

Quality assurance is paramount in the production of DEF drums, particularly given the implications of DEF purity on engine performance and emissions compliance. International standards such as ISO 9001 provide a framework for quality management systems, while industry-specific certifications like API (American Petroleum Institute) and CE (Conformité Européenne) attest to the safety and efficacy of the products.

How Are Quality Control Checkpoints Integrated Into the Manufacturing Process?

Quality control (QC) checkpoints are integral throughout the manufacturing process. Common QC stages include:

-

Incoming Quality Control (IQC): This involves testing raw materials upon arrival to ensure they meet specified standards. It is crucial for preventing defects from the outset.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to verify that processes adhere to defined parameters. This includes monitoring machine settings, temperature controls, and material consistency.

-

Final Quality Control (FQC): After production, each drum undergoes comprehensive testing, including checks for leaks, structural integrity, and compliance with specifications. This stage is essential for ensuring that only high-quality products reach the market.

What Testing Methods Are Commonly Used for DEF Drums?

Testing methods for DEF drums include:

- Leak Testing: Ensures that the drums are airtight and prevent contamination.

- Impact Resistance Testing: Assesses the drum’s ability to withstand physical stress during handling and transportation.

- Chemical Compatibility Testing: Confirms that the materials used do not react negatively with DEF, which could compromise its quality.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is crucial. Here are several approaches:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, compliance with international standards, and overall quality management practices.

-

Reviewing Quality Reports: Requesting access to quality control reports can help assess a supplier’s performance over time, including any incidents of non-compliance or product recalls.

-

Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased evaluation of the supplier’s operations and product quality. This is particularly important for buyers in regions with stringent import regulations or varying quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must be aware of several nuances related to quality control:

-

Regulatory Compliance: Different countries may have specific regulations regarding the import of chemical products, including DEF. Understanding these regulations is essential for ensuring compliance and avoiding costly delays.

-

Cultural Differences: Communication styles and business practices can vary significantly between regions. Establishing clear expectations regarding quality standards and product specifications is crucial for successful partnerships.

-

Logistics and Supply Chain Considerations: The integrity of DEF can be compromised during transportation if proper handling procedures are not followed. Buyers should ensure that suppliers have robust logistics solutions in place to maintain product purity.

Conclusion: Ensuring Quality in DEF Drum Manufacturing

The manufacturing processes and quality assurance measures for DEF drums are vital to ensure the product’s effectiveness and compliance with emissions regulations. For B2B buyers, particularly those operating in diverse international markets, understanding these processes and standards is essential for making informed purchasing decisions. By focusing on supplier audits, quality reports, and third-party inspections, buyers can mitigate risks and ensure they source high-quality DEF drums that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘def drum’

Introduction

This practical sourcing guide is designed for B2B buyers looking to procure Diesel Exhaust Fluid (DEF) in drum form. With the increasing global focus on emissions regulations, understanding the procurement process for DEF is crucial for maintaining compliance and ensuring operational efficiency. This checklist will help streamline your sourcing process and ensure that you select a high-quality product from a reputable supplier.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for your DEF procurement is the first step in ensuring you meet your operational needs. Consider factors such as the urea content (ideally around 32.5%), purity levels, and compatibility with your existing equipment. This clarity will help you avoid costly mistakes and ensure compliance with industry standards.

Step 2: Research Regulatory Compliance

Ensure that the DEF you are sourcing complies with relevant regulations in your region, such as ISO 22241 standards. Non-compliance can lead to significant penalties and operational disruptions. Familiarize yourself with both local and international regulations to safeguard your investment.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record in providing high-quality DEF that meets stringent purity and performance standards.

Step 4: Assess Product Quality and Purity

Evaluate the product specifications to ensure high purity and low impurity levels. DEF should be clear and non-toxic, with minimal biuret and metallic content to avoid catalyst poisoning in SCR systems. Request a safety data sheet (SDS) and product data sheet for detailed information on quality metrics.

Step 5: Check for Certifications and Testing

Verify that the supplier’s DEF has been certified by recognized organizations, such as the American Petroleum Institute (API). Certifications are a testament to the quality and reliability of the product. Additionally, inquire about the supplier’s quality control measures and any testing they conduct to ensure product consistency.

