A B2B Buyer’s Guide to Elasticized Cord: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for elasticized cord

Navigating the complexities of sourcing elasticized cord can be a daunting challenge for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. As demand for versatile, high-quality elastic cords increases across various industries—from crafting to manufacturing—understanding the nuances of this product is crucial. This guide aims to provide a comprehensive overview of elasticized cord, covering its types, applications, and supplier vetting processes.

International buyers will benefit from insights into cost considerations, quality assessments, and the latest trends that influence purchasing decisions. Whether you are in Germany seeking durable solutions for industrial applications or in Nigeria looking for elastic cord for creative projects, this guide is designed to empower you with the knowledge necessary to make informed choices.

By equipping B2B buyers with actionable insights and expert recommendations, we aim to streamline the sourcing process and enhance the overall purchasing experience. With a focus on quality and reliability, this guide serves as a valuable resource for businesses aiming to navigate the global market for elasticized cord effectively.

Understanding elasticized cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Braided Elastic Cord | Made of multiple strands for enhanced strength | Fashion, jewelry making, crafts | Pros: High durability; Cons: Less stretch than other types |

| Flat Elastic Cord | Flat design for even distribution of tension | Apparel, medical devices, straps | Pros: Comfort and flexibility; Cons: Limited load capacity |

| Round Elastic Cord | Classic round shape, widely available | General purpose, outdoor equipment | Pros: Versatile and easy to use; Cons: Can lose elasticity over time |

| Silicone Elastic Cord | Made from silicone for increased weather resistance | Outdoor applications, sports gear | Pros: High temperature resistance; Cons: Higher cost compared to traditional cords |

| Shock Cord | Features a core surrounded by a woven sheath | Camping, boating, and industrial uses | Pros: Excellent shock absorption; Cons: Can be bulky for small projects |

What Are the Characteristics of Braided Elastic Cord?

Braided elastic cord is composed of multiple strands woven together, providing enhanced strength and durability. This type is particularly suitable for applications in fashion, jewelry making, and various crafts where a robust yet flexible cord is required. When purchasing braided elastic cord, B2B buyers should consider the cord’s tensile strength, stretchability, and resistance to wear and tear, ensuring it meets the demands of their specific projects.

Why Choose Flat Elastic Cord for B2B Applications?

Flat elastic cord is characterized by its flat design, which allows for even distribution of tension across the material. This makes it ideal for applications in apparel, medical devices, and straps where comfort and flexibility are paramount. Buyers should evaluate the cord’s width and thickness, as these factors directly influence its load capacity and comfort level for end-users.

How Does Round Elastic Cord Compare to Other Types?

Round elastic cord is the most commonly used type, known for its versatility and ease of use across a wide range of applications, including general-purpose crafting and outdoor equipment. While it offers good stretchability, buyers must be aware that it can lose elasticity over time, particularly in high-stress environments. Evaluating the quality of the material and the intended use is crucial for ensuring long-term performance.

What Benefits Does Silicone Elastic Cord Offer?

Silicone elastic cord stands out due to its increased resistance to weather conditions and high temperatures, making it an excellent choice for outdoor applications and sports gear. While it is typically more expensive than traditional elastic cords, its durability and performance in challenging environments can justify the cost. B2B buyers should assess the specific environmental conditions their products will face to determine if silicone is the right choice.

When to Use Shock Cord in B2B Purchases?

Shock cord, featuring a core wrapped in a woven sheath, is designed for applications requiring excellent shock absorption, such as camping, boating, and industrial uses. This type offers significant resilience under stress, but its bulkiness may not be suitable for smaller projects. Buyers should consider the specific requirements of their applications, including load capacity and flexibility, when opting for shock cord.

Key Industrial Applications of elasticized cord

| Industry/Sector | Specific Application of elasticized cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile and Fashion | Garment construction and elasticized waistbands | Enhances comfort and fit, reduces production costs | Quality of elasticity, durability under stress, and environmental standards. |

| Automotive | Securing components in manufacturing | Improves safety during transport, reduces damage risk | Compliance with automotive safety standards and tensile strength. |

| Sports and Recreation | Equipment manufacturing (e.g., sports bags, tents) | Increases product longevity and user satisfaction | UV resistance, weatherproofing, and customization options. |

| Arts and Crafts | Crafting and jewelry making | Versatile use for various projects, appealing to hobbyists | Material variety, thickness options, and ease of use for consumers. |

| Medical Supplies | Medical device assembly and securement | Ensures safety and reliability in medical applications | Sterility, hypoallergenic properties, and compliance with medical regulations. |

How is Elasticized Cord Used in the Textile and Fashion Industry?

In the textile and fashion industry, elasticized cord is primarily utilized in garment construction, particularly for waistbands and cuffs. It provides a comfortable fit while allowing garments to stretch and retain their shape. For B2B buyers in this sector, sourcing high-quality elasticized cord is essential to ensure durability and longevity, especially in high-wear areas. Buyers should consider the cord’s elasticity, tensile strength, and compliance with sustainable practices, as consumer demand for eco-friendly materials continues to rise.

What Role Does Elasticized Cord Play in Automotive Manufacturing?

In the automotive sector, elasticized cord is used to secure components during manufacturing and transportation. It helps prevent damage to parts by absorbing shock and maintaining stability. For businesses in this industry, sourcing elasticized cord that meets stringent safety standards is crucial. Buyers should evaluate the cord’s tensile strength, flexibility, and resistance to environmental factors, ensuring it performs reliably in various conditions.

How is Elasticized Cord Beneficial for Sports and Recreation Products?

