Air Solenoid: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for air solenoid

In today’s fast-paced industrial environment, sourcing the right air solenoid valves can be a daunting task for B2B buyers, especially those operating across diverse global markets. With a myriad of options available, ranging from pneumatic applications to fluid control systems, understanding the specific requirements of your application is crucial. This guide aims to simplify the process by providing a comprehensive overview of air solenoid valves, including various types, applications, and essential factors such as voltage, port sizes, and materials.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Nigeria—face unique challenges when it comes to supplier vetting and cost considerations. This guide empowers you to navigate these complexities with confidence, offering insights into reliable suppliers and strategies to optimize your procurement process. By equipping you with actionable information, this resource not only streamlines your decision-making but also enhances your operational efficiency and competitiveness in the global market.

Whether you are looking to improve your pneumatic systems, enhance fluid control, or simply understand the nuances of air solenoid technology, this guide is designed to provide the clarity and knowledge you need to make informed purchasing decisions that align with your business objectives.

Understanding air solenoid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Acting Solenoid Valve | Operates directly on the valve seat, suitable for low-pressure applications. | HVAC systems, irrigation, water control | Pros: Quick response time; Cons: Limited flow capacity. |

| Pilot Operated Solenoid Valve | Uses system pressure to assist in operation, ideal for high flow rates. | Industrial automation, pneumatic systems | Pros: High flow capability; Cons: Requires higher pressure to operate. |

| 2-Way Solenoid Valve | Controls flow in a single direction, available in normally open/closed configurations. | Fluid control in pipelines, gas systems | Pros: Simple design; Cons: Limited to on/off control. |

| 3-Way Solenoid Valve | Manages flow between two outputs, allowing for more complex control. | Air compressors, pneumatic actuators | Pros: Versatile for switching applications; Cons: More complex installation. |

| 4-Way Solenoid Valve | Controls double-acting cylinders, allowing for forward and reverse motion. | Robotics, manufacturing machinery | Pros: Essential for actuator control; Cons: Requires precise installation and setup. |

What are the Characteristics of Direct Acting Solenoid Valves?

Direct acting solenoid valves are designed to operate directly on the valve seat, making them ideal for low-pressure applications. These valves are commonly used in HVAC systems, irrigation, and water control applications. When considering a direct acting solenoid valve, buyers should focus on their quick response time, which is crucial in systems requiring immediate action. However, it’s important to note that they have a limited flow capacity, which may not be suitable for high-demand applications.

How Do Pilot Operated Solenoid Valves Function?

Pilot operated solenoid valves utilize the pressure from the system to assist in their operation, making them highly effective for applications requiring high flow rates. They are typically found in industrial automation and pneumatic systems. When purchasing these valves, businesses should consider their ability to handle larger flows, which can enhance system efficiency. However, they require a higher pressure to function, which may necessitate additional system adjustments.

What are the Applications of 2-Way Solenoid Valves?

2-way solenoid valves are designed to control the flow of fluids in a single direction and are available in normally open or normally closed configurations. These valves find extensive use in fluid control within pipelines and gas systems. Their simple design makes them easy to integrate into existing systems. However, buyers should be aware that their functionality is limited to on/off control, which may not suit more complex fluid management needs.

Why Choose a 3-Way Solenoid Valve?

3-way solenoid valves are versatile components that manage flow between two outputs, facilitating more complex control systems. They are commonly used in air compressors and pneumatic actuators. For B2B buyers, the key advantage of these valves lies in their ability to switch between applications, enhancing operational flexibility. However, their installation can be more complex compared to simpler valve types, requiring careful planning and execution.

What is the Importance of 4-Way Solenoid Valves in Automation?

4-way solenoid valves are critical for controlling double-acting cylinders, allowing for both forward and reverse motion. They are predominantly used in robotics and manufacturing machinery. Buyers should consider these valves essential for actuator control, as they enable precise motion management. However, the need for accurate installation and setup can be a drawback, requiring skilled personnel to ensure optimal performance.

Key Industrial Applications of air solenoid

| Industry/Sector | Specific Application of air solenoid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Control of pneumatic actuators in assembly lines | Increases efficiency and precision in production processes | Voltage compatibility, response time, and durability |

| Automotive | Activation of air suspension systems | Enhances vehicle performance and comfort | Resistance to harsh environments, size, and weight |

| Agriculture | Automation of irrigation systems | Optimizes water usage and reduces labor costs | Compatibility with existing systems and maintenance needs |

| Food & Beverage | Operation of packaging machinery | Ensures product integrity and compliance with safety standards | Hygiene standards, material compatibility, and reliability |

| Oil & Gas | Regulation of gas flow in processing plants | Improves safety and operational efficiency | Material durability, pressure ratings, and sourcing logistics |

How is Air Solenoid Used in Manufacturing, and What Are the Benefits?

In the manufacturing sector, air solenoids are critical for controlling pneumatic actuators used in assembly lines. These valves enable precise control over the movement of machinery, enhancing production efficiency and accuracy. For international buyers, especially in regions like Africa and South America, sourcing solenoids that are compatible with local voltage standards and offer fast response times is crucial. Additionally, durability is essential to withstand the rigors of industrial environments.

