Top 5 Copper Sheet Metal 4X8 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for copper sheet metal 4×8

In the dynamic global market, sourcing copper sheet metal 4×8 presents a unique set of challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the task of securing high-quality copper sheets at competitive prices can be daunting. Factors such as fluctuating market prices, varying supplier reliability, and the need for specific material grades complicate the procurement process. This guide is designed to empower you with the knowledge necessary to navigate these complexities effectively.

We will explore the diverse types of copper sheet metal available, including their specifications and applications across industries such as construction, electrical, and decorative arts. Additionally, we will provide insights on how to vet suppliers to ensure you are partnering with reputable sources, thus minimizing risks associated with quality and delivery. Understanding the cost structures and pricing trends will also be covered, enabling you to make informed purchasing decisions that align with your budget and project requirements.

By the end of this guide, you will be equipped with actionable strategies and insights that enhance your sourcing capabilities, ultimately leading to more successful procurement outcomes. Whether you’re looking to fulfill a large-scale construction project in Saudi Arabia or seeking reliable material for artisanal work in Nigeria, this comprehensive resource will serve as your go-to reference for all things related to copper sheet metal 4×8.

Understanding copper sheet metal 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Soft Copper Sheet | Highly malleable, excellent thermal/electrical conductivity | Electrical wiring, decorative elements | Pros: Easy to work with, great conductivity. Cons: Less strength compared to harder variants. |

| Half-Hard Copper Sheet | Balanced malleability and strength, retains some ductility | Roofing, gutters, and trim | Pros: Good for structural applications. Cons: Slightly less malleable than soft copper. |

| Hard Copper Sheet | High strength, less malleable, ideal for demanding applications | Industrial applications, heavy-duty uses | Pros: Strong and durable. Cons: More challenging to work with and shape. |

| Copper Alloy Sheet | Mixed with other metals for enhanced properties | Specialty applications, marine uses | Pros: Corrosion-resistant, tailored properties. Cons: Potentially higher costs and limited availability. |

| Decorative Copper Sheet | Often pre-finished, designed for aesthetic applications | Architectural features, art installations | Pros: Visually appealing, ready for installation. Cons: May have a higher price point due to finish. |

What are the Characteristics of Soft Copper Sheet?

Soft copper sheets are characterized by their high malleability and excellent electrical and thermal conductivity. This type is ideal for applications where flexibility and ease of installation are paramount, such as in electrical wiring and decorative elements. When purchasing, buyers should consider the thickness and the potential for patina development, which can impact aesthetics over time.

How Does Half-Hard Copper Sheet Compare to Other Types?

Half-hard copper sheets strike a balance between malleability and strength, making them suitable for roofing, gutters, and trim applications. They provide adequate durability while still being relatively easy to work with. B2B buyers should evaluate the specific project requirements, as this type is often preferred for structural applications where some flexibility is needed without sacrificing strength.

What Makes Hard Copper Sheet Suitable for Industrial Applications?

Hard copper sheets are known for their high strength and reduced malleability, making them a preferred choice for demanding industrial applications. These sheets are often used in heavy-duty environments where durability is critical. Buyers should be aware that while they provide excellent performance, they may require specialized tools for shaping and installation.

Why Choose Copper Alloy Sheets for Specialty Applications?

Copper alloy sheets are typically mixed with other metals to enhance specific properties, such as corrosion resistance or strength. These sheets are used in specialized applications, including marine environments where exposure to moisture is a concern. When sourcing these materials, B2B buyers should consider the specific alloy composition and its suitability for their intended use.

What are the Benefits of Decorative Copper Sheets?

Decorative copper sheets are often pre-finished and designed for aesthetic applications, making them ideal for architectural features and art installations. They offer the advantage of being visually appealing and ready for installation, which can save time on project execution. However, buyers should be mindful of the potential higher costs associated with decorative finishes and ensure that the product meets their design specifications.

Key Industrial Applications of copper sheet metal 4×8

| Industry/Sector | Specific Application of copper sheet metal 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Roofing | Roofing systems, gutters, and flashing | High durability and corrosion resistance | Ensure compliance with local building codes and standards |

| Electrical & Electronics | Electrical wiring, connectors, and circuit boards | Excellent electrical conductivity and reliability | Verify material grades and thickness for specific electrical needs |

| HVAC & Refrigeration | Heat exchangers and ductwork | Superior thermal conductivity | Consider the thermal requirements and size specifications |

| Art & Design | Decorative elements and sculptures | Aesthetic appeal and malleability | Look for custom fabrication capabilities and design support |

| Automotive & Transportation | Components for electric vehicles and wiring harnesses | Lightweight and efficient conductivity | Assess the compatibility with existing materials and performance criteria |

How is Copper Sheet Metal 4×8 Used in Construction & Roofing?

Copper sheet metal 4×8 is extensively utilized in roofing systems, gutters, and flashing due to its exceptional durability and resistance to corrosion. This material can withstand harsh weather conditions, making it ideal for long-term applications. For international buyers, particularly in regions like Saudi Arabia or Nigeria, sourcing copper that meets local building codes is crucial. Additionally, understanding the specific thickness required for different roofing applications is vital to ensure optimal performance and longevity.

What Role Does Copper Sheet Metal Play in Electrical & Electronics Industries?