Step 6: Understand Packaging and Delivery Options

Discuss packaging options, such as 55-gallon drums or larger totes, and confirm that they meet your logistical needs. Assess the supplier’s delivery capabilities, including lead times and shipping costs, especially for international orders. Ensure that they offer safe handling practices to maintain DEF purity during transit.

Step 7: Negotiate Terms and Conditions

Finally, engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment terms, and warranties to protect your investment. Ensure that you clearly understand the return policy and any contingencies regarding product quality or delivery delays.

By following this checklist, you can navigate the DEF sourcing process with confidence, ensuring that you acquire a product that meets your operational needs while adhering to regulatory requirements.

Illustrative image related to def drum

Comprehensive Cost and Pricing Analysis for def drum Sourcing

What Are the Key Cost Components for Sourcing DEF Drums?

When considering the procurement of Diesel Exhaust Fluid (DEF) in drums, understanding the cost structure is critical for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

Materials: The main ingredient in DEF is high-purity urea, which can fluctuate in price based on global supply and demand dynamics. Buyers should be aware that sourcing urea from different regions may affect material costs, particularly for buyers in Africa and South America, where local availability can vary.

-

Labor and Manufacturing Overhead: Labor costs can differ significantly depending on the country of production. In regions like Europe and the Middle East, higher labor costs may be offset by advanced manufacturing technologies that enhance efficiency. Manufacturing overhead, which encompasses utilities, maintenance, and facility costs, is also a crucial factor.

-

Tooling and Quality Control (QC): Effective tooling is necessary for the production of DEF drums to maintain consistency and compliance with industry standards (e.g., ISO 22241). Investing in quality control ensures that the DEF meets the required purity levels, preventing costly issues down the line.

-

Logistics: Transportation costs can be substantial, particularly for international shipping. Factors such as distance, shipping method, and local infrastructure impact logistics costs. For example, shipping DEF from North America to Europe may involve complex logistics and higher costs than intra-regional shipping.

-

Margin: Suppliers typically factor in a profit margin that varies based on competition, market demand, and the specific service level provided to customers. Buyers should compare multiple suppliers to gauge fair pricing.

How Do Pricing Influencers Impact DEF Drum Costs?

Several factors influence the pricing of DEF drums, which are vital for buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Establishing long-term contracts can also provide pricing stability.

-

Specifications and Customization: Custom formulations or packaging may increase costs. Buyers should assess whether they need tailored solutions or if standard products suffice.

-

Material Quality and Certifications: Higher quality materials typically command a premium. Certifications such as API standards can also affect pricing. Buyers should ensure that the DEF meets local regulations to avoid future compliance issues.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can influence pricing. Established suppliers may charge more for their extensive experience and customer service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost of the product.

What Are Essential Tips for Buyers to Optimize DEF Drum Sourcing Costs?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility in their pricing based on volume or commitment levels. Building a good relationship can also yield better deals.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, storage, and handling costs, as well as potential costs related to quality issues or non-compliance.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and trade tariffs that can affect overall costs. It’s advisable to lock in prices or use hedging strategies for long-term contracts.

-

Supplier Diversification: Avoid dependency on a single supplier to mitigate risks associated with price volatility and supply chain disruptions. Having multiple sources can provide leverage in negotiations.

Disclaimer on Indicative Prices

Prices for DEF drums can vary widely based on multiple factors, including market conditions and regional differences. The figures mentioned in this analysis are indicative and subject to change. Buyers should conduct thorough market research and supplier comparisons to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing def drum With Other Solutions

When considering solutions for managing diesel exhaust emissions, particularly in regions with stringent environmental regulations, B2B buyers often seek alternatives to traditional Diesel Exhaust Fluid (DEF) drums. Understanding the available options can help organizations make informed decisions that align with their operational needs and sustainability goals.

