Menards Fence Panels: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for menards fence panels

In the ever-evolving landscape of global trade, sourcing Menards fence panels presents unique challenges for international B2B buyers. With diverse materials like wood, vinyl, and chain-link options available, understanding the nuances of each type is crucial for making informed decisions. This guide is designed to navigate the complexities of the Menards fencing product line, addressing key factors such as applications, supplier vetting, pricing strategies, and logistical considerations.

B2B buyers from regions like Africa, South America, the Middle East, and Europe, including Vietnam and Saudi Arabia, will find actionable insights tailored to their specific market dynamics. The guide will delve into the different styles and functionalities of Menards fence panels, ensuring that businesses can select the right solutions to meet their operational needs.

Moreover, it emphasizes the importance of thorough supplier evaluation to mitigate risks and ensure quality. By equipping buyers with essential knowledge about product specifications, compliance standards, and cost-effective sourcing strategies, this comprehensive resource empowers them to make confident purchasing decisions. Ultimately, understanding the global market for Menards fence panels not only enhances procurement efficiency but also fosters long-term business relationships built on trust and reliability.

Understanding menards fence panels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wood Fence Panels | Natural aesthetics, customizable finishes, various heights | Residential properties, parks, farms | Pros: Eco-friendly, customizable. Cons: Requires maintenance, susceptible to rot. |

| Vinyl Fence Panels | Durable, low maintenance, available in various colors | Commercial properties, residential areas | Pros: Long-lasting, resistant to weather. Cons: Higher initial cost, less customizable. |

| Chain-Link Fence Panels | Cost-effective, easy to install, provides visibility | Security fencing, industrial sites | Pros: Affordable, versatile. Cons: Limited privacy, less aesthetic appeal. |

| Privacy Fence Panels | Taller designs, solid construction, often made of wood or vinyl | Residential areas, commercial properties | Pros: Enhanced privacy, noise reduction. Cons: Can be more expensive, may require permits. |

| Lattice Top Fence Panels | Decorative top design, combines privacy with visibility | Gardens, patios, decorative boundaries | Pros: Aesthetic appeal, allows light and air. Cons: Less privacy than solid panels. |

What Are the Key Characteristics of Wood Fence Panels?

Wood fence panels are a popular choice for their natural aesthetics and versatility. They can be customized with various finishes and can accommodate different heights, making them suitable for diverse applications, from residential properties to parks and farms. When considering wood panels, B2B buyers should keep in mind the necessity for regular maintenance to prevent rot and degradation, particularly in humid or wet climates. While they offer a rustic charm, the long-term durability can be a concern without proper upkeep.

How Do Vinyl Fence Panels Stand Out for B2B Buyers?

Vinyl fence panels are recognized for their durability and low maintenance requirements. Available in a variety of colors, these panels are ideal for both commercial and residential applications. Their resistance to weather, pests, and fading makes them a practical investment. However, the higher initial cost compared to wood may deter some buyers. It’s essential for B2B purchasers to evaluate the long-term savings on maintenance and replacement when considering vinyl options.

What Are the Advantages of Chain-Link Fence Panels?

Chain-link fence panels are known for their cost-effectiveness and ease of installation. They are widely used in security applications, especially for industrial sites and commercial properties, due to their visibility and strength. Buyers should consider the balance between affordability and aesthetics, as chain-link fences offer limited privacy and may not be as visually appealing as other options. Nonetheless, they are versatile and can be enhanced with privacy slats if needed.

Why Choose Privacy Fence Panels for Commercial Applications?

Privacy fence panels are specifically designed to provide enhanced privacy and noise reduction, making them ideal for both residential areas and commercial properties. Typically constructed from wood or vinyl, these panels can be taller and more solid than other types. While they offer significant benefits in terms of seclusion, buyers should be aware of potential higher costs and the need for permits in some regions. Understanding local regulations is crucial for B2B buyers considering privacy solutions.

What Makes Lattice Top Fence Panels a Unique Option?

Lattice top fence panels combine the benefits of privacy with an aesthetic appeal, featuring a decorative top design that allows light and air to pass through. These panels are often used in gardens and patios to create decorative boundaries while still providing some level of privacy. While they enhance the visual appeal of a space, buyers should note that they offer less privacy than solid panels. Evaluating the intended use and desired aesthetic will help B2B buyers make an informed decision regarding lattice options.

Key Industrial Applications of menards fence panels

| Industry/Sector | Specific Application of menards fence panels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Livestock containment and paddock fencing | Enhances security and reduces livestock loss | Durability against weather conditions, ease of installation |

| Residential Construction | Privacy and decorative fencing for homes | Increases property value and aesthetic appeal | Compliance with local regulations, design options, material availability |

| Commercial Real Estate | Boundary demarcation and security for commercial properties | Protects assets and deters unauthorized access | Cost-effectiveness, maintenance requirements, scalability |

| Landscaping and Gardening | Garden fencing and decorative panels | Protects plants from animals and enhances garden design | Variety of styles, resistance to pests, and weather durability |

| Industrial Facilities | Safety barriers and enclosures for equipment | Ensures safety and compliance with regulations | Strength, height specifications, and customization options |

How Can Menards Fence Panels Benefit the Agriculture Sector?