In the electrical and electronics sectors, copper sheet metal 4×8 is essential for manufacturing wiring, connectors, and circuit boards. Its outstanding electrical conductivity ensures reliable performance in various applications, from household wiring to complex electronic devices. B2B buyers should prioritize sourcing high-grade copper sheets that meet international standards for conductivity and thickness, ensuring they can support their specific electrical applications efficiently.

How is Copper Sheet Metal Beneficial in HVAC & Refrigeration?

Copper sheet metal 4×8 is a preferred choice for heat exchangers and ductwork in HVAC systems due to its superior thermal conductivity. This characteristic allows for efficient heat transfer, which is critical in maintaining optimal system performance. Buyers in Africa and the Middle East should consider sourcing copper sheets that are specifically designed for HVAC applications, taking into account local climate conditions and the necessary specifications for durability and efficiency.

In What Ways is Copper Sheet Metal Used in Art & Design?

In the art and design sectors, copper sheet metal 4×8 is often used for decorative elements, sculptures, and architectural features. Its aesthetic appeal, combined with its malleability, allows artists and designers to create intricate designs while maintaining structural integrity. For businesses in Europe looking to source copper for artistic applications, it is important to find suppliers who can provide custom fabrication services and guidance on design possibilities.

How is Copper Sheet Metal Applied in Automotive & Transportation?

Copper sheet metal 4×8 is increasingly being used in the automotive and transportation industries, particularly for electric vehicles and wiring harnesses. Its lightweight nature and excellent conductivity make it an ideal choice for enhancing vehicle efficiency. International buyers should ensure that the copper sourced meets automotive industry standards for performance and compatibility with other materials, which is critical for the success of their applications.

3 Common User Pain Points for ‘copper sheet metal 4×8’ & Their Solutions

Scenario 1: Sourcing High-Quality Copper Sheet Metal

The Problem: B2B buyers often struggle with sourcing high-quality 4×8 copper sheet metal that meets specific project requirements. Many suppliers offer products with aesthetic imperfections such as wrinkles, dents, or discoloration, which can compromise the integrity and appearance of the final product. This is especially challenging for buyers in industries like construction and manufacturing, where quality and visual appeal are crucial for client satisfaction. Additionally, fluctuating prices and limited stock can create uncertainty, making it difficult for buyers to secure the materials they need at a consistent quality and price.

The Solution: To ensure you source high-quality copper sheet metal, start by establishing relationships with reputable suppliers who specialize in copper products. Look for suppliers that provide detailed product specifications, including thickness, alloy type, and finish. Consider ordering samples before placing a larger order to evaluate the quality firsthand. Additionally, leverage technology by using online platforms that allow for real-time inventory checks and price comparisons. This will help you avoid overstock situations and ensure you’re getting the best value for your investment. By thoroughly vetting suppliers and utilizing advanced sourcing tools, you can secure the high-quality materials necessary for your projects.

Scenario 2: Managing Cost Fluctuations in Copper Sheet Metal Purchases

The Problem: International buyers, particularly in regions like Africa and South America, often face significant challenges due to the volatility of copper prices. This unpredictability can lead to budget overruns, impacting project timelines and profitability. Suppliers may also require price confirmations before proceeding with orders, which can delay procurement and affect project delivery schedules. Buyers need a strategy to manage these financial risks effectively.

The Solution: To mitigate the impact of price fluctuations, B2B buyers should consider implementing a strategic purchasing plan that includes bulk buying or long-term contracts with suppliers. Establishing a relationship with a supplier that offers price-lock agreements can also be beneficial. This agreement allows you to secure current pricing for a set period, providing predictability in budgeting. Additionally, consider diversifying your supplier base to include local and international options, which can offer competitive pricing and reduce reliance on a single source. By adopting these strategies, you can better manage costs and minimize the risks associated with price volatility.

Scenario 3: Understanding the Technical Specifications of Copper Sheet Metal

The Problem: Many buyers may not fully understand the technical specifications and applications of different copper sheet metal grades, which can lead to inappropriate material choices for specific applications. For instance, using a softer copper grade for structural applications could result in failure, while a harder grade might be more difficult to work with. This lack of understanding can lead to increased waste, project delays, and financial losses.

The Solution: To address this knowledge gap, buyers should invest in education and training regarding copper sheet metal specifications. Engage with suppliers who offer comprehensive product guides and technical support to help you understand the nuances of different grades. Utilize online resources and industry seminars to stay updated on best practices for selecting and using copper sheet metal. Additionally, consider collaborating with engineers or materials specialists who can provide insights tailored to your specific project needs. By enhancing your knowledge of copper materials, you can make informed decisions that align with your project requirements, ultimately leading to more successful outcomes.

Strategic Material Selection Guide for copper sheet metal 4×8

What are the Key Properties of Common Copper Sheet Metal Materials?

When selecting copper sheet metal, particularly in the 4×8 size, understanding the specific properties of various materials is crucial for ensuring optimal performance in end applications. Below are analyses of four common copper sheet metal types that international B2B buyers should consider.

What are the Properties of C110 Copper Sheets?

C110 copper, also known as electrolytic tough pitch (ETP) copper, is the most commonly used type of copper sheet. It boasts excellent electrical and thermal conductivity, making it ideal for applications requiring efficient energy transfer. C110 copper exhibits good corrosion resistance, particularly in non-oxidizing environments, and can withstand moderate temperatures without significant degradation.

Pros: The high conductivity and formability of C110 make it suitable for a variety of applications, including electrical components and architectural features. It is also relatively cost-effective.