| Comparison Aspect | Def Drum | Alternative 1: Bulk DEF Supply | Alternative 2: On-site DEF Generation |

|---|---|---|---|

| Performance | High purity, essential for SCR systems; reduces NOx emissions effectively. | Consistent quality; large volumes can be delivered to meet high demand. | Produces DEF on-demand, ensuring freshness and avoiding storage issues. |

| Cost | Moderate initial purchase cost; ongoing replenishment required. | Potentially lower long-term costs with bulk purchasing; upfront investment for storage. | High initial setup costs; potential savings on transportation and storage over time. |

| Ease of Implementation | Straightforward installation and usage; requires periodic refilling. | Requires infrastructure for storage; may need specialized equipment for dispensing. | Complex installation; requires training and maintenance for on-site production systems. |

| Maintenance | Low maintenance; regular checks needed for purity and leaks. | Moderate maintenance; storage tanks and dispensers require upkeep. | Higher maintenance due to equipment complexity; regular checks essential for operational efficiency. |

| Best Use Case | Ideal for fleets with moderate DEF needs and limited storage. | Suitable for large fleets or businesses with high DEF consumption. | Best for organizations with consistent high demand and space for equipment. |

What Are the Benefits of Using Bulk DEF Supply Over Def Drums?

Bulk DEF supply allows organizations to purchase large quantities of DEF, often at a reduced cost per gallon compared to individual drum purchases. This option is ideal for businesses with high DEF usage, such as logistics companies operating large fleets. However, the initial investment in storage tanks and dispensing equipment can be significant. Additionally, maintaining the quality of DEF in bulk storage requires careful management to prevent contamination and ensure compliance with industry standards.

How Does On-site DEF Generation Compare to Def Drums?

On-site DEF generation systems offer a unique solution by producing DEF as needed, eliminating the need for storage and reducing the risk of spoilage. This approach can be particularly advantageous for companies with fluctuating DEF needs or those operating in remote areas where supply logistics can be challenging. However, the setup costs for these systems can be high, and they require ongoing maintenance and operational oversight, which may not be feasible for all organizations.

Conclusion: How to Choose the Right Diesel Exhaust Fluid Solution for Your Business?

Selecting the right DEF solution depends on various factors, including your organization’s size, DEF consumption, budget, and operational capabilities. For companies with moderate needs and space constraints, DEF drums provide a reliable and straightforward option. In contrast, businesses with high consumption rates may find bulk supply more economical, while those seeking flexibility and freshness might benefit from on-site generation systems. Assessing your specific requirements and operational context will guide you in making the most informed choice to meet both compliance and performance objectives.

Essential Technical Properties and Trade Terminology for def drum

What Are the Key Technical Properties of Diesel Exhaust Fluid (DEF) Drums?

When sourcing Diesel Exhaust Fluid (DEF) in drums, understanding the essential technical properties is crucial for ensuring product quality and compliance. Here are some critical specifications to consider:

-

Urea Content

DEF is primarily composed of a 32.5% urea solution. This specific concentration is vital as it is the optimal formulation for Selective Catalytic Reduction (SCR) systems, which reduce harmful NOx emissions in diesel engines. Ensuring the correct urea concentration helps maintain engine performance and compliance with emissions regulations. -

Density

The density of DEF at 20°C is typically around 1090 kg/m³. This property is significant for logistics and storage, as it influences shipping costs and how the fluid is handled in the supply chain. Buyers should ensure that their storage and dispensing systems are calibrated to accommodate this density. -

Shelf Life

DEF has a shelf life of approximately three years when stored correctly. Understanding this property is crucial for inventory management, particularly for businesses operating in regions with variable demand. Proper storage conditions can prolong the shelf life and maintain product integrity. -

Purity Standards

DEF must meet industry specifications such as ISO 22241. Adherence to these standards ensures that the fluid is free from contaminants that could damage SCR systems. Buyers should verify that their suppliers provide documentation confirming compliance with these standards to protect their investments. -

Temperature Stability

DEF begins to crystallize at temperatures below -11°C but can be used normally after thawing. This property is essential for buyers in colder climates, as it impacts storage solutions and transportation methods. Understanding the thermal properties of DEF can prevent operational disruptions during colder months. -

Packaging Specifications

DEF is commonly available in 55-gallon drums, with dimensions typically around 23 inches in diameter and 35 inches in height. Knowing the packaging specifications is vital for warehouse management and shipping logistics, ensuring that sufficient space is allocated for storage and transportation.