In the agriculture sector, Menards fence panels are essential for livestock containment and paddock fencing. These panels provide a reliable barrier that keeps animals secure and prevents them from wandering off, thus minimizing loss. Buyers in this sector need to consider the durability of the panels against harsh weather conditions, as well as the ease of installation, which can significantly reduce labor costs. Furthermore, selecting pressure-treated wood or vinyl options can enhance longevity, making them a smart investment for farms in diverse climates across Africa and South America.

What Role Do Menards Fence Panels Play in Residential Construction?

For residential construction, Menards fence panels serve both privacy and decorative purposes. They can increase property value by providing an aesthetically pleasing boundary that enhances curb appeal. International buyers should focus on compliance with local zoning regulations, which may dictate the height and type of fencing allowed. Additionally, the availability of various styles—such as shadow box or stockade—enables homeowners to choose panels that best fit their landscape design while ensuring that the materials can withstand local environmental conditions.

Illustrative image related to menards fence panels

How Are Menards Fence Panels Utilized in Commercial Real Estate?

In commercial real estate, Menards fence panels are vital for boundary demarcation and security. These panels help protect assets and deter unauthorized access, which is crucial for businesses operating in high-risk areas. Buyers should prioritize cost-effectiveness and maintenance requirements when sourcing fencing solutions. Additionally, scalability is a key consideration, as businesses may need to expand their fencing as operations grow. The ability to customize the height and style of the panels can also enhance the overall security strategy for commercial properties in regions like the Middle East and Europe.

What Advantages Do Menards Fence Panels Offer for Landscaping and Gardening?

Menards fence panels are widely used in landscaping and gardening, providing both functional and aesthetic benefits. They protect plants from animals while enhancing the overall design of gardens and outdoor spaces. Buyers should look for a variety of styles that complement their landscaping vision, as well as materials that resist pests and withstand different weather conditions. This versatility makes them an attractive option for landscaping projects across diverse climates, including tropical regions in Africa and temperate zones in Europe.

How Do Menards Fence Panels Enhance Safety in Industrial Facilities?

In industrial facilities, Menards fence panels are crucial for creating safety barriers and enclosures around equipment. These panels ensure compliance with safety regulations, protecting workers and minimizing liability for businesses. When sourcing these panels, companies should consider strength and height specifications to meet safety standards. Customization options may also be necessary to fit specific facility layouts or operational needs, making them a practical choice for industrial applications in regions with stringent safety regulations, such as those found in South America and the Middle East.

3 Common User Pain Points for ‘menards fence panels’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Fence Panels for Specific Projects

The Problem: B2B buyers often face challenges when trying to source the appropriate Menards fence panels for various construction projects. They may require panels that meet specific height, durability, or aesthetic standards, especially when catering to diverse markets in Africa, South America, the Middle East, or Europe. Miscommunication with suppliers regarding specifications can lead to delays, increased costs, and dissatisfaction from clients who expect high-quality fencing solutions.

The Solution: To overcome sourcing difficulties, buyers should conduct thorough market research to understand the specific fencing needs of their target demographics. They can begin by creating a detailed specification sheet that outlines the exact requirements for each project, including dimensions, material type (wood, vinyl, or chain-link), and desired finishes. When contacting Menards or other suppliers, presenting this specification sheet will ensure clarity and help the supplier recommend the most suitable products. Additionally, leveraging online tools and platforms that aggregate supplier information can facilitate the comparison of different panels available at Menards, allowing buyers to make informed decisions based on their project needs.

Scenario 2: Managing Logistics and Shipping Delays for International Orders

The Problem: International B2B buyers frequently encounter logistical challenges when ordering Menards fence panels, particularly regarding shipping times and customs clearance. Delays in delivery can disrupt project timelines and lead to financial losses, especially if the panels are essential for an ongoing construction project. Furthermore, the complexity of international shipping regulations can make it difficult for buyers to anticipate potential hurdles.

The Solution: To mitigate logistical issues, buyers should establish a robust supply chain strategy that incorporates reliable shipping partners experienced in handling international orders. It is advisable to work closely with logistics experts who can provide insights into the best shipping methods and timelines. Buyers can also inquire about Menards’ shipping options, including expedited delivery services, to ensure timely arrivals. Additionally, maintaining open communication with suppliers regarding the status of orders will allow buyers to proactively address any potential delays. Establishing a local presence or partnering with local distributors in target regions can further streamline logistics, reducing reliance on lengthy shipping processes.

Scenario 3: Navigating Product Quality and Durability Concerns

The Problem: Quality assurance is a significant concern for B2B buyers sourcing Menards fence panels, particularly in regions with extreme weather conditions or heavy usage. Buyers may worry about the durability of wood versus vinyl panels, the potential for warping, rotting, or fading, and whether the product will meet local building codes and regulations. These concerns are heightened when trying to ensure customer satisfaction and long-term performance.

