Unlocking Value: A Strategic Analysis of the Vibrating Screen For Dirt Residential Use…

Introduction: Navigating the Global Market for vibrating screen for dirt residential use

The global market for vibrating screens tailored for dirt residential use presents a unique set of challenges for B2B buyers. Sourcing the right vibrating screen can be daunting, especially when navigating diverse regional requirements and varying soil types. This guide aims to demystify the complexities of selecting the ideal equipment, covering essential aspects such as types of vibrating screens, their applications in landscaping and gardening, supplier vetting, and cost considerations.

By providing a comprehensive overview, this guide empowers international B2B buyers from regions like Africa, South America, the Middle East, and Europe—specifically Germany and Nigeria—to make informed purchasing decisions. Understanding the nuances of vibrating screens not only enhances operational efficiency but also ensures that investments yield high-quality topsoil, vital for successful landscaping and gardening projects.

Furthermore, this resource highlights technological advancements in soil screening, emphasizing how modern equipment can transform otherwise unusable dirt into valuable resources. With insights on maintenance and optimal usage, buyers will be equipped to maximize their investment while minimizing operational downtime. Explore the depths of this guide to confidently navigate the global market for vibrating screens, ensuring your projects thrive with the best equipment available.

Understanding vibrating screen for dirt residential use Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Vibrating Screen | Compact, easy to transport, often trailer-mounted | Landscaping, small construction projects | Pros: Versatile, easy to set up. Cons: Limited capacity compared to larger models. |

| Heavy-Duty Vibrating Screen | Robust construction, high throughput, large screening area | Large-scale landscaping, agricultural use | Pros: Efficient for large volumes, durable. Cons: Higher initial investment. |

| Electric Vibrating Screen | Powered by electric motors, quieter operation | Urban landscaping, residential projects | Pros: Lower operating costs, eco-friendly. Cons: May require electrical infrastructure. |

| DIY Vibrating Screen | Custom-built, often using repurposed materials | Small gardens, personal projects | Pros: Cost-effective, tailored to specific needs. Cons: Time-consuming to build, may lack efficiency. |

| Multi-Deck Vibrating Screen | Multiple screening levels, allows for different soil grades | Quarrying, mining, extensive landscaping | Pros: Versatile, efficient for sorting various materials. Cons: Complex design, maintenance can be challenging. |

What Are the Key Characteristics of Portable Vibrating Screens?

Portable vibrating screens are designed for mobility, making them ideal for small to medium-sized projects. Typically trailer-mounted, these screens can be easily transported to various job sites. They are perfect for landscaping and small construction projects where space is limited. Buyers should consider the screen’s size, weight capacity, and ease of setup, as well as whether they require a machine that can adapt to different soil types.

How Do Heavy-Duty Vibrating Screens Stand Out?

Heavy-duty vibrating screens are built for high throughput and durability, making them suitable for large-scale landscaping and agricultural applications. Their robust construction allows them to handle significant volumes of material, efficiently separating debris from high-quality topsoil. When considering a heavy-duty screen, buyers should assess the machine’s capacity, power requirements, and the types of materials it can process, as well as its long-term maintenance needs.

What Advantages Do Electric Vibrating Screens Offer?

Electric vibrating screens are notable for their quieter operation and lower environmental impact, making them particularly suitable for urban landscaping and residential projects. These screens typically require an electrical power source, which can be a consideration for some buyers. When purchasing, it’s essential to evaluate the power consumption, potential need for electrical infrastructure, and the machine’s efficiency in processing various soil types.

Why Consider a DIY Vibrating Screen?

DIY vibrating screens are an excellent option for individuals or small businesses looking to save costs while tailoring a solution to their specific needs. Often constructed from repurposed materials, these screens can be designed to meet unique project requirements. However, buyers should be prepared for the time investment required for construction and may need to compromise on efficiency compared to commercial models.

What Makes Multi-Deck Vibrating Screens Beneficial for B2B Buyers?

Multi-deck vibrating screens are designed with several screening levels, allowing for the separation of different grades of soil or materials simultaneously. This feature makes them highly efficient for industries like quarrying and extensive landscaping projects. Buyers should consider the complexity of the design, potential maintenance challenges, and the versatility of the machine to handle various materials when evaluating their options.

Key Industrial Applications of vibrating screen for dirt residential use

| Industry/Sector | Specific Application of vibrating screen for dirt residential use | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Landscaping | Screening topsoil for residential landscaping projects | Ensures high-quality topsoil, enhancing plant growth and aesthetic appeal | Durability, ease of maintenance, and adaptability to various soil types |

| Agriculture | Preparing soil for gardening and crop cultivation | Improves soil quality by removing debris, enhancing water retention and aeration | Screen size options, motor power, and efficiency in large-scale operations |

| Construction | Sorting materials for residential building sites | Reduces waste and ensures proper material grading for foundation work | Robust construction, portability, and compatibility with existing machinery |

| Waste Management | Sifting through compost and organic waste | Facilitates recycling and composting efforts, leading to better soil amendments | Screening efficiency, ease of use, and capacity for bulk material handling |

| Environmental Remediation | Cleaning contaminated soil for residential sites | Ensures safe and healthy environments by removing harmful substances | Compliance with local regulations, effectiveness in various soil types, and operational support |

How is Vibrating Screen Used in Landscaping Projects?

In landscaping, vibrating screens are pivotal for screening topsoil, ensuring it is free from debris such as rocks and plant material. This process is essential for creating aesthetically pleasing and healthy garden spaces, as fine, well-aerated soil promotes better plant growth. Buyers from regions like Africa and South America should consider the durability of the machinery, especially in areas with challenging soil conditions. Additionally, the ability to adjust screen sizes allows landscapers to customize their output based on specific project requirements, enhancing efficiency and reducing labor costs.

What Role Does Vibrating Screen Play in Agriculture?