Which Trade Terms Should B2B Buyers Understand When Purchasing DEF Drums?

Understanding trade terminology can significantly impact negotiations and procurement processes. Here are several essential terms relevant to DEF drum purchases:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are then sold under another brand’s name. In the context of DEF, knowing whether a supplier is an OEM can assure buyers of product quality and compatibility with their specific SCR systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQs is crucial for budgeting and inventory planning, especially for businesses with fluctuating demand for DEF. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotations based on specified requirements. Crafting a detailed RFQ can help buyers receive accurate pricing and terms, leading to better-informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers clarify shipping responsibilities, risk management, and cost allocation, which is particularly important for international shipments of DEF. -

Closed System vs. Open System

A closed system for dispensing DEF minimizes contamination and maintains fluid integrity during transfer. Understanding the difference between these systems can help businesses choose the right dispensing method to protect their SCR technologies. -

Cross Reference

This term refers to the practice of matching products from different manufacturers to ensure compatibility. For DEF buyers, knowing cross-reference products can facilitate sourcing and ensure that they receive quality fluids that meet their specifications.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when purchasing DEF drums, ensuring compliance, quality, and efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the def drum Sector

What Are the Current Market Dynamics and Key Trends Affecting DEF Drum Sourcing?

The Diesel Exhaust Fluid (DEF) drum sector is witnessing significant growth driven by stringent emissions regulations across various regions, particularly in Europe, the Middle East, and parts of Africa and South America. The global push towards cleaner transportation solutions, especially for heavy-duty vehicles, has made DEF an essential component in diesel engines equipped with Selective Catalytic Reduction (SCR) systems. This market is characterized by a shift toward bulk purchasing and long-term contracts, allowing B2B buyers to secure competitive pricing and stable supply chains.

Emerging technologies such as IoT-enabled monitoring systems are enhancing supply chain transparency and efficiency, enabling companies to track DEF quality and inventory levels in real-time. Moreover, the rise of e-commerce platforms facilitates easier access to suppliers and pricing comparisons, empowering international buyers to make informed decisions. In regions like Saudi Arabia and Vietnam, the increasing adoption of diesel-powered vehicles, coupled with infrastructural investments, is further stimulating demand for DEF products.

Illustrative image related to def drum

How Is Sustainability Shaping the Sourcing of DEF Drums?

Sustainability is becoming a cornerstone of B2B sourcing strategies in the DEF drum sector. The environmental impact of DEF production and transportation is significant, prompting buyers to seek suppliers that prioritize eco-friendly practices. This includes sourcing high-purity urea with minimal impurities to ensure compliance with ISO standards, which not only enhances engine performance but also reduces harmful emissions.

Moreover, ethical supply chains are gaining traction, with buyers increasingly favoring manufacturers who demonstrate commitment to sustainable practices, such as using recyclable materials for packaging and minimizing waste. Certifications like ISO 14001 (Environmental Management) and ISO 22241 (DEF Quality Standards) are becoming essential credentials for suppliers. Buyers who align with these ethical sourcing standards not only contribute to a cleaner environment but also enhance their brand reputation, appealing to environmentally-conscious consumers and stakeholders.

What Is the Evolution of the DEF Drum Sector and Its Relevance to B2B Buyers?

The DEF sector has evolved significantly since its inception in the early 2000s, driven by regulatory frameworks aimed at reducing nitrogen oxide (NOx) emissions from diesel engines. Initially, DEF was primarily used in Europe, but the adoption has expanded globally as manufacturers adapted to comply with increasingly stringent emissions regulations, such as Euro 5 and Euro 6 standards.

The transition from a niche product to a mainstream necessity for diesel engines has prompted innovations in DEF production and distribution, including the development of closed-system dispensing technologies. These advancements ensure DEF purity and minimize contamination risks, crucial for maintaining SCR system efficiency. For B2B buyers, understanding this evolution is essential, as it highlights the importance of sourcing high-quality DEF that meets regulatory standards while also ensuring operational efficiency and compliance with environmental mandates.

