A B2B Buyer’s Guide to Kiss Cutting: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for kiss cutting

Kiss cutting is an essential technique in the manufacturing sector, particularly for international B2B buyers seeking to streamline their production processes while enhancing product usability. A common challenge faced by businesses across regions—such as Africa, South America, the Middle East, and Europe—is sourcing reliable suppliers who can deliver high-quality kiss-cut products tailored to specific application needs. This guide comprehensively explores the various types of kiss cutting, its diverse applications, and the critical factors to consider when vetting suppliers.

From adhesive tapes to gaskets and beyond, understanding the nuances of kiss cutting will empower you to make informed purchasing decisions. The guide delves into cost considerations, production capabilities, and the latest industry trends, providing actionable insights that cater to your unique business requirements. By equipping yourself with this knowledge, you can confidently navigate the global market, ensuring that your sourcing strategies align with your operational goals and quality standards. Whether you are based in Nigeria, Brazil, or any other region, this resource aims to facilitate a smoother procurement process, helping you to optimize your supply chain and drive business success.

Understanding kiss cutting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Kiss Cutting | Cuts through material but leaves backing intact. | Stickers, labels, and decals | Pros: Easy to peel; maintains organization. Cons: Limited to lighter materials. |

| Foam Kiss Cutting | Uses foam materials, allowing for varied thicknesses. | Packaging, cushioning, and insulation | Pros: Excellent for uneven surfaces; customizable. Cons: May require specific adhesives. |

| Gasket Kiss Cutting | Specifically designed for creating gaskets. | Automotive and machinery applications | Pros: High precision; tailored to specific needs. Cons: Can be more expensive due to customization. |

| Double-Sided Kiss Cutting | Cuts parts with adhesive on both sides. | Mounting applications and displays | Pros: Versatile; enhances product functionality. Cons: Complexity in production can increase costs. |

| Custom Kiss Cutting | Tailored designs based on unique specifications. | Specialized products across industries | Pros: Fully customizable; meets specific client needs. Cons: Longer lead times; potentially higher costs. |

What Are the Characteristics of Standard Kiss Cutting?

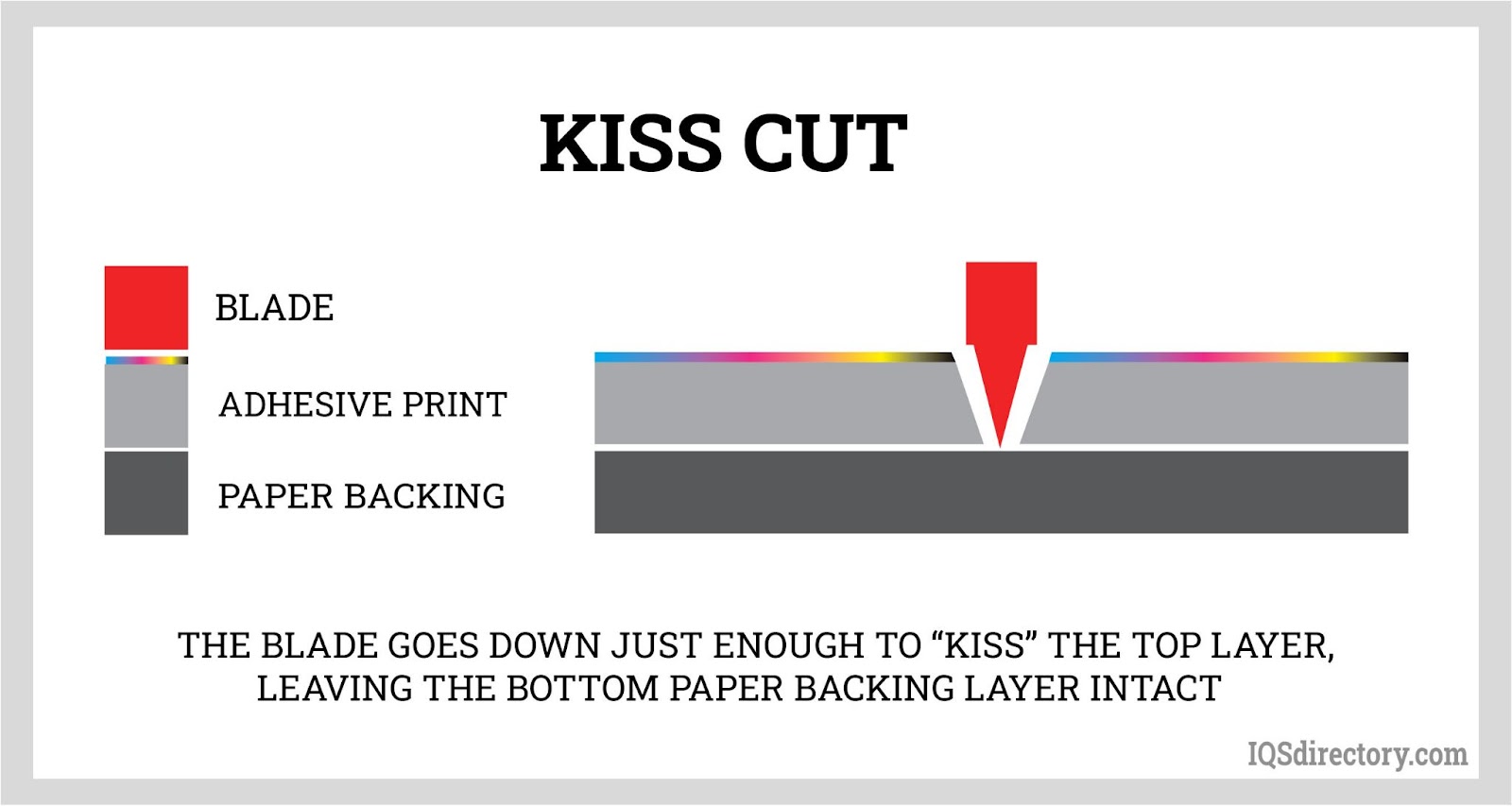

Standard kiss cutting is a fundamental technique where the cutting blade penetrates the material but does not cut through the backing layer. This method is primarily used for producing stickers, labels, and decals, making it ideal for businesses that require easy-to-peel products. Buyers should consider the material’s weight and adhesive properties, as this technique is best suited for lighter materials that maintain integrity during peeling. The convenience of having parts organized on a single backing layer enhances operational efficiency.

How Does Foam Kiss Cutting Differ from Other Methods?

Foam kiss cutting involves cutting through foam materials, allowing for various thicknesses and textures. This method is particularly advantageous for applications like packaging, cushioning, and insulation, where adaptability to uneven surfaces is crucial. Buyers should evaluate the specific foam type and adhesive compatibility, as these factors can influence the final product’s performance. The ability to create custom shapes and sizes enhances its appeal, although it may necessitate more specialized adhesives for optimal results.

Why Choose Gasket Kiss Cutting for Industrial Applications?

Gasket kiss cutting focuses on producing precise gaskets for automotive and machinery applications. The process ensures a tight seal by tailoring the gasket shape and material to specific requirements. Buyers in these sectors should prioritize precision and material compatibility when sourcing gaskets, as improper seals can lead to significant operational issues. While the customization may come at a higher price point, the benefits of durability and performance often justify the investment.

What Are the Benefits of Double-Sided Kiss Cutting?

Double-sided kiss cutting produces parts with adhesive on both sides, making it ideal for mounting applications and displays. This versatility allows businesses to create products that require strong adhesion without visible fasteners. Buyers should consider the adhesive strength and material compatibility, as these factors can affect the final product’s effectiveness. While this method offers enhanced functionality, the complexity involved in production can lead to increased costs, which should be factored into budget considerations.

How Does Custom Kiss Cutting Cater to Unique Business Needs?

Custom kiss cutting provides tailored designs based on specific client specifications, making it suitable for specialized products across various industries. This flexibility allows businesses to meet unique demands, from intricate shapes to specialized materials. Buyers should be aware that while customization offers significant advantages, it may result in longer lead times and potentially higher costs. Understanding the trade-offs between customization and cost is essential for businesses looking to optimize their product offerings.

Key Industrial Applications of kiss cutting

| Industry/Sector | Specific Application of kiss cutting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of gaskets and seals | Enhances vehicle durability and performance | Material compatibility, temperature resistance, and certification standards |

| Electronics | Custom foam inserts for packaging | Protects sensitive components during transport | Precision cutting, material density, and shock absorption properties |

| Consumer Goods | Sticker production for branding and promotions | Increases brand visibility and customer engagement | Adhesive quality, design complexity, and production volume |

| Construction | Carpet and flooring installation materials | Ensures stability and safety in installations | Adhesive strength, ease of application, and weather resistance |

| Medical Devices | Production of adhesive pads and dressings | Enhances patient comfort and treatment efficacy | Biocompatibility, sterilization requirements, and regulatory compliance |

How is Kiss Cutting Used in the Automotive Sector?