The Solution: To address quality and durability concerns, buyers should prioritize sourcing panels from reputable manufacturers that offer guarantees or warranties on their products. Conducting pre-purchase inspections, when possible, or requesting samples can provide tangible insights into the quality of the materials. Additionally, buyers should familiarize themselves with the specifications of different panel types, such as pressure-treated wood for increased longevity or UV-resistant vinyl for color retention. Engaging with other businesses or industry professionals to share experiences and recommendations can also guide buyers in selecting the most reliable products. Finally, staying informed about local building codes will ensure compliance and enhance the overall quality of installations.

Illustrative image related to menards fence panels

Strategic Material Selection Guide for menards fence panels

What Are the Key Properties of Wood for Menards Fence Panels?

Wood is a traditional material for fencing, offering aesthetic appeal and structural integrity. Common types include pressure-treated pine and cedar. Pressure-treated wood is treated with preservatives to resist rot and insect damage, making it suitable for outdoor applications. It typically withstands temperatures ranging from -30°F to 120°F, maintaining structural integrity under various conditions. However, wood can be susceptible to warping and splitting under extreme weather fluctuations.

Pros include its natural appearance, ease of installation, and cost-effectiveness. However, cons include the need for regular maintenance, such as staining or sealing, to prolong its lifespan. For international buyers, compliance with local standards is essential; for instance, ASTM standards for treated wood may apply. Additionally, regions with high humidity or insect activity may require more robust treatments.

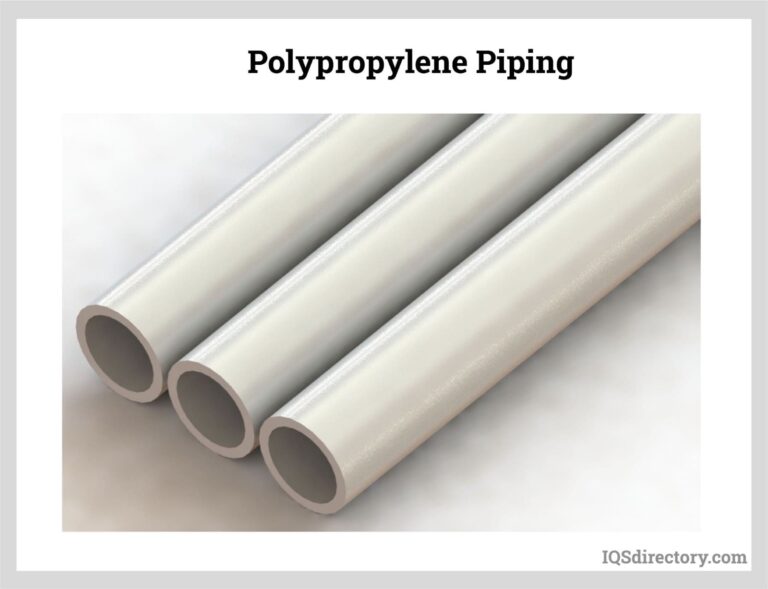

How Does Vinyl Compare as a Material for Menards Fence Panels?

Vinyl fencing is a popular alternative to wood, known for its durability and low maintenance requirements. It is made from polyvinyl chloride (PVC), which provides excellent resistance to moisture, UV rays, and insects. Vinyl panels can withstand temperatures from -40°F to 140°F, making them suitable for diverse climates.

The key advantages of vinyl include its longevity, as it does not warp or fade, and its ease of cleaning. However, the disadvantages include a higher initial cost and potential brittleness in extremely cold temperatures. For international buyers, it is crucial to consider local regulations regarding plastic materials, as some countries may have restrictions on PVC use. Additionally, buyers should verify that the vinyl meets relevant standards, such as ASTM D638 for tensile strength.

Illustrative image related to menards fence panels

What Are the Benefits and Limitations of Chain-Link Fencing?

Chain-link fencing is a versatile option widely used in commercial and industrial applications. Made from galvanized steel, it offers excellent corrosion resistance and can withstand harsh environmental conditions. Chain-link fences are typically rated for high tensile strength, making them suitable for security applications.

The pros of chain-link fencing include its affordability, ease of installation, and low maintenance. However, the cons involve limited aesthetic appeal and potential rusting if not properly coated. For international buyers, understanding local standards for fencing materials is vital, particularly regarding galvanization standards, which can vary by region. Compliance with safety regulations is also essential, especially in high-security applications.

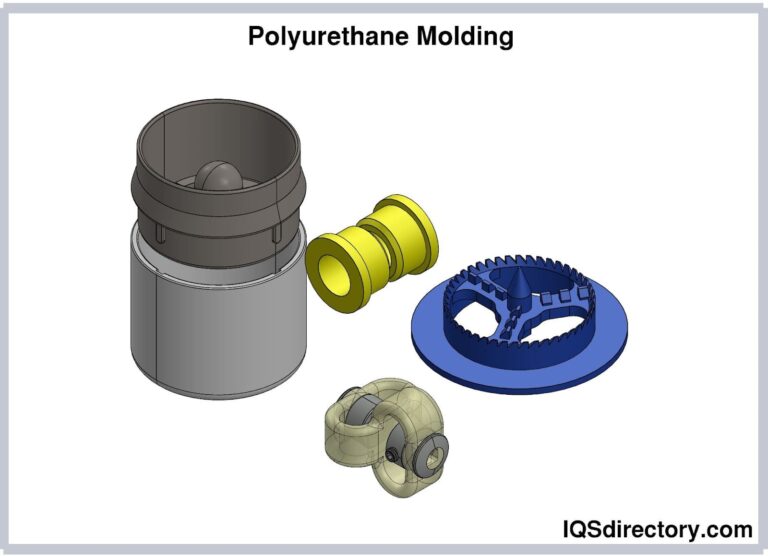

What Are the Considerations for Composite Materials in Menards Fence Panels?