Elasticized cord finds extensive application in the manufacturing of sports equipment, such as bags and tents. Its stretchability enhances product durability and user comfort, making it a popular choice among manufacturers. For international buyers, particularly in regions with diverse climates, sourcing elasticized cord that offers UV resistance and weatherproofing is vital to ensure products withstand harsh conditions. Additionally, customization options can cater to specific market demands, enhancing product appeal.

Why is Elasticized Cord Essential in Arts and Crafts?

In the arts and crafts sector, elasticized cord serves multiple purposes, from jewelry making to various DIY projects. Its versatility allows crafters to create dynamic and adjustable pieces easily. B2B buyers, especially those targeting hobbyist markets, should consider the variety of materials and thicknesses available to cater to different crafting needs. Sourcing from reliable suppliers who provide consistent quality and a range of options can significantly enhance product offerings.

How is Elasticized Cord Utilized in Medical Supplies?

In the medical industry, elasticized cord is crucial for the assembly and securement of medical devices. It ensures that components remain stable and safe during use, which is critical for patient safety. Buyers in this sector must prioritize sourcing elasticized cords that are sterile and hypoallergenic, adhering to strict medical regulations. Understanding the material properties and compliance requirements can help businesses maintain high standards in product quality and safety.

3 Common User Pain Points for ‘elasticized cord’ & Their Solutions

Scenario 1: Sourcing Quality Elasticized Cord for Diverse Applications

The Problem: For B2B buyers sourcing elasticized cord, ensuring consistent quality across different batches can be a significant challenge. Discrepancies in thickness, elasticity, and material composition can lead to production delays and increased costs. Buyers in sectors such as manufacturing, crafting, and textile production often encounter variability that affects the final product’s performance, leading to customer dissatisfaction and potential financial loss. The risk is amplified when sourcing from multiple suppliers, especially in regions with varying manufacturing standards.

The Solution: To mitigate these quality concerns, buyers should establish a robust supplier evaluation process that includes quality control protocols. Begin by requesting samples from potential suppliers to assess their product consistency firsthand. Look for suppliers who provide certifications, such as ISO standards, which ensure adherence to quality benchmarks. Additionally, consider implementing a quality assurance (QA) system that includes regular audits of suppliers and batch testing of elasticized cords upon receipt. This proactive approach not only enhances product reliability but also builds a trustworthy relationship with suppliers, ensuring better negotiation terms and consistent quality over time.

Scenario 2: Selecting the Right Elasticized Cord for Specific Applications

The Problem: Different applications require different types of elasticized cords, yet many buyers struggle to identify which cord is best suited for their specific needs. For example, a buyer in the apparel industry may need a lightweight, high-stretch cord for waistbands, while a manufacturer of outdoor equipment might require a heavy-duty cord that can withstand harsh weather conditions. The wrong choice can lead to product failures, increased returns, and a tarnished reputation.

The Solution: To navigate this complexity, buyers should invest time in understanding the technical specifications of various elasticized cords, including diameter, stretchability, and material properties. Creating a detailed application matrix can help categorize different cords based on their intended use. Furthermore, engaging with suppliers for expert recommendations can provide valuable insights into the most suitable products for each application. Buyers can also consider utilizing a pilot testing phase where they can trial the cord in real-world scenarios before committing to larger orders. This method not only minimizes risk but also ensures that the selected cord meets performance expectations.

Scenario 3: Managing Supply Chain Disruptions Affecting Elasticized Cord Availability

The Problem: Global supply chain disruptions can severely impact the availability of elasticized cords, particularly for businesses that rely on just-in-time inventory practices. Buyers may face unexpected delays in receiving critical materials, leading to halted production lines and missed deadlines. This scenario is especially pertinent in regions with less stable logistics networks, where transportation and customs delays can exacerbate the situation.