In the automotive industry, kiss cutting is employed to produce gaskets and seals that are essential for preventing fluid leaks and enhancing the overall durability of vehicles. This technique allows manufacturers to create precise shapes that fit various engine components, ensuring a reliable seal. For international buyers, particularly in regions like Africa and South America, sourcing materials that withstand extreme temperatures and environmental conditions is crucial. Buyers should also consider the certifications of materials used to comply with automotive standards.

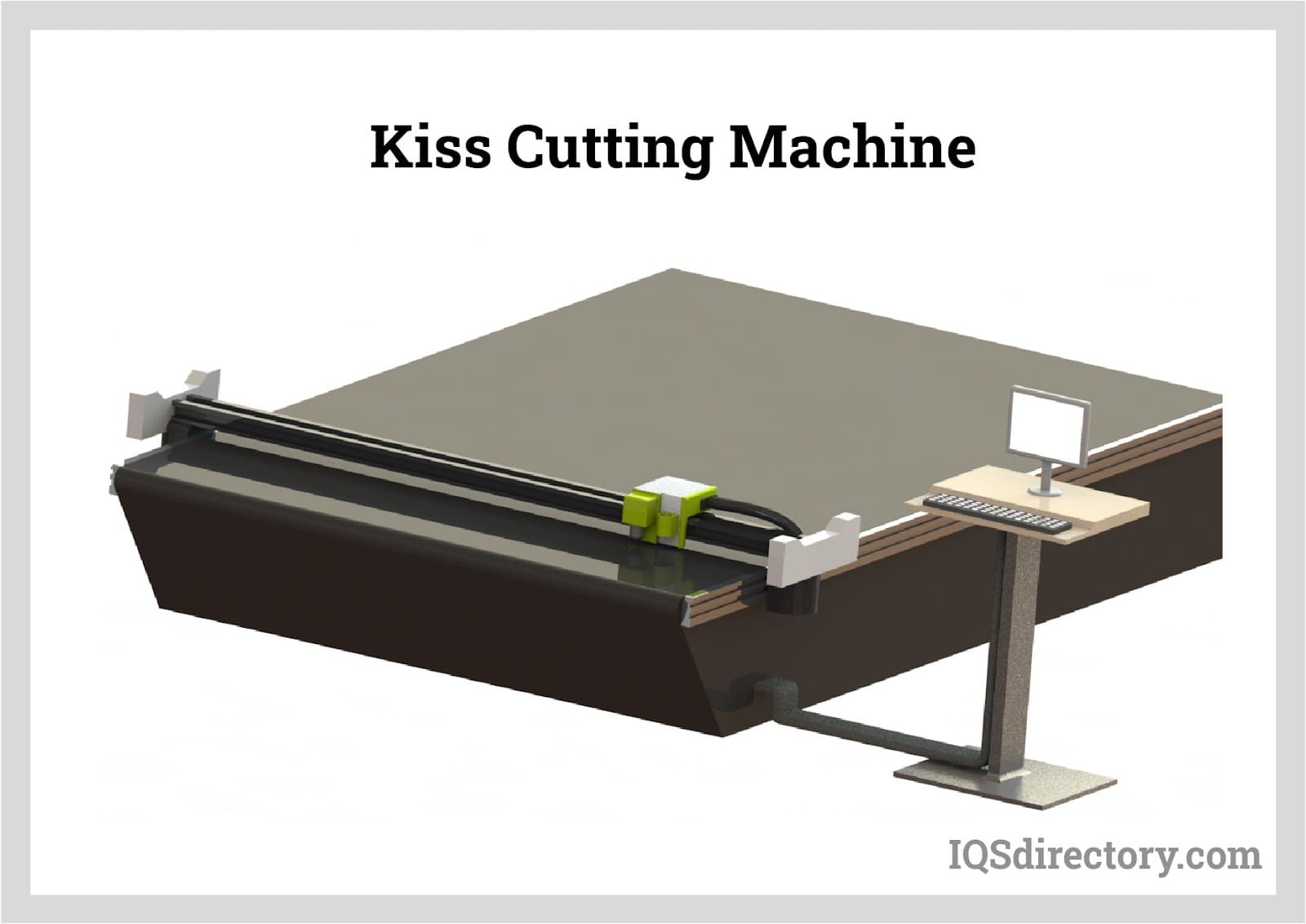

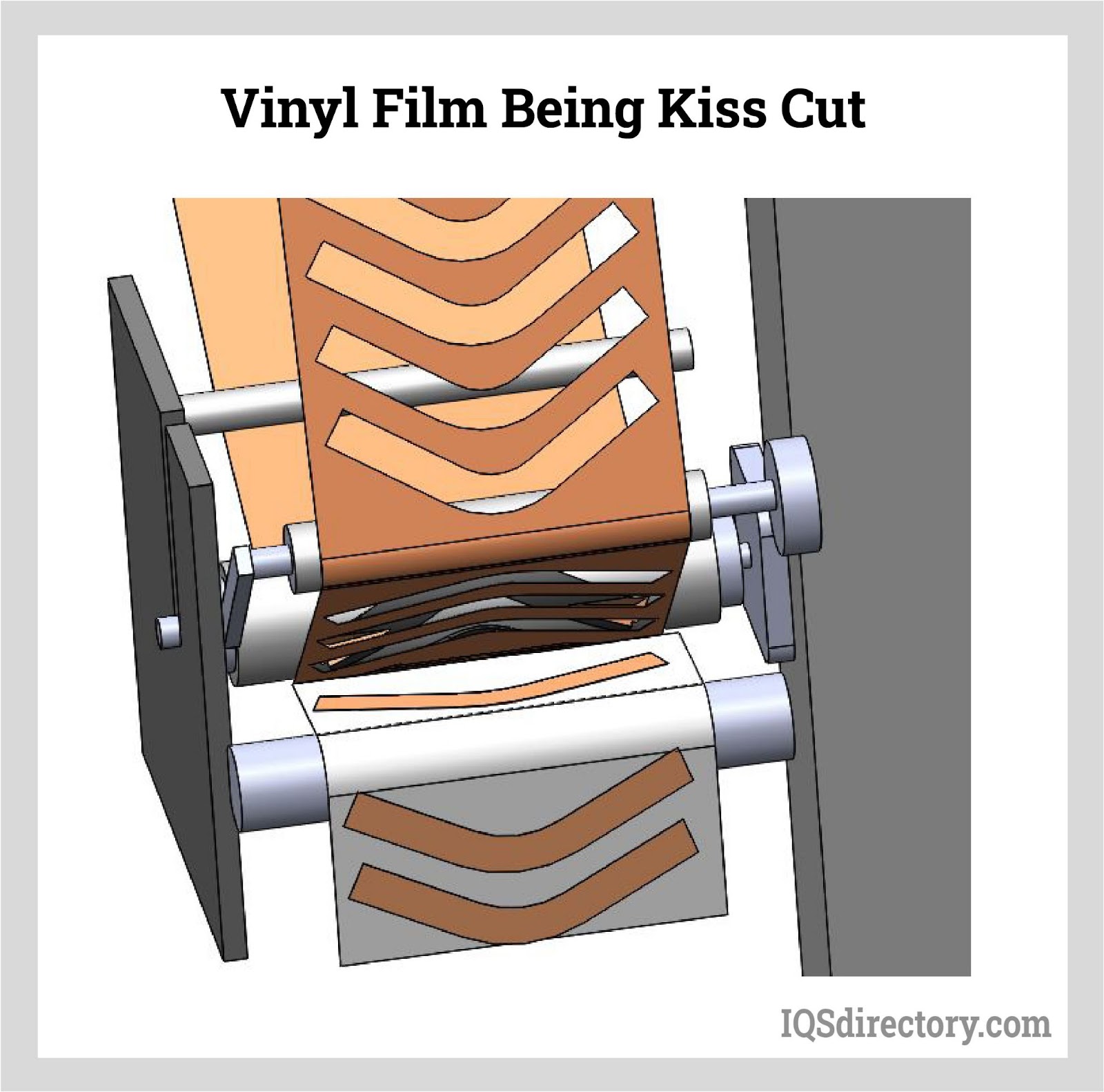

Illustrative image related to kiss cutting

What Role Does Kiss Cutting Play in Electronics Manufacturing?