What Role Do Air Solenoids Play in Automotive Applications?

In the automotive industry, air solenoids are employed to activate air suspension systems, which adjust the vehicle’s height and comfort level. This capability not only improves ride quality but also contributes to better handling and safety. For buyers in the Middle East and Europe, sourcing solenoids that can endure extreme temperatures and vibrations is vital. Understanding the specific size and weight requirements for installation can further enhance performance.

How Are Air Solenoids Enhancing Agricultural Automation?

In agriculture, air solenoids automate irrigation systems, allowing for precise control of water flow. This automation leads to optimized water usage, reducing costs and labor requirements. For businesses in regions like Nigeria, where water scarcity is a pressing issue, sourcing solenoids that can integrate seamlessly with existing irrigation technology is essential. Buyers should also consider the maintenance requirements and the solenoid’s compatibility with various environmental conditions.

In What Ways Are Air Solenoids Utilized in Food and Beverage Processing?

The food and beverage industry relies on air solenoids to operate packaging machinery, ensuring the integrity and safety of products. These valves help maintain compliance with stringent safety standards while optimizing production processes. For international buyers, especially in Europe, sourcing solenoids that meet hygiene standards and are made from food-grade materials is critical. Reliability and ease of maintenance are additional factors that should influence purchasing decisions.

How Are Air Solenoids Used in Oil and Gas Industries?

In the oil and gas sector, air solenoids regulate gas flow in processing plants, enhancing safety and operational efficiency. These valves play a pivotal role in managing pressure and ensuring the safe transport of materials. For buyers in the Middle East, sourcing solenoids made from materials that can withstand high pressures and corrosive environments is essential. Additionally, understanding the logistics of sourcing and maintaining these components can significantly impact operational success.

3 Common User Pain Points for ‘air solenoid’ & Their Solutions

Scenario 1: Sourcing the Right Air Solenoid for Specific Applications

The Problem: B2B buyers often face the daunting task of selecting the correct air solenoid valve for their specific operational needs. With a plethora of options available, including various sizes, materials, and voltage specifications, buyers can feel overwhelmed. For instance, a manufacturer in Nigeria may require a solenoid that can withstand high humidity and corrosive environments, yet they struggle to identify which product will meet these requirements without incurring excessive costs or delays in delivery.

The Solution: To effectively source the right air solenoid, buyers should begin by conducting a thorough needs assessment that includes understanding the specific environmental conditions and operational demands of their application. Collaborating with suppliers who specialize in solenoid valves can provide valuable insights into product specifications that align with these needs. Additionally, buyers should consider suppliers that offer customization options, allowing them to order valves tailored to their unique conditions. It’s crucial to engage with knowledgeable sales representatives who can recommend products based on real-world performance in similar applications, thus ensuring both compatibility and reliability.

Scenario 2: Maintenance and Longevity of Air Solenoid Valves

The Problem: Many B2B buyers are frustrated by the frequent failure of air solenoid valves in their systems, leading to unplanned downtime and increased maintenance costs. For example, a manufacturing plant in Saudi Arabia may experience solenoid valve failures due to dust and dirt accumulation, which can obstruct the valve’s operation and reduce its lifespan. This not only affects productivity but also strains relationships with customers relying on timely delivery of products.

The Solution: Implementing a proactive maintenance program is essential for extending the life of air solenoid valves. Buyers should invest in regular cleaning and inspection routines that specifically target the areas most prone to contamination, such as the valve body and actuator. Additionally, using filters in conjunction with solenoid valves can help mitigate dirt and debris ingress. It’s also wise to establish a relationship with a supplier that offers technical support and replacement parts, ensuring that any maintenance issues can be resolved quickly. Training maintenance staff on proper handling and troubleshooting of solenoids can further enhance system reliability and reduce downtime.

Scenario 3: Understanding Voltage and Power Requirements

The Problem: Another common pain point arises when B2B buyers are unsure about the voltage and power requirements for their air solenoids. This confusion can lead to purchasing errors, resulting in components that either do not operate correctly or require additional modifications, which can be both costly and time-consuming. For instance, a company in South America might purchase a 24V solenoid for a 12V system, leading to immediate functionality issues.

The Solution: To avoid voltage-related issues, buyers must have a clear understanding of their system’s electrical requirements before making a purchase. It is advisable to consult technical specifications and, if necessary, involve an electrical engineer to ensure compatibility. Buyers should also familiarize themselves with common industry standards for solenoids, including the differences between AC and DC voltage systems. Many suppliers provide voltage compatibility charts or guidance on their websites. Engaging with suppliers that offer comprehensive technical documentation and customer support can also help clarify these specifications. Additionally, consider opting for solenoids that are adaptable to different voltage levels, providing greater flexibility and reducing the risk of future purchasing errors.

Strategic Material Selection Guide for air solenoid

What are the Key Properties of Common Materials Used in Air Solenoids?