In agriculture, vibrating screens are utilized to prepare soil for gardening and crop cultivation. By sifting out unwanted materials, these machines improve soil quality, enhance water retention, and promote aeration, which are crucial for healthy plant growth. For international buyers, particularly in the Middle East and Europe, sourcing machines that offer adjustable screen sizes and high throughput can significantly impact productivity. Moreover, energy efficiency is a key consideration, as agricultural operations often seek to minimize operational costs while maximizing output.

How is Vibrating Screen Beneficial in Construction?

In the construction sector, vibrating screens are essential for sorting materials at residential building sites. They help ensure that the right materials are used for foundations and landscaping, reducing waste and enhancing the quality of construction. For buyers in regions like Germany and Nigeria, the robustness and portability of these machines are critical factors, as construction sites may require frequent relocation. Additionally, compatibility with existing machinery can streamline operations and improve overall project timelines.

How is Vibrating Screen Used in Waste Management?

Vibrating screens play a vital role in waste management by sifting through compost and organic waste. This process helps separate usable compost from larger materials that need further decomposition, facilitating more efficient recycling efforts. For businesses in Africa and South America focused on sustainability, investing in high-efficiency screens can enhance their environmental initiatives. Key sourcing considerations include the machine’s ability to handle various waste types and the ease of operation, especially in regions with limited technical support.

What is the Importance of Vibrating Screen in Environmental Remediation?

Vibrating screens are crucial in environmental remediation, particularly for cleaning contaminated soil at residential sites. They effectively remove harmful substances, ensuring a safe environment for residents. Buyers from the Middle East and Europe should prioritize machines that comply with local regulations regarding soil safety. The effectiveness of the screen in different soil types and its operational support are also vital considerations, as they can significantly influence the success of remediation projects.

3 Common User Pain Points for ‘vibrating screen for dirt residential use’ & Their Solutions

Scenario 1: Inefficient Soil Separation Leading to Increased Costs

The Problem: B2B buyers, such as landscapers and contractors, often face challenges when separating high-quality topsoil from debris like rocks and plant matter. Without efficient equipment, these buyers may struggle to deliver quality soil for projects, leading to delays and increased labor costs. The manual sifting process can be time-consuming and labor-intensive, ultimately affecting project timelines and profit margins. Additionally, using subpar screening equipment may result in a lower quality end product, causing dissatisfaction among clients and potential damage to the buyer’s reputation.

The Solution: Investing in a high-quality vibrating screen specifically designed for dirt residential use can significantly enhance soil separation efficiency. Buyers should prioritize machines that offer adjustable screen sizes and varying vibration levels to accommodate different soil types and project requirements. It is essential to select a model with durable construction, ensuring longevity and reliability under regular use. To optimize performance, buyers should familiarize themselves with the operation and maintenance of the vibrating screen, including regular cleaning to prevent material buildup that could impede functionality. Sourcing equipment from reputable suppliers who offer warranties and after-sales support can further ensure the buyer receives a machine that meets their specific needs.

Scenario 2: Limited Understanding of Soil Types and Screening Requirements

The Problem: Many B2B buyers lack in-depth knowledge of soil composition and the appropriate screening methods for different soil types. This knowledge gap can lead to purchasing the wrong equipment or using ineffective screening techniques, resulting in poor soil quality and project inefficiencies. For instance, buyers may not understand how moisture content affects soil sifting or how to choose the right mesh size for their specific applications. This lack of expertise can be particularly challenging for buyers in emerging markets, where access to expert advice and resources may be limited.

The Solution: To overcome this challenge, buyers should invest time in understanding the specific soil types they will be working with and their corresponding screening requirements. Engaging with industry experts or attending workshops and seminars can provide valuable insights into soil characteristics and the impact of moisture on screening efficiency. Buyers should also consider collaborating with suppliers who offer educational resources, such as guides or consultations, to help them make informed decisions. Implementing a trial period with different screen sizes and vibration settings can also assist buyers in determining the most effective setup for their unique soil conditions, ultimately leading to better project outcomes.

Scenario 3: Equipment Maintenance and Downtime Issues

The Problem: Regular maintenance and potential downtime of vibrating screens can be a significant pain point for B2B buyers. Many users may not be aware of the maintenance requirements, leading to equipment failure during critical project phases. This can result in costly delays and lost revenue, particularly in regions where time-sensitive projects are the norm. Additionally, a lack of readily available replacement parts can exacerbate downtime issues, especially in remote areas where suppliers may not have the necessary inventory.

The Solution: To mitigate maintenance-related challenges, buyers should establish a comprehensive maintenance schedule that includes regular inspections, cleaning, and replacement of worn components. Creating a checklist can help ensure that all parts of the vibrating screen are regularly serviced. Buyers should also develop relationships with local suppliers or manufacturers to ensure that replacement parts are readily available, reducing potential downtime. Furthermore, purchasing equipment with readily available parts and robust customer support can facilitate quicker repairs. Lastly, documenting maintenance activities can help buyers track performance over time, enabling them to proactively address issues before they escalate into costly breakdowns.

Strategic Material Selection Guide for vibrating screen for dirt residential use

What Are the Key Materials for Vibrating Screens in Dirt Residential Use?

When selecting materials for vibrating screens used in dirt residential applications, several factors must be considered, including durability, cost, and performance characteristics. Below, we analyze four common materials: steel, stainless steel, polyurethane, and rubber, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform in Vibrating Screens?

Key Properties: Steel is known for its strength and rigidity, making it suitable for heavy-duty applications. It typically exhibits high temperature resistance and can withstand significant mechanical stress.

Pros & Cons: The primary advantage of steel is its durability and load-bearing capacity, which is essential for handling large volumes of dirt and debris. However, steel is prone to corrosion, especially in humid or wet environments, which may lead to increased maintenance costs over time. Manufacturing complexity is moderate, as steel can be easily fabricated into various shapes.

Impact on Application: Steel screens are compatible with a wide range of media, including gravel and soil, making them versatile for different residential projects. However, they may require protective coatings to enhance corrosion resistance.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards regarding material quality and safety. Common standards such as ASTM may apply, and buyers should consider the availability of corrosion-resistant options.