Cons: However, C110 copper can be susceptible to corrosion in harsh environments, particularly those involving sulfur compounds. Additionally, its softness may limit its use in heavy-duty applications.

Impact on Application: C110 is compatible with a range of media, including water and air, but care should be taken in environments with corrosive agents.

How Does 24 oz. Copper Sheet Compare?

The 24 oz. copper sheet is a thicker option, providing enhanced durability and strength. This material is commonly used in roofing, gutters, and architectural applications where structural integrity is paramount. It also retains the excellent conductivity properties of copper while offering improved resistance to physical damage.

Pros: The increased thickness translates to better performance in demanding applications, making it a preferred choice for roofing and flashing. It is less prone to bending and warping compared to thinner sheets.

Cons: The primary drawback is the higher cost associated with thicker sheets, which may not be justified for lighter applications. Additionally, the weight can complicate handling and installation.

Impact on Application: The 24 oz. copper sheet is particularly suitable for outdoor applications where exposure to elements is a concern, as it can withstand significant wear and tear.

What is the Advantage of Using 16 oz. Copper Sheets?

The 16 oz. copper sheet is often chosen for its balance between cost and performance. It is lightweight, making it easier to handle and install, while still providing adequate strength for various applications, including decorative elements and light-duty roofing.

Pros: Its lower cost and ease of handling make it an attractive option for projects with budget constraints. It is versatile and can be used in a variety of applications.

Cons: However, its thinner profile may not be suitable for applications requiring high durability or resistance to heavy loads. It is also more prone to damage from impacts.

Impact on Application: While it can be used in roofing and decorative applications, care should be taken in environments where heavy rain or snow loads are expected.

What are the Considerations for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider compliance with local standards such as ASTM, DIN, or JIS. Additionally, preferences for specific copper grades may vary by region based on local climatic conditions and application requirements. Buyers should also be aware of import regulations and potential tariffs that could affect overall costs.

Summary Table of Copper Sheet Metal Options

| Material | Typical Use Case for copper sheet metal 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| C110 Copper | Electrical components, architectural features | Excellent conductivity and formability | Susceptible to corrosion in harsh environments | Medium |

| 24 oz. Copper | Roofing, gutters, architectural applications | Enhanced durability and strength | Higher cost and heavier weight | High |

| 16 oz. Copper | Decorative elements, light-duty roofing | Cost-effective and easy to handle | Less durable and prone to damage | Low |

| 32 oz. Copper | Heavy-duty roofing, industrial applications | Superior strength and longevity | Very high cost and difficult to handle | High |

This guide serves as a strategic overview for B2B buyers looking to make informed decisions regarding copper sheet metal selections. By understanding the properties, advantages, and limitations of each type, buyers can better align their material choices with specific project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for copper sheet metal 4×8

What Are the Main Stages of Manufacturing Copper Sheet Metal 4×8?

The manufacturing of copper sheet metal, particularly in the 4×8 size, involves several critical stages that ensure the final product meets the required specifications for various applications.

-

Material Preparation: This initial stage involves sourcing high-quality raw copper, typically in the form of ingots or cathodes. The purity of the copper is crucial, as it directly affects the conductivity and corrosion resistance of the finished sheet. Suppliers often opt for C110 copper, which has a purity of 99.9%, making it ideal for electrical and architectural applications. The material is then cut into manageable sizes for further processing.

-

Forming: In this stage, the prepared copper material is subjected to processes such as rolling and annealing. Rolling involves passing the copper through a series of rollers to achieve the desired thickness—commonly available in gauges ranging from 16 oz. (0.0216 inches) to 48 oz. (0.0646 inches). Annealing, which involves heating the material and then cooling it, is essential for restoring ductility and reducing hardness, allowing for easier handling and shaping.

-

Assembly: Although copper sheets are typically sold as standalone products, they may be assembled into larger components or systems, such as roofing panels or flashing systems. This stage may involve cutting, bending, or soldering, depending on the end-use requirements.

-

Finishing: The finishing stage is crucial for enhancing the aesthetic appeal and durability of the copper sheets. This may include surface treatments to remove any oxidation or imperfections. A standard mill finish is common, although suppliers may offer additional options depending on customer specifications.

What Quality Assurance Measures Are Essential for Copper Sheet Metal Production?

Quality assurance (QA) is critical in ensuring that copper sheet metal products meet international standards and customer expectations. For B2B buyers, understanding these processes can help in selecting reliable suppliers.

-

International Standards Compliance: Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. This certification indicates that the manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific certifications like CE marking for European markets or API for the oil and gas industry may be necessary, depending on the intended application of the copper sheets.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Materials are inspected upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, random samples are taken for testing to ensure the processes are yielding products that meet quality standards.

– Final Quality Control (FQC): Once the sheets are produced, a final inspection is conducted to verify that the finished products meet all specifications before shipment. -

Common Testing Methods: Various testing methods are utilized to assess the properties of copper sheets, including:

– Visual Inspection: Checking for surface defects such as scratches, dents, or discoloration.

– Dimensional Testing: Verifying that the thickness, width, and length conform to specified tolerances.

– Mechanical Testing: Assessing properties such as tensile strength and ductility to ensure the material can withstand intended applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of copper sheet metal suppliers is paramount.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control systems in place. During these audits, buyers can examine production facilities, review QA documentation, and engage with staff to ensure compliance with industry standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their QA processes. These reports should outline the methods used for testing, results from recent batches, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These services can conduct inspections at various stages of production and provide certification that the products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B transactions often involve additional complexities regarding quality control:

-

Cultural and Regulatory Differences: Buyers should be aware of the varying quality standards and regulatory requirements across different regions. For instance, while CE marking is a must in Europe, similar certifications may not be required in other markets. Understanding these differences can help avoid compliance issues.