In the electronics sector, kiss cutting is vital for creating custom foam inserts used in packaging sensitive components. These inserts protect devices during shipping and handling, minimizing the risk of damage. For businesses in the Middle East and Europe, the precision of the cut is essential to ensure a snug fit that provides adequate cushioning. Buyers should prioritize sourcing from suppliers who can meet specific density and thickness requirements to match their product dimensions effectively.

How is Kiss Cutting Beneficial for Consumer Goods?

The consumer goods industry utilizes kiss cutting for the production of stickers that serve as branding tools. This method allows businesses to create intricate designs that can be easily peeled off for application, enhancing customer interaction with products. In markets like Nigeria and Brazil, where brand visibility is key, sourcing high-quality adhesive materials is critical. Companies should also evaluate the design capabilities of their suppliers to ensure that they can produce complex shapes that align with branding strategies.

How is Kiss Cutting Applied in Construction?

Kiss cutting finds its application in the construction industry, particularly for producing carpet and flooring installation materials. Double-sided carpet tape, for example, is kiss cut to allow easy application without the mess of traditional adhesives. For buyers in Europe and South America, ensuring that the adhesive used can withstand various environmental conditions is vital. Additionally, businesses should consider the ease of installation and the longevity of the adhesive to ensure safety and stability in flooring applications.

What is the Importance of Kiss Cutting in Medical Devices?

In the medical device industry, kiss cutting is essential for creating adhesive pads and dressings that enhance patient care. This method allows for the precise cutting of materials that need to be biocompatible and sterilized. For international buyers, especially in regions like Africa and the Middle East, sourcing from manufacturers that comply with health regulations is paramount. Buyers must also consider the materials’ comfort and adhesion properties to ensure effective treatment and patient satisfaction.

3 Common User Pain Points for ‘kiss cutting’ & Their Solutions

Scenario 1: Difficulty in Maintaining Production Efficiency

The Problem: In high-volume production environments, B2B buyers often encounter challenges with kiss cutting that can lead to significant inefficiencies. For instance, if the kiss cutting process is not properly calibrated, it can result in inconsistent cuts. This inconsistency can slow down production lines, as workers must inspect and potentially rework defective parts. Buyers in industries such as packaging or automotive components may find themselves facing delays and increased labor costs, ultimately impacting their ability to meet customer demand.

The Solution: To address these efficiency issues, it is essential to establish a robust quality control process around the kiss cutting operation. Buyers should work closely with their kiss cutting service providers to ensure that cutting dies are regularly maintained and calibrated. Implementing a routine check for blade sharpness and die alignment can prevent inconsistencies. Additionally, investing in automated kiss cutting machines that offer real-time feedback on cut quality can enhance efficiency. This proactive approach allows companies to maintain a consistent production rate while minimizing waste and labor costs.

Scenario 2: Challenges in Material Selection for Kiss Cutting

The Problem: Another common pain point for B2B buyers is the challenge of selecting the right materials for kiss cutting. Different applications require different types of materials, such as foam, rubber, or adhesive-backed films. Buyers often struggle to identify which material will yield the best performance for their specific application, leading to suboptimal product quality and increased costs due to material wastage or rework.

The Solution: To make informed material selections, buyers should conduct thorough research and engage in discussions with material suppliers who specialize in kiss cutting. It is beneficial to request samples and conduct small-scale tests to evaluate how different materials perform during the kiss cutting process. Additionally, creating a detailed specification sheet that outlines the intended application, performance requirements, and environmental considerations can guide suppliers in recommending the best materials. Collaborating with experienced converters can also provide insights into material behavior during kiss cutting, ensuring that the selected materials meet both performance and cost-effectiveness criteria.

Scenario 3: Difficulty in Scaling Production for Diverse Product Lines

The Problem: As companies expand their product offerings, they often face difficulties in scaling their kiss cutting processes to accommodate a more diverse range of products. This is particularly true for businesses entering new markets or launching new product lines that require different shapes and sizes. The inability to efficiently kiss cut various designs can lead to production bottlenecks and limit a company’s agility in responding to market demands.

The Solution: To effectively scale production capabilities, buyers should consider partnering with a kiss cutting service provider that has experience in handling diverse product specifications. It is advantageous to invest in flexible kiss cutting technologies that allow for quick changeovers between different designs without extensive downtime. Buyers should also maintain an open line of communication with their converters to ensure that they can adapt to changing needs. Incorporating a modular approach to the kiss cutting process can facilitate faster adjustments, allowing companies to respond swiftly to market trends and customer preferences while maintaining high-quality standards.

Strategic Material Selection Guide for kiss cutting

What Are the Key Materials for Kiss Cutting and Their Properties?

Kiss cutting is a versatile manufacturing process that relies heavily on the selection of appropriate materials. The choice of material significantly influences the performance, durability, and cost-effectiveness of the final product. Here, we analyze four common materials used in kiss cutting, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Foam in Kiss Cutting?

Foam is a popular choice for kiss cutting, especially in applications requiring cushioning or insulation. Key properties of foam include its lightweight nature, flexibility, and ability to absorb shock. It typically has a temperature resistance ranging from -40°C to 100°C, making it suitable for various environments.

Pros: Foam is cost-effective and easy to cut, allowing for complex shapes and designs. Its compressibility provides excellent cushioning, making it ideal for packaging and protective applications.

Cons: Foam can degrade over time when exposed to UV light or certain chemicals, limiting its long-term use in outdoor applications. Additionally, it may not be suitable for high-pressure applications.

Impact on Application: Foam is compatible with adhesives, making it ideal for products like gaskets and seals. However, buyers should consider the specific type of foam (e.g., polyurethane, polyethylene) based on their application needs.

Considerations for International Buyers: Compliance with local standards such as ASTM or ISO is crucial. Buyers in regions like Africa and South America should ensure that the foam meets local environmental regulations regarding VOC emissions.

How Does Rubber Perform in Kiss Cutting Applications?

Rubber is another common material used in kiss cutting, known for its elasticity and durability. It can withstand a wide temperature range, typically from -30°C to 120°C, and offers excellent resistance to wear and tear.

Pros: Rubber gaskets and seals produced through kiss cutting are highly effective in preventing leaks. The material’s flexibility allows it to conform to uneven surfaces, enhancing its sealing capabilities.

Illustrative image related to kiss cutting

Cons: The cost of high-quality rubber can be significant, making it less suitable for low-budget projects. Additionally, rubber can be sensitive to certain chemicals, which may limit its application in specific industries.

Impact on Application: Rubber is often used in automotive and industrial applications where sealing is critical. Buyers must ensure compatibility with the specific fluids or gases involved in their applications.

Considerations for International Buyers: Compliance with international standards such as ASTM D2000 is essential for rubber products. Buyers should also consider the sourcing of rubber, as sustainable practices are increasingly demanded in markets across Europe and the Middle East.

What Are the Advantages of Using Adhesive Tapes in Kiss Cutting?

Adhesive tapes, particularly pressure-sensitive tapes, are frequently used in kiss cutting for applications like labels and stickers. These tapes feature a backing material coated with adhesive, allowing for easy application.

Pros: The primary advantage of adhesive tapes is their ease of use and versatility. They can be applied to various surfaces without the need for additional adhesives, making them ideal for quick applications.

Cons: Adhesive tapes may not perform well in extreme temperatures or high-stress environments, leading to potential failure in critical applications. Additionally, the lifespan of adhesive tapes can be limited compared to other materials.

Illustrative image related to kiss cutting

Impact on Application: Adhesive tapes are suitable for temporary applications, such as promotional stickers or temporary labels. However, they may not be ideal for long-term or heavy-duty applications.

Considerations for International Buyers: Buyers should ensure that the adhesive tapes comply with local standards, such as JIS in Japan or DIN in Germany. Variations in adhesive formulations can also affect performance, so understanding local preferences is crucial.

How Does Paper Perform as a Backing Material in Kiss Cutting?

Paper is often used as a backing material in kiss cutting, particularly for products like stickers and labels. It is lightweight and can be easily printed on, making it a popular choice.

Illustrative image related to kiss cutting

Pros: Paper is cost-effective and readily available in various grades and finishes, allowing for customization. It is also easy to kiss cut, providing clean edges and precise shapes.

Cons: Paper is susceptible to moisture and may not be suitable for outdoor applications. Its durability is limited compared to other materials, which can affect the longevity of the final product.