What Are the Advantages of Stainless Steel for Vibrating Screens?

Key Properties: Stainless steel offers excellent corrosion resistance and is suitable for applications where moisture is prevalent. It maintains its strength at various temperatures, making it a reliable choice for diverse environmental conditions.

Pros & Cons: The key advantage of stainless steel is its longevity and minimal maintenance needs, which can lead to lower total cost of ownership. However, it is generally more expensive than regular steel, which may be a concern for budget-conscious buyers. Manufacturing complexity can also be higher due to the material’s hardness.

Impact on Application: Stainless steel is particularly effective for sifting fine materials and is less likely to contaminate the soil, making it suitable for residential gardening and landscaping projects.

Considerations for International Buyers: Buyers from Europe, particularly Germany, may favor stainless steel due to stringent quality standards. Compliance with European Union directives on materials may also be necessary.

How Does Polyurethane Compare in Vibrating Screens?

Key Properties: Polyurethane is a flexible material known for its abrasion resistance and ability to withstand impact. It can operate effectively in a range of temperatures, though it may not be suitable for extreme conditions.

Pros & Cons: The main advantage of polyurethane is its lightweight nature, which makes it easier to handle and install. It also offers excellent noise dampening properties. However, its durability may not match that of metals, particularly under heavy loads, and it can be more susceptible to UV degradation.

Impact on Application: Polyurethane screens are ideal for fine sifting applications, especially in residential gardening, where soil quality is paramount. They can also be customized for specific mesh sizes to cater to different soil types.

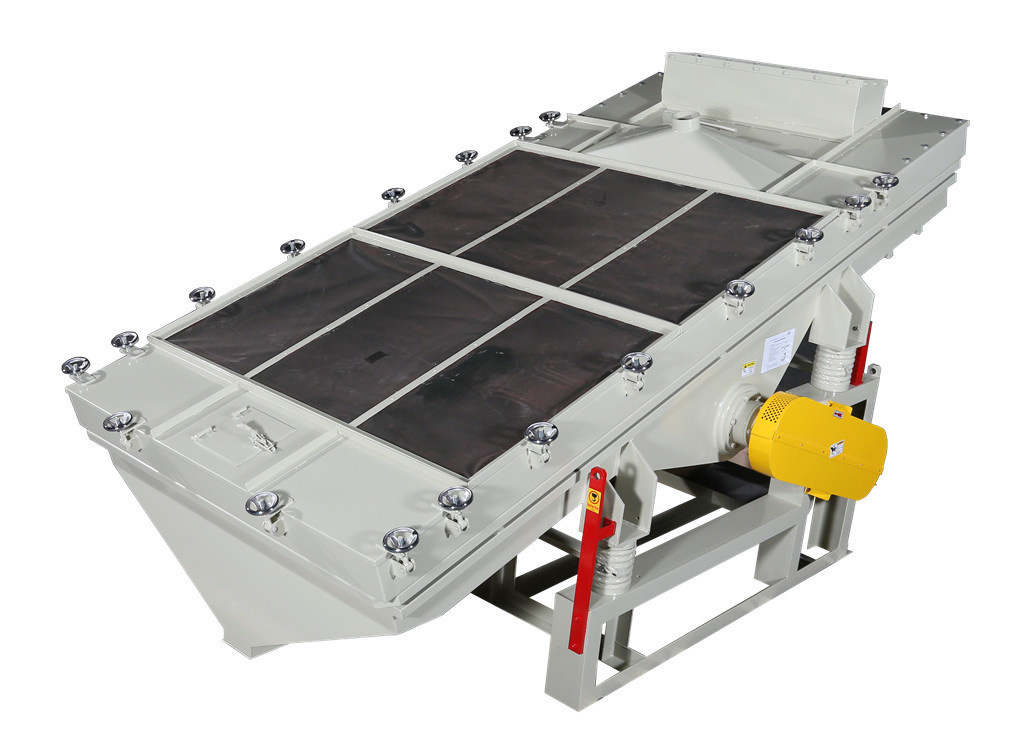

Illustrative image related to vibrating screen for dirt residential use

Considerations for International Buyers: Buyers should check local regulations regarding the use of synthetic materials, as some regions may have restrictions. Understanding the local climate is also crucial, as UV exposure can affect the longevity of polyurethane.

What Role Does Rubber Play in Vibrating Screens?

Key Properties: Rubber is highly elastic and provides excellent shock absorption, making it suitable for applications requiring flexibility. It is resistant to wear and can handle moderate temperatures.

Pros & Cons: The flexibility of rubber allows it to conform to varying shapes and surfaces, which can enhance screening efficiency. However, rubber may not withstand heavy loads as effectively as metal options, and its lifespan can be shorter in abrasive environments.

Impact on Application: Rubber screens are particularly useful for applications where noise reduction is desired, such as residential areas. They can effectively separate larger debris from soil without damaging the finer particles.

Considerations for International Buyers: Buyers should consider the availability of high-quality rubber that meets international standards for durability and environmental impact, especially in regions with varying climate conditions.

Illustrative image related to vibrating screen for dirt residential use

Summary Table of Material Selection

| Material | Typical Use Case for vibrating screen for dirt residential use | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications for large volumes of dirt | High durability and load capacity | Prone to corrosion | Medium |

| Stainless Steel | Fine sifting and moisture-prone environments | Excellent corrosion resistance | Higher cost | High |

| Polyurethane | Lightweight screening for fine materials | Abrasion resistance and flexibility | Susceptible to UV degradation | Medium |

| Rubber | Noise-sensitive applications and shock absorption | Flexibility and shock absorption | Shorter lifespan under heavy loads | Low |

This strategic material selection guide provides B2B buyers with essential insights into choosing the right vibrating screen materials for dirt residential use, ensuring effective performance while considering regional compliance and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vibrating screen for dirt residential use

What Are the Main Stages of Manufacturing Vibrating Screens for Dirt Residential Use?