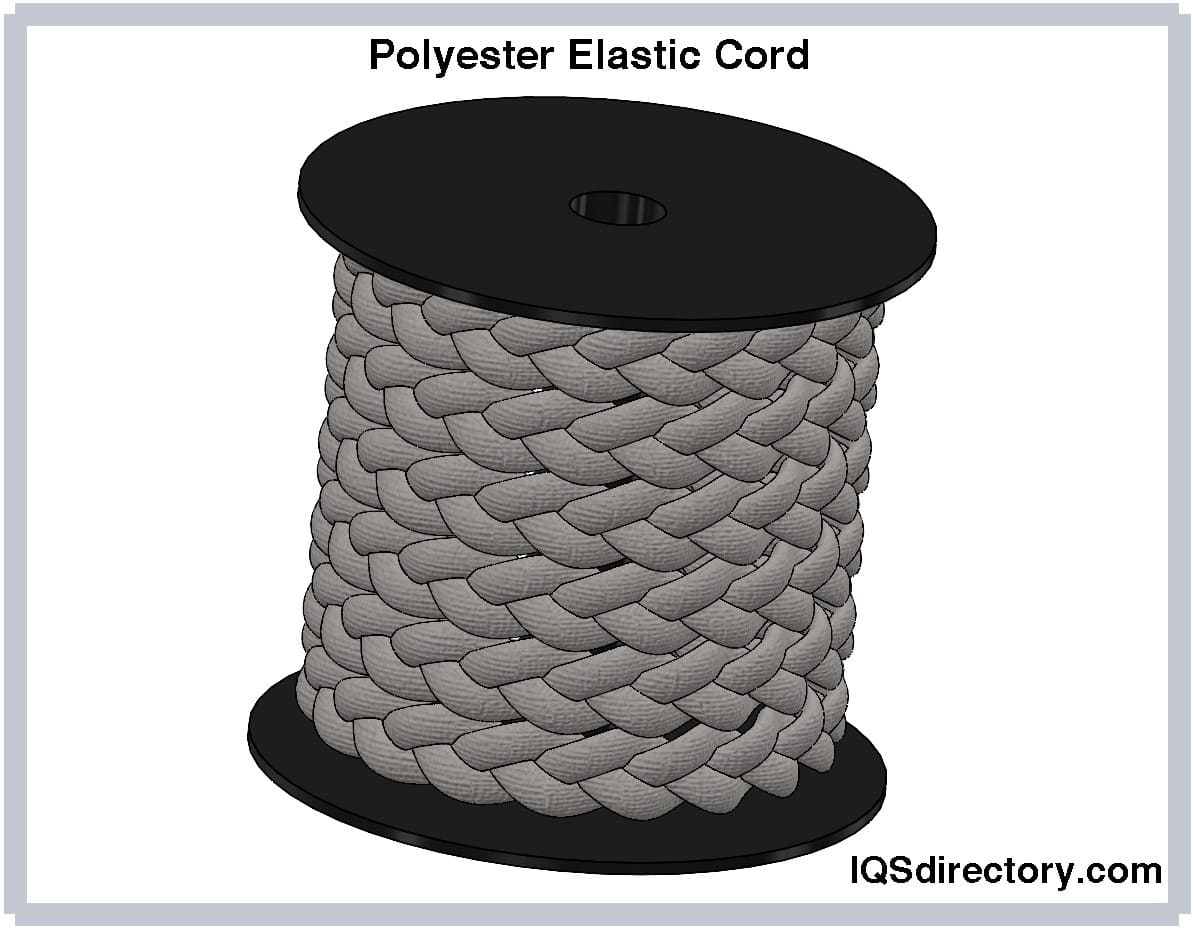

Illustrative image related to elasticized cord

The Solution: To effectively manage these supply chain risks, B2B buyers should develop a diversified sourcing strategy that includes multiple suppliers across different geographic locations. By not relying on a single supplier, companies can minimize the impact of localized disruptions. Additionally, maintaining a buffer stock of essential materials, including various elasticized cords, can provide a safety net during unforeseen shortages. Implementing advanced inventory management software can also assist in tracking stock levels in real-time, allowing for timely reorders. Finally, establishing strong communication channels with suppliers can facilitate quicker responses to potential disruptions, ensuring that buyers are always informed and prepared to adapt their strategies as needed.

Strategic Material Selection Guide for elasticized cord

What Are the Key Materials Used in Elasticized Cord Production?

When selecting elasticized cord for various applications, understanding the properties and implications of different materials is crucial. Here, we analyze four common materials used in the production of elasticized cords: natural rubber, synthetic rubber (like EPDM), nylon, and polyester. Each material offers distinct advantages and disadvantages, impacting their suitability for specific applications.

How Does Natural Rubber Perform in Elasticized Cord Applications?

Natural rubber is renowned for its excellent elasticity and flexibility. It can withstand a wide range of temperatures, typically from -40°C to 80°C, making it suitable for various environments. However, natural rubber is susceptible to degradation from UV exposure and ozone, which can limit its durability in outdoor applications.

Pros:

– High elasticity and tensile strength.

– Cost-effective for bulk production.

Cons:

– Limited UV and ozone resistance.

– May require additional treatments for outdoor use.

For international buyers, particularly in regions with high UV exposure like Africa and the Middle East, it is essential to consider the environmental conditions when opting for natural rubber. Compliance with ASTM standards is often necessary to ensure quality and performance.

What Advantages Does Synthetic Rubber (EPDM) Offer?

Ethylene Propylene Diene Monomer (EPDM) rubber is a synthetic alternative that provides superior weather resistance, making it ideal for outdoor applications. It has a temperature range of -50°C to 150°C, ensuring performance in extreme conditions. EPDM is also resistant to UV light and ozone, which enhances its longevity.

Pros:

– Excellent weather and UV resistance.

– High durability and flexibility.

Cons:

– Higher manufacturing costs compared to natural rubber.

– May not be as elastic as natural rubber.

For B2B buyers in Europe and South America, where compliance with environmental regulations is stringent, EPDM’s resistance to degradation is a significant advantage. It meets various international standards, including DIN and JIS, making it a reliable choice for diverse applications.

How Does Nylon Contribute to Elasticized Cord Performance?

Nylon is known for its strength and abrasion resistance. It offers good elasticity and is less prone to stretching out over time compared to rubber materials. Nylon cords can operate effectively in varying temperatures, typically between -40°C to 120°C.

Illustrative image related to elasticized cord

Pros:

– High tensile strength and durability.

– Good resistance to abrasion and chemicals.

Cons:

– Absorbs moisture, which can affect performance.

– Generally more expensive than rubber options.

For international buyers, particularly in industrial applications, nylon’s strength makes it suitable for heavy-duty uses. However, moisture absorption can be a concern in humid climates, requiring buyers to evaluate the specific environmental conditions of their applications.

What Role Does Polyester Play in Elasticized Cord Applications?

Polyester is another popular material for elasticized cords, known for its excellent dimensional stability and resistance to stretching. It performs well in temperatures ranging from -40°C to 150°C and offers good UV resistance, making it suitable for outdoor applications.

Pros:

– High resistance to UV light and chemicals.

– Maintains shape and elasticity over time.

Cons:

– Can be less flexible than rubber options.

– Higher cost compared to natural rubber.