Impact on Application: Paper is ideal for indoor applications, such as packaging and promotional materials. However, buyers should consider the environmental impact of paper sourcing and disposal.

Considerations for International Buyers: Compliance with environmental regulations, such as those set by the Forest Stewardship Council (FSC), is essential. Buyers in regions like Africa and South America should also consider local paper quality standards.

Summary Table of Material Selection for Kiss Cutting

| Material | Typical Use Case for kiss cutting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Foam | Packaging, cushioning | Lightweight and flexible | Degrades under UV exposure | Low |

| Rubber | Gaskets, seals | Excellent sealing capabilities | Sensitive to chemicals | High |

| Adhesive Tapes | Labels, stickers | Easy application | Limited lifespan in extreme conditions | Medium |

| Paper | Stickers, promotional materials | Cost-effective and customizable | Susceptible to moisture | Low |

This strategic material selection guide provides insights into the most common materials used in kiss cutting, helping international B2B buyers make informed decisions tailored to their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for kiss cutting

Kiss cutting is a specialized manufacturing process that requires careful attention to detail and quality assurance. For B2B buyers looking to understand this process, it’s essential to grasp the typical manufacturing stages, quality control measures, and how to verify supplier practices.

What Are the Main Stages in the Kiss Cutting Manufacturing Process?

The kiss cutting process involves several key stages, each critical for producing high-quality products. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

Material preparation is the first step in the kiss cutting process. The choice of raw materials—such as foam, rubber, or adhesive films—plays a vital role in the final product’s performance. Suppliers must ensure that materials meet specific standards and are free from defects. This may involve sourcing materials from certified vendors and conducting preliminary inspections to confirm compliance with specifications.

2. Forming

Once materials are prepared, they are layered appropriately for the kiss cutting process. The raw material is placed on a backing layer, typically made of paper or foil. This setup is then fed into a kiss cutting press, where a sharp blade cuts through the material without penetrating the backing. The precision of the blade and the pressure applied are crucial to achieving accurate cuts that maintain the integrity of the backing layer.

Illustrative image related to kiss cutting

3. Assembly

In some cases, kiss cutting may involve the assembly of multiple components. For example, manufacturers might combine several kiss-cut products onto a single backing sheet for ease of transportation and application. This stage requires meticulous planning to ensure that all components fit together correctly and that the final assembly meets customer specifications.

4. Finishing

The finishing stage involves quality checks and any necessary post-processing treatments. This can include trimming excess material, applying protective coatings, or packaging the final product for shipment. Effective finishing ensures that products are not only functional but also visually appealing, which is particularly important for consumer-facing applications.

How Is Quality Assurance Implemented in Kiss Cutting?

Quality assurance is critical in the kiss cutting manufacturing process. It ensures that products meet international standards and customer expectations. Here are some key components of a robust quality assurance framework.

What International Standards Are Relevant for Kiss Cutting?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring consistency and reliability in manufacturing processes. Compliance with these standards demonstrates a commitment to quality and can enhance a supplier’s credibility in the global marketplace.

Illustrative image related to kiss cutting

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in Europe or API standards for applications in the oil and gas sector may also be relevant. These certifications help B2B buyers ensure that products meet specific regulatory requirements, which can vary by region.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are essential for maintaining product integrity throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive at the facility. It ensures that materials meet specified criteria before production begins.

-

In-Process Quality Control (IPQC): During the kiss cutting process, regular inspections are conducted to monitor the quality of cuts and ensure adherence to specifications. This may involve real-time adjustments to machinery or processes as needed.

-

Final Quality Control (FQC): After production, finished products undergo a final inspection to verify that they meet all quality standards before being shipped to customers.

What Testing Methods Are Commonly Used in Kiss Cutting Quality Control?

Various testing methods are employed to ensure the quality of kiss-cut products. These may include:

-

Adhesion Testing: Evaluating the bond strength of adhesive materials to ensure proper performance.

-

Dimensional Inspection: Measuring products to confirm they meet specified dimensions and tolerances.

-

Performance Testing: Assessing the functional capabilities of products, such as peel strength and durability under stress.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring the reliability of kiss-cut products. Here are some effective strategies:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their quality management systems and manufacturing processes. This can help buyers assess compliance with international standards and industry-specific certifications.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including records of inspections and testing results. Reviewing these reports can help buyers gauge the supplier’s commitment to quality.

-

Engage Third-Party Inspection Services: Utilizing third-party inspectors can provide an unbiased evaluation of a supplier’s quality assurance practices. This can be particularly valuable for B2B buyers operating in regions where local regulations may differ from international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Regulatory requirements may differ significantly between countries, affecting how quality assurance is managed.

Buyers should ensure that suppliers are familiar with the regulations applicable in their home countries, as non-compliance can lead to significant legal and financial repercussions. Additionally, language barriers and cultural differences may impact communication regarding quality expectations. Establishing clear lines of communication and setting mutual expectations at the outset can help mitigate these issues.

Conclusion

Understanding the manufacturing processes and quality assurance measures involved in kiss cutting is essential for B2B buyers looking to source high-quality products. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices and international standards, buyers can ensure they select reliable suppliers. Verifying supplier practices through audits, quality reports, and third-party inspections will further enhance confidence in the sourcing process, leading to successful business partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kiss cutting’

In the dynamic landscape of B2B manufacturing, kiss cutting serves as an essential technique for producing products like stickers, gaskets, and other adhesive components efficiently. This guide aims to provide a structured approach for international buyers seeking to source kiss cutting services, ensuring they make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, clearly outline the technical specifications for your kiss-cut products. This includes dimensions, materials, adhesive types, and any specific design requirements. A well-defined specification will not only streamline your communication with potential suppliers but also ensure that the final product meets your quality standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in kiss cutting. Utilize online directories, industry associations, and trade shows to compile a list of manufacturers. Pay attention to their experience in the industry and their ability to handle your specific materials and production volumes.

- Look for suppliers with a proven track record in your region, as they may better understand local market demands and logistics.

- Consider suppliers who offer additional services, such as custom design and prototyping, to simplify your procurement process.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of your shortlisted suppliers by requesting detailed information about their kiss cutting processes. This should include the types of materials they can work with, the technology they employ, and their production capacity. Understanding these elements is crucial for ensuring that they can meet your requirements.

Illustrative image related to kiss cutting

- Inquire about the precision of their cutting techniques and whether they can accommodate intricate designs.

- Ask about lead times and flexibility in scaling production up or down based on your demand.

Step 4: Verify Quality Assurance Practices

Quality assurance is vital in kiss cutting to ensure that the final products meet industry standards and your specifications. Request information about the supplier’s quality control processes, including testing methods and certifications.

- Ensure they have established protocols for inspecting cut parts for defects and consistency.

- Look for suppliers with relevant certifications, such as ISO 9001, which indicate a commitment to quality management.

Step 5: Request Samples

Before making a final decision, request samples of their kiss-cut products. This step allows you to evaluate the quality, precision, and overall suitability of the products for your application.

- Assess how well the samples meet your specifications and whether they perform as expected in real-world conditions.

- Use this opportunity to gauge the supplier’s responsiveness and willingness to collaborate on adjustments if necessary.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to finalize terms and conditions. This includes pricing, payment terms, delivery schedules, and any potential penalties for delays or quality issues.

- Be transparent about your budget and expectations to foster a mutually beneficial relationship.

- Ensure that both parties agree on the terms to avoid misunderstandings in the future.

Step 7: Establish a Communication Plan

Effective communication is key to successful procurement. Establish a clear communication plan that outlines how you will interact with your supplier throughout the production process.

- Specify points of contact for various stages of the project and set regular check-in meetings to address any concerns.

- Utilize project management tools to track progress and ensure alignment on timelines and deliverables.

By following this checklist, B2B buyers can confidently navigate the sourcing process for kiss cutting, ensuring they partner with the right suppliers to meet their manufacturing needs.

Comprehensive Cost and Pricing Analysis for kiss cutting Sourcing

What Are the Key Cost Components in Kiss Cutting Sourcing?

When evaluating the cost structure for kiss cutting services, several components come into play. Key cost elements include:

-

Materials: The choice of materials significantly impacts pricing. Common materials like foam, rubber, and adhesive films vary in cost based on quality and supplier. Specialty materials or those with specific certifications can drive prices higher.

-

Labor: Skilled labor is required to operate kiss cutting machinery and manage production processes. Labor costs can fluctuate based on geographical location and the complexity of the designs being produced.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, rent, and equipment maintenance. Efficient operations can help mitigate overhead costs.