The manufacturing process for vibrating screens designed for dirt residential use involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a pivotal role in ensuring that the final product meets performance standards and customer expectations.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in manufacturing vibrating screens involves selecting the right materials. Typically, high-quality steel is utilized due to its strength and durability, often with a protective coating to prevent rust and wear. For specific applications, suppliers may also use stainless steel or other alloys that can withstand harsh environmental conditions.

Once the materials are selected, they undergo various preparation processes, such as cutting, machining, and surface treatment. This ensures that the raw materials are ready for the subsequent forming stage. Quality checks are implemented during this phase to ensure that the materials meet specific standards, including dimensional accuracy and surface finish.

How Are Vibrating Screens Formed and Assembled?

The forming stage involves shaping the prepared materials into the desired components of the vibrating screen. This may include processes such as bending, welding, and punching. Advanced techniques like laser cutting and CNC machining are often employed to ensure precision and reduce waste.

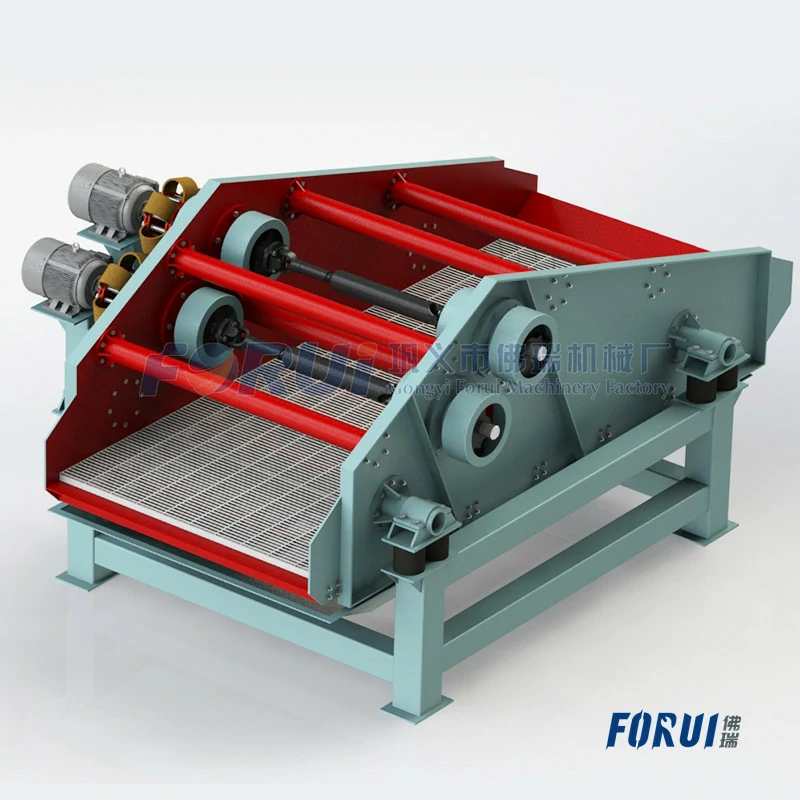

Illustrative image related to vibrating screen for dirt residential use

After forming, the components are assembled into the final product. This stage typically involves multiple sub-assemblies, including the screen deck, frame, and drive mechanism. Careful alignment and fitting are essential to ensure optimal performance and longevity of the vibrating screen.

What Finishing Processes Are Essential for Quality Vibrating Screens?

Finishing processes are crucial for both aesthetics and functionality. Common finishing techniques include powder coating, galvanizing, or painting, which provide a protective layer against corrosion and wear. Additionally, these processes enhance the visual appeal of the equipment.

Quality control measures are also implemented during the finishing stage to ensure that the protective coatings are applied evenly and adhere properly to the surface. This is particularly important for equipment that will be used outdoors or in challenging environments.

How Is Quality Assurance Implemented in Manufacturing Vibrating Screens?

Quality assurance (QA) is a vital component of the manufacturing process for vibrating screens. Adhering to international standards, such as ISO 9001, and industry-specific certifications like CE and API, ensures that manufacturers maintain high-quality production practices.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure the final product meets specified requirements. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial stage checks the quality of raw materials before they are used in production. Suppliers must provide certification and documentation to verify that the materials meet established standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves continuous monitoring of production techniques and components. This ensures that any deviations from established protocols are caught early, minimizing waste and rework.

-

Final Quality Control (FQC): Before shipping, the finished vibrating screens undergo thorough inspections and testing. This includes checking for dimensional accuracy, functionality, and adherence to safety standards.

What Testing Methods Are Commonly Used for Vibrating Screens?

Several testing methods are employed to validate the performance and durability of vibrating screens. Common methods include:

-

Vibration Testing: This assesses the screen’s ability to handle the expected loads and vibrations during operation.

-

Load Testing: Ensures that the screen can support the weight of the material it will process without failure.

-

Visual Inspections: These are conducted to identify any surface defects or inconsistencies in the finish.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should conduct thorough due diligence when selecting suppliers for vibrating screens. Here are several strategies to verify quality control practices:

Illustrative image related to vibrating screen for dirt residential use

What Steps Should Buyers Take to Conduct Supplier Audits?

-

Supplier Audits: Buyers can request audits of the manufacturing facilities to evaluate quality control processes. This includes examining the production line, QC checkpoints, and documentation practices.

-

Certification Verification: Request copies of relevant certifications (ISO, CE, API) to ensure that the supplier adheres to international quality standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing processes and product quality.

What Are the Unique QC and Certification Considerations for International Buyers?

When dealing with international suppliers, particularly from regions such as Africa, South America, the Middle East, and Europe, several nuances in quality control and certification should be considered:

-

Understanding Regional Standards: Different regions may have specific regulations and standards that impact product quality and safety. Buyers should familiarize themselves with these standards to ensure compliance.