-

Language Barriers: Language differences can pose challenges in communication regarding quality specifications. It is advisable for buyers to ensure that all documentation, including contracts and specifications, is clearly articulated in a mutually understood language.

-

Logistics and Shipping Considerations: Quality assurance does not end at the factory. Buyers should also consider the conditions under which products are transported. Ensuring that proper handling and storage procedures are followed during shipping can mitigate risks of damage and maintain product integrity upon arrival.

In conclusion, understanding the manufacturing processes and quality assurance measures for copper sheet metal is essential for B2B buyers seeking reliable suppliers. By leveraging these insights, buyers can make informed decisions that align with their specific needs and standards, ultimately fostering successful international trade relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘copper sheet metal 4×8’

When sourcing copper sheet metal, particularly in the common 4×8 size, a systematic approach is essential to ensure that your procurement meets both quality and cost-effectiveness. This guide provides a step-by-step checklist tailored for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for the copper sheet metal. This includes the desired thickness (e.g., 16 oz., 20 oz.), finish (mill finish, patina), and any specific applications (roofing, gutters, or decorative purposes). Having precise specifications helps in communicating with suppliers and ensures that you receive products tailored to your needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers that specialize in copper sheet metal. Look for companies with a proven track record in the industry and positive customer reviews. Online directories, trade shows, and industry associations can provide valuable leads. Consider the supplier’s geographic location, as it may affect shipping costs and delivery times.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications and quality standards, such as ISO 9001 or specific industry-related certifications. These credentials demonstrate a commitment to maintaining high-quality processes and products. Request documentation to ensure compliance with international standards, especially if you are importing materials across borders.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the copper sheet metal to assess quality. Examine the samples for surface finish, thickness accuracy, and any defects. This step is crucial to ensure that the product meets your specifications and expectations before making a larger financial commitment.

Step 5: Inquire About Pricing and Payment Terms

Engage with suppliers to obtain detailed pricing information, including potential discounts for bulk orders. Be aware of any price volatility in the copper market and clarify payment terms upfront. Understanding the total cost, including shipping and any additional fees, will help you make an informed purchasing decision.

Step 6: Discuss Shipping Logistics

Ensure that the supplier can accommodate your shipping requirements, especially if you are located in regions with specific logistical challenges. Discuss delivery timelines, shipping methods, and responsibilities for unloading materials. This is particularly important for heavy products like copper sheets, which may require specialized transportation.

Step 7: Review and Finalize the Purchase Agreement

Once you have selected a supplier, carefully review the purchase agreement. Ensure all terms, including delivery dates, payment schedules, and return policies, are clearly outlined. Confirm that the agreement protects your interests, especially in cases of defective products or late deliveries.