Composite fencing combines wood fibers and plastic to create a durable, low-maintenance product. It offers the appearance of wood with enhanced weather resistance and durability. Composite materials typically perform well in temperatures ranging from -20°F to 120°F, making them suitable for various climates.

Key advantages of composite fencing include its resistance to fading, rotting, and insect damage, along with minimal maintenance requirements. However, disadvantages include a higher cost compared to traditional wood and potential issues with expansion and contraction in extreme temperatures. For international buyers, it is essential to ensure that composite materials meet local environmental standards, as some regions may have regulations regarding the use of recycled materials.

Summary Table of Material Selection for Menards Fence Panels

| Material | Typical Use Case for menards fence panels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Residential fencing, decorative applications | Natural appearance, cost-effective | Requires maintenance, susceptible to weather | Low |

| Vinyl | Privacy fencing, pool enclosures | Low maintenance, durable | Higher initial cost, may be brittle | High |

| Chain-Link | Security fencing, industrial applications | Affordable, easy to install | Limited aesthetic appeal, potential rust | Med |

| Composite | Residential and commercial fencing | Weather-resistant, low maintenance | Higher cost, potential expansion issues | High |

This guide provides a comprehensive overview of the materials available for Menards fence panels, helping international B2B buyers make informed decisions based on their specific needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for menards fence panels

What Are the Key Stages in the Manufacturing Process of Menards Fence Panels?

The manufacturing process of Menards fence panels involves several critical stages, each designed to ensure high-quality end products that meet customer expectations. Understanding these stages is essential for B2B buyers looking to source reliable and durable fencing solutions.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in manufacturing Menards fence panels is material preparation. Depending on the type of fencing—wood, vinyl, or metal—different raw materials are sourced. For wooden panels, high-quality timber is selected, often pressure-treated to enhance durability and resistance to rot. For vinyl panels, high-density polyethylene (HDPE) is commonly used, which is known for its resilience and low maintenance.

Once the materials are sourced, they undergo processes such as cutting, drying, and treating. For instance, wood may be cut to specific dimensions and treated with preservatives to extend its life. Vinyl sheets are typically manufactured using extrusion processes, where heated resin is shaped into sheets before cooling and cutting into the desired sizes.

Forming: How Are Fence Panels Shaped and Assembled?

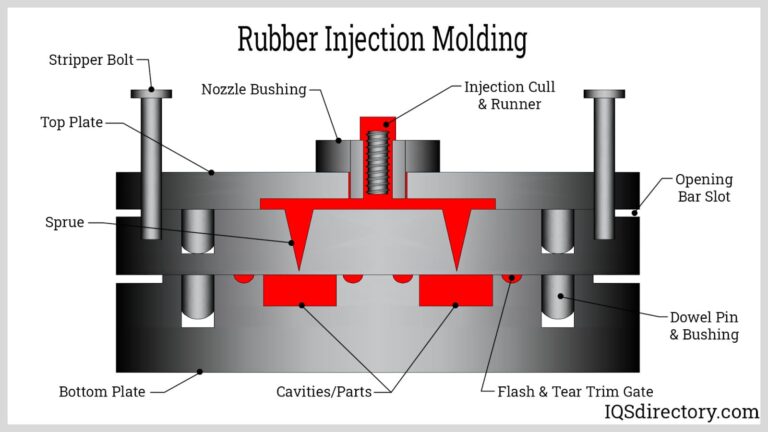

The forming stage involves shaping the prepared materials into fence panels. For wooden panels, this often includes assembling individual slats into a framework that supports the overall structure. Techniques like finger-jointing may be used to join shorter pieces of wood to create longer panels, enhancing strength and reducing waste.

For vinyl panels, the process involves molding the extruded sheets into the required shapes. This can include adding decorative elements such as lattice tops or privacy features. Advanced manufacturing techniques such as computer numerical control (CNC) machining may be employed to ensure precision in cutting and shaping.

Finishing: What Treatments Are Applied for Aesthetic and Functional Quality?

The finishing stage is crucial for both aesthetics and functionality. Wooden panels typically receive protective coatings, such as stains or sealants, to enhance appearance and provide weather resistance. Vinyl panels may undergo color treatments during the extrusion process, ensuring uniformity and reducing the need for painting.

Quality assurance checks are often performed during the finishing stage to identify any defects or inconsistencies. This can include visual inspections and measurements to ensure that the dimensions and finish meet specified standards.

How Does Quality Assurance Ensure the Reliability of Menards Fence Panels?

Quality assurance (QA) is integral to the manufacturing process of Menards fence panels. It ensures that products meet international standards and customer expectations, which is especially important for international B2B buyers.