-

Cultural Differences in Quality Assurance: Variations in quality assurance practices may exist based on cultural and regional norms. Buyers should be aware of these differences and establish clear communication with suppliers regarding expectations.

-

Documentation and Transparency: Buyers should seek suppliers who maintain comprehensive records of QC processes and testing results. This transparency can build trust and ensure that the products meet the necessary quality standards.

In conclusion, understanding the manufacturing processes and quality assurance practices for vibrating screens is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, along with robust quality control checkpoints and testing methods, buyers can ensure that they select reliable suppliers that deliver high-quality products for dirt residential use.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vibrating screen for dirt residential use’

In the competitive landscape of B2B procurement, finding the right vibrating screen for dirt residential use can streamline operations, enhance productivity, and lead to significant cost savings. This guide serves as a practical checklist for international buyers looking to make informed decisions when sourcing these essential machines.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing a vibrating screen. Consider factors such as the type of material to be screened (soil, gravel, etc.), desired mesh size, throughput capacity, and the machine’s overall dimensions. This clarity will help you communicate effectively with potential suppliers and ensure you select a model that meets your specific needs.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing will empower you to make a competitive purchase. Investigate various suppliers to gauge the average price range and features offered. Pay attention to regional differences, as prices may vary significantly across Africa, South America, the Middle East, and Europe. This research not only helps in negotiating better deals but also ensures you are aware of any emerging technologies that could enhance efficiency.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record of delivering quality equipment and excellent customer service. Additionally, check for online reviews or testimonials to gauge their reputation in the market.

Step 4: Verify Compliance with Industry Standards

Ensuring that your supplier’s equipment complies with industry standards is crucial for operational efficiency and safety. Check for certifications such as ISO, CE, or any local regulatory compliance that may be applicable in your region. Compliance not only guarantees quality but also mitigates risks associated with equipment failure or safety hazards.

Step 5: Assess Warranty and After-Sales Support

A robust warranty and reliable after-sales support can save you significant costs in the long run. Ensure that the supplier offers a comprehensive warranty that covers parts and labor, as well as ongoing technical support. Inquire about their maintenance services and availability of spare parts, as this will impact your operational downtime in case of repairs.

Step 6: Request Demonstrations or Trials

Whenever possible, request demonstrations or trials of the vibrating screens you are considering. This hands-on experience will allow you to assess the machine’s performance, ease of use, and suitability for your specific applications. It can also help in comparing different models side by side, leading to a more informed purchasing decision.

Step 7: Negotiate Terms and Finalize the Purchase

Once you have selected a supplier and equipment model, it’s time to negotiate the terms of the purchase. Discuss payment options, delivery schedules, and installation services to ensure everything aligns with your operational timelines. A clear agreement will help avoid misunderstandings and ensure a smooth procurement process.

By following this step-by-step checklist, B2B buyers can confidently navigate the sourcing process for vibrating screens tailored for dirt residential use, ultimately leading to improved efficiency and productivity in their operations.

Illustrative image related to vibrating screen for dirt residential use

Comprehensive Cost and Pricing Analysis for vibrating screen for dirt residential use Sourcing

What Are the Key Cost Components for Sourcing a Vibrating Screen for Dirt Residential Use?

When sourcing a vibrating screen for dirt residential use, understanding the cost structure is crucial for effective budgeting. The primary components that contribute to the overall cost include:

-

Materials: The choice of materials significantly impacts the cost. High-grade steel and durable rubber components may raise the upfront price but enhance longevity and performance. Conversely, opting for lower-quality materials can save money initially but lead to higher replacement costs in the long run.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor is required for precise welding and assembly, which can increase costs. Automation in production can reduce labor costs, but the initial investment in machinery must be considered.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production facilities. Efficient manufacturing processes can minimize overhead costs, allowing for competitive pricing.

-

Tooling: Initial tooling costs can be significant, especially for customized screens. Depending on the complexity of the design, specialized tools may be required, which can affect the price.

-

Quality Control (QC): Implementing robust QC measures ensures that the screens meet safety and performance standards. While this adds to the cost, it mitigates the risk of future failures and associated costs.

-

Logistics: Transporting the screens from the manufacturer to the buyer is a critical cost component. Factors such as distance, shipping method, and customs duties can affect overall logistics expenses.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit. This margin can vary based on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect the Cost of Vibrating Screens?

Several factors influence the pricing of vibrating screens, particularly in international B2B markets:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders generally lead to lower per-unit costs. Suppliers may offer discounts for larger orders, making it beneficial for businesses with high demand.

-

Specifications and Customization: Customized screens tailored to specific requirements can incur higher costs. Standard models are usually more affordable, but may not meet all operational needs.

-

Material Quality and Certifications: Screens made from high-quality materials or those that comply with international safety and performance certifications may command a premium price. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their experience and quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Understanding these terms can prevent unexpected expenses during transportation.

What Buyer Tips Should Be Considered for Cost-Efficiency?

To maximize cost-efficiency when sourcing vibrating screens, consider the following strategies:

-

Negotiate Pricing: Engage suppliers in discussions about pricing. Highlighting your volume needs and long-term potential can create leverage for better deals.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the costs associated with maintenance, repair, and potential downtime. Screens with lower TCO may offer better long-term value.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe must consider currency fluctuations, import tariffs, and local regulations that could affect pricing. It’s advisable to work with local experts who understand the market landscape.

-

Research and Compare Suppliers: Utilize online platforms to compare prices and features of different suppliers. This can provide insight into the market rates and help in making informed purchasing decisions.