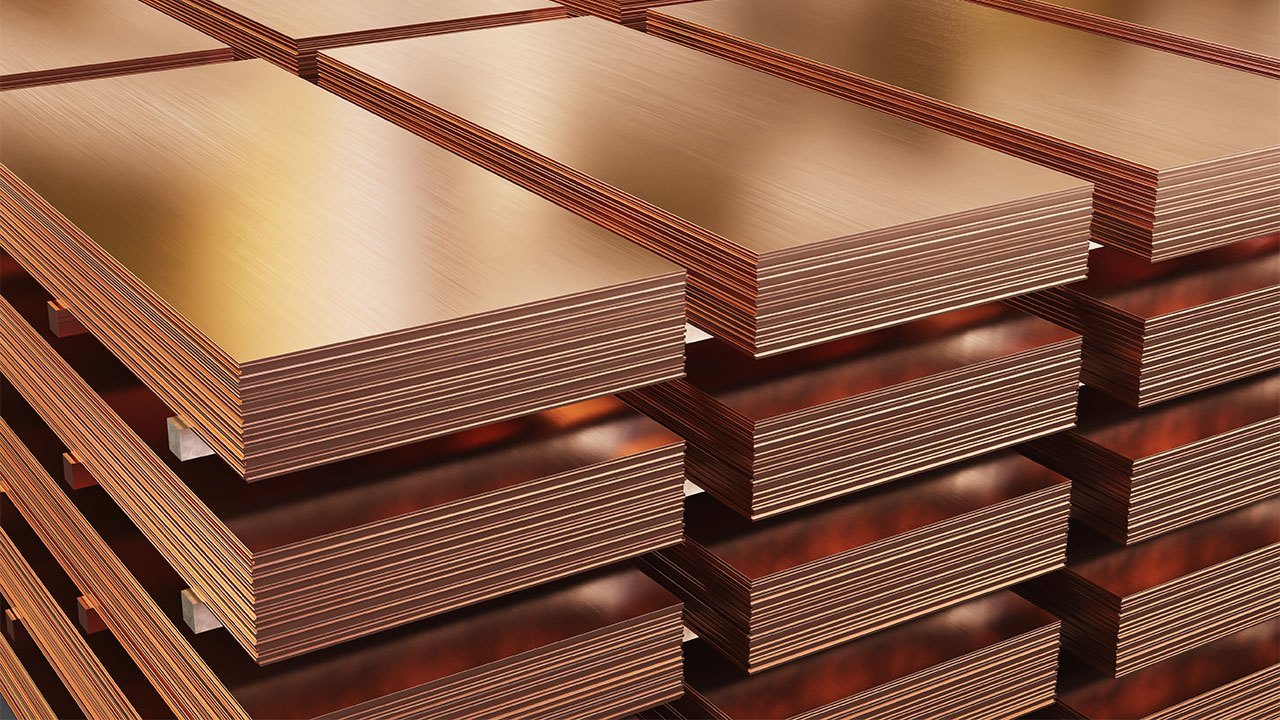

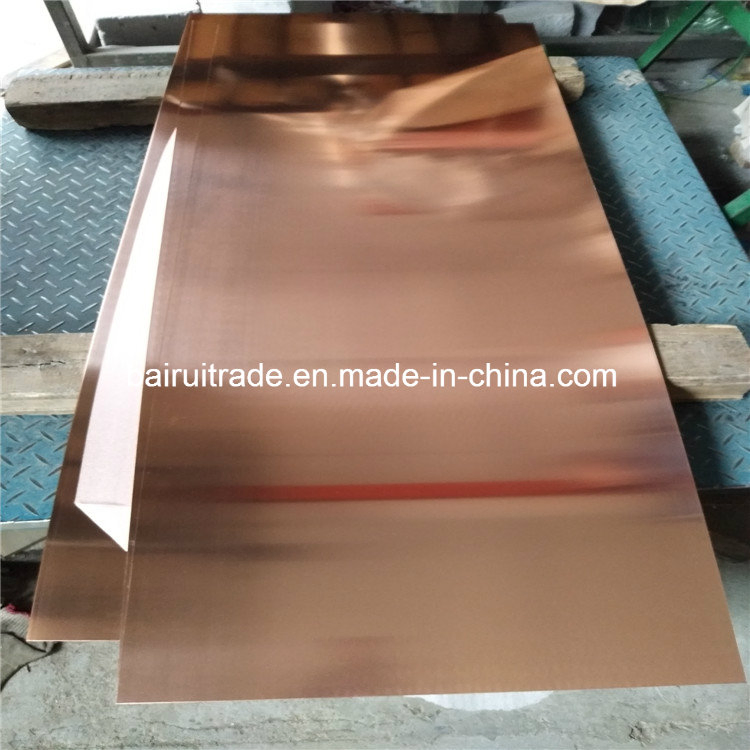

Illustrative image related to copper sheet metal 4×8

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for copper sheet metal, ensuring a smooth procurement experience while minimizing risks.

Comprehensive Cost and Pricing Analysis for copper sheet metal 4×8 Sourcing

What Are the Key Cost Components in Copper Sheet Metal 4×8 Sourcing?

When sourcing copper sheet metal, particularly the 4×8 size, several cost components contribute to the final pricing. The primary elements include:

-

Materials: The cost of raw copper fluctuates based on market demand and availability. As of late 2023, copper prices have been volatile, influenced by global supply chain issues and geopolitical factors. Buyers should keep abreast of these fluctuations to negotiate effectively.

-

Labor: Labor costs associated with processing copper sheets, including cutting and finishing, vary by region. In high-wage countries, labor may constitute a significant portion of the total cost, while in regions with lower labor costs, this component could be minimized.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Manufacturers with more efficient operations may offer lower prices.

-

Tooling: The cost of tools and machinery used in the production of copper sheets can be substantial, especially for customized orders. High-quality tooling can lead to better finished products, impacting overall quality and pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures product consistency and compliance with international standards. This may increase costs but is crucial for maintaining quality, especially for international buyers requiring certifications.

-

Logistics: Shipping costs are a critical factor, particularly for international transactions. Freight costs can vary widely based on distance, shipping method, and Incoterms, which dictate responsibilities for delivery and risk.

-

Margin: Suppliers typically apply a margin that reflects their operational costs and desired profit. Understanding the margin structure can help buyers assess the fairness of pricing.

How Do Price Influencers Affect Copper Sheet Metal Costs?

Several factors can significantly influence the pricing of copper sheets:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer discounts for larger orders. Buyers should consider consolidating orders to achieve better pricing.

-

Specifications and Customization: Custom thickness, finish, and dimensions can affect cost. More specialized requirements generally lead to higher prices due to increased manufacturing complexity.

-

Material Quality and Certifications: Higher-quality copper with certifications (such as CDA Alloy 110) tends to be more expensive. Buyers should assess whether the additional cost aligns with their project needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but offer assurance of quality and service.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is crucial, as they define the cost responsibilities and risk transfer points. Buyers should negotiate terms that minimize their costs and risks.

What Tips Can Help International Buyers Optimize Costs?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, can benefit from these strategies:

-

Negotiation: Engaging in effective negotiation can yield better pricing and terms. Building a relationship with suppliers can also facilitate future negotiations.

-

Cost-Efficiency: Analyze the total cost of ownership, including shipping, duties, and potential tariffs. This comprehensive view helps in comparing supplier quotes more accurately.

-

Pricing Nuances: Be aware of seasonal price fluctuations and market trends. Timing your purchases can lead to significant savings.

-

Supplier Diversification: Explore multiple suppliers to compare pricing and service levels. This not only aids in finding competitive prices but also reduces dependency on a single source.

-

Documentation and Compliance: Ensure all necessary documentation is in order to avoid delays and additional costs at customs. Familiarity with import regulations in your country can prevent unexpected expenses.