What International Standards Are Applicable to Menards Fence Panels?

Menards adheres to several international quality standards, including ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 indicates that the company has established processes to ensure consistent quality in manufacturing.

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in Europe and other relevant certifications (e.g., American National Standards Institute (ANSI), American Society for Testing and Materials (ASTM)) may apply. These certifications provide assurance that the products have been tested for safety, durability, and performance.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing checks are performed during production to monitor processes and catch defects early.

- Final Quality Control (FQC): Completed fence panels undergo rigorous testing and inspection before packaging and shipping.

Common testing methods may include tensile strength tests, moisture content analysis for wood, and impact resistance tests for vinyl. These checks help to maintain the integrity and reliability of the finished products.

How Can B2B Buyers Verify the Quality Assurance Processes of Suppliers?

For international B2B buyers, verifying a supplier’s quality assurance processes is crucial in ensuring that the products meet their specific needs and standards. Here are some effective ways to assess supplier quality:

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers should consider conducting supplier audits, which involve visiting manufacturing facilities to assess production practices, quality control measures, and compliance with international standards. This firsthand observation can provide insights into the supplier’s commitment to quality.

Illustrative image related to menards fence panels

How Important Are Quality Assurance Reports and Third-Party Inspections?

Requesting quality assurance reports can also be beneficial. Suppliers should be able to provide documentation that outlines their QC processes, inspection results, and certifications. Third-party inspections by independent organizations can further validate the supplier’s claims and provide an unbiased assessment of product quality.

What Quality Control Nuances Should International Buyers Consider?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control. Different regions may have varying standards and regulations, which can impact the importation and use of fencing products.

Understanding local regulations regarding materials and safety standards is essential. For instance, certain countries may have restrictions on specific chemicals used in the treatment of wood or vinyl. Therefore, it is advisable for buyers to conduct thorough research and engage with local experts to ensure compliance and avoid potential issues during importation.

In summary, understanding the manufacturing processes and quality assurance practices of Menards fence panels equips B2B buyers with the knowledge necessary to make informed purchasing decisions. By prioritizing quality and compliance, buyers can secure reliable fencing solutions that meet their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘menards fence panels’

In the competitive landscape of international fencing supply, sourcing Menards fence panels requires a structured approach to ensure quality, cost-effectiveness, and compliance with local regulations. This guide provides a practical checklist for B2B buyers aiming to procure these products efficiently.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to sourcing the right fence panels. Consider factors such as material (wood, vinyl, or chain-link), dimensions, and design features (e.g., privacy, aesthetics). This clarity helps in narrowing down options and ensures that suppliers understand your exact needs.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers of Menards fence panels. Utilize online platforms, trade shows, and industry publications to find reputable vendors. Focus on suppliers that have a proven track record in international shipping and can cater to your specific regional requirements, such as import regulations and tariffs.

Step 3: Evaluate Supplier Credentials

Before making a commitment, verify the credentials of your shortlisted suppliers. Request documentation such as business licenses, product certifications, and compliance with international quality standards. This step is crucial to mitigate risks associated with subpar products or unreliable vendors.

Step 4: Request Samples for Quality Assessment

Always request samples of the fence panels you intend to purchase. Analyzing physical samples allows you to assess the material quality, durability, and finish. Consider factors such as weather resistance and maintenance needs, especially if the panels will be used in harsh environments.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. Look beyond the initial cost; consider shipping fees, import duties, and potential discounts for bulk orders. Understanding the total cost of ownership will help in making an informed decision.

Step 6: Assess Delivery and Logistics Options

Evaluate the logistics capabilities of your suppliers, including delivery timelines and shipping methods. Consider suppliers that offer reliable shipping options, as timely delivery is critical for project schedules. Inquire about their experience with customs clearance in your region to avoid delays.

Step 7: Establish Communication and Support Channels

Effective communication is key to successful sourcing. Ensure that your chosen supplier has dedicated support channels for order tracking, product inquiries, and issue resolution. A responsive supplier can significantly enhance your sourcing experience and mitigate potential disruptions.

By following this checklist, B2B buyers can streamline their sourcing process for Menards fence panels, ensuring they select the right products from reliable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for menards fence panels Sourcing

What Are the Key Cost Components in Sourcing Menards Fence Panels?

When sourcing Menards fence panels, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: This is typically the largest expense, influenced by the type of fence panel—wood, vinyl, or chain-link. For instance, pressure-treated wood panels may incur higher raw material costs compared to standard vinyl options.

-

Labor: Labor costs vary significantly based on the manufacturing location. In regions with higher wage standards, such as Europe, you may find labor costs to be more substantial compared to countries in Africa or South America.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities and facility expenses. Efficient manufacturing processes can help reduce these overheads.

-

Tooling Costs: Custom designs or specifications may require specific tooling, which can add to the initial costs. Buyers should consider whether they need standard panels or custom solutions.

-

Quality Control (QC): Ensuring the panels meet international standards involves QC processes that can add to the overall costs. Investing in quality can prevent future issues related to durability and compliance.