-

Tooling: The creation of custom dies or cutting tools adds to initial setup costs. However, these costs can be amortized over larger production runs, making them less significant per unit in high-volume orders.

-

Quality Control (QC): Ensuring that products meet specified standards incurs additional costs. Implementing rigorous QC processes can prevent costly errors but may increase overall production expenses.

-

Logistics: Transportation costs, including shipping and handling, are critical, especially for international buyers. Factors such as distance, mode of transport, and Incoterms can all influence logistics costs.

-

Margin: Finally, suppliers will include a profit margin in their pricing. This margin can vary widely depending on the supplier’s market positioning and the competitive landscape.

How Do Volume and Customization Affect Pricing?

Volume and Minimum Order Quantities (MOQs) play a pivotal role in determining pricing for kiss cutting services. Generally, higher volumes lead to lower per-unit costs due to economies of scale. Suppliers are often willing to negotiate better terms for larger orders, which is beneficial for buyers planning long-term projects.

Customization is another significant pricing influencer. Complex designs or unique specifications may require more intricate tooling and additional labor, resulting in higher costs. Buyers should clearly communicate their needs to receive accurate quotations and avoid unexpected expenses.

What Are the Quality and Certification Implications on Kiss Cutting Prices?

Quality certifications can substantially impact pricing. Products that require compliance with international standards (e.g., ISO or ASTM) typically incur higher costs due to the rigorous testing and documentation required. Buyers in regions like Africa or South America should consider these factors when evaluating suppliers, as it might affect both the price and the reliability of the products.

What Buyer Tips Can Enhance Cost-Efficiency in Kiss Cutting Sourcing?

-

Negotiate Effectively: Building a strong relationship with suppliers can facilitate better pricing negotiations. Leverage bulk orders or long-term contracts to secure favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with logistics, storage, and potential waste. A lower upfront price may result in higher TCO if quality is compromised.

-

Understand Pricing Nuances for International Transactions: For buyers in Africa, South America, the Middle East, and Europe, it’s crucial to be aware of currency fluctuations and import tariffs, which can affect overall pricing. Utilize Incoterms effectively to clarify responsibilities and costs associated with shipping.

-

Request Detailed Quotes: Ensure that suppliers provide comprehensive breakdowns of costs. This transparency helps identify areas where you might negotiate for better pricing or alternative solutions.

Disclaimer on Pricing Information

Pricing for kiss cutting services is subject to fluctuation based on market conditions, material costs, and supplier pricing strategies. It is advisable for buyers to request updated quotes and conduct market comparisons to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing kiss cutting With Other Solutions

Understanding Alternatives to Kiss Cutting in Manufacturing

In the manufacturing sector, choosing the right cutting technique can significantly influence product quality, production efficiency, and overall costs. While kiss cutting is a popular method for creating products like stickers and pads, other alternatives may offer unique advantages depending on specific operational needs and product requirements. This analysis compares kiss cutting with die cutting and laser cutting, two viable alternatives that serve similar purposes but differ in execution and outcomes.

| Comparison Aspect | Kiss Cutting | Die Cutting | Laser Cutting |

|---|---|---|---|

| Performance | High precision; suitable for layered materials | Excellent for bulk production; versatile | Exceptional detail; complex shapes possible |

| Cost | Moderate initial setup cost; low operational cost | Higher initial setup cost; lower per-unit cost in large runs | High initial cost; variable operational costs depending on complexity |

| Ease of Implementation | Requires specific tooling; relatively straightforward | Requires die creation; setup can be complex | Requires skilled operators; software and maintenance necessary |

| Maintenance | Low maintenance; periodic checks needed | Moderate maintenance; die replacement necessary | Higher maintenance; equipment servicing required |

| Best Use Case | Ideal for stickers, labels, and parts needing easy peel-off | Best for high-volume parts like automotive components | Perfect for intricate designs and materials like metal and acrylic |

Analyzing Die Cutting as an Alternative

Die cutting is a method where a die is used to cut through material layers to create specific shapes. This technique excels in high-volume production scenarios, where the cost per unit decreases as the quantity increases. However, the initial setup cost for die creation can be significant, making it less ideal for smaller runs. Die cutting is excellent for uniform products, such as gaskets or automotive parts, but lacks the flexibility of kiss cutting when it comes to creating products that need to remain on a backing layer.

Exploring Laser Cutting as an Alternative

Laser cutting employs a focused beam of light to cut through various materials, allowing for intricate designs and high precision. This method is particularly advantageous for complex shapes and detailed patterns, making it suitable for applications in industries like electronics and signage. However, the initial investment in laser cutting technology can be quite high, and operational costs can fluctuate based on the complexity of the designs being produced. Additionally, laser cutting requires skilled operators and regular maintenance, which can complicate implementation compared to kiss cutting.

Choosing the Right Solution for Your Needs

When selecting between kiss cutting and its alternatives, it’s essential for B2B buyers to consider specific project requirements, including production volume, material types, and budget constraints. Kiss cutting is best suited for applications needing convenience and easy handling, such as stickers and labels. In contrast, die cutting is preferable for large production runs of uniform parts, while laser cutting is ideal for detailed designs and intricate patterns. Understanding these differences will enable buyers to make informed decisions that align with their manufacturing goals and operational capabilities.

Essential Technical Properties and Trade Terminology for kiss cutting

What Are the Key Technical Properties of Kiss Cutting?

Understanding the essential technical properties of kiss cutting is crucial for B2B buyers involved in manufacturing and product design. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality and type of raw material used for kiss cutting, such as foam, rubber, or adhesives. Each material grade offers unique properties, such as flexibility, durability, and adhesion strength. Selecting the right material grade is vital for ensuring that the final product meets performance requirements and customer expectations.

2. Tolerance

Tolerance in kiss cutting defines the allowable variation in dimensions of the cut parts. It is essential for ensuring that the components fit accurately in their intended applications. Tight tolerances may be necessary for high-precision industries like automotive or electronics, while looser tolerances may suffice for less critical applications. Understanding tolerance requirements helps manufacturers avoid costly rework or product failures.

3. Adhesive Strength

Adhesive strength indicates how well the adhesive backing holds the cut part to its substrate. This property is especially important for products like stickers or labels, where peeling off the backing should be effortless without leaving residue. Evaluating adhesive strength is crucial for ensuring that the end product performs as expected in various environmental conditions.

4. Die Cutting Depth

Die cutting depth refers to how deep the cutting blade penetrates the material layers. In kiss cutting, the blade cuts through the primary material but only “kisses” the backing layer. This depth must be carefully controlled to ensure that the product is easy to peel off while maintaining the integrity of the backing. Understanding die cutting depth is essential for optimizing production efficiency and product usability.

Illustrative image related to kiss cutting

5. Production Speed

Production speed measures how quickly kiss-cut parts can be produced. This is a critical factor for manufacturers needing to meet tight deadlines and high-volume orders. A faster production speed can lead to reduced costs per unit, making it an attractive option for B2B buyers looking to maximize profitability.

6. Material Thickness

Material thickness affects both the kiss cutting process and the final product’s performance. Thicker materials may require adjustments in cutting pressure and depth. Understanding the implications of material thickness can help in making informed decisions about product design and production techniques.

What Are Common Trade Terms in Kiss Cutting?

Familiarity with industry terminology is essential for effective communication in B2B transactions. Here are some common terms relevant to kiss cutting:

Illustrative image related to kiss cutting

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In kiss cutting, OEMs often require customized solutions, making it essential for manufacturers to understand their specifications and quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it affects inventory management and cash flow. Understanding MOQs helps B2B buyers plan their purchases and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing for specific products or services. In kiss cutting, submitting an RFQ allows buyers to compare offers from different manufacturers, ensuring they get the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms is crucial for B2B buyers to clarify shipping costs, risk, and delivery responsibilities associated with kiss-cut products.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. In kiss cutting, lead times can vary based on material availability and production capacity. Buyers need to consider lead times in their planning to ensure timely delivery of products to customers.

By grasping these technical properties and trade terminology, B2B buyers can make informed decisions that enhance their supply chain efficiency and product quality in the kiss cutting process.

Navigating Market Dynamics and Sourcing Trends in the kiss cutting Sector

What Are the Key Market Dynamics and Trends in the Kiss Cutting Sector?

The kiss cutting sector is experiencing significant growth driven by increasing demand for customized products across various industries, including automotive, electronics, and consumer goods. The global market is expanding as international B2B buyers seek innovative solutions that enhance efficiency and reduce waste. Notably, regions such as Africa, South America, the Middle East, and Europe are witnessing a surge in demand for kiss-cut products, particularly in manufacturing and packaging. The trend towards personalization and unique branding is propelling businesses to adopt kiss cutting methods to create custom shapes and designs that cater to specific customer needs.