In summary, the DEF drum sector presents a landscape ripe with opportunities for B2B buyers, driven by regulatory pressures and a growing emphasis on sustainability. Adapting to these market dynamics and sourcing trends will be crucial for companies looking to maintain a competitive edge in the international arena.

Frequently Asked Questions (FAQs) for B2B Buyers of def drum

-

1. How do I ensure the quality of Diesel Exhaust Fluid (DEF) when sourcing from suppliers?

To ensure the quality of Diesel Exhaust Fluid (DEF), verify that suppliers provide API certification and adhere to ISO 22241 standards. Request a Certificate of Analysis (CoA) with each shipment, detailing the chemical composition and impurity levels. Additionally, consider suppliers with a proven track record in DEF distribution, as well as those who utilize closed systems to maintain DEF purity. Regular quality audits and sample testing can further help ensure compliance with industry standards. -

2. What is the best way to determine the right DEF drum size for my operations?

Selecting the right DEF drum size depends on your usage rate and storage capabilities. For smaller fleets or operations, 55-gallon drums may suffice, allowing for manageable handling and storage. Larger operations with higher consumption can benefit from 275 or 330-gallon totes, which reduce the frequency of deliveries. Analyze your consumption patterns and consult with your suppliers to identify the most efficient size that aligns with your operational needs. -

3. What are the typical payment terms for purchasing DEF in bulk?

Payment terms for bulk DEF purchases can vary significantly by supplier and region. Common arrangements include net 30, net 60, or even upfront payments for first-time orders. International buyers should consider payment methods like letters of credit or escrow services to mitigate risks. Always clarify terms before finalizing any agreement, including any potential discounts for early payments or bulk orders. -

4. How can I vet suppliers for DEF drums in international markets?

To vet suppliers for DEF drums in international markets, conduct thorough research on their reputation and experience. Look for suppliers with positive customer reviews and industry certifications. Request references and check their compliance with international shipping regulations. Engaging with local trade associations or using platforms like Alibaba can also provide insights into suppliers’ credibility and reliability. -

5. Are there any specific logistics considerations for importing DEF drums?

When importing DEF drums, consider the regulatory requirements of both the exporting and importing countries. Ensure that the supplier adheres to international shipping standards and provides necessary documentation like Safety Data Sheets (SDS). Work with logistics partners experienced in hazardous materials to manage transportation safely and efficiently. Additionally, factor in customs clearance times and potential tariffs or taxes that may apply. -

6. What are the minimum order quantities (MOQ) for DEF drums?

Minimum order quantities (MOQ) for DEF drums typically range from one drum to full pallets, depending on the supplier. Some suppliers may have a MOQ of four drums (one pallet) to optimize shipping efficiency. It’s essential to discuss your specific needs with suppliers, as they may offer flexibility based on your purchasing patterns or establish a trial order to assess the product quality and service. -

7. Can I customize the DEF product or packaging to suit my needs?

Many suppliers offer customization options for DEF, including packaging sizes and branding on the drums. If you require specific formulations or additives, communicate this during your initial discussions. Customization may incur additional costs, so it’s important to weigh the benefits against your budget. Make sure to confirm that any modifications comply with industry standards to avoid issues with product integrity. -

8. What are the implications of using non-compliant DEF on my equipment?

Using non-compliant DEF can severely affect your equipment’s performance, leading to issues such as SCR system malfunction, increased emissions, and potential warranty voidance. Poor-quality DEF can cause catalyst poisoning, resulting in costly repairs and downtime. To safeguard your investment, always source DEF that meets or exceeds the required specifications and maintain proper handling and storage protocols to preserve its quality.

Top 8 Def Drum Manufacturers & Suppliers List

1. BlueDEF – Diesel Exhaust Fluid (DEF)

Domain: kellerheartt.com

Registered: 2011 (14 years)

Introduction: Product: Diesel Exhaust Fluid (DEF) – 55 Gallon Drums

Brand: BlueDEF

Price: $284.00

Rating: 5.0 / 5.0 (37 Reviews)

Description: Diesel exhaust fluid is a key element of the Selective Catalytic Reduction (SCR) process used by most medium and heavy-duty engine builders.