-

Logistics: Shipping and handling costs can be a significant factor, especially for international buyers. Considerations include the distance from the supplier, mode of transport, and any tariffs or taxes applicable in the destination country.

-

Margin: Finally, suppliers will add their profit margin, which can vary based on market competition and demand.

How Do Price Influencers Affect the Cost of Menards Fence Panels?

Several factors influence the pricing of Menards fence panels, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often come with bulk pricing discounts. Understanding the MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Custom designs may attract higher prices. Buyers should assess whether customization is necessary for their projects or if standard options suffice.

-

Material Quality and Certifications: Panels that meet specific standards or certifications may carry a premium price. Buyers should evaluate the importance of these certifications based on their project requirements.

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier can affect pricing. Conducting thorough due diligence can ensure a sound investment.

-

Incoterms: The terms of shipping can significantly impact costs. Understanding the responsibilities of both the buyer and seller regarding shipping, insurance, and tariffs is crucial for accurate budgeting.

What Buyer Tips Can Help Optimize Sourcing Costs?

International B2B buyers should consider several strategies to enhance cost-efficiency when sourcing Menards fence panels:

-

Negotiation Strategies: Building strong relationships with suppliers can facilitate better pricing. Be prepared to negotiate terms, including payment schedules and delivery timelines.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, durability, and potential repair costs when evaluating the total cost of ownership over the lifecycle of the fence panels.

-

Pricing Nuances for International Buyers: Be aware of the currency exchange rates and potential fluctuations. Additionally, factors such as local taxes and import duties should be factored into the final cost.

-

Market Research: Understanding the competitive landscape can provide leverage in negotiations. Researching similar products and their pricing can help buyers make informed decisions.

Disclaimer on Pricing

Please note that the prices for Menards fence panels are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always request formal quotes from suppliers to get accurate pricing tailored to your needs.

Alternatives Analysis: Comparing menards fence panels With Other Solutions

Introduction: Exploring Alternatives to Menards Fence Panels

In the competitive landscape of fencing solutions, B2B buyers must consider various alternatives to Menards fence panels. While Menards offers a range of fencing options, such as wood, vinyl, and chain-link panels, understanding the strengths and weaknesses of alternative solutions can help businesses make informed purchasing decisions. This analysis compares Menards fence panels with two prominent alternatives: composite fencing and wrought iron fencing.

Comparison Table

| Comparison Aspect | Menards Fence Panels | Composite Fencing | Wrought Iron Fencing |

|---|---|---|---|

| Performance | Durable and weather-resistant | Highly durable; mimics wood look | Extremely durable; high security |

| Cost | Moderate cost, varies by material | Higher initial cost, long-term savings | High initial cost, low maintenance |

| Ease of Implementation | Easy to install with pre-fabricated options | Moderate; requires special tools | Complex installation; often requires professionals |

| Maintenance | Moderate; periodic staining or sealing for wood | Low; minimal upkeep required | Low; rust-resistant coatings available |

| Best Use Case | Residential and light commercial applications | Residential, parks, and landscapes | Commercial properties, security fencing |

Detailed Breakdown of Alternatives

Composite Fencing

Composite fencing is an innovative solution that combines wood fibers and recycled plastic. This alternative offers a wood-like appearance without the drawbacks of traditional wood, such as warping or rotting. The performance of composite fencing is commendable, providing durability and resistance to fading. Although the initial cost is higher than that of Menards fence panels, it can lead to long-term savings due to its low maintenance requirements. Composite fencing is best suited for residential areas and landscaped environments, where aesthetics and durability are priorities.

Wrought Iron Fencing

Wrought iron fencing is another compelling alternative, especially for businesses looking for enhanced security. It is known for its strength and longevity, making it ideal for commercial properties or high-security areas. The performance of wrought iron fencing is unmatched in terms of durability; it can withstand harsh weather conditions without compromising structural integrity. However, the initial cost is significant, and installation can be complex, often necessitating professional services. While maintenance is low, periodic inspections and rust prevention measures are essential to maintain its appearance and functionality.

Conclusion: How to Choose the Right Fencing Solution

When selecting a fencing solution, B2B buyers should assess their specific needs, including budget, aesthetic preferences, and the intended use of the fencing. Menards fence panels offer a balance of affordability and ease of installation, making them a solid choice for many applications. However, alternatives like composite and wrought iron fencing provide distinct advantages that may better align with certain business objectives. By evaluating the performance, cost, maintenance, and best use cases of each option, buyers can make informed decisions that align with their long-term goals. Ultimately, the right choice will depend on the unique requirements of the project at hand.

Essential Technical Properties and Trade Terminology for menards fence panels

What Are the Key Technical Properties of Menards Fence Panels?

When selecting Menards fence panels for your business needs, understanding their technical properties is crucial. Here are some essential specifications that every B2B buyer should consider:

-

Material Grade

– Definition: This indicates the quality and durability of the material used in the fence panels, such as wood, vinyl, or metal.

– Importance: Higher material grades ensure longevity and resistance to environmental factors, reducing the need for replacements and maintenance. For international buyers, this can impact shipping costs and overall project budgets. -

Height and Width Specifications

– Definition: The dimensions of fence panels, typically measured in feet (e.g., 6 x 8 feet).