Disclaimer on Indicative Prices

Prices for copper sheet metal can vary significantly based on market conditions, supplier policies, and specific buyer requirements. The information provided should be considered indicative, and it is advisable for buyers to seek updated quotes and engage in thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing copper sheet metal 4×8 With Other Solutions

Introduction: Exploring Alternatives to Copper Sheet Metal 4×8

When considering materials for construction or manufacturing, copper sheet metal (4×8) is a popular choice due to its durability, conductivity, and aesthetic appeal. However, it’s essential to evaluate other viable alternatives that may offer similar benefits or suit specific project requirements. This analysis will compare copper sheet metal with aluminum sheets and stainless steel sheets, highlighting their respective advantages and disadvantages.

Comparison Table

| Comparison Aspect | Copper Sheet Metal 4×8 | Aluminum Sheets | Stainless Steel Sheets |

|---|---|---|---|

| Performance | Excellent conductivity and corrosion resistance. Develops patina over time. | Good conductivity, lightweight, and corrosion-resistant. | High strength, excellent corrosion resistance, and durability. |

| Cost | Moderate to high, depending on thickness and market fluctuations. | Generally lower cost, especially for standard sizes. | Higher cost due to processing and material quality. |

| Ease of Implementation | Requires specialized tools for cutting and installation. | Easier to cut and shape; can be handled with basic tools. | More challenging to cut and shape; requires specialized equipment. |

| Maintenance | Low maintenance; patina can be seen as desirable. | Low maintenance; does not rust but may require cleaning to avoid oxidation. | Very low maintenance; resistant to stains and corrosion. |

| Best Use Case | Ideal for roofing, gutters, and decorative applications. | Best for lightweight structures, signage, and heat exchangers. | Suited for applications requiring high strength and corrosion resistance, like industrial environments. |

Detailed Breakdown of Alternatives

Aluminum Sheets

Aluminum sheets are a lightweight and cost-effective alternative to copper. Their lower density makes them easier to handle and install, which can reduce labor costs. Aluminum also offers good corrosion resistance, making it suitable for outdoor applications. However, it has lower electrical and thermal conductivity than copper, which may be a drawback for specific applications like electrical wiring or heat transfer systems. Additionally, while aluminum is resistant to rust, it can oxidize, requiring occasional maintenance.

Stainless Steel Sheets

Stainless steel sheets are another alternative that provides exceptional strength and corrosion resistance. They are ideal for environments where durability is paramount, such as in industrial applications or areas exposed to harsh conditions. While stainless steel is more robust than copper, it lacks the same level of conductivity, which can limit its use in electrical applications. The cost of stainless steel can be higher, and it often requires specialized tools for cutting and installation, making it less accessible for smaller projects or businesses.

Conclusion: Choosing the Right Material for Your Needs

Selecting the appropriate material for your project involves assessing various factors, including performance, cost, ease of implementation, and maintenance. Copper sheet metal excels in conductivity and aesthetic appeal, making it suitable for decorative and functional applications. However, for projects with budget constraints or specific performance requirements, aluminum or stainless steel may provide viable alternatives. By carefully considering the unique needs of your project and weighing the pros and cons of each material, you can make an informed decision that aligns with your business objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for copper sheet metal 4×8

What Are the Key Technical Properties of Copper Sheet Metal 4×8?

Understanding the technical specifications of copper sheet metal is crucial for B2B buyers, particularly when sourcing materials for various industrial applications. Here are the essential properties to consider:

-

Material Grade

Copper sheet metal is typically classified under various grades, with C110 being the most common for electrical and thermal applications. The grade indicates the metal’s purity and performance characteristics. For instance, higher-grade copper offers better conductivity and corrosion resistance, making it essential for applications such as electrical wiring and roofing. -

Thickness

The thickness of copper sheets is a vital specification, often measured in ounces (oz) or inches. Common thicknesses include 16 oz. (0.0216 inches) to 48 oz. (0.0646 inches). The thickness determines the sheet’s strength, durability, and suitability for specific applications. For example, thicker sheets are better suited for roofing and flashing, while thinner sheets may be used for decorative purposes. -

Tolerance

Tolerance refers to the permissible limit of variation in the thickness and dimensions of the copper sheets. It is critical for ensuring that the sheets fit precisely in applications like gutters and roofing systems. A tighter tolerance often results in higher costs but guarantees better performance and fewer complications during installation. -

Finish Type

Copper sheets usually come with a mill finish, which is the raw, unprocessed state of the metal. This finish may have minor scratches or discoloration but is preferred for many industrial applications due to its natural patina development over time. Understanding the finish type is crucial for aesthetic considerations in architectural projects. -

Weight

The weight of copper sheets is typically expressed in pounds per square foot. For instance, a 16 oz. copper sheet weighs approximately 1 lb. per square foot. Knowing the weight is essential for logistics and transportation planning, as it impacts shipping costs and handling requirements.

What Are Common Trade Terms Associated with Copper Sheet Metal?