When selecting materials for air solenoids, it is essential to consider their properties, performance, and suitability for specific applications. The most common materials include brass, stainless steel, aluminum, and plastic. Each material presents unique characteristics that can significantly impact the solenoid’s functionality and longevity.

How Does Brass Perform in Air Solenoid Applications?

Brass is a popular choice for air solenoids due to its excellent machinability and corrosion resistance. It typically has a good temperature rating, making it suitable for various environments. Brass solenoids can withstand pressures up to 150 psi, which is adequate for many pneumatic applications.

Pros: Brass is durable and offers good thermal conductivity, which can enhance performance in high-temperature applications. It is also relatively cost-effective compared to stainless steel.

Illustrative image related to air solenoid

Cons: While brass resists corrosion well, it can be susceptible to dezincification in certain environments, which may compromise its integrity over time.

Impact on Application: Brass is compatible with air and many non-corrosive fluids, making it a versatile option for various industries, including automotive and manufacturing.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider the availability of brass components in their region, especially in developing markets like Africa and South America.

What Advantages Does Stainless Steel Offer for Air Solenoids?

Stainless steel is known for its superior strength and corrosion resistance, making it an ideal choice for harsh environments. It can handle high-pressure applications, often exceeding 300 psi, and operates effectively in a wide temperature range.

Pros: Stainless steel’s durability and resistance to corrosion make it suitable for applications involving aggressive media, such as chemicals or high humidity.

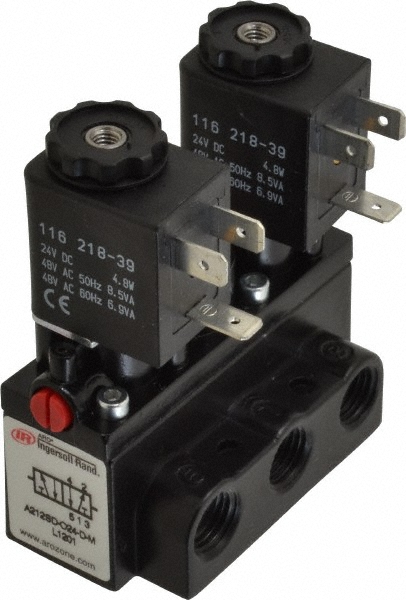

Illustrative image related to air solenoid

Cons: The primary drawback is its higher cost compared to brass and aluminum, which may impact budget-sensitive projects.

Impact on Application: Stainless steel solenoids are particularly effective in the food and beverage industry, pharmaceuticals, and other applications where hygiene and corrosion resistance are critical.

Considerations for International Buyers: Buyers should ensure compliance with food safety regulations and standards, particularly in Europe and the Middle East, where stringent guidelines exist.

How Does Aluminum Compare in Terms of Cost and Performance?

Aluminum is lightweight and offers good corrosion resistance, making it an attractive option for applications where weight is a concern. It typically operates well at pressures up to 150 psi.

Pros: The lightweight nature of aluminum can reduce overall system weight, which is beneficial in mobile applications. It is also less expensive than stainless steel.

Cons: Aluminum is not as strong as brass or stainless steel, which may limit its use in high-pressure applications.

Impact on Application: Aluminum solenoids are commonly used in automotive and aerospace applications, where weight savings are critical.

Considerations for International Buyers: Aluminum components should meet standards such as JIS or ASTM to ensure quality and performance in various environments.

What Role Does Plastic Play in Air Solenoid Design?

Plastic solenoids are often used in low-pressure applications where cost-effectiveness is essential. They are generally rated for pressures up to 100 psi and are resistant to corrosion.

Pros: Plastic solenoids are lightweight, cost-effective, and resistant to many chemicals, making them suitable for various applications.

Cons: They are less durable than metal options and may not perform well in high-temperature environments.

Impact on Application: Plastic solenoids are ideal for applications involving water or air, such as irrigation systems or HVAC systems.

Considerations for International Buyers: Buyers should be aware of the specific chemical compatibility of the plastic used in solenoids and ensure compliance with local regulations.

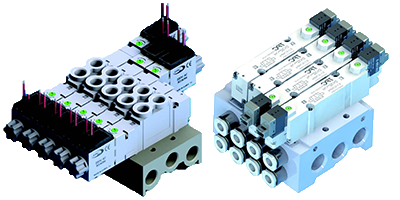

Illustrative image related to air solenoid

Summary Table of Material Selection for Air Solenoids

| Material | Typical Use Case for air solenoid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General pneumatic applications | Good machinability and cost-effective | Susceptible to dezincification | Medium |

| Stainless Steel | Food and beverage, pharmaceuticals | Superior strength and corrosion resistance | Higher cost | High |

| Aluminum | Automotive and aerospace | Lightweight and cost-effective | Limited strength for high-pressure | Medium |

| Plastic | Irrigation and HVAC systems | Lightweight and resistant to chemicals | Lower durability and temperature limits | Low |

By understanding the properties and implications of different materials, international B2B buyers can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air solenoid

What Are the Main Stages of the Manufacturing Process for Air Solenoids?