For B2B buyers in Germany and other European countries, polyester’s compliance with various standards makes it a trustworthy option. Its durability and resistance to environmental factors align well with the demands of outdoor and industrial applications.

Summary of Material Selection for Elasticized Cord

| Material | Typical Use Case for elasticized cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Crafting, light-duty applications | High elasticity and cost-effective | Limited UV and ozone resistance | Low |

| Synthetic Rubber (EPDM) | Outdoor applications, automotive | Excellent weather resistance | Higher manufacturing costs | Medium |

| Nylon | Heavy-duty applications, industrial | High tensile strength | Absorbs moisture | High |

| Polyester | Outdoor gear, industrial uses | UV resistance and dimensional stability | Less flexibility than rubber | Medium |

This guide provides a comprehensive overview of the materials used in elasticized cord production, offering valuable insights for B2B buyers in diverse global markets. Understanding these materials will enable informed decisions that align with specific application requirements and environmental conditions.

Illustrative image related to elasticized cord

In-depth Look: Manufacturing Processes and Quality Assurance for elasticized cord

What are the Main Stages in the Manufacturing Process of Elasticized Cord?

The manufacturing process of elasticized cord involves several crucial stages, each designed to ensure that the final product meets quality and performance standards. Understanding these stages can help B2B buyers evaluate potential suppliers more effectively.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Elasticized cords are typically made from a blend of natural and synthetic elastomers, such as rubber, polyester, or nylon. The choice of material significantly influences the cord’s elasticity, durability, and application suitability.

During this stage, manufacturers source high-quality materials from reliable suppliers. They may conduct preliminary quality checks to ensure that the elastomers meet specific technical specifications. This is crucial, as the elasticity and strength of the cord depend on the quality of the raw materials.

2. Forming

Once the materials are prepared, the next stage is forming. This involves mixing the raw materials and processing them into the desired form. The blending process may include adding additives to enhance properties such as UV resistance, color, or abrasion resistance.

Manufacturers typically use extrusion or spinning techniques to shape the cord. In extrusion, the mixed material is forced through a die to create long strands of elastic cord. Alternatively, spinning involves twisting fibers together to form a strong, flexible cord.

Illustrative image related to elasticized cord

3. Assembly

After forming, the elastic cord may undergo additional assembly processes, especially if it is being integrated into finished products like bracelets or other craft items. This stage may involve cutting the cord to specified lengths, tying knots, or attaching clasps and other components.

In this phase, the focus is on ensuring that the assembly is done with precision to maintain the integrity and elasticity of the cord. Any defects in assembly can lead to product failure, making quality checks essential at this stage.

4. Finishing

The final stage of manufacturing is finishing, which includes processes such as coating, coloring, or additional treatments to enhance performance. For instance, some elastic cords are coated to improve water resistance or to add color.

Finishing processes also involve quality checks to ensure that the cords meet the specified dimensions and performance criteria. This stage is vital for ensuring that the product is ready for packaging and shipment.

How is Quality Assurance Implemented in the Production of Elasticized Cord?

Quality assurance (QA) is a critical component of the manufacturing process for elasticized cords. It ensures that the final products meet both international and industry-specific standards.

International Standards for Quality Assurance

Manufacturers often adhere to international standards such as ISO 9001, which provides a framework for quality management systems. Compliance with ISO 9001 ensures that manufacturers consistently produce products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the intended use of the elastic cord. For instance, cords used in automotive or industrial applications may require adherence to specific safety and performance standards.

What are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor and ensure product quality. Key checkpoints include:

Illustrative image related to elasticized cord

-

Incoming Quality Control (IQC): This is the first line of defense against quality issues. Raw materials are inspected upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early. This includes monitoring the mixing, forming, and assembly stages.

-

Final Quality Control (FQC): Before packaging, finished products undergo rigorous testing to verify that they meet performance specifications. This may include tensile strength tests, elasticity assessments, and dimensional checks.

What Testing Methods are Commonly Used for Elasticized Cord?

Various testing methods are employed to evaluate the quality and performance of elasticized cords. These tests may include:

-

Tensile Strength Testing: Measures the maximum load the cord can withstand before breaking, which is crucial for applications requiring high durability.

-

Elasticity Testing: Assesses how much the cord can stretch and return to its original length, determining its suitability for various applications.

-

UV Resistance Testing: Evaluates how well the cord can withstand exposure to sunlight, which is particularly important for outdoor use.

-

Abrasion Resistance Testing: Determines the cord’s durability against wear and tear, which is vital for products subjected to friction.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are actionable strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing process, quality control systems, and compliance with international standards firsthand.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their testing methods, results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Are the QC Considerations for International Buyers?

For international buyers, understanding the nuances of quality control in different regions is essential. Buyers from Africa, South America, the Middle East, and Europe should be aware of the following:

-

Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Familiarize yourself with local standards to ensure compliance.

-

Cultural Differences: Quality expectations may differ based on regional practices. Open communication with suppliers can help clarify standards and expectations.

-

Logistics and Supply Chain Issues: Consider how transportation and storage conditions may affect product quality. Ensure that suppliers have robust logistics management practices in place.

Conclusion

In summary, the manufacturing processes and quality assurance measures for elasticized cord are critical factors that B2B buyers must understand. By focusing on the manufacturing stages, quality control checkpoints, and testing methods, buyers can make informed decisions when selecting suppliers. Additionally, implementing strategies to verify supplier quality control practices will help mitigate risks and ensure that the products meet the required standards for their specific applications.