Emerging B2B technologies, such as advanced die-cutting machinery and automation, are reshaping the kiss cutting landscape. Companies are increasingly investing in state-of-the-art equipment that allows for precise cutting with minimal material waste. Additionally, digital transformation is enabling businesses to streamline their sourcing processes, optimize inventory management, and enhance communication with suppliers. This trend is particularly pronounced in regions like Nigeria and Brazil, where local manufacturers are adopting digital platforms to connect with international suppliers and improve their operational efficiency.

Illustrative image related to kiss cutting

How Is Sustainability and Ethical Sourcing Reshaping the Kiss Cutting Industry?

Sustainability has become a critical concern for international B2B buyers, pushing companies in the kiss cutting sector to adopt more environmentally friendly practices. The environmental impact of manufacturing processes, including waste generation and resource consumption, is prompting buyers to prioritize suppliers that demonstrate a commitment to sustainability. This includes sourcing materials that are recyclable or biodegradable, thereby reducing the overall carbon footprint of kiss-cut products.

Ethical sourcing is equally important, as buyers are increasingly aware of the social implications of their supply chains. Ensuring that suppliers adhere to fair labor practices and responsible sourcing standards is essential for building trust and maintaining brand integrity. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable forestry are becoming vital for businesses looking to enhance their credibility in the market. By choosing suppliers with these certifications, B2B buyers can ensure that their kiss-cut products align with their sustainability goals and resonate with environmentally conscious consumers.

How Has the Kiss Cutting Process Evolved Over Time?

The kiss cutting process has evolved significantly from its early applications in the production of simple labels and stickers to a sophisticated manufacturing technique used across various industries. Initially, kiss cutting was primarily utilized for low-stress applications; however, advancements in technology have expanded its capabilities. Today, kiss cutting is employed to create intricate designs and multi-layered products, making it a preferred choice for businesses seeking versatility and efficiency.

The introduction of automated and digital cutting technologies has further transformed the kiss cutting landscape, allowing manufacturers to achieve higher precision and faster production times. This evolution has not only improved the quality of kiss-cut products but also enabled businesses to respond more effectively to market demands and customization requests. As the industry continues to innovate, international B2B buyers can expect even more advanced solutions that enhance operational efficiency and product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of kiss cutting

-

How do I choose the right kiss cutting supplier for my business needs?

Selecting the right kiss cutting supplier involves several critical steps. First, assess their expertise in handling materials relevant to your project, such as foam or rubber. Request samples to evaluate their cutting precision and quality. Additionally, check their certifications, customer reviews, and industry experience to ensure reliability. It’s also beneficial to discuss their ability to meet your specific requirements, including customization options, turnaround times, and their capacity to handle international orders. -

What is the minimum order quantity (MOQ) for kiss cutting services?

Minimum order quantities for kiss cutting services can vary significantly by supplier and product type. Typically, MOQs may range from a few hundred to several thousand units, depending on the complexity of the design and the materials used. When negotiating with suppliers, clarify your needs and discuss potential flexibility in MOQs, especially if you’re a smaller business or testing a new product line. Some suppliers may offer lower MOQs for initial orders or prototypes. -

What are the most common applications for kiss cutting?

Kiss cutting is commonly used for producing items such as stickers, labels, felt pads, and protective films. It’s particularly advantageous when products need to be easily removed from a backing layer, facilitating user convenience and enhancing packaging efficiency. Industries such as automotive, electronics, and consumer goods frequently utilize kiss cutting for applications that require precision and ease of application. Understanding your specific application will help you communicate effectively with suppliers to meet your needs. -

How do I ensure quality assurance in kiss cutting production?

To ensure quality assurance in kiss cutting production, establish clear specifications and standards with your supplier before production begins. Request detailed documentation of their quality control processes, including inspection protocols and testing methods. Regular communication and on-site visits can also help maintain quality standards. Additionally, consider implementing a third-party quality inspection service, especially for international shipments, to verify that the final products meet your specifications before acceptance. -

What payment terms should I expect when sourcing kiss cutting services?

Payment terms for kiss cutting services can vary widely between suppliers and depend on factors such as order size and the buyer’s relationship with the supplier. Common arrangements include partial payment upfront, with the balance due upon delivery or after inspection. Some suppliers may offer net 30 or net 60 terms for established customers. Always clarify payment terms in your initial discussions and ensure they are documented in the contract to avoid misunderstandings. -

What are the shipping and logistics considerations for international orders of kiss-cut products?

When ordering kiss-cut products internationally, consider factors such as shipping methods, delivery times, and customs regulations. Work with suppliers who have experience in international logistics and can provide guidance on shipping options, including air freight for urgent deliveries or sea freight for cost-effective solutions. Ensure that all necessary documentation, such as invoices and customs declarations, is prepared to facilitate smooth customs clearance. Discuss with your supplier whether they offer drop shipping or direct shipping to your location. -

How can I customize kiss-cut products for my specific needs?

Customization options for kiss-cut products typically include size, shape, material, adhesive type, and packaging. When discussing your project with suppliers, provide detailed specifications and any design files to ensure accurate production. Many suppliers have design teams that can assist you in creating custom solutions that meet your requirements. It’s also beneficial to inquire about their capabilities for small runs or prototypes to test your designs before committing to larger orders. -

What factors should I consider regarding the sustainability of kiss-cut materials?

When sourcing kiss-cut materials, consider the environmental impact of the materials used, including their recyclability and the sustainability of their production processes. Ask suppliers about their sourcing practices and whether they offer eco-friendly options, such as biodegradable adhesives or recyclable backing materials. Additionally, inquire about their waste management practices during production, as responsible suppliers will have measures in place to minimize waste and reduce their overall carbon footprint.