Familiarity with industry jargon can significantly streamline the purchasing process. Here are several key trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers who require specific quality standards for their copper sheets. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is vital for budget planning, as it influences the overall cost and inventory management. Buyers should negotiate MOQs to align with their project needs and cash flow. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and terms from suppliers. It is a critical step in the procurement process, allowing buyers to compare prices and terms from different vendors, ensuring they get the best deal for their copper sheet requirements. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, risks, and delivery responsibilities, which can vary significantly across regions like Africa, South America, and the Middle East. -

Lead Time

Lead time is the period between placing an order and its delivery. This term is crucial for project planning, particularly in industries with tight deadlines. Buyers should inquire about lead times when sourcing copper sheets to ensure timely delivery.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing copper sheet metal, ultimately enhancing their procurement strategies and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the copper sheet metal 4×8 Sector

What Are the Key Market Dynamics and Trends for Copper Sheet Metal 4×8?

The global copper sheet metal market is experiencing significant growth, driven by the increasing demand across various sectors including construction, electrical, and automotive industries. The 4×8 size, particularly popular in roofing, flashing, and architectural applications, is seeing a surge in demand due to its versatility and ease of handling. Emerging technologies in sourcing, such as blockchain for supply chain transparency and advanced inventory management systems, are revolutionizing how international buyers procure copper sheet metal. This is especially pertinent for B2B buyers from regions like Africa, South America, the Middle East, and Europe, where sourcing strategies are evolving to ensure faster delivery and lower costs.

Market dynamics are also influenced by fluctuating copper prices, which can be affected by geopolitical tensions and supply chain disruptions. For instance, ongoing issues such as mining regulations and labor strikes in major producing countries can impact availability and pricing. Buyers are encouraged to stay informed on these global trends and consider establishing long-term relationships with suppliers to mitigate risks associated with price volatility.

How Can Sustainability and Ethical Sourcing Impact Copper Sheet Metal Sourcing?

Sustainability is becoming a critical consideration for B2B buyers in the copper sheet metal market. The environmental impact of copper mining and processing is significant, leading to a growing demand for ethically sourced materials. International buyers are increasingly looking for suppliers who adhere to sustainable practices, such as using recycled copper or implementing eco-friendly production processes.

The importance of ethical supply chains cannot be overstated. Buyers should prioritize suppliers with certifications that demonstrate adherence to environmental standards, such as ISO 14001 for environmental management systems or the Responsible Copper Initiative. These certifications not only ensure compliance with environmental regulations but also enhance a company’s reputation, making it more attractive to environmentally conscious consumers and partners.

Furthermore, incorporating ‘green’ materials into projects can yield long-term financial benefits, as energy-efficient practices often lead to reduced operational costs. This trend is particularly relevant for buyers in regions like Europe, where sustainability regulations are stringent.

How Has the Copper Sheet Metal Market Evolved Over Time?

The history of copper sheet metal dates back thousands of years, with its applications ranging from ancient coins to modern electronics. Initially, copper was valued for its malleability and resistance to corrosion, making it a preferred material in various industries. Over the centuries, advancements in metallurgy and manufacturing processes have led to more refined and diverse copper products, including the widely used 4×8 sheets.

In recent decades, the demand for copper sheet metal has surged, driven by urbanization and industrialization across the globe. Technological innovations, such as improved smelting and recycling processes, have made it more accessible and cost-effective. Today, copper sheet metal is not just a staple in traditional applications; it is also increasingly being utilized in cutting-edge technologies, such as renewable energy systems and electric vehicles, further underscoring its importance in the modern economy.

In summary, understanding the market dynamics, embracing sustainability, and recognizing the historical context of copper sheet metal can empower B2B buyers to make informed sourcing decisions that align with both current needs and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of copper sheet metal 4×8

-

How can I ensure the quality of copper sheet metal before purchasing?

To ensure the quality of copper sheet metal, request material certifications from your supplier, which should detail the copper grade, thickness, and any relevant industry standards. Conducting a visual inspection can also be beneficial; look for uniform color, absence of corrosion, and confirm that the thickness matches specifications. If possible, request samples to evaluate the material’s properties before placing a larger order. Utilizing third-party inspection services can provide additional assurance regarding the quality and compliance of the copper sheets. -

What are the different applications for 4×8 copper sheet metal?

4×8 copper sheet metal is versatile and used in various applications, including roofing, gutters, flashing, electrical components, and decorative elements. Its excellent conductivity makes it ideal for electrical applications, while its corrosion resistance is beneficial in outdoor settings. Additionally, it is commonly used in architectural features and art installations due to its aesthetic appeal. Understanding the intended application will help you choose the appropriate thickness and finish for your specific needs. -

What thickness of copper sheet should I choose for my project?

The thickness of copper sheet you select should align with the specific demands of your project. For roofing and gutter applications, 16 oz. (0.0216 inches) or 20 oz. (0.027 inches) are popular choices due to their balance of durability and weight. For structural applications requiring more strength, consider thicker options like 24 oz. (0.032 inches) or 32 oz. (0.041 inches). Always consult with your supplier for recommendations based on your project’s requirements and local building codes. -

What are the common payment terms for international B2B copper sheet transactions?

Payment terms can vary significantly among suppliers, but common practices include advance payments, letters of credit, or payment upon delivery. For international transactions, it is advisable to negotiate terms that protect both parties, such as partial payment in advance and the remainder upon shipment or delivery. Always clarify currency and payment methods accepted, and consider using escrow services to mitigate risk. Ensure that all payment terms are documented in the purchase agreement to avoid misunderstandings. -

How do I verify the credibility of a copper sheet metal supplier?

To verify a supplier’s credibility, start by checking their business credentials, such as registration, industry certifications, and customer reviews. Request references from previous clients and contact them to inquire about their experiences. Additionally, assess the supplier’s responsiveness and willingness to provide detailed product information, certifications, and samples. Trade associations or industry forums can also offer insights into the supplier’s reputation and reliability within the market. -

What are the logistics considerations when importing copper sheet metal?