Illustrative image related to elasticized cord

Practical Sourcing Guide: A Step-by-Step Checklist for ‘elasticized cord’

Introduction

Sourcing high-quality elasticized cord is essential for businesses involved in crafting, manufacturing, and various applications that require flexible materials. This guide provides a systematic checklist to help B2B buyers navigate the procurement process effectively, ensuring they secure reliable suppliers and suitable products for their needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clarify your requirements for elasticized cord. Consider factors such as thickness, elasticity, material composition, and color. Knowing these specifications will help you communicate effectively with potential suppliers and ensure you receive products that meet your operational needs.

- Common thicknesses range from 0.5mm to 1.0mm; determine what best suits your application.

- Material options can include polyester, rubber, or nylon; each has unique properties impacting durability and stretch.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in elasticized cord. Utilize online platforms, trade shows, and industry networks to compile a list of potential vendors. A well-researched supplier base can increase your chances of finding a reliable partner.

- Look for suppliers with positive customer reviews and a solid reputation in the industry.

- Consider suppliers who offer various product lines to ensure they can meet future needs.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that the suppliers you are considering comply with relevant industry standards and certifications. This step is crucial for ensuring product quality and safety, especially if you are sourcing for industries with stringent regulations.

Illustrative image related to elasticized cord

- Check for certifications such as ISO 9001 or compliance with local standards in your region.

- Ask for documentation that verifies their manufacturing processes and material safety.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of the elasticized cord. Testing samples allows you to assess the quality, elasticity, and durability of the product firsthand.

- Evaluate the stretchability and return properties to ensure they meet your application needs.

- Inspect the color fastness and resistance to wear, especially if the cord will be used in consumer products.

Step 5: Negotiate Terms and Pricing

Effective negotiation can lead to favorable terms that benefit your budget and operational needs. Discuss pricing, minimum order quantities, lead times, and payment terms with your selected suppliers.

- Be clear about bulk purchase discounts if you plan to order large quantities.

- Understand the shipping costs and timelines to avoid unexpected expenses or delays.

Step 6: Establish a Trial Order

Before committing to a long-term contract, place a trial order to evaluate the supplier’s performance in real-world conditions. This step helps to assess not only the product quality but also the supplier’s reliability in fulfilling orders.

- Monitor the delivery timelines and customer service responsiveness during this phase.

- Use this opportunity to gather feedback from your team on the product’s performance.

Step 7: Review and Document Performance

After receiving your trial order, review the entire sourcing process and document your findings. Evaluate the quality of the elasticized cord, supplier communication, and overall satisfaction.

Illustrative image related to elasticized cord

- Keep records of supplier performance metrics for future reference.

- Make a decision on whether to continue sourcing from this supplier or explore other options based on your assessment.

Following this checklist will empower B2B buyers to make informed decisions while sourcing elasticized cord, ensuring quality products and reliable suppliers that meet their business needs.

Comprehensive Cost and Pricing Analysis for elasticized cord Sourcing

What Are the Key Cost Components in Elasticized Cord Production?

Understanding the cost structure of elasticized cord is crucial for B2B buyers aiming to make informed sourcing decisions. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts pricing. Elastic cords are typically made from rubber, latex, or synthetic fibers, each carrying different costs. High-quality materials can lead to higher durability and performance but will increase the initial price.

-

Labor: Labor costs vary by region and can influence the overall cost of production. In countries with higher wage standards, such as Germany, labor costs may be a more substantial component compared to regions like Nigeria or Brazil.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, maintenance, and administrative costs. Efficient manufacturing processes can help reduce these overheads, leading to competitive pricing.

-

Tooling: Initial setup costs for production machinery can be significant, especially if custom tooling is required for specific cord specifications. This cost is often amortized over larger production runs.

-

Quality Control (QC): Ensuring product quality through rigorous testing can add to the cost. However, investing in quality control can prevent costly defects and returns, thus providing long-term savings.

-

Logistics: Shipping and handling costs play a vital role, particularly for international transactions. Factors such as freight costs, customs duties, and delivery timelines should be considered in the total cost.

-

Margin: Suppliers will factor in their desired profit margins, which can vary widely based on market conditions and competition.

How Do Price Influencers Affect Elasticized Cord Pricing?

Several factors can influence the pricing of elasticized cords, and understanding these can help buyers negotiate better deals:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders. Buyers should assess their needs carefully to leverage better pricing based on volume commitments.

-

Specifications and Customization: Custom specifications, such as diameter, elasticity, and color, can lead to increased costs. Standardized products usually come at a lower price point.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or compliance with safety standards) can increase costs but may also enhance product value and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international buyers, as they define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. This knowledge can help buyers avoid unexpected charges.

What Are the Best Tips for Negotiating Prices on Elasticized Cord?

B2B buyers can adopt several strategies to negotiate better pricing on elasticized cord:

-

Conduct Comprehensive Market Research: Understanding market prices and trends allows buyers to approach negotiations with solid data. Knowing competitor pricing can provide leverage in discussions.

-

Focus on Total Cost of Ownership (TCO): Consider not only the purchase price but also factors like durability, maintenance costs, and potential savings over time. Presenting a case for TCO can justify a higher upfront price for better quality.

-

Build Long-term Relationships: Establishing a good rapport with suppliers can lead to more favorable terms over time. Suppliers may be more willing to negotiate prices for trusted clients.

-

Explore Multiple Suppliers: Diversifying suppliers can create competitive pressure, which often leads to better pricing and terms.

-

Be Open to Flexible Terms: Sometimes, suppliers may be willing to adjust payment terms or offer additional services, such as free shipping, instead of lowering prices.