Top 7 Kiss Cutting Manufacturers & Suppliers List

1. IQS Directory – Kiss Cutting Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

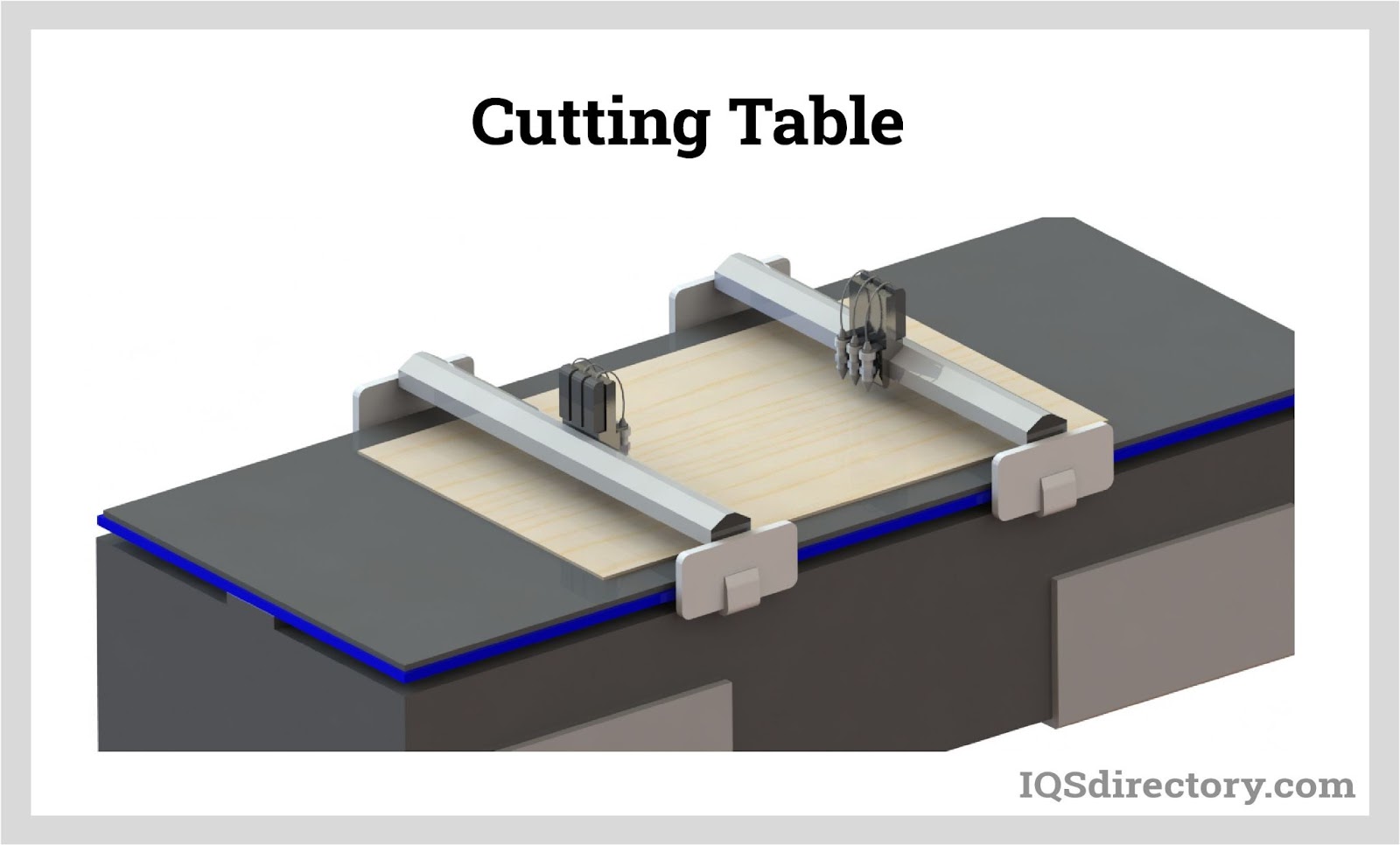

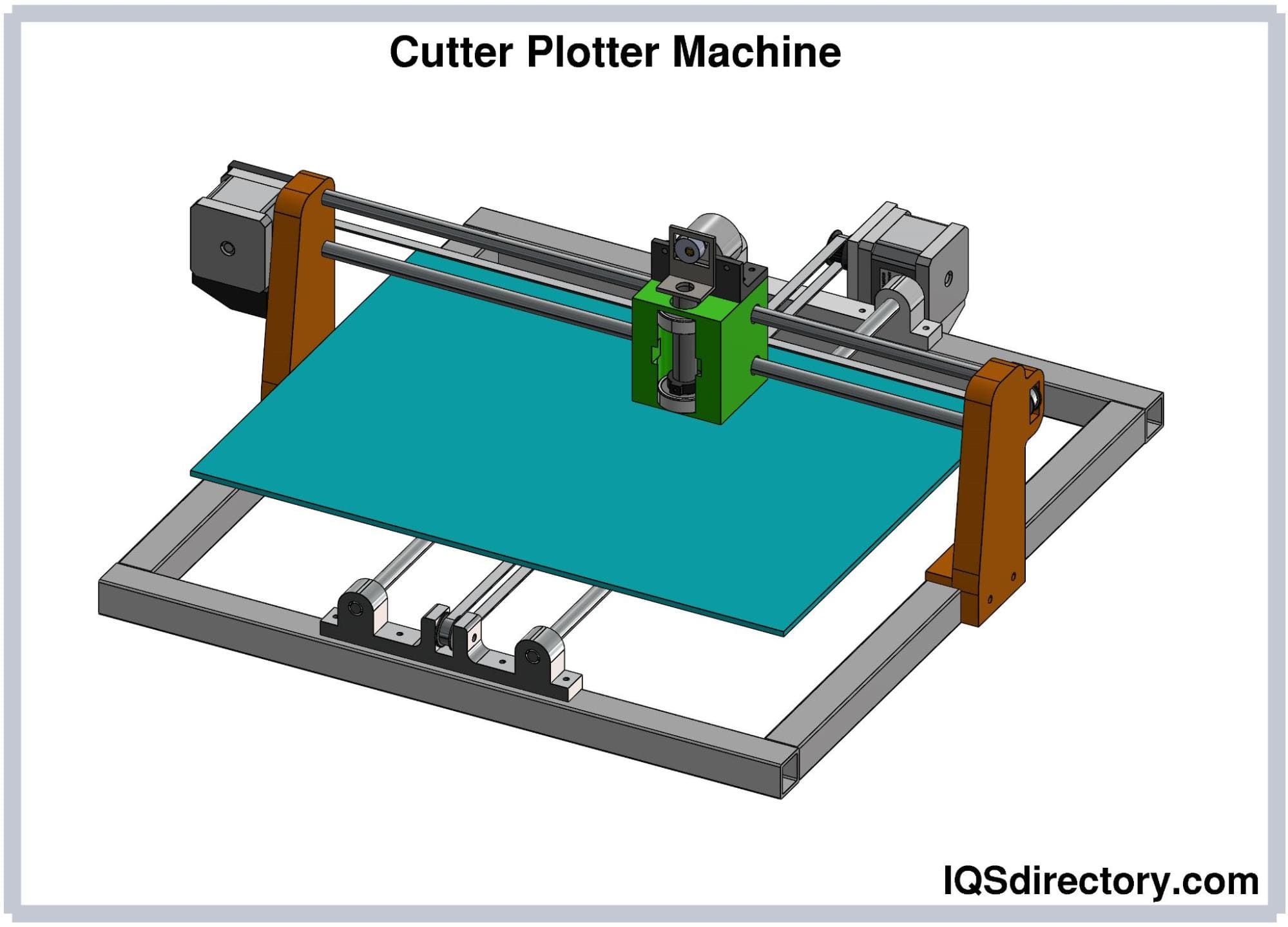

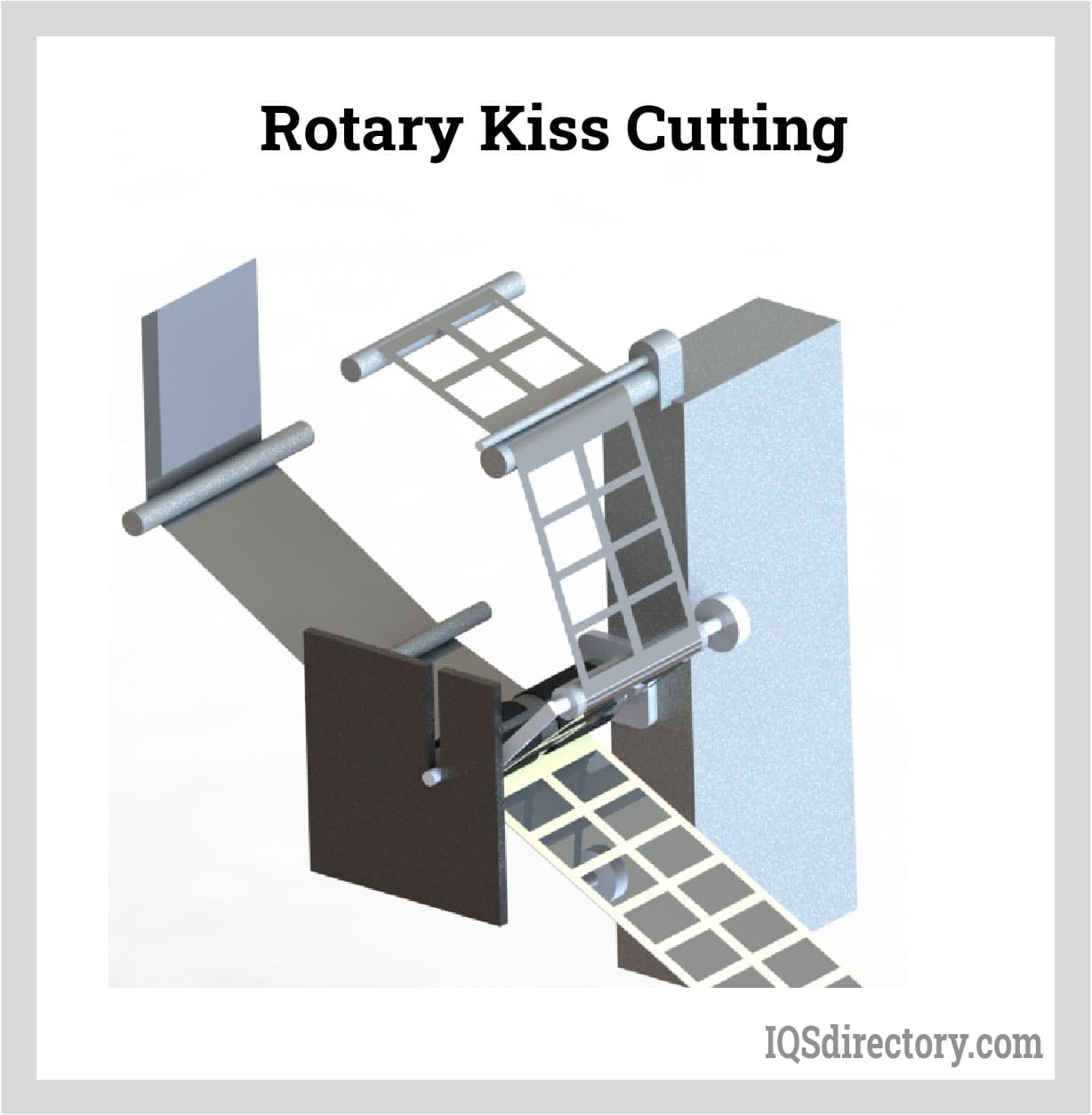

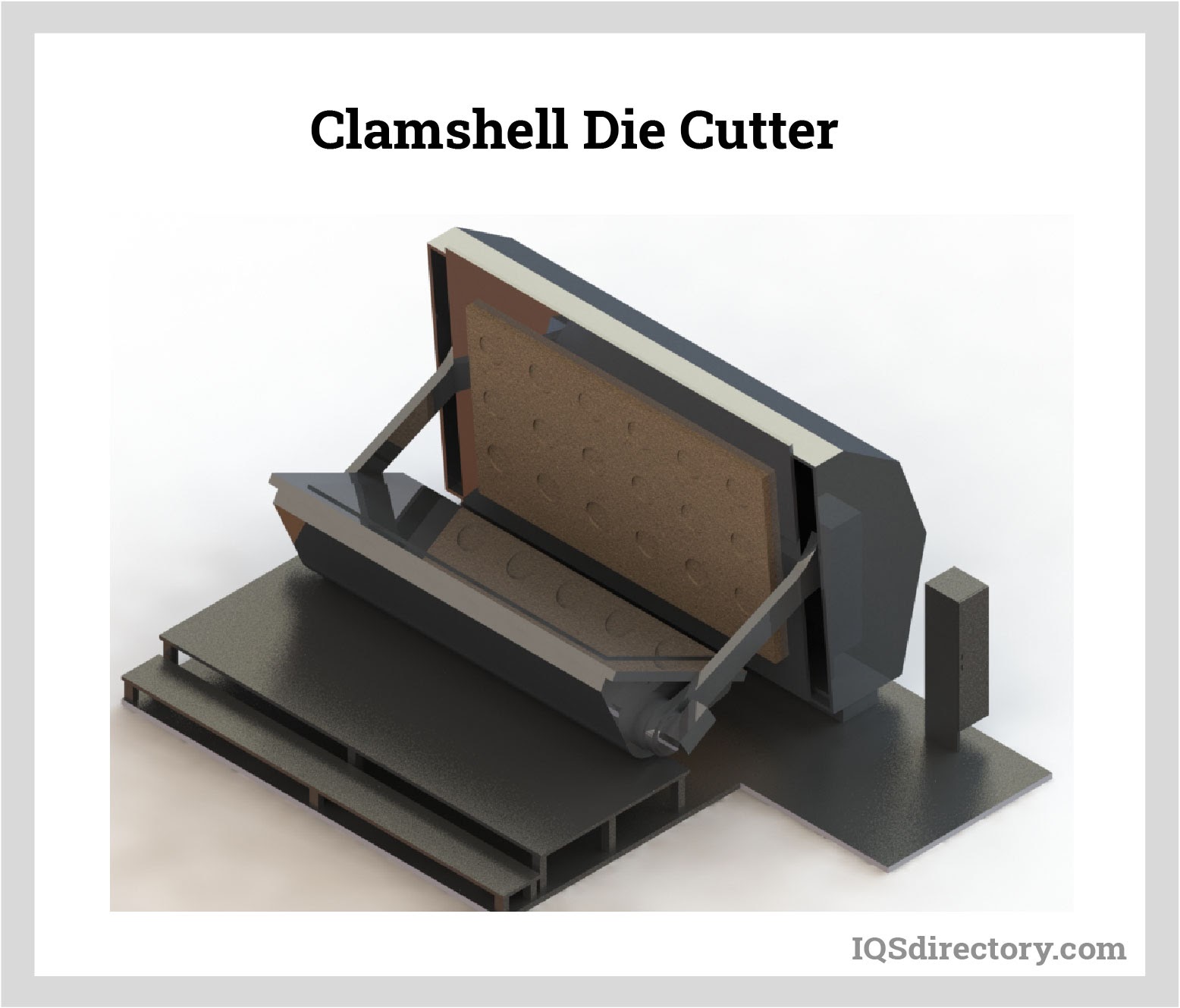

Introduction: Kiss cutting is a die cutting process that slices through the top layers of a material while leaving the bottom layer intact. It is used to create custom gaskets, seals, pressure-sensitive adhesive labels, and protective pads. Kiss cutting machines include rotary die cutters, flatbed die cutters, laser die cutters, thermal die cutters, CNC routers, cutting tables, plotter cutters, hydraulic and me…

2. Kongsberg – Kiss Cutting Solutions

Domain: kongsbergsystems.com

Registered: 2020 (5 years)

Introduction: Kiss cutting is a method used for cutting materials such as vinyl, stickers, decals, car wrappers, window graphics, and labels. Kongsberg cutting tables can be equipped with various tools for applications in signage, packaging, and display production. The Kongsberg Kiss Cut Knife Tool is specifically designed for kiss cutting adhesive vinyl and foils, ensuring that only the top film is cut while k…

3. Silhouette – Cameo 4

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user is considering purchasing a Silhouette Cameo 4 for making die cut and kiss cut stickers, as they have been frustrated with their Cricut Explore Air 2. They are seeking recommendations and experiences from others regarding the Cameo 4 specifically for kiss cut stickers. The user is open to trying any brand except Cricut due to poor customer service experiences.

4. PGC Solutions – Kiss Cutting Expertise

Domain: pgc-solutions.com

Registered: 2010 (15 years)

Introduction: Kiss cutting is a specialized technique that creates a shallow incision in materials using a die or laser method, only penetrating the top layer of the material while leaving the pressure-sensitive adhesive liner intact. It is effective for closed-cell sponges, foams, and adhesive-backed materials like paper and foil. Advantages include improved assembly efficiency, exceptional precision and stabi…

5. GF Cole – Kiss Cutting Solutions

Domain: gfcole.com

Registered: 1998 (27 years)

Introduction: Kiss cutting is a process where a sheet or roll of laminated material is cut through while only touching the removable liner. It can be accomplished using laser, rotary, or flatbed presses. The finished parts remain on a removable liner, making them easy to peel off and use. Parts can be provided on rolls or in sheet form, with or without the web removed. Kiss cutting is beneficial for part handli…