Conclusion and Disclaimer

Prices for vibrating screens can vary widely based on the factors outlined above. It is crucial for international buyers to conduct thorough research and engage in strategic negotiations to achieve the best possible deal. Note that prices can fluctuate based on market conditions and supplier availability, so it’s recommended to seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing vibrating screen for dirt residential use With Other Solutions

Introduction: Exploring Alternatives to Vibrating Screens for Soil Screening

When considering soil screening solutions for residential use, it is essential to evaluate various technologies that can achieve similar results. While vibrating screens are popular for their efficiency in separating debris from soil, there are alternative methods and tools that may suit different needs and budgets. This analysis will compare vibrating screens with two viable alternatives: manual soil sifters and trommel screens, providing B2B buyers with insights into their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Vibrating Screen For Dirt Residential Use | Manual Soil Sifter | Trommel Screen |

|---|---|---|---|

| Performance | High efficiency in separating fine soil from debris | Moderate; labor-intensive and time-consuming | High; effective for larger volumes |

| Cost | Moderate to high; initial investment required | Low; inexpensive and often DIY | High; requires significant investment |

| Ease of Implementation | Requires setup and power source | Simple; requires no machinery | Complex; needs proper installation |

| Maintenance | Low; minimal wear and tear if used properly | None; only requires cleaning | Moderate; regular inspections needed |

| Best Use Case | Large-scale residential landscaping projects | Small gardens or light-duty tasks | Large operations needing high volume processing |

Detailed Breakdown of Alternatives

Manual Soil Sifter

Manual soil sifters are simple tools that typically consist of a frame with mesh or perforated screens. They allow users to sift soil by hand, making them ideal for small gardens or home projects. The main advantages of manual sifters include low cost and ease of use, as they require no power source or complex setup. However, they can be labor-intensive and time-consuming, especially for larger volumes of soil. For residential users with limited sifting needs, a manual sifter can be a practical and cost-effective solution.

Trommel Screen

Trommel screens are cylindrical devices that rotate to separate materials based on size. They are particularly effective for handling large volumes of soil and can process debris quickly. The advantages of trommel screens include high efficiency and the ability to handle various materials, making them suitable for larger landscaping or construction projects. However, they come with a higher price tag and require a more complex setup, including a power source. Regular maintenance is also necessary to ensure optimal performance. Trommel screens are best suited for commercial applications where high throughput is essential.

Conclusion: How to Choose the Right Soil Screening Solution for Your Needs

When deciding between a vibrating screen and its alternatives, B2B buyers should consider the specific requirements of their projects. For large-scale landscaping tasks where efficiency is paramount, a vibrating screen or trommel screen may be the best choice. Conversely, for smaller, residential projects with budget constraints, a manual soil sifter could provide an adequate solution. Ultimately, understanding the volume of soil to be processed, the desired speed of operation, and available resources will guide buyers in selecting the most appropriate soil screening method for their unique needs.

Essential Technical Properties and Trade Terminology for vibrating screen for dirt residential use

What are the Key Technical Properties of Vibrating Screens for Dirt Residential Use?

When selecting a vibrating screen for dirt residential use, several technical properties can significantly impact performance and longevity. Understanding these specifications is crucial for B2B buyers aiming to invest wisely.

1. Material Grade

The material used in the construction of vibrating screens is pivotal for durability and resistance to wear. Common materials include high-carbon steel for the screen mesh and heavy-duty steel for the frame. High-quality materials can withstand harsh conditions, reducing maintenance costs and downtime.

Illustrative image related to vibrating screen for dirt residential use

2. Screen Mesh Size

The screen mesh size determines the particle size that can pass through the screen. Typical mesh sizes range from 1/8 inch to 1 inch, with finer meshes suitable for sifting topsoil and coarser meshes for gravel. Selecting the appropriate mesh size ensures efficient sorting, impacting the quality of the final product and operational efficiency.

3. Vibration Frequency and Amplitude

Vibration frequency (measured in Hz) and amplitude (the distance of the screen’s movement) are critical for effective screening. Higher frequencies can increase throughput by allowing finer materials to pass through the screen more quickly, while appropriate amplitude ensures that larger debris is effectively separated. Understanding these parameters helps buyers optimize their screening process.

4. Capacity

This refers to the volume of material that the vibrating screen can process per hour, typically measured in cubic meters. A higher capacity allows for larger projects to be completed in a shorter time, thus improving productivity. Buyers should assess their project requirements to ensure they select a machine that meets their capacity needs.

5. Power Source

Vibrating screens can be powered by electric motors or gasoline engines. Electric motors are often more cost-effective and require less maintenance, while gasoline engines may be more suitable for remote locations. Understanding the power source’s implications on operating costs and maintenance is essential for making an informed choice.

Illustrative image related to vibrating screen for dirt residential use

What are Common Trade Terms Related to Vibrating Screens?

Familiarity with trade terminology can facilitate smoother transactions and negotiations. Here are several key terms relevant to the vibrating screen market:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. When sourcing vibrating screens, buyers may prefer OEMs for quality assurance and compatibility with existing equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their purchases and manage inventory costs effectively, especially in bulk buying scenarios.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers. When considering a vibrating screen, issuing an RFQ can help buyers compare costs and features from multiple vendors, ensuring they make the best financial decision.

4. Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping costs, risks, and logistics associated with acquiring vibrating screens from international suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for project planning, especially for large-scale operations where timing can impact overall productivity.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when procuring vibrating screens for dirt residential use, ultimately enhancing operational efficiency and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the vibrating screen for dirt residential use Sector

What Are the Key Market Dynamics and Trends Influencing the Vibrating Screen for Dirt Residential Use Sector?

The vibrating screen market for dirt residential use is witnessing a robust transformation driven by several global factors. The increasing demand for efficient soil management solutions in landscaping, gardening, and agricultural applications is a primary driver. Emerging economies in Africa and South America are experiencing a surge in residential development, which further fuels the need for effective soil sifting technologies. Technological advancements, such as the integration of IoT and automation in vibrating screen machines, are enhancing their efficiency and usability. This tech-savvy approach allows for real-time monitoring and adjustments, making these machines more attractive to international B2B buyers looking for high-performance equipment.

