Ceramic Machining: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for ceramic machining

Navigating the complex landscape of ceramic machining can be a daunting challenge for international B2B buyers. With unique properties such as high hardness, thermal resistance, and chemical stability, ceramics are increasingly utilized across diverse industries, from aerospace to electronics. However, sourcing reliable suppliers who can deliver high-quality ceramic components while maintaining cost-effectiveness is critical. This guide aims to illuminate the key factors involved in ceramic machining, including the various types of machining methods, applications, and the essential criteria for vetting suppliers.

By delving into the intricacies of the ceramic machining process, buyers from Africa, South America, the Middle East, and Europe—including regions like Germany and Nigeria—will gain valuable insights into the nuances of this specialized field. This guide empowers decision-makers to navigate the global market confidently, ensuring that they can procure the right ceramic solutions tailored to their specific needs. Whether you’re exploring the latest advancements in CNC machining or seeking to understand the cost implications of high-tolerance technical ceramics, this resource serves as a comprehensive roadmap to informed purchasing decisions. With actionable insights and expert recommendations, buyers can optimize their sourcing strategies, enhance operational efficiency, and foster long-term partnerships in the dynamic world of ceramic machining.

Understanding ceramic machining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Milling | Utilizes computer-controlled machines for precision shaping. | Aerospace, electronics, medical devices | Pros: High precision; versatile for complex geometries. Cons: Higher initial setup costs. |

| Grinding | Involves abrasive materials to achieve fine surface finishes. | Automotive, industrial components, ceramics | Pros: Excellent surface finish; tight tolerances. Cons: Tool wear can increase operational costs. |

| Turning | Rotates the workpiece while a stationary cutting tool removes material. | Tubes, shafts, and cylindrical components | Pros: Efficient for cylindrical shapes; quick material removal. Cons: Limited to round geometries. |

| Electrical Discharge Machining (EDM) | Uses electrical discharges to shape hard materials. | Aerospace, tooling, and molds | Pros: Ideal for complex shapes; effective on hard materials. Cons: Slower than traditional methods. |

| Laser Machining | Employs laser beams for cutting and engraving ceramics. | Electronics, automotive, artistic applications | Pros: High precision; minimal thermal impact. Cons: Higher energy consumption; equipment cost. |

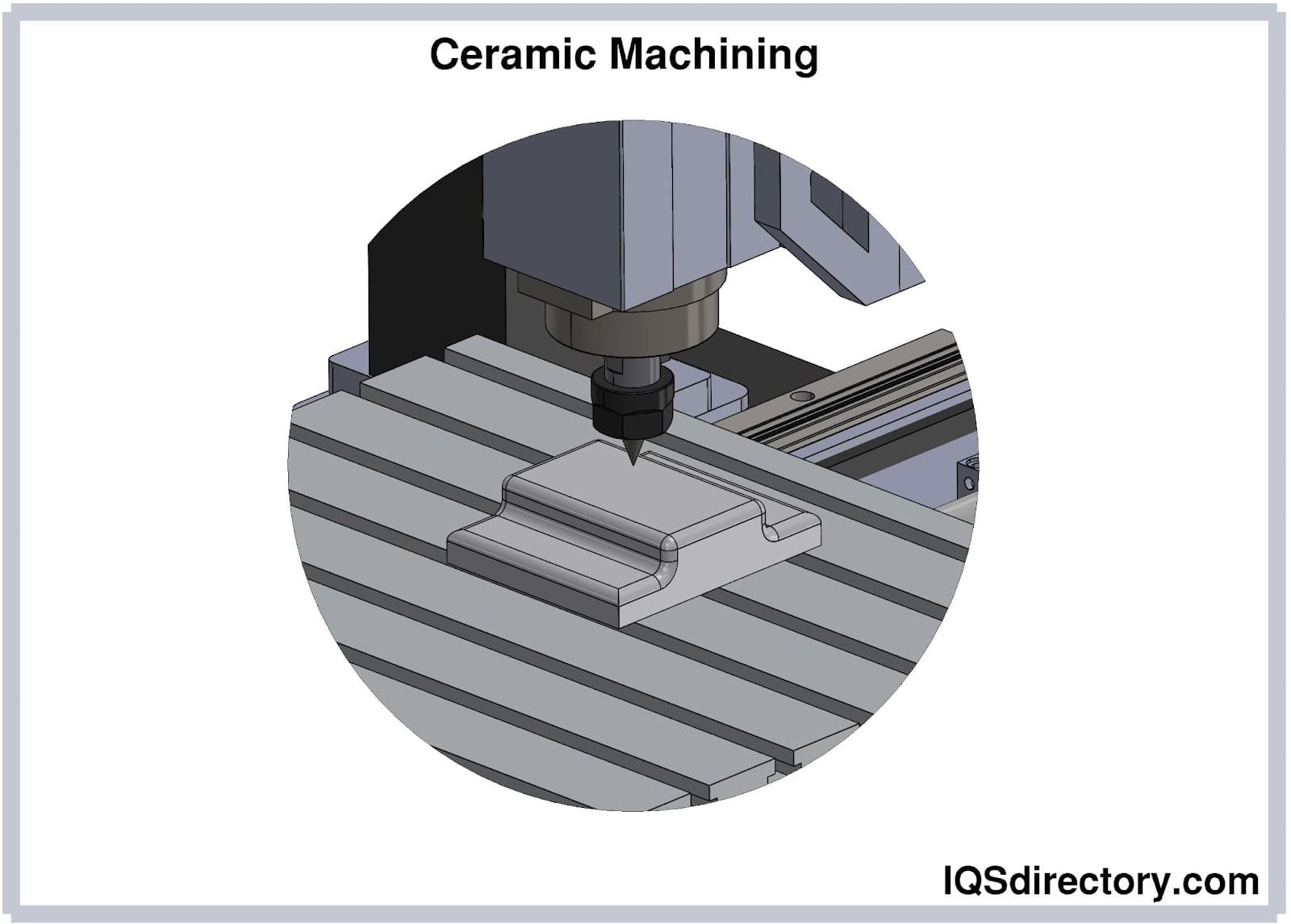

What Are the Characteristics of CNC Milling in Ceramic Machining?

CNC milling is a highly precise ceramic machining technique that employs computer-controlled tools to shape materials with exceptional accuracy. This method is particularly suitable for producing intricate designs and complex geometries, making it ideal for applications in industries such as aerospace and medical devices. Buyers should consider the initial setup costs, which can be higher due to the technology and expertise required, but the long-term benefits of precision and repeatability often justify the investment.

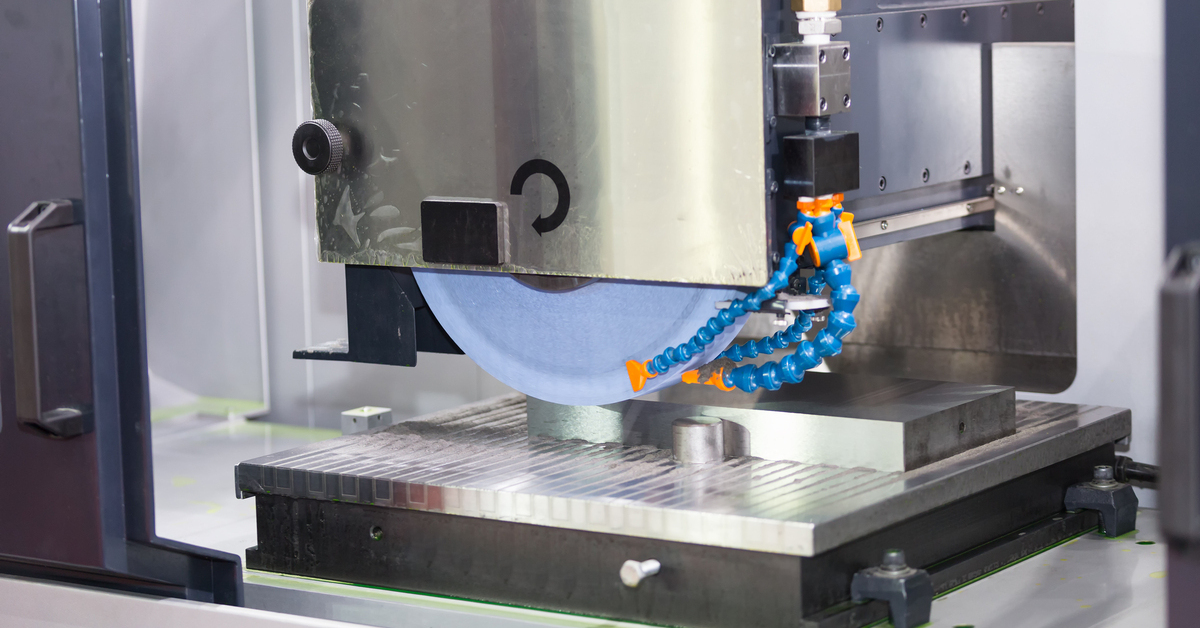

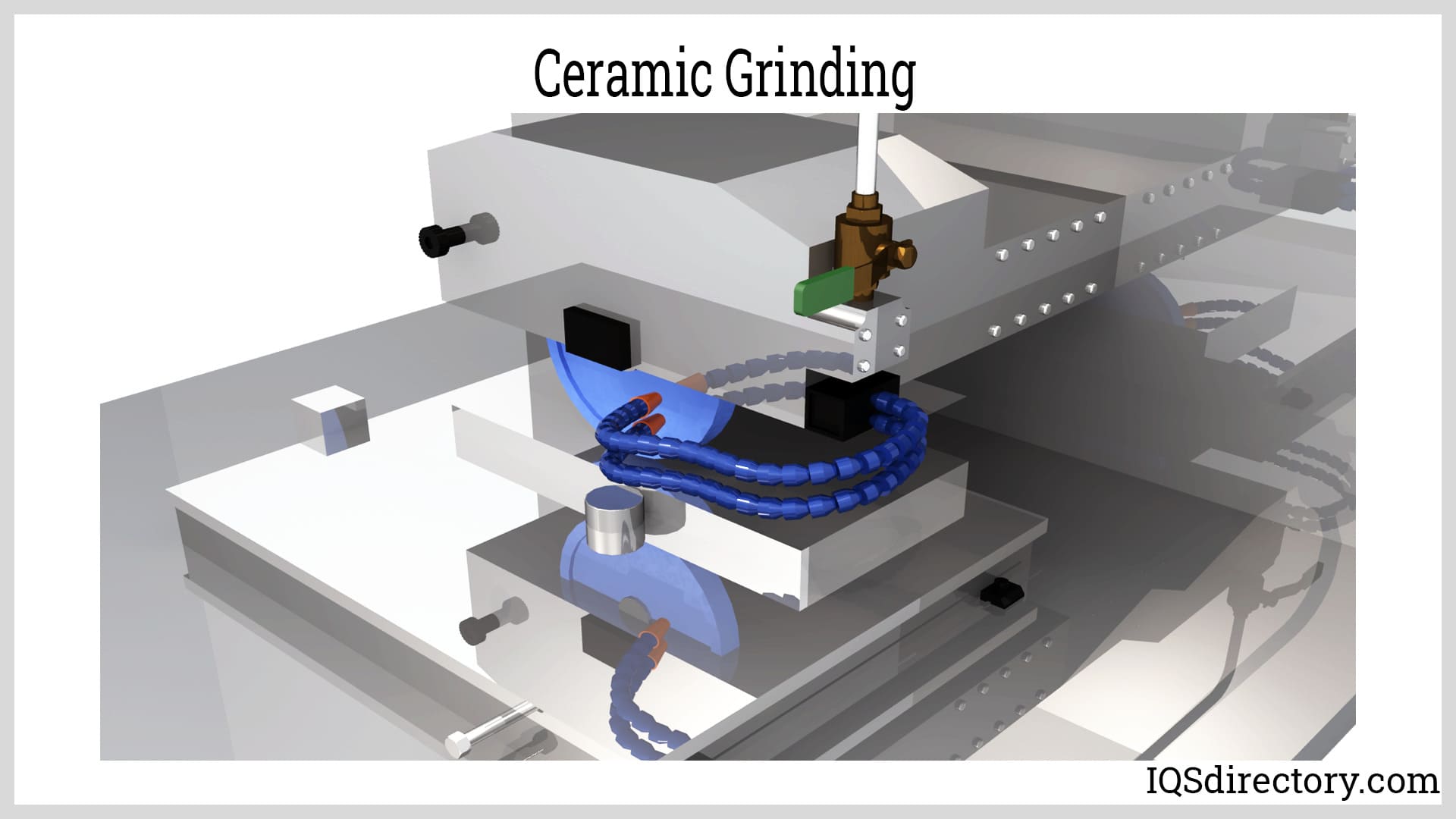

How Does Grinding Contribute to Ceramic Machining Efficiency?

Grinding is a widely utilized technique that employs abrasive particles to refine ceramic surfaces. It excels in achieving fine surface finishes and tight tolerances, making it essential for industries like automotive and industrial components. While grinding can deliver outstanding results, buyers must be aware of the potential for increased tool wear, which can lead to higher operational costs. Careful selection of grinding parameters can mitigate some of these challenges.

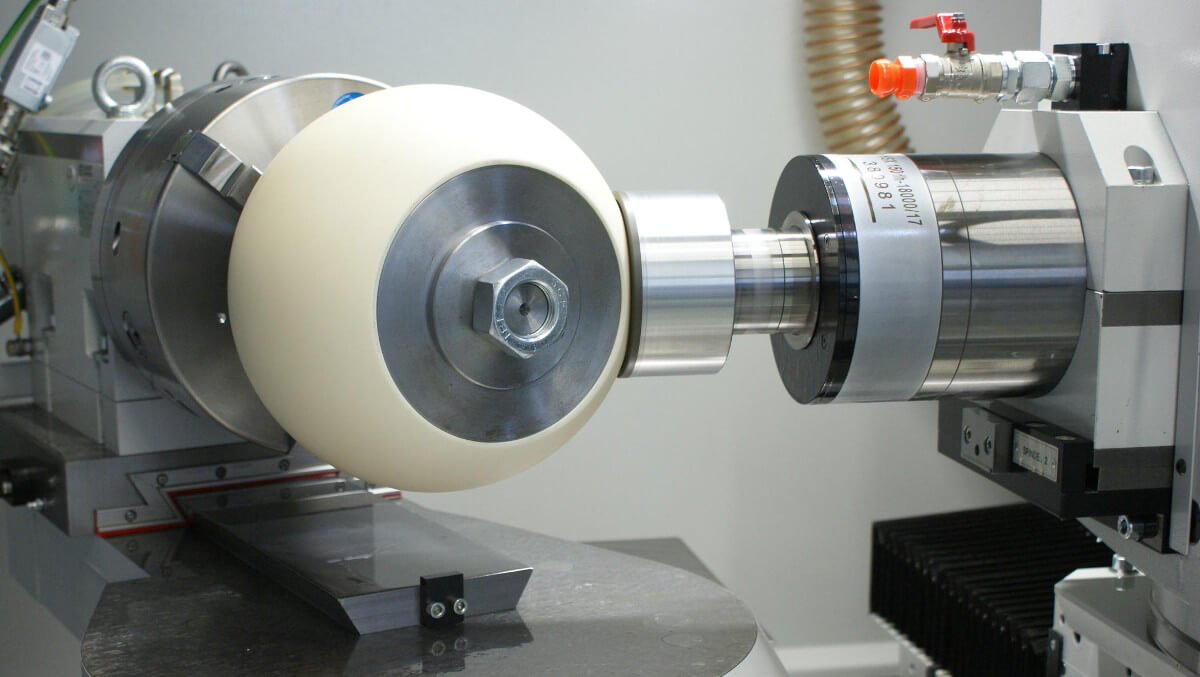

What Are the Advantages of Turning for Ceramic Components?

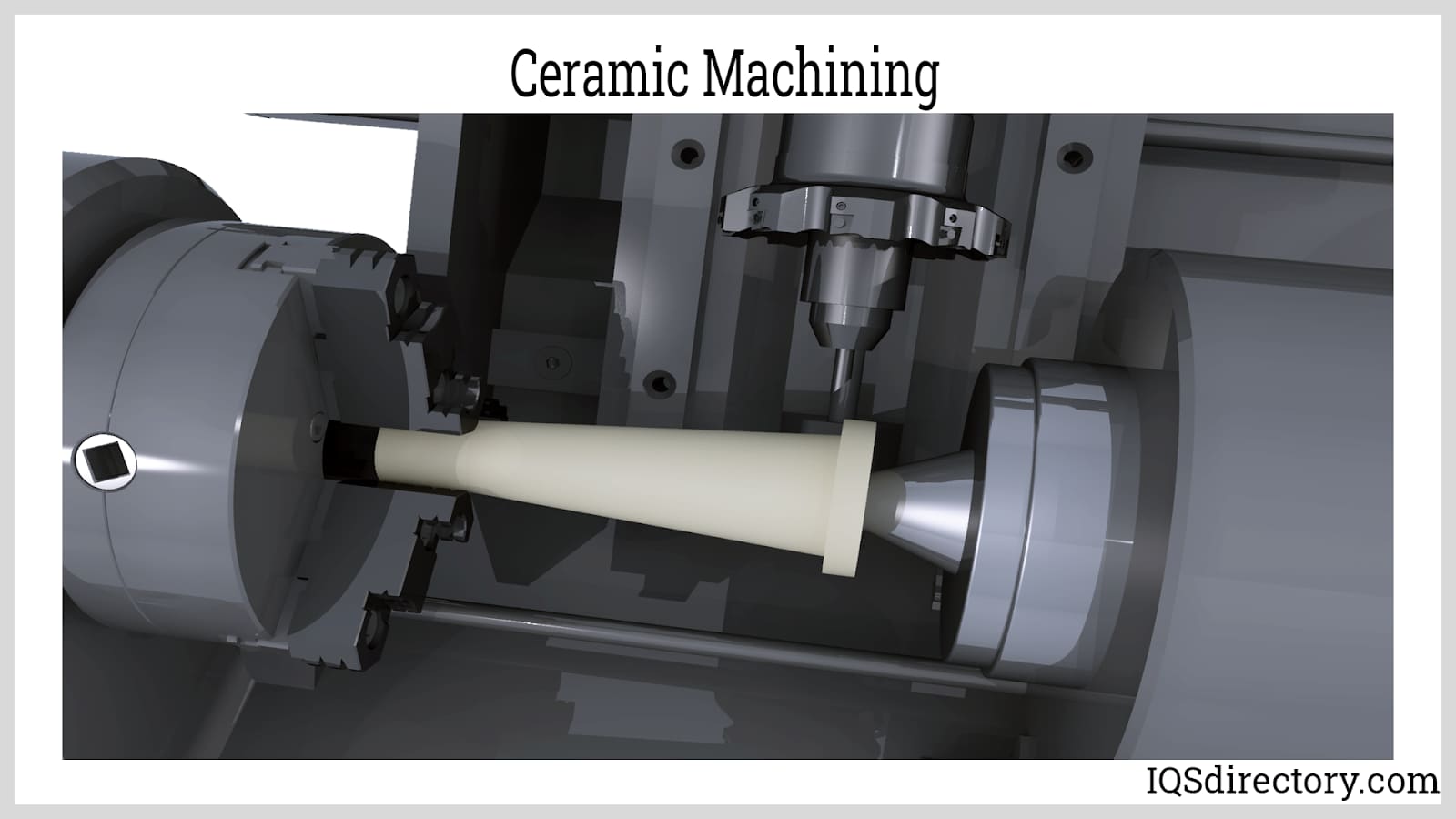

Turning is a method that involves rotating a ceramic workpiece against a stationary cutting tool, making it especially effective for creating cylindrical components such as tubes and shafts. This technique allows for rapid material removal and is efficient for mass production. However, its application is limited to round geometries, which may not suit all project requirements. Buyers should assess their specific needs to determine if turning is the right choice for their ceramic machining projects.

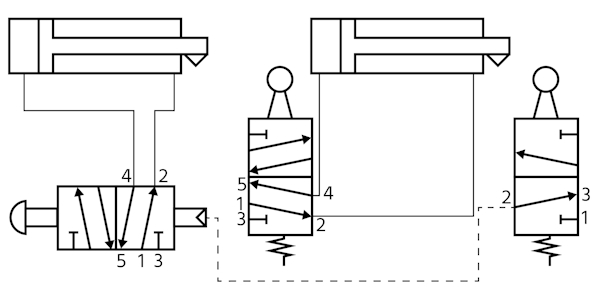

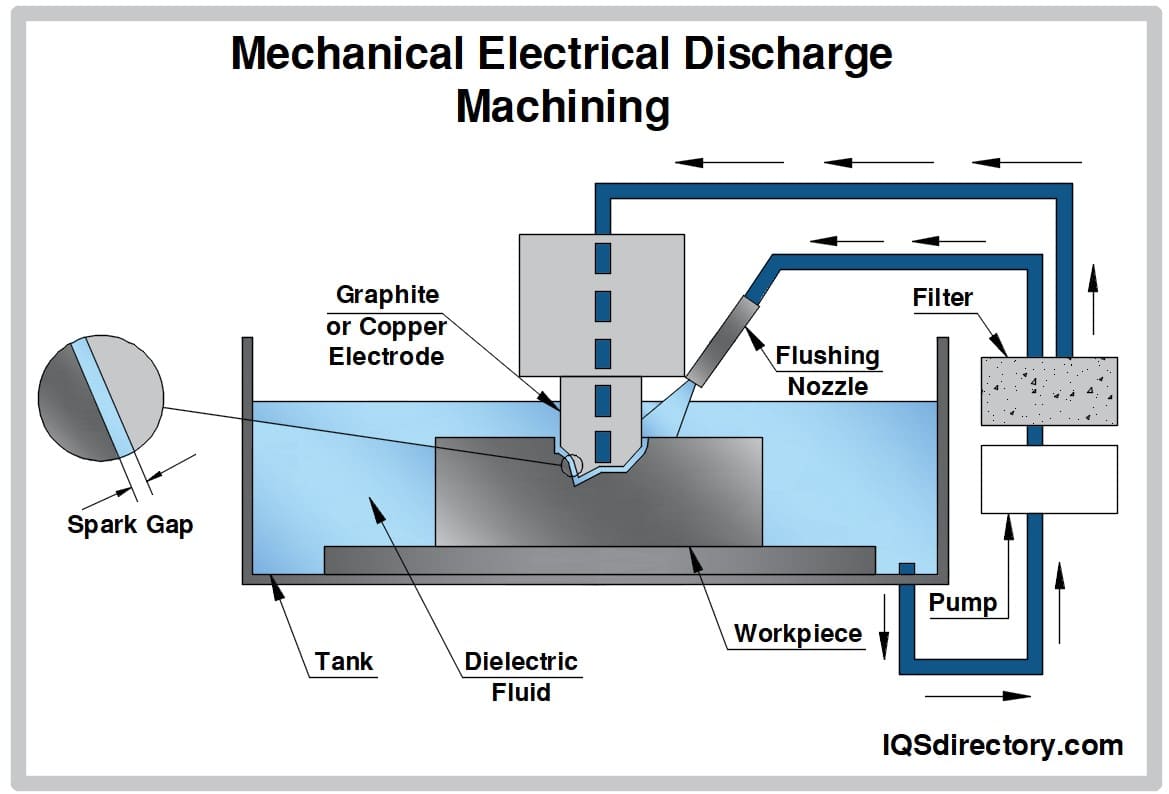

How Does Electrical Discharge Machining (EDM) Enhance Precision?

Electrical Discharge Machining (EDM) is a non-traditional method that uses electrical discharges to remove material from hard ceramics. This technique is particularly advantageous for crafting complex shapes and intricate details, making it popular in aerospace and tooling applications. While EDM can provide exceptional precision, it is generally slower than conventional machining methods. Buyers should consider the trade-off between precision and production speed when evaluating EDM for their needs.

Illustrative image related to ceramic machining

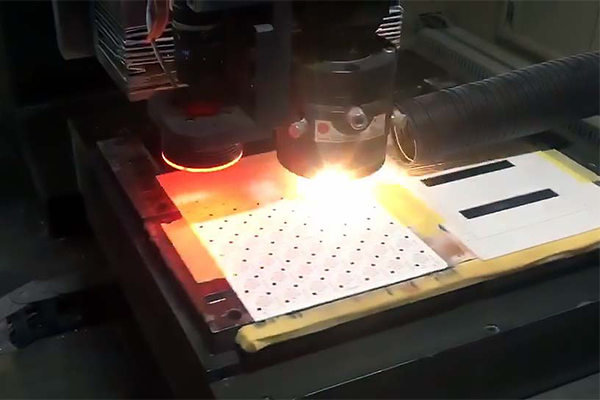

What Are the Key Benefits of Laser Machining in the Ceramic Industry?

Laser machining utilizes focused laser beams for cutting and engraving ceramic materials, offering high precision and minimal thermal impact. This method is versatile and can be applied across various industries, including electronics and automotive. However, buyers should be mindful of the higher energy consumption and equipment costs associated with laser machining. The technology’s ability to produce clean cuts with reduced waste can ultimately enhance operational efficiency and sustainability.

Key Industrial Applications of ceramic machining

| Industry/Sector | Specific Application of Ceramic Machining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for turbine engines | Enhanced performance and reliability in high-stress environments | Material certifications and stringent quality controls |

| Electronics | Ceramic substrates for circuit boards | Improved thermal conductivity and electrical insulation | Compatibility with existing assembly processes |

| Medical Devices | Custom ceramic implants and prosthetics | Biocompatibility and longevity in medical applications | Regulatory compliance and material traceability |

| Automotive | Engine components and wear-resistant parts | Increased durability and reduced maintenance costs | Supplier reliability and advanced machining capabilities |

| Oil & Gas | Seals and insulators for high-temperature applications | Enhanced safety and performance in extreme conditions | High-performance material specifications and certifications |

How Is Ceramic Machining Utilized in Aerospace Applications?

In the aerospace industry, ceramic machining is crucial for producing precision components used in turbine engines. These parts, such as blades and seals, require exceptional strength and thermal resistance to perform reliably under high-stress conditions. By utilizing advanced machining techniques, manufacturers can create components that not only meet stringent industry standards but also improve overall engine efficiency. International buyers should ensure that suppliers have the necessary material certifications and quality control processes to guarantee the reliability of these critical components.

What Role Does Ceramic Machining Play in Electronics Manufacturing?

Ceramic machining is extensively used in the electronics sector for crafting ceramic substrates that serve as the foundation for circuit boards. These substrates are valued for their excellent thermal conductivity and electrical insulation properties, which are essential for the reliable operation of electronic devices. Buyers in this market should focus on sourcing materials that are compatible with their existing assembly processes, while also ensuring that the machining techniques employed maintain the integrity and precision required for high-performance electronics.

How Are Custom Ceramic Implants Created for the Medical Devices Industry?

In the medical devices sector, ceramic machining is employed to manufacture custom implants and prosthetics that are biocompatible and durable. These implants must adhere to strict regulatory standards to ensure patient safety and longevity. Machining techniques allow for the precise shaping of these components, addressing challenges such as wear resistance and the need for complex geometries. Buyers should prioritize suppliers who can demonstrate compliance with medical regulations and provide traceability for their materials.

Illustrative image related to ceramic machining

What Benefits Does Ceramic Machining Offer in Automotive Applications?

The automotive industry leverages ceramic machining to produce engine components and wear-resistant parts that enhance vehicle performance. Ceramics provide benefits such as increased durability and reduced maintenance costs, making them an attractive option for manufacturers aiming to improve their products. When sourcing these components, international buyers should consider the reliability of suppliers and their ability to employ advanced machining techniques that meet the demanding specifications of the automotive sector.

How Is Ceramic Machining Essential for the Oil & Gas Sector?

Ceramic machining plays a vital role in the oil and gas industry, particularly for creating seals and insulators that operate under high-temperature conditions. The durability and chemical resistance of ceramic materials enhance safety and performance in challenging environments. Buyers should ensure that suppliers can provide high-performance material specifications and relevant certifications to meet the rigorous demands of this sector, ensuring that components can withstand the extreme conditions commonly found in oil and gas applications.

3 Common User Pain Points for ‘ceramic machining’ & Their Solutions

Scenario 1: Overcoming Tool Wear Challenges in Ceramic Machining

The Problem:

B2B buyers often face significant challenges related to tool wear when machining ceramics. The exceptional hardness of ceramic materials can lead to rapid degradation of cutting tools, resulting in increased downtime and higher operational costs. This issue is particularly pronounced in high-volume production environments where maintaining tool integrity is crucial for sustaining productivity and quality. If tools wear out too quickly, manufacturers may struggle to meet delivery deadlines, which can jeopardize customer relationships and contracts.

The Solution:

To mitigate tool wear, buyers should prioritize the selection of advanced cutting tools specifically designed for ceramic machining. Options like diamond-coated tools or ceramic-based cutting tools provide superior hardness and thermal stability, effectively enhancing tool longevity. Additionally, optimizing machining parameters—such as adjusting cutting speeds, feed rates, and depth of cut—can significantly reduce wear. Implementing a comprehensive tool management strategy, which includes regular monitoring and replacement schedules, will also help maintain operational efficiency. Furthermore, integrating high-quality coolants or lubricants during the machining process can aid in heat dissipation, minimizing thermal damage and extending tool life.

Scenario 2: Preventing Fractures and Chipping During Machining

The Problem:

Ceramics, while robust in many aspects, are also notoriously brittle. This brittleness poses a significant risk during machining processes, where even slight misalignments or excessive forces can lead to fractures or chipping. For B2B buyers, especially those in industries such as aerospace or electronics, the failure of a ceramic component during machining can result in costly waste and the potential for catastrophic failures in final applications. This challenge requires precise handling and machining techniques to ensure product integrity.

The Solution:

To minimize the risk of fractures and chipping, buyers should invest in specialized machining equipment that offers enhanced stability and precision. Employing vibration-damping technology in CNC machines can help reduce the impact of vibrations that often lead to workpiece damage. Additionally, using softer machining strategies—such as slower feed rates and lighter cutting pressures—can significantly decrease the chances of brittle failure. Employing fixtures that securely hold the ceramic workpieces can also prevent movement during machining, further reducing the risk of fractures. Lastly, incorporating post-machining processes, like thermal stress relieving, can alleviate residual stresses that may contribute to brittleness.

Scenario 3: Achieving Desired Surface Finish on Ceramic Components

The Problem:

Achieving a high-quality surface finish on ceramic components is a common pain point for B2B buyers. The unique properties of ceramics, such as their hardness and brittleness, make it challenging to obtain the desired surface quality without introducing microcracks or surface roughness. In industries like medical devices and electronics, where precision is paramount, subpar surface finishes can lead to functional issues or even product recalls, impacting both reputation and bottom line.

The Solution:

To address surface finish challenges, buyers should focus on employing a multi-step finishing process that combines various machining techniques. For instance, starting with grinding to remove bulk material followed by finer polishing techniques can yield superior results. The selection of appropriate abrasives is critical; utilizing diamond abrasives can enhance the surface finish due to their hardness. Additionally, implementing stringent quality control measures throughout the machining process—such as regular inspections with high-precision measurement tools—can help identify issues early and ensure compliance with specifications. Finally, consider post-machining treatments, such as surface coatings or thermal treatments, to enhance surface properties and mitigate any residual stress that may affect the final product’s performance.

Strategic Material Selection Guide for ceramic machining

What Are the Key Properties of Alumina Ceramics in Machining Applications?

Alumina ceramics, primarily composed of aluminum oxide, are widely recognized for their exceptional hardness and wear resistance. They can withstand high temperatures, often rated up to 1600°C, making them suitable for applications in harsh environments. Additionally, alumina exhibits excellent chemical stability, resisting corrosion from various acids and bases. These properties make alumina ceramics ideal for use in electronics, aerospace, and automotive components, where durability and reliability are paramount.

However, while alumina ceramics are highly durable, they come with challenges. The manufacturing process can be complex, requiring advanced techniques like diamond grinding to achieve the desired shape and finish. This complexity can lead to higher production costs, which may affect overall pricing strategies for B2B buyers. Furthermore, alumina’s brittleness can lead to chipping or cracking during machining, necessitating careful handling and precise machining parameters.

Illustrative image related to ceramic machining

How Does Zirconia Ceramic Compare in Terms of Performance and Applications?

Zirconia ceramics, or zirconium dioxide ceramics, are known for their remarkable toughness and resistance to fracture. They can endure high pressures and temperatures, making them suitable for applications in the medical field, such as dental implants, as well as in automotive and aerospace components. Zirconia also offers excellent corrosion resistance and low thermal conductivity, which enhances its performance in thermal barrier applications.

Despite these advantages, zirconia ceramics can be more expensive than alumina due to their complex manufacturing processes and the need for specialized equipment. Additionally, while zirconia is less brittle than alumina, it can still be prone to wear under certain conditions, which may limit its use in high-abrasion environments. B2B buyers should consider these factors when selecting materials for specific applications, particularly in regions where cost efficiency is crucial.

What Are the Benefits and Limitations of Silicon Nitride Ceramics?

Silicon nitride ceramics are recognized for their high strength and toughness, even at elevated temperatures. They exhibit excellent thermal shock resistance and are often used in applications where rapid temperature changes occur, such as in gas turbine engines and cutting tools. Silicon nitride also has good chemical resistance, making it suitable for use in harsh environments.

However, the manufacturing of silicon nitride can be more complex and costly compared to other ceramics. The processing often requires advanced techniques such as hot pressing or sintering, which can increase lead times and production costs. For international buyers, especially in developing regions like Africa and South America, understanding the cost implications and potential supply chain challenges is essential for effective procurement.

How Do Technical Ceramics Impact Application-Specific Compatibility?

Technical ceramics, including various composites and specialized formulations, offer tailored properties for specific applications. For instance, certain ceramics can be engineered to enhance electrical insulation or to provide specific thermal properties. This versatility allows B2B buyers to select materials that meet stringent industry requirements, such as those outlined by international standards like ASTM or DIN.

Illustrative image related to ceramic machining

Nonetheless, the customization of technical ceramics can lead to increased costs and longer development times. Buyers must weigh the benefits of specialized properties against budget constraints and project timelines. Compliance with local regulations and standards is also critical, particularly in regions with stringent quality control measures.

Summary Table of Material Selection for Ceramic Machining

| Material | Typical Use Case for ceramic machining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina Ceramics | Electronics, aerospace components | High hardness and wear resistance | Brittle, prone to chipping during machining | Medium |

| Zirconia Ceramics | Medical implants, automotive parts | Excellent toughness and corrosion resistance | Higher production costs, limited wear resistance | High |

| Silicon Nitride | Gas turbine engines, cutting tools | High strength and thermal shock resistance | Complex manufacturing process, higher costs | High |

| Technical Ceramics | Custom applications in various industries | Tailored properties for specific applications | Increased costs and longer development times | Medium to High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for ceramic machining, ensuring informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic machining

What Are the Main Stages in the Manufacturing Process of Ceramic Machining?

Ceramic machining is a multifaceted process that transforms raw ceramic materials into high-precision components. The manufacturing process typically involves several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to ceramic machining

How Is Material Prepared for Ceramic Machining?

The first step in ceramic machining is material preparation. This involves selecting the appropriate ceramic material based on the desired properties and application. Common materials include alumina, zirconia, and silicon carbide, each offering unique characteristics like hardness and thermal stability.

Once the material is chosen, it undergoes various treatments such as milling and granulation to achieve a uniform particle size and distribution. This ensures consistent material behavior during subsequent processing stages. Additionally, additives may be included to enhance specific properties, such as strength or flexibility.

What Techniques Are Used for Forming Ceramic Components?

Forming is the next critical stage in the ceramic machining process. Several techniques are employed, depending on the complexity and design of the final product. The most common methods include:

-

Injection Molding: This technique is suitable for mass production, allowing for intricate shapes and designs. The ceramic powder is mixed with a binder and injected into molds.

-

Isostatic Pressing: This method applies uniform pressure to the ceramic powder, resulting in a dense and uniform green body. It is particularly effective for complex geometries.

-

Slip Casting: In this technique, a liquid slurry of ceramic material is poured into a porous mold. Once the desired thickness is achieved, the excess slurry is drained, and the mold is removed.

-

Dry Pressing: This method involves compacting dry ceramic powder into a mold under high pressure, producing a compact green part ready for further machining.

Each technique has its advantages and is selected based on the specific requirements of the application, such as part geometry, size, and production volume.

How Is the Assembly Process Managed in Ceramic Machining?

In cases where multiple ceramic components are required for a final product, the assembly stage becomes crucial. This can involve processes such as brazing or joining, where different ceramic parts are fused together using specialized materials.

Quality control during assembly is vital, as the integrity of the joints can significantly affect the performance of the final product. Advanced techniques like laser welding or adhesive bonding may be employed to ensure a strong and reliable assembly.

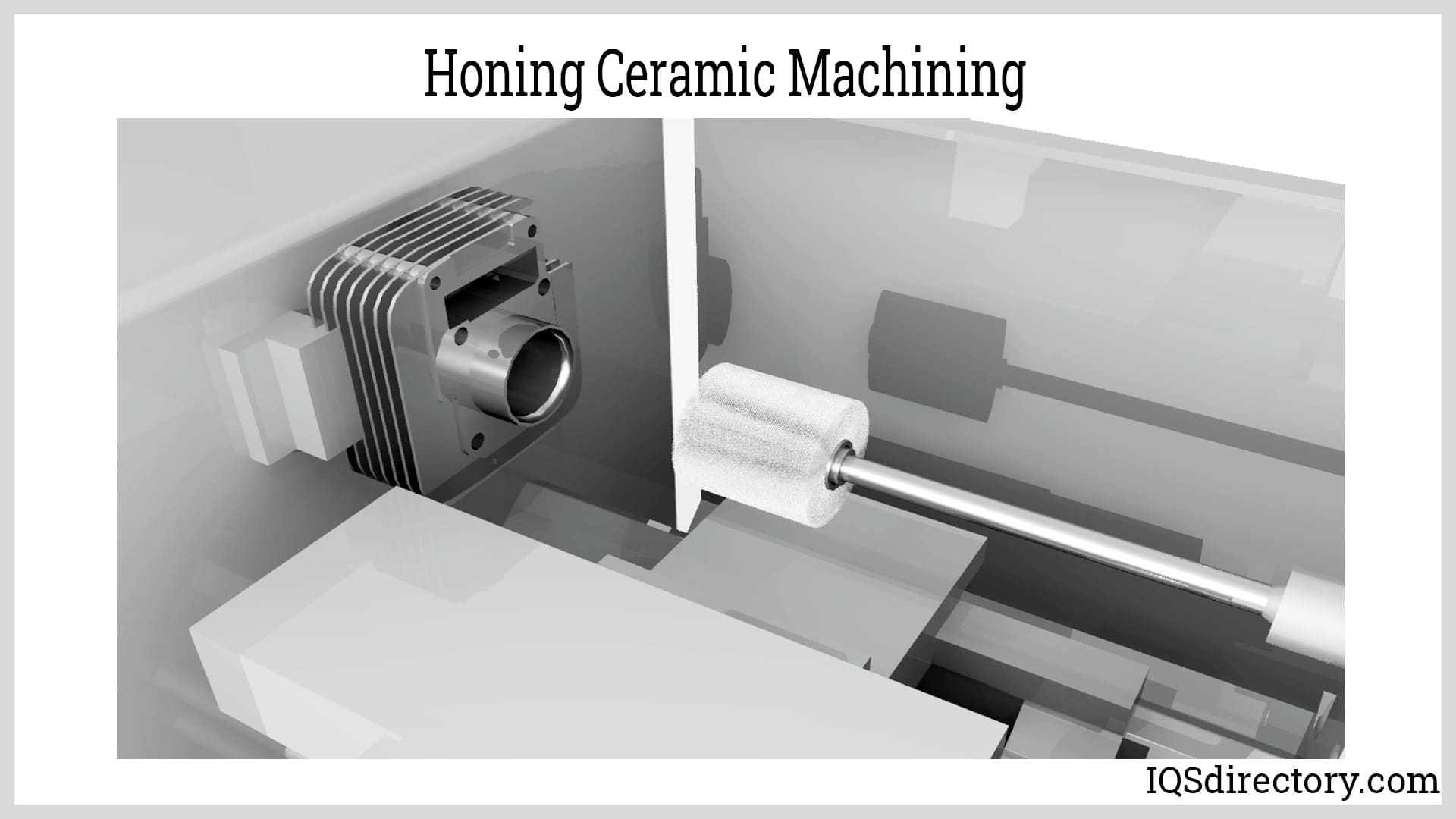

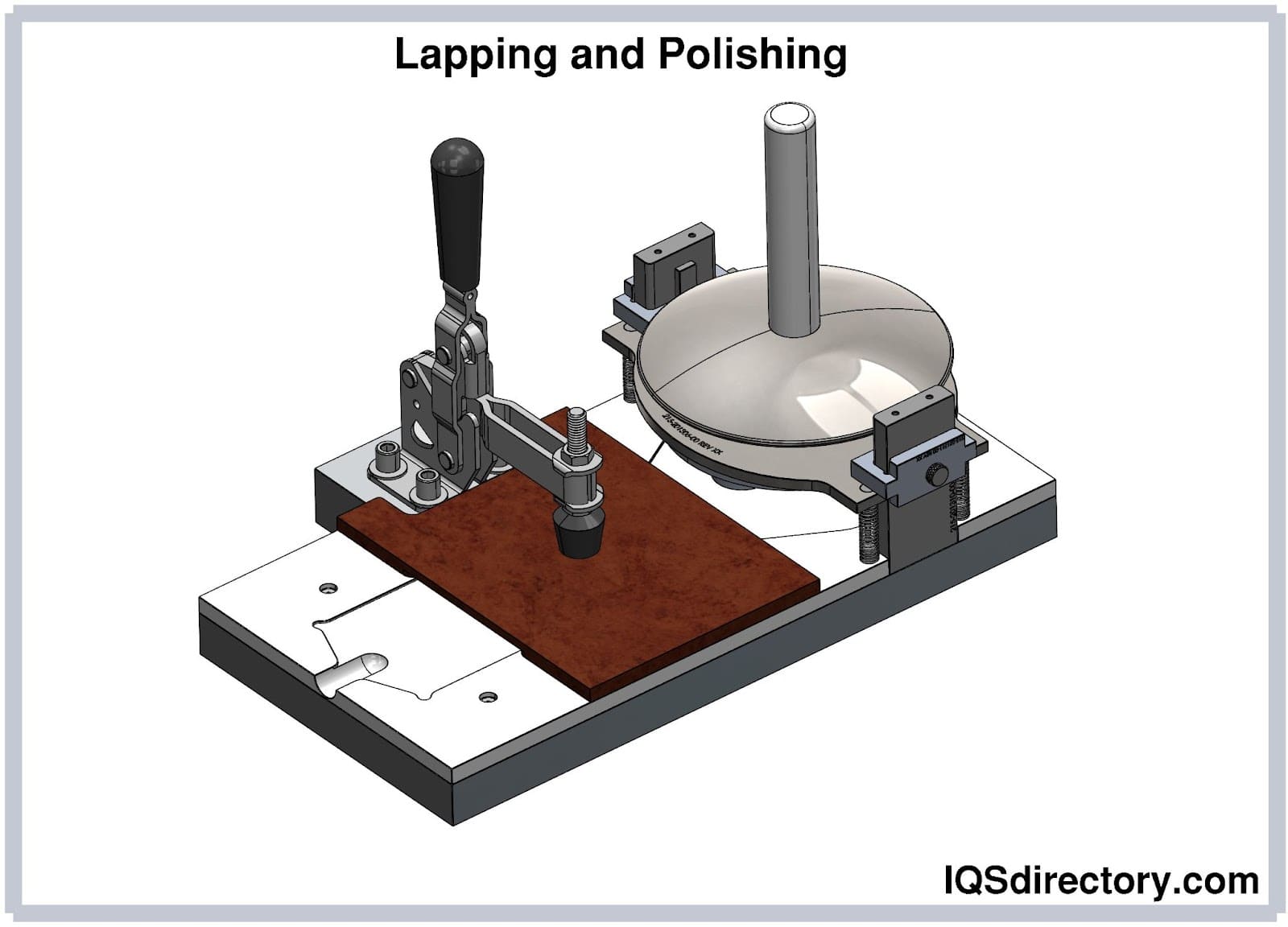

What Finishing Techniques Enhance the Quality of Ceramic Products?

Finishing processes are essential for achieving the desired surface finish and tolerances in ceramic components. Common finishing techniques include:

-

Grinding: This is one of the most prevalent finishing methods, utilizing abrasive wheels to refine the surface and achieve precise dimensions.

-

Polishing: This process enhances the surface finish, reducing roughness and improving aesthetics.

-

Lapping: A technique that uses a slurry of abrasives to achieve ultra-fine finishes and tight tolerances.

-

Coating: Applying protective coatings can enhance wear resistance and provide additional properties such as chemical resistance.

These finishing techniques not only improve the appearance of ceramic components but also ensure they meet rigorous industry standards.

What Quality Assurance Practices Are Essential in Ceramic Machining?

Quality assurance (QA) is a critical aspect of the ceramic machining process, ensuring that the final products meet international standards and customer specifications. Effective QA practices encompass various stages of manufacturing and involve several checkpoints.

Which International and Industry-Specific Standards Should Be Considered?

For B2B buyers, understanding relevant international standards is crucial. ISO 9001 is the most recognized quality management standard, emphasizing a process-based approach to ensure consistent quality. In addition to ISO 9001, industry-specific certifications may be required, such as:

-

CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

-

API Certification: Relevant for ceramics used in the oil and gas industry, ensuring adherence to stringent performance and safety standards.

These certifications not only serve as a mark of quality but also facilitate smoother international trade.

What Are the Key Quality Control Checkpoints in Ceramic Machining?

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor and ensure product quality. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps identify defects early, reducing waste and rework.

-

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing to verify that they meet all specifications before shipment.

These checkpoints are essential for maintaining high standards and ensuring customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. This can be achieved through:

-

Audits: Conducting on-site audits allows buyers to evaluate the supplier’s quality management system and manufacturing processes firsthand.

-

Documentation Review: Requesting quality reports, inspection records, and certifications can provide insights into the supplier’s adherence to standards.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality practices and product quality.

These measures help mitigate risks associated with sourcing ceramic components and ensure that buyers receive products that meet their expectations.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must navigate various quality control nuances that may vary by region. For instance, regulations in Europe may differ significantly from those in Africa or South America. Buyers should be aware of local compliance requirements and any additional certifications that may be necessary for specific markets.

Illustrative image related to ceramic machining

Additionally, cultural differences in business practices and communication styles can impact quality assurance expectations. Establishing clear communication channels and expectations with suppliers is vital for successful international collaborations.

Conclusion

Understanding the manufacturing processes and quality assurance measures in ceramic machining is crucial for B2B buyers seeking high-quality ceramic components. By comprehensively evaluating suppliers based on their manufacturing techniques, quality control practices, and compliance with international standards, buyers can ensure they source reliable and high-performance products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ceramic machining’

To assist B2B buyers in procuring ceramic machining services, this guide outlines critical steps and considerations to ensure successful sourcing. Whether you’re sourcing for aerospace, electronics, or medical applications, following this checklist will help you identify the right suppliers and achieve high-quality results.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is vital for effective communication with potential suppliers. Include details such as material types (e.g., alumina, zirconia), desired tolerances, dimensions, and any specific surface finishes required. This will help suppliers assess their capability to meet your needs and provide accurate quotes.

Step 2: Research Industry Standards and Certifications

Understanding relevant industry standards and certifications is crucial for ensuring product quality and compliance. Look for suppliers who adhere to ISO certifications or specific industry standards pertinent to your application, such as ASTM or DIN. This not only assures quality but also enhances credibility in international markets.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions. Pay particular attention to their experience with the specific types of ceramics you require, as well as their ability to handle complex geometries or high tolerances.

- Sub-bullet: Ask for sample products to assess quality directly.

- Sub-bullet: Investigate their production capabilities and technology used.

Step 4: Assess Manufacturing Capabilities

Investigate the manufacturing technologies employed by the suppliers. Key techniques such as CNC milling, grinding, and electrical discharge machining (EDM) should be evaluated based on your specifications. Understanding their equipment and processes will help you determine their ability to produce intricate components and meet your delivery timelines.

Step 5: Inquire About Quality Control Measures

Quality control is paramount in ceramic machining due to the material’s unique properties. Ensure that the supplier has robust quality assurance processes in place, including in-process inspections, final product testing, and traceability for materials used. This will help mitigate risks associated with defects and ensure consistent quality.

Step 6: Understand Pricing Structure and Terms

Discuss pricing models and payment terms upfront to avoid surprises later. Be clear about what is included in the pricing, such as tooling, setup fees, and potential costs for revisions. Understanding the total cost of ownership will aid in budgeting and ensure that you are comparing suppliers on a like-for-like basis.

Illustrative image related to ceramic machining

Step 7: Establish Communication Protocols

Effective communication is essential for successful partnerships. Establish clear channels for regular updates and project milestones. Discuss the preferred methods of communication, frequency of updates, and points of contact to ensure transparency throughout the project lifecycle.

Following this checklist will empower you to make informed decisions when sourcing ceramic machining services, ultimately leading to higher quality products and more reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for ceramic machining Sourcing

What Are the Key Cost Components in Ceramic Machining?

When analyzing the cost structure for ceramic machining, it is essential to consider several key components:

-

Materials: The type of ceramic material significantly influences costs. High-performance ceramics, such as zirconia or alumina, are typically more expensive due to their superior properties. The choice of raw material impacts not only the initial cost but also the longevity and performance of the final product.

-

Labor: Skilled labor is required for ceramic machining due to the complexities involved in handling brittle materials. Labor costs can vary based on the region and the expertise of the machinists. In regions like Europe or North America, labor costs may be higher, while in Africa or South America, they could be lower but may come with different challenges related to skill levels.

-

Manufacturing Overhead: This includes costs associated with equipment maintenance, facility management, and administrative expenses. High-tech machinery used in ceramic machining, such as CNC machines, requires significant investment and upkeep, which can drive overhead costs.

-

Tooling: Specialized tools are necessary for machining ceramics, including diamond-coated cutting tools. The cost of these tools can be substantial, and their lifespan is often shorter due to the wear and tear associated with machining hard materials.

-

Quality Control (QC): Ensuring the precision and quality of ceramic components involves rigorous QC processes. This may include advanced measuring techniques and testing equipment, which add to the overall cost but are crucial for maintaining standards.

-

Logistics: Transporting ceramic components, especially internationally, can incur significant shipping and handling costs. Factors such as packaging, insurance, and customs duties must also be considered.

-

Margin: Suppliers typically build in a profit margin that reflects their operational costs, market conditions, and competitive landscape. Understanding how margins fluctuate based on demand and supply dynamics can aid in negotiations.

How Do Price Influencers Affect Ceramic Machining Costs?

Several factors can influence the pricing of ceramic machining services:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specifications can lead to higher costs due to the additional processing and unique tooling required. Clearly defined requirements can streamline the manufacturing process and potentially lower costs.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., ISO, ASTM) typically come at a premium. Buyers should weigh the cost against the potential performance benefits.

-

Supplier Factors: The reputation, location, and capabilities of the supplier can affect pricing. Established suppliers with advanced technology may charge more but offer better quality assurance.

-

Incoterms: The terms of shipping and responsibility (Incoterms) can also influence costs. For instance, terms like FOB (Free on Board) can shift responsibilities and risks, impacting total costs for buyers.

What Are Some Effective Buyer Tips for Sourcing Ceramic Machining?

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing structures. Leveraging long-term partnerships can lead to better pricing and favorable terms. Don’t hesitate to ask for volume discounts or explore alternative material options that may reduce costs.

-

Focus on Total Cost of Ownership (TCO): Beyond initial pricing, consider the long-term costs associated with performance, maintenance, and potential failures. Selecting high-quality materials may lead to reduced replacement or repair costs over time.

-

Understand Pricing Nuances for International Procurement: International buyers should be aware of currency fluctuations, tariffs, and additional logistics costs that can impact the final price. Building relationships with local suppliers in target regions (e.g., Africa, South America) may yield better pricing and service.

-

Research and Compare Suppliers: Conduct thorough research to compare various suppliers based on price, quality, and service capabilities. Request samples and quotes to make informed decisions.

-

Stay Informed About Market Trends: Keeping an eye on market conditions and technological advancements in ceramic machining can provide insights into pricing trends and help identify potential cost-saving opportunities.

Disclaimer

Prices for ceramic machining services can vary widely based on the factors mentioned above. It is advisable for buyers to obtain quotes from multiple suppliers and consider all aspects of the cost structure before making a decision.

Alternatives Analysis: Comparing ceramic machining With Other Solutions

When evaluating manufacturing solutions, it’s essential to consider various alternatives that can meet specific project requirements. Ceramic machining is a highly specialized process known for its precision and durability, but other methods may also provide viable options depending on the application. This analysis will compare ceramic machining with two alternative solutions: metal machining and plastic machining, highlighting their respective advantages and disadvantages.

| Comparison Aspect | Ceramic Machining | Metal Machining | Plastic Machining |

|---|---|---|---|

| Performance | High precision; excellent for intricate designs; suitable for high-temperature applications. | Strong durability; can handle heavy loads and stress; versatile for various shapes. | Lightweight; good for high-volume production; can be engineered for specific properties. |

| Cost | Generally higher due to specialized tools and techniques; may require custom tooling. | Moderate cost; tooling can be expensive but offers long-term durability. | Lower material costs; tooling costs can vary based on complexity. |

| Ease of Implementation | Requires specialized equipment and skilled technicians; longer setup time. | Well-established processes; readily available machinery; skilled workforce. | Easier setup; often involves simpler machinery; less technical expertise required. |

| Maintenance | High maintenance due to tool wear; requires regular monitoring and replacement. | Moderate maintenance; tools last longer but require periodic checks. | Low maintenance; tools are typically less susceptible to wear. |

| Best Use Case | Ideal for aerospace, medical devices, and high-performance applications. | Best for automotive, construction, and heavy machinery components. | Suitable for consumer products, packaging, and electronic housings. |

What Are the Pros and Cons of Metal Machining Compared to Ceramic Machining?

Metal machining is a widely used alternative that excels in producing robust components. It is especially advantageous for industries that require high strength and durability, such as automotive and construction. The established processes and availability of skilled labor make it easy to implement. However, metal machining may not achieve the same level of precision as ceramic machining for intricate designs and often involves higher energy consumption during the machining process. Additionally, metal parts may not perform as well in high-temperature environments compared to ceramics.

How Does Plastic Machining Compare to Ceramic Machining in Terms of Efficiency?

Plastic machining offers a cost-effective and efficient alternative for high-volume production. It is ideal for applications where weight reduction is crucial, such as in consumer electronics and packaging. The ease of implementation and lower tooling costs make plastic machining an attractive option for many manufacturers. However, plastic components generally lack the heat resistance and mechanical strength of ceramics, limiting their use in high-performance applications. Furthermore, the environmental impact of plastic waste is a growing concern, which may influence decision-making for eco-conscious buyers.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right machining solution, B2B buyers should thoroughly evaluate their specific requirements, including performance criteria, budget constraints, and operational capabilities. If precision and durability are paramount, ceramic machining may be the best choice. Conversely, for applications requiring strength and ease of production, metal machining could be more suitable. For projects focused on cost and volume, plastic machining may offer the most efficient solution. By aligning their operational needs with the strengths of each machining method, buyers can make informed decisions that enhance their production efficiency and product quality.

Essential Technical Properties and Trade Terminology for ceramic machining

What Are the Key Technical Properties in Ceramic Machining?

Understanding the essential technical properties of ceramic machining is crucial for B2B buyers aiming to procure high-quality ceramic components. Here are some critical specifications to consider:

Material Grade

Material grade refers to the classification of ceramic materials based on their composition and properties. Common grades include alumina, zirconia, and silicon carbide, each offering distinct advantages such as hardness, thermal stability, and chemical resistance. Selecting the right material grade is vital for ensuring the performance and longevity of the final product in its intended application.

Illustrative image related to ceramic machining

Tolerance

Tolerance indicates the allowable deviation in dimensions during the machining process. In ceramic machining, tolerances can range from ±0.02mm to ±0.01mm, depending on the complexity of the part. Precision in tolerance is essential for applications where fit and functionality are critical, such as in aerospace or medical devices. Meeting stringent tolerance requirements can significantly impact production efficiency and product reliability.

Surface Finish

Surface finish refers to the texture and quality of a machined ceramic component’s surface. Common surface finish classifications include N2, N3, N4, and N5, with lower numbers indicating a smoother finish. A high-quality surface finish is important not only for aesthetic purposes but also for performance, as it can affect wear resistance, friction, and even the component’s interaction with other materials.

Hardness

Hardness is a measure of a material’s resistance to deformation or scratching. Ceramics are known for their high hardness levels, often requiring diamond tools for effective machining. This property is particularly significant for applications that demand durability, such as wear-resistant components in industrial settings.

Brittleness

Brittleness characterizes a material’s tendency to fracture under stress rather than deform. While ceramics offer exceptional hardness, their brittleness poses challenges during machining. Understanding brittleness helps in selecting appropriate machining techniques and tools to minimize the risk of fractures, thereby reducing scrap rates and production costs.

What Are Common Trade Terminologies in Ceramic Machining?

Familiarity with industry jargon is essential for effective communication in the ceramic machining sector. Here are some commonly used terms:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In ceramic machining, OEMs often require customized components for their products, necessitating clear specifications and collaboration during the design and manufacturing phases.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In ceramic machining, MOQs can affect procurement strategies, especially for international buyers. Understanding MOQs helps businesses plan their inventory and manage costs effectively, ensuring they meet demand without overcommitting resources.

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. In the context of ceramic machining, submitting an RFQ allows buyers to compare offers from different suppliers, facilitating informed decision-making regarding cost, quality, and lead times.

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers engaged in cross-border ceramic sourcing, as they clarify shipping responsibilities, risk management, and cost allocation.

CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools via a computer. This technology is prevalent in ceramic machining, enabling precise shaping and finishing of components. Familiarity with CNC capabilities allows buyers to better understand production processes and the quality assurance mechanisms involved.

By grasping these essential technical properties and trade terminologies, B2B buyers can enhance their decision-making processes, ensuring they select the right ceramic components for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the ceramic machining Sector

What Are the Key Trends Shaping the Ceramic Machining Market?

The ceramic machining sector is experiencing a transformative phase, driven by technological advancements and evolving market demands. A significant global driver is the increasing application of ceramics in high-tech industries such as electronics, aerospace, and automotive. The demand for lightweight, durable, and high-performance materials is propelling the growth of advanced ceramics, particularly in regions like Europe and North America, where innovation is at the forefront.

Illustrative image related to ceramic machining

Emerging B2B tech trends include the integration of automation and artificial intelligence in machining processes, enhancing efficiency and precision. CNC (Computer Numerical Control) machining is becoming the standard, allowing for complex geometries and tighter tolerances that were previously unattainable. Furthermore, advancements in tooling materials, such as diamond-coated tools, are helping to mitigate common challenges associated with machining ceramics, such as tool wear and brittleness.

For international buyers, particularly from Africa, South America, and the Middle East, understanding local market dynamics is crucial. The growth of manufacturing hubs in these regions presents opportunities for sourcing high-quality ceramic components. However, buyers must navigate challenges such as fluctuating raw material prices and varying quality standards. The focus on supply chain resilience and transparency is becoming paramount, as companies seek reliable partners who can deliver quality while adhering to strict timelines.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in Ceramic Machining?

Sustainability has emerged as a critical consideration in the ceramic machining sector, influencing purchasing decisions and supplier relationships. The environmental impact of ceramic production, including energy consumption and waste generation, underscores the need for sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through energy-efficient processes and waste reduction strategies.

Ethical sourcing is also gaining traction as companies recognize the importance of responsible supply chains. This includes ensuring that raw materials are sourced from suppliers who adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential for suppliers aiming to establish credibility in the international market.

Moreover, the introduction of ‘green’ materials—such as those with lower environmental impact during production—can enhance a company’s marketability. By aligning with suppliers who offer sustainable ceramic solutions, businesses can not only meet regulatory requirements but also appeal to environmentally conscious consumers and stakeholders.

How Has the Ceramic Machining Sector Evolved Over Time?

The evolution of the ceramic machining sector can be traced back to the early adoption of ceramics in industrial applications. Initially, ceramics were primarily used for their aesthetic and insulating properties. However, as technology advanced, the unique characteristics of ceramics—such as high hardness, heat resistance, and chemical stability—became more widely recognized.

Illustrative image related to ceramic machining

In the late 20th century, innovations in machining techniques, including CNC technology and advanced grinding methods, significantly improved the precision and efficiency of ceramic machining. This period marked a shift towards the use of ceramics in high-performance applications, including aerospace components and medical devices, solidifying ceramics’ status as a critical material in modern manufacturing.

Today, the sector continues to evolve with a focus on sustainability and the integration of digital technologies, positioning itself to meet the challenges of a rapidly changing global market. As B2B buyers increasingly seek high-quality, ethically sourced ceramic components, the industry is poised for further growth and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic machining

-

How do I solve challenges related to machining ceramics?

Machining ceramics presents unique challenges such as brittleness, high hardness, and thermal sensitivity. To address these issues, consider using advanced tooling materials like diamond-coated tools which enhance wear resistance. Optimize cutting parameters, including speed and feed rate, to minimize tool wear and heat generation. Employing coolants during machining can help dissipate heat and reduce friction. Additionally, implementing vibration damping techniques and performing post-machining treatments, such as thermal stress relieving, can improve surface quality and reduce residual stresses in the final product. -

What is the best machining technique for hard ceramics?

For hard ceramics, grinding is often the most effective machining technique. This method utilizes abrasive particles to remove material and is suitable for achieving precise shapes and surface finishes. It can handle various ceramic types and is versatile for both large-scale material removal and tight tolerances. However, care must be taken in selecting the right grinding parameters and tools to prevent damage or fracturing due to the brittleness and hardness of the material. CNC grinding offers automated precision, enhancing consistency and reducing human error. -

What factors should I consider when selecting a ceramic machining supplier?

When choosing a ceramic machining supplier, evaluate their experience and expertise in working with specific ceramic materials relevant to your needs. Review their capabilities in terms of machining techniques, equipment used, and quality control processes. It’s also vital to check their certifications and compliance with international standards. Request samples or case studies to assess the quality of their work. Additionally, consider their ability to customize products, lead times, and communication effectiveness, which are crucial for a smooth procurement process. -

What are the typical minimum order quantities (MOQs) for ceramic machining?

Minimum order quantities (MOQs) for ceramic machining can vary significantly based on the supplier and the complexity of the components. Generally, MOQs can range from a few dozen to several hundred pieces, especially for custom parts. Suppliers may impose higher MOQs for specialized materials or intricate designs due to setup costs. It is advisable to discuss your specific needs with potential suppliers to understand their policies and negotiate terms that fit your production requirements, especially if you are a smaller business or testing a new product line. -

What payment terms should I expect when sourcing ceramic machining services?

Payment terms for ceramic machining services typically vary by supplier and can include options such as upfront deposits, progress payments, or payment upon delivery. Commonly, a 30% deposit is required to initiate production, with the balance due upon completion or before shipping. Some suppliers may offer favorable terms for long-term contracts or large orders. It’s crucial to clarify payment terms upfront to avoid misunderstandings and ensure that they align with your cash flow requirements. Additionally, consider using secure payment methods to protect your financial interests. -

How can I ensure quality assurance in ceramic machining?

To ensure quality assurance in ceramic machining, inquire about the supplier’s quality control processes. Look for suppliers that utilize advanced inspection techniques, such as CNC coordinate measuring machines (CMM), to verify tolerances and surface finishes. Request documentation of their quality certifications, like ISO 9001, which demonstrates their commitment to consistent quality. Additionally, establish clear specifications and tolerances in your purchase orders, and consider conducting random inspections or requesting samples before full production runs to verify the quality of the components. -

What logistics considerations should I keep in mind when sourcing ceramic components internationally?

When sourcing ceramic components internationally, logistics considerations include shipping methods, lead times, and customs regulations. Choose a shipping method that balances cost and delivery speed, such as air freight for urgent orders or sea freight for bulk shipments. Be aware of customs duties and import regulations in your country, as these can impact overall costs and delivery times. Collaborate with suppliers who have experience with international shipping to ensure proper documentation and compliance, which can help prevent delays and additional charges upon arrival. -

How do I manage communication with international suppliers effectively?

Effective communication with international suppliers is vital for successful sourcing. Establish clear lines of communication through preferred channels, whether email, video calls, or messaging apps. Be explicit about your requirements, timelines, and expectations to minimize misunderstandings. Regularly check in on project progress and encourage suppliers to provide updates or raise any concerns promptly. Utilizing translation services can also help bridge language barriers, ensuring that both parties fully understand technical specifications and contractual obligations, leading to a smoother collaboration.

Top 9 Ceramic Machining Manufacturers & Suppliers List

1. Precision Ceramics – Technical Ceramic Machining Services

Domain: precision-ceramics.com

Registered: 2013 (12 years)

Introduction: Precision Ceramics offers high-tolerance technical ceramic machining services including CNC Milling, Grinding, Brazing, Joining, Glazing, Lapping, Polishing, and Metalizing. The company utilizes state-of-the-art equipment and has capabilities for machining tolerances of ±.02mm, with the potential to achieve ±.01mm depending on the part’s size, shape, and geometry. Specific capabilities include: CN…

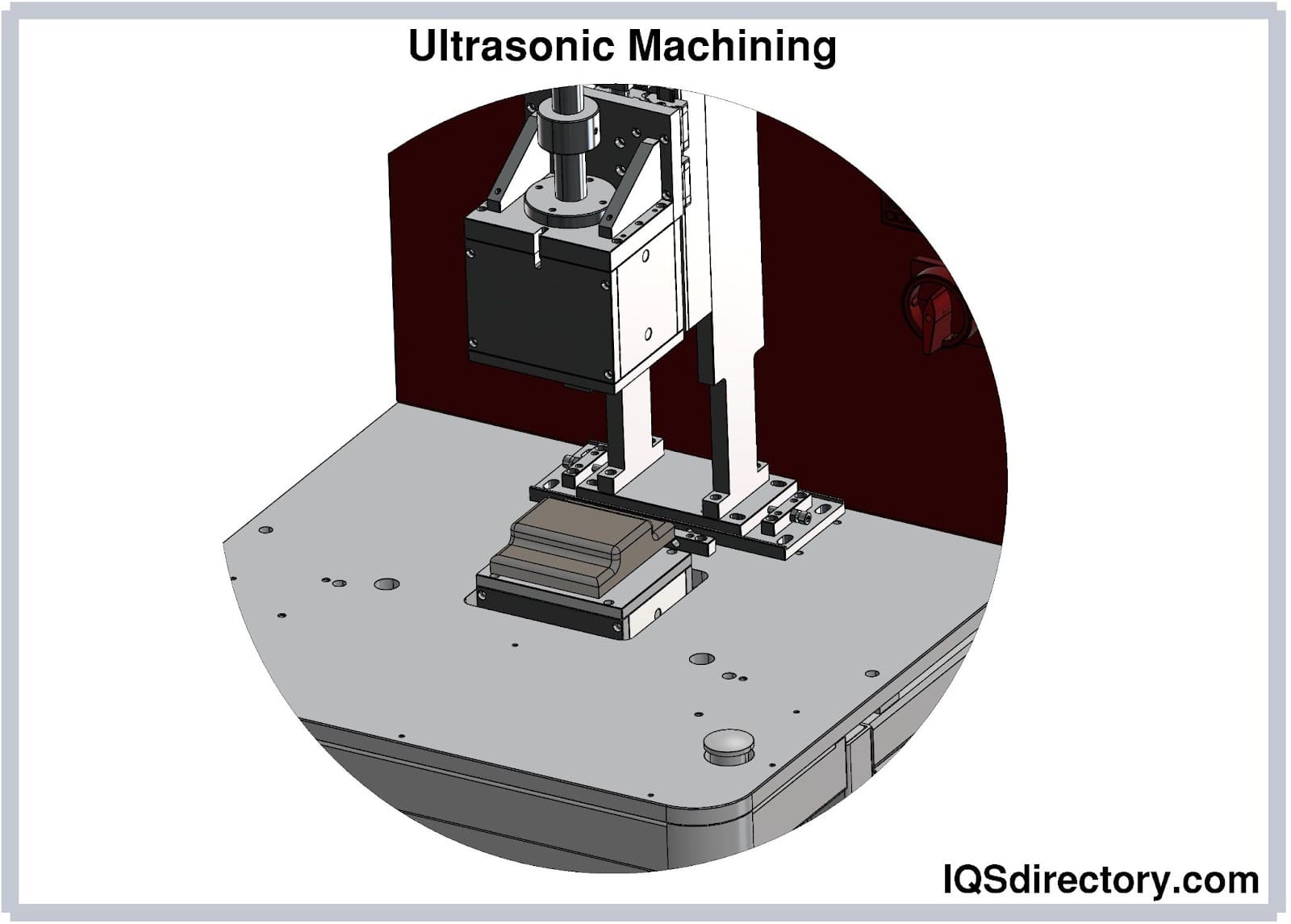

2. Bullen Ultrasonics – Advanced Ceramic Machining Services

Domain: bullentech.com

Registered: 2006 (19 years)

Introduction: Bullen Ultrasonics offers advanced ceramic machining services, including Diamond Tool Machining and Ultrasonic Machining. Key features include:

– Diamond Tool Machining: Utilizes diamond-coated tools for high precision and extended tool life, customizable for specific ceramic types.

– Ultrasonic Machining: Employs ultrasonic vibrations for controlled abrasions, ideal for intricate designs and de…

3. TQ Abrasive Machining – Precision Ceramic Components

Domain: tqabrasivemachining.com

Registered: 2005 (20 years)

Introduction: TQ Abrasive Machining Company offers precision ceramic machining services specializing in complex designs for a wide range of technical industrial and OEM applications. Key products include:

– Ceramic Tiles

– Insulator Rods

– Microwave Tubes

– Vacuum Tubes

– Corrosion Resistance Ceramics

– Aerospace Ceramics

– Wear Components

– Nuclear Ceramics

– Boron Carbide Tiles

– Ceramic Discs

– Sputtering Ta…

4. Ceramic Cutting Tools – High-Speed Machining Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Machining metals at high speeds using ceramics, specifically designed for dry machining. Ceramics are effective for cutting superalloys that generate significant heat, as they do not soften at high temperatures. The process relies on high temperatures to soften the material being cut, and coolant cannot be used due to the risk of shattering the ceramic tools.

5. Applied Ceramics – Custom Ceramic Solutions

Domain: appliedceramics.net

Registered: 2001 (24 years)

Introduction: Applied Ceramics supplies and fabricates custom ceramics, quartz, silicon, and sapphire parts for various industries including semiconductor, solar, fuel cell, oil drilling, and nuclear. Key materials include ACI-998 Alumina (Al2O3), ACI-995 Alumina (Al2O3), Aluminum Nitride (ACI-AlN), Sapphire (EFG), Silicon, Silicon Carbide (SiC), Silicon Nitride (ACI-SiN), Pyrolytic Graphite, and Zirconia. The …

6. Karnasch – Rotary Burrs

Domain: karnasch.tools

Introduction: Karnasch offers a range of ceramic machining tools including solid carbide end mills, drills, taps, whirling thread cutters, thread mills, and deburrers. Key products include:

1. **Rotary Burrs**:

– ZYB, with End Cut, HP11 Cut, Uncoated – From €13.10

– WRC, Ball Nosed Cylinder, HP11 Cut, Uncoated – From €12.85

– KUD, Ball, HP11 Cut, Uncoated – From €20.70

– SPG, Tree, HP11 Cut, Uncoat…

7. Practical Machinist – Alumina and Machinable Ceramics

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: Alumina (Al2O3) – a form of aluminum oxide, available in grades from 90% to 99.95% purity. Machinable ceramic options include Macor, which can be machined with HSS tools but wears them faster than tough steels. Diamond grinding wheels and tooling are recommended for machining ceramics. Machinable ceramic is described as similar to machining chalk and can be tapped. Mcmaster-Carr lists machinable c…

8. Valley Design – Precision Ceramic CNC Machining

Domain: valleydesign.com

Registered: 1995 (30 years)

Introduction: Valley Design offers Ceramic CNC Machining Services specializing in precision machining of various ceramics including 96% Alumina, 99.6% Alumina, Aluminum Nitride, and Silicon Carbide. Their capabilities include 3, 4, and 5 axis CNC machining, with a focus on high-quality, rapid on-demand services. They can process parts from as small as 0.127mm to larger sizes, with polished surfaces on ceramics …

9. Ceramic Manufacturing – Precision Ceramic Components

Domain: ceramicmanufacturing.net

Registered: 2015 (10 years)

Introduction: Ceramic machining is the process of designing and creating precision ceramic components using various machining processes. Key products include: Alumina Ceramic, Alumina Crucible, Ceramic Bearing, Ceramic Insulator, Ceramic Nozzle, Ceramic Rod, Ceramic Spacer, Ceramic Tube, Custom Ceramic, Industrial Ceramic, Machined Ceramic, Sapphire Machining, Silicon Carbide, and Zirconia Ceramic. Notable manu…

Strategic Sourcing Conclusion and Outlook for ceramic machining

In the evolving landscape of ceramic machining, strategic sourcing has emerged as a critical component for businesses aiming to harness the unique properties of ceramics while mitigating the inherent challenges of machining these materials. Key takeaways for international buyers include the importance of selecting suppliers with advanced machining capabilities and a proven track record in precision manufacturing. By prioritizing partnerships that emphasize quality control, innovative tooling solutions, and expert machining techniques, companies can enhance their operational efficiency and product reliability.

Furthermore, as industries increasingly demand high-performance ceramic components for applications in electronics, aerospace, and medical devices, the need for robust supply chains becomes paramount. Engaging with suppliers who understand the specific needs of diverse markets—whether in Africa, South America, the Middle East, or Europe—will facilitate the development of tailored solutions that meet regional demands.

Looking ahead, businesses must remain proactive in exploring new technologies and methodologies in ceramic machining. By doing so, they can position themselves at the forefront of innovation, ensuring their competitiveness in a global marketplace. We encourage international buyers to assess their sourcing strategies today, fostering relationships that will drive growth and success in the ceramic machining sector.

Illustrative image related to ceramic machining

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.