6. Glowforge – Kiss Cutting Laser Cutter

Domain: community.glowforge.com

Registered: 2014 (11 years)

Introduction: The Glowforge laser cutter is capable of kiss cutting, which involves cutting through decal material without cutting into the backing or carrier sheet. Users can manually adjust power and speed settings to achieve the desired cut depth, which is essential for successful kiss cutting. The machine comes with presets for ProofGrade materials, but full manual controls are available for custom settings…

7. MFG Sup – Guidolin Girotto Kiss Cutting Presses

Domain: mfgsup.com

Registered: 1997 (28 years)

Introduction: Guidolin Girotto Kiss Cutting Presses are high-speed, mechanical flat-bed die cutting presses designed for a variety of non-metallic flexible materials. They can kiss-cut and totally cut materials such as adhesive tapes (3M, Tesa, Avery, Lohmann, Scapa), VHB, foam materials, plastics, felts, abrasives, filters, Velcro, rubber, gaskets, labels, and more. Key sectors served include packaging, automo…

Strategic Sourcing Conclusion and Outlook for kiss cutting

How Can Strategic Sourcing Enhance Your Kiss Cutting Operations?

In summary, kiss cutting presents a versatile and efficient method for producing customized products, such as stickers and pads, while streamlining logistics and improving usability for end-users. The strategic sourcing of kiss cutting services enables businesses to leverage high-quality materials and advanced manufacturing techniques, ensuring that products meet specific industry standards and customer expectations. By partnering with experienced converters, international buyers can enhance their product offerings and optimize supply chain management.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for innovative and reliable manufacturing solutions will only grow. Embracing kiss cutting not only simplifies the production process but also enhances customer satisfaction through convenience and ease of use.

Now is the time for B2B buyers to explore strategic partnerships with kiss cutting specialists who can provide tailored solutions to meet diverse needs. By investing in these capabilities, companies can position themselves for future growth and success in an increasingly competitive landscape. Engage with experienced suppliers today to unlock the full potential of kiss cutting for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.