Additionally, the rising trend of sustainable landscaping practices is influencing purchasing decisions. Buyers are increasingly seeking machines that can process local soil resources into usable topsoil, reducing transportation costs and environmental impact. The shift towards online procurement is notable, as it provides access to a broader range of suppliers and pricing options, allowing buyers to make informed decisions based on market trends and product availability. Furthermore, the competitive landscape has intensified, leading manufacturers to innovate continuously and offer versatile solutions tailored to specific regional requirements.

How Does Sustainability and Ethical Sourcing Impact the Vibrating Screen Market?

Sustainability is becoming a pivotal consideration in the vibrating screen sector, particularly as environmental awareness grows among consumers and businesses. The ecological impact of soil processing equipment is significant, with energy consumption and material waste being central concerns. Buyers are increasingly prioritizing suppliers that utilize environmentally friendly practices and materials, including recycled components in their machinery.

Ethical sourcing is also gaining traction, as companies are held accountable for their supply chain practices. Buyers are now more inclined to partner with manufacturers who demonstrate transparency in sourcing raw materials and adhere to fair labor practices. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications can enhance a supplier’s credibility in this market. By investing in sustainable machinery, businesses not only comply with regulatory standards but also position themselves as responsible corporate citizens, appealing to a growing segment of eco-conscious consumers.

Illustrative image related to vibrating screen for dirt residential use

What Historical Developments Have Shaped the Vibrating Screen Industry?

The evolution of vibrating screens for dirt residential use can be traced back to traditional soil sifting methods, which relied heavily on manual labor. Over the decades, the introduction of mechanical sifting solutions significantly transformed this sector. The mid-20th century saw the first iterations of vibrating screens, which utilized simple mechanical vibrations to enhance soil separation processes.

As technology advanced, innovations such as electric-powered vibrating screens emerged, making the process more efficient and less labor-intensive. The late 20th century introduced automated features, allowing for greater precision and productivity. Today, the industry is witnessing a shift towards smart technologies, where digital integration and automation play a crucial role in enhancing operational efficiency. This historical progression underscores the importance of continuous innovation in meeting the evolving needs of B2B buyers in various global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of vibrating screen for dirt residential use

-

How do I choose the right vibrating screen for dirt residential use?

Selecting the appropriate vibrating screen requires considering several factors, including the type of soil you are sifting, the size of the project, and your budget. For residential use, lightweight and portable options are ideal. Look for screens with adjustable mesh sizes to accommodate different soil types, from fine to coarse. Additionally, consider the machine’s efficiency, as a more powerful unit can save time and labor costs. Always review manufacturer specifications and user feedback to ensure you choose a model that meets your specific needs. -

What is the best vibrating screen for residential landscaping projects?

The best vibrating screen for residential landscaping typically includes features like adjustable screen sizes, portability, and ease of operation. Models designed for compact tractors or small excavators are often suitable for residential projects. Brands that offer robust customer support and warranty options are also preferable. It’s beneficial to seek machines that allow for easy maintenance and part replacement, ensuring longevity and reliability for ongoing landscaping tasks. -

What are the common issues with vibrating screens for dirt, and how can I resolve them?

Common issues with vibrating screens include clogging, uneven vibration, and mechanical failures. To prevent clogging, ensure that the soil is dry before screening, as wet soil can lead to excessive clumping. Regular maintenance, such as checking for wear and tear on the screens and motors, can resolve mechanical issues. If uneven vibration occurs, inspect the mounting and springs for damage, and adjust the weight distribution on the screen as necessary. Consulting the manufacturer’s guidelines can provide specific troubleshooting tips. -

How do I vet suppliers for vibrating screens in international markets?

When vetting suppliers, start by researching their reputation through online reviews and industry forums. Verify their certifications, such as ISO or CE, which indicate adherence to quality standards. Request references from previous clients and assess their responsiveness and professionalism during initial communications. It’s also advisable to inquire about their production capabilities, lead times, and after-sales support. Establishing a trial order can provide insights into their reliability before committing to larger purchases. -

What are the typical minimum order quantities (MOQs) for vibrating screens?

Minimum order quantities (MOQs) can vary significantly between manufacturers and regions. Generally, MOQs for vibrating screens can range from 1 to 10 units for smaller manufacturers, while larger manufacturers may require higher quantities. When negotiating with suppliers, clarify MOQs upfront and consider discussing flexibility for pilot orders. Some suppliers may offer lower MOQs for new clients to establish a business relationship, so it is worth exploring these options. -

What payment terms should I expect when sourcing vibrating screens internationally?

Payment terms can differ based on the supplier’s policies and your negotiation skills. Common terms include upfront payments, such as a deposit of 30-50% with the balance due upon delivery. Letters of credit are often used for larger transactions to ensure security for both parties. It’s essential to clarify payment methods accepted, such as wire transfers or PayPal, and to ensure compliance with any relevant international trade regulations to avoid delays. -

How can I ensure quality assurance (QA) for vibrating screens sourced internationally?

To ensure quality assurance, ask potential suppliers about their QA processes, including materials used, manufacturing methods, and testing protocols. Request samples or certifications demonstrating compliance with international standards. If feasible, arrange for a factory inspection or hire third-party quality control services to verify the manufacturing process. Establishing clear specifications and performance metrics in your purchase agreement can also help ensure that the final product meets your expectations. -

What logistics considerations should I keep in mind when importing vibrating screens?

Logistics are crucial when importing vibrating screens. Consider shipping methods (air vs. sea) based on cost and urgency. Ensure compliance with customs regulations in your country, including import duties and taxes. Work with experienced freight forwarders who can handle documentation and customs clearance effectively. Additionally, factor in lead times for shipping and potential delays, and maintain open communication with your supplier to track the shipment status throughout the process.

Top 10 Vibrating Screen For Dirt Residential Use Manufacturers & Suppliers List

1. EZ-Screen – Portable Topsoil Screeners

Domain: ez-screen.com

Registered: 1998 (27 years)

Introduction: EZ-Screen offers a range of portable topsoil screeners made in the USA, including the following models: EZ-600, EZ-800, EZ-1000XL, EZ-1200XLS, and EZ-1700. They also provide trommel screens like the EZ-512, attachments such as the EZ Screen 100 for skid steers, and excavator screeners like SB Screening Buckets. Key features include:

– EZ-Kinetic Drive System for efficient operation.