The manufacturing process for air solenoids involves several critical stages that ensure the final product meets performance and quality standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials, such as brass, stainless steel, and engineering plastics, which are essential for durability and functionality. Suppliers often undergo rigorous selection processes to ensure that materials meet specific mechanical and chemical properties. Material quality directly affects the solenoid’s performance, particularly in demanding environments.

-

Forming: This stage encompasses various techniques such as machining, stamping, and molding. Machining is often used for creating precise components like the valve body, while stamping might be employed for producing complex shapes. Molding is particularly relevant for producing plastic components, where high-volume production is required. The choice of forming technique impacts the solenoid’s performance characteristics, such as response time and operational efficiency.

-

Assembly: Once the components are formed, they are meticulously assembled. This process can be manual or automated, depending on the production scale. Key components, including the coil, armature, and housing, are brought together in a clean environment to avoid contamination. Precision during assembly is crucial to ensure that the solenoid operates correctly and reliably.

-

Finishing: The final stage involves surface treatments, such as anodizing, plating, or painting, which enhance the solenoid’s resistance to corrosion and wear. This step also includes any necessary testing to ensure the solenoid meets operational specifications and aesthetic requirements.

How Is Quality Assurance Implemented in Air Solenoid Manufacturing?

Quality assurance (QA) in air solenoid manufacturing is vital for ensuring that products meet international standards and customer expectations. This involves adherence to relevant international standards such as ISO 9001, as well as industry-specific certifications like CE and API.

-

International Standards Compliance: ISO 9001 is a widely recognized quality management standard that emphasizes a process-oriented approach. Manufacturers often adopt this standard to enhance operational efficiency and customer satisfaction. Compliance with CE marking is crucial for products sold in the European market, indicating conformity with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: The QA process includes several critical checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of work in progress. This helps identify and rectify defects early in the production cycle.

– Final Quality Control (FQC): After assembly and finishing, the final product undergoes comprehensive testing to ensure it meets all operational and safety requirements before being dispatched. -

Common Testing Methods: Various testing methods are employed to verify the solenoid’s performance. These include:

– Electrical Testing: Ensures that the solenoid operates at the required voltage and current specifications.

– Leak Testing: Identifies any leaks in the valve mechanism, which could compromise functionality.

– Functional Testing: Simulates operational conditions to assess performance metrics such as response time and operational reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for mitigating risk and ensuring product quality. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality management systems, and compliance with international standards. This firsthand observation is invaluable for assessing a supplier’s capabilities.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, including IQC, IPQC, and FQC results. Reports should also include certifications and compliance documentation, ensuring transparency in quality practices.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These services can conduct audits, testing, and certification processes on behalf of the buyer.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances that can affect procurement decisions:

-

Understanding Regional Standards: Different regions may have specific certification requirements. For instance, products sold in the EU must comply with CE marking, while those in the Middle East might need to adhere to Gulf Standards (GSO). Buyers should familiarize themselves with these regional standards to ensure compliance.

-

Cultural and Regulatory Differences: Variations in manufacturing practices and regulatory environments can influence quality. For example, manufacturing processes in Europe may emphasize stricter environmental regulations compared to those in other regions. Understanding these differences can help buyers make informed decisions when selecting suppliers.

-

Building Relationships with Suppliers: Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations and compliance issues. This can also lead to improved transparency and responsiveness in addressing any quality concerns that arise.

In conclusion, the manufacturing processes and quality assurance for air solenoids are intricate and critical to ensuring high-quality products. By understanding these processes, B2B buyers can make informed decisions and establish partnerships that meet their operational needs and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air solenoid’

When sourcing air solenoids, it is essential for B2B buyers to navigate the process effectively to ensure they select the right products for their applications. This checklist provides a systematic approach to help you make informed decisions and procure high-quality solenoid valves that meet your operational needs.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your air solenoid application. Consider factors such as port size, voltage (12V, 24V, or 110V), and whether you need normally open or normally closed valves. Accurate specifications will help you narrow down your options and ensure compatibility with your existing systems.

- Port Size: Determine the diameter required for your system to maintain optimal airflow.

- Voltage Type: Identify if your system operates on AC or DC power to select the appropriate solenoid.

Step 2: Research Industry Standards and Compliance

Ensure that the solenoids you are considering comply with relevant industry standards and certifications. This is vital for maintaining safety and reliability in your operations, particularly if you are in regulated industries such as automotive or food processing.

- Certifications: Look for products that meet ISO, CE, or UL standards.

- Material Compliance: Check if the materials used are suitable for your application, especially in terms of corrosion resistance and durability.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly assess potential suppliers. Request company profiles, case studies, and references from other buyers in your industry or region. This due diligence will help you gauge their reliability and the quality of their products.

- Supplier Reputation: Research online reviews and testimonials to understand the experiences of other customers.

- Product Range: Ensure the supplier offers a variety of solenoid options to meet your diverse needs.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, ask for samples of the air solenoids you are interested in. Testing these samples in your actual system will allow you to evaluate their performance and compatibility before making a larger investment.