– Importance: Selecting the right height and width is essential for compliance with local regulations and aesthetic considerations. Understanding these specifications helps in accurate project planning and ensures that panels fit the intended space effectively. -

Pressure Treatment

– Definition: A process applied to wood panels to enhance resistance to rot, insects, and weather conditions.

– Importance: Pressure-treated wood panels are vital for outdoor applications, particularly in regions with harsh climates. This property can significantly reduce long-term costs associated with maintenance and replacements. -

Warranty and Lifespan

– Definition: The manufacturer’s commitment to cover defects or issues for a specified period.

– Importance: A robust warranty indicates confidence in the product’s quality. Understanding warranty terms can help buyers assess the risk associated with their investment and ensure they have recourse in case of product failures. -

Finish and Color Options

– Definition: The surface treatment and colors available for the panels, which may include painted, stained, or natural finishes.

– Importance: Aesthetic appeal is crucial for many buyers, especially in residential projects. Availability of various finishes allows for customization, which can enhance property value and appeal to potential customers. -

Installation Requirements

– Definition: Guidelines and tools necessary for installing the fence panels.

– Importance: Understanding installation requirements can help businesses budget for labor costs and ensure that they have the right tools and expertise available, minimizing delays in project timelines.

What Common Trade Terms Should B2B Buyers Know When Purchasing Fence Panels?

Navigating the purchasing process involves understanding specific terminology that can impact your transaction. Here are some common trade terms relevant to Menards fence panels:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Knowing if Menards panels are OEM products can help assess quality and compatibility with other components in your project. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding the MOQ is essential for budgeting and inventory management. It ensures that buyers can meet minimum purchase requirements without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A document issued to suppliers requesting price quotes for specific products or services.

– Importance: An RFQ can help buyers compare prices and terms from multiple suppliers, ensuring that they secure the best deal for Menards fence panels. -

Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements.

– Importance: Familiarity with Incoterms can aid in understanding shipping costs, delivery responsibilities, and risk management, which is crucial for international transactions. -

Lead Time

– Definition: The amount of time between the initiation of a process and its completion.

– Importance: Knowing the lead time for Menards fence panels can help businesses plan their projects effectively, ensuring materials arrive on schedule and avoiding costly delays. -

Customization Options

– Definition: The ability to modify products according to specific requirements or preferences.

– Importance: Understanding customization options allows buyers to tailor their selections to meet unique project needs, enhancing customer satisfaction and potentially increasing sales.

By familiarizing yourself with these technical properties and trade terminologies, you can make informed decisions when sourcing Menards fence panels, ensuring that your business requirements are met effectively and efficiently.

Navigating Market Dynamics and Sourcing Trends in the menards fence panels Sector

What Are the Key Market Dynamics and Trends Influencing Menards Fence Panels?

In the global fencing market, several key drivers are shaping the sourcing and purchasing decisions of B2B buyers. The growing emphasis on residential and commercial property security, particularly in regions like the Middle East and Africa, has led to increased demand for high-quality fence panels. In addition, urbanization and infrastructure development in South America and Europe are fostering investments in durable and aesthetically pleasing fencing solutions.

Emerging technologies, such as smart fencing solutions, are revolutionizing the sector by integrating IoT capabilities into traditional fencing products. This trend is particularly appealing to tech-savvy buyers in regions like Vietnam and Saudi Arabia, where innovation is highly valued. Moreover, the rise of e-commerce platforms is streamlining the procurement process, allowing international buyers to access Menards’ diverse offerings from anywhere in the world, enhancing the efficiency of sourcing operations.

Another significant trend is the shift towards customization. B2B buyers are increasingly seeking tailored solutions that cater to specific needs, including unique designs and materials. This has led to the expansion of product lines at Menards, featuring options such as vinyl, wood, and composite panels that cater to varying aesthetic preferences and functional requirements.

How Is Sustainability Shaping B2B Sourcing for Menards Fence Panels?

Sustainability is no longer just a buzzword; it is an essential consideration for B2B buyers in the fencing sector. The environmental impact of sourcing and manufacturing processes has led to an increased focus on sustainable materials. Menards has responded to this demand by offering products made from responsibly sourced wood and recycled materials.

Ethical sourcing practices are critical in establishing a positive brand image and fostering consumer trust. Buyers are increasingly scrutinizing supply chains, seeking transparency in sourcing practices. This trend is particularly pronounced in Europe, where regulatory frameworks often mandate compliance with stringent environmental standards.

Additionally, certifications such as Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) have become pivotal in the decision-making process for international buyers. These certifications assure that the materials used in Menards fence panels meet high environmental standards, providing an added layer of assurance for B2B buyers concerned with sustainability.

What Is the Historical Context of Menards Fence Panels in the B2B Landscape?

Menards has established itself as a prominent player in the home improvement and building materials sector since its inception in 1958. Originally focused on retail, the company has expanded its reach, catering to B2B buyers through a wide array of fencing products. Over the decades, Menards has continually adapted to changing market demands, introducing innovative fencing solutions that combine functionality with aesthetics.