– Durable con…

2. IDM – Topsoil Screeners

Domain: idmcabc.com

Registered: 2014 (11 years)

Introduction: Topsoil Screeners – IDM

1. **Models and Prices:**

– SLG 108VFRB: $17,700 USD / $23,300 CDN

– SLG 108VF: $15,500 USD / $18,400 CDN

– SLG 78VFRB: $11,050 USD / $11,900 CDN

– SLG 78VF: $9,750 USD / $9,950 CDN

– SLG 68V: $6,250 USD / $6,995 CDN

2. **Feeding Equipment Compatibility:**

– SLG 108VFRB: Excavators, Backhoes, Wheel Loaders

– SLG 108VF: Skidsteers, Backhoes, Wheel Load…

3. Instructables – Homemade Soil Screener/Sifter

Domain: instructables.com

Introduction: Homemade Soil Screener/Sifter

– Designed by: nlinventor

– Features: Springs and hinges made from old car tires, no need for regular steel springs and metal hinges, screen floats on rubber.

– Engine: 6-1/2 HP gasoline engine, can be converted to electric motor.

– Capacity: Screened about 100 tons of material without major problems.

– Chassis: Made from an old galvanized steel work table, dimensions…

4. Houzz – Vibration Plate for Soil Sifting

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: Vibration plate for sifting soil, used to automate the process of separating small particles from materials for gardening. Suggested use includes securing a five-gallon bucket to the vibration plate and using a timer for operation. Alternatives discussed include bullet reloading shell case tumblers and DIY solutions, but the author seeks a commercially available option under $300.

5. VIKING – 3rd Generation Mobile Deck Screen

Domain: eydescreen.com

Registered: 2015 (10 years)

Introduction: Product Name: VIKING Mobile Deck Screen

Type: Mobile deck screen equipment

Generation: 3rd generation

Market Position: No 1 mobile deck screen in Europe

Key Features:

– Portable wheeled, double deck vibrating screen

– Screening capabilities: top soil, compost, building waste, gravel, sand, and other waste materials

– Outstanding screening capacity: up to 120 m3/hour of top soil

– Rosta Swiss vibra…

6. Rigs4Less – Vibratory Rock/Dirt Screener

7. DeSite – Portable Vibratory Screeners

Domain: topsoilscreenersbyomh.com

Registered: 2010 (15 years)

Introduction: DeSite manufactures portable vibratory soil/rock screeners designed for small to medium sized landscaping, excavating, and construction. Key models include SLG-78 and SLG-108. Features include factory direct pricing starting at $3995, 50% interest financing, a 1-year parts warranty, and quick delivery times from East and West Coast locations. The screeners are designed for use with skidsteers, buc…

8. Topsoil Screening Equipment – Vibratory Screeners

Domain: topsoilscreeningequipment.com

Registered: 2023 (2 years)

Introduction: {“Vibratory Screeners”: {“SLG-108VFRB”: {“Compatibility”: “Wheel Loaders/Backhoes/Excavators”, “Stock”: “IN STOCK”}, “SLG-78VFRB”: {“Compatibility”: “Skid Steers/Bucket Tractors/Compact Loaders”, “Stock”: “IN STOCK”}, “SLG-78 STATIC”: {“Compatibility”: “Skid Steers/Bucket Tractors/Compact Loaders”, “Stock”: “IN STOCK”}, “SLG-68VF”: {“Compatibility”: “Mini Skids/Mini Excavators/Compact Tractors”, “…

9. TMG – 70 Vibratory Topsoil Rock Screen

Domain: tmgindustrial.com

Registered: 2015 (10 years)

Introduction: {“name”: “70” Vibratory Topsoil Rock Screen”, “engine”: “5.5 HP Kohler Engine”, “features”: [“Cantilever Leaf-Springs”, “30° Screen Deck”], “sku”: “TMG-RSV70G”, “price”: “$8,299.00”, “shipping”: “FREE shipping to most locations in USA”, “delivery_time”: “Delivered in 10 to 15 business days”, “capacity”: “750 lb”, “applications”: [“sand”, “topsoil”, “compost”, “gravel”, “rock”, “crushed concrete”, …

10. Remlinger – Vibrating Screening Bucket PFM-700

Domain: equipmentland.com

Registered: 1999 (26 years)

Introduction: Product Name: Remlinger Vibrating Screening Bucket for Skid Steers PFM-700

Price: $5,565

Shipping Cost: $690 (flat rate for immediate purchases)

Dimensions: 70″L x 48″W x 36″H

Weight: 1,170 lbs

Capacity: 7/8 cubic yard

Hydraulic Requirements: 13-16 GPM at 1500 psi

Included: One free screen up to 2.5″ of choice (various sizes available)

Features:

– Ideal for landscaping, farms, industrial uses, go…

Strategic Sourcing Conclusion and Outlook for vibrating screen for dirt residential use

The importance of strategic sourcing in the vibrating screen market for residential dirt use cannot be overstated. By leveraging advanced technologies and innovative designs, businesses can enhance their operational efficiency while reducing costs. The trend towards eco-friendly and efficient equipment is reshaping the landscape, making it essential for buyers to consider not only the initial purchase price but also the long-term value and sustainability of their investments.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics and supplier capabilities is crucial. Engaging with reputable manufacturers who offer quality products can lead to significant savings and improved project outcomes.

As you explore the opportunities within this sector, consider conducting thorough market research to identify the best suppliers and products that meet your specific needs. The vibrating screen technology is evolving, and those who act now can position themselves advantageously in this competitive market. Embrace the opportunity to elevate your projects with high-quality screening solutions that will drive success for years to come.

Illustrative image related to vibrating screen for dirt residential use

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to vibrating screen for dirt residential use