- Performance Testing: Check for responsiveness, durability, and any leakage issues.

- Compatibility Testing: Ensure that the solenoid integrates seamlessly with your existing equipment.

Step 5: Compare Pricing and Terms of Sale

Gather detailed quotations from your shortlisted suppliers and compare them not only on price but also on the terms of sale. Factors such as bulk discounts, payment terms, and shipping costs can significantly affect your overall procurement budget.

- Total Cost of Ownership: Consider long-term costs including maintenance and potential failure rates.

- Warranty and Support: Evaluate the warranty period and the availability of customer support post-purchase.

Step 6: Finalize Order and Confirm Delivery Schedules

After selecting the supplier that best meets your criteria, finalize your order. Confirm delivery schedules to ensure that the solenoids arrive when needed to avoid disruptions in your operations.

- Lead Time: Understand the expected production and shipping times.

- Logistics Coordination: Ensure that logistics are in place for a smooth delivery process.

Step 7: Establish a Relationship for Future Procurement

Building a long-term relationship with your chosen supplier can provide advantages for future purchases. Regular communication can lead to better pricing, priority service, and insights into new product offerings.

- Regular Reviews: Schedule periodic evaluations of the supplier’s performance.

- Feedback Mechanism: Provide feedback on products to foster improvement and innovation.

By following this checklist, B2B buyers can confidently navigate the procurement of air solenoids, ensuring they select products that enhance operational efficiency and reliability.

Comprehensive Cost and Pricing Analysis for air solenoid Sourcing

What Are the Key Cost Components in Air Solenoid Sourcing?

When analyzing the costs associated with sourcing air solenoids, several key components come into play. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Materials represent a significant portion of the cost, varying based on the type of solenoid (e.g., brass, stainless steel, or plastic) and the specific components required. For instance, high-quality materials may increase the initial cost but can lead to better durability and performance, ultimately affecting the total cost of ownership (TCO).

Labor costs can fluctuate based on the region of production and the complexity of the solenoid’s design. Countries with lower labor costs might offer competitive pricing, but this can sometimes compromise quality.

Illustrative image related to air solenoid

Manufacturing overhead includes expenses related to facilities, utilities, and equipment, which are essential for producing reliable air solenoids. Tooling costs also contribute to the overall price, especially for custom designs that require specialized molds or machines.

Quality control is crucial in ensuring that the solenoids meet industry standards. Stricter QC processes can increase costs, but they are vital for minimizing defects and enhancing product reliability.

Logistics costs encompass shipping, warehousing, and distribution expenses, which can vary significantly depending on the supplier’s location and the buyer’s destination. Finally, the supplier margin is added to cover their operational costs and profit, which can vary widely between manufacturers.

How Do Price Influencers Affect Air Solenoid Costs?

Various factors influence the pricing of air solenoids, including order volume (MOQ), specifications/customization, materials, quality certifications, supplier factors, and Incoterms.

Illustrative image related to air solenoid

Higher order volumes typically lead to better pricing due to economies of scale. Buyers should consider negotiating for lower prices by placing larger orders or entering long-term contracts with suppliers.

Specifications and customization can significantly affect costs. Custom solutions, while tailored to specific needs, often come at a premium. Buyers should weigh the benefits of customized solenoids against their budget constraints.

The quality and certifications of the solenoids can also impact pricing. Products that meet international standards may command higher prices but can provide assurance regarding performance and safety, particularly in regulated industries.

Illustrative image related to air solenoid

Supplier factors, such as reputation and location, can also influence costs. Established suppliers with a track record of reliability may charge more but can offer better service and support.

Finally, understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total landed cost.

What Are the Best Buyer Tips for Cost-Efficient Air Solenoid Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency in air solenoid sourcing.

Negotiation is key. Buyers should leverage their purchasing power to negotiate better terms, especially when dealing with multiple suppliers. Establishing long-term relationships can also yield favorable pricing and terms.

Understanding the total cost of ownership (TCO) is essential. This includes not just the purchase price but also maintenance, operational costs, and potential downtime. Investing in higher-quality solenoids may lead to lower TCO in the long run, despite a higher upfront cost.

Buyers should also be aware of the pricing nuances that come with international sourcing. Currency fluctuations, tariffs, and shipping costs can affect the final price. It is advisable to conduct a thorough cost analysis, factoring in these elements to avoid unexpected expenses.

Lastly, maintaining clear communication with suppliers about expectations and requirements can help avoid costly misunderstandings and ensure that the final products meet the buyer’s needs.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for air solenoids vary widely, understanding the comprehensive cost structure and pricing influences is crucial for effective sourcing. By focusing on key cost components, recognizing price influencers, and employing strategic buyer tips, international B2B buyers can make informed decisions that align with their operational goals and budgetary constraints.