Logistics for importing copper sheet metal involve several factors, including shipping methods, customs regulations, and delivery timelines. It’s essential to work with a freight forwarder experienced in handling metal imports to navigate these complexities. Consider the weight and size of the sheets, as these will influence shipping costs and methods. Ensure you have all necessary documentation, including invoices, packing lists, and import permits, to facilitate smooth customs clearance. -

Can I customize the size or thickness of copper sheets for my project?

Yes, many suppliers offer customization options for size and thickness of copper sheets. When placing your order, specify the desired dimensions and thickness to ensure they meet your project specifications. Be mindful that custom orders may have minimum order quantities (MOQs) and longer lead times compared to standard sizes. Always confirm pricing and availability for customized sheets before finalizing your purchase. -

What should I expect regarding delivery times for copper sheet metal orders?

Delivery times for copper sheet metal orders can vary based on factors such as order size, supplier location, and shipping method. Standard lead times may range from a few days to several weeks, particularly for custom orders. It is advisable to discuss estimated delivery times with your supplier at the time of order placement. Additionally, consider potential delays due to customs clearance, especially for international shipments, and plan your project timeline accordingly.

Top 5 Copper Sheet Metal 4X8 Manufacturers & Suppliers List

1. Basic Copper – Discounted Copper Sheets

Domain: basiccopper.com

Registered: 2006 (19 years)

Introduction: Discounted Copper Sheets available in many sizes and thicknesses. Products include: 1 Mil Copper Foil, 1.4 Mil Copper Foil, 3 Mil Copper Foil, 5 Mil/36 Ga. Copper Sheet, 8 Mil/32 Ga. Copper Sheet, 10 Mil/30 Ga. Copper Sheet, 16 Mil/26 Ga. Copper Sheet, 22 Mil/16 Oz. Copper Sheet, 32 Mil (20 Gauge) Copper Sheet, 40 Mil (18 Gauge) Copper Sheet, and various Copper Sheets with Patina. Discounted items…

2. KMSheetMetal – Copper Sheets

Domain: kmsheetmetal.com

Registered: 2012 (13 years)

Introduction: {“Product Name”: “Copper Sheets”, “Available Thicknesses”: [“16 oz.”, “20 oz.”, “24 oz.”, “32 oz.”, “48 oz.”], “SKU”: “CU_SHEET”, “Price”: “$279.00”, “Discounted Pricing”: {“10 or more”: “$263.00 (6% off)”, “20 or more”: “$248.00 (11% off)”, “68 or more”: “$237.00 (15% off)”}, “Dimensions”: {“Width”: [“36 inches”, “48 inches”], “Length”: “120 inches”}, “Material Thicknesses”: {“16 oz.”: “0.0216 in…

3. Saturn Industries – Copper Sheet Alloy 110

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Copper Sheet Alloy 110”, “Dimensions”: “1/8\” X 4\” X 8\””, “Brand”: “Saturn Industries, Inc.”, “Condition”: “New”, “Quantity Available”: 9, “Quantity Sold”: 13, “Shipping Cost”: “$10.65”, “Shipping Method”: “USPS Ground Advantage®”, “Location”: “Hudson, New York, United States”, “Delivery Estimate”: “between Wed, Sep 10 and Sat, Sep 13”, “Returns”: “Seller does not accept return…

4. Metal Supermarkets – Copper Sheet C110

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Copper Sheet C110, excellent electrical and thermal conductivity, good strength, good formability, resistance to corrosion. Typical applications include vacuum devices, switches, interrupters, deposition units, and components for superconductive magnets. Available cut to size, no minimum order required.

5. Riverside Sheet Metal – Copper Sheets & Coils

Domain: riversidesheetmetal.net

Registered: 2007 (18 years)

Introduction: Copper sheets & coils available in 16 oz, 20 oz, 24 oz, and 48 oz. Offered in sheet sizes of 3′ x 8′, 3′ x 10′, 4′ x 8′, and 4′ x 10′. Coils available in widths of 10″, 11.75″, 12″, 15″, 18″, 20″, 24″, 36″, and 48″. Various finishes available include: Brushed Finish, Satin Finish, Dark Patina, Green Patina, and Burnished Finish. Copper is primarily used for roofing applications, gutters, hangers, …

Strategic Sourcing Conclusion and Outlook for copper sheet metal 4×8

In summary, strategic sourcing of copper sheet metal, particularly the 4×8 size, offers significant advantages for international B2B buyers. The unique properties of copper—its excellent electrical and thermal conductivity, corrosion resistance, and aesthetic appeal—make it a prime choice for diverse applications, including roofing, gutters, and decorative elements. By considering various thickness options and understanding the implications of price volatility, businesses can optimize their procurement strategies to ensure cost-effectiveness and quality.

Moreover, engaging with suppliers that offer flexible pricing and discounts on bulk orders can enhance your sourcing strategy, allowing for more competitive pricing in a global market. With an increasing demand for sustainable materials, the focus on sourcing high-quality copper products is more critical than ever.

As you look ahead, leveraging strategic sourcing practices will not only streamline your supply chain but also position your business for growth in emerging markets across Africa, South America, the Middle East, and Europe. We encourage you to explore diverse supplier options and stay abreast of market trends to capitalize on opportunities in this dynamic sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.