Conclusion

Navigating the cost and pricing landscape of elasticized cord requires a keen understanding of various cost components and influencing factors. By leveraging this knowledge, international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, can make well-informed sourcing decisions that align with their business goals.

Disclaimer: Prices and terms discussed are indicative and may vary based on market conditions and supplier negotiations.

Illustrative image related to elasticized cord

Alternatives Analysis: Comparing elasticized cord With Other Solutions

Exploring Viable Alternatives to Elasticized Cord

When considering solutions for applications requiring flexibility and stretch, it is essential to evaluate various options in the market. While elasticized cord is a popular choice for crafting, strapping, and various industrial applications, other alternatives may offer unique advantages depending on specific use cases. This analysis compares elasticized cord with two viable alternatives: braided rope and bungee cord.

| Comparison Aspect | Elasticized Cord | Braided Rope | Bungee Cord |

|---|---|---|---|

| Performance | Good elasticity and flexibility; ideal for light-duty applications | Strong tensile strength; less flexible but durable | Excellent stretch and recoil; ideal for dynamic loads |

| Cost | Moderate; varies by diameter and length | Generally lower; bulk purchasing reduces costs | Higher; typically used for specialized applications |

| Ease of Implementation | Easy to use; requires minimal tools for crafting | Requires knots or additional tools for securing | Simple to use; often designed with hooks for quick attachment |

| Maintenance | Low maintenance; can degrade with UV exposure | Moderate; prone to fraying but can be repaired | Low; but may need periodic inspection for wear and tear |

| Best Use Case | Crafting, light-duty strapping, and jewelry making | Heavy-duty applications, towing, and marine use | Outdoor activities, securing loads, and elastic tensioning |

What Are the Pros and Cons of Braided Rope?

Braided rope is a strong alternative that excels in applications requiring durability and tensile strength. It is commonly used in outdoor settings, marine environments, and heavy-duty tasks. The main advantage of braided rope is its resistance to fraying and ability to handle significant loads. However, it lacks the flexibility of elasticized cord, making it less suitable for applications requiring stretch or recoil. Additionally, users need to be familiar with knot-tying techniques, which can complicate its implementation.

How Does Bungee Cord Compare to Elasticized Cord?

Bungee cord is designed for applications that require significant elasticity and energy absorption. Its unique construction allows it to stretch significantly and return to its original length, making it ideal for securing loads in transit or during outdoor activities like camping and hiking. The primary advantage of bungee cord is its dynamic performance; however, it can be more expensive than elasticized cord and may not be suitable for static applications. Furthermore, users should regularly inspect bungee cords for wear, especially if used in high-stress situations.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between elasticized cord, braided rope, and bungee cord, B2B buyers should assess their specific requirements, including performance needs, budget constraints, and intended applications. Elasticized cord is ideal for craft projects and light-duty tasks, while braided rope is better suited for heavy-duty applications requiring strength. Bungee cord stands out for dynamic applications where stretch and recoil are critical. By carefully considering these factors, buyers can make informed decisions that align with their operational needs and budgetary constraints.

Essential Technical Properties and Trade Terminology for elasticized cord

Understanding the essential technical properties and trade terminology for elasticized cord is crucial for B2B buyers who aim to make informed purchasing decisions. This section outlines key specifications and terminology that can significantly impact procurement processes.

Illustrative image related to elasticized cord

What Are the Key Technical Properties of Elasticized Cord?

-

Material Composition

– Elastic cords are primarily made from rubber, polyester, or a blend of synthetic fibers. The choice of material affects the cord’s elasticity, durability, and resistance to environmental factors. For B2B buyers, selecting the right material ensures the cord meets the specific application requirements, whether for crafting, industrial use, or packaging. -

Diameter

– The diameter of elastic cord typically ranges from 0.5 mm to 1.5 mm. A smaller diameter is suitable for lightweight applications like jewelry making, while larger diameters provide greater strength for heavy-duty use. Understanding diameter specifications is vital for buyers to ensure compatibility with end-use products. -

Tensile Strength

– This property measures the maximum load the cord can withstand before breaking. It is usually expressed in pounds or kilograms. High tensile strength is essential for applications requiring significant stretch and load-bearing capacity, making it a critical factor in procurement decisions. -

Elasticity and Recovery

– Elasticity refers to the cord’s ability to stretch and return to its original shape. This property is typically tested under various loads and is crucial for applications that demand consistent performance over time. B2B buyers must assess elasticity to avoid product failure in dynamic environments. -

Color and Finish

– Elastic cords come in various colors and finishes, including clear, opaque, and metallic. The aesthetic aspect may be important for craft applications, while specific colors might be required for branding purposes in industrial uses. Buyers should consider color options to align with product design requirements. -

UV Resistance

– For outdoor applications, UV resistance is a key property that prevents degradation from sun exposure. This is particularly important for buyers in regions with high sunlight intensity. Cords that lack UV resistance may lead to premature failure, impacting product longevity.

What Are Common Trade Terms Used in the Elasticized Cord Industry?

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products that are then sold under another company’s brand. Understanding OEM relationships is essential for buyers looking for custom solutions or specific product branding. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units a supplier is willing to sell. This is a crucial consideration for B2B buyers as it affects inventory management and cost-effectiveness. Knowing the MOQ helps in planning purchase orders that align with business needs. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and terms from suppliers. This is particularly useful when comparing multiple suppliers. B2B buyers should prepare detailed RFQs to ensure they receive comprehensive and competitive proposals. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariff responsibilities. Familiarity with Incoterms helps B2B buyers minimize risks and misunderstandings in cross-border transactions. -

Lead Time

– This term refers to the time taken from placing an order to receiving the goods. Understanding lead times is vital for inventory management and ensuring timely product launches or project completions. -

Customs Duties and Tariffs

– These are taxes imposed on goods when they are transported across international borders. B2B buyers should be aware of applicable duties and tariffs to accurately calculate total landed costs and avoid unexpected expenses.