Alternatives Analysis: Comparing air solenoid With Other Solutions

When evaluating the best solutions for fluid control in industrial applications, it’s essential to consider alternatives to air solenoids. Each option comes with its unique benefits and drawbacks, making it crucial for B2B buyers to understand their choices. This analysis compares air solenoids with two viable alternatives: electric solenoid valves and pneumatic actuators.

| Comparison Aspect | Air Solenoid | Electric Solenoid Valves | Pneumatic Actuators |

|---|---|---|---|

| Performance | Fast response, precise control of airflow. | High precision; suitable for gas, water, and air. | Strong force output; suitable for heavy loads. |

| Cost | Moderate initial cost, long-term savings due to efficiency. | Varies widely; generally higher than air solenoids. | Higher upfront costs due to installation and components. |

| Ease of Implementation | Relatively easy to install in existing systems. | Requires electrical wiring knowledge for installation. | More complex setup; requires air supply and control systems. |

| Maintenance | Low maintenance; occasional cleaning may be needed. | Low maintenance; however, electrical components can fail. | Higher maintenance due to moving parts and potential air leaks. |

| Best Use Case | Ideal for applications requiring rapid actuation in pneumatic systems. | Best for applications needing precise fluid control across various mediums. | Perfect for heavy-duty applications requiring significant force. |

What are the Pros and Cons of Electric Solenoid Valves?

Electric solenoid valves are a robust alternative to air solenoids, known for their versatility in controlling various fluids, including gas, water, and oil. Pros include high precision and the ability to handle different mediums. They can be used in applications ranging from HVAC systems to chemical processing. However, cons involve a generally higher cost and the need for electrical expertise during installation, which may not be feasible for all businesses, especially in regions with limited access to skilled labor.

How Do Pneumatic Actuators Compare to Air Solenoids?

Pneumatic actuators offer significant force output and are suitable for applications involving heavy loads. They are particularly effective in industrial environments that require substantial motion and control. Pros of pneumatic actuators include their ability to handle heavy-duty tasks and their relatively low cost of operation once installed. However, they require a more complex setup, including air supply and control systems, making them less straightforward to implement compared to air solenoids. Additionally, maintenance can be more demanding due to potential air leaks and the need for regular checks on moving components.

Illustrative image related to air solenoid

Conclusion: How Can B2B Buyers Choose the Right Fluid Control Solution?

Choosing the right fluid control solution depends on specific application needs, budget constraints, and available expertise. For applications requiring quick actuation and minimal maintenance, air solenoids may be the best fit. Electric solenoid valves offer versatility and precision, making them suitable for a broader range of fluids but may involve higher costs and installation complexity. Pneumatic actuators excel in heavy-duty applications but require more extensive setup and maintenance. By evaluating these factors, B2B buyers can make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for air solenoid

What Are the Key Technical Properties of Air Solenoids?

When selecting air solenoids for industrial applications, understanding their technical properties is crucial. Here are some of the key specifications that B2B buyers should consider:

-

Material Grade

Air solenoids are typically constructed from various materials including brass, stainless steel, and plastic. The choice of material affects durability, corrosion resistance, and overall performance. Stainless steel is preferred for applications in harsh environments, while brass is often used for its cost-effectiveness and reliability in less demanding settings. -

Voltage Rating

Air solenoids operate on different voltage ratings, such as 12V, 24V, or 110V. Choosing the correct voltage is essential for compatibility with existing systems and for ensuring optimal performance. B2B buyers should verify the voltage requirements of their machinery to prevent malfunctions. -

Port Size and Configuration

The port size, usually measured in inches, dictates the flow capacity and compatibility with piping systems. Common sizes include 1/4″, 1/2″, and 1″. Additionally, the configuration—whether 2-way, 3-way, or 4-way—determines how the solenoid will control airflow, which is vital for applications requiring precise air control. -

Response Time

This property refers to how quickly the solenoid can open or close once activated. A faster response time is crucial for applications that demand immediate airflow adjustments, such as in pneumatic systems used in manufacturing or automotive industries. Buyers should assess their operational needs to choose a solenoid with an appropriate response time. -

Operating Pressure Range

The operating pressure range indicates the maximum and minimum pressures the solenoid can handle. Selecting a solenoid with the correct pressure specifications is vital for maintaining system integrity and preventing leaks or failures. -

Duty Cycle

The duty cycle defines how long a solenoid can operate continuously before needing a rest period. This is particularly important for applications with high-frequency operations, as exceeding the duty cycle can lead to overheating and premature failure.

What Are Common Trade Terms Related to Air Solenoids?

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to air solenoids:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. B2B buyers often seek OEM parts for quality assurance and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it affects inventory management and budgeting. Knowing the MOQ helps in planning purchases efficiently. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request price quotes for specific products. For B2B buyers, issuing an RFQ is a strategic way to compare prices and terms from multiple suppliers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for buyers to comprehend shipping costs, insurance, and risk management in their procurement processes. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for project planning and inventory management, ensuring that operations run smoothly without delays. -

Certification Standards

Many air solenoids must meet specific industry standards (e.g., ISO, CE) to ensure safety and quality. Buyers should verify that the products they are considering are certified to avoid compliance issues and ensure reliability in their applications.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing air solenoids, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the air solenoid Sector

What Are the Current Market Dynamics and Key Trends in the Air Solenoid Sector?