2. JMESales – DEF Carts & Pump Systems

Domain: jmesales.com

Registered: 1998 (27 years)

Introduction: This company, JMESales – DEF Carts & Pump Systems, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Sinopec – DEF Diesel Exhaust Fluid

Domain: buysinopec.com

Registered: 2013 (12 years)

Introduction: {‘product_name’: ‘DEF Diesel Exhaust Fluid’, ‘pack_size’: ’55 Gallon Drum’, ‘price’: ‘$225.00’, ‘shipping’: ‘Free Shipping on all Pails, Jugs, Totes, 2+ Drums’, ‘stock’: ‘In Stock’, ‘pickup_locations’: [‘Houston Warehouse’, ‘Jacksonville Warehouse’, ‘Ontario Warehouse’, ‘Toms River Warehouse’], ‘description’: ‘API certified Diesel Exhaust Fluid formulated using high purity urea and water, 32.5% so…

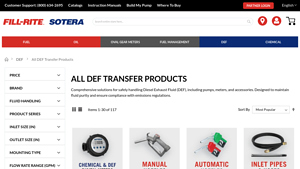

4. Fill-Rite – DEF Transfer Products

Domain: fillrite.com

Registered: 1998 (27 years)

Introduction: All DEF Transfer Products include: 1. Digital Meters for Chemical & DEF – Starting at $335.00 2. Manual Nozzles – Starting at $42.00 3. Automatic Nozzles – Starting at $74.00 4. Inlet Pipes & Hoses – Starting at $25.00 5. RPV Couplers – Starting at $190.00 6. Air-Operated Pump – Starting at $526.00 7. FRH07512 ¾” X 12″ Fuel Transfer Hose – $37.00 8. DEF Hand Pumps Series – Starting at $148.00 9. F…

5. Terracair – Diesel Exhaust Fluid 55 Gallon Drum

Domain: ruralking.com

Registered: 1996 (29 years)

Introduction: Terracair Diesel Exhaust Fluid, 55 Gallon Drum – DEF 55, SKU: 46771049

6. Reef Central – DEF Barrels

Domain: reefcentral.com

Registered: 1999 (26 years)

Introduction: DEF barrels are 55-gallon drums made of food-grade plastic. They previously contained DEF (Diesel Exhaust Fluid), which is 32% Urea and the rest is water (H2O). The barrel has a screw cap (approximately 3″ diameter) and a second cap that may require a tool to remove. Users have discussed cleaning and flushing the barrel for safe use, particularly for top-off water in aquariums.

7. Hirschman Inc – Diesel Exhaust Fluid 55 Gallon Drum

Domain: hirschmaninc.com

Registered: 2016 (9 years)

Introduction: Diesel Exhaust Fluid – DEF 55 Gallon Drum

– Size: 55 Gallon Drum

– Price: $129.00 ($2.35 per gallon)

– Delivery: Local delivery only, shipping not available

– Product Description: Non-toxic solution essential for modern diesel engines to meet emission standards. Conforms to high-quality standards for emission reduction and aids in compliance with environmental regulations. Manufactured with ultra-…

8. Grainger – Diesel Exhaust Fluid (DEF)

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Diesel Exhaust Fluid (DEF), is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for def drum

How Can Strategic Sourcing Enhance Your DEF Drum Procurement?

In today’s competitive landscape, strategic sourcing of Diesel Exhaust Fluid (DEF) in 55-gallon drums is paramount for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By selecting reliable suppliers who offer high-purity DEF, you ensure compliance with stringent emissions regulations and enhance the operational efficiency of your fleet. This not only safeguards your investment in heavy-duty vehicles but also prolongs the life of critical components such as SCR systems.

Emphasizing the importance of quality, buyers should prioritize suppliers who adhere to industry standards such as ISO 22241 to mitigate risks associated with contamination. Moreover, leveraging closed system dispensing solutions can significantly improve DEF integrity, reduce waste, and lower overall operational costs.

As you navigate the global DEF market, consider establishing long-term partnerships with reputable suppliers who can provide consistent quality and support. With the increasing focus on sustainability and emissions reduction, now is the time to act. Invest in strategic sourcing for your DEF needs to drive efficiency and compliance while positioning your business for future growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.