By grasping these technical properties and industry terms, B2B buyers can navigate the complexities of sourcing elasticized cord more effectively, ensuring that their procurement strategies align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the elasticized cord Sector

What are the Current Market Dynamics and Key Trends Affecting the Elasticized Cord Sector?

The elasticized cord sector is experiencing significant growth driven by diverse applications across various industries, including crafting, fashion, and industrial sectors. Increasing demand for versatile and durable materials is propelling the market, particularly in regions such as Africa, South America, the Middle East, and Europe. In Africa and South America, the crafting and DIY markets are expanding rapidly, fueled by a growing middle class and increased access to online shopping platforms. Meanwhile, in Europe, countries like Germany are witnessing a surge in sustainability-focused products, influencing buyer preferences toward eco-friendly elastic cords.

Emerging B2B technologies, such as digital sourcing platforms and supply chain management software, are reshaping procurement strategies. International buyers are leveraging these tools to identify reliable suppliers, compare prices, and streamline their purchasing processes. Additionally, the rise of customization in manufacturing allows buyers to source elasticized cords tailored to their specific needs, enhancing product differentiation.

Furthermore, the impact of global supply chain disruptions, particularly due to the COVID-19 pandemic, has led to an increased focus on local sourcing. Buyers are increasingly prioritizing suppliers with regional capabilities to mitigate risks associated with long lead times and logistical challenges. This shift is particularly evident in the Middle East, where localized production is becoming a strategic advantage.

How is Sustainability and Ethical Sourcing Influencing the Elasticized Cord Market?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the elasticized cord sector. The environmental impact of manufacturing processes, particularly in the use of synthetic materials, has prompted buyers to seek out eco-friendly alternatives. This includes sourcing elastic cords made from recycled materials or biodegradable options that minimize ecological footprints.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices to ensure compliance with labor laws and environmental regulations. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® Standard 100 are gaining traction as indicators of responsible sourcing. Buyers in Europe, for instance, are more inclined to partner with manufacturers who demonstrate a commitment to sustainability, as this aligns with the broader European Union Green Deal objectives.

In addition, businesses are recognizing that a commitment to sustainability not only enhances brand reputation but also attracts environmentally conscious consumers. As such, integrating sustainability into procurement strategies is becoming a competitive differentiator, especially in markets like Germany and Nigeria, where consumer preferences are shifting towards sustainable products.

What is the Historical Context of Elasticized Cord Development in B2B?

The evolution of elasticized cord can be traced back to the early 20th century, initially developed for the military and industrial applications. Its elasticity made it ideal for use in parachutes and other equipment requiring flexibility and strength. Over the decades, the cord found its way into various consumer products, including clothing, accessories, and crafting materials.

The rise of DIY culture in the late 20th century further propelled the popularity of elasticized cords, as they became staples in crafting projects, from jewelry making to home decor. This shift not only expanded the market but also diversified the types of elastic cords available, catering to different consumer needs and preferences.

In recent years, the focus has shifted towards sustainability, with manufacturers exploring environmentally friendly materials and ethical production processes. This historical trajectory highlights how the elasticized cord sector has adapted to changing consumer demands and market dynamics, paving the way for future innovations and trends that prioritize sustainability and customization.

Frequently Asked Questions (FAQs) for B2B Buyers of elasticized cord

-

How do I choose the right elasticized cord for my project?

Choosing the right elasticized cord depends on your specific application. For light-duty crafting, a thinner cord (0.5mm) may suffice, while heavier applications like industrial use may require thicker options (1.0mm or more). Consider factors such as elasticity, material type (natural vs. synthetic), and durability against environmental conditions. Request samples from suppliers to evaluate the cord’s performance before making a bulk order. -

What is the best elasticized cord for jewelry making?

For jewelry making, particularly stretch bracelets and necklaces, a clear elastic cord with a diameter of 0.5mm to 0.8mm is typically recommended. This thickness provides sufficient strength while remaining discreet. Look for cords that are UV-resistant and durable to prevent wear over time. Suppliers often offer specialized cords designed specifically for jewelry, ensuring a professional finish. -

What are the minimum order quantities (MOQs) for elasticized cord?

Minimum order quantities for elasticized cord can vary significantly by supplier and region. Typically, MOQs range from 100 meters to several thousand meters, depending on the cord’s specifications and the supplier’s production capabilities. It’s advisable to inquire directly with potential suppliers to understand their MOQs, as some may offer flexibility for first-time buyers or smaller businesses. -

How can I ensure the quality of the elasticized cord I source?

To ensure quality, request certifications and product samples from suppliers. Look for third-party testing reports that confirm the cord meets industry standards for elasticity and durability. It’s also beneficial to establish a quality assurance (QA) process, including regular audits and inspections during production and before shipment. Building a long-term relationship with a reputable supplier can enhance quality consistency. -

What payment terms should I expect when ordering elasticized cord internationally?

Payment terms can vary widely among suppliers, but common practices include advance payment, letters of credit, or payment upon delivery. For international transactions, it’s crucial to clarify terms upfront to avoid disputes. Consider using secure payment methods such as PayPal or escrow services for large transactions to protect your investment. Negotiate terms that align with your cash flow and risk tolerance. -

How do I vet suppliers of elasticized cord?