The air solenoid market is experiencing significant growth driven by various global factors. Key drivers include the increasing automation across industries such as manufacturing, automotive, and agriculture, particularly in regions like Africa and South America where industrialization is ramping up. Emerging technologies such as IoT and Industry 4.0 are also influencing sourcing trends as businesses look for smart solutions that offer real-time monitoring and control capabilities. This shift is pushing manufacturers to adopt more advanced solenoid valve designs that integrate seamlessly with digital systems.

International B2B buyers are increasingly prioritizing suppliers that offer high-performance solenoid valves, particularly those designed for durability and efficiency in harsh environments. In the Middle East and Europe, where stringent regulations on energy efficiency and emissions are becoming the norm, the demand for solenoids that can operate reliably under varying conditions is on the rise. Additionally, there is a growing emphasis on customization, with buyers seeking specific features such as voltage options, port sizes, and material compatibility tailored to their unique applications.

How Are Sustainability and Ethical Sourcing Impacting the Air Solenoid Industry?

Sustainability has become a crucial consideration for B2B buyers in the air solenoid sector, as companies face increasing pressure to reduce their environmental footprint. The manufacturing processes for solenoid valves can have significant environmental impacts, including energy consumption and waste generation. Therefore, buyers are more inclined to partner with suppliers who prioritize eco-friendly practices and materials in their production processes.

Ethical sourcing is equally important, as businesses aim to create transparent supply chains that support fair labor practices and responsible resource use. Certifications such as ISO 14001 for environmental management and RoHS for hazardous substances are becoming essential for suppliers to demonstrate their commitment to sustainability. Additionally, the use of ‘green’ materials, such as recycled metals and eco-friendly coatings, is gaining traction. By prioritizing sustainability and ethical sourcing, international buyers not only mitigate risks but also enhance their brand reputation in a competitive market.

What Is the Brief Evolution of Air Solenoid Technology Relevant to B2B Buyers?

The evolution of air solenoid technology has been marked by significant advancements since its inception. Initially, solenoid valves were primarily mechanical devices, limited in functionality and efficiency. However, with the advent of electronic controls and automation, modern air solenoids have transformed into sophisticated devices capable of precise control and integration with digital systems.

In recent years, innovations such as low-power solenoids and materials that withstand extreme conditions have further enhanced their utility across various applications. This evolution is particularly relevant for B2B buyers, as the latest technologies enable better performance, energy efficiency, and adaptability to diverse operational requirements. As industries continue to evolve, understanding the historical context of air solenoid technology can help buyers make informed decisions that align with their operational goals and sustainability objectives.

By keeping these insights in mind, international B2B buyers can navigate the complex landscape of the air solenoid sector, ensuring they select products that meet their needs while also adhering to modern sustainability standards.

Frequently Asked Questions (FAQs) for B2B Buyers of air solenoid

-

How do I select the right air solenoid for my application?

Choosing the right air solenoid valve involves assessing your specific application requirements. Key factors include the port size, voltage (e.g., 12V, 24V, 110V), and whether you need a normally open or normally closed valve. Consider the fluid type, pressure, and temperature conditions as well. Additionally, evaluate whether a single valve or a manifold setup is more suitable for your system. Consulting with suppliers about your application can provide insights into the most effective solenoid options. -

What are the common voltage options for air solenoids?

Air solenoids are typically available in several voltage options, including 12V DC, 24V DC, and 110V AC. The choice of voltage depends on your power supply and application needs. For instance, 12V and 24V are common in automotive and portable applications, while 110V is often used in fixed installations. It’s crucial to match the solenoid’s voltage with your system’s specifications to ensure optimal performance and reliability. -

What is the minimum order quantity (MOQ) for air solenoids?

Minimum order quantities (MOQs) for air solenoids can vary significantly between suppliers and depend on the specific model and customization options. Generally, MOQs may range from as low as 10 units to several hundred. When negotiating with suppliers, it’s beneficial to discuss your needs and explore flexibility on MOQs, especially if you are testing new products or entering a new market. -

How can I ensure the quality of the air solenoids I purchase?

To ensure the quality of air solenoids, consider sourcing from reputable manufacturers with established quality control processes. Request certifications (such as ISO 9001) and inquire about their testing procedures. Additionally, ask for samples before placing a bulk order to assess performance in your specific application. Engaging with suppliers who offer warranties or guarantees can also provide peace of mind regarding product quality. -

What payment terms should I expect when sourcing air solenoids internationally?

Payment terms can vary by supplier and region, but common practices include advance payment, letters of credit, or payment upon delivery. It’s essential to clarify payment terms upfront to avoid misunderstandings. For larger orders, negotiating favorable terms, such as a partial upfront payment with the remainder upon delivery, can help manage cash flow. Consider using secure payment methods to protect your transaction. -

What shipping options are available for international orders of air solenoids?

International shipping options for air solenoids typically include air freight, sea freight, and express courier services. The choice of shipping method should balance cost, delivery speed, and the urgency of your project. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Discuss logistics with your supplier to determine the best shipping option based on your timeline and budget. -

Are customization options available for air solenoids?