The evolution of Menards fence panels reflects broader industry trends, including the shift towards sustainable practices and the integration of technology in traditional products. This history of innovation positions Menards favorably in the global market, making it a reliable partner for B2B buyers seeking quality and sustainability in their fencing solutions.

In conclusion, understanding these market dynamics, sustainability considerations, and the historical context of Menards fence panels can empower international B2B buyers to make informed sourcing decisions. By aligning their purchasing strategies with these trends, buyers can enhance their competitive edge in the evolving fencing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of menards fence panels

-

How do I ensure the quality of Menards fence panels before purchasing?

To ensure quality, request samples from the supplier before making a bulk purchase. Evaluate the materials used, such as the type of wood or vinyl, and verify that they meet your local standards for durability and safety. Additionally, check for certifications or quality assurance documentation that the panels comply with international standards. Engaging in third-party quality inspections can also provide an extra layer of assurance. -

What is the best type of Menards fence panel for a commercial project?

For commercial projects, vinyl fence panels such as the Yardworks® Belmont series offer durability and low maintenance. They are resistant to weather, fading, and pests, making them ideal for long-term installations. If aesthetics are a priority, consider wood panels, like the pressure-treated options, which provide a classic look but may require more upkeep. Assess your project’s specific needs, such as security, privacy, and budget, to make an informed choice. -

What are the minimum order quantities (MOQ) for Menards fence panels?

Minimum order quantities vary by supplier and product type. Typically, for bulk purchases of Menards fence panels, the MOQ can range from a few dozen to several hundred units. It’s advisable to negotiate with your supplier based on your project requirements and to confirm if they can accommodate smaller orders. If you are sourcing internationally, be aware of shipping costs, which may affect the total quantity you should consider. -

How can I customize Menards fence panels to suit my needs?

Customization options depend on the supplier’s capabilities. Many suppliers offer choices in size, color, and material finish. For unique requirements, discuss your needs directly with the supplier. They may provide tailored solutions, such as specific dimensions or design features. Ensure you get written confirmation of any custom specifications and timelines to avoid misunderstandings. -

What payment terms should I expect when sourcing Menards fence panels internationally?

Payment terms can vary widely among suppliers. Common terms include a deposit upfront (usually 30-50%) with the balance due upon delivery or after a specified period. It’s crucial to establish clear terms before placing an order, including accepted payment methods (e.g., wire transfer, credit card) and any potential for financing options. Always consider using escrow services for larger transactions to protect your investment. -

What logistics considerations should I be aware of when importing Menards fence panels?

Logistics for importing fence panels include shipping methods, customs clearance, and delivery times. Assess the best shipping option (air freight for speed or sea freight for cost-effectiveness) based on your timeline and budget. Work with a freight forwarder experienced in international trade to ensure compliance with local regulations and to facilitate smooth customs processes. Additionally, factor in lead times for production and shipping when planning your project timeline. -

How do I vet a supplier for Menards fence panels?

When vetting suppliers, check their reputation through online reviews and industry references. Request documentation of their business licenses, certifications, and compliance with international quality standards. Engage in direct communication to assess their responsiveness and willingness to provide detailed product information. Visiting the supplier’s facility, if feasible, can also offer valuable insights into their operations and reliability. -

What are the common shipping options for Menards fence panels to international locations?

Common shipping options for Menards fence panels include sea freight and air freight. Sea freight is often more economical for large orders but takes longer, while air freight is faster but typically more expensive. Consider factors such as the urgency of your project, the volume of panels, and your budget when selecting a shipping method. Additionally, ensure your supplier can handle the logistics and customs documentation necessary for international shipments.

Top 1 Menards Fence Panels Manufacturers & Suppliers List

1. Maner Builders Supply – Premium Construction Materials

Domain: maner.com

Registered: 1997 (28 years)

Introduction: Maner Builders Supply offers a wide range of premium construction materials and supplies, including:

– Access Control

– Architectural Hardware

– Concrete & Masonry Accessories

– Commercial Doors & Hardware

– Custom Glass, Showers, Closets

– Doors

– Decking & Railing

– Engineered Wood Products

– Fence

– Finishing

– Gypsum Division

– Construction Supply

– Lumber & Plywood

– Masonry

– …

Strategic Sourcing Conclusion and Outlook for menards fence panels

As the demand for high-quality fencing solutions continues to grow globally, strategic sourcing of Menards fence panels presents an exceptional opportunity for international B2B buyers. The diverse range of options, from traditional wood to modern vinyl, allows businesses to cater to various market preferences and requirements. By leveraging Menards’ robust supply chain and competitive pricing, buyers can enhance their product offerings while ensuring customer satisfaction.

Focusing on strategic sourcing not only mitigates risks associated with supply chain disruptions but also positions businesses to capitalize on emerging market trends. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize establishing strong partnerships with suppliers like Menards to secure quality materials that meet local standards and regulations.

Looking ahead, the fencing industry is poised for growth, driven by increasing investments in infrastructure and urban development. By integrating Menards fence panels into their offerings, international buyers can stay ahead of the competition and drive value for their customers. Now is the time to explore these sourcing opportunities and strengthen your supply chain to meet the demands of a dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.