When vetting suppliers, consider their experience, reputation, and production capabilities. Look for customer reviews and references, and check their compliance with international quality standards. Additionally, visiting the supplier’s facility or requesting a virtual tour can provide insights into their operational practices. Establishing a reliable communication channel is essential for fostering a trustworthy relationship. -

What logistics options are available for shipping elasticized cord?

Logistics options for shipping elasticized cord include air freight for faster delivery and sea freight for cost-effective shipping of larger quantities. Consider your delivery timeline, budget, and destination when choosing a shipping method. Collaborating with a logistics partner experienced in international trade can streamline the process, ensuring compliance with customs regulations and timely delivery. -

Can I customize the specifications of the elasticized cord?

Yes, many suppliers offer customization options for elasticized cord, including diameter, color, length, and material composition. Custom orders may require a higher MOQ and longer lead times, so it’s essential to discuss your specific requirements early in the negotiation process. Providing detailed specifications and examples can help suppliers meet your expectations effectively.

Top 7 Elasticized Cord Manufacturers & Suppliers List

1. Paracord Planet – High Quality Elastic Cords

Domain: paracordplanet.com

Registered: 2011 (14 years)

Introduction: High Quality Elastic Cords in various sizes. Free Standard Shipping with Orders of $8.99+ (US ONLY). Available sizes include 1/32″ Elastic Cord, 1/16″ Elastic Cord, and more. Prices range from $3.99 to $72.99 with free shipping options. Multiple color options available for each size.

2. Beadalon – Elasticity Stretch Cord 0.8 mm

Domain: beadalon.com

Registered: 1999 (26 years)

Introduction: This company, Beadalon – Elasticity Stretch Cord 0.8 mm, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. University Products – Elastic Cord

Domain: universityproducts.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Elastic Cord”, “sku”: “2304”, “length”: “75 feet (22.86 meters)”, “color”: “gray”, “price”: “$92.30”, “related_products”: [{“name”: “Freestanding Barriers”, “starting_price”: “$170.45”}, {“name”: “Barrier Wall Terminators”, “starting_price”: “$49.70”}] }

4. Etsy – Stretch Magic and Alternatives

Domain: community.etsy.com

Registered: 2004 (21 years)

Introduction: 1. Stretch Magic: Recommended for its strength and durability; users report never having it break. 2. Opelon Stretch Cord: Mentioned as an alternative, but some users noted it can separate into fibrous strands. 3. Strong and Stretchy Crystal String: Inquired about by a user, specific details not provided. 4. Zap a Gap: Glue recommended for securing knots, noted for its longevity compared to super …

5. RightRope – Shock Cord

Domain: rightrope.com

Registered: 2018 (7 years)

Introduction: {‘name’: ‘Shock Cord | Stretch Cord’, ‘material’: ‘Natural rubber with diamond braided polyester cover’, ‘elasticity’: ‘120% +/- 5%’, ‘features’: [‘UV resistant’, ‘Abrasion resistant’, ‘Marine grade’], ‘diameters’: [‘1/8 in.’, ‘3/16 in.’, ‘1/4 in.’, ‘5/16 in.’, ‘3/8 in.’, ‘1/2 in.’], ‘lengths’: [‘100 ft.’, ‘150 ft.’, ‘200 ft.’, ‘300 ft.’, ‘500 ft.’, ‘1000 ft.’, ‘Custom Length’], ‘colors’: [‘White …

6. Rope and Cord – Bungee Cords

Domain: ropeandcord.com

Registered: 2017 (8 years)

Introduction: Bungee Cord is designed for flexibility, stretch, and versatility, making it suitable for various projects such as tying down tarps, tents, or objects in a truck bed. Ideal for camping, fishing, and hiking, it can also be used at home in garages or shops. The nylon jacket provides resistance against rot and UV fade, ensuring durability. Available sizes include: 1/8″ (20 inner rubber strands), 3/16…

7. Powercord – Elastic Cord

Domain: firemountaingems.com

Registered: 1998 (27 years)

Introduction: Elastic Cord from Powercord and Beadalon, available in various sizes and colors. Key products include: 1. Powercord® elastic, clear, 0.8mm, 8.5 pound test, sold per 25-meter spool, price ranges from $6.04 to $7.55 depending on quantity. 2. Powercord® elastic, clear, 0.5mm, 4-pound test, sold per 25-meter spool, price ranges from $4.98 to $6.23. 3. Powercord® elastic, clear, 0.7mm, 7-pound test, so…

Strategic Sourcing Conclusion and Outlook for elasticized cord

In conclusion, effective strategic sourcing of elasticized cord is paramount for businesses aiming to optimize their supply chains and enhance product offerings. By focusing on reliable suppliers and understanding regional market dynamics, international B2B buyers can ensure access to high-quality elastic cords that meet diverse applications—from crafting and apparel to industrial uses.

The versatility of elasticized cord, combined with its growing demand across various sectors, presents significant opportunities for businesses in Africa, South America, the Middle East, and Europe. Buyers should prioritize long-term partnerships with manufacturers that offer competitive pricing, consistent quality, and timely delivery. This approach not only mitigates risks but also fosters innovation and responsiveness to market needs.

As the global market continues to evolve, staying ahead requires proactive sourcing strategies. We encourage buyers to explore new suppliers, leverage technology for sourcing efficiencies, and remain adaptable to shifts in consumer preferences. By doing so, businesses can position themselves to thrive in the elasticized cord market and capitalize on emerging trends.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to elasticized cord

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.