Many suppliers offer customization options for air solenoids, including modifications to size, voltage, or materials used. Customization can be particularly beneficial for unique applications or specific industry standards. When discussing your requirements, provide detailed specifications to the supplier. Keep in mind that custom orders may have longer lead times and higher costs, so plan accordingly. -

What are the best practices for maintaining air solenoids in a B2B setting?

To maintain air solenoids effectively, establish a routine inspection schedule to check for leaks, wear, and overall functionality. Regularly clean the valves and ensure they are free from debris that can affect performance. Implement preventive maintenance protocols, such as replacing seals and lubricating moving parts as needed. Training staff on proper handling and operational procedures can also enhance the longevity and reliability of your solenoid valves.

Top 8 Air Solenoid Manufacturers & Suppliers List

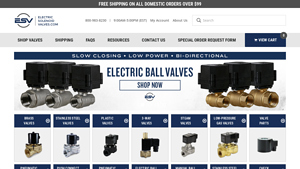

1. Electric Solenoid Valves – 1/2 Stainless Electric Solenoid Valve

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: Electric Solenoid Valves available in 12V, 24V & 110 Volt for Gas, Water, Air, and Oil. Free shipping on domestic orders over $99. Key products include: 1/2″ Stainless Electric Solenoid Valve ($81.86), 1/4″ 110V AC Stainless Electric Solenoid Valve ($44.10), 1/2″ 24V AC Electric Brass Solenoid Valve ($59.16), 2″ 12V DC Electric Brass Solenoid Valve ($278.46), 2″ Stainless Electric Ball Valve – 2 W…

2. McMaster – Pneumatic Solenoid Valves

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Pneumatic Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. SMC USA – Solenoid Valves

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: This company, SMC USA – Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Motion – Single Solenoid Valve

Domain: ai.motion.com

Registered: 1994 (31 years)

Introduction: This company, Motion – Single Solenoid Valve, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

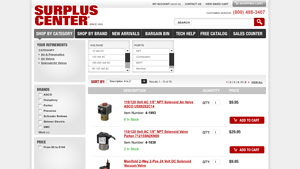

5. Solenoid Air Valves – Key Product Details

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Key product details for Solenoid Air Valves include:

– Voltage options: 12 Volt DC, 24 Volt DC, 110/120 Volt AC, 180-264 Volt AC, 90-132 Volt AC, 100 Volt DC, 240 Volt AC.

– Port types: NPT, BSPT, Manifold, Metric.

– Brands: ASCO, Humphrey, Parker, Pneumax, Schrader Bellows, Skinner Electric, SMC.

– Example products:

1. 110/120 Volt AC 1/8″ NPT Solenoid Air Valve ASCO USX8262C14 – Price: $9.95

…

6. Emerson – Air Solenoid Valves

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Air Solenoid Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Fabco-Air – Pneumatic Directional Control Valves

Domain: fabco-air.com

Registered: 1995 (30 years)

Introduction: Fabco-Air offers a variety of solenoid and directional control valves, including:

1. **Pneumatic Directional Control Valves**:

– **Hex Body and Miniature Modular Manifolded Poppet Valves**:

– Flow rate range: Cv = 0.05 to Cv = 0.23

– Port sizes: ⅛ NPT and ¼ NPT (Hex body), 10-32 and ⅛ NPT Modular

– Compatible with air, water, and other fluids with standard Buna-N seals

– Ex…

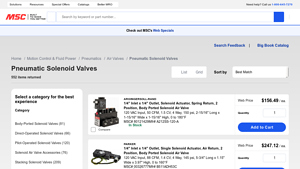

8. MSC Direct – Valve Solutions

Domain: mscdirect.com

Registered: 1996 (29 years)

Introduction: This company, MSC Direct – Valve Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for air solenoid

What Are the Key Takeaways for Strategic Sourcing of Air Solenoids?

In navigating the complexities of air solenoid sourcing, it is crucial for B2B buyers to prioritize quality, reliability, and compatibility with existing systems. Understanding the various specifications, such as voltage, port size, and material, can significantly impact operational efficiency and cost-effectiveness. Engaging with reputable suppliers who offer a range of options—from stainless steel to brass solenoids—ensures that businesses can meet their specific fluid control needs while maintaining high performance.

How Can Strategic Sourcing Enhance Operational Efficiency?

Strategic sourcing not only streamlines procurement processes but also fosters long-term partnerships that can lead to innovation and improved product offerings. By leveraging insights on market trends and supplier capabilities, companies can better position themselves to respond to evolving demands in diverse regions, including Africa, South America, the Middle East, and Europe.

What’s Next for International Buyers of Air Solenoids?

As industries increasingly adopt automation and advanced fluid control technologies, the demand for high-quality air solenoids will continue to rise. International buyers should remain proactive in exploring new suppliers, evaluating product innovations, and assessing market dynamics. Embrace this opportunity to enhance your sourcing strategy today—invest in air solenoids that will propel your operations toward greater efficiency and reliability in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to air